Fast and highly-efficient tunneling method for large section of hard-rock tunnel in coal mine by combination of fully-mechanized tunneling and blasting driving

A large-section, hard-rock technology, which is applied to the field of fast and efficient excavation of large-section hard rock roadways in coal mines, can solve the problems of inability to excavate normally, affect the speed and efficiency of hard rock artillery excavation, and reduce the effect of fully mechanized excavation, and achieve the drilling workload. And the effect of reducing time, reducing the amount of single detonating charge, and increasing the speed of tunnel excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

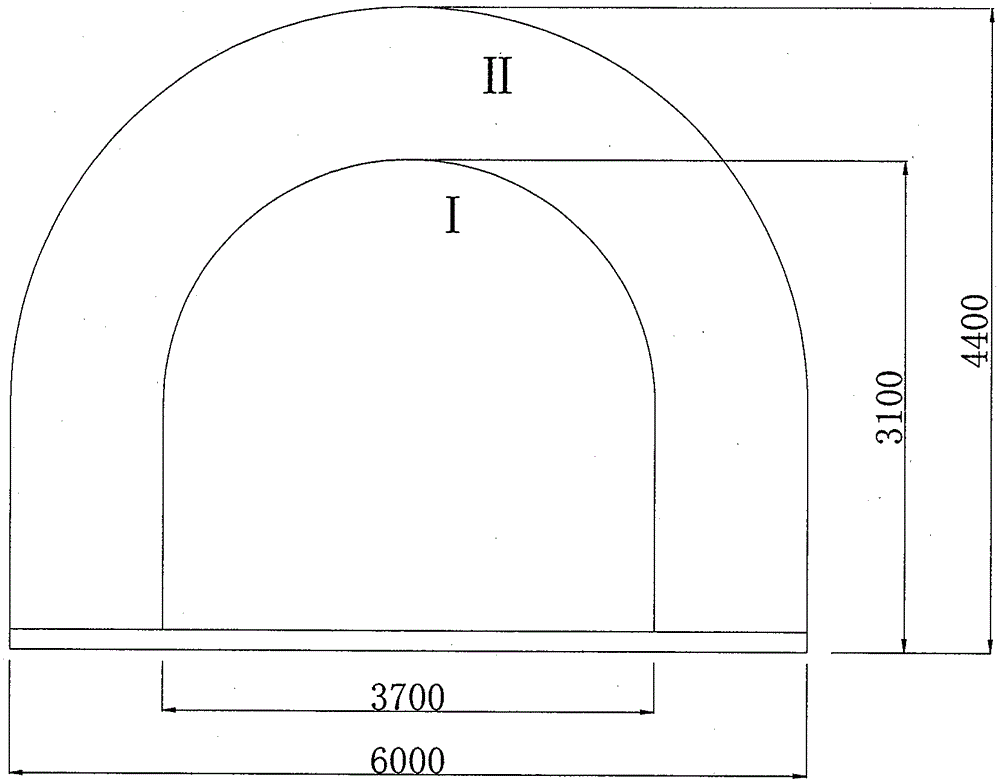

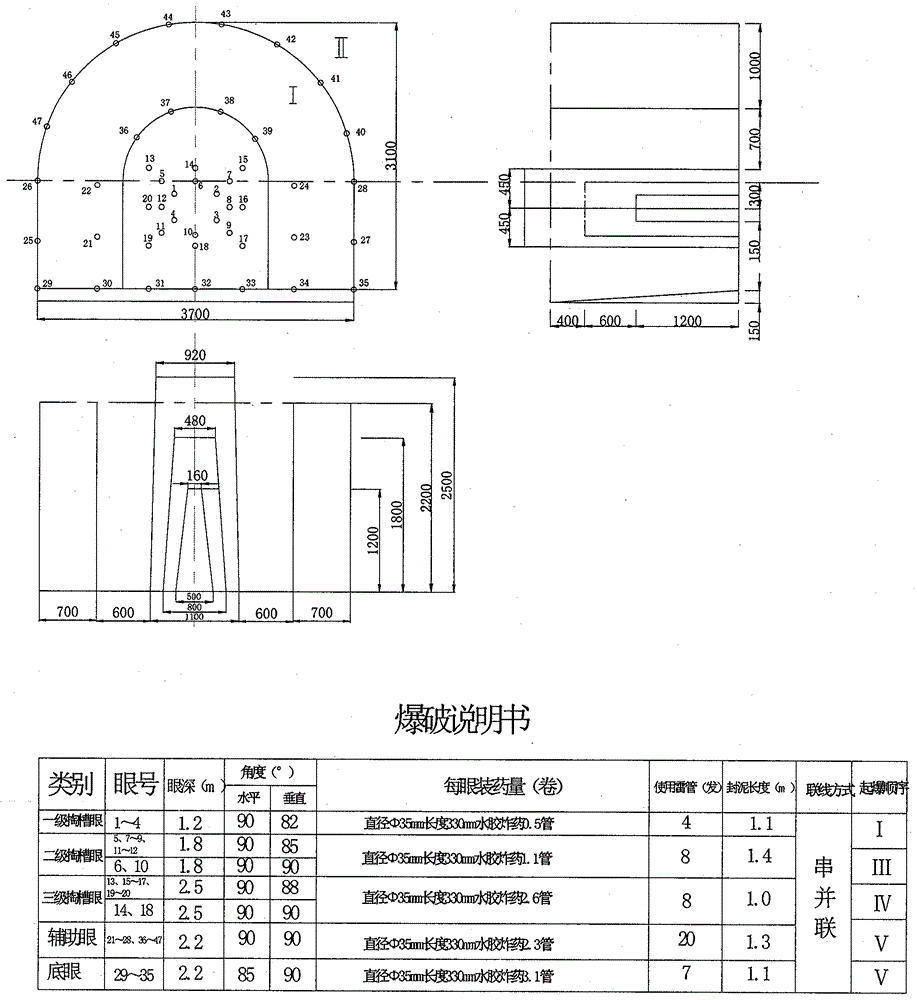

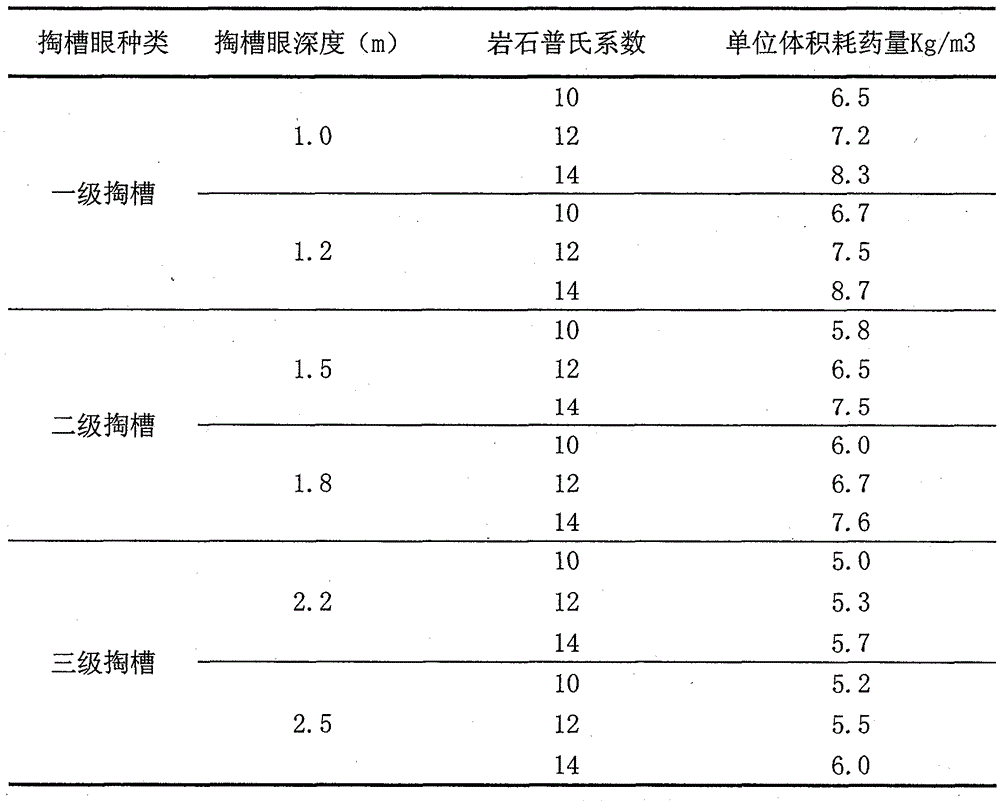

[0016] picture 2 Blasting for Excavating Cavity I by Blasting picture Table: The layout of the blast hole is divided into two parts, the cutting hole and the auxiliary hole. The cutting hole is divided into three levels of cutting, and each level of cutting is gradually deepened, and the inclination angle is gradually increased. , That is, the millisecond detonator of section I is selected for the first-level cut, the millisecond detonator of section III is selected for the second-level cut, and the millisecond detonator of section IV is selected for the third-level cut. The charge consumption per unit volume of the eye is determined according to the charge consumption per unit volume and the blasting rock volume borne by each blasthole. The detonation is delayed for a period of milliseconds, and the total delay is about 100.0ms, not exceeding 130.0ms. In order to fully break the rock and ensure sufficient mud plugging length, the currently commonly used Φ32.0mm small-dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com