Patents

Literature

82results about How to "Reduce the number of holes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

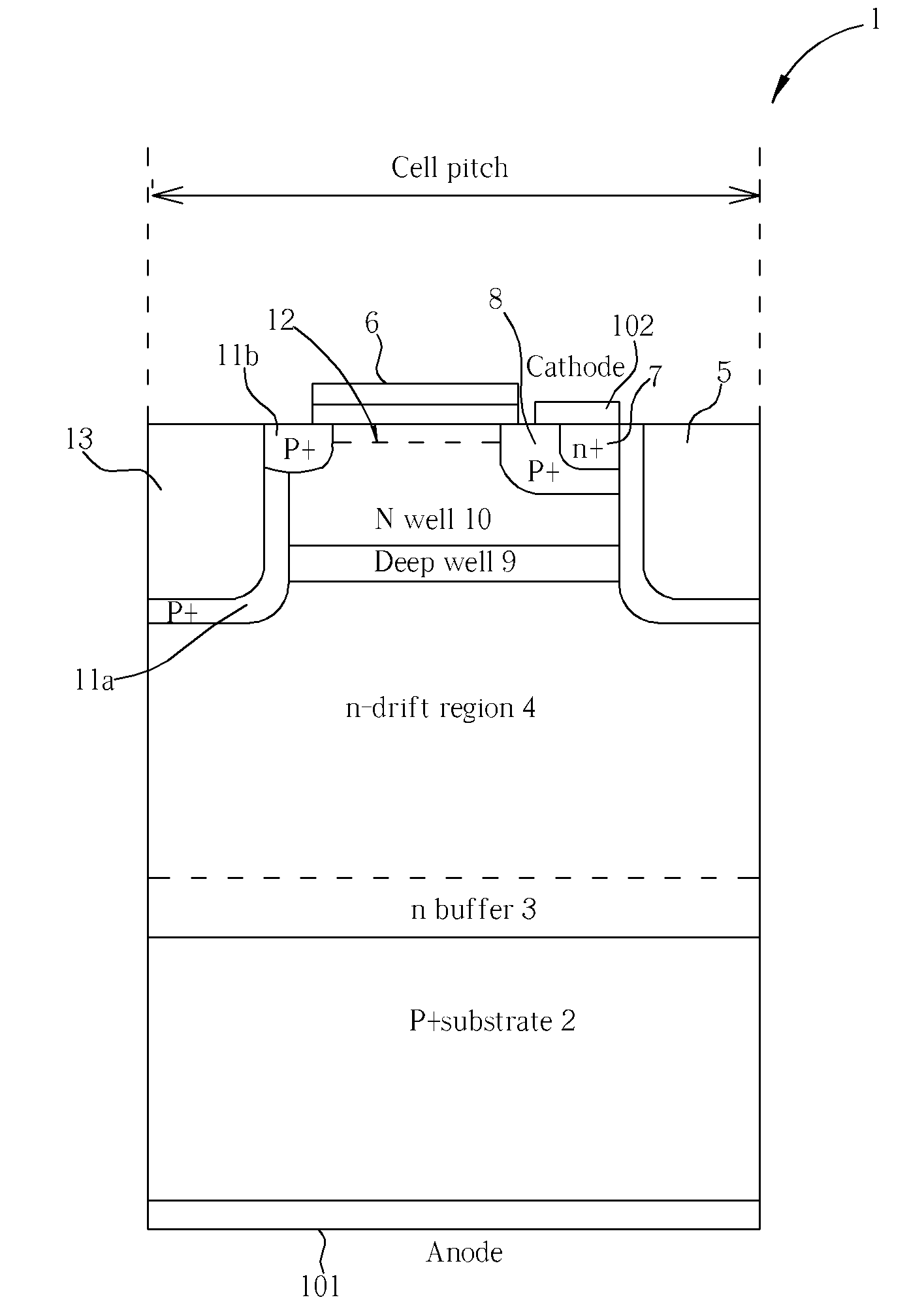

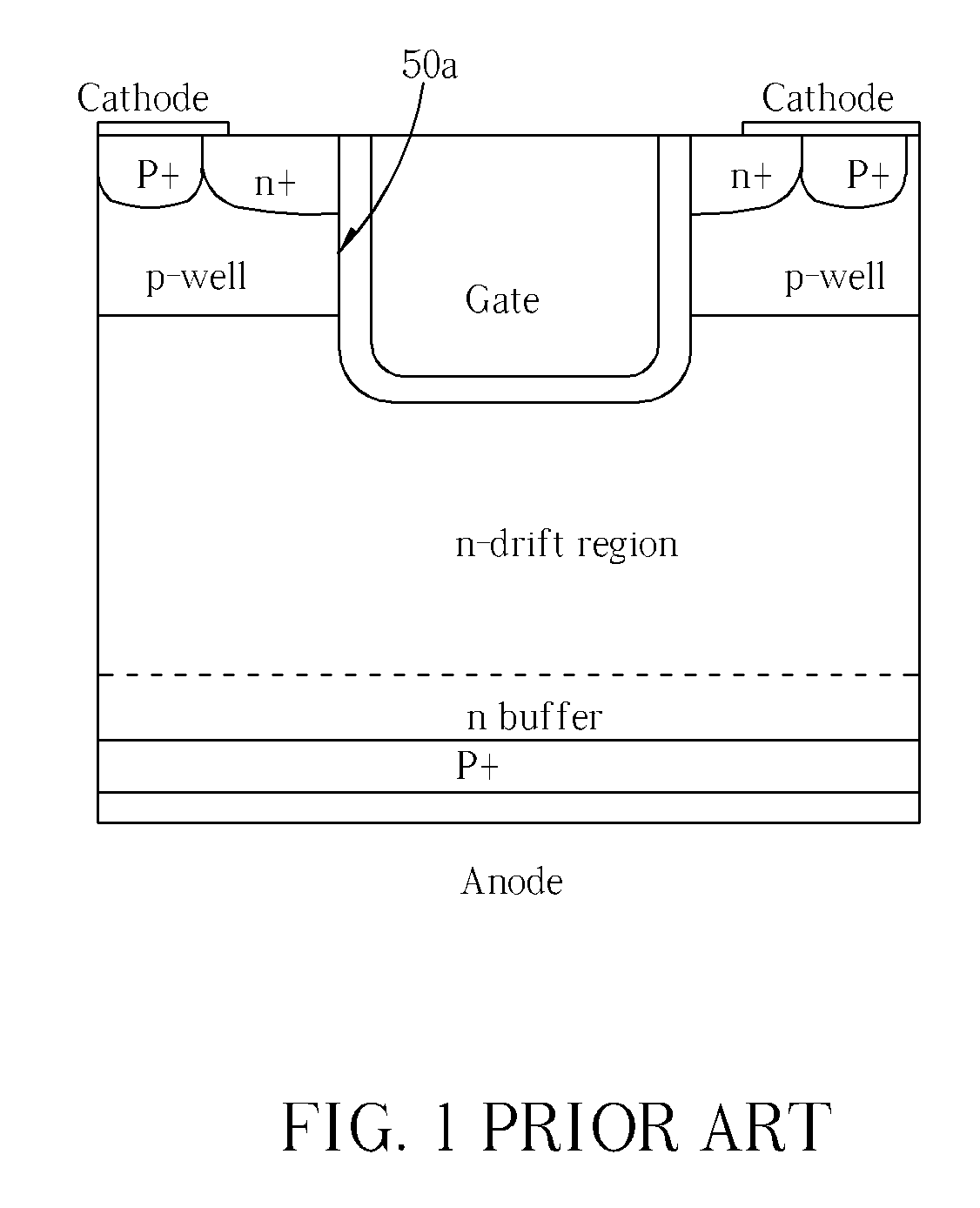

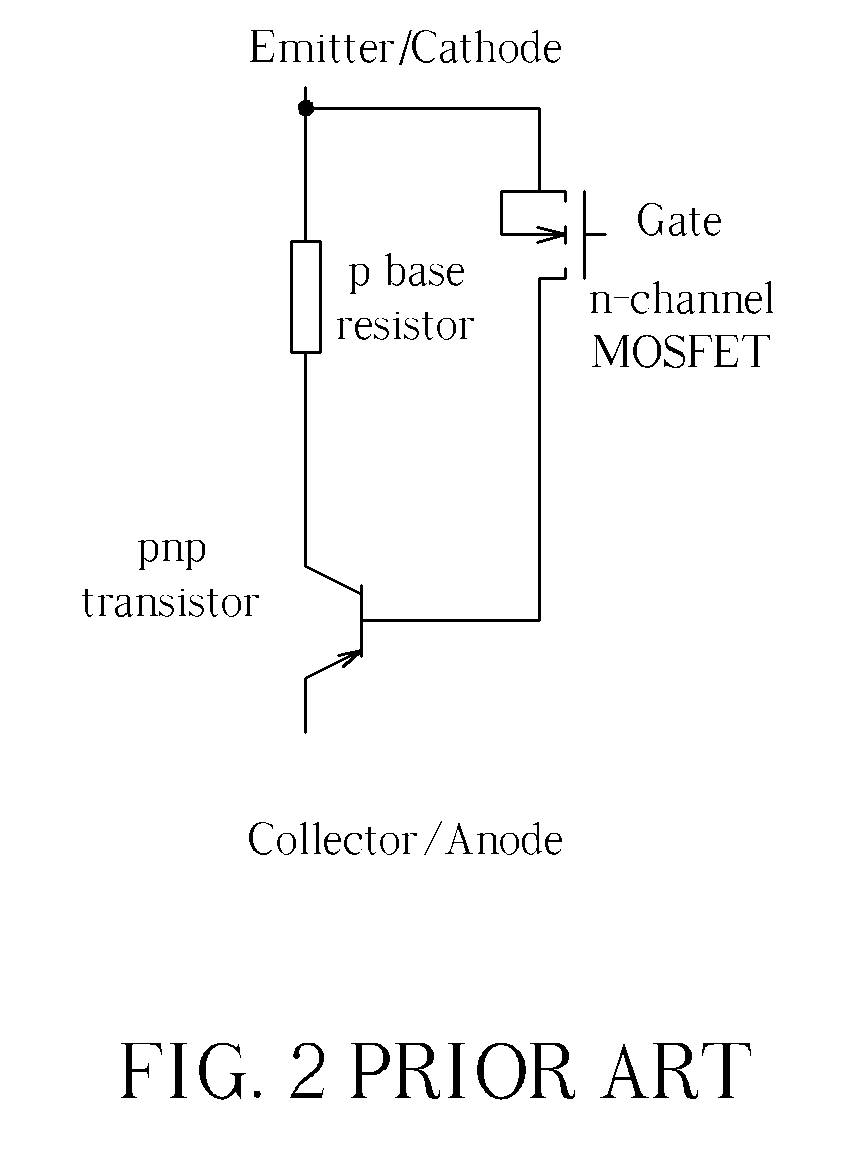

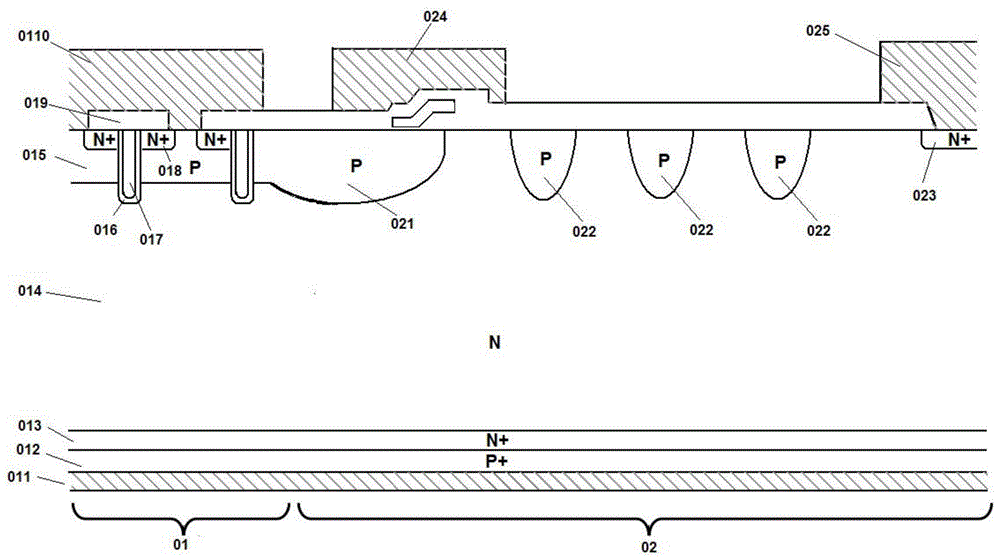

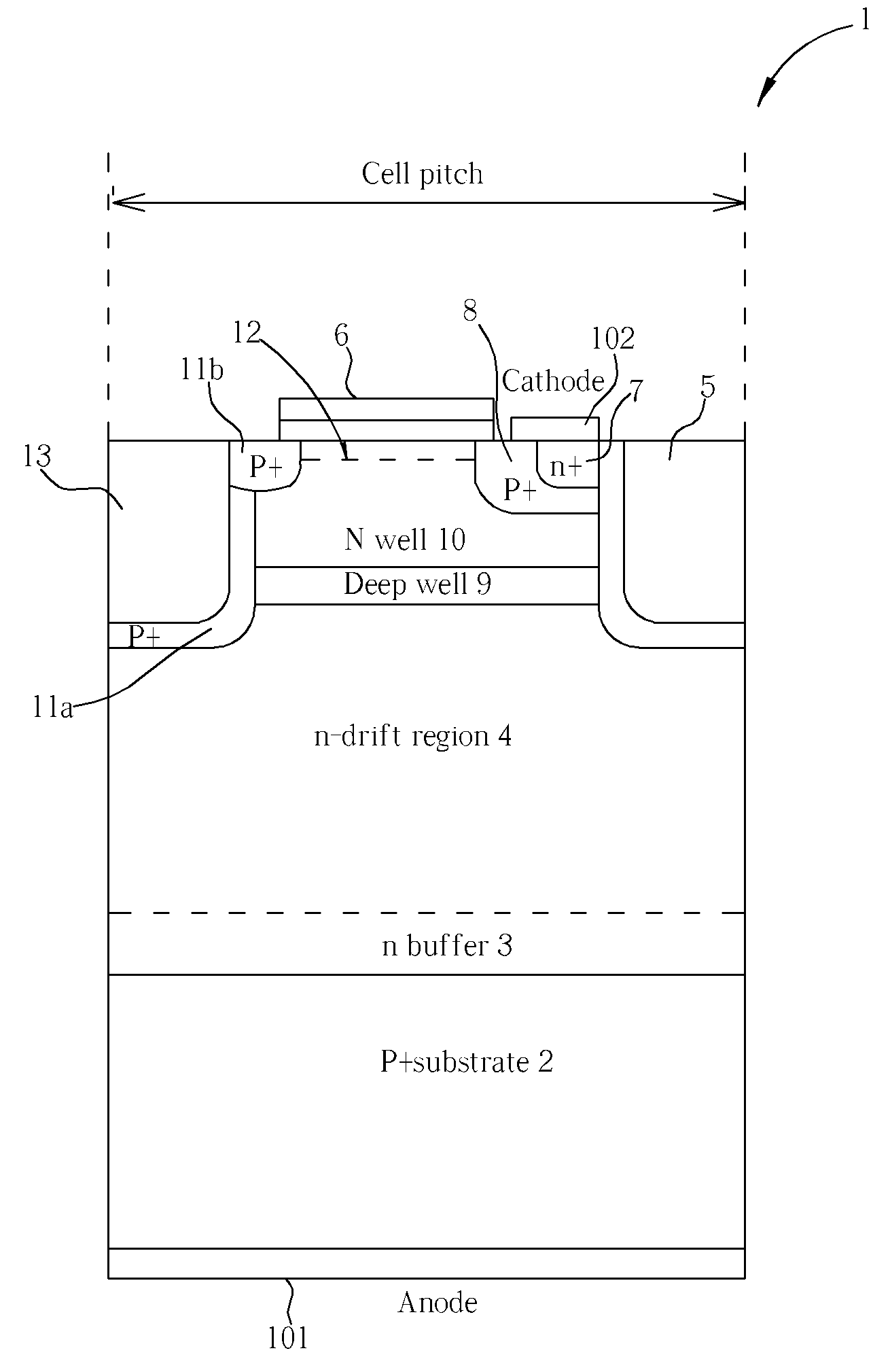

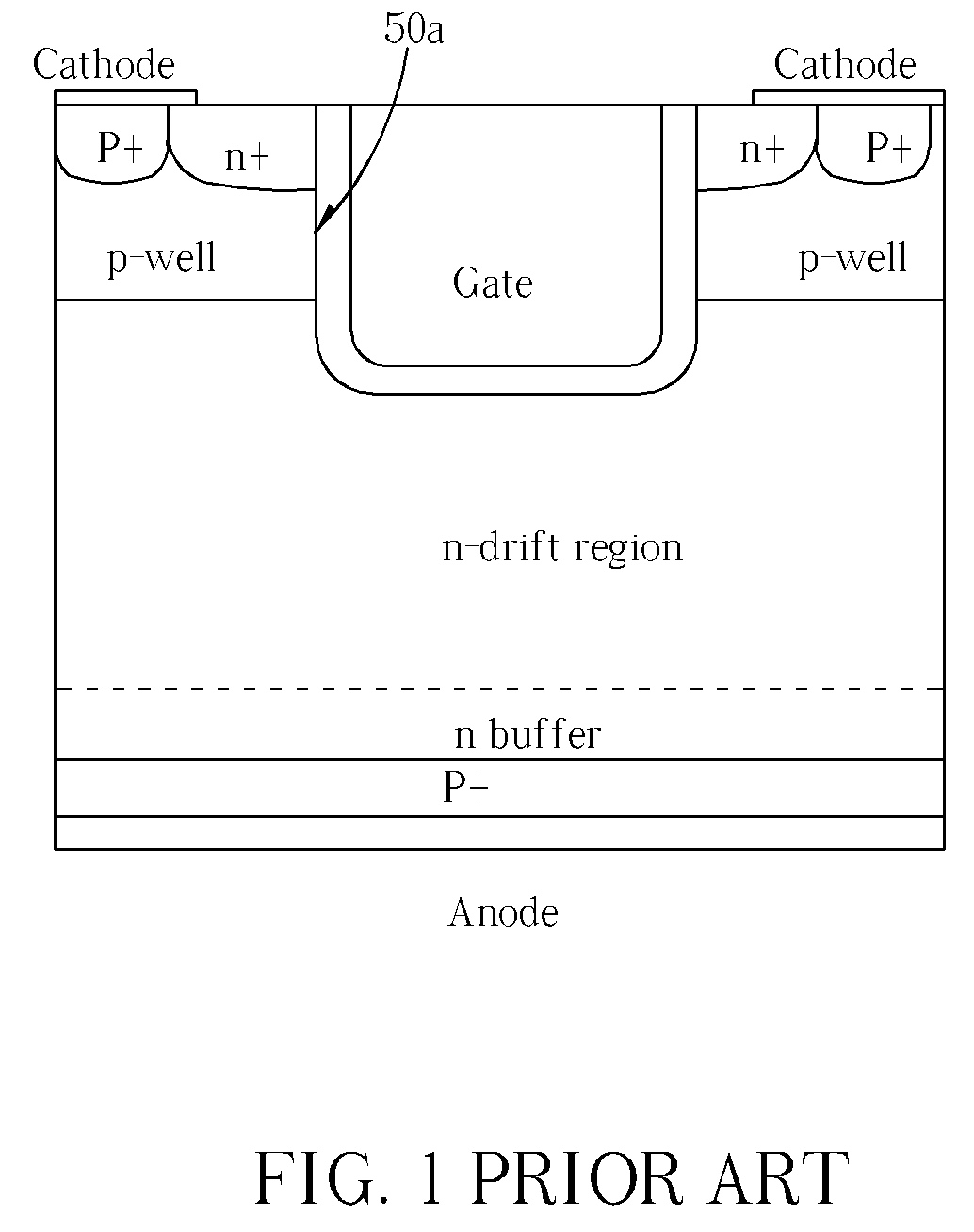

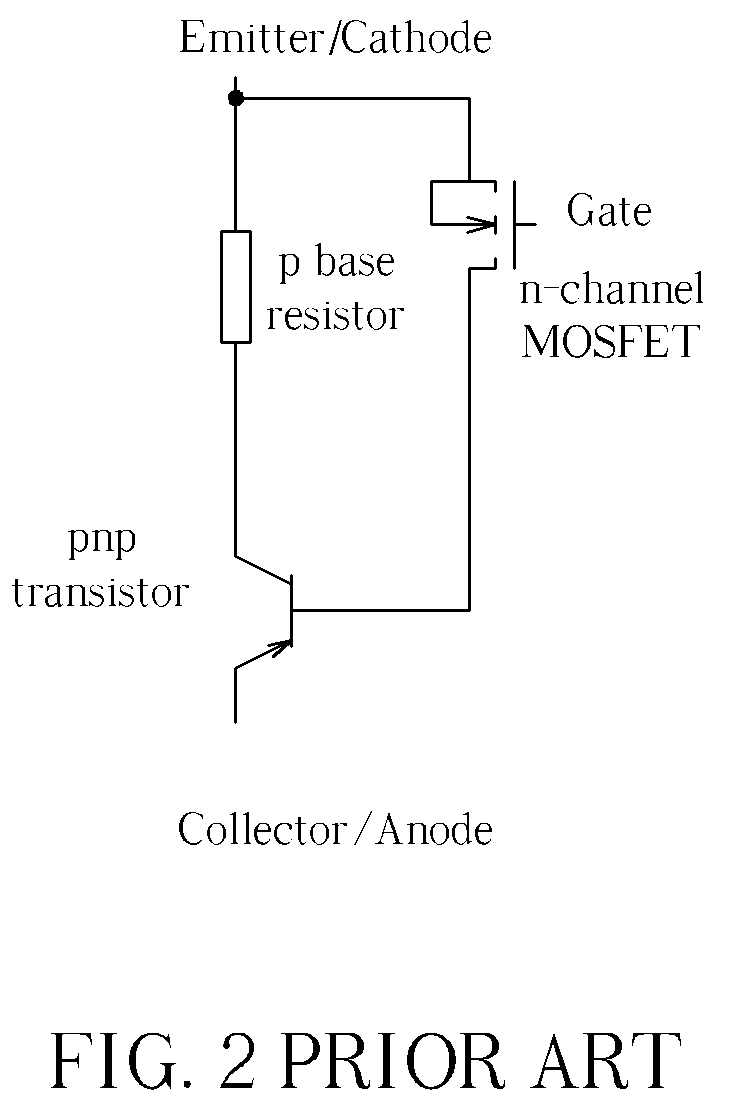

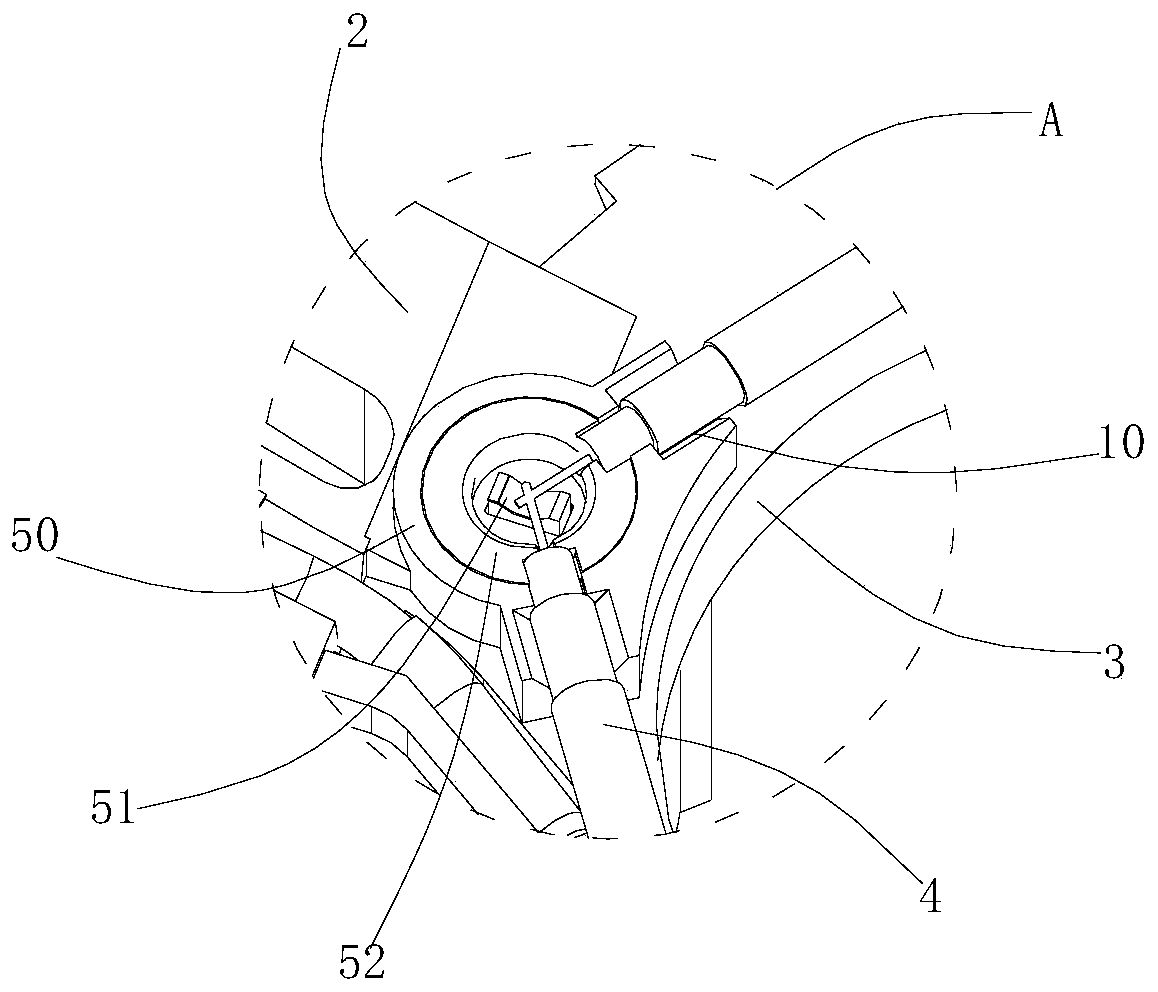

Double gate insulated gate bipolar transistor

InactiveUS20090008674A1Reduce the number of holesReduce transportationTransistorSolid-state devicesParasitic bipolar transistorEngineering

