Patents

Literature

408results about How to "Increase the speed of excavation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

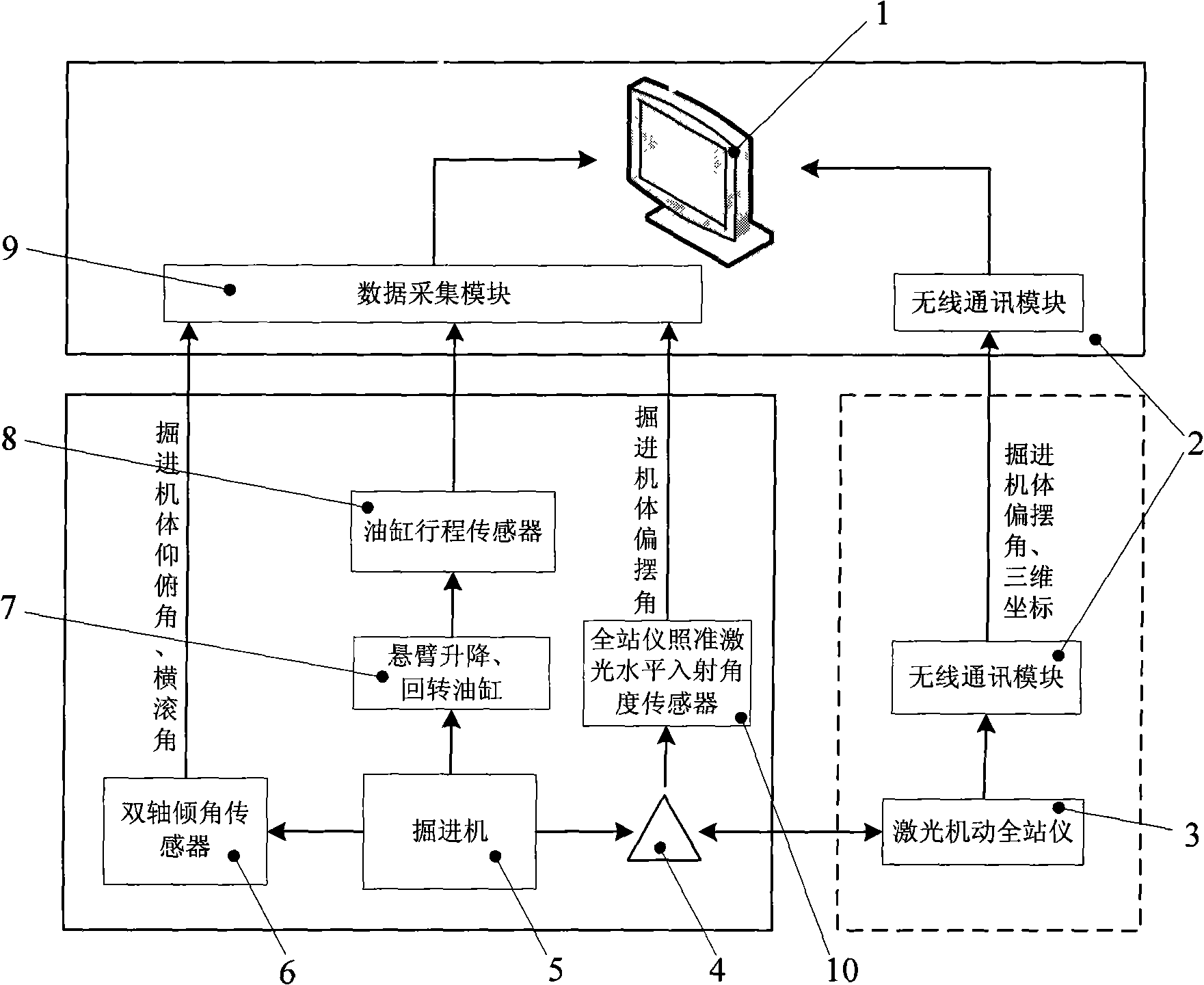

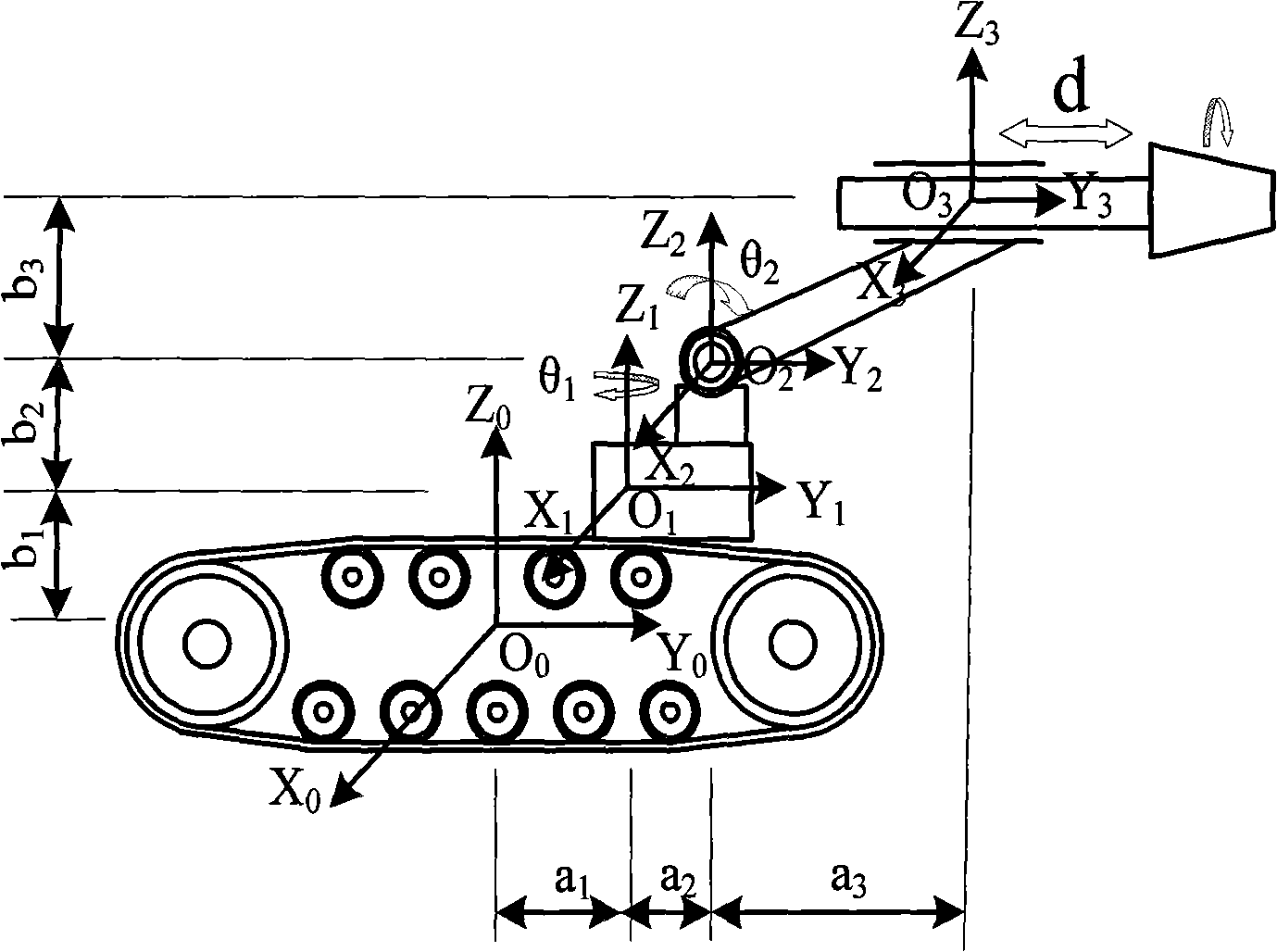

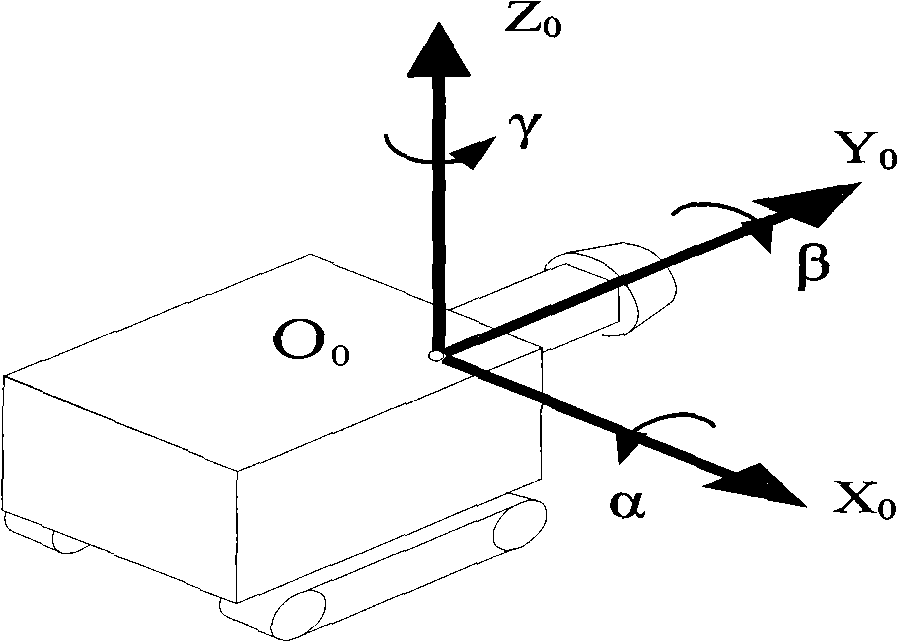

Cantilever driving frame head posture measuring systems and its method

ActiveCN101266134AHigh accuracy of pose measurementReduce labor intensityUsing optical meansCutting machinesTotal stationRolling angle

The invention relates to the measurement system of a cantilever tunneling head pose and the method, which is characterized in that a laser mobile electrical total station is arranged on a formed tunnel wall, and measures the coordinate of the tunneling machine body in the earth coordinate system, a body deflection angle sensor is installed behind a reflector prism, and measures to the deflection angle of the tunneling machine body, a biaxial inclination angle sensor surveys the pitching angle and the roll angle of the tunneling machine body, oil cylinder stroke sensors install in a cantilever lifting oil cylinder, a cantilever revolving oil cylinder and a tunneling head flexible oil cylinder to survey the oil cylinder stroke, a wireless communication module and a data acquisition module transmit the metrical data of the laser mobile electrical total station, the cylinder stroke sensor, the biaxial inclination angle sensor and the body deflection angle sensor to the computer, which gathers, processes, and calculates the pose of the tunneling head relative to the body and the earth coordinate system, so as to realize the surveying of the tunneling head pose. The invention has the advantages of good timeliness, high precision, and suitable for the measurement and the position of the tunneling head pose of a tunneling equipment such as the cantilever tunneling machine.

Owner:SHANXI COKING COAL GROUP +1

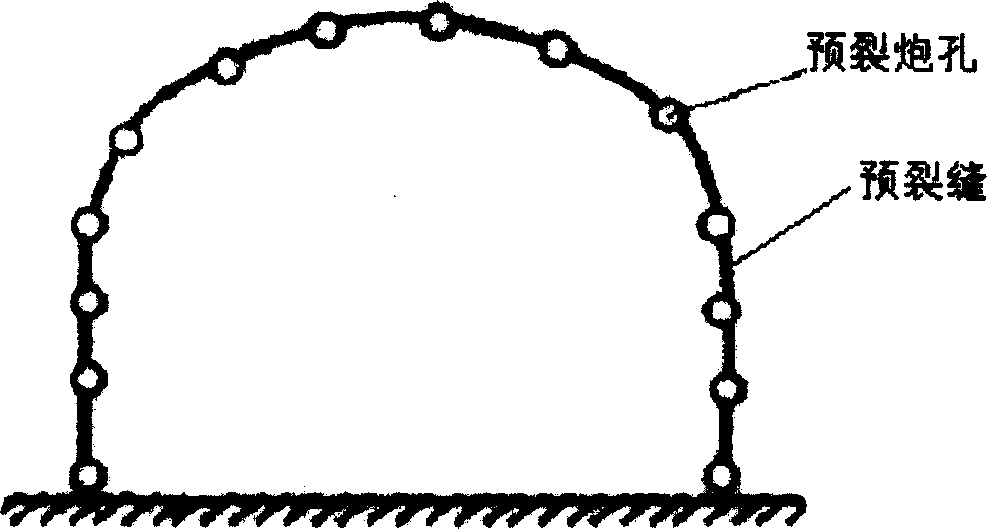

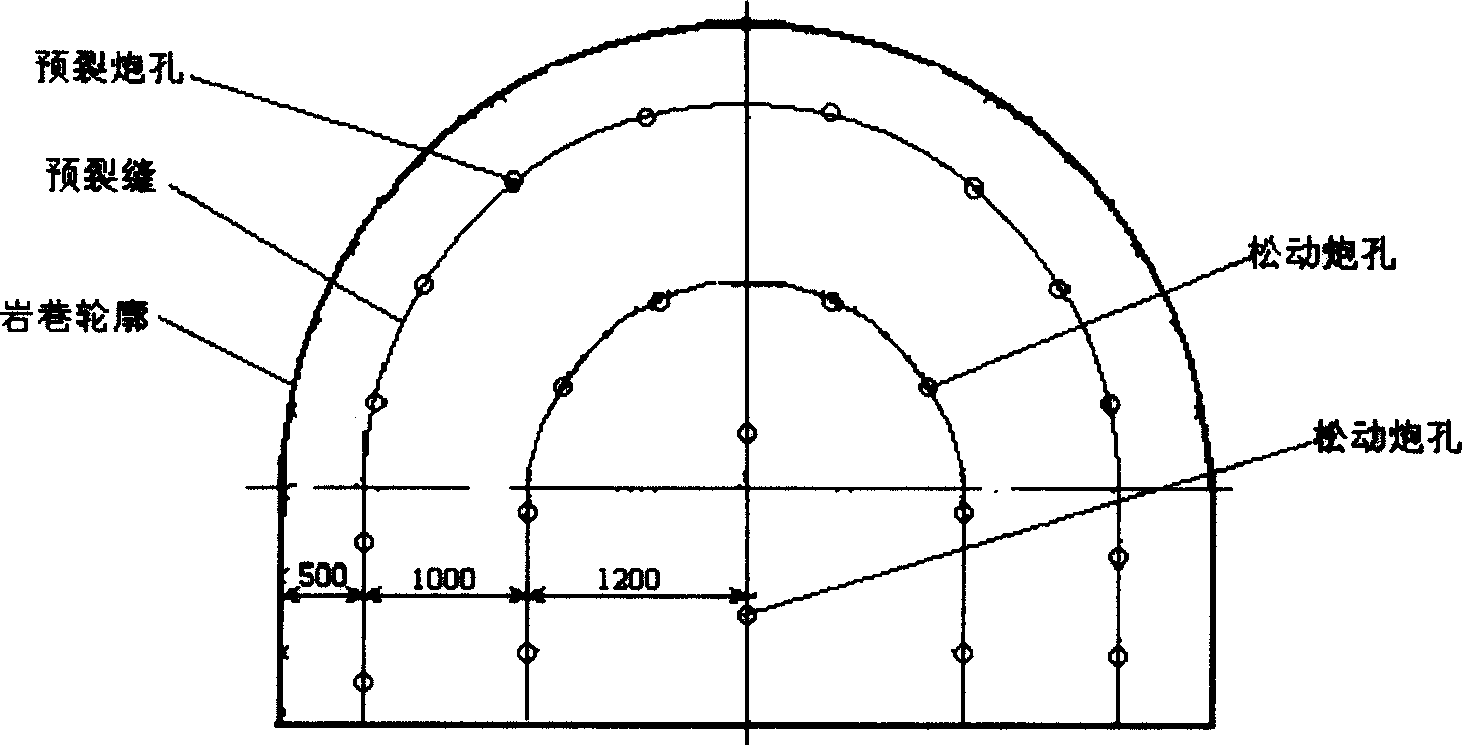

Rock lane digging method

The invention discloses a rock gangway drifting method. Firstly, directional blasting technology is adopted, and presplitting cracks are arranged close to the periphery of a rock gangway through blasting. Secondly, loosening blasting technology is adopted to break rocks in the presplitting cracks; directional blasting and loosening blasting can be performed separately and also can be performed synchronously and initiated in sequence; the directional blasting is initiated before the loosening blasting. Finally, a rock gangway drifting machine is adopted to drill broken rocks. By adoption of combination of drifting of the drifting machine and controlled blastings, the invention has the advantages of great reduction of damage on surrounding rocks, increase of safety, improvement of drifting speed and reduction of cost, and is a rock gangway drifting method having the advantages of high efficiency, safety, low cost, good operating environment and low labor intensity. The invention is suitable for drifting various rock gangways and particularly suitable for drifting rock drifts with high hardness.

