Construction method of high-tension water-rich extra-large-section weak breccia tunnel

A construction method and breccia technology, which are applied in tunnels, tunnel lining, drainage, etc., can solve the problems of inability to meet the requirements of tunnel drainage and water blocking, and the inability to achieve the reinforcement effect of surrounding rocks, and achieve significant drainage and pressure relief effects. The effect of reducing the number of holes, reducing water pressure and water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

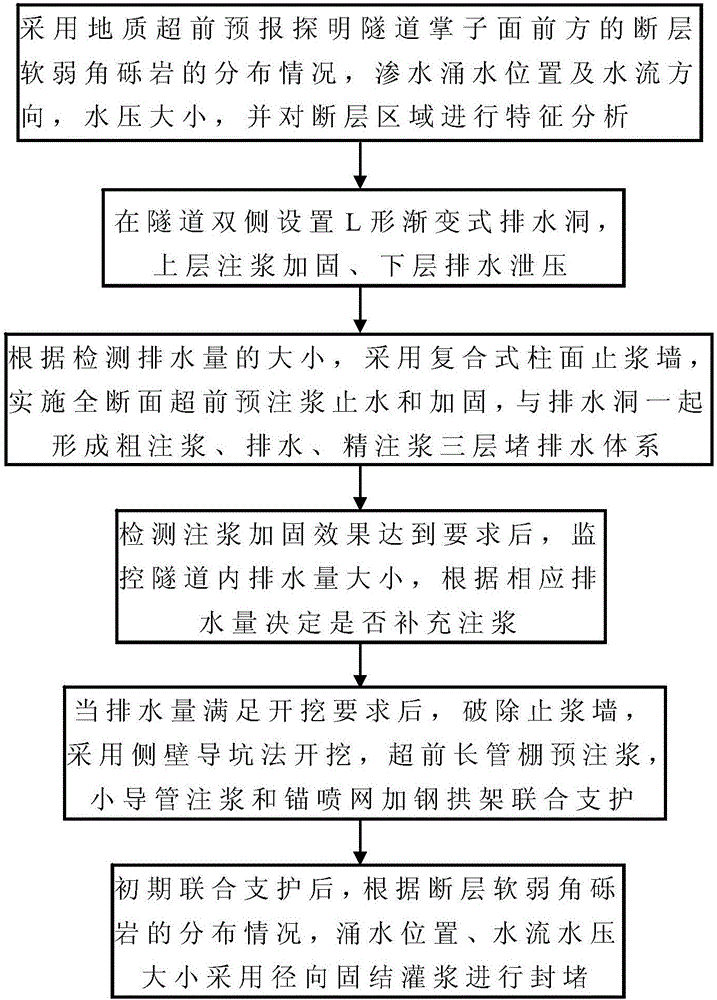

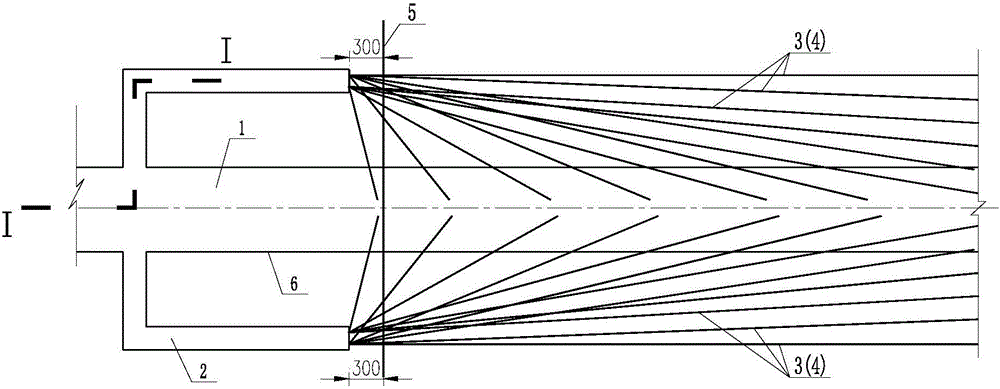

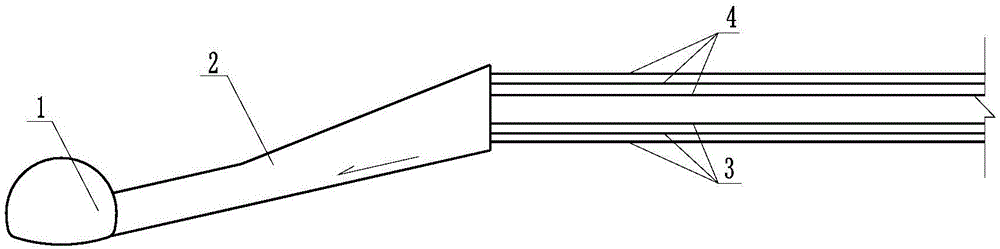

[0053] combine Figure 1-Figure 8 , taking the treatment of landslides in the fractured zone of a high-pressure, water-rich super-large fault in a tunnel as an example, and specifically describe the treatment methods and steps during tunnel construction.

[0054] A highway tunnel crosses the fault F18, the fault width is 120m, the length is 1500m, and the surface covering layer above the cave roof is 130m, which is rare in scale. The materials filled in the fault fracture zone are mainly weak breccia and fragments, etc. Most of the muddy cement is relatively dense, and the rich groundwater is pore water, with well-developed joints and fissures, and the rock mass is very broken without cementation. The F18 fault receives the recharge of the surface water in the gully and the groundwater of the mountains on both sides. The recharge source is rich, and the drainage in the tunnel reaches 8500m 3 / d.

[0055] The specific method of implementation is:

[0056] Step 1: Use advance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com