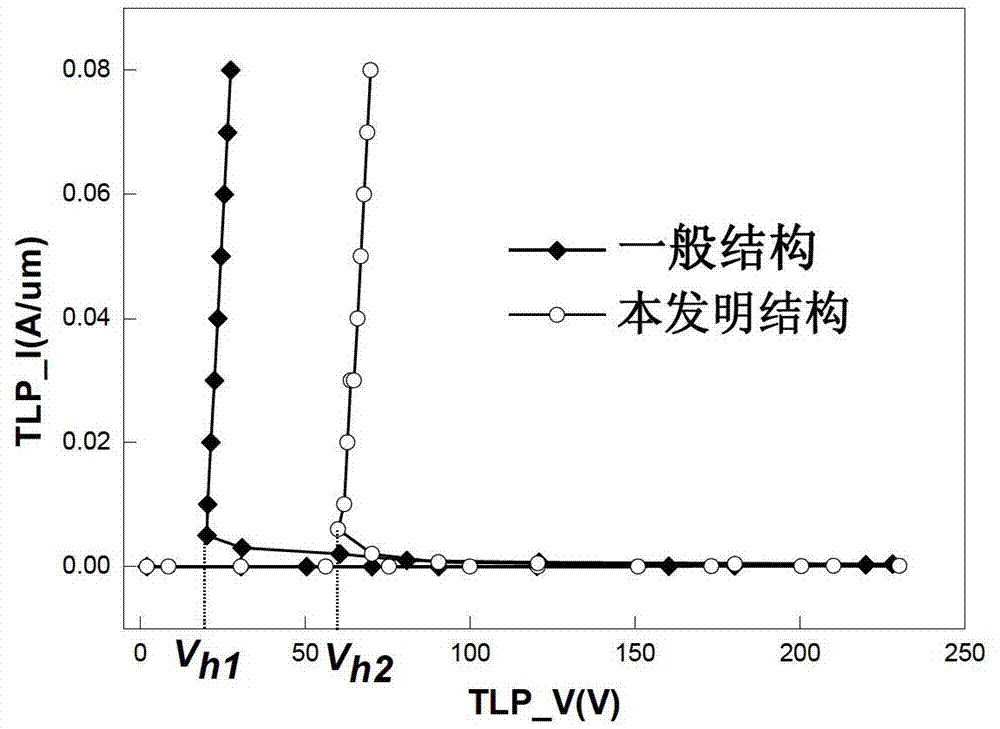

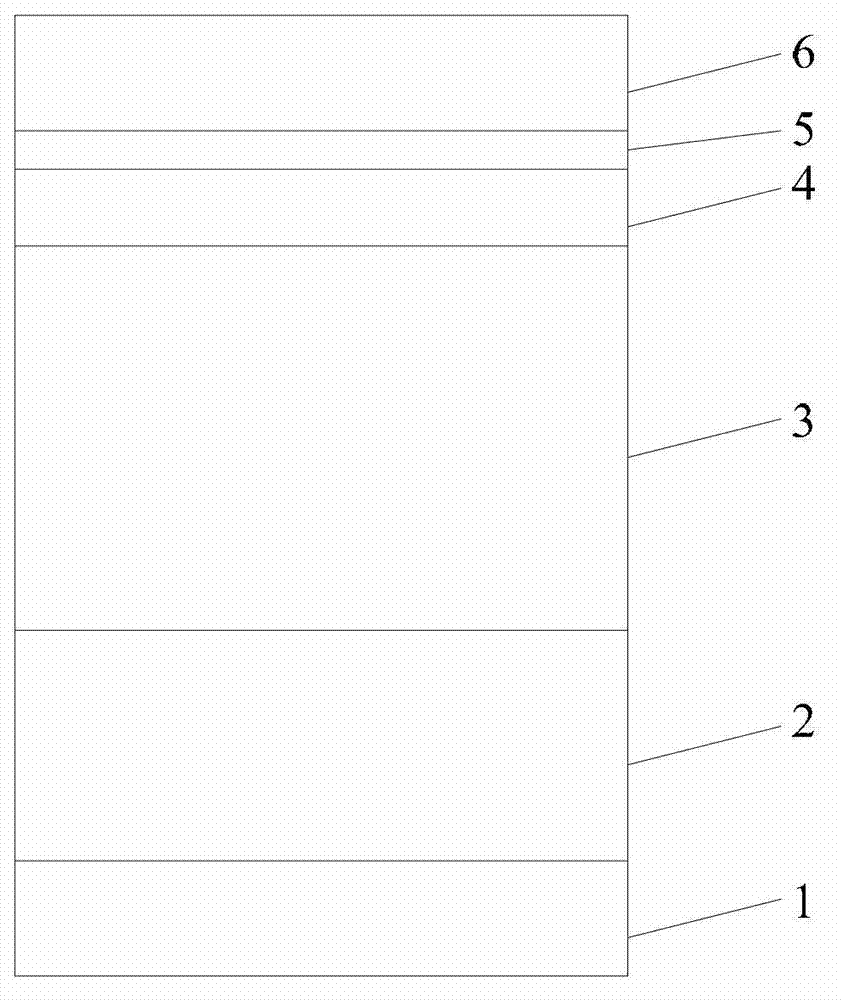

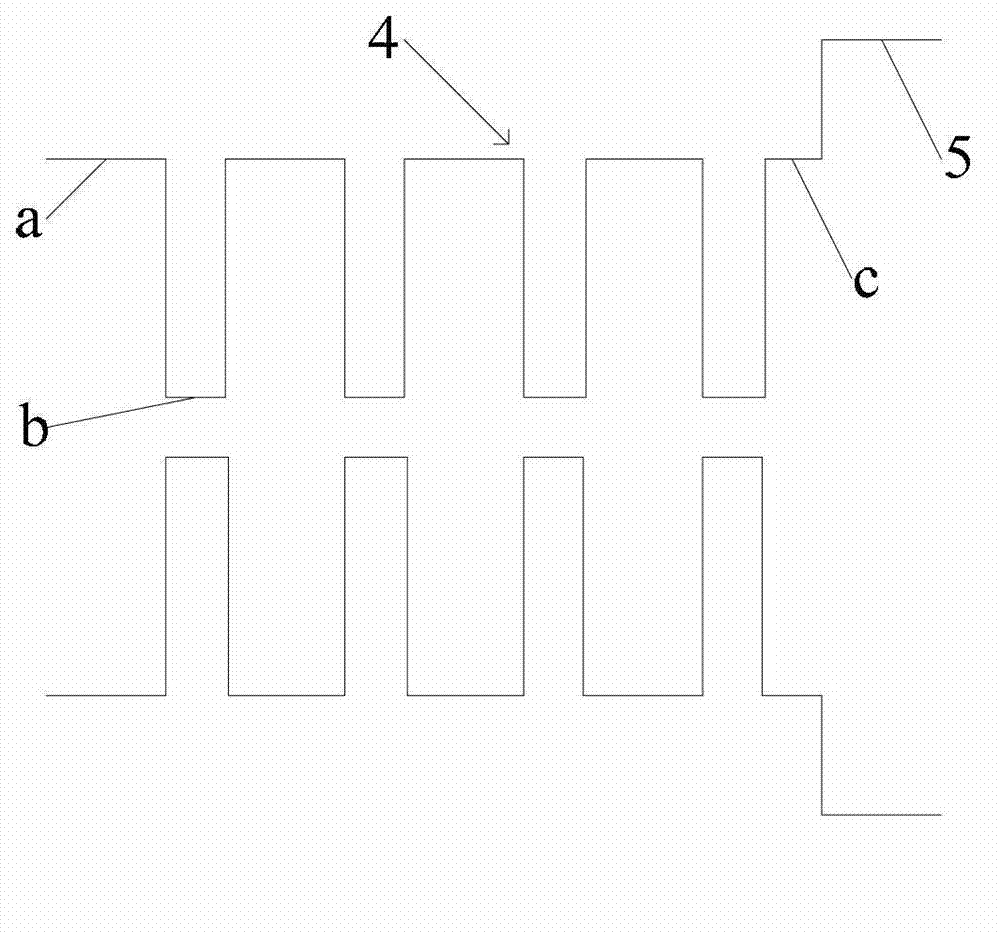

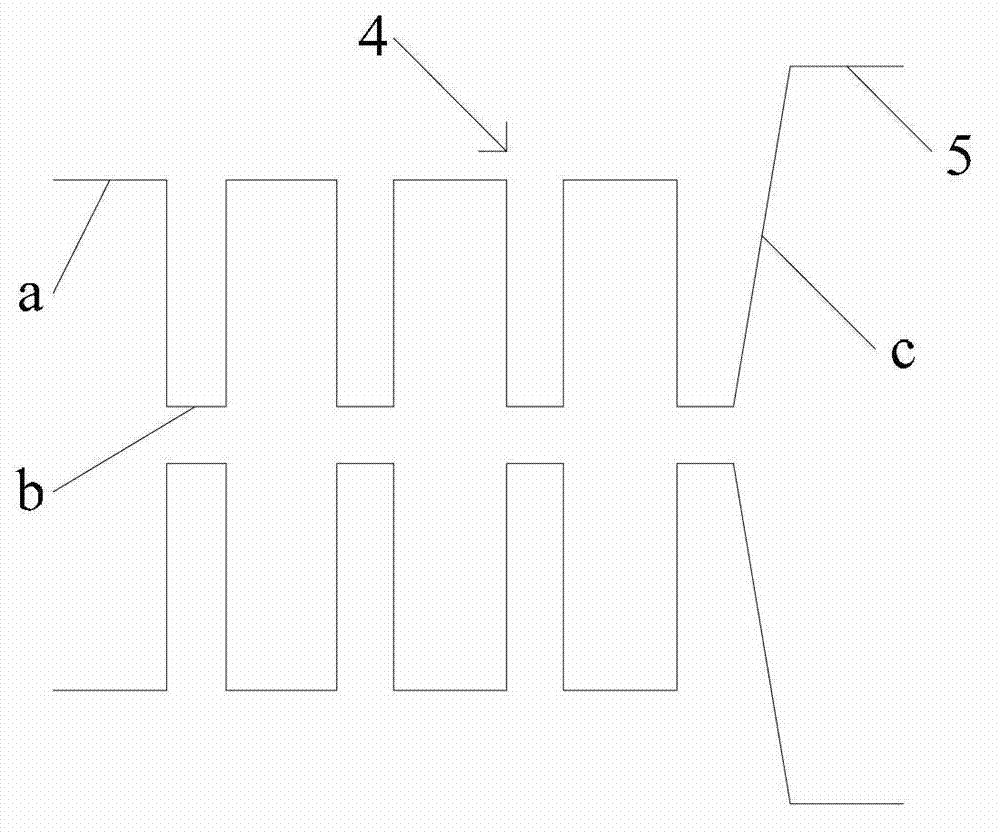

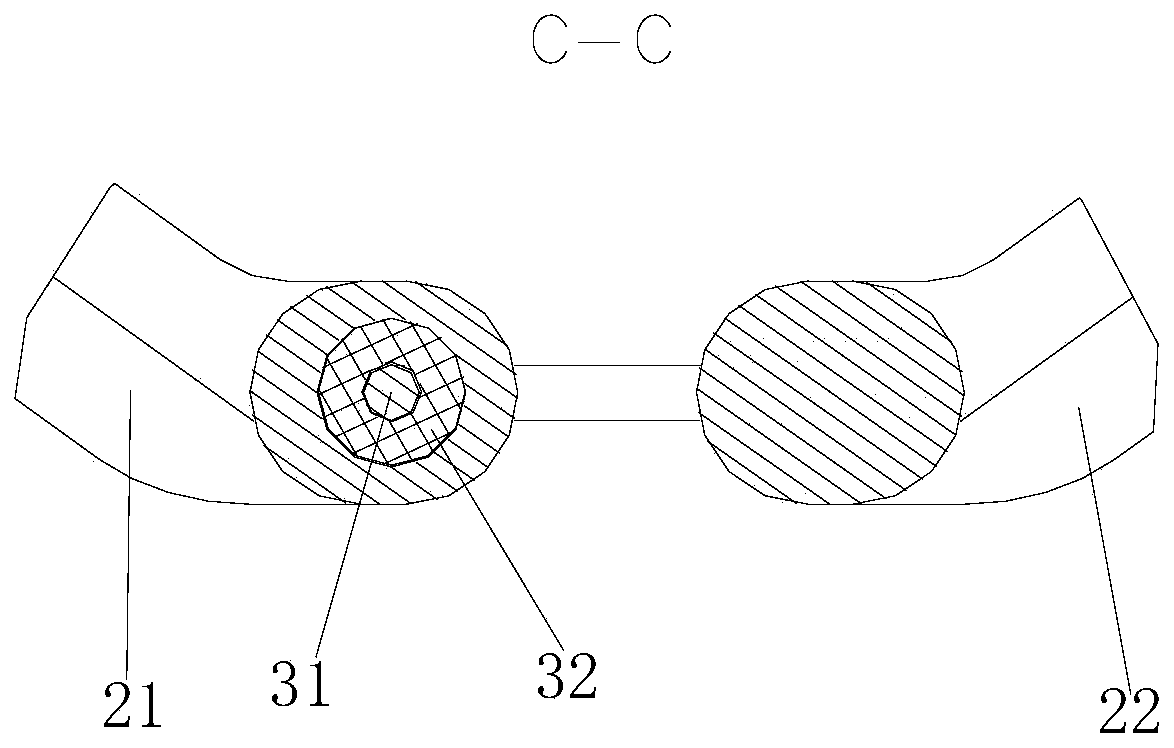

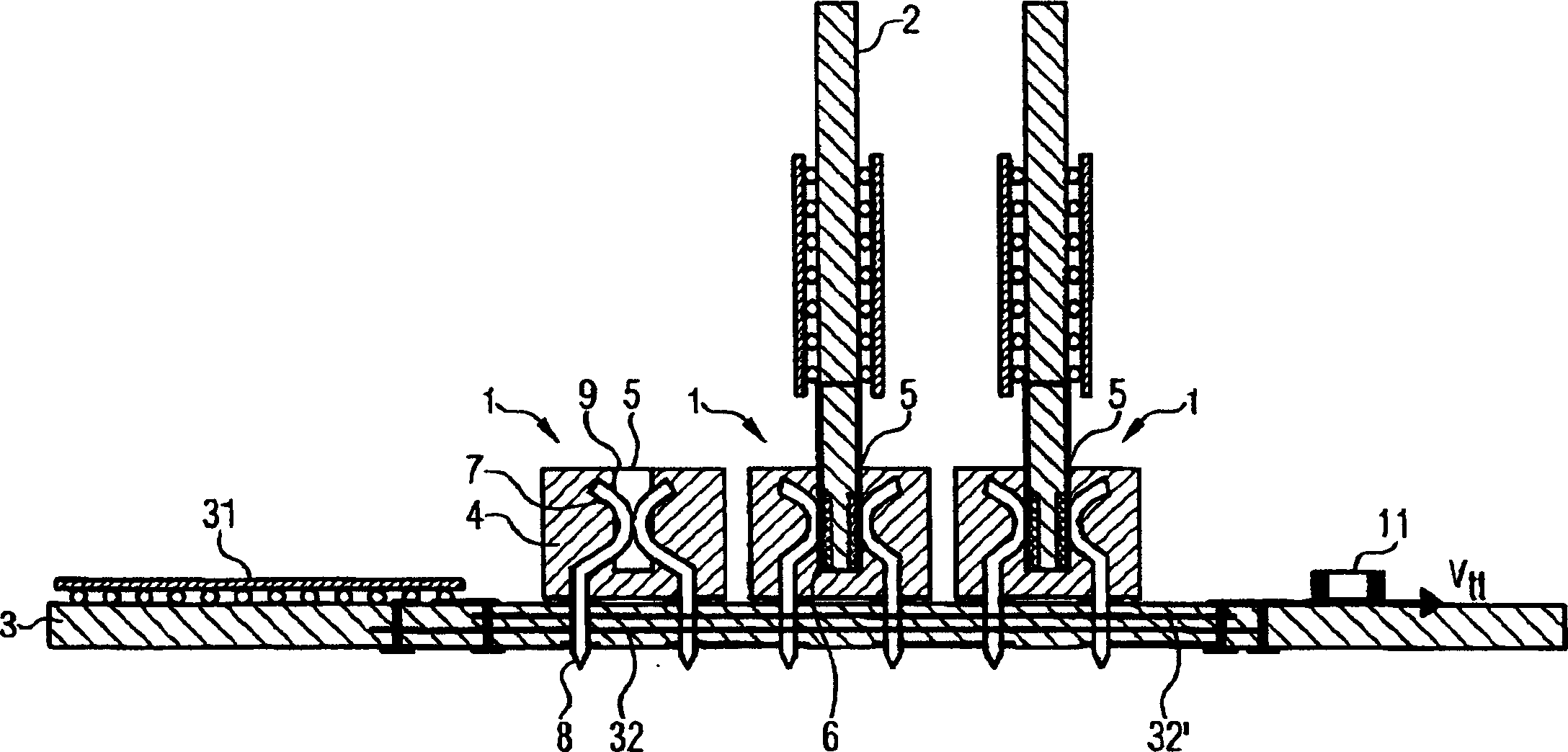

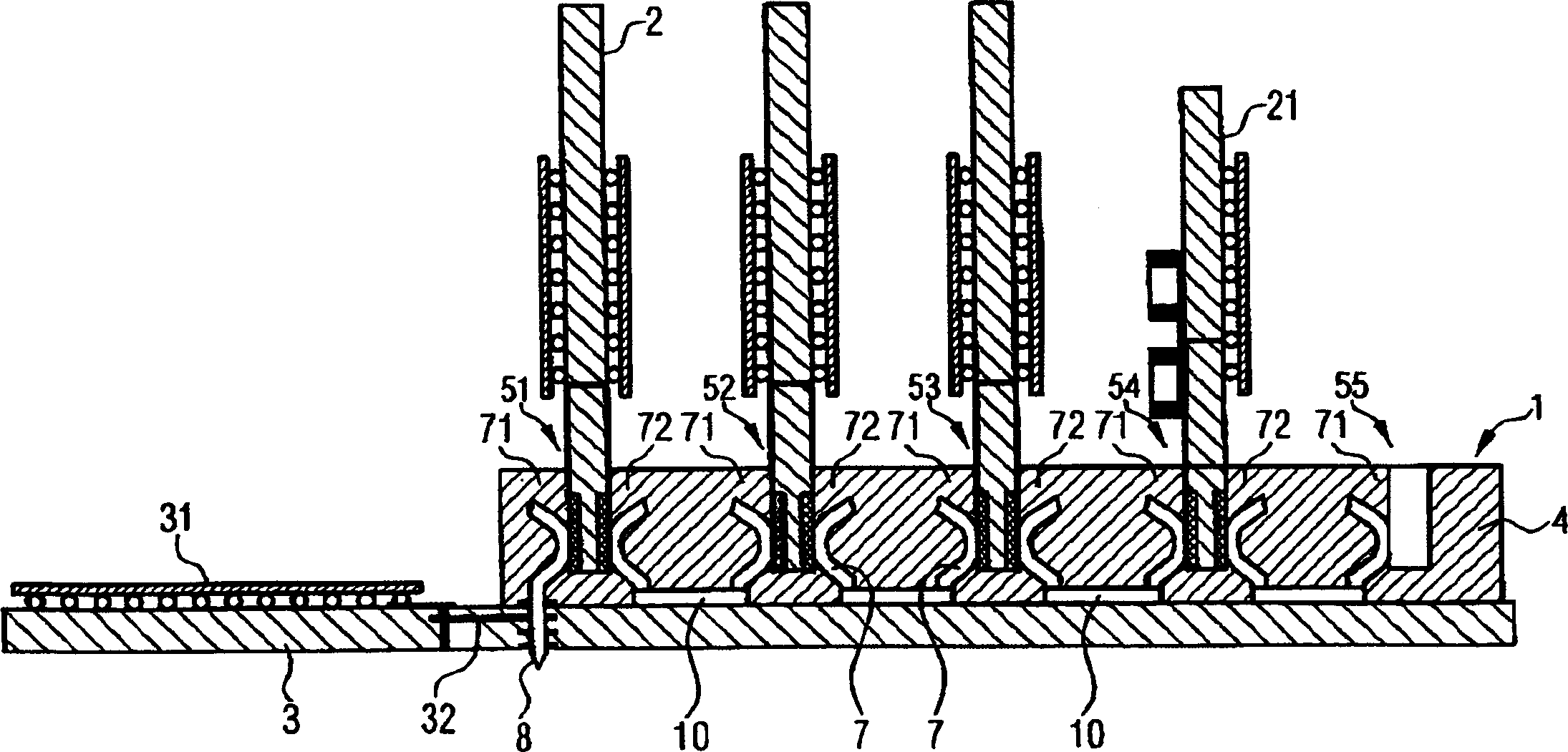

Double gate IGBT having both gates referred to a cathode in which a second gate is for controlling flow of hole current. In on-state, hole current can be largely suppressed. While during switching, hole current is allowed to flow through a second channel. Incorporating a depletion-mode p-channel MOSFET having a pre-formed hole channel that is turned ON when 0V or positive voltages below a specified threshold voltage are applied between second gate and cathode, negative voltages to the gate of p-channel are not used. Providing active control of holes amount that is collected in on-state by lowering base transport factor through increasing doping and width of n well or by reducing injection efficiency through decreasing doping of deep p well. Device includes at least anode, cathode, semiconductor substrate, n− drift region, first & second gates, n+ cathode region; p+ cathode short, deep p well, n well, and pre-formed hole channel.