Owner:杨仁树

Method for performing through-going seam cutting, pressure relief, permeability enhancement and quick tunneling on soft and high-outburst coal seam

InactiveCN102900460AIncrease the speed of excavationIncrease extraction concentrationGas removalStress distributionType fracture

The invention discloses a method for performing through-going seam cutting, pressure relief, permeability enhancement and quick tunneling on a soft and high-outburst coal seam, and in particular is applied to quick tunneling in a coal seam which is high in outburst danger and a laneway is difficult to support in a coal mine. The method comprises the following steps of: forming a network type fractured net by high-pressure jet flow seam cutting, pressure relief and permeability enhancement technologies, and enhancing an effect of extracting strip-type coal seam gas on a coal laneway subjected to through-going drilling and pre-extraction; and forming a network type filling region by pressing and injecting filling materials, so that the strength and stress distribution of a coal body are improved, the coal laneway is easy to maintain in the tunneling process, a phenomenon that the gas rushes out of a tunneled laneway is avoided, gas accidents are eliminated in the tunneling process, and an aim of safely and quickly tunneling the laneway is fulfilled.

Owner:CHINA UNIV OF MINING & TECH

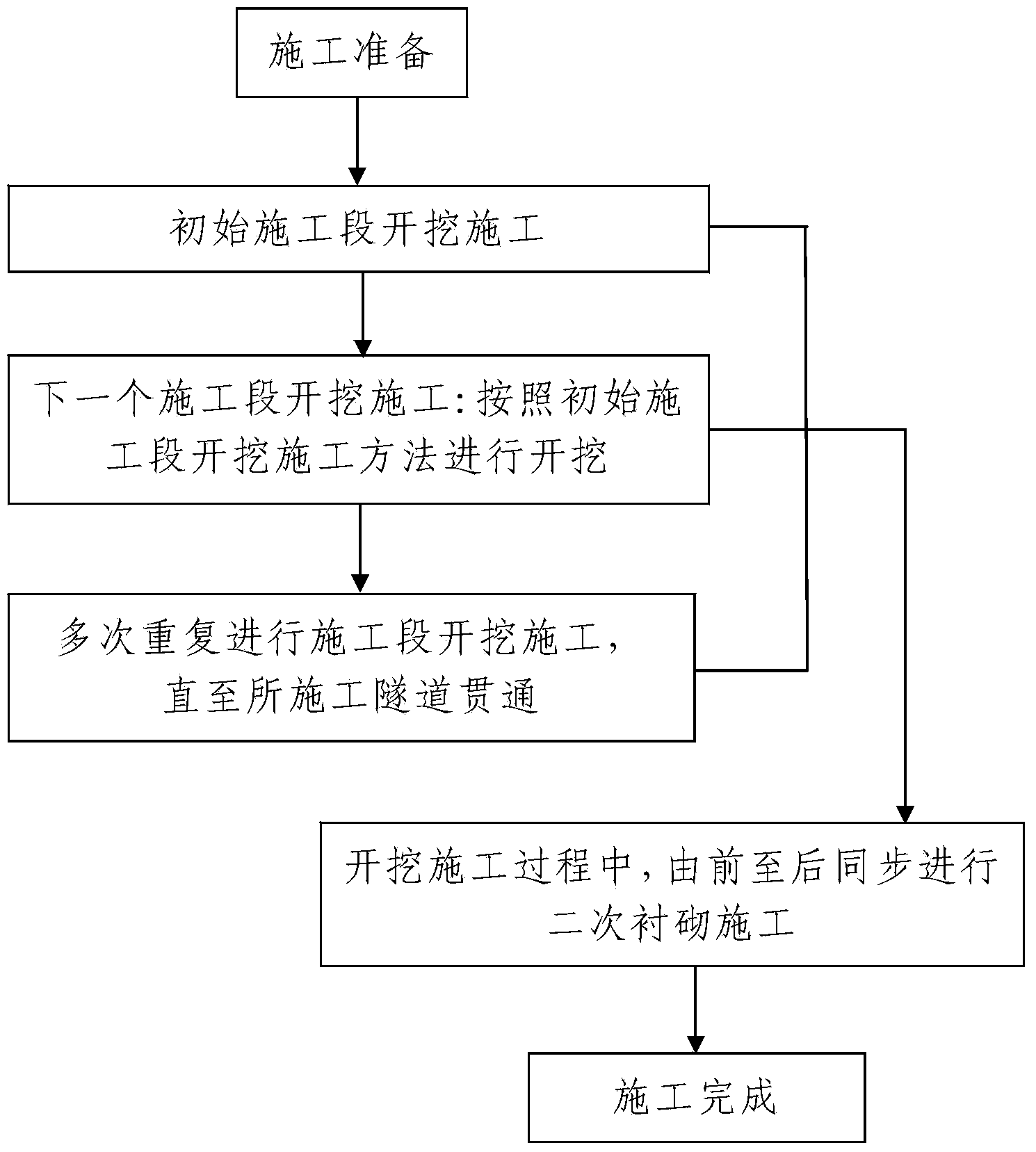

Long tunnel fast construction process

ActiveCN103470267AReasonable designSimplify construction stepsUnderground chambersTunnel/mines ventillationTunnel constructionWater seepage

The invention discloses a long tunnel fast construction process. The tunnel construction method in the direction from the entrance to the exit and the tunnel construction method in the direction from the exit to the entrance are the same and each construction section is respectively constructed from back to front. The construction process is as follows: 1, excavating construction at an initial construction section, the process is as follows: performing advance geology forecast, determining the excavating construction method for the current construction section, excavating and primary supporting; 2, excavating construction at the next construction section; 3, repeating the step 2 for multiple times until the construction tunnel is through, wherein in the tunnel construction process, found water seepage areas are timely subjected to draining treatment, and the secondary lining construction is synchronously performed on the tunnel holes formed by excavating from front to back. The long tunnel fast construction method is reasonable in design, simple and convenient in construction, safe in the construction process, short in construction process and fast in construction progress, thus effectively solving the defects and shortcomings such as large equipment investment, long construction period and slow construction progress of the existing long tunnel construction.

Owner:中铁二十局集团第二工程有限公司

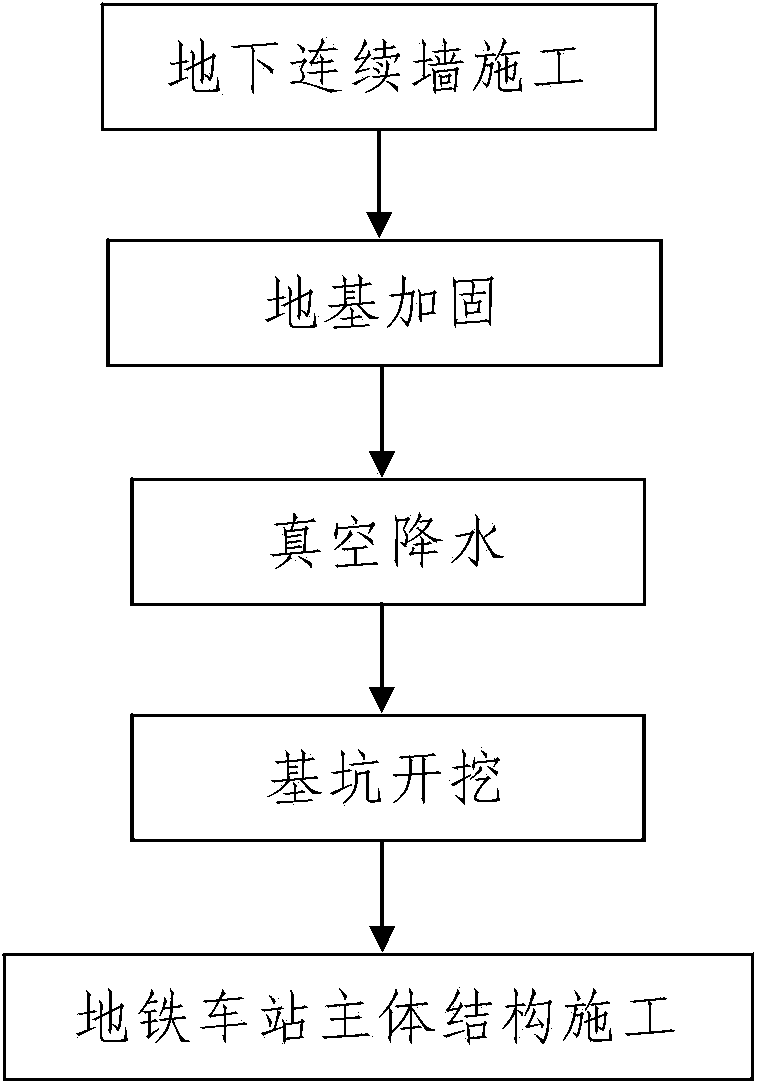

Peaty soft soil stratum subway station construction technology

ActiveCN103590425ASimplify construction stepsEasy constructionArtificial islandsProtective foundationSlurry wallReinforced concrete

The invention discloses a peaty soft soil stratum subway station construction technology. A main structure of a constructed subway station comprises base plates, side walls, top plates and middle plates distributed between the top plates and the base plates. Underground consecutive walls are arranged on outer sides of the two side walls. The base plates, the side walls, the middle plates and the top plates are all of a rebar concrete structure formed by pouring waterproof concrete. The subway station construction technology comprises the following steps: (1) underground consecutive wall construction, (2) foundation reinforcement, namely, three-shaft stirring piles are used for reinforcing the foundation of excavated foundation pits, (3) vacuum water falling, namely conducting vacuum well point water falling construction on the foundation pits needing excavating, (4) foundation pit excavation, namely, an open excavation method is used for conducting earthwork excavation on the foundation pits needing excavating with a plurality of excavating layers from top to bottom, (5) subway station main structure construction. The method is simple, convenient to realize, quick in construction speed, capable of being ensured in construction quality easily, and good in construction effect, and enables the subway station construction process of peaty soft soil stratum to be completed simply, quickly and with high quality.

Owner:中铁二十局集团第五工程有限公司

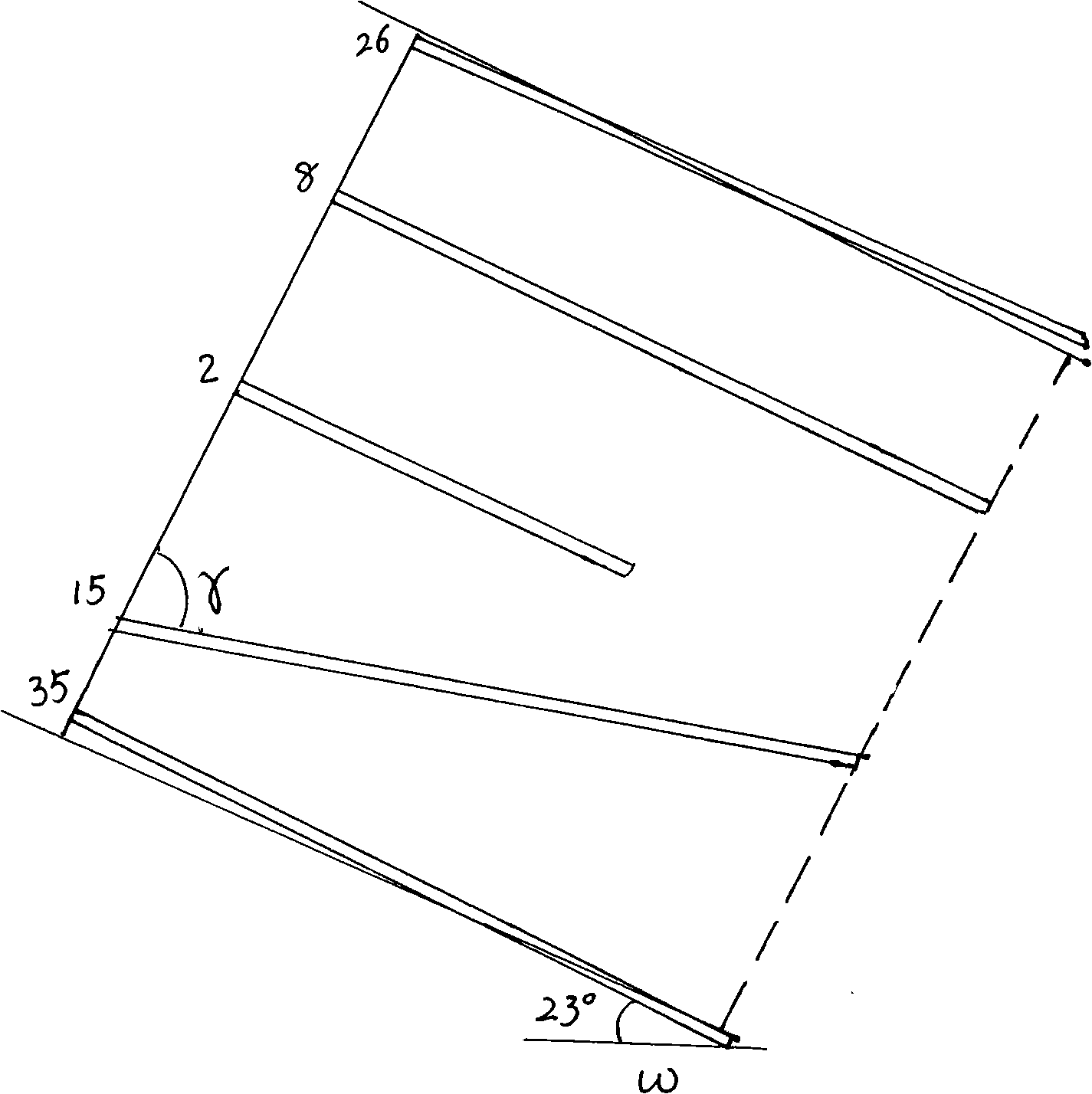

Dip laneway digging hole layout mode

The invention discloses a mine downhill roadway tunnelling shot hole arrangement way, which comprises cut holes, auxiliary holes, a peripheral hole and a bottom hole, wherein the cut holes are in a wedge arrangement way, and are arranged on the middle upper portion of a roadway cross section, wherein the pitch of two rows of wedge cut holes is larger 30% than the pitch of current wedge cut holes, a row of auxiliary straight holes are arranged between two rows of wedge cut holes, and the width of the auxiliary straight hole is 0.5 time than that of the cut holes, and a row of auxiliary throwing holes are further arranged under the two rows of the cut holes, and the drilling direction of the auxiliary throwing holes is drilled to the oblique upper portion in smaller than 90 degrees with the roadway cross section, and the auxiliary throwing holes are finally detonated with the bottom hole in the same section. The invention fully utilizes the least resistance line principle, reasonably distributes the wedge cut holes, and increases the blasting efficiency and tunnelling velocity.

Owner:山东科技大学科技产业总公司

Supporting method of laneway under multiple goafs in ultra-close coal seam group

InactiveCN102425438ASolve the technical problems of roadway supportSolve support technical problemsAnchoring boltsProtective coversSocial benefitsEngineering

The invention specifically relates to a supporting method of a laneway under multiple goafs in an ultra-close coal seam group, which can be used for solving the problem of incomplete support of the laneway under the multiple goafs in the ultra-close coal seam group. The supporting method of the laneway under the multiple goafs in the ultra-close coal seam group comprises the following steps: performing preparation work, performing temporary supporting, laying a steel wire mesh, loading steel beams, mounting an anchor rod of a top plate, mounting the anchor rod of an upper part, mounting an anchor rope of the top plate and the like. By utilizing the effective supporting scheme according to the invention, the technical difficult problem of supporting the laneway under the multiple goafs in the ultra-close coal seam group in Datong mining area is solved, and the great safety economic effect and the great social benefits are achieved.

Owner:DATONG COAL MINE GRP

'Three-soft' low permeability high gas coal seam rapidly digging method

InactiveCN101382073AImprove parsing speedImprove the pumping effectUnderground miningSurface miningPunchingPressure controlled ventilation

The invention discloses a method for rapidly digging 'three soft' low permeability and high gas coal layer, which comprises the steps of arranging a stone head in a bottom plate rock under the coal layer, and constructing pre-extracted penetrating drill holes of gas in the bottom plate rock layer and pulling the bit back to the bottom plate of the coal layer after the bit penetrates the coal layer, and punching the drill holes by pressure water with the depth of the punching holes being less than or equal to three meters, and the control radius of the punching holes being from two to six meters to realize continuously, draining gas in the holes, and stopping draining while the gas draining amount is at 0.1 cubic meter per hour; injecting water to the coal layer by using the drained gas drill holes, with water injection pressure controlled between ten to fifteen Mpa, and stopping water injection when the water injection effect reaches the demands of construction in coal layer; and draining goaf by the drill holes after extraction in mining face. The digging method increases the resolving speed of the 'three soft' low permeability coal layer gas, improves the gas draining effect and realizes the low gas construction in the high gas coal layer and one hole for three purposes, not only ensures the safety during construction, but also improves the digging speed in the roadway maximally.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

Channeling method in rapid roadway explosion

The invention discloses a channeling method in rapid roadway explosion. The arrangement structure of channeling holes is as follows: a large-diameter central hole of which the diameter is phi 100-120mm and the depth is more than 4m is drilled in the central position of a channeling area at a roadway cross section; 4-6 smashing swelling holes are formed around the central hole; a row of smashing holes are formed among the smashing swelling holes; a row of auxiliary throwing holes at intervals of 0.5m are further formed below the smashing swelling holes at the lowermost part; the drilling direction of the auxiliary throwing holes inclines towards to a position above a roadway, so as to form an inclined angle which is less than 85 degrees with the roadway cross section; and subsequently explosive is filled for exploding to form channel cavities. The channeling method utilizes the minimum resistance line theory, and the central hole enlarges the smashing free surface and the smashing swelling space of a drilled channel, deeper channel cavities are formed, and the depths of the ordinary auxiliary holes and the ordinary around holes are further deepened to 4m, so that the explosion efficiency is improved, and the once explosion depth is increased.

Owner:SHANDONG UNIV OF SCI & TECH

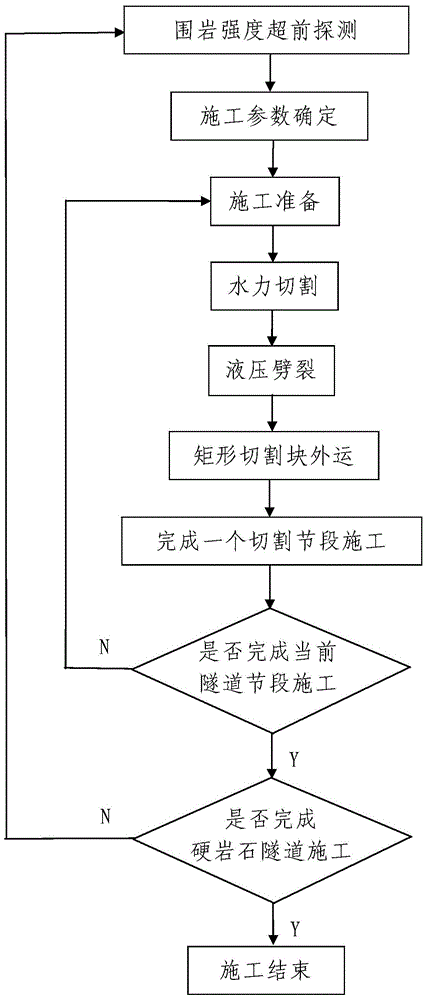

Hard rock tunnel construction method based on water power cutting

The invention discloses a hard rock tunnel construction method based on water power cutting. The hard rock tunnel construction method based on the water power cutting is characterized by constructing multiple tunnel sections from back to front along the longitudinal extending direction of a tunnel. When any one tunnel section is constructed, the process is as follows: 1, surrounding rock classification advanced detection; 2, construction parameter confirmation, wherein the confirmed construction parameters comprise cutting parameters of a water power cutting machine and split force of a hydraulic splitter; 3, current constructed tunnel section construction: constructing multiple cutting sections of the current constructed tunnel sections from back to front along the longitudinal extending direction of the tunnel, wherein when any one cutting section is constructed, the process is as follows: construction preparation, water power cutting, hydraulic splitting and rectangular cutting block outward transporting; 4, repeating steps one, two and three for many times until the construction process of the constructed hard rock tunnel is finished. The method provided by the invention is simple in steps, convenient to implement, lower in input cost, high in construction efficiency, good in construction effect, and can simply, conveniently and quickly finish the construction process of the hard rock tunnel.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

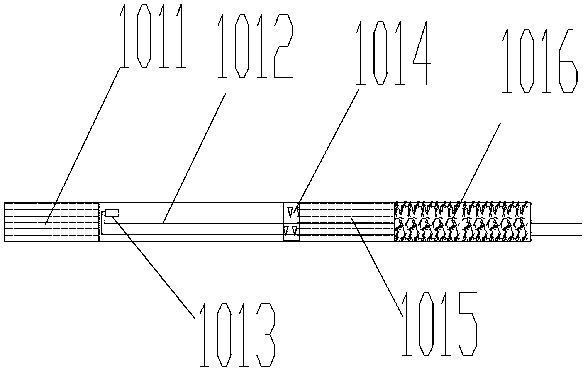

Coalmine rock roadway excavation shaped-charge water-pressure smooth blasting structure and method

InactiveCN108225137AIncrease the speed of excavationImprove energy utilizationBlastingShaped chargeStructure of the Earth

The invention relates to the field of shaped-charge water-pressure smooth blasting, in particular to a coalmine rock roadway excavation shaped-charge water-pressure smooth blasting structure and method. The coalmine rock roadway excavation shaped-charge water-pressure smooth blasting structure is characterized in that rock breaking holes are formed in the center line of a section of a rock roadway; cutting holes are symmetrically formed in two sides of the rock breaking holes; secondary cutting holes are formed in one side of the cutting holes; tertiary cutting holes are formed in one side ofthe secondary cutting holes; auxiliary holes are formed in one side of the tertiary cutting holes; peripheral holes are formed in the outer sides of the auxiliary holes; and bottom holes are formed inthe bottoms of the peripheral holes. The invention further provides the coalmine rock roadway excavation shaped-charge water-pressure smooth blasting method. Through the coalmine rock roadway excavation shaped-charge water-pressure smooth blasting structure and method provided by the invention, the big rock occurrence ratio can at least be obviously reduced; the coalmine rock roadway excavation speed can be improved by adoption of shaped-charge water-pressure blasting; and meanwhile, the explosive energy utilization ratio can be improved, the smooth blasting quality can be improved, and underground blasting dust can be efficiently reduced.

Owner:HENAN SUNHO COAL & POWER CO LTD

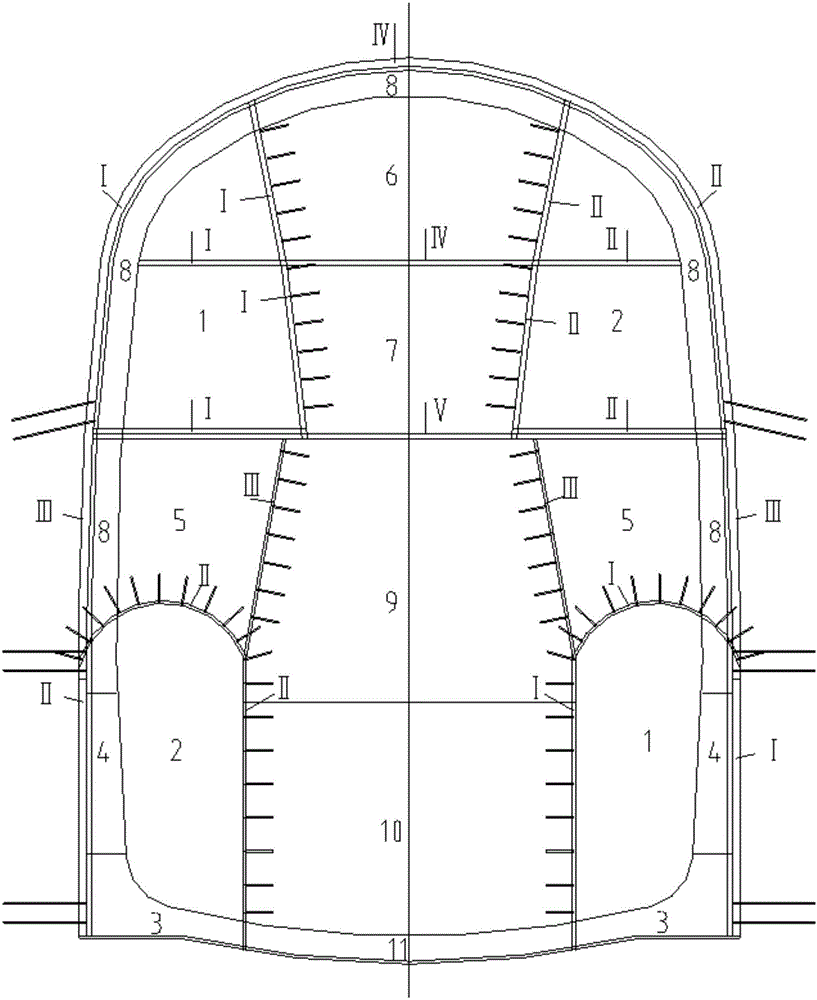

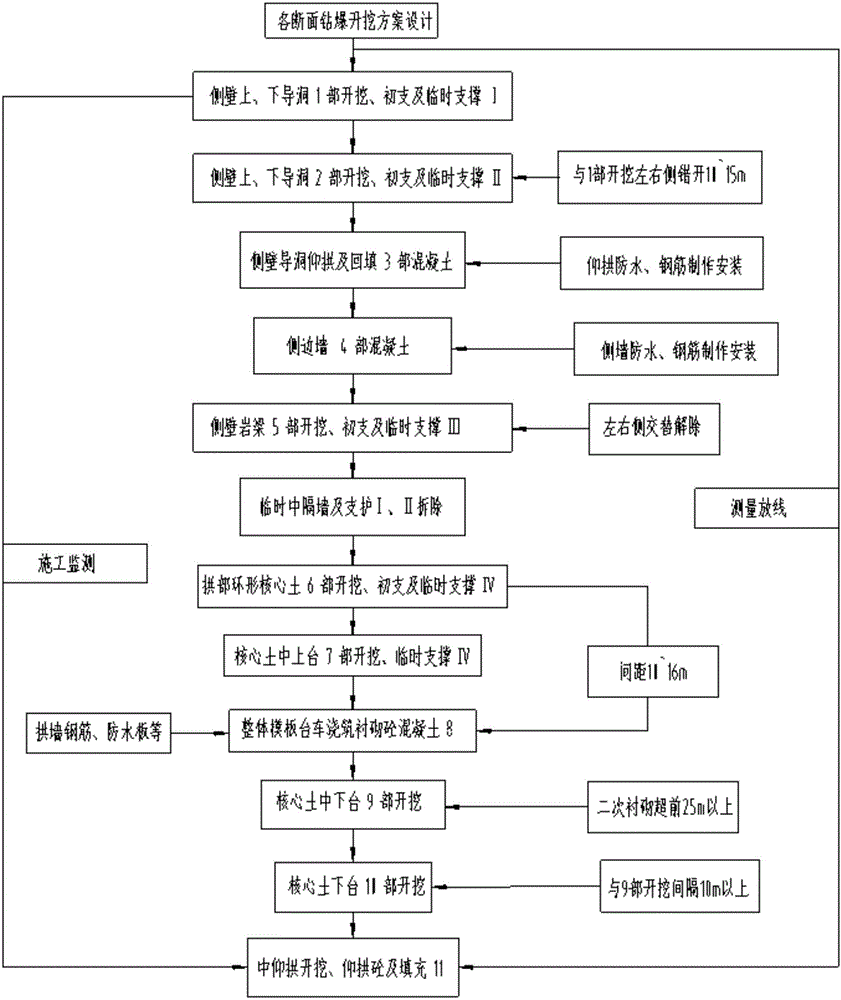

Construction method for excavating upper drift heading and lower drift heading in two side walls of ultra-large subsurface tunnel

InactiveCN106643361AReduce unit consumptionReduce the impactBlastingDrilling and blastingBuilding construction

The invention provides a construction method for excavating an upper drift heading and a lower drift heading in the two side walls of an ultra-large subsurface tunnel and belongs to the technical field of construction engineering. The method comprises the steps of drilling and blasting scheme design; construction requirements meeting of drilling and blasting design; blasting parameter selection; surveying and setting out; excavation of the upper pilot tunnel portion and the lower pilot tunnel portion of the two side walls; removal of reserved rock beam portions; excavation of an annular core soil portion of an arch portion; and excavation of core soil middle-upper steps, middle-lower steps and lower steps. Compared with a traditional two-side-wall drift heading method, according to the method, the way of excavating the upper drift heading and the lower drift heading at the same time is adopted, and the characteristics of the large-section tunnel can be fully utilized; a working face which can be excavated is increased; tunnel excavation conducted at the early stage is accelerated; and the construction period is effectively shortened. According to the method, reserved rock beams are utilized, so that horizontal support strength and global stability are effectively enhanced; horizontal convergence deformation and arch top settlement of the tunnel are decreased; and safety of buildings on the upper portion of the tunnel is guaranteed. According to the construction method, after the high side walls are constructed by means of the bottom of a lower pilot tunnel of the tunnel, backfilling is conducted, the height of a second lining construction section of the tunnel is reduced, and the construction problem of an ultra-large-section formwork trolley is solved.