Owner:ANPEC ELECTRONICS CORPORATION

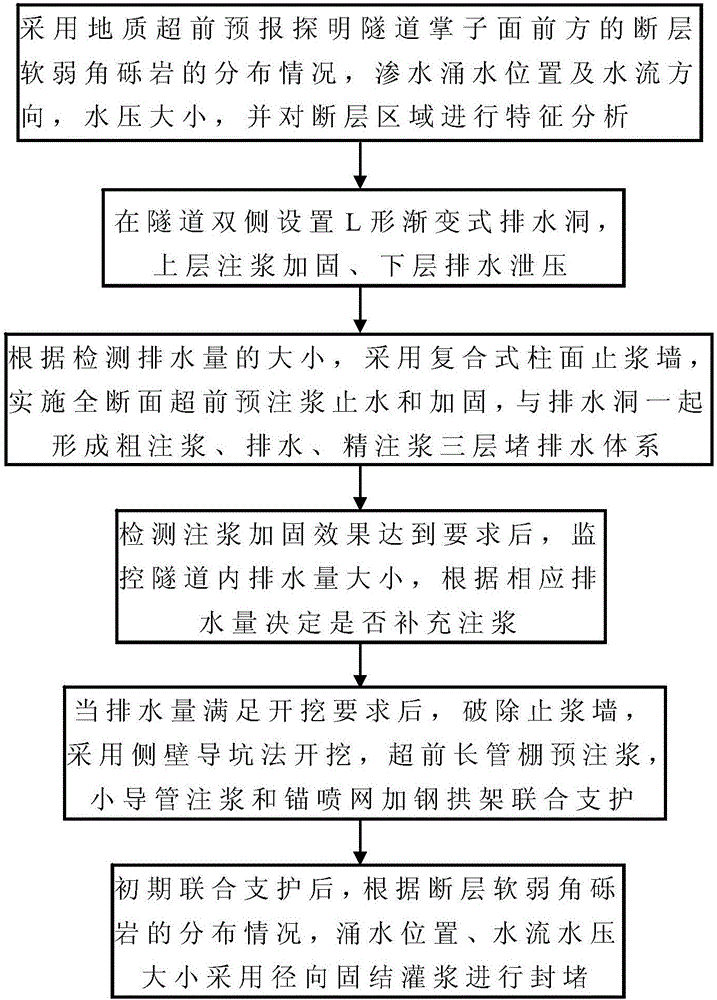

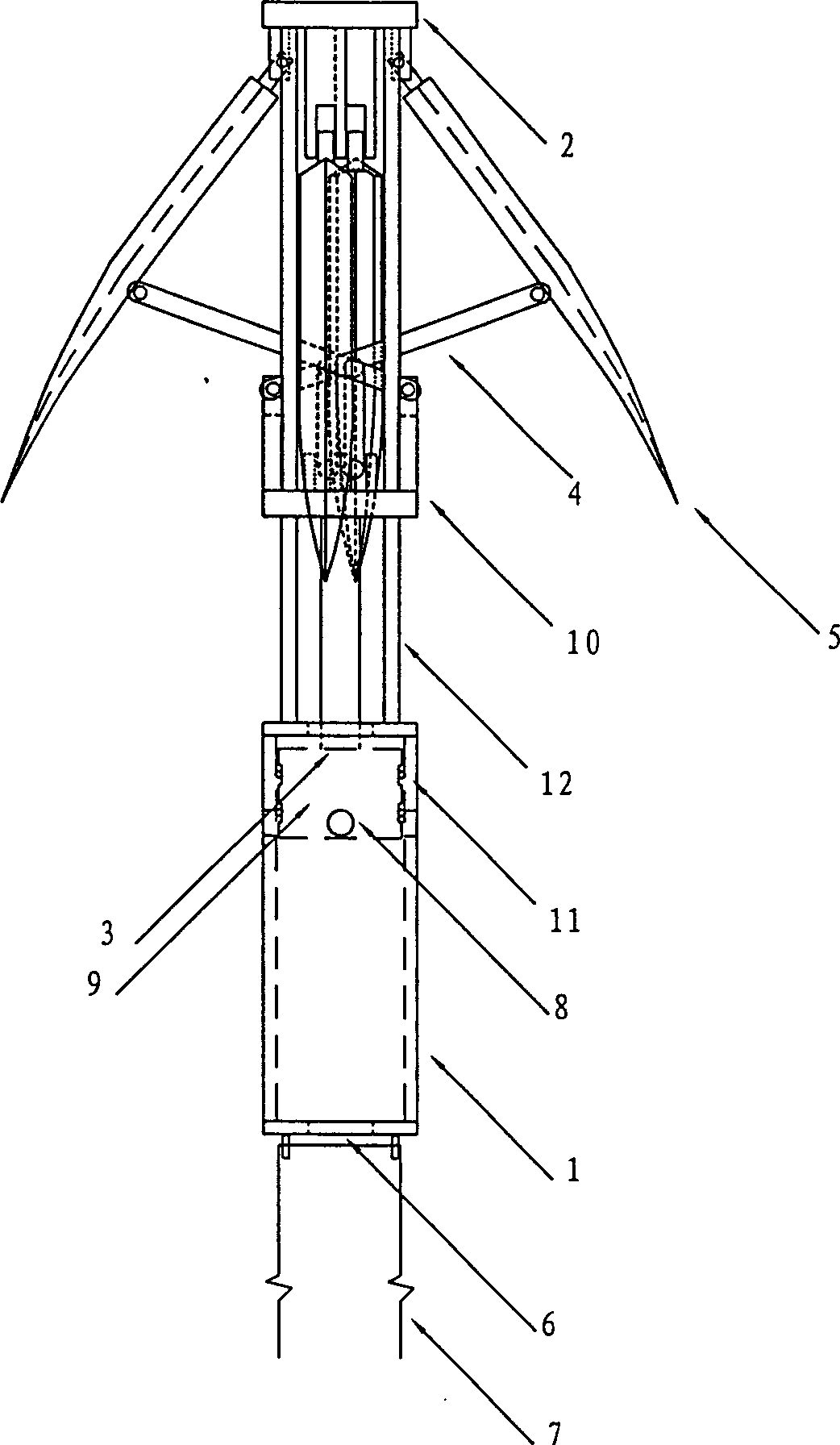

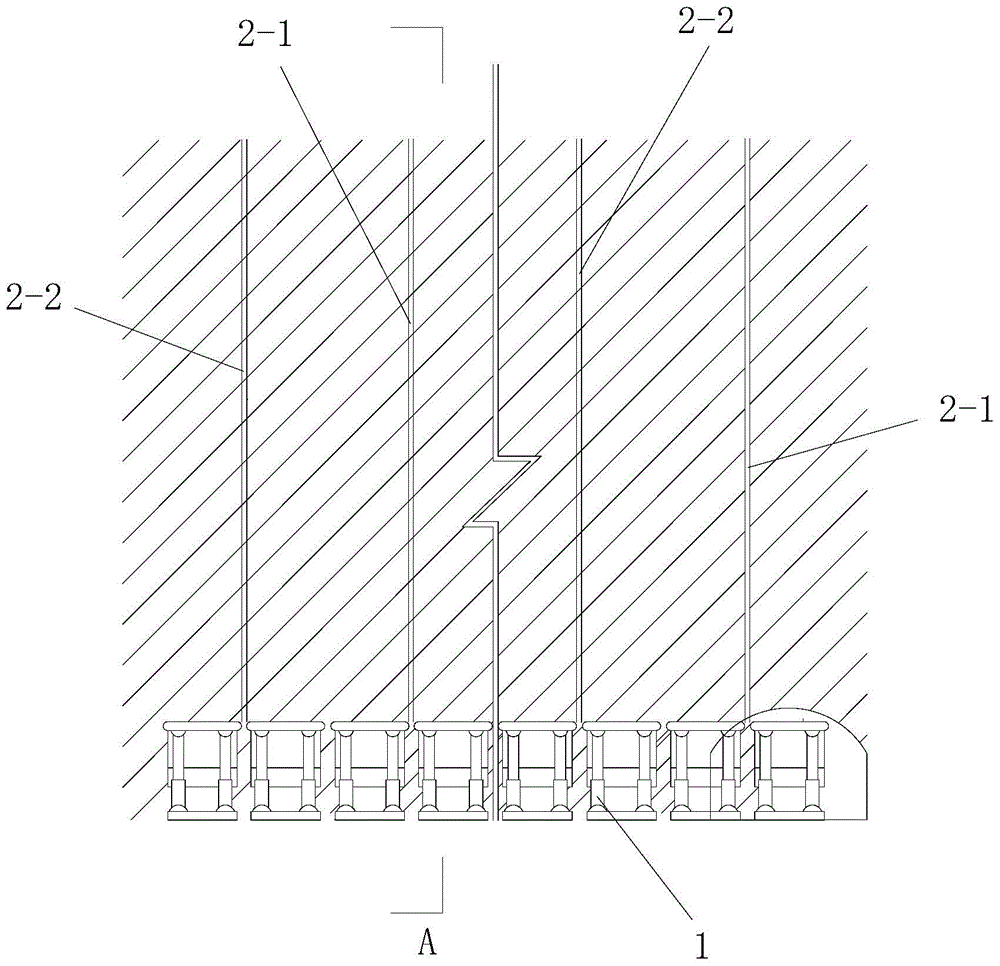

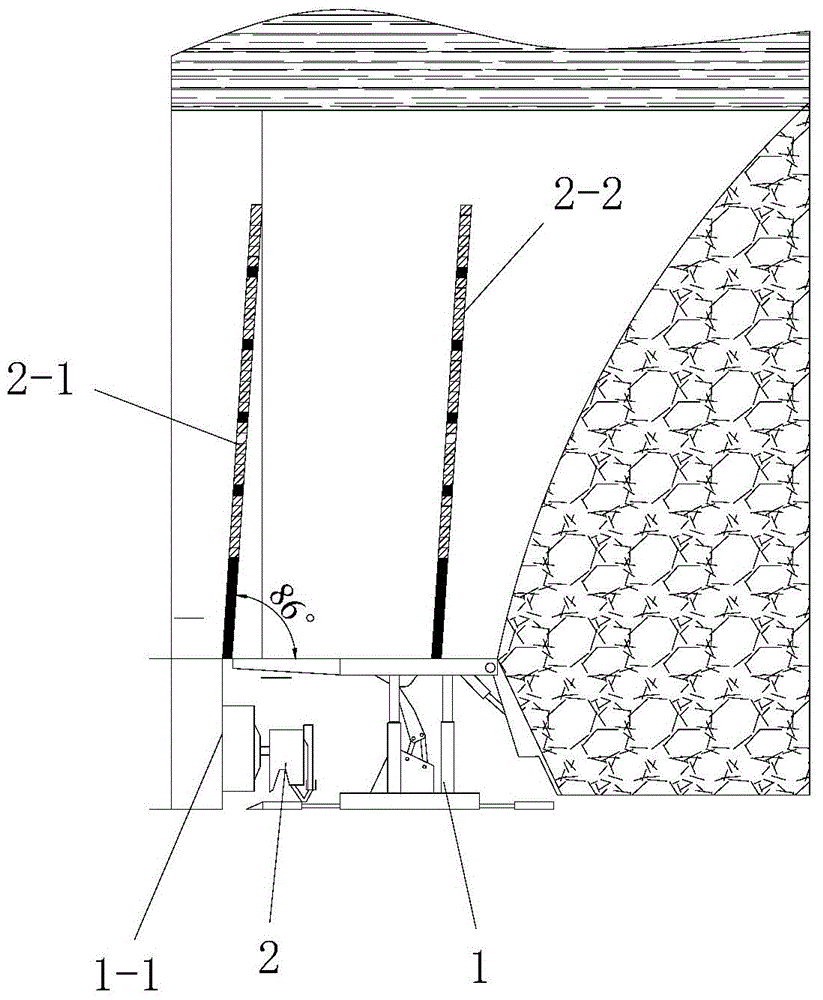

Construction method of high-tension water-rich extra-large-section weak breccia tunnel

The invention discloses a construction method of a high-tension water-rich extra-large-section weak breccia tunnel. The method includes the steps of exploring distribution of fault weak breccia in front of a tunnel face by an advanced geological forecast method; distributing L-shaped gradient drain holes in two inner sides of the tunnel, providing sector drain holes and grouting holes, and allowing upper grouting and lower drainage; providing a combined cylinder grout-stopping wall, and performing a full-face advanced chemical grouting consolidation; constructing an advanced long tube shed with a circumferential closed advanced tube shed guide wall having a foundation, distributing tapered quincunx examining drain holes to detect grouting effect, and finally excavating the tunnel. Through the use of the techniques such as three-layer stereoscopic grouting and drainage, and cement-water glass and epoxy resin sequential grouting, the problem that a high-tension water-rich surrounding rock area with loose weak breccia has ineffective grouting consolidation and non-obvious water plugging effect is solved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

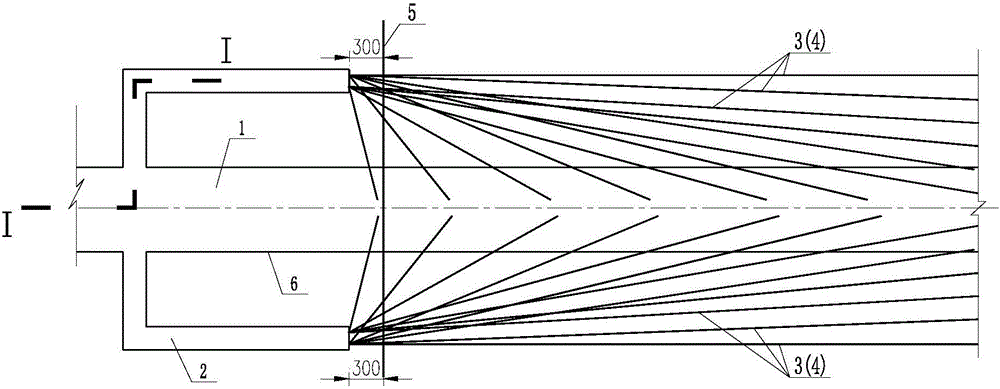

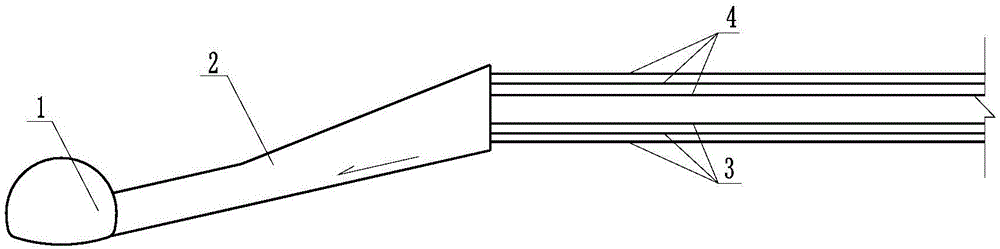

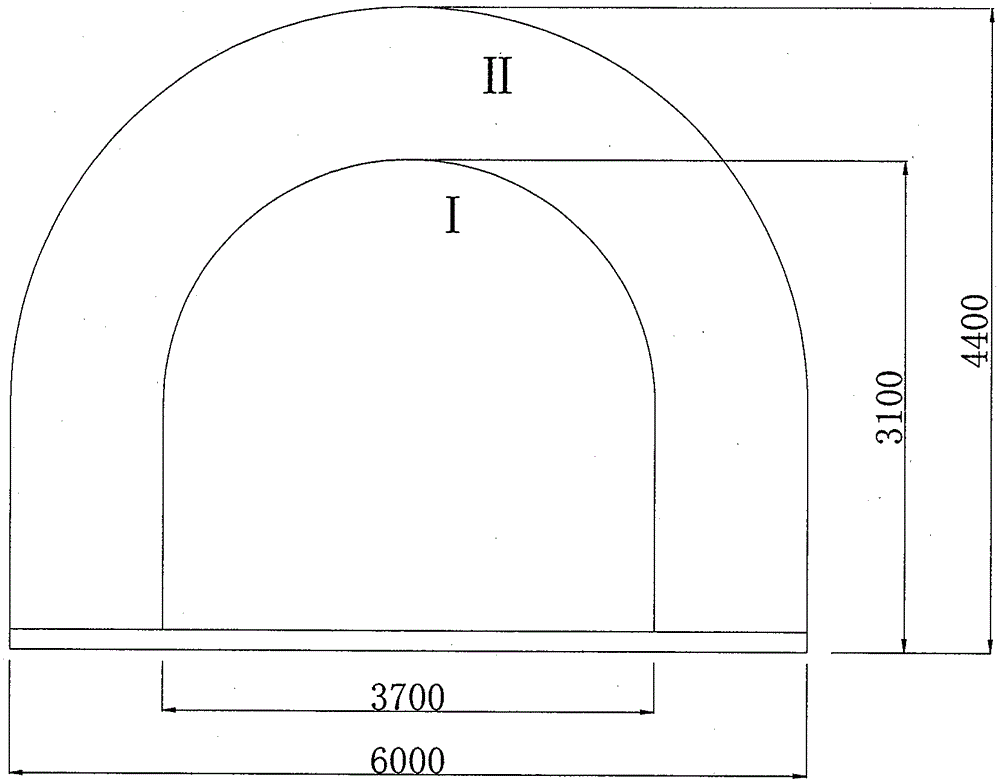

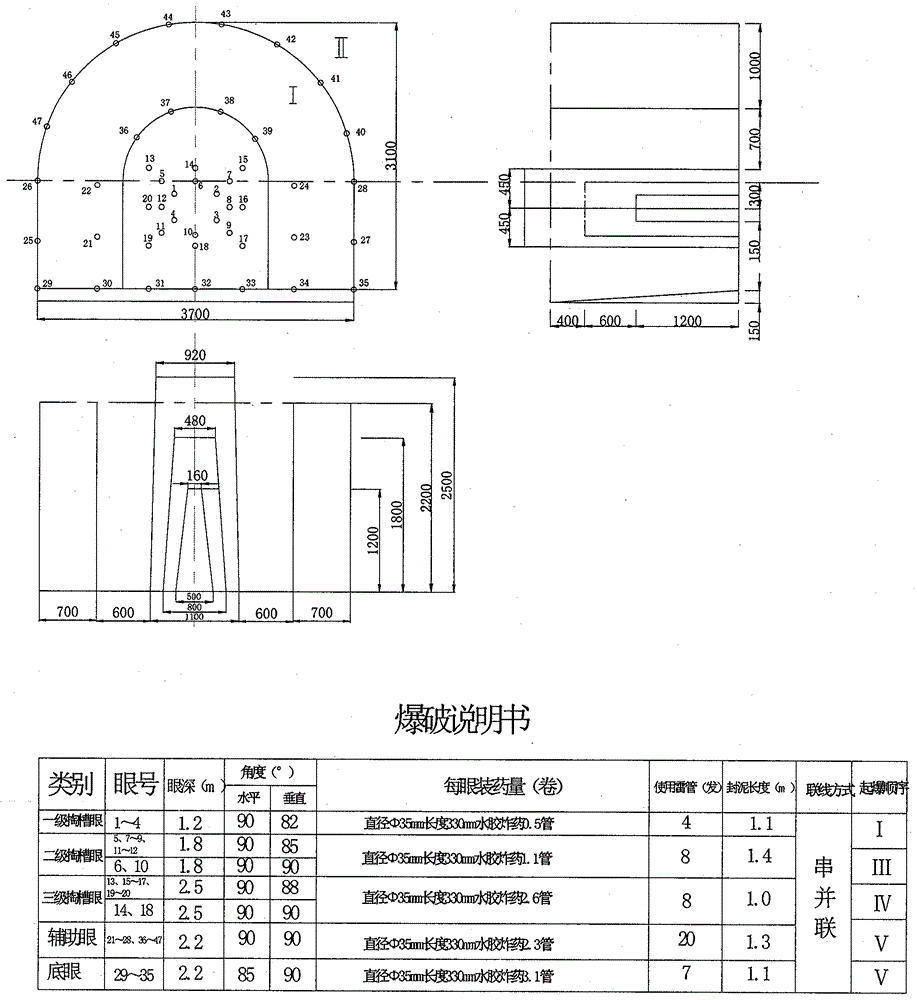

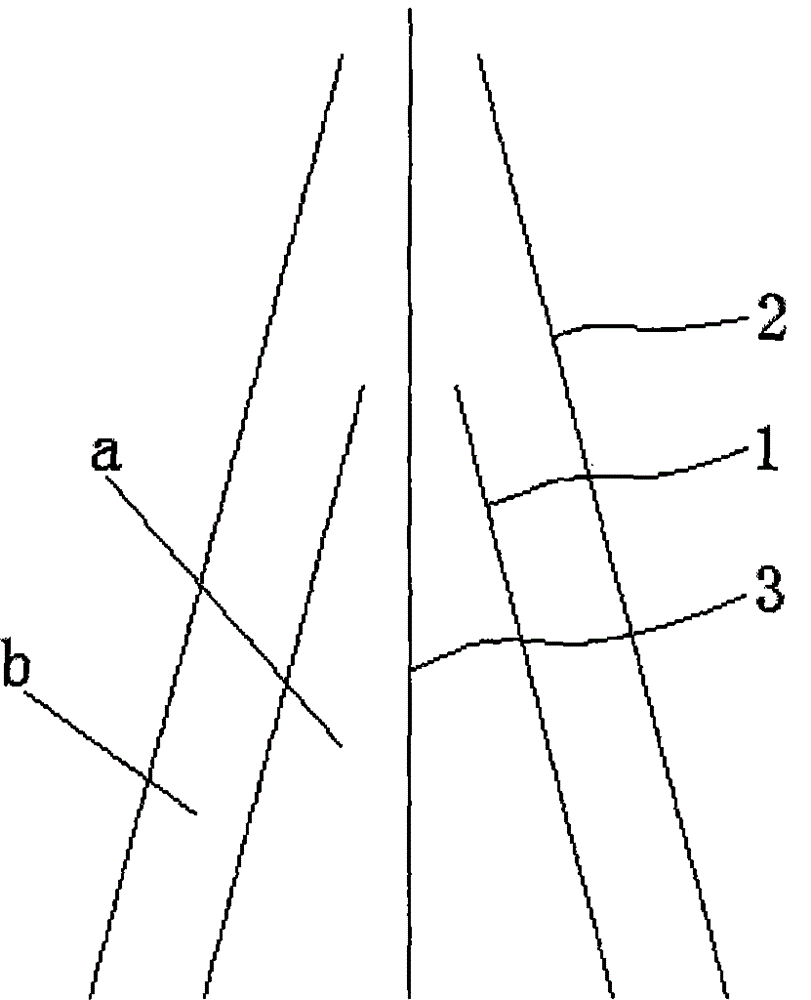

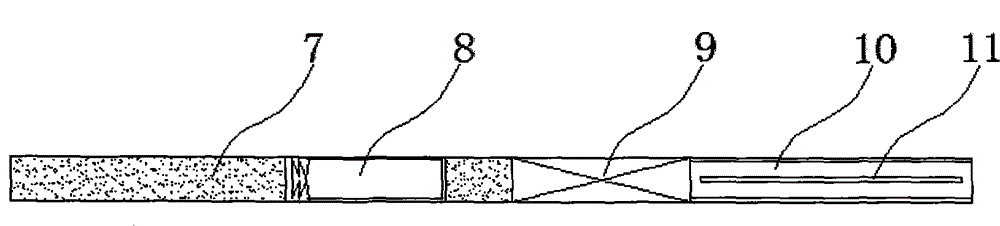

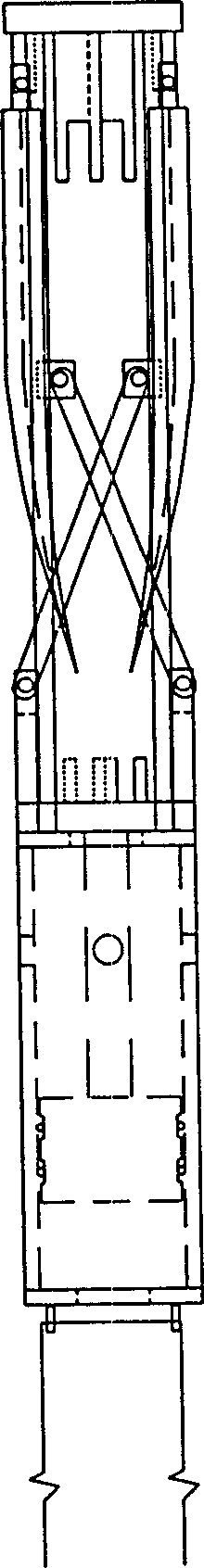

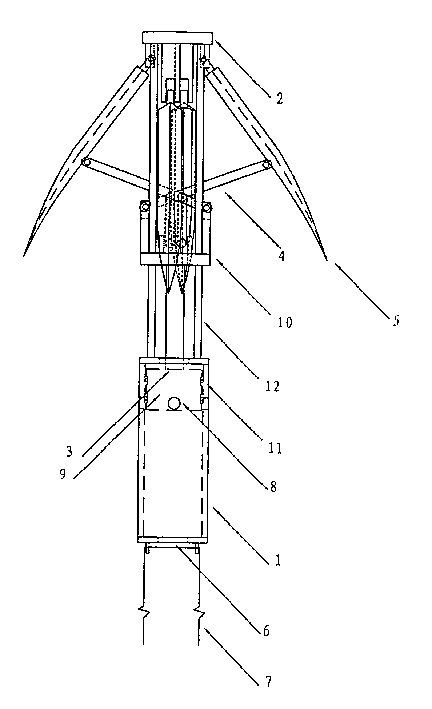

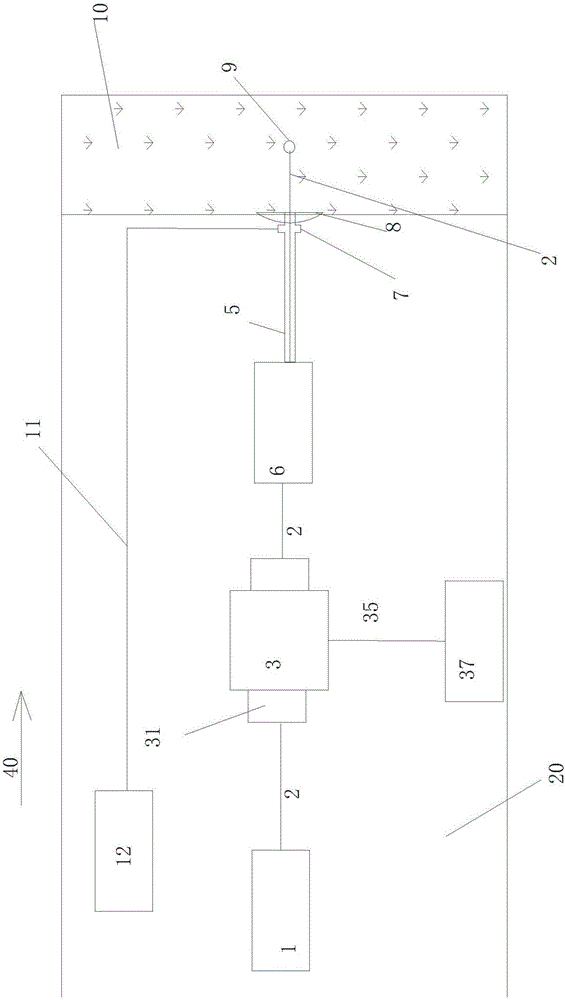

Fast and highly-efficient tunneling method for large section of hard-rock tunnel in coal mine by combination of fully-mechanized tunneling and blasting driving

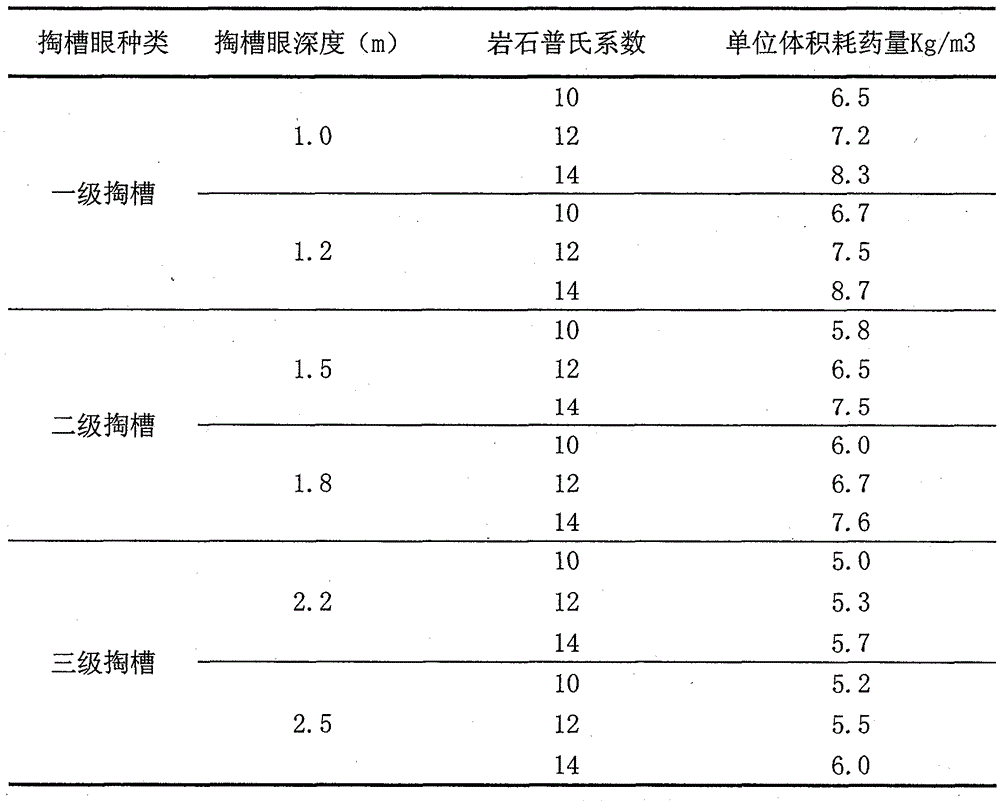

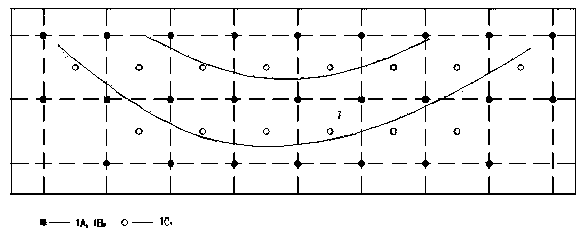

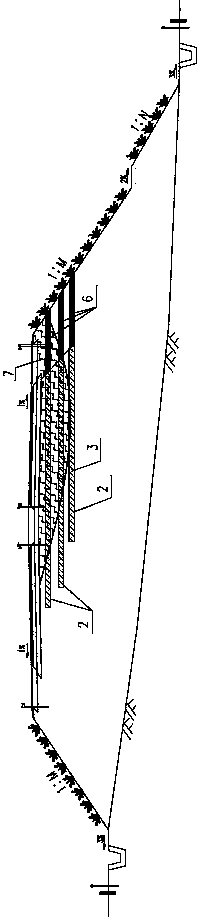

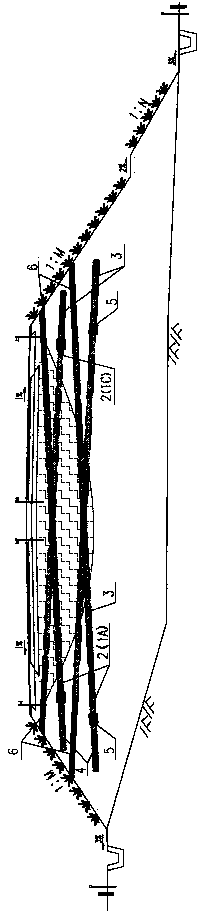

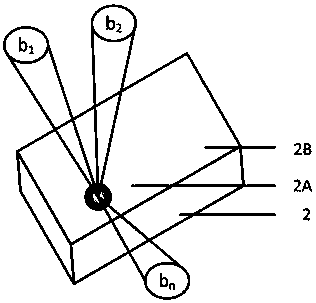

The invention relates to a fast and highly-efficient tunneling method for a large section of a hard-rock tunnel in a coal mine by combination of fully-mechanized tunneling and blasting driving. As shown in the figure 1, a cut hole with the borehole diameter of Phi 40.0 mm and a reliever hole with the charge diameter of Phi 35.0 mm are arranged in the section of the hard-rock tunnel with the protodyakonov coefficient f larger than 10.0 for digging out a groove cavity with s approximately equal to 14.0 m<2>. As shown in the figure 2, the cut hole adopts a three-stage oblique cut with stages deepening and angles of inclination increasing stage by stage. The consumption of charge in unit volume is determined based on the hard-rock protodyakonov coefficient and shot hole depth according to quantification of the figure 3. Three stages of oblique cuts respectively select I, III, IV-section millisecond delay detonators. A V-section millisecond delay detonator is selected by the reliever hole. The oblique cuts and the whole section of the reliever hole are detonated once with the total delay time no more than 130.0ms. After the groove cavity is formed in a blasting method. The reasonable tooth parameters are selected to rapidly expand the groove cavity to the design section and contour is finished under effect of a free surface of a fully-mechanized coal winning machine. Due to millisecond delay detonation of the oblique cut in three stages and larger borehole diameter, stemming is blocked to increase so that rocks do not affect the fully-mechanized coal winning machine after the working surface during the throwing process. The safe and efficient effect can be achieved.