Owner:CHINA CONSTR EIGHTH ENG DIV

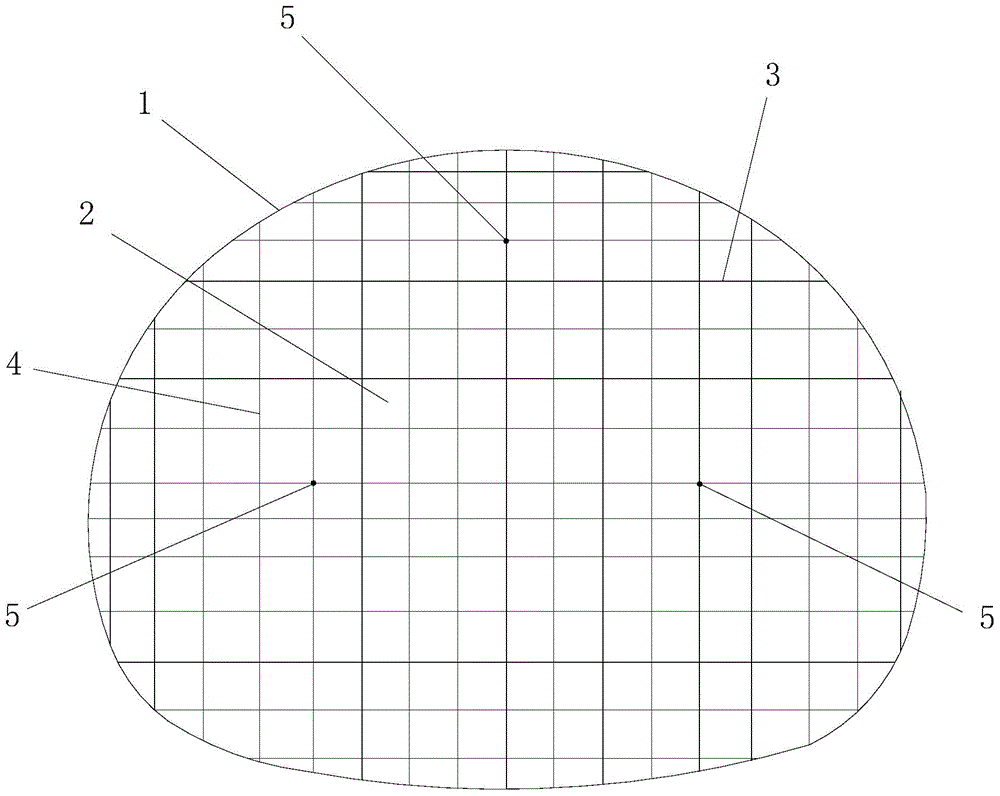

Excavation construction method for mine hard rock roadway

The invention discloses an excavation construction method for a mine hard rock roadway. A cutting device is used for cutting out the outline of the roadway, cutting in the horizontal direction and in vertical direction is carried out in the outline of the roadway to obtain parallel horizontal cut grooves and parallel vertical cut grooves, and the horizontal cut grooves and the vertical cut grooves intersect and cut the section of the roadway inside the cut grooves of the outline to a longitudinally and transversely intersected grid-shaped structure. A crushing device is used for crushing or breaking a first rock inside the grid-shaped structure of the section of the roadway in a prizing mode and then crushing or breaking other rocks in the prizing mode, the crushed or broke rocks are taken out until all the rocks within the cutting depth are taken out, and a manual or mechanical conveying device is used for conveying cut rocks. The excavation construction method for the mine hard rock roadway resolves the problem of excavation of hard rocks or superhard rocks through a mechanical method, eliminates an explosion work procedure, is safe and efficient, and is not restrained by use and management regulations of explosive products. The roadway is good in forming performance, damage to surrounding rocks is small, supporting can be simplified or eliminated, operation time and engineering cost are saved, the construction speed is improved, and excavation cost is lowered.

Owner:重庆能投渝新能源有限公司

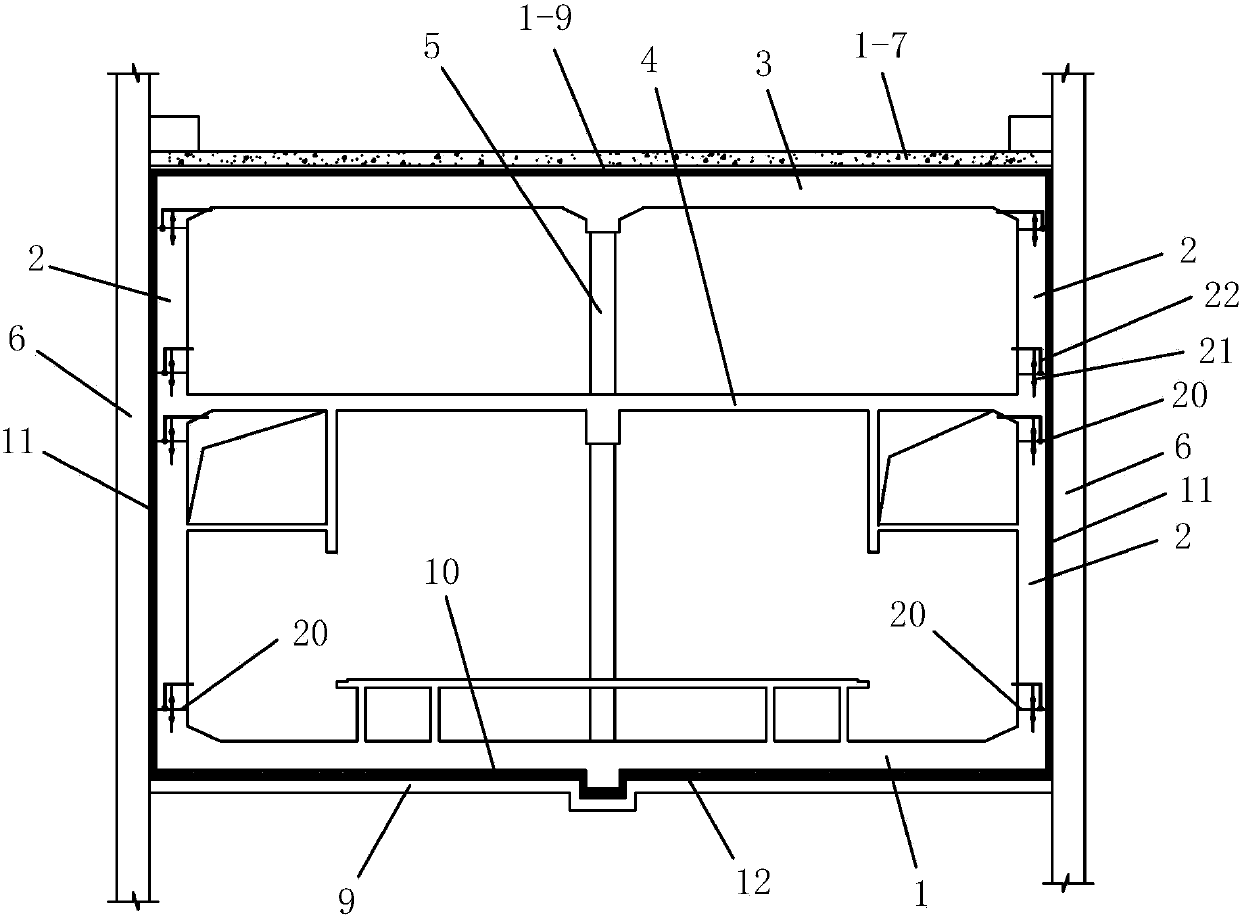

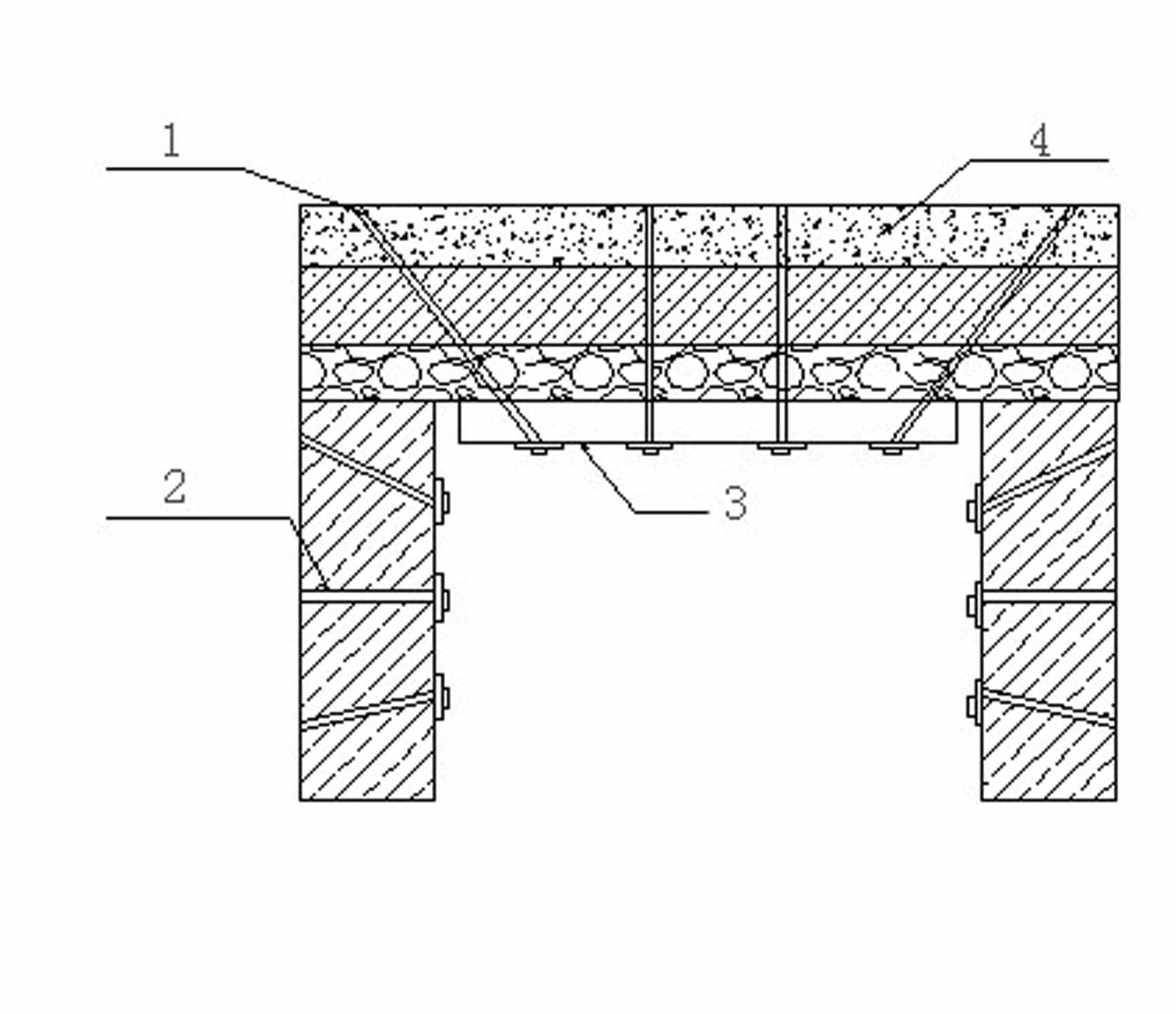

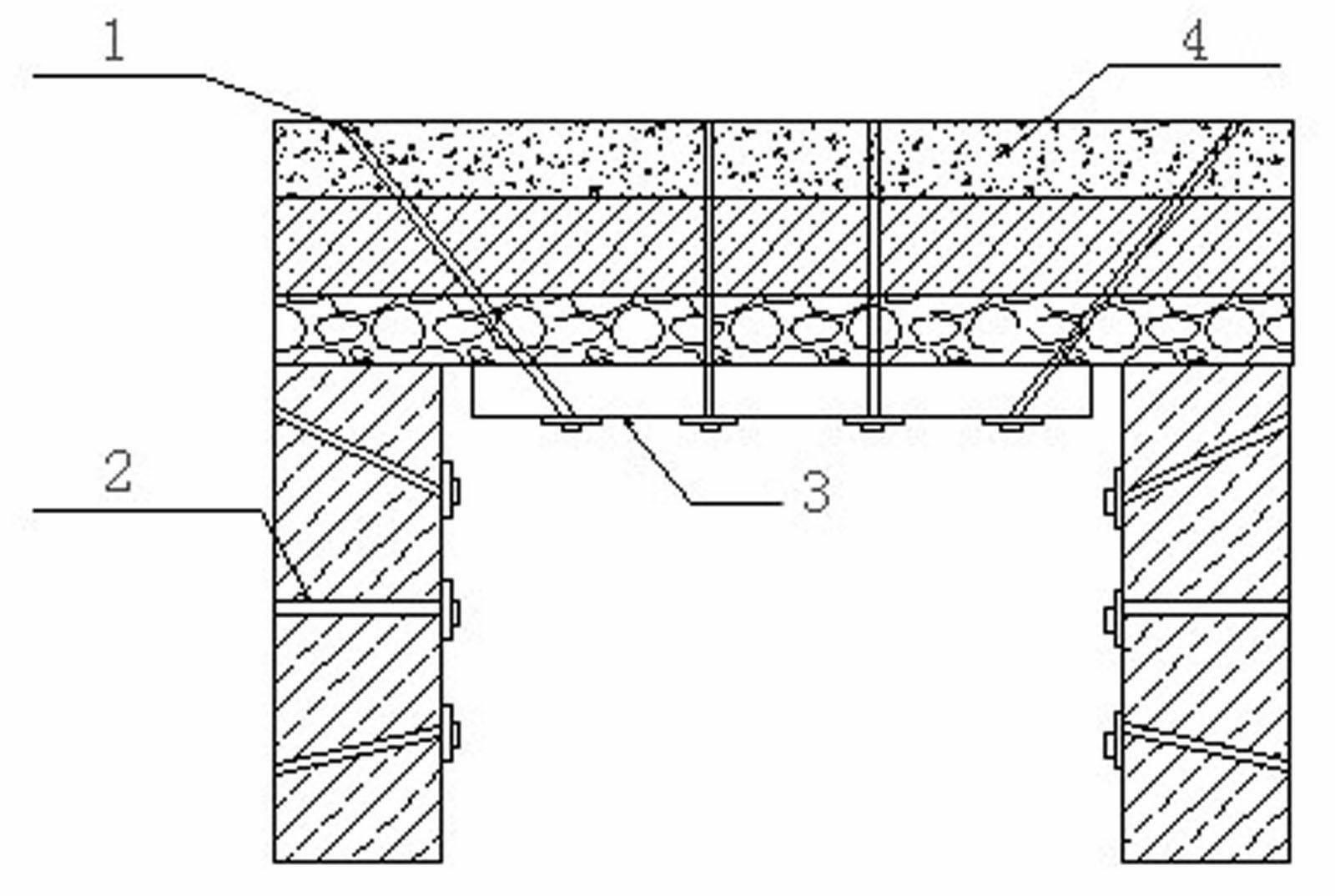

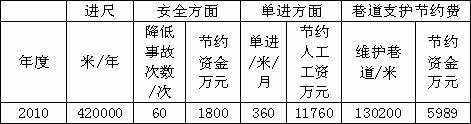

Supporting type continuous tunnelling machine

InactiveCN1987046AIncrease the speed of excavationImprove securitySlitting machinesMine roof supportsEngineeringCoal

A support-type continuous digging machine for coal road or half-coal-and-half-rock road is composed of an improved digging machine and a supporting stack type hydraulic support. Its main body is fixed onto the base of hydraulic support, which is also used as the slide shoe for making the digging machine to run. The front and back hydraulic supports with two hydraulic jacks are used for automatic running. The roof suporting can be performed behind the support while the coal road is continuously dug.

Owner:郑生 +1

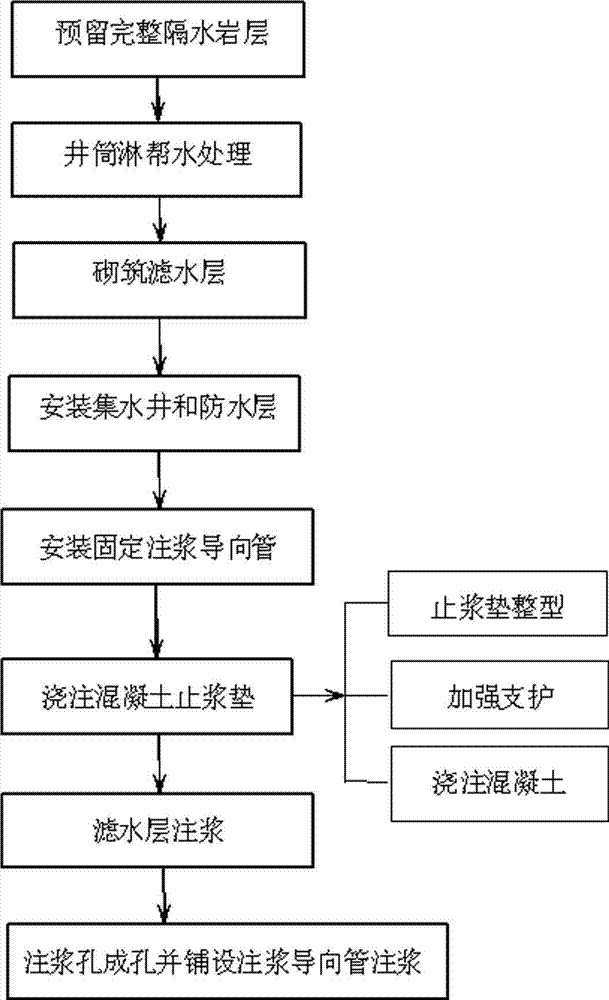

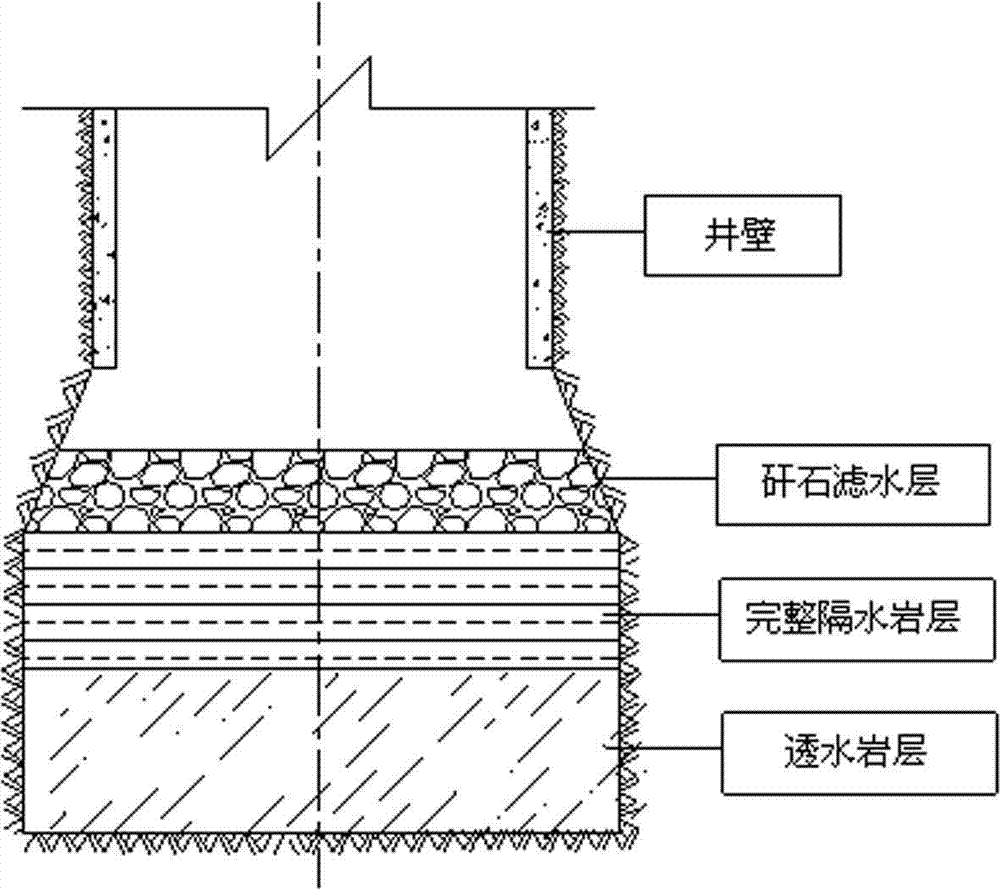

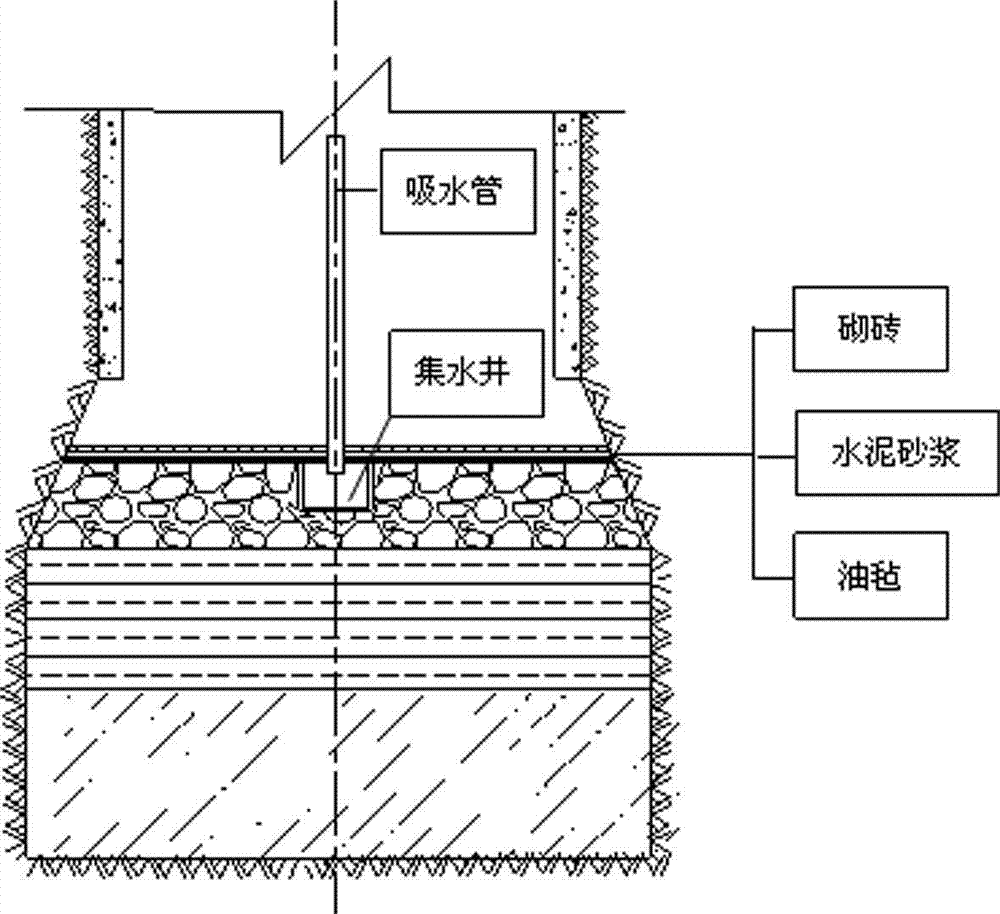

Pre-grouting and water plugging method for permeable layer in vertical shaft

A pre-grouting and water plugging method for a permeable layer in a vertical shaft includes the steps of reserving complete waterproof rock strata, performing spraying water treatment for a shaft body, building a water filtering layer, mounting a drainage sump and a waterproof layer, mounting and fixing a grouting guide pipe, pouring concrete grouting pad, performing water filtering layer grouting and performing grouting hole formation and laying the grouting guide pipe for grouting. The pre-grouting and water plugging method has the advantages that high grouting pressure meeting design requirements can be borne, grouting and water plugging effects under high water pressure and high grouting pressure during construction of the vertical shaft are guaranteed, the thickness of the grouting pad can be decreased to the greatest extent, and grouting pad construction and detachment workload is reduced, so that grouting effect is guaranteed, shaft body advancement speed is increased, and more obvious effect is achieved particularly as for a large-thickness permeable layer. Therefore, the pre-grouting and water plugging method can be effectively applied to pre-grouting and water plugging of the permeable layer in the vertical shaft and has good effect on experimental verification.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