Owner:湖南省煤业集团红卫矿业有限公司

Method and structure for reinforcing flat hole grouting roadbed without damaging road surface

ActiveCN103981782AGuaranteed integrityAvoid damageRoadwaysSoil preservationStructural engineeringCement grout

The invention discloses a method and a structure for reinforcing flat hole grouting roadbed without damaging road surface. The method comprises the following steps of A. determining the positions of grouting holes; B. drilling horizontal or slant grouting holes to ensure that the drilling angle is orthogonal to the main damaging direction of the roadbed; C. striking the grouting holes in an interlaced mode; D. drilling and grouting from the periphery of the damaged roadbed to the inside; E. arranging grouting floral pipes; F. arranging seamless grouting outer pipes at the front ends of the grouting holes which penetrate through the cross section of the roadbed and are dimensionally and crossly distributed; G. uniformly filling cement grouts and determining grouting pressure through tests and areas; and H. performing sedimentation, inclination, deformation and displacement observation on the roadbed surfaces, structures and surrounding buildings during grouting. Horizontal or inclined drilling is carried out on roadbed slopes in the affected area for forming the grouting holes, the grouting floral pipes and the seamless grouting outer pipes are arranged, and the grouting floral pipes are connected with the seamless grouting outer pipes by virtue of joint by screws. The method is feasible and convenient to carry out; because of no-damage road surface structure, the bearing capacity and the stability of the roadbed structure in the affected area are obviously improved, and the reinforcement effect is high.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

Preparing method and application of high-strength soft magnetic composite material

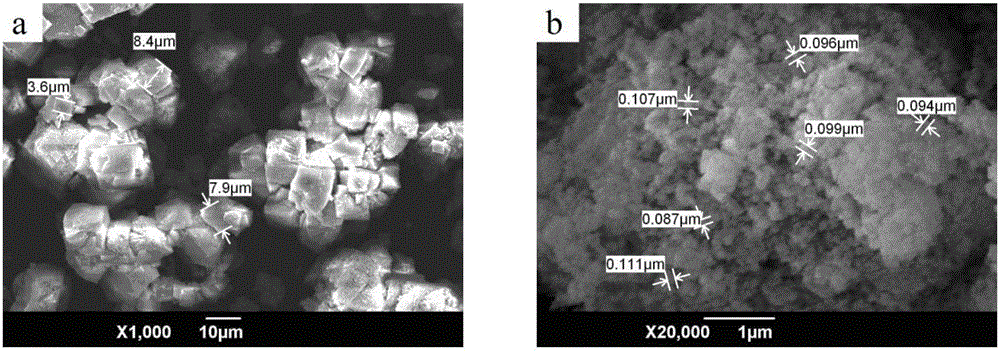

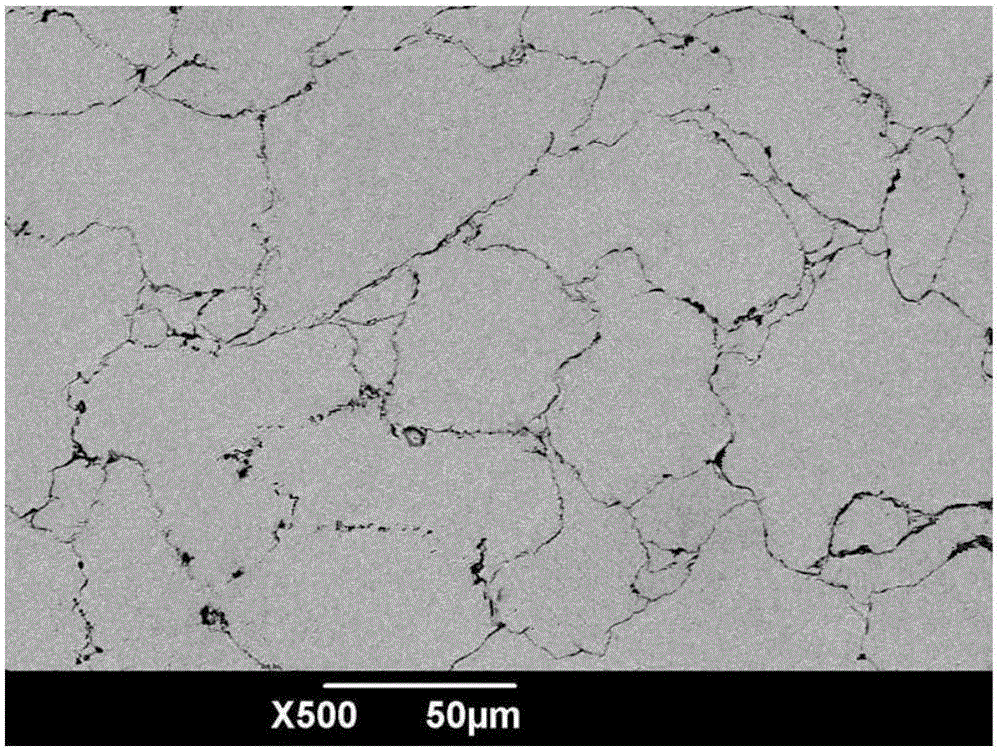

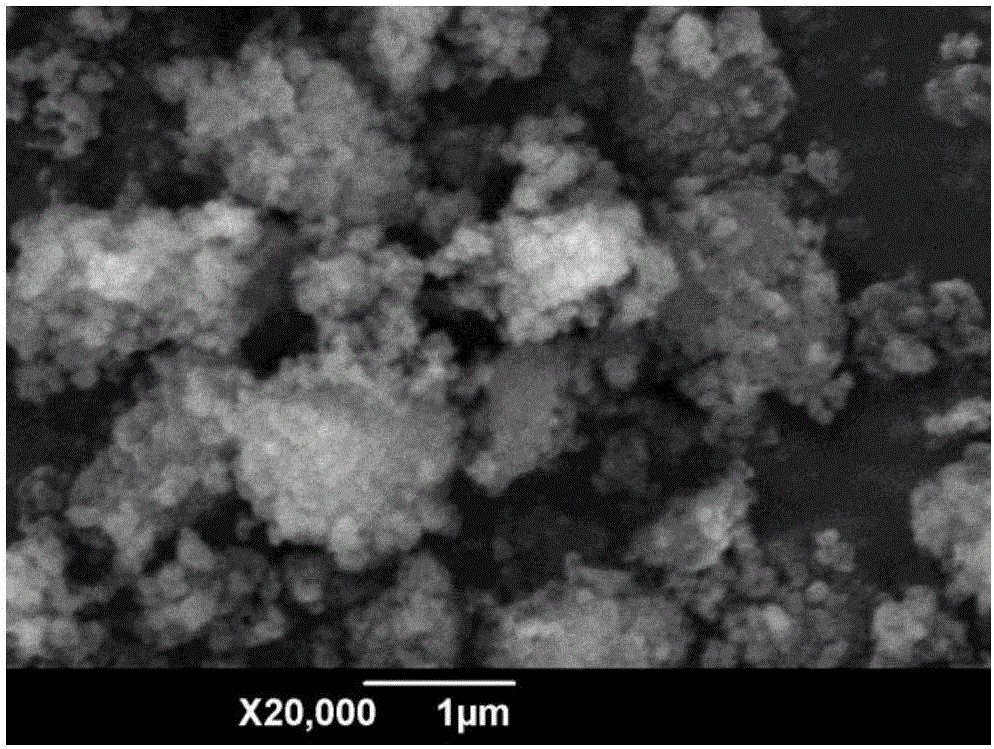

ActiveCN105132786AHigh strengthReduce the number of holesInorganic material magnetismBearingsMagnetic powderMagnesium

The invention provides a preparing method of a high-strength soft magnetic composite material. According to the method, Fe with a great reserve volume is selected to be used as a magnetic powder material, so that the cost of the raw material is low; a liquid phase reducing method is used for obtaining passivated iron powder; then, a high-energy ball mill is used for performing ball milling on high-purity magnesium oxide powder; particles with the granularity being 80nm to 100nm are obtained; then, the passivated iron powder and the refined magnesium oxide powder are uniformly mixed by a mechanical mixing method; and the high-strength soft magnetic composite material is obtained through pressing and heat treatment. The prepared soft magnetic composite material has the advantages of high resistivity, small eddy current loss, few hole defects and high strength. The high-strength soft magnetic composite material is applied to a stator and a thrust disc of an electromagnetic thrust bearing.

Owner:宁波合荣磁业有限公司

Medium-length hole mixed wedge cut blasting method capable of realizing directed fracture using cutting cartridge bag for solid rock roadway

InactiveCN103983146AReduce unit consumptionControl disturbance damageBlastingEngineeringUltimate tensile strength

The invention discloses a medium-length hole mixed wedge cut blasting method capable of realizing directed fracture using a cutting cartridge bag for a solid rock roadway. According to the method disclosed by the invention, 3-4 pairs of vertical wedge cutting holes are arranged at lower half places of an excavating working face; the vertical wedge cutting holes comprise mirror-arranged primary cutting holes and secondary cutting holes that are arranged at the two sides of the primary cutting holes; the primary cutting holes comprise three blast holes that are arranged side by side; the secondary cutting holes comprise four blast holes that are arranged side by side; 1-2 straight holes are formed in the middle portion of each primary cutting hole; a distance between every two adjacent blast holes in the primary cutting holes is 800-1000mm. According to the method disclosed by the invention, the advantage of directed fracture blasting of the cutting cartridge bag is fully utilized, so that an orifice distance and a row distance of the primary cutting holes are increased, the number of blasting holes is reduced, explosive unit consumption is decreased, disturbance damage to the roadway surrounding rocks by cut blasting is effectively controlled, the original strength and stability of the roadway surrounding rocks are guaranteed, and favourable conditions are provided for repairing and maintenance works during later roadway support and operation progresses.

Owner:HENAN POLYTECHNIC UNIV

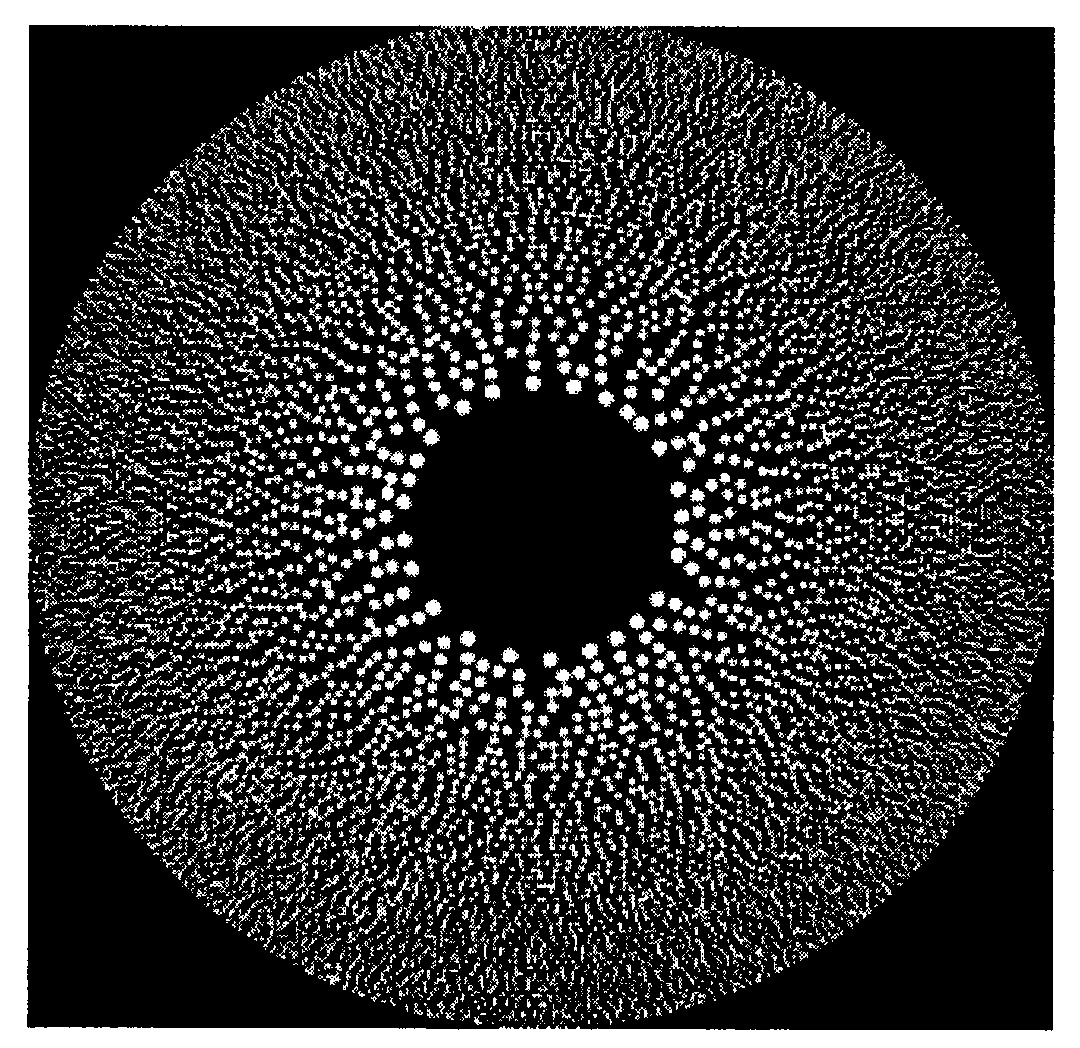

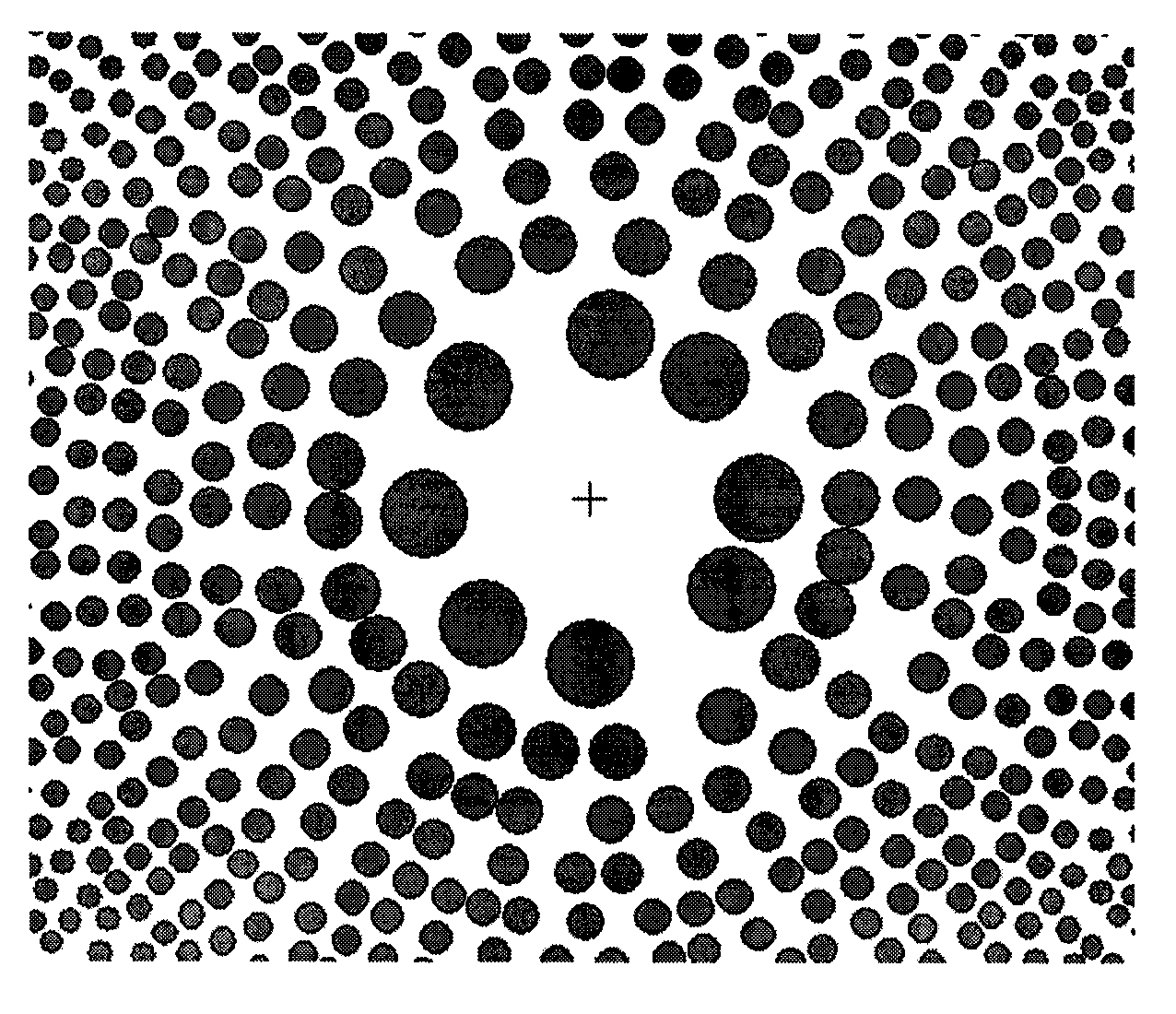

Large-aperture imaging photon sieve and production method thereof

InactiveCN101630027AHigh-resolutionSharp focal spotDiffraction gratingsImage resolutionOptoelectronics

The invention discloses a large-aperture imaging photon sieve and a production method thereof, which belong to the technical field of diffractive optical elements. The large-aperture imaging photon sieve comprises a transparent substrate and an opaque metal thin film plated on the transparent substrate, wherein, a plurality of transparent small holes are randomly distributed on the opaque metal thin film, and the transparent small holes which are randomly distributed lead diffraction light to generate mutual interference, thereby effectively suppressing sidelobe effect and high-level diffraction, improving resolution and obtaining more sharp focal spots. The production method adopts a Connes shaping function for shaping the small holes which are randomly distributed, thereby reducing the number of the holes, reducing the data amount of a layout, optimizing the overall distribution of the small holes, leading the imaging focal spots to be more sharp and leading the level of the existing processing technology to be capable of meeting the manufacturing needs of the large-aperture photon sieve.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

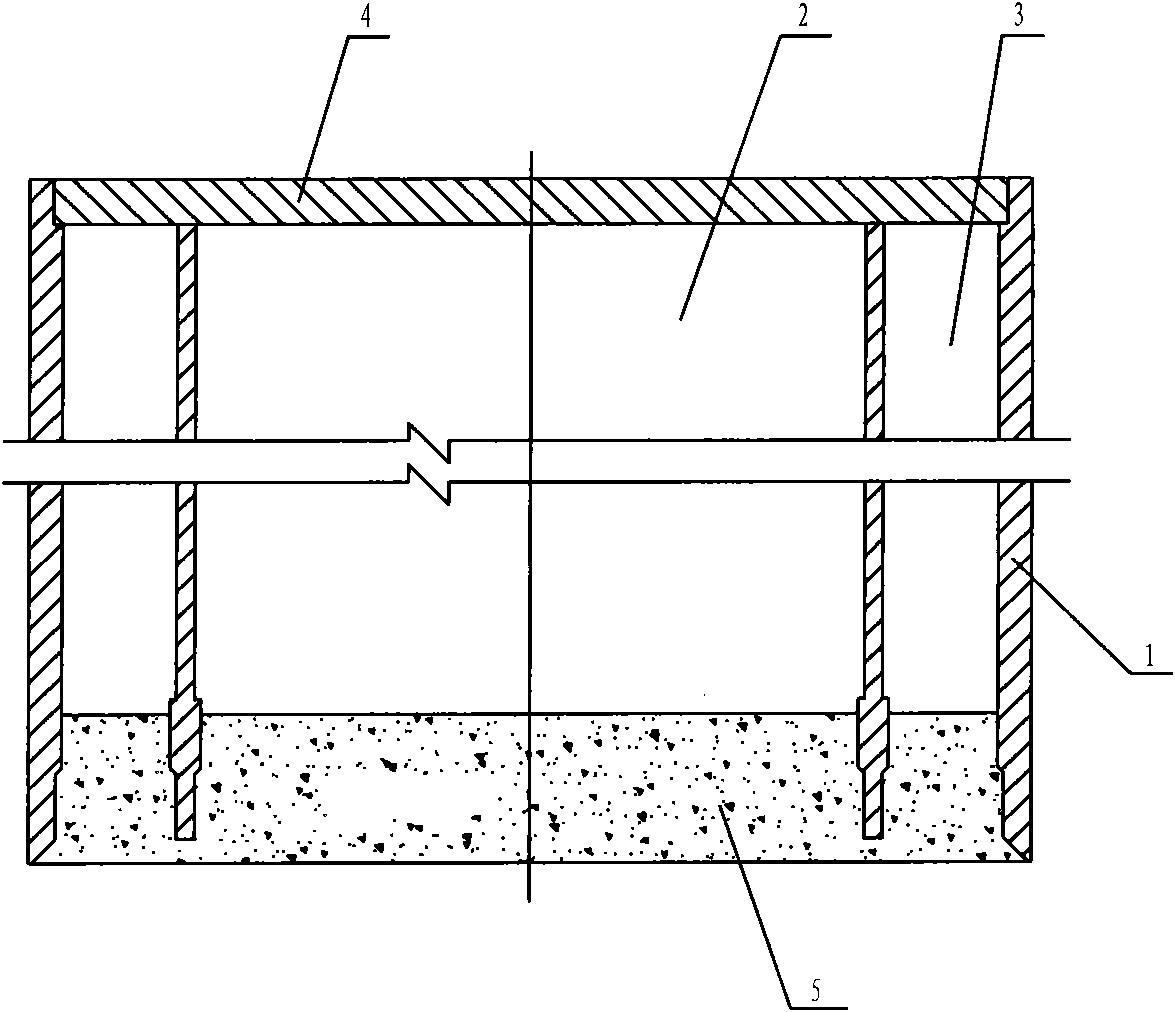

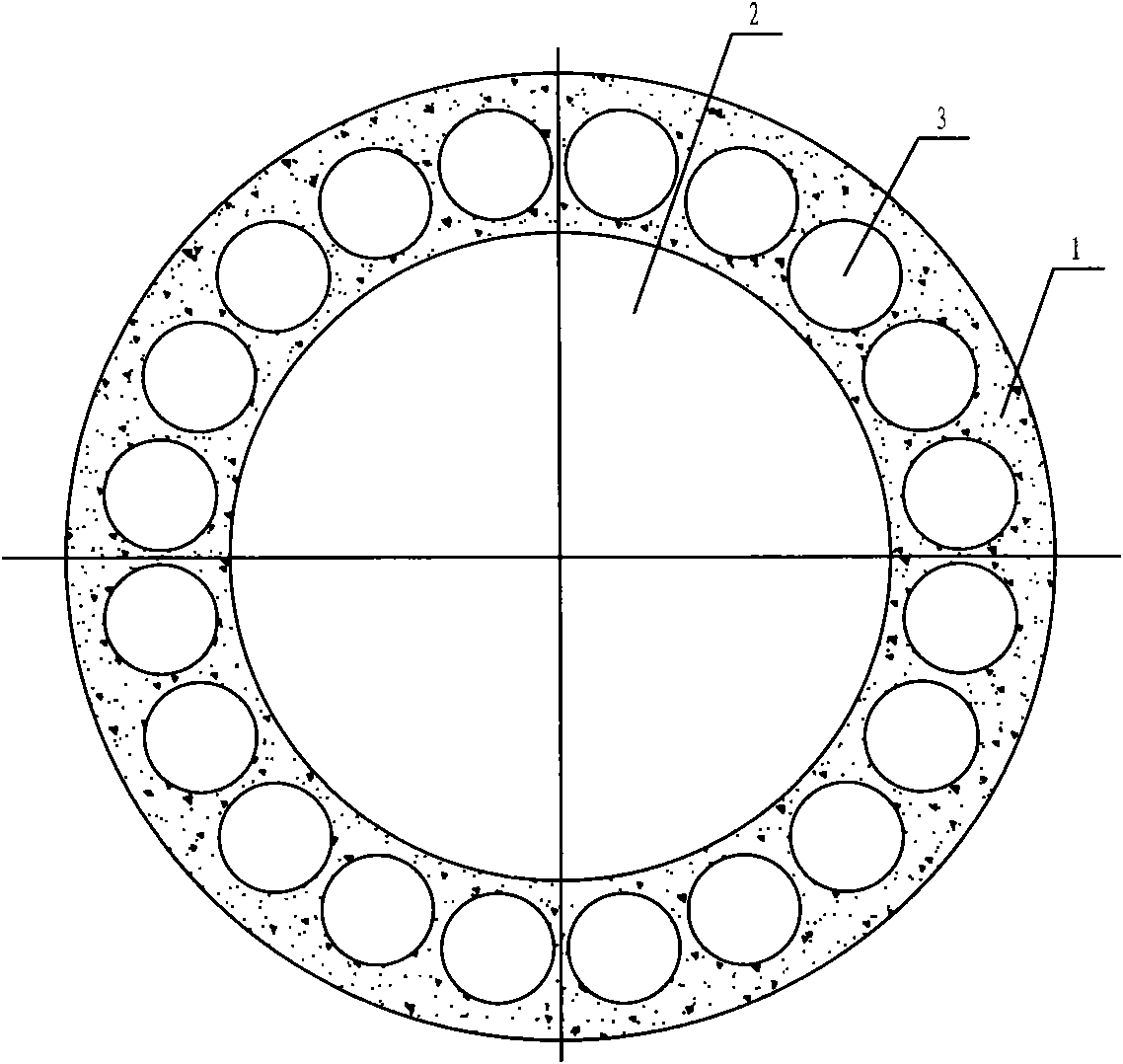

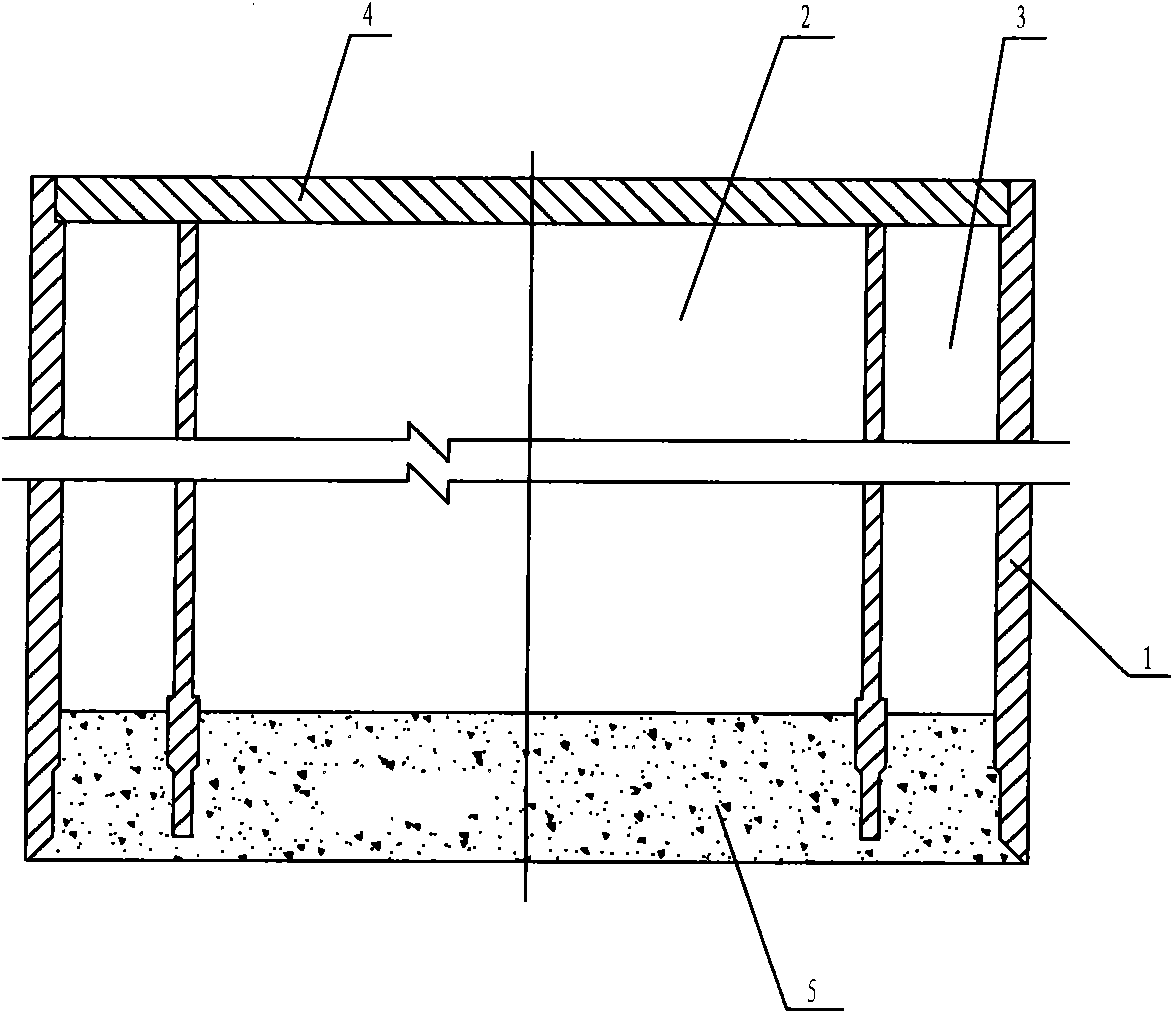

Sunk well structure and construction method thereof

The invention discloses a sunk well structure, comprising a well body which is round in the outer profile of the section and provided with a central hole in the center, a well wall is formed on the well body on the periphery of the central hole and provided with a plurality of round holes parallel to the central hole, and the round holes are symmetrically distributed with the axis of the well body as a center. The sunk well structure of the invention has the advantages of simple structure, fewer hole number and reasonable stress, and the section of the sunk well is in a centrosymmetry structure and the well holes comprises big holes and small hole, therefore, construction operation and positioning control are convenient when sinking.