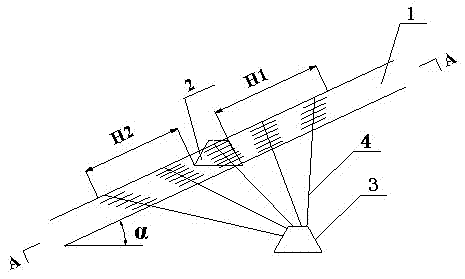

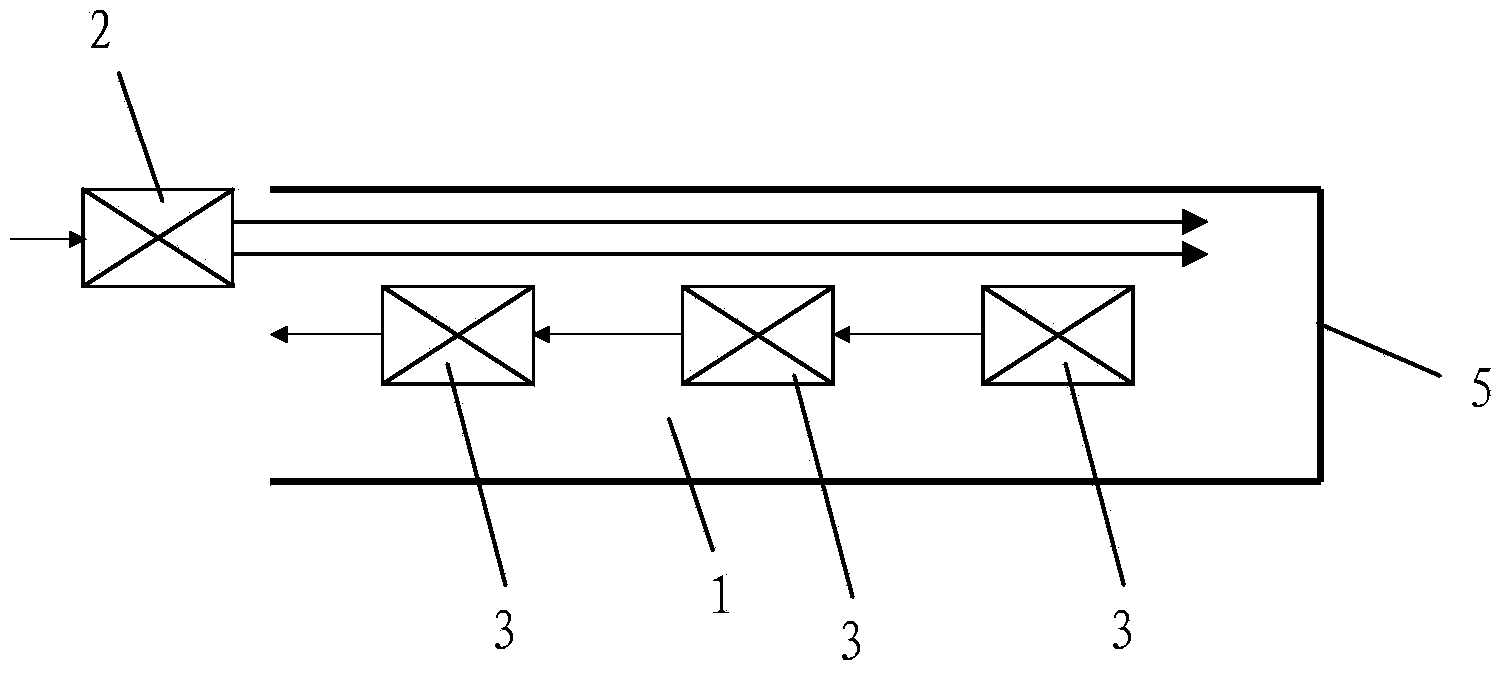

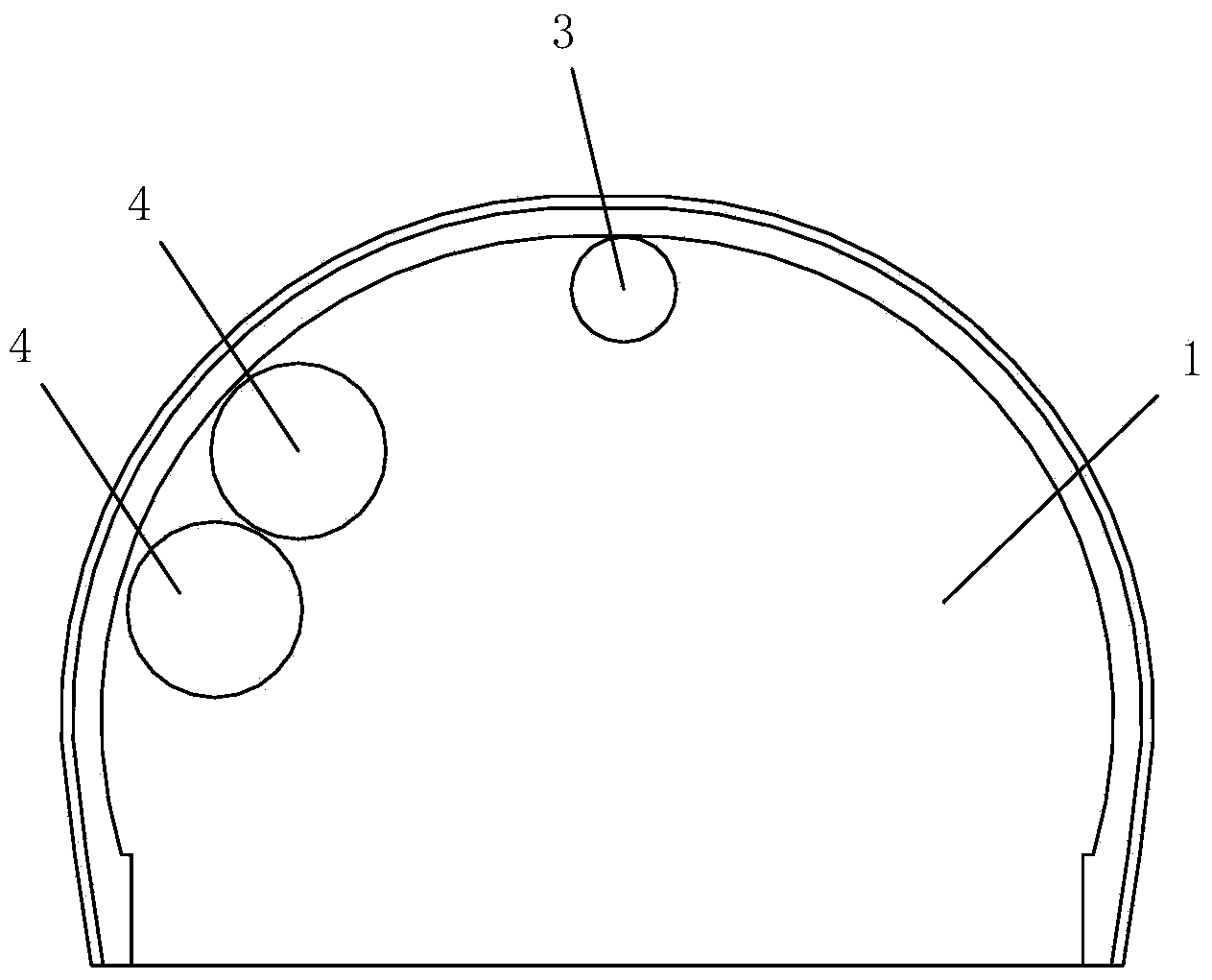

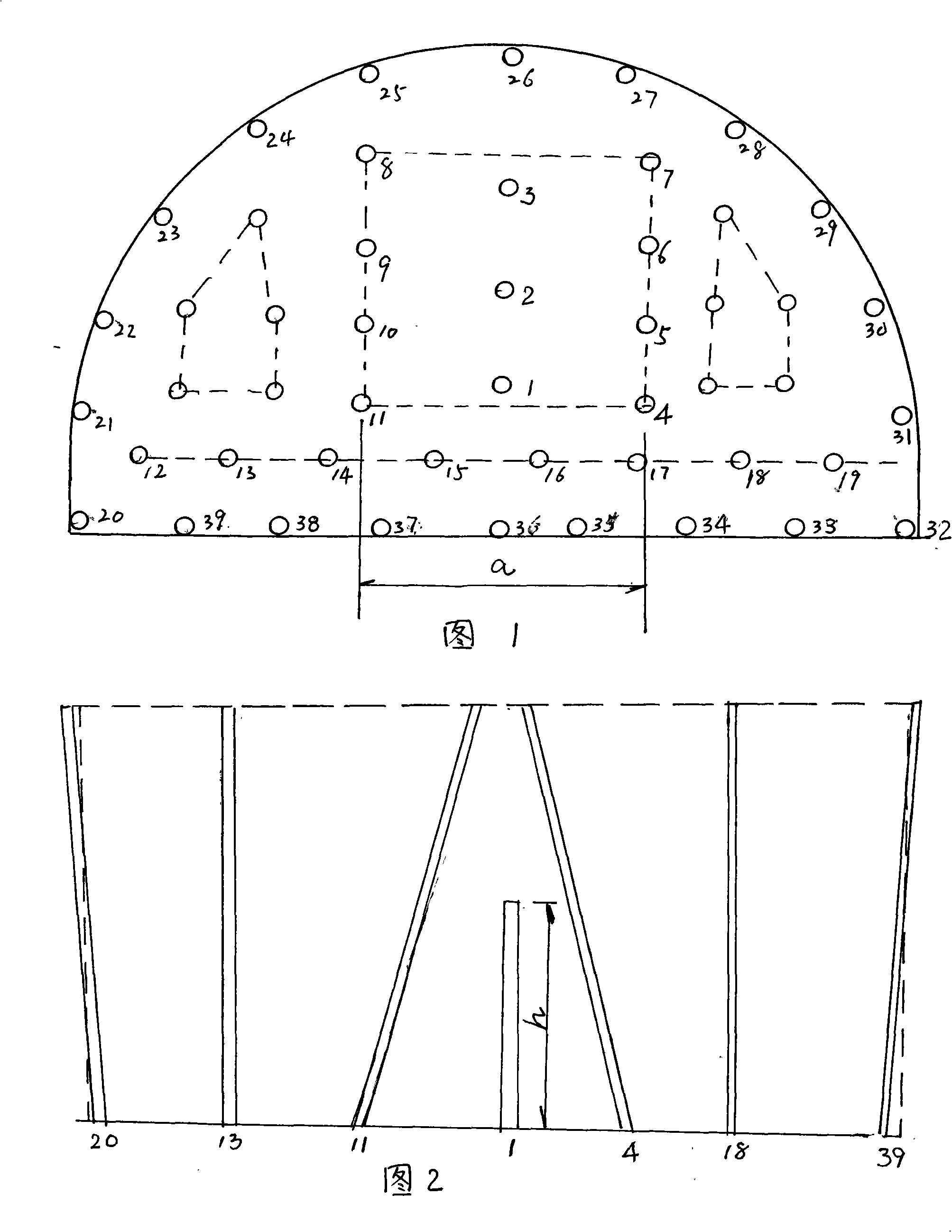

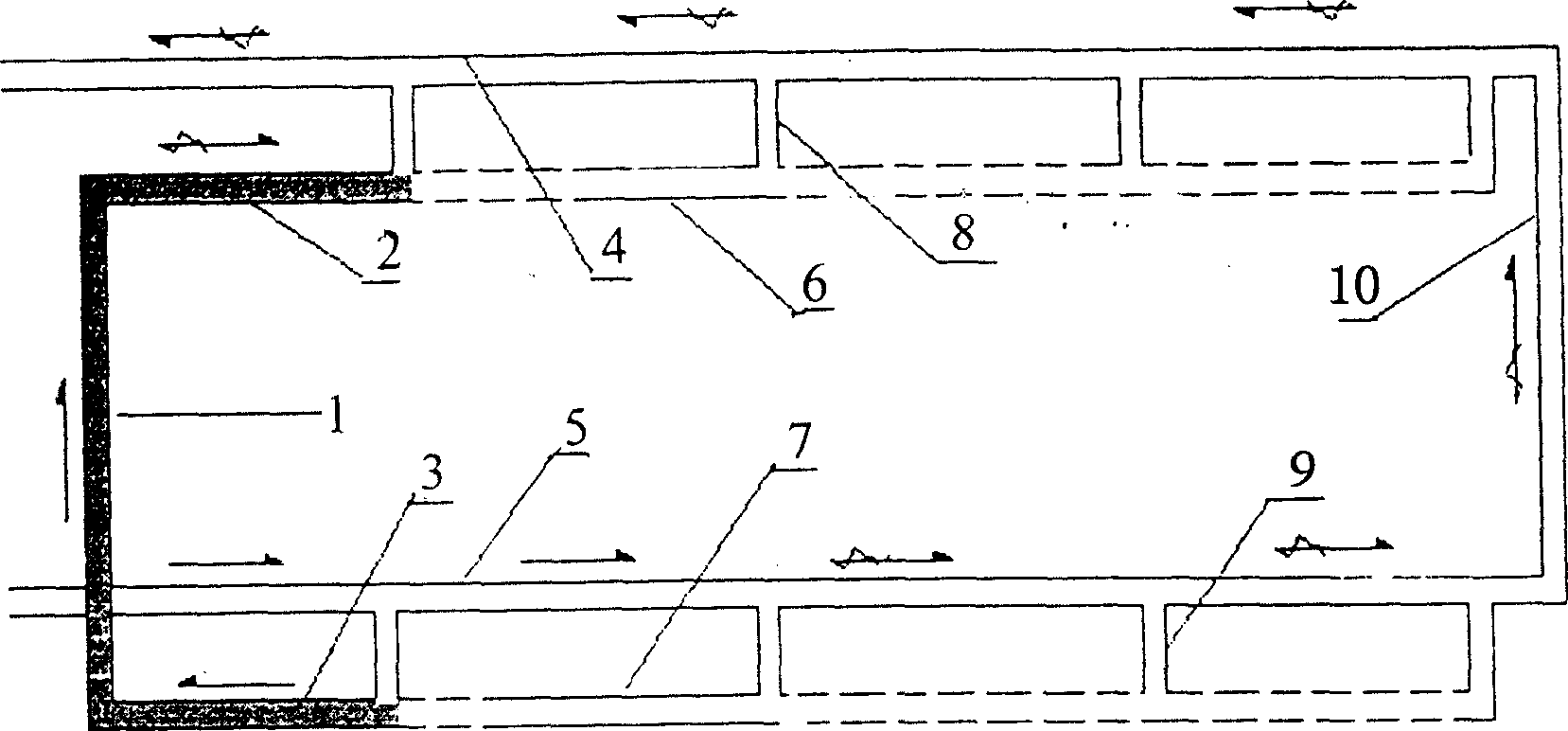

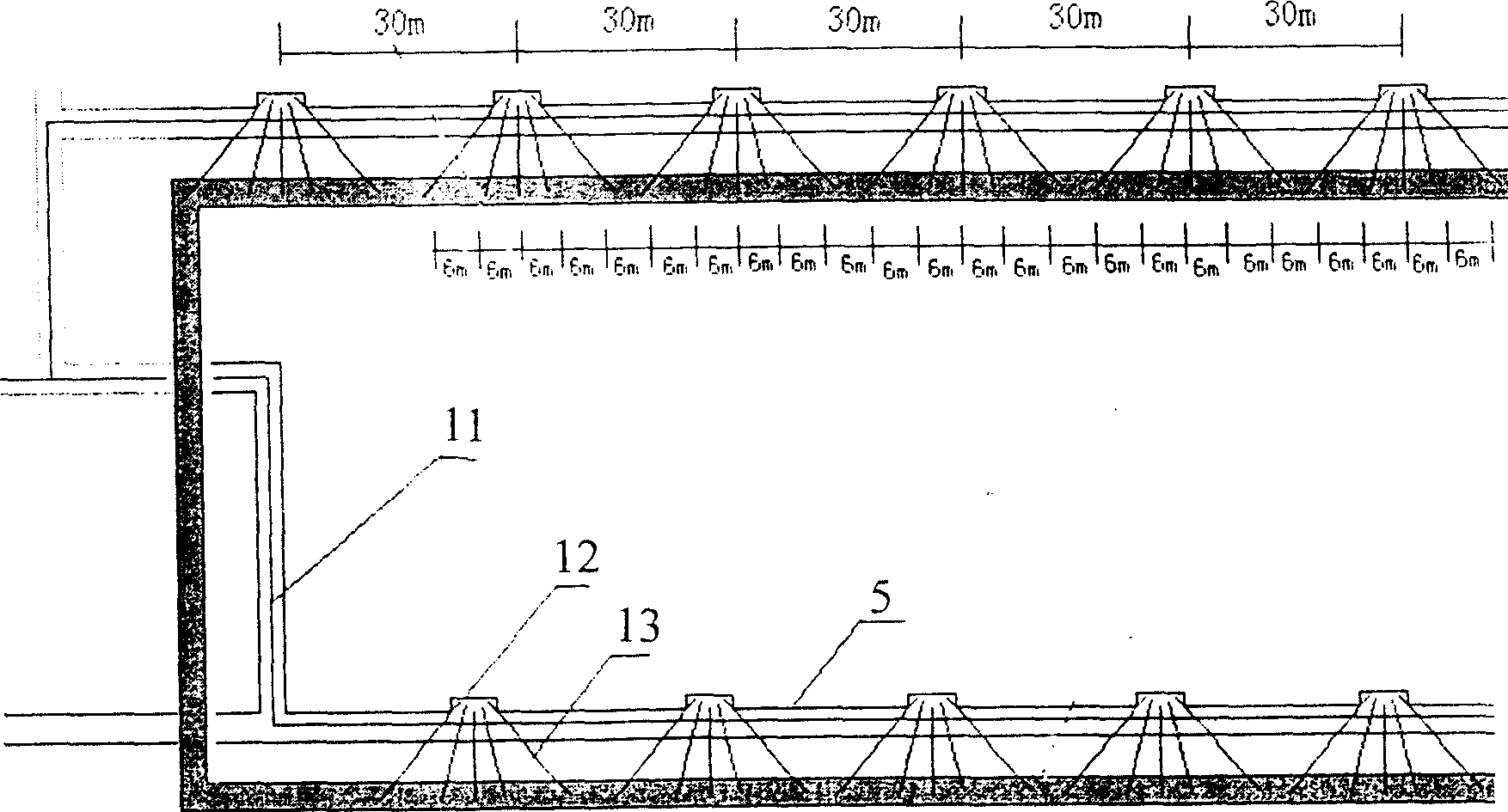

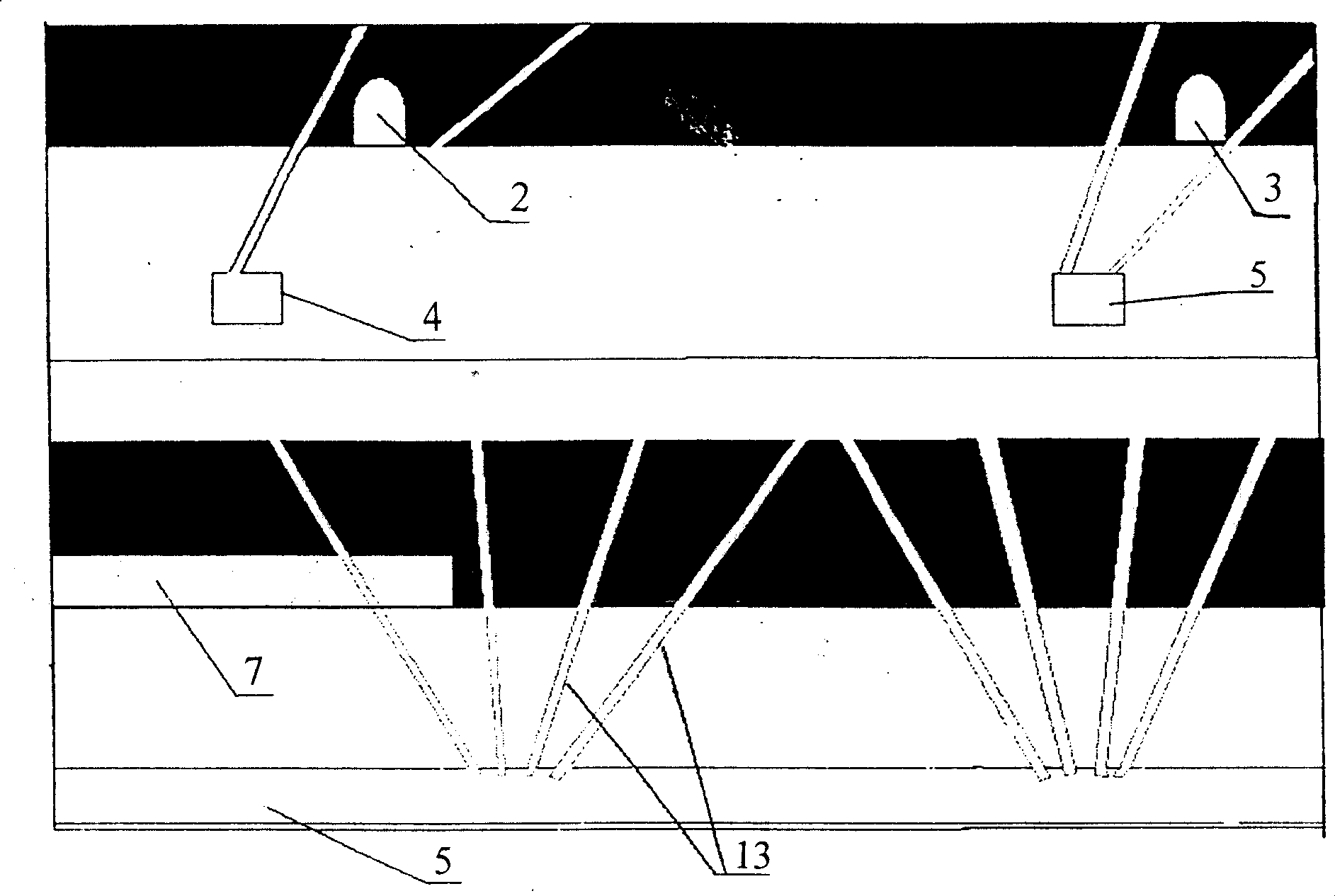