Owner:ZHONGTIE MAJOR BRIDGE RECONNAISSANCE & DESIGN INST

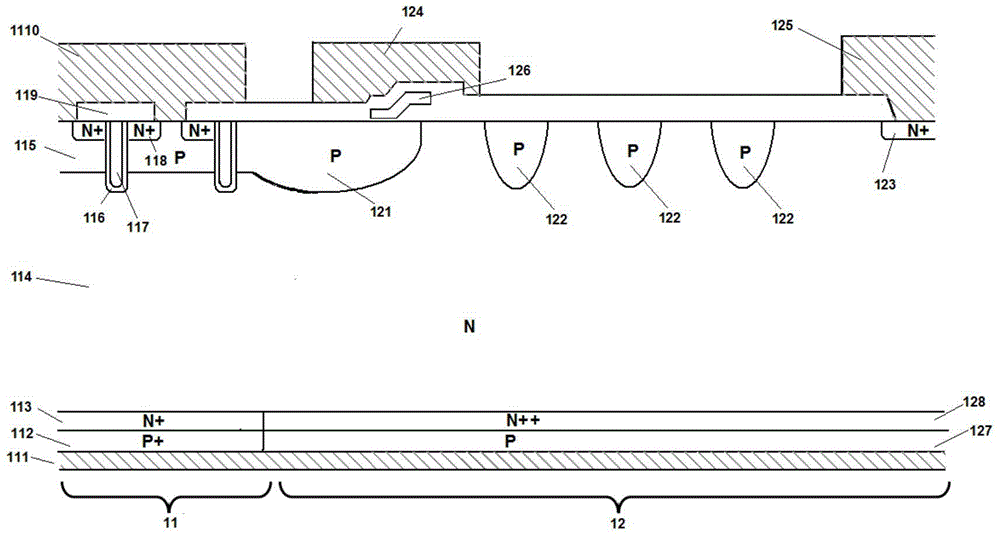

Field stop type IGBT device with terminal structure and manufacturing method thereof

InactiveCN104143568AReduce the possibility of secondary breakdownIncrease the number of compoundSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactCell region

The invention relates to a field stop type IGBT device with a terminal structure and a manufacturing method of the field stop type IGBT device. An IGBT device structure is arranged in a cell region of the first primary side of a semiconductor substrate, and a terminal protection structure is arranged in a terminal region of the first primary side. Collector metal making ohmic contact with a second conduction type collector region is arranged on the second primary side of the semiconductor substrate, and the second conduction type collector region is isolated from a first conduction type drifting region through a first conduction type buffer region. The second conduction type collector region comprises a second conduction type first collector region located in the cell region and a second conduction type second collector region located in the terminal region. The first conduction type buffer region comprises a first conduction type first buffer region located in the cell region and a first conduction type second buffer region located in the terminal region. According to the field stop type IGBT device, switching losses of an existing field stop type IGBT device can be effectively reduced, and use reliability of the IGBT device is improved.

Owner:WUXI NCE POWER

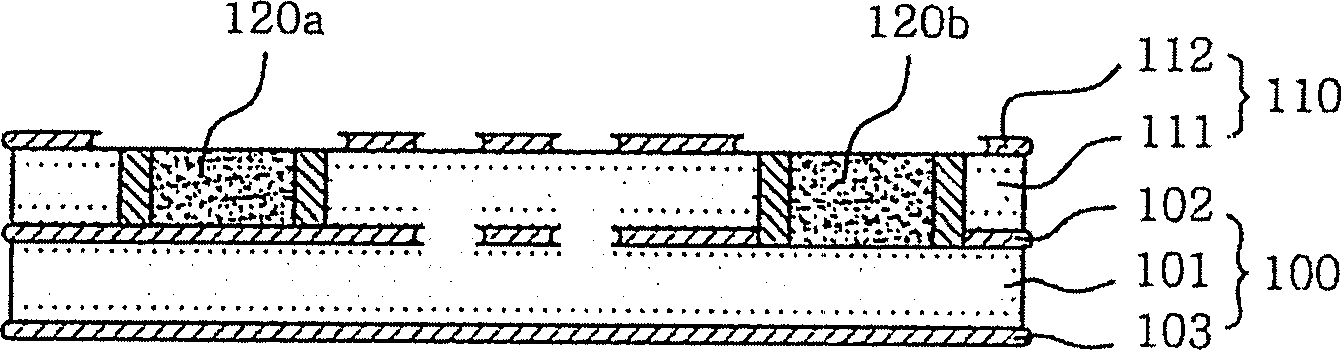

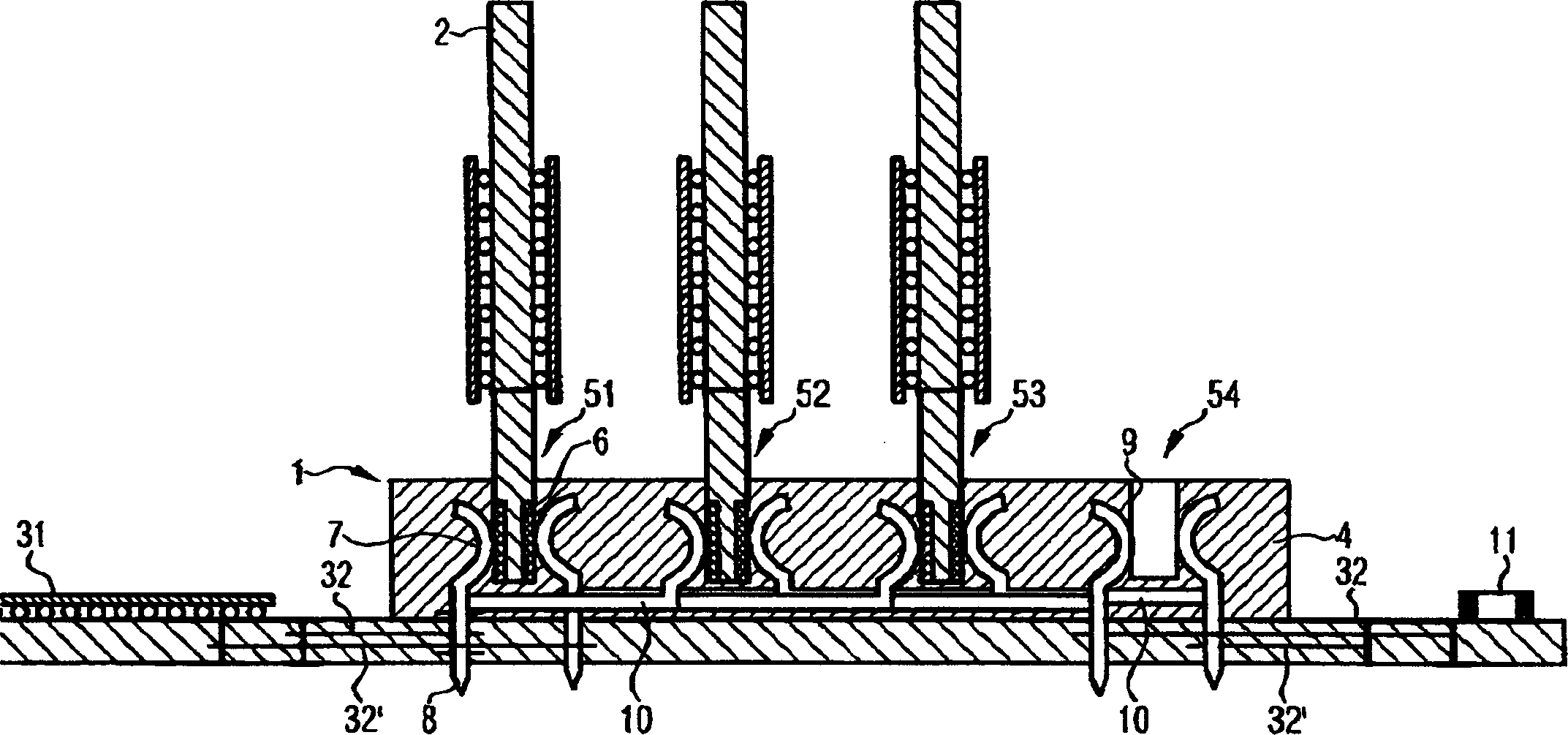

Method of fabricating PCB including embedded passive chip

InactiveCN1722935AWon't fall outEasy to embedPrinted circuit assemblingFinal product manufactureElectrical and Electronics engineeringBlind hole

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

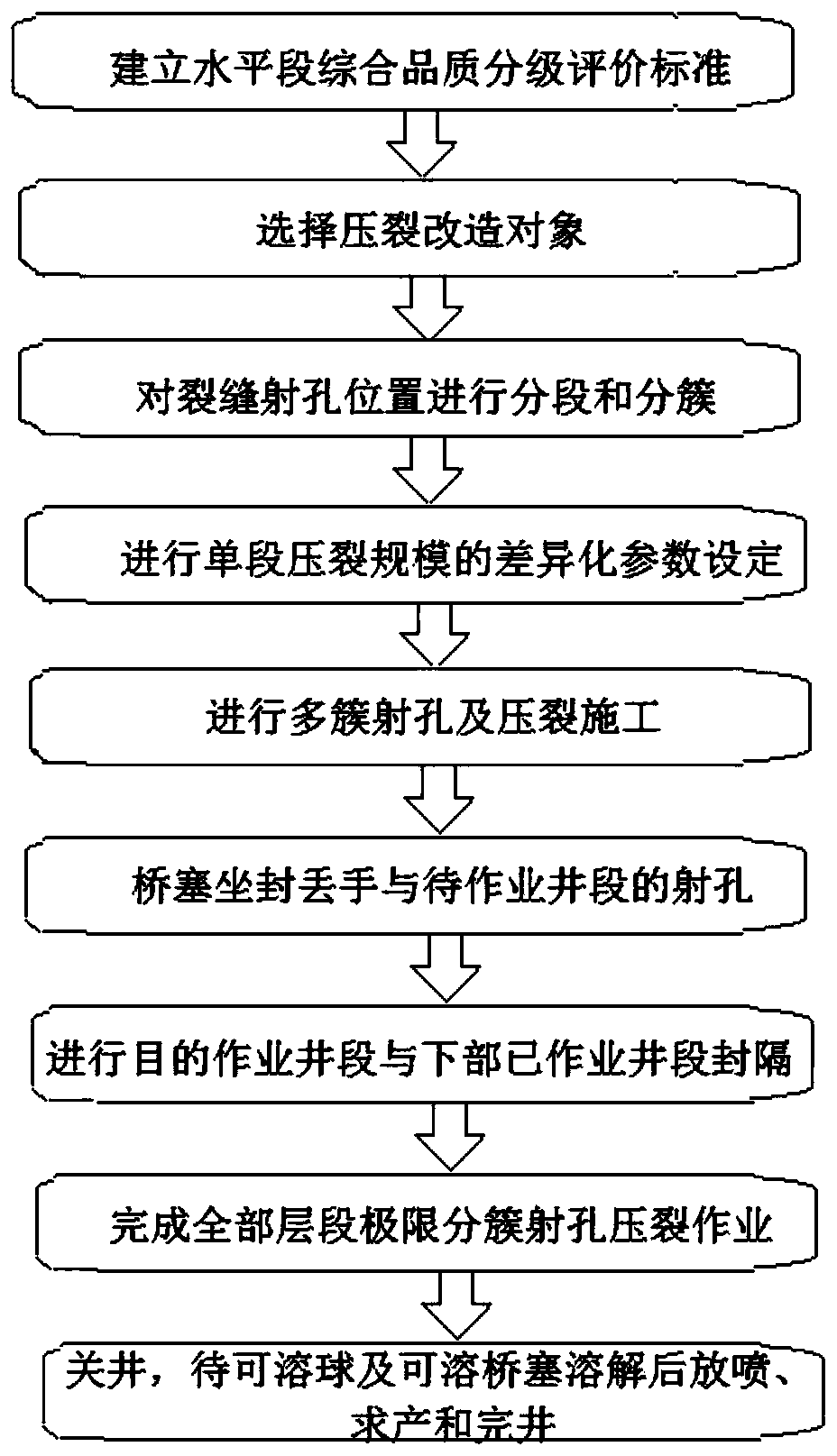

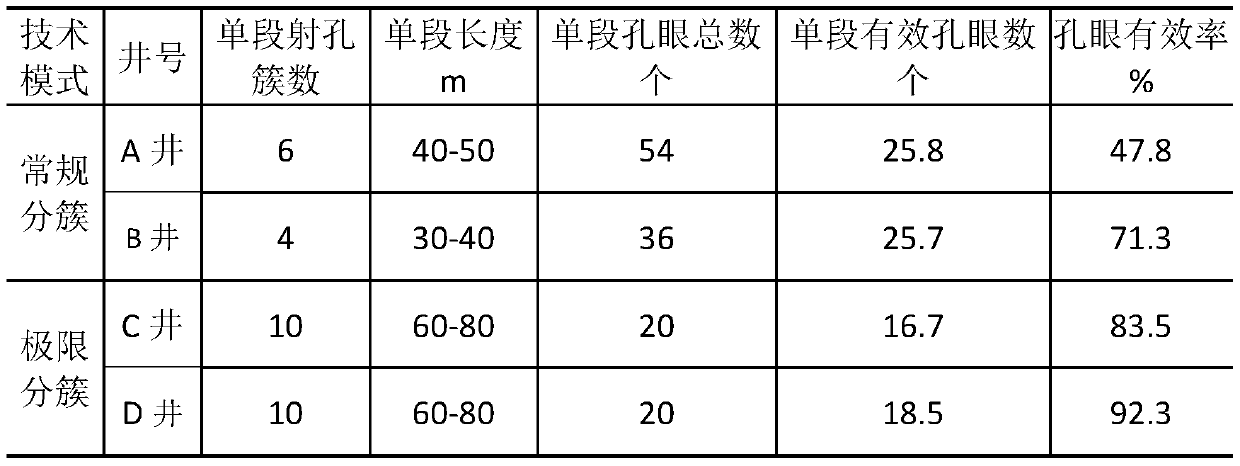

Dense reservoir long horizontal well limit clustering perforation fracturing method

ActiveCN110984943AReduce the number of holesHigh degree of controlFluid removalHorizontal wellsUnconventional oil

The invention belongs to the technical field of oil reservoir measure yield increase in oil production engineering, and particularly relates to a dense reservoir long horizontal well limit clusteringperforation fracturing method. The perforation opening efficiency is improved by greatly reducing the number of single cluster holes, the uniformity of fluid distribution among a plurality of clustersis greatly improved, multi-cluster balanced crack initiation and effective extension are achieved, then the number of intra-segment clustering perforation clusters is greatly increased, and the control degree of single-segment cracks on the oil layer segment length is improved. On the premise that the fracturing transformation strength is not reduced, multi-cluster cracks can be better effectively opened, and full transformation of a dense reservoir horizontal well is achieved. The effectiveness of the intra-segment multi-cluster fracturing cracks can be effectively improved, the control degree of the single-segment cracks on the oil layer segment length is improved, the number of fracturing segments is greatly reduced, the construction efficiency is improved, the operation cost is reduced, and the method has wide application prospects in the aspect of efficiency improvement and reduction of unconventional oil and gas long horizontal wells.

Owner:PETROCHINA CO LTD

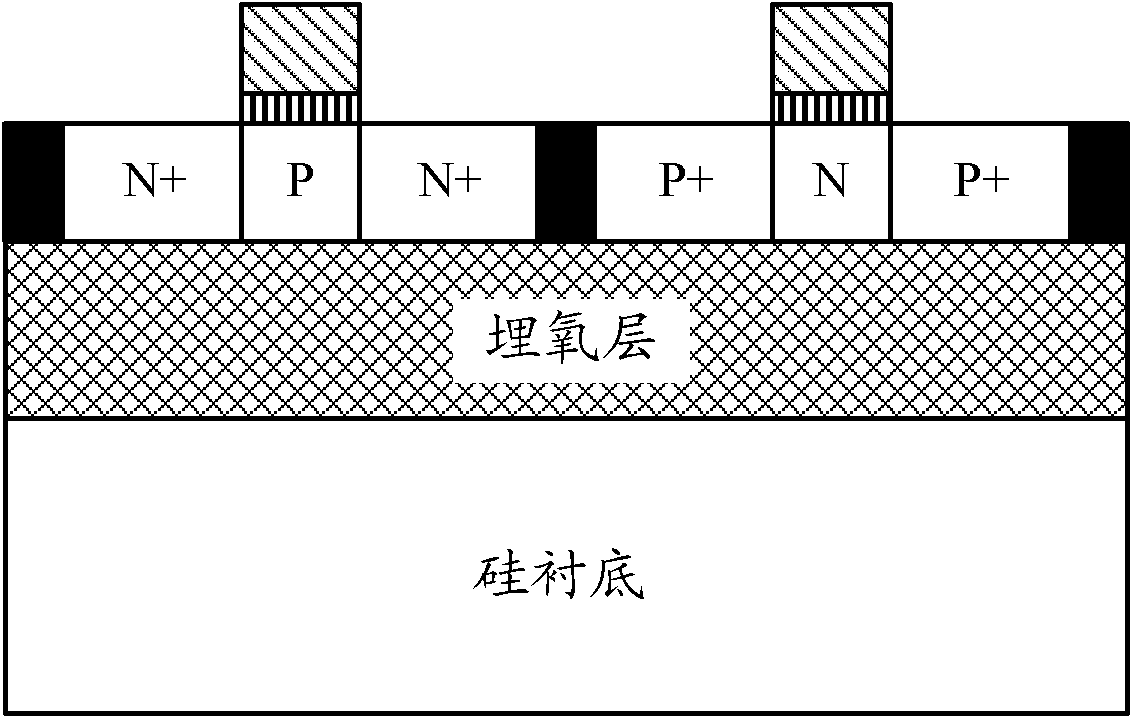

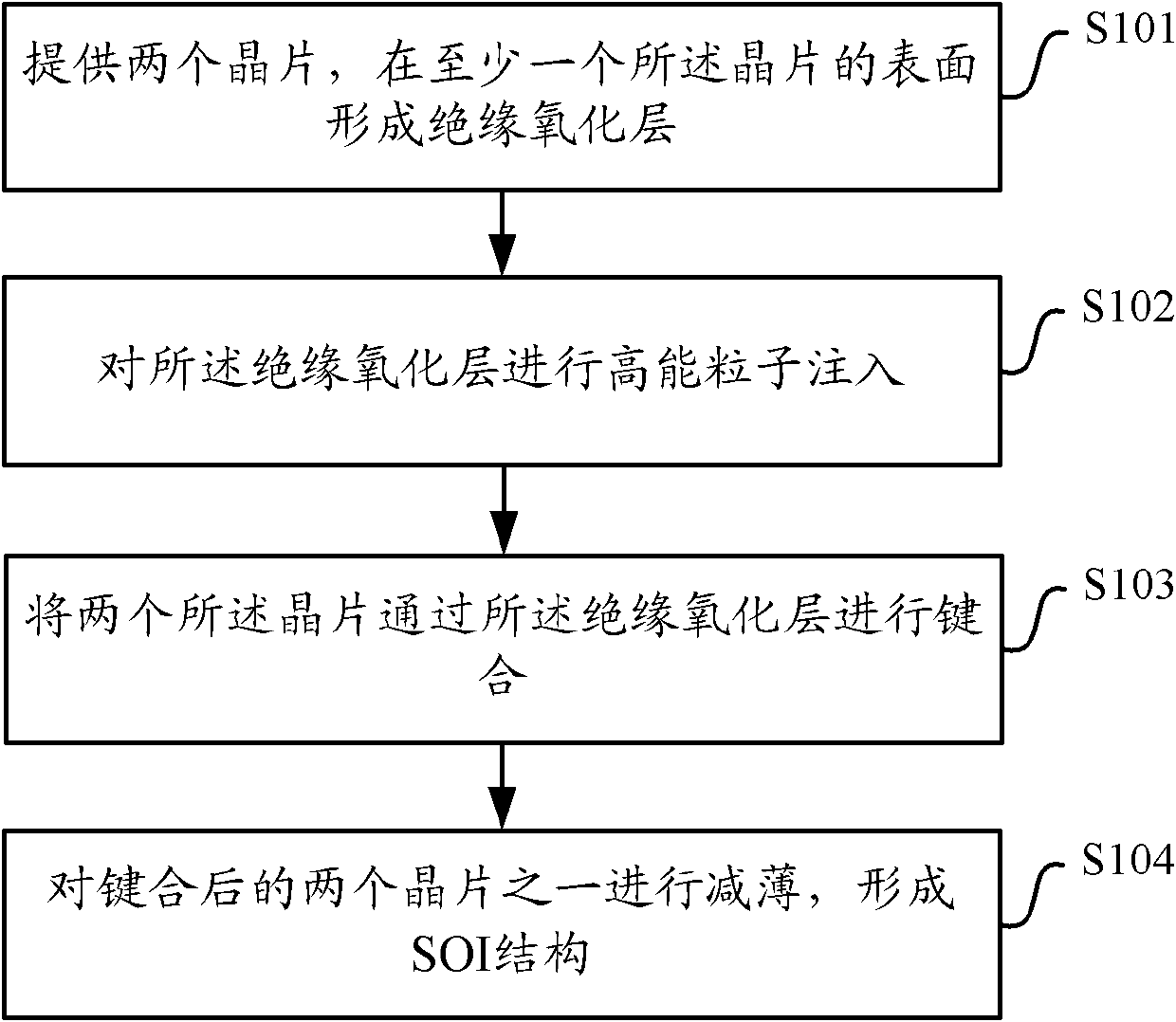

SOI structure with reinforced anti-irradiation performance and manufacturing method thereof

ActiveCN102437087AShort lifeThe effect of electrical neutralitySemiconductor/solid-state device manufacturingProtonEngineering

The invention provides an SOI (Silicon-On-Insulator) structure with reinforced anti-irradiation performance and a manufacturing method thereof. The manufacturing method of the SOI structure with reinforced anti-irradiation performance comprises the following steps: providing two wafers, and forming an insulation oxide layer on a surface of at least one wafer; carrying out injection of an irradiation proton, an irradiation neutron and the like on the insulation oxide layer, and introducing displacement damage in the insulation oxide layer; carrying out bonding of the two wafers through the insulation oxide layer; thinning one of the two wafers after bonding to form an SOI structure. In a process of utilizing bonding technology to prepare an SOI, through a method of injecting the proton, the neutron and the like into a buried oxide layer and introducing the displacement damage to form a composite center, anti-irradiation performance of an SOI device is raised, simultaneously, damage of a top silicon layer is avoided, and the performance of the device is not influenced.

Owner:BEIJING ZHONGKE XINWEITE SCI & TECH DEV

Preparation method of waterproof compressive autoclaved aerated concrete block

The invention discloses a preparation method of a waterproof compressive autoclaved aerated concrete block, and belongs to the technical field of building materials. Aminated silicon dioxide and tri-n-dodecylamine modified tetratitanate are used for preparing modified tetratitanate, and the modified tetratitanate is dried in the carbon dioxide atmosphere, so that the modified tetratitanate adsorbing the carbon dioxide is obtained, then concentrated sulfuric acid is used for sulfonating a polystyrene microsphere, the sulfonated polystyrene microsphere is used for preparing a porous polystyrenemicrosphere under the action of a porogenic agent, the modified tetratitanate, the porous polystyrene microsphere and modified sodium lignin sulfonate are added into a basic material of a product together, and the waterproof compressive autoclaved aerated concrete block is obtained after stirring, mixing and curing the materials. A large-aperture pore in the inner part of the prepared waterproof compressive autoclaved aerated concrete block is relatively small, and the waterproof compressive autoclaved aerated concrete block is internally provided with a lamellar protection layer, so that thewaterproofness of the product is improved under the condition that the compressive strength of the product is effectively improved, and the significant progress is made by compared with the current product.