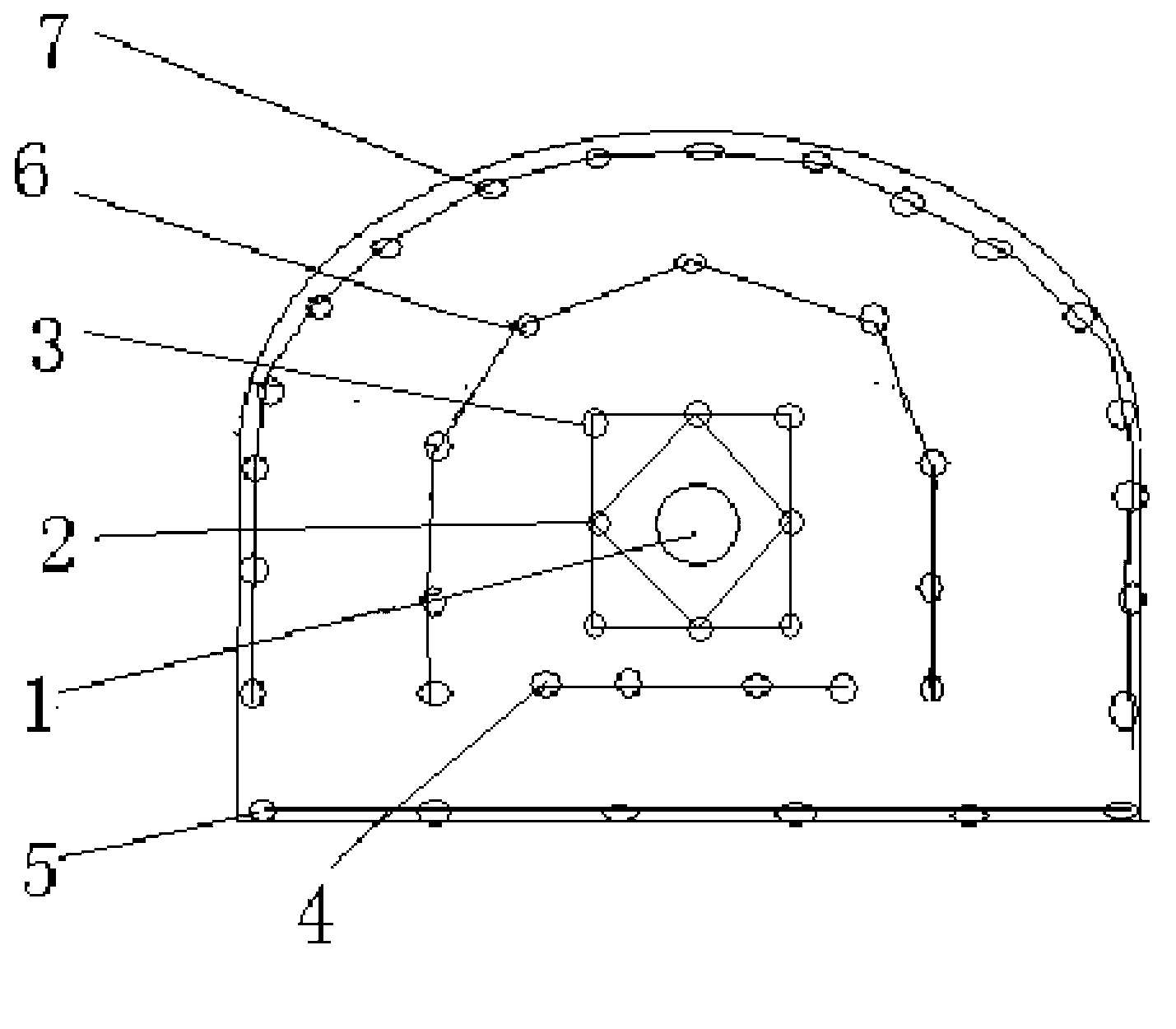

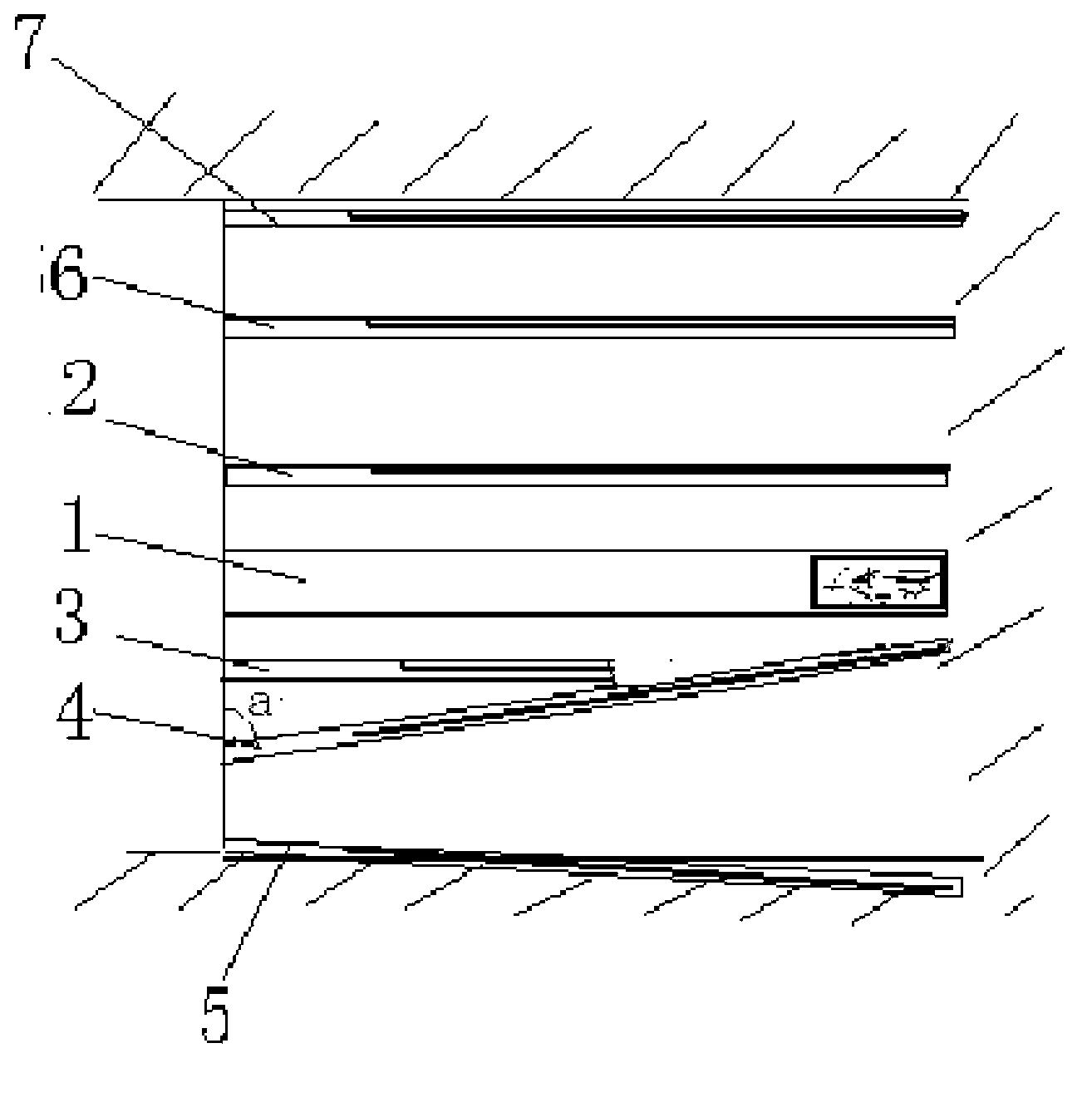

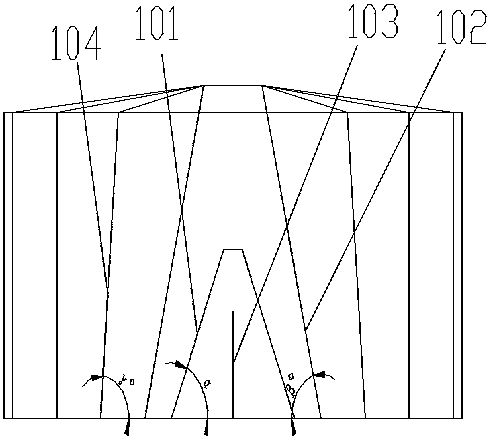

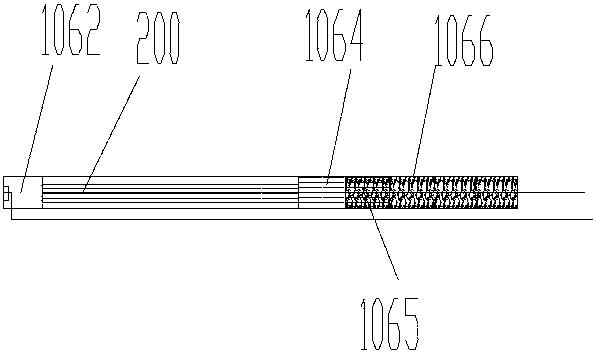

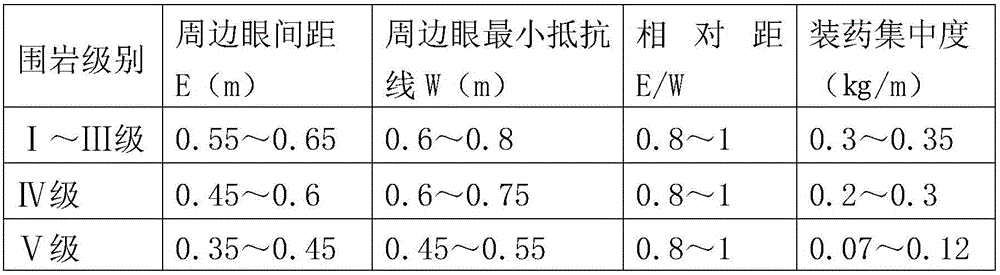

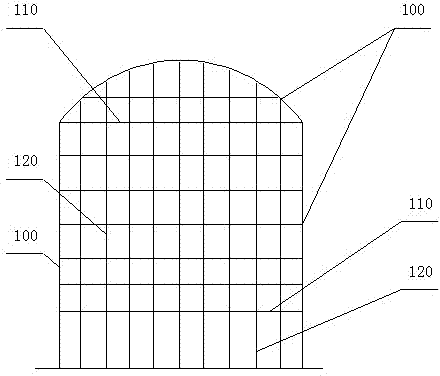