Owner:姜建国

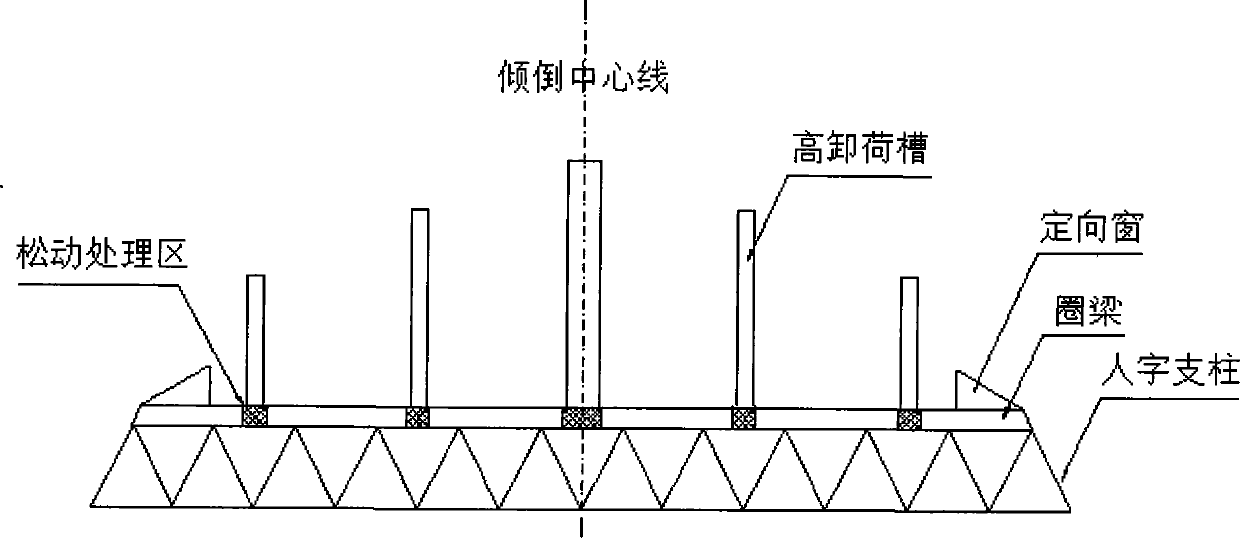

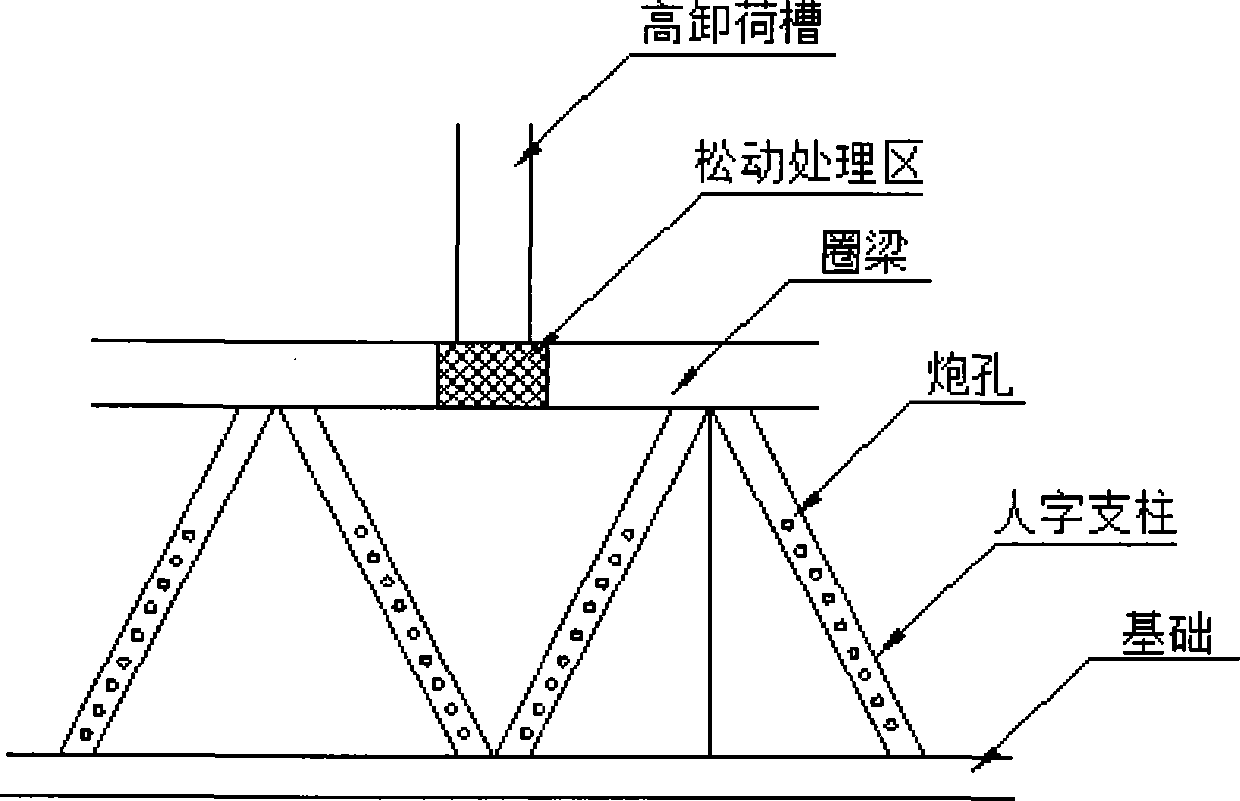

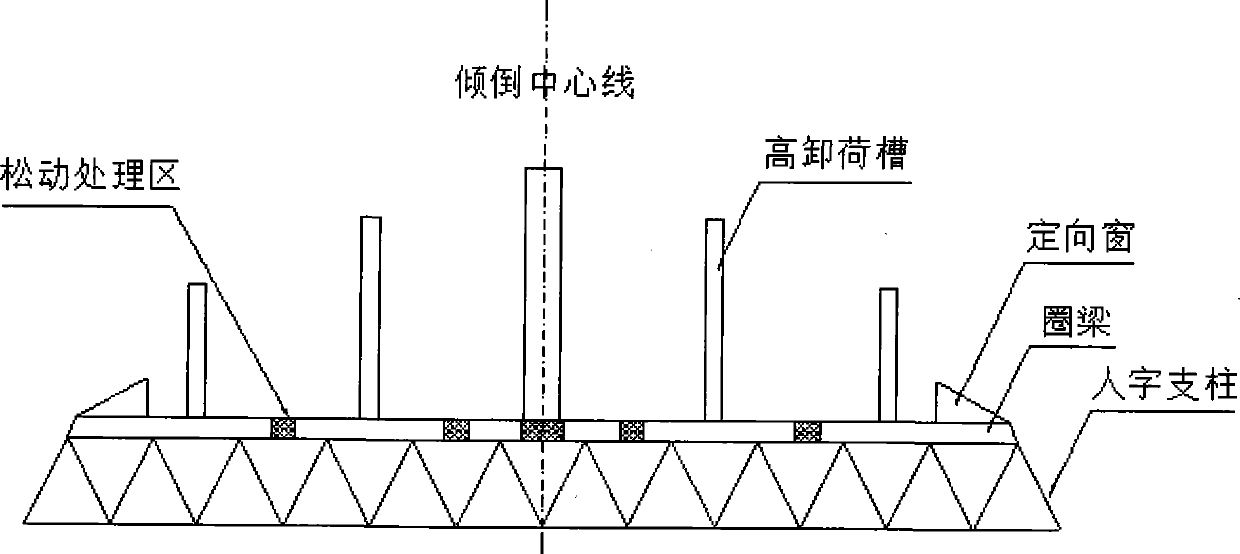

High-unloading slot composite-incision demolition blasting method for reinforced concrete cooling tower

InactiveCN104089550AReduce blasting vibrationReduce drilling workloadBlastingRebarReinforced concrete

The invention discloses a high-unloading slot composite-incision demolition blasting method for a reinforced concrete cooling tower, and relates to a demolition blasting method for the reinforced concrete cooling tower. The demolition blasting method comprises the following steps: pre-demolishing an internal sprinkling platform and an external ladder of the reinforced concrete cooling tower to be demolished by blasting; arranging a composite blasting incision including a rectangular herringbone pillar area, a trapezoidal ring beam area, an acute triangular directional window and a high unloading slot on the lower part of the tower body, wherein the high unloading slot and the directional window are mechanically arranged so as to ensure the construction precision; drilling at the herringbone pillar and a ring beam which is locally required to be loosened by blasting (a ring beam loosening area is constructed by a mechanical method and a blasting method), filling explosive, fencing, and strengthening blasting of a millisecond delay blasting network through non-electric bidirectional multi-point excitation. By the demolition blasting method, the falling direction can be accurately controlled, the number of boreholes and the amount of the explosive can be greatly reduced, the collapsing disintegration degree and the touchdown impact state of the tower body can be regulated and controlled, and the touchdown vibration can be effectively controlled.

Owner:HENAN POLYTECHNIC UNIV

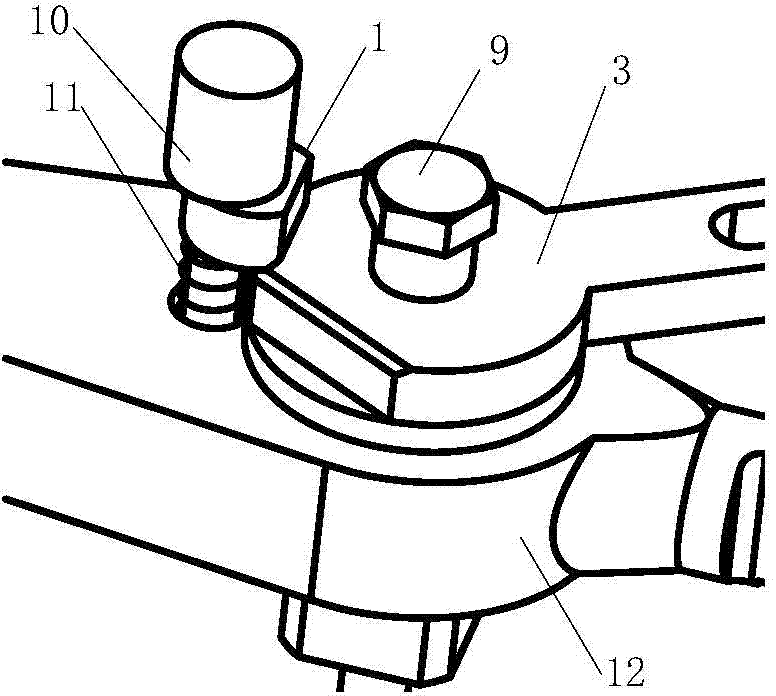

Vernier index plate unit

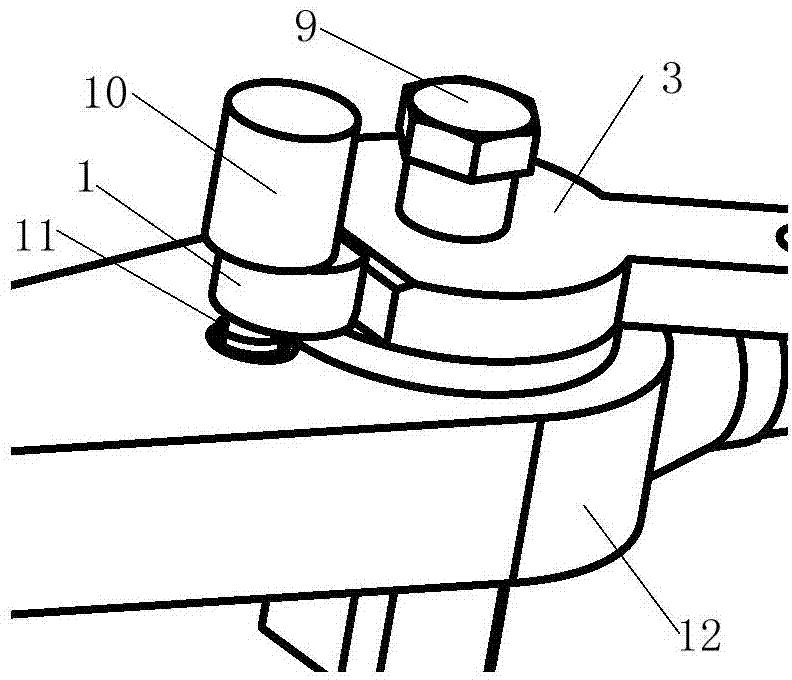

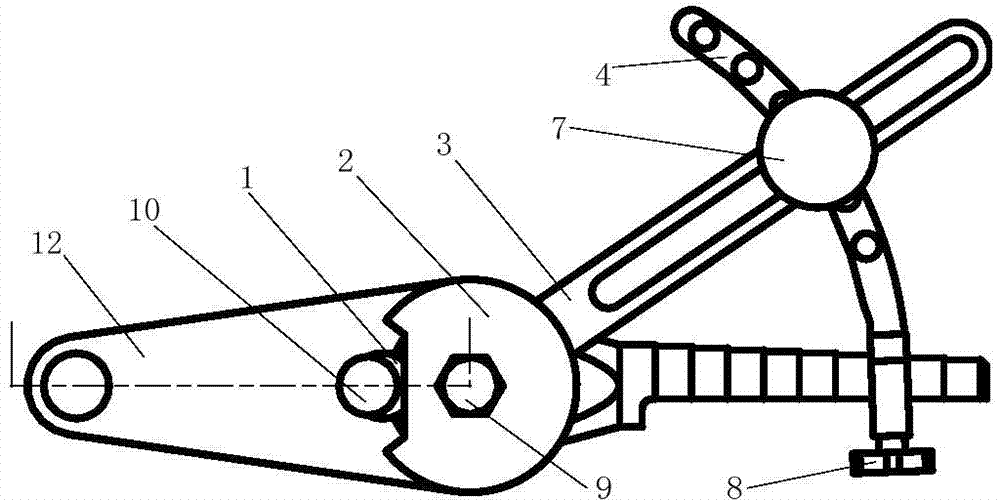

InactiveCN103921168AExquisite structureEasy to operatePrecision positioning equipmentVernier scaleEngineering

The invention provides a vernier index plate unit comprising a positioning pad, a fixed top cover, a swing rod, a vernier scale, an orifice disc pin, a pin spring, a pin handle, a fixing screw, a bolt, a positioning bolt, a pad spring, and a rod carrier. The vernier index plate unit is available in two operating modes when applied to a universal index head. When the vernier scale is not mounted, the positioning pad fastens the swing rod to a set position by rotating a positioning pin, and the vernier index plate unit is used in the same as a common index rocker. When the vernier scale is mounted, the vernier scale is mounted on the rod carrier first, the swing rod is loosened and can rotate freely, and meanwhile, an index disc and the vernier scale are used together for indexing according to the principle of vernier caliper, so that indexing capacity of the universal index head is greatly improved. The vernier index plate unit has the advantages of ingenious structure, simplicity in operation, stable performance, economy and the like; indexing capacity can be greatly improved without changing the universal index head.

Owner:HARBIN ENG UNIV

Silicon-controlled rectifier lateral double diffused metal oxide semiconductor with high maintaining voltage

InactiveCN102832232AIncrease holding voltageReduced risk of latch failureSemiconductor devicesSilicon-controlled rectifierBody contact

A silicon-controlled rectifier lateral double diffused metal oxide semiconductor with high maintaining voltage comprises an N-type substrate. Buried oxide is arranged on the N-type substrate, an N-type epitaxial layer is arranged on the buried oxide, an N-type buffer trap and a P-type body region are arranged in the N-type epitaxial layer, a P-type anode region and an N-type contact region are arranged in the N-type buffer trap, an N-type cathode region and a P-type body contact region are arranged in the P-type body region, a gate oxide layer and a field oxide layer are arranged on the surface of the N-type epitaxial layer, a shallow P-type trap region is arranged on the surface of the N-type cathode region and the surface of the P-type body contact region, and a polysilicon gate is arranged on the surface of the gate oxide layer. The silicon-controlled rectifier lateral double diffused metal oxide semiconductor is characterized in that a deep N-type trap region is arranged under the P-type anode region and the N-type body contact region, a deep P-type trap region is arranged under the shallow P-type trap region, and a carrier double-injection effect can be effectively suppressed by the shallow P-type trap region and the deep P-type trap region, so that the quantity of neutralized free carriers in a drift region is reduced. Accordingly, the maintaining voltage of a device is improved, and risks of breech lock in an electrostatic release process are reduced.

Owner:SOUTHEAST UNIV

Blue and green diode epitaxial slice and manufacturing method thereof

ActiveCN102931302AImprove luminous efficiencyReduce the number of electronsSemiconductor devicesQuantum wellLength wave

The invention discloses a blue and green diode epitaxial slice and belongs to the technical field of diodes. The epitaxial slice comprises a substrate layer and a buffering layer, an N-type layer, a multi-quantum well layer, a P-type electronic barrier layer and a P-type layer which sequentially cover the substrate layer, wherein the multi-quantum well layer comprises a composite layer and a transitional layer covering the composite layer and the composite layer consists of a plurality of quantum barrier layers and a plurality of quantum well layers which are arranged alternately; and one layer (in contact with the transitional layer) in the composite layer is the quantum well layer. According to the blue and green diode epitaxial slice, the translational layer replaces a quantum barrier layer (in contact with the P-type electronic barrier layer) in the multi-quantum well layer of the conventional epitaxial slice, so that the number of electrons stopped in the layer is reduced, and the number of cavities in the layer is also reduced; therefore, the electrons and the cavities which are compounded in the layer are reduced, and light of which the wavelength is close to that of the ultrasonic band is reduced; and finally, the luminous efficiency of a blue and green diode is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

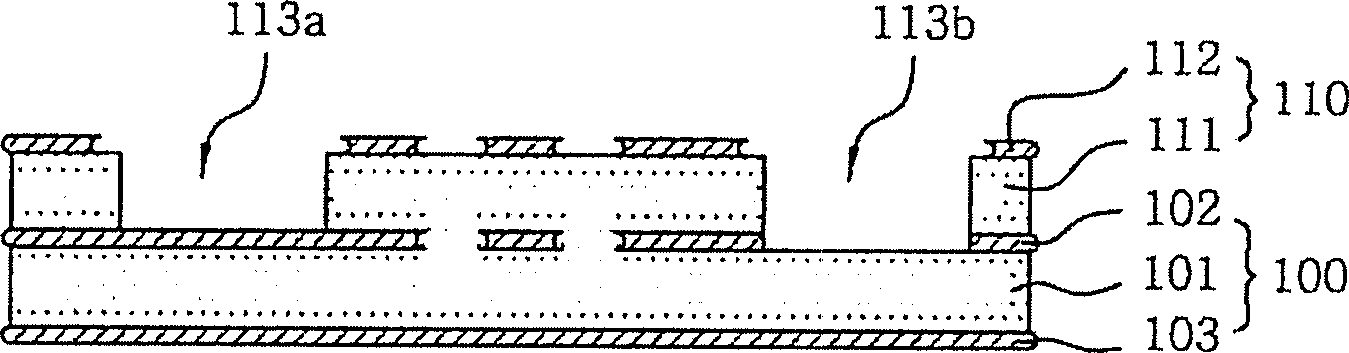

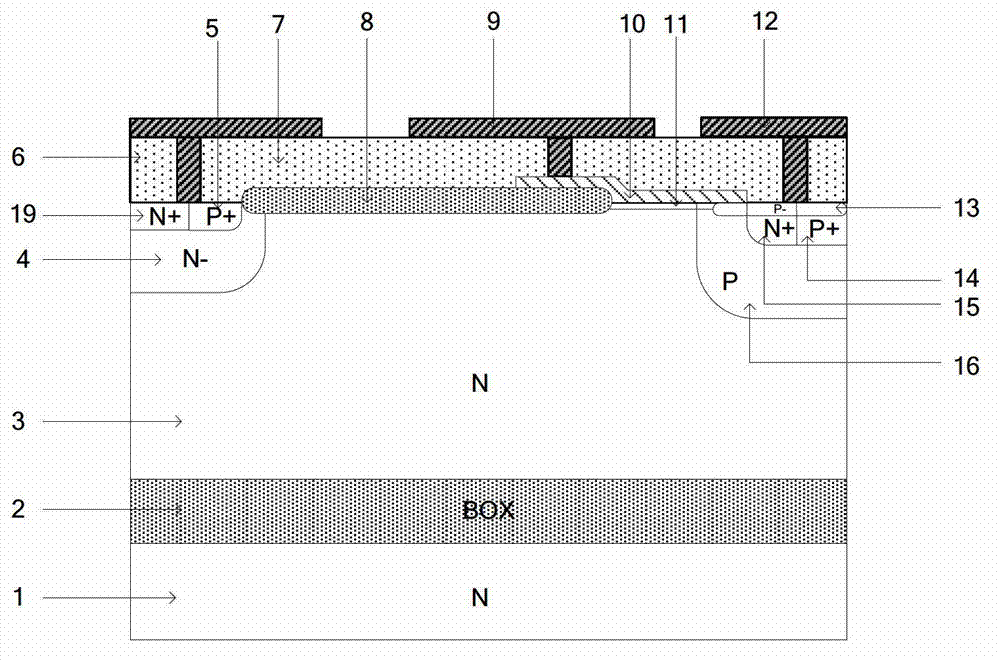

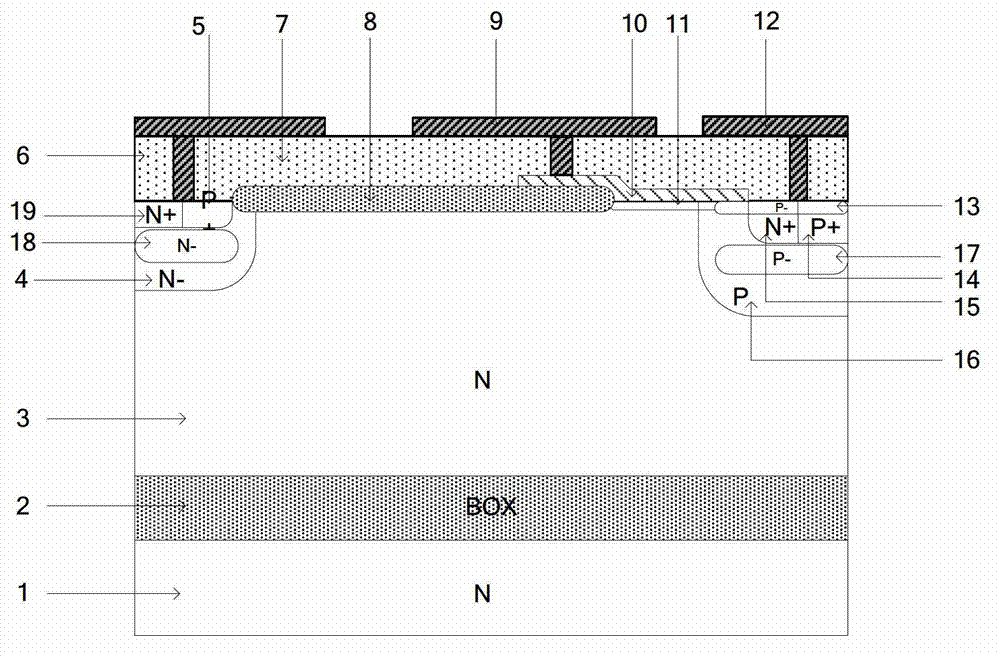

Insulated gate bipolar transistor device comprising a depletion-mode MOSFET

InactiveUS7968940B2Reduce the number of holesReduce transportationTransistorSolid-state devicesEngineeringDouble gate

Double gate IGBT having both gates referred to a cathode in which a second gate is for controlling flow of hole current. In on-state, hole current can be largely suppressed. While during switching, hole current is allowed to flow through a second channel. Incorporating a depletion-mode p-channel MOSFET having a pre-formed hole channel that is turned ON when 0V or positive voltages below a specified threshold voltage are applied between second gate and cathode, negative voltages to the gate of p-channel are not used. Providing active control of holes amount that is collected in on-state by lowering base transport factor through increasing doping and width of n well or by reducing injection efficiency through decreasing doping of deep p well. Device includes at least anode, cathode, semiconductor substrate, n− drift region, first & second gates, n+ cathode region; p+ cathode short, deep p well, n well, and pre-formed hole channel.

Owner:ANPEC ELECTRONICS CORPORATION

Ship anchor type anchor head of ground anchor stretching when grouting

InactiveCN1162589CEasy constructionIncrease anchoring forceBulkheads/pilesAnchoring boltsPropellerHigh pressure

This invention includes: thin wall steel tube, fluke top seat, piston propeller, bar and fluke in which the fluke top seat is fixedly connected with the thin wall steel tube, both ends of the bar are connected to its base seat of the piston probeller and fluke separately by flexible pins, the anchor head is linked to the fluke top seat by pins and middle of the fluke is linked with the bar, and connection holes connect the anchor chain at the back of the anchor head. Using the character of large fixed area and powerful force of fluke, this invention provides pulling resistance like anchor, in operation the back of anchor head is connected with the chain then put in anchor eyes to grout with high pressure from thin-wall steel tube to force the fluke open into the anchor eye wall to provide anchor force.

Owner:SHANGHAI JIAO TONG UNIV

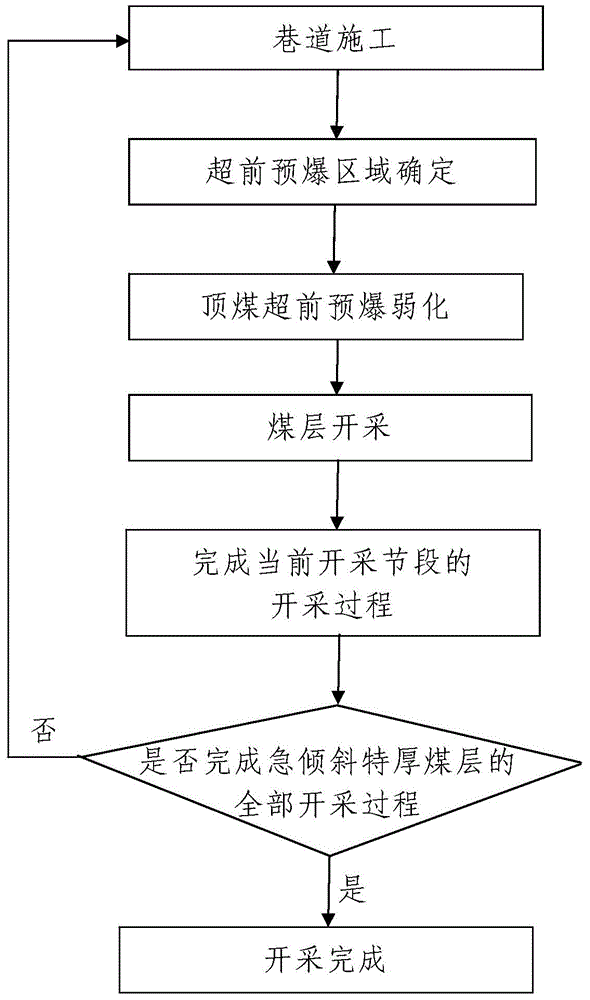

Steep-dip ultra-thick coalbed mining technique based on top-coal advancing pre-detonation weakening

InactiveCN104879128AThe process steps are simpleReasonable designUnderground miningSurface miningDetonationCoal

The invention discloses a steep-dip ultra-thick coalbed mining technique based on top-coal advancing pre-detonation weakening. The steep-dip ultra-thick coalbed mining technique includes exploiting steep-dip ultra-thick coalbed from back to front along coalbed bearing in several exploiting periods. In one of the exploiting period, the steps include firstly, constructing a roadway; secondly, weakening top-coal advancing pre-detonation, to be specifically, 201, determining a coalbed to be detonated; 202, drilling blast holes from an intake airflow road by a drilling machine; 203, charging and sealing the blast holes; 204, detonating for the first time; 205, detonating for the second time; thirdly, exploiting the coalbed; fourthly starting the next exploiting period; repeating the fourth step for many times until the steep-dip ultra-thick coalbed is completely exploited. The steep-dip ultra-thick coalbed mining technique is simple in steps, reasonable in design, high in exploitation efficiency and working-face recovery ratio, and good in using effect, and the problem that an existing mining technique is complicated, low in working-face recovery ratio and low in exploitation efficiency and causes many potential safety hazards is solved.

Owner:XIAN UNIV OF SCI & TECH

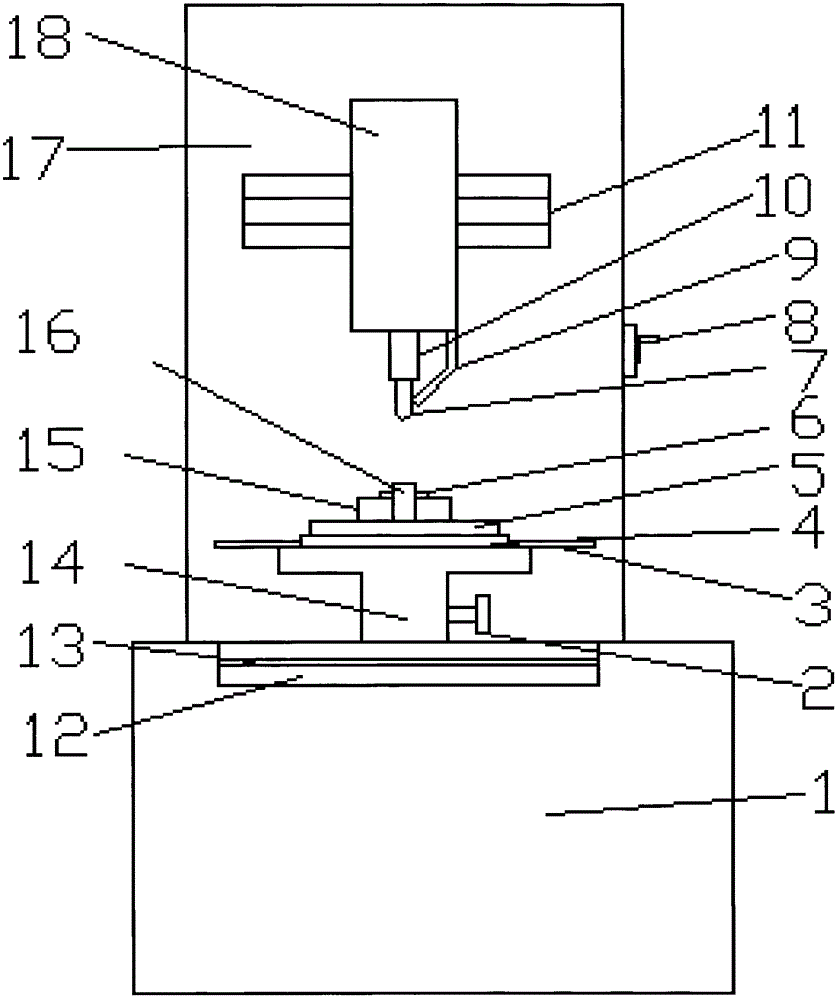

Simple numerically-controlled machine tool for machining blind holes

InactiveCN103658736AEasy to adjustEasy adjustment; locking pliers are hydraulically controlledMeasurement/indication equipmentsFeeding apparatusNumerical controlFuel tank

The invention discloses a simple numerically-controlled machine tool for machining blind holes. The simple numerically-controlled machine tool comprises a machine tool electrical cabinet, a machine tool spindle box, a numerical control panel, a cutting fluid box body, a hydraulic oil tank and a workbench. The machine tool spindle box is arranged at the front end of the machine tool electrical cabinet. The workbench is arranged below the machine tool spindle box. The cutting fluid box body is arranged below the workbench. The hydraulic oil tank is arranged on one side of the machine tool electrical cabinet and connected with the machine tool electrical cabinet through a hydraulic oil tube. Supporting tables are arranged on the two sides of the workbench. Delivery rollers are arranged at the upper ends of the supporting tables. Air pressure supports are arranged at the lower ends of the supporting tables. An index chuck is arranged on one side of each supporting table. According to the simple numerically-controlled machine tool for machining the blind holes, machining can be conducted as long as the height of the machine tool is adjusted simply and simple setting is conducted, a lot of time for adjustment and programming of the machine tool is saved, and the machining of perforating guns with few holes in a small batch is more convenient; moreover, the simple numerically-controlled machine tool is simple in structure and lowers production cost.

Owner:杨国栋

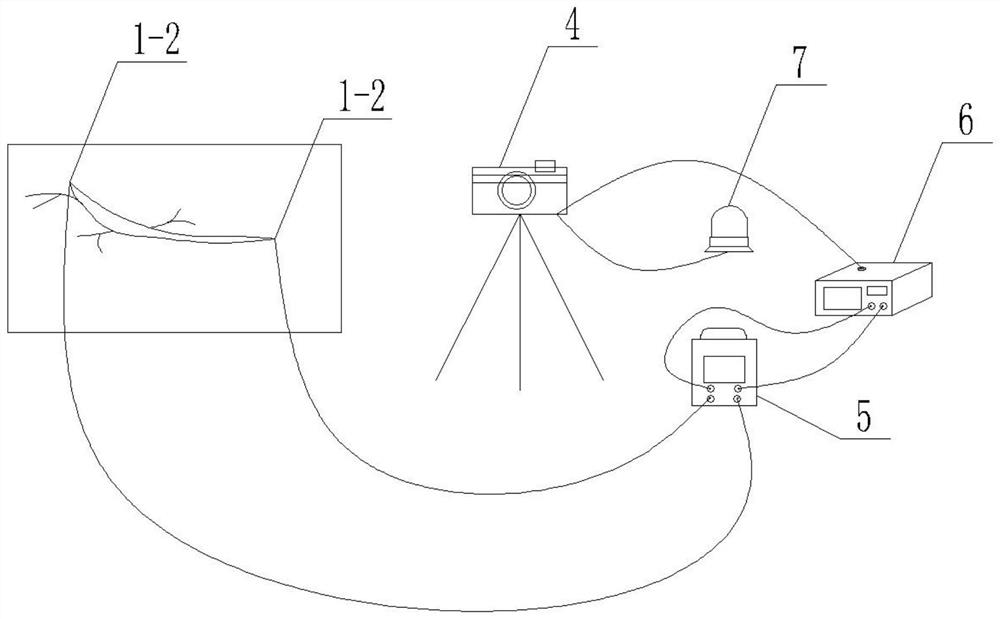

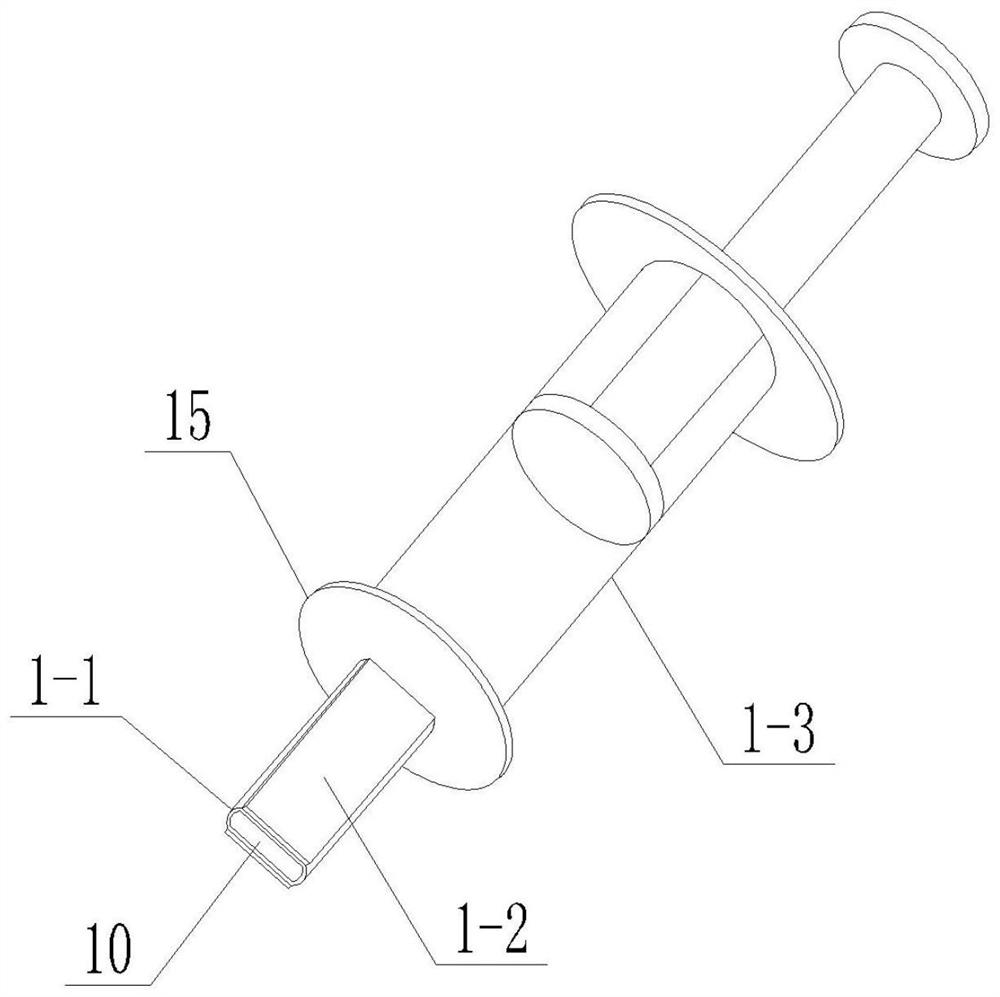

Filling type maintenance device and method for concrete crack repairing in winter in cold regions

ActiveCN112727139AEasy to useAvoid the defect of incoherent maintenance effectUnderground chambersBuilding repairsTemperature controlContinuous use

The invention discloses a filling type maintenance device and method for concrete crack repairing in winter in cold regions. The device and the method aim to overcome the defects that after a concrete structure is cracked in winter in a cold region, an existing method cannot achieve rapid repairing on site, and great problems are brought to continuous use of the structure. According to the filling type maintenance device, each electrode type injector of comprises a flat needle head, electrode plates and an injection body; the flat needle head is detachably connected to the discharging end of the injection body, a feeding port communicating with the discharging end of the injection body is machined in one end of the flat needle head, and a discharging port is machined in the other end of the flat needle head; and the electrode plates are arranged on the outer wall of the flat needle head, the injection body is filled with conductive concrete, the two electrode plates of the two electrode type injectors are electrically connected with a voltage regulator, the voltage regulator is connected with a thermal infrared imager through a temperature control switch, and the thermal infrared imager is further provided with an alarm in a matched mode. The filling type maintenance device is used for rapid repairing of the cracking part of the concrete structure in winter in the cold region.

Owner:HARBIN INST OF TECH

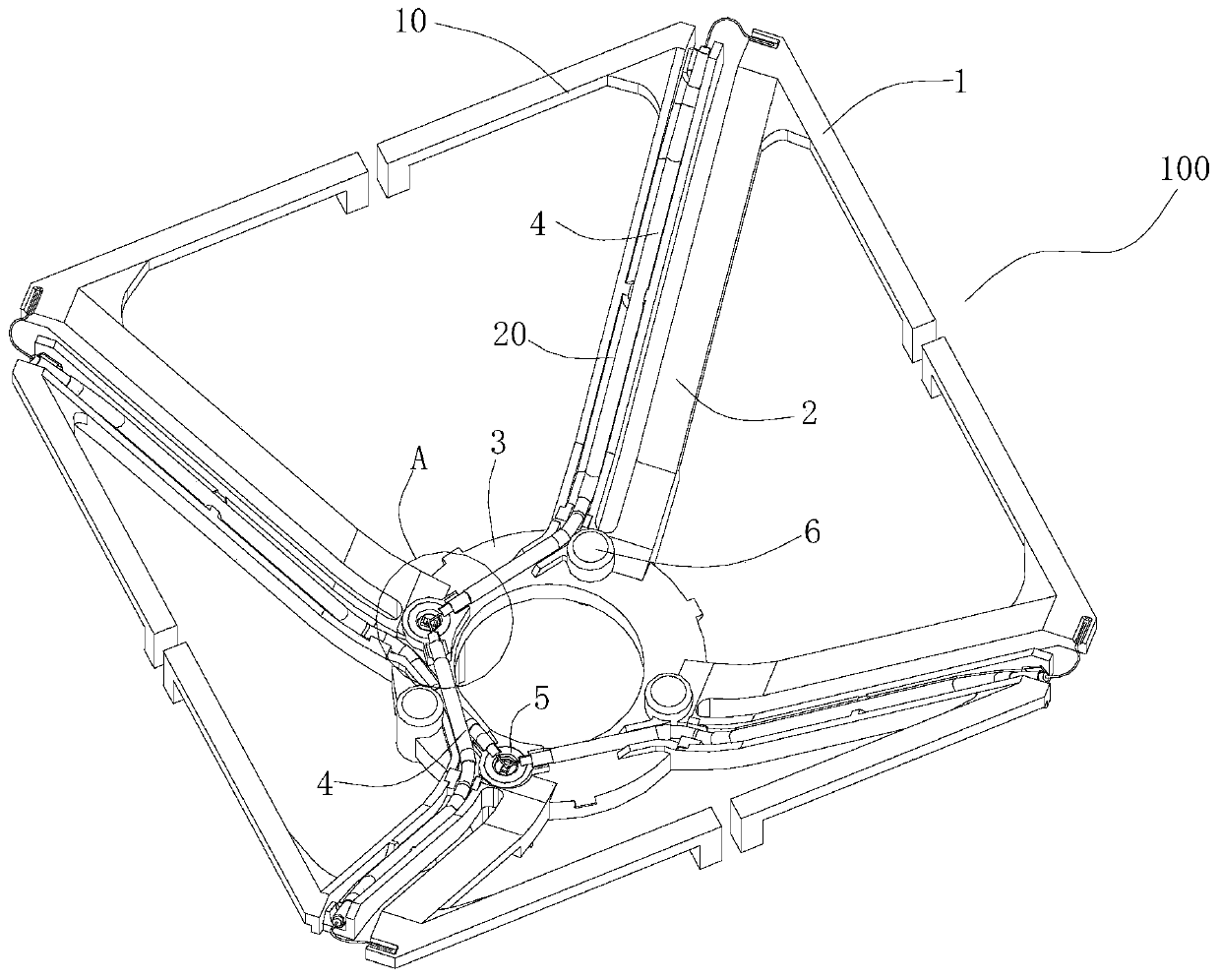

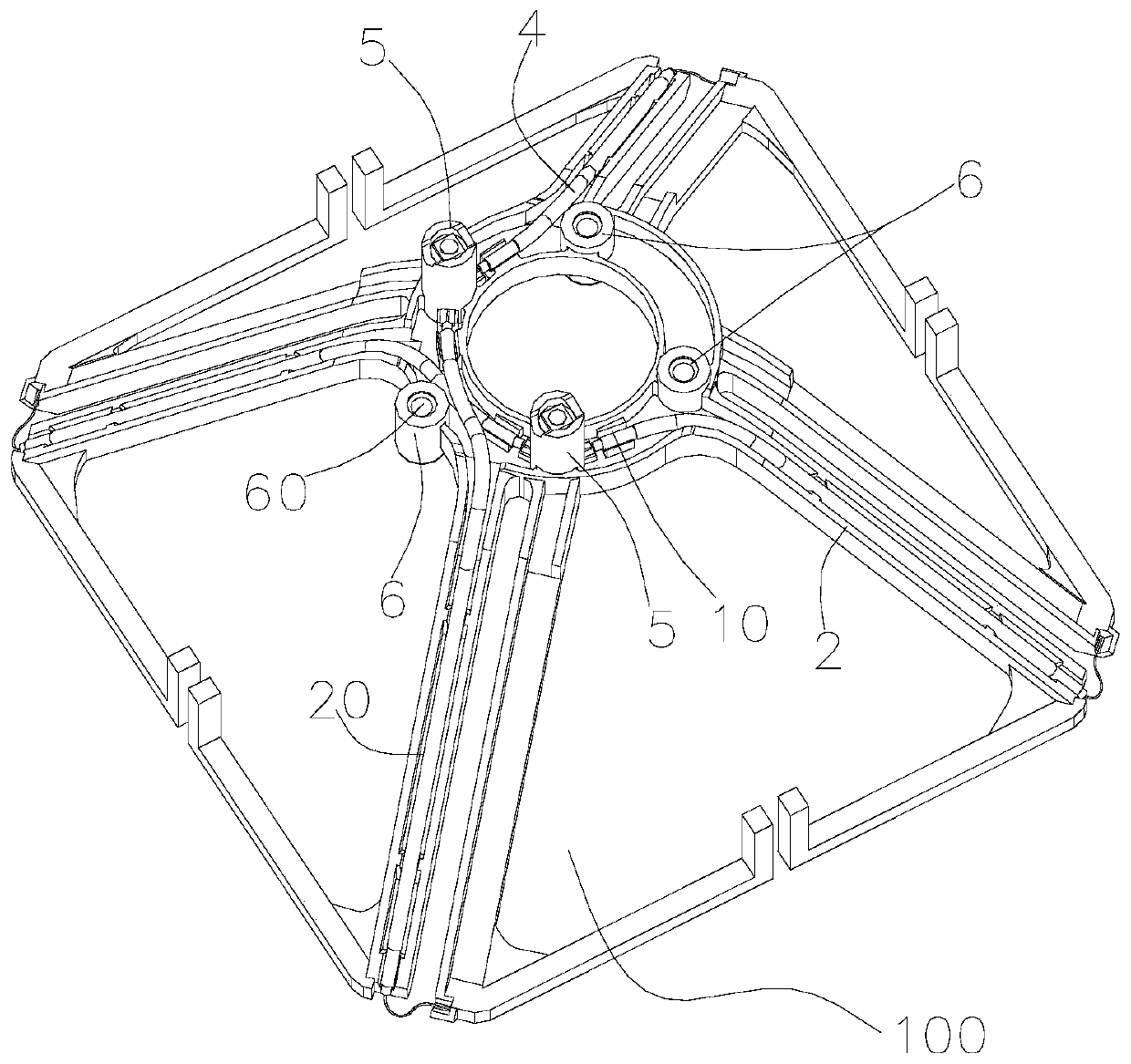

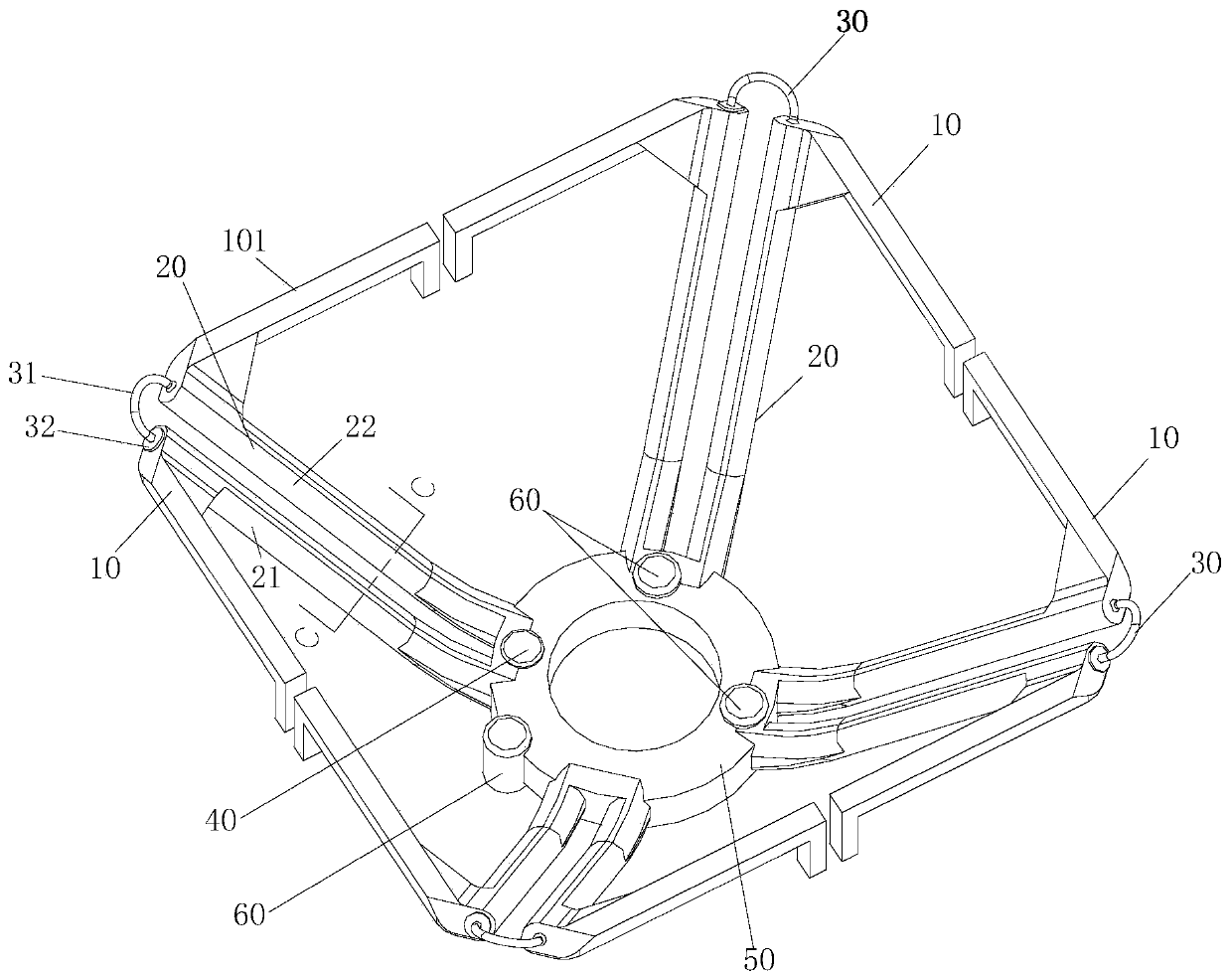

Base station antenna and radiation unit thereof

ActiveCN111092296AImprove stabilityLess fixed pointsSimultaneous aerial operationsAntenna supports/mountingsMechanical engineeringElectrical and Electronics engineering

The invention provides a base station antenna and a radiation unit thereof. The radiation unit comprises a balun structure, a dipole supported on the balun structure, and a feed part extending along the balun structure to feed a dipole, wherein the balun structure comprises a base and a balun arm connected to the base and supporting the dipole, the base is provided with three mounting holes, the mounting holes extend from the bottom end of the base to the top end of the base, and the three mounting holes are arranged on the base in a non-collinear manner. The three mounting holes are only formed in the base of the balun structure and are arranged in a non-collinear mode to form a triangular mounting framework, and therefore the radiation unit is ensured to have high stability when being mounted on the reflecting plate through screws. In the base station antenna adopting the radiation unit, as the fixed points of the radiation unit are reduced, the hole sites needing to be formed in thereflecting plate can be correspondingly reduced, the cross modulation problem caused by burrs in the hole sites is reduced, and the antenna performance is relatively stable.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

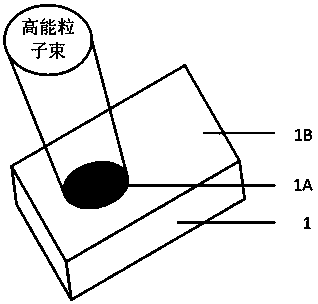

Method for reducing irradiation damage based on dislocation

InactiveCN108054089AControl dislocation densityControl dislocation regionSemiconductor/solid-state device manufacturingDislocationHigh energy

The invention discloses a method for reducing irradiation damage based on dislocation. The method mainly comprises the following steps of injecting protons, neutrons, gamma rays and other high-energyparticles for a silicon material and a device and carrying out annealing operation, so that the purpose of reducing irradiation damage due to the fact that dislocation with controllable density and controllable position serves as a composite center can be achieved. According to the invention, dislocation is introduced at the specified positions of the silicon material and the device, and dislocation density and dislocation area can be controlled. The dislocation is introduced into the silicon material and the device through irradiation of the high-energy particles to form defects, similar to acomposite center, so that the service life of the carriers is reduced. A large amount of electron-cavity generated in the irradiation process can be compounded by the composite center, so that the number of cavities captured by cavity traps is greatly reduced. Compared with the prior art, the method is advantageous in that for the introduced dislocation, high-energy particles may not affect the electric neutral characteristic of the silicon material and the device, and the irradiation damage of the silicon material and the device is also reduced.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

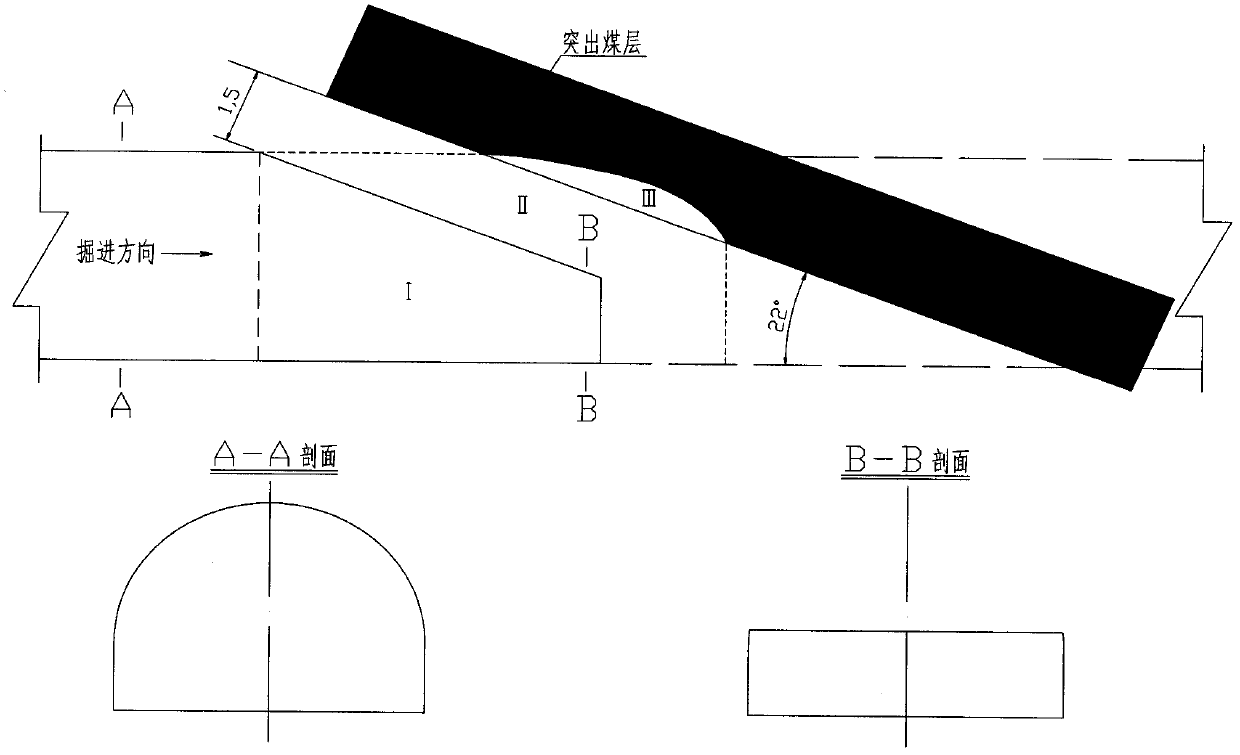

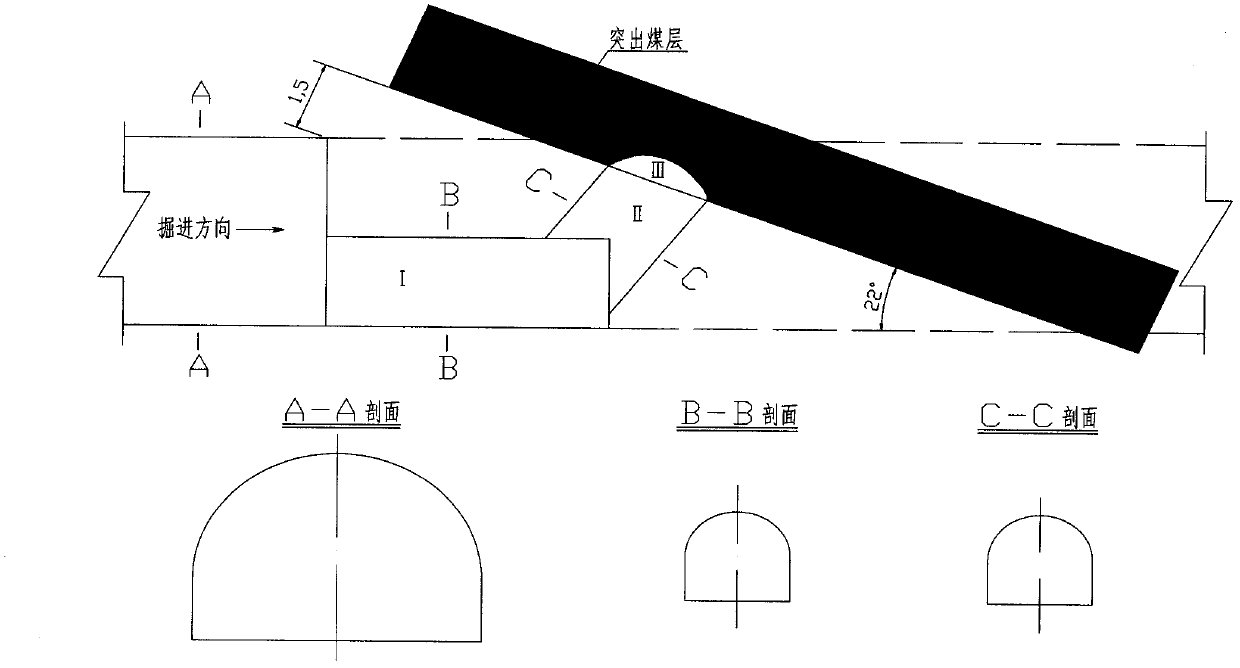

Pilot-tunneling method for coal uncovering

The invention relates to a pilot-tunneling method for coal uncovering, and belongs to the technical field of mine sinking and driving engineering. The method helps to solve problems that: when an uncovered outburst coal seam has a laneway sectional area more than 10m<2> or an inclined angle from the laneway to the coal seam less than 40 DEG, safe rock pillars for working face brush expension are difficult to control, shot holes are deep, explosive consumption is large, and vibration induced protrusion is easy to happen. Safe and effective coal uncovering is realized by that: the laneway sectional area is reduced, the angle of pilot-tunneling is changed, and technologies of smooth blasting, anchor-net temporary supporting and anchor-net permanent supporting etc. are employed. The method of the invention is especially suitable for coal uncovering when the laneway sectional area is large, surrounding rocks are broken, and the inclined angle is small. Advantages are that: working places need no finishing, the pilot-tunneling is flexible for operation, so that drilling by pneumatic drills is convenient, the safe rock pillars are easy to control, and operation is simple; uncovered sectional area is small, the number of working people is small, the number of blast hole is small, the amount of explosive is small, blasting disturbance is less, gas emission amount is small, and the safety is high; pilot-tunneling sectional area is small, operation technology is simple, speed is fast, and work efficiency is high.