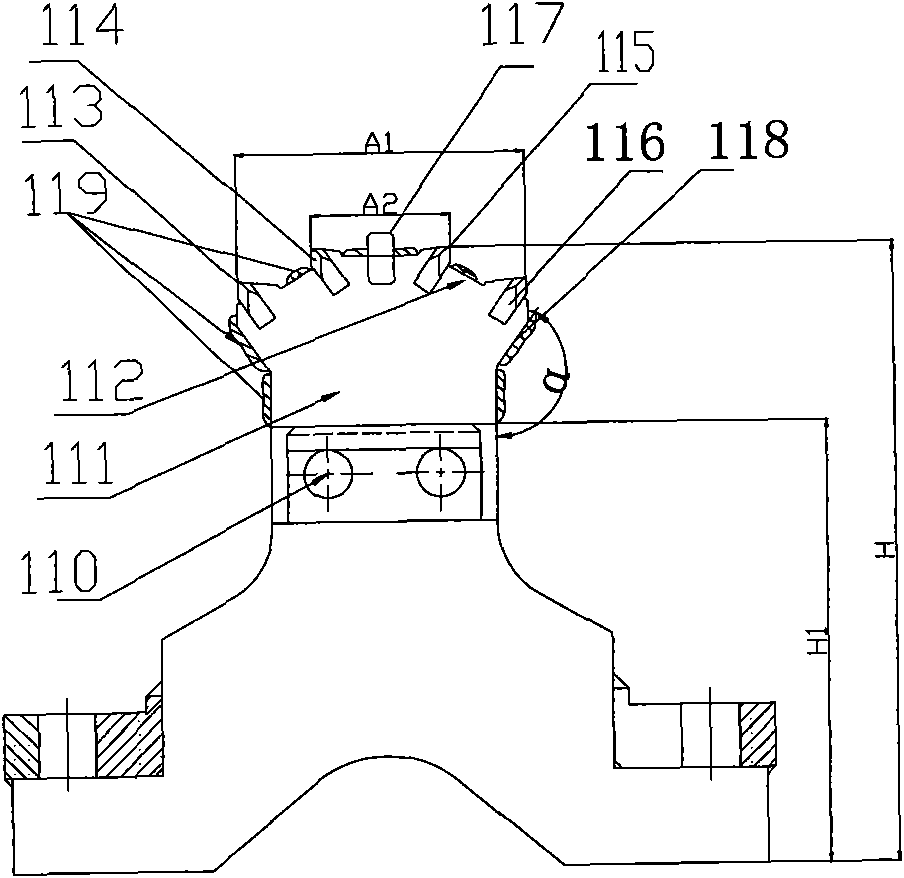

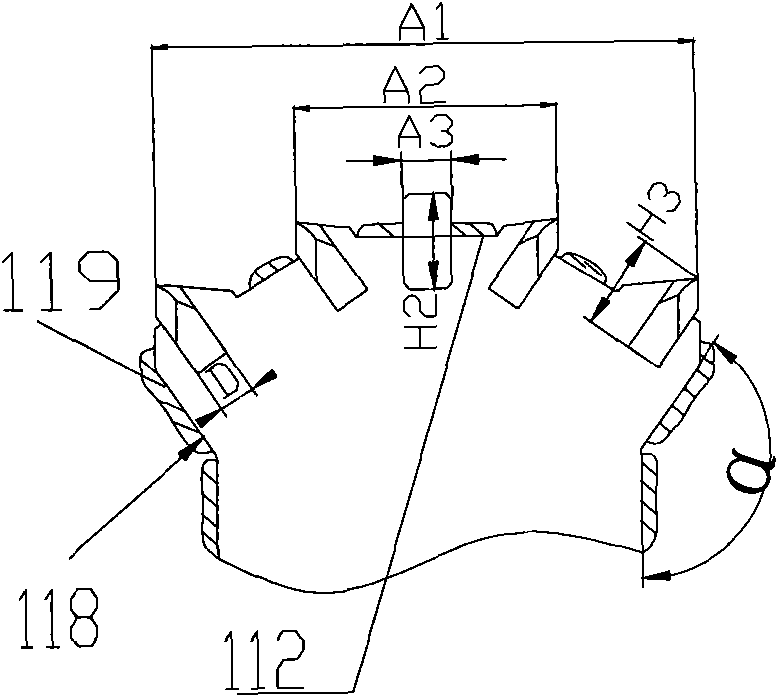

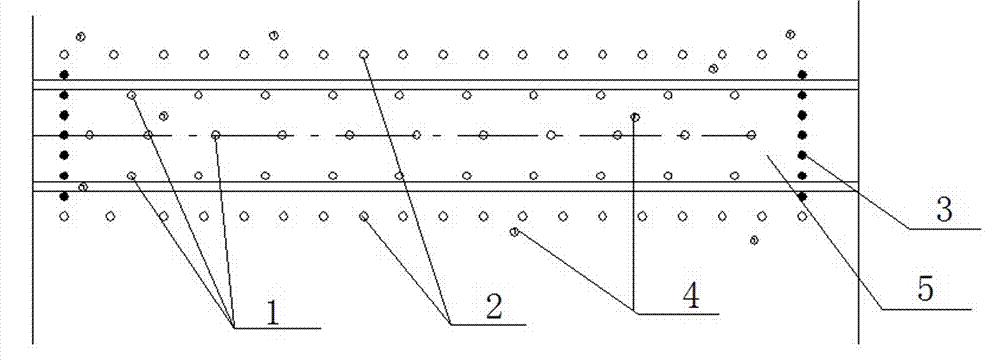

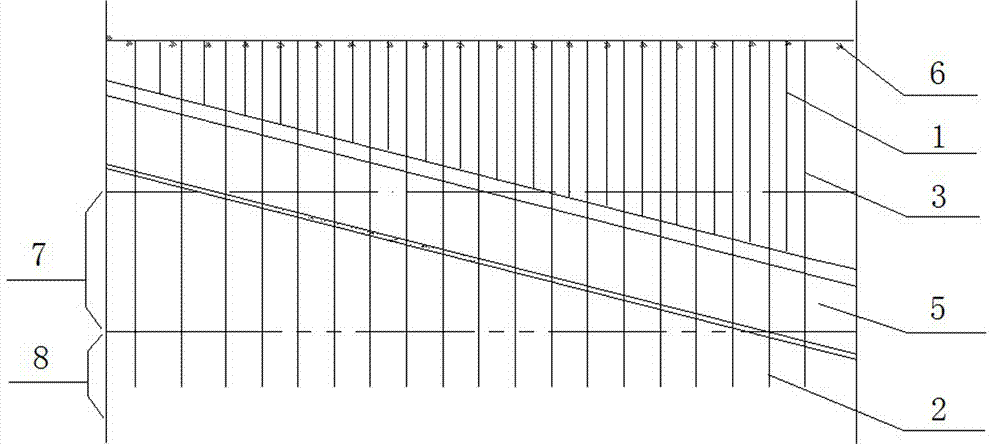

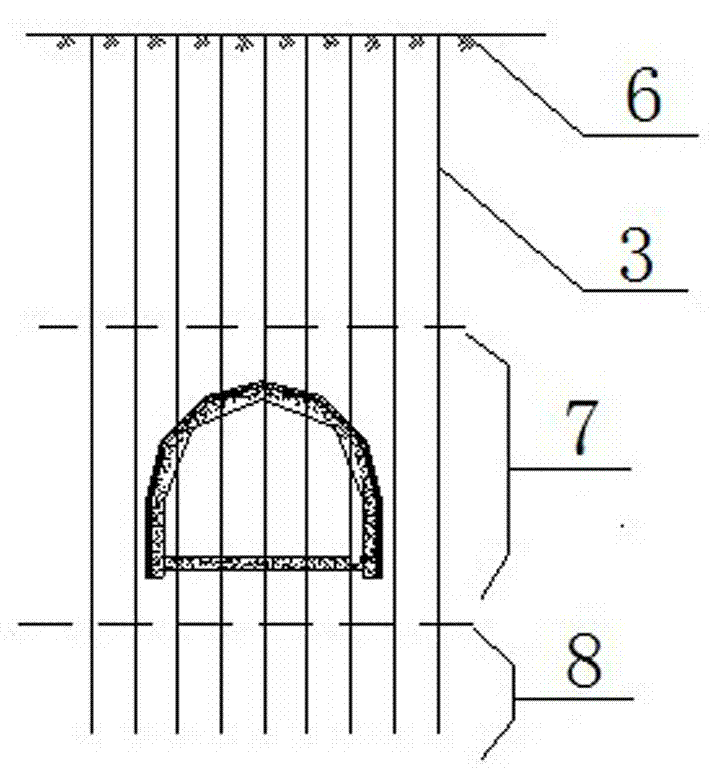

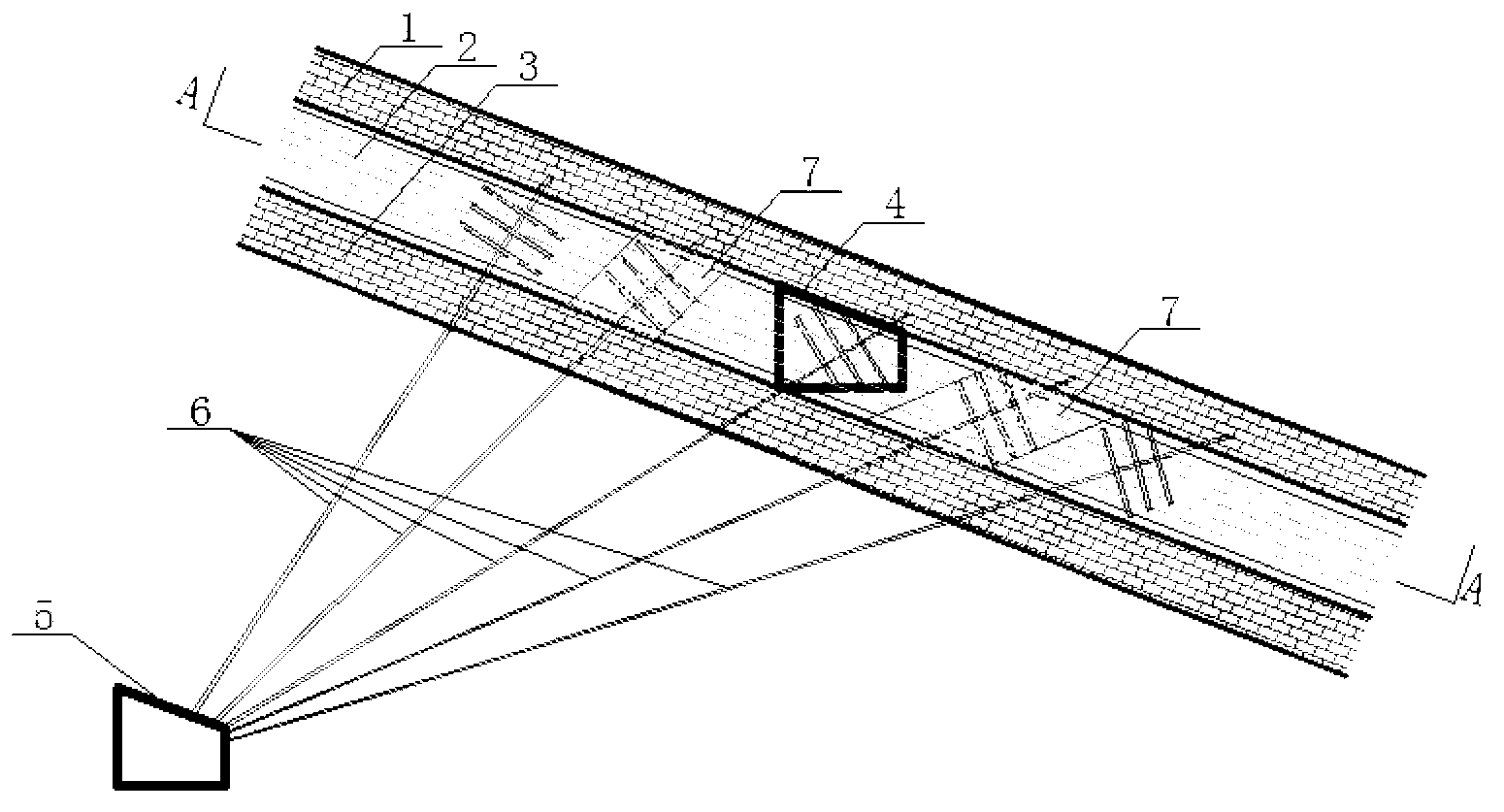

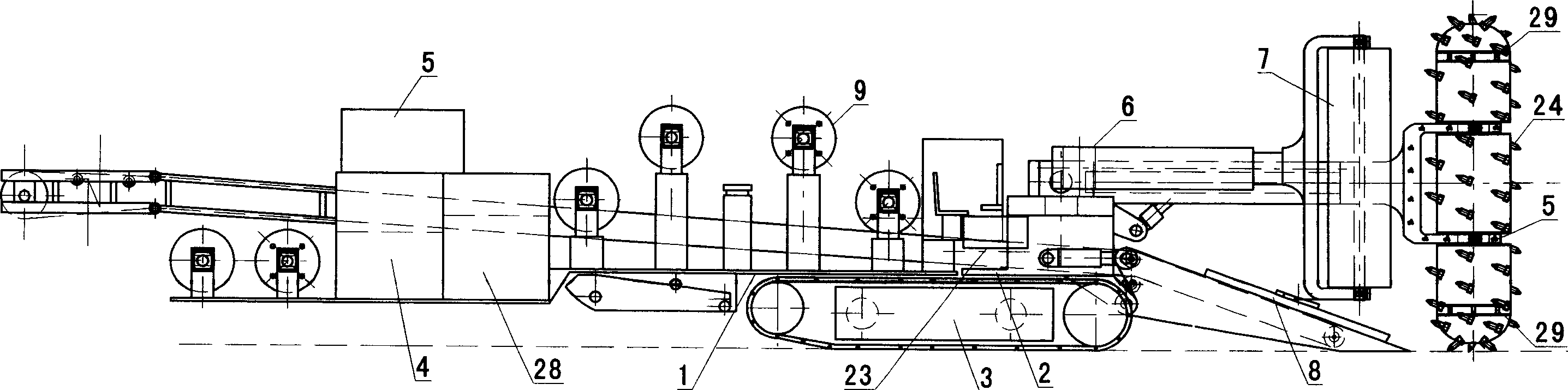