Owner:CHONGQING JUNENG CONSTR GRP +1

Base station antenna and radiation unit thereof

ActiveCN111180860AReduce welding man-hoursReduce electrical performance instability factorsSimultaneous aerial operationsAntenna supports/mountingsElectrical conductorCoaxial cable

The invention provides a base station antenna and a radiation unit thereof. The radiation unit comprises a dipole, a balun supporting the dipole, and a feeding pack for feeding the dipole. The balun comprises a pair of balun arms which are oppositely arranged, at least one balun arm being arranged in a hollow mode; the feed part comprises a feed conductor and an insulating medium, wherein the feedconductor is arranged in the hollow balun arm in a penetrating mode and connected with one radiation arm supported by the other balun arm; and the insulating medium is filled between the feed conductor and the inner wall of the balun arm and enables the feed conductor to be fastened in the balun arm. A feed part composed of a feed conductor and an insulating medium is arranged in an inner cavityof a hollow balun arm; and the feeding part and the balun arm form a structure similar to a coaxial cable, so that coaxial cable feeding is not needed, welding is not needed, welding time is saved, unstable factors of electrical performance caused by welding are reduced, and meanwhile, cost can be reduced due to the fact that the coaxial cable is not used.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

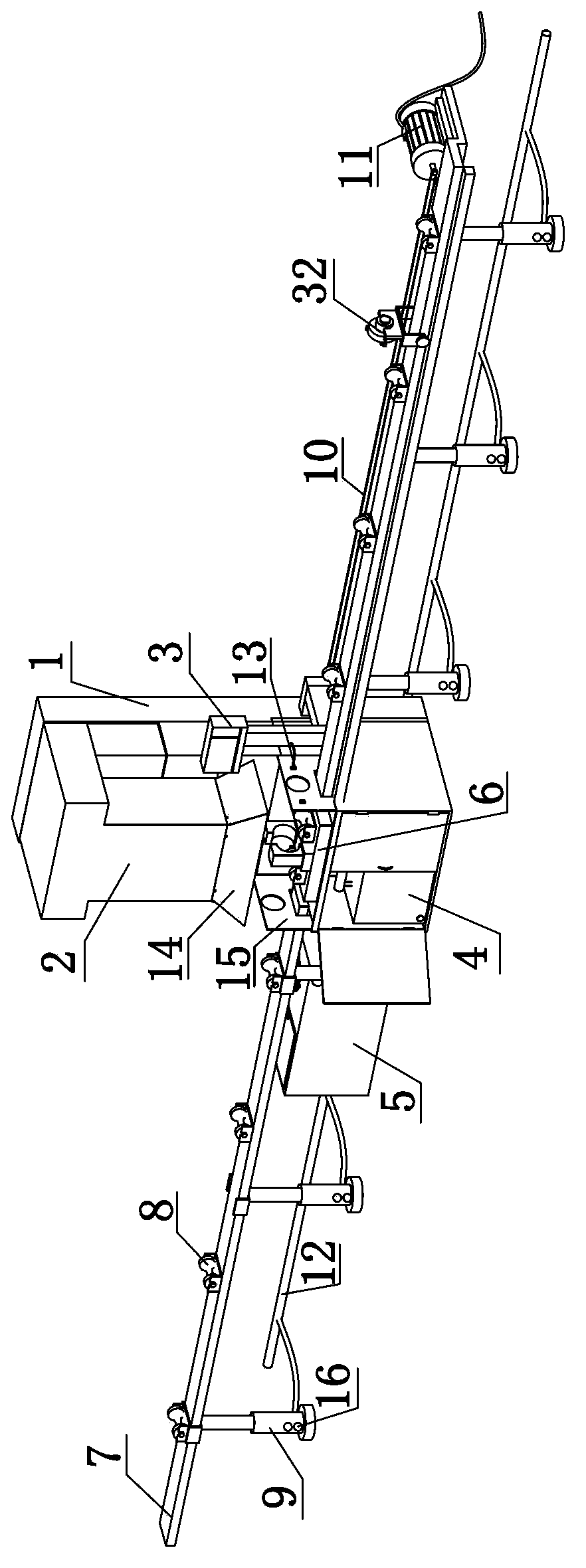

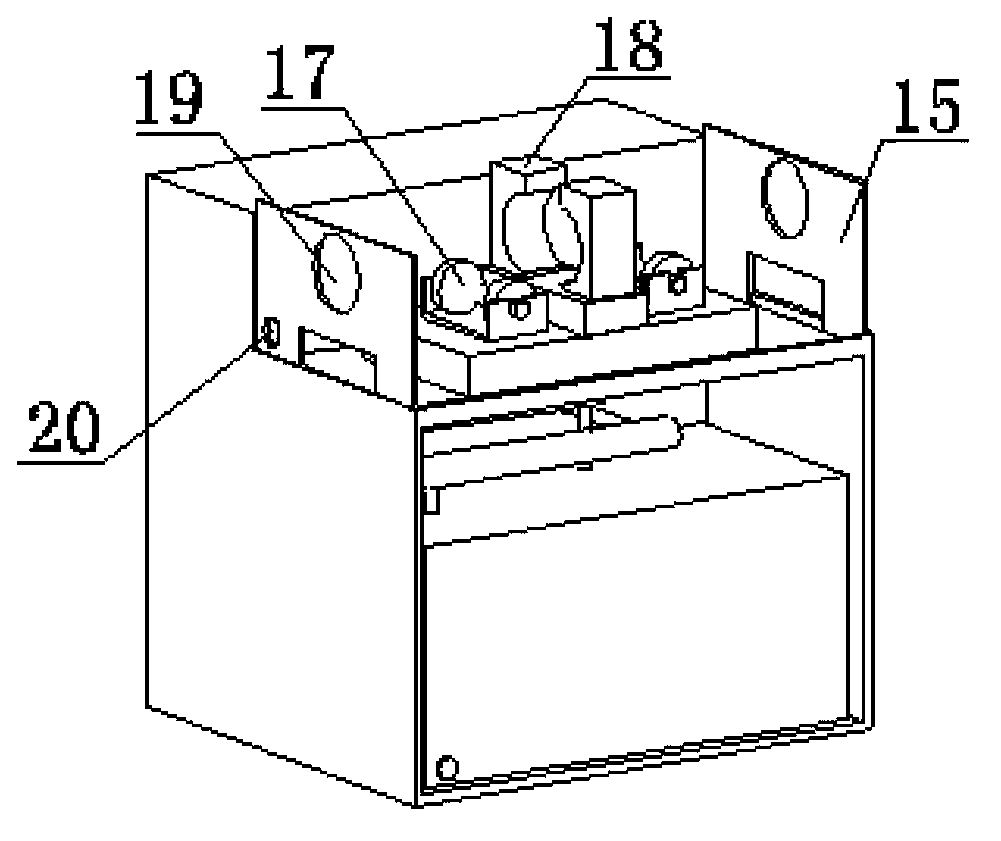

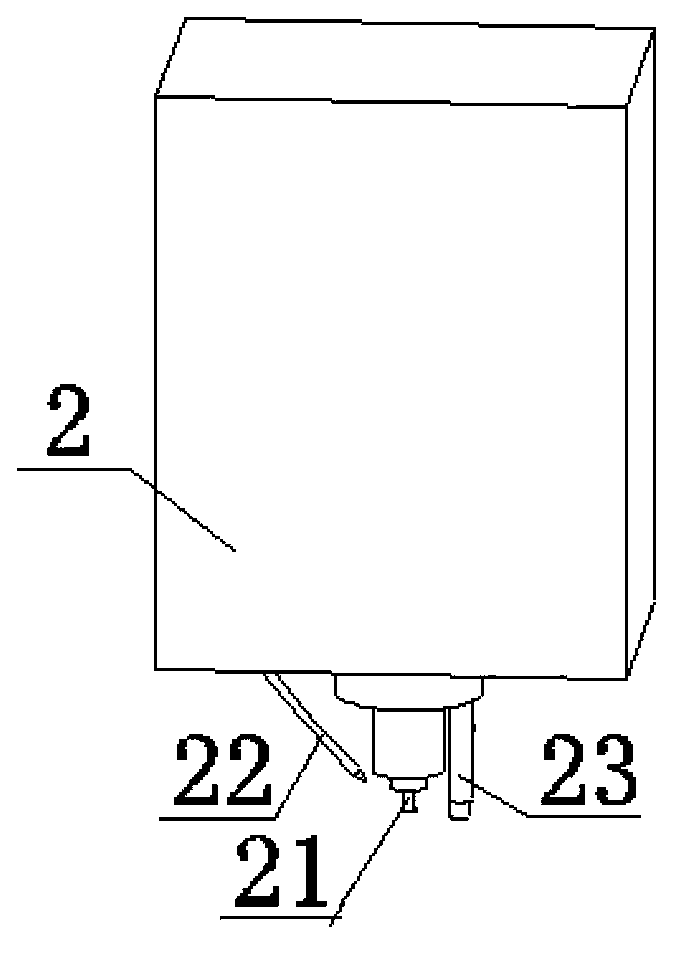

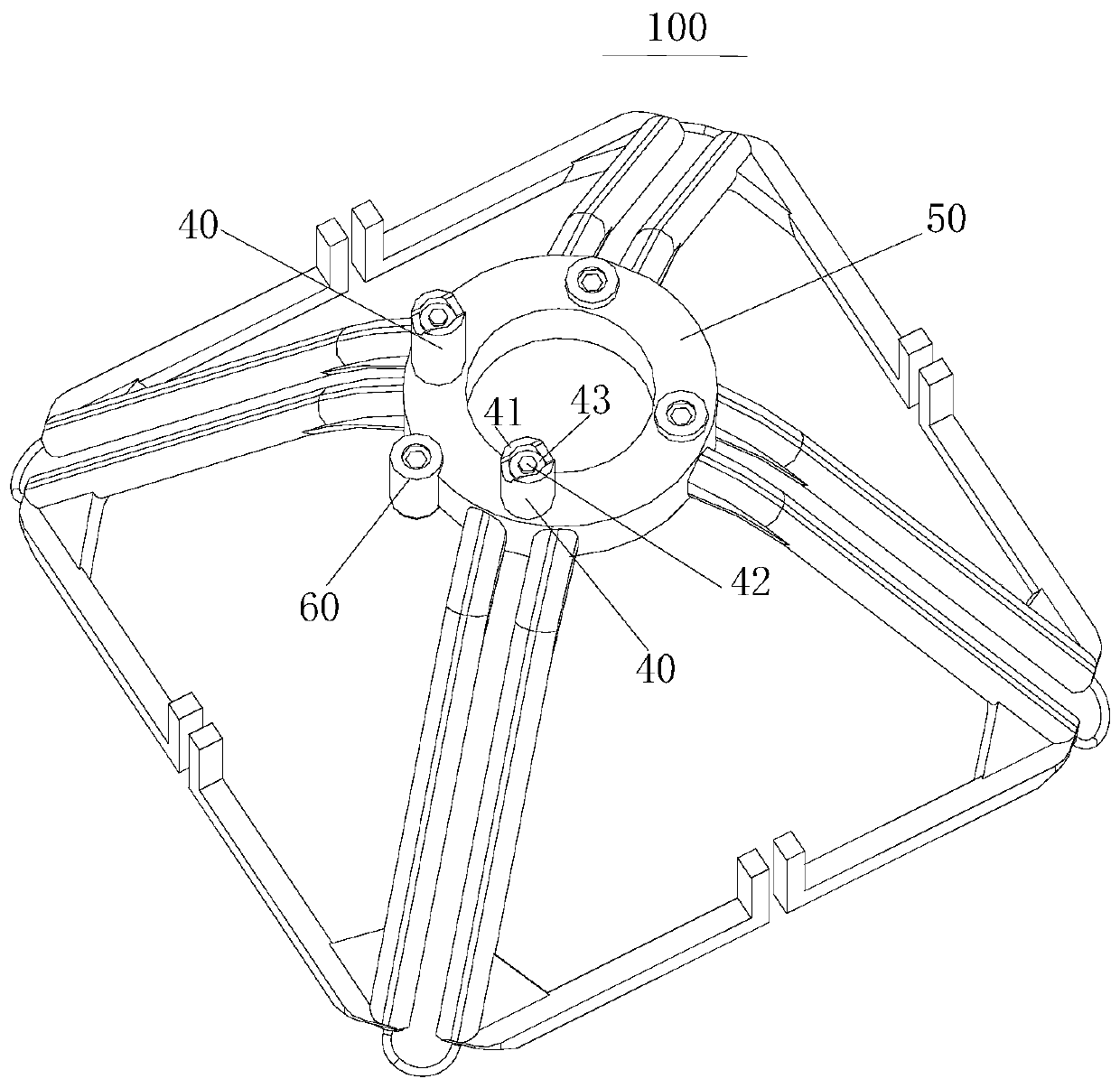

Drilling equipment for heat exchanger tube sheet

InactiveCN104400056AIncrease productivityReduce the number of holesPrecision positioning equipmentLarge fixed membersEngineeringThreaded rod

The invention discloses drilling equipment for a heat exchanger tube sheet. The drilling equipment comprises a machine base, a knob, handles, a dial, the tube sheet, a holding pin, a drill, a rocking handle, a cutting fluid pipe, a plunger, a cutting fluid bath, a filter screen, a rotating platform, a pressing plate, a threaded rod and a machine body; the machine base is located at the lower part of the machine body; the cutting fluid bath is formed in the machine base; the filter screen is arranged in the cutting fluid bath; the filter screen is provided with the rotating platform; the rotating platform is provided with the knob; the rotating platform is provided with the dial; the handles are respectively arranged at two ends of the dial; the dial is provided with the threaded rod; the upper end of the threaded rod is provided with the holding pin; the tube sheet is provided with the pressing plate; the drill is arranged above the pressing plate; the tail part of the drill is provided with the plunger; the right side of the plunger is provided with the cutting fluid pipe; when a circumferential upper hole is processed, only the handles need to be adjusted to enable the drill to move horizontally, and a first hole position is further determined, and the remaining holes are adjusted only by reading the dial, so that the hole alignment time is reduced, and the production efficiency of the tube sheet is increased.

Owner:WUXI YUDA HEAT EXCHANGER

Connector with plural switching assemblies of compatible interface

InactiveCN1472845AConvenient ArrangementReduce the number of solder jointsCoupling device detailsTwo-part coupling devicesClock ratePropagation time

A connector is described for fixing a plurality of switching assemblies on a substrate. The connector is also for making contact with the plurality of switching assemblies, which have compatible interfaces. The connector has a plurality of receptacle devices with contact elements and internal contact connections between corresponding contact elements, as a result of which, the length of the connections between the switching assemblies is reduced, signal propagation times are shortened and a higher clock rate for operating the switching assemblies is made possible.

Owner:INFINEON TECH AG

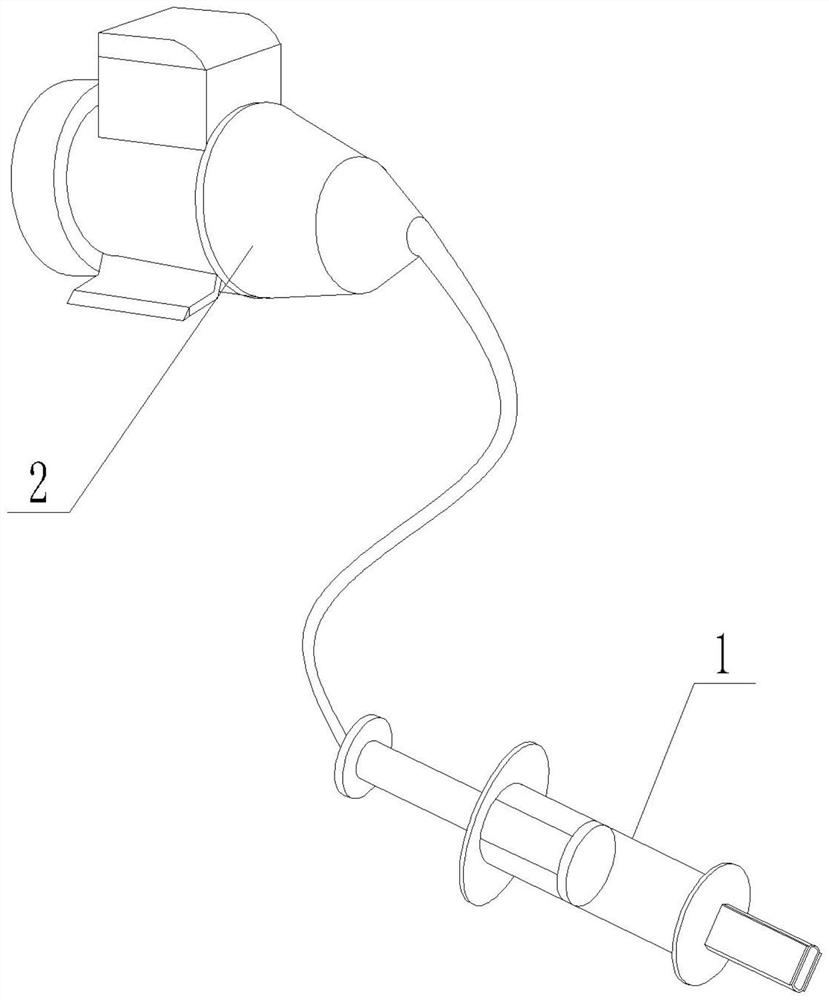

Underground coal mine auto-drilling apparatus and method

InactiveCN106703698APropulsion adjustableAdjustable drilling speedLiquid/gas jet drillingGas removalLine tubingCoiled tubing

The invention provides an underground coal mine auto-drilling apparatus and method; the underground coal mine auto-drilling apparatus comprises: a pressure pump truck; a coiled tubing having an inlet and an outlet, with the inlet of the coiled tubing connected to the pressure pump truck and the outlet of the coiled tubing extending into a raw coal working support face; a tubing rotator connected to the coiled tubing; a protective tube sleeving the coiled tubing, abutted to the raw coal working support face and connected downstream of the tubing rotator, wherein the protective tube is a cross tube, and the protective tube has an axial passage for conveying the coiled tubing and a side passage for returning pulverized coal; a rotary nozzle connected to the outlet of the coiled tubing; a pulverized coal returning line connected to the side passage of the protective tube; a gas return recycling and detection device connected to the pulverized coal return line. The underground coal mine auto-drilling method employs the underground coal mine auto-drilling apparatus. The underground coal mine auto-drilling apparatus and method provide improved gas drainage efficiency and reduced cost and ensure safety.

Owner:泰尔达能源科技(北京)有限公司

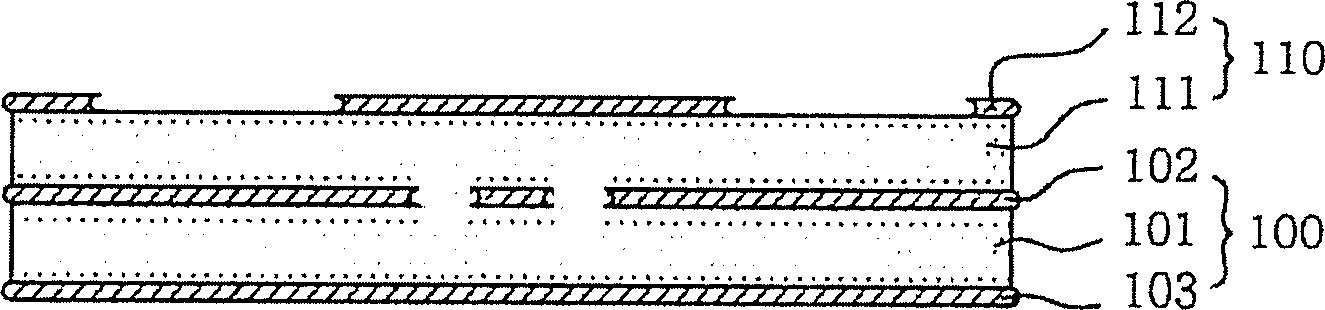

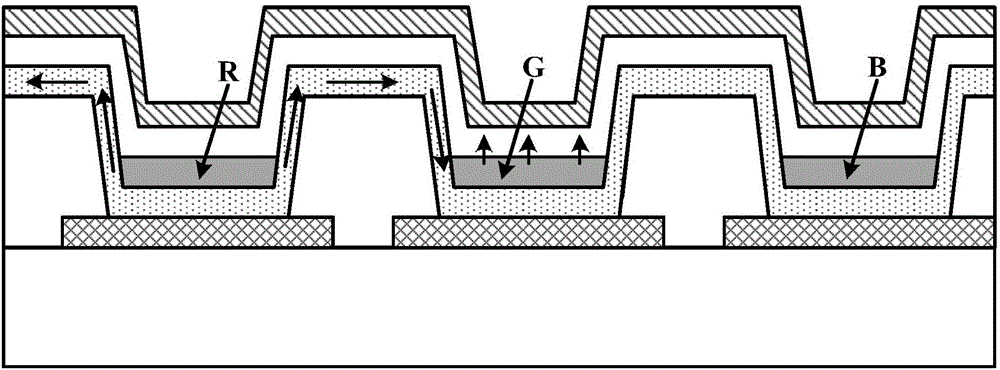

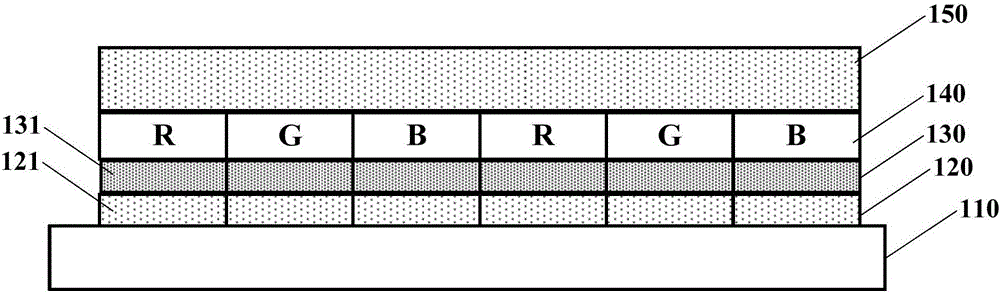

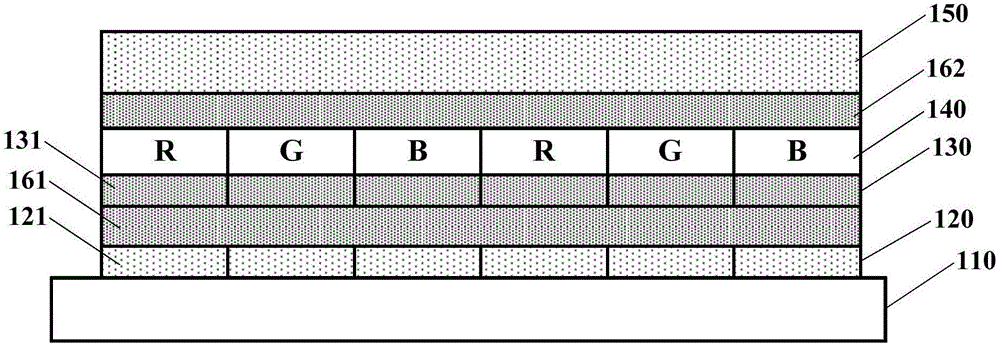

Organic light emitting display panel and organic light emitting display device

ActiveCN106409877ALower lateral currentReduce the effect of stealing lightSolid-state devicesSemiconductor/solid-state device manufacturingPower flowTransport layer

According to the embodiments of the invention, an organic light emitting display panel and organic light emitting display device are provided wherein the organic light emitting display panel comprises a first substrate; a first electrode layer arranged on the first substrate and comprising a plurality of first electrodes; a first hole transport layer arranged on one side surface of the substrate deviating from the first electrode layer and comprising a plurality of hole transport units arranged at positions corresponding to the plurality of the first electrodes respectively; a plurality of light emitting elements arranged at positions corresponding to the plurality of hole transport units, disposed on one side surface of the first electrode layer deviating from the first hole transport layer and comprising m colors so that the mobility of the hole transport units corresponding to the light emitting elements in any two colors varies from each other; and a second electrode layer arranged on one side surface of the first hole transport layer deviating from the plurality of the light emitting elements. According to the embodiments of the invention, the transverse current across the hole is reduced so as to achieve the effect of reducing the sub-pixels for dim lightings.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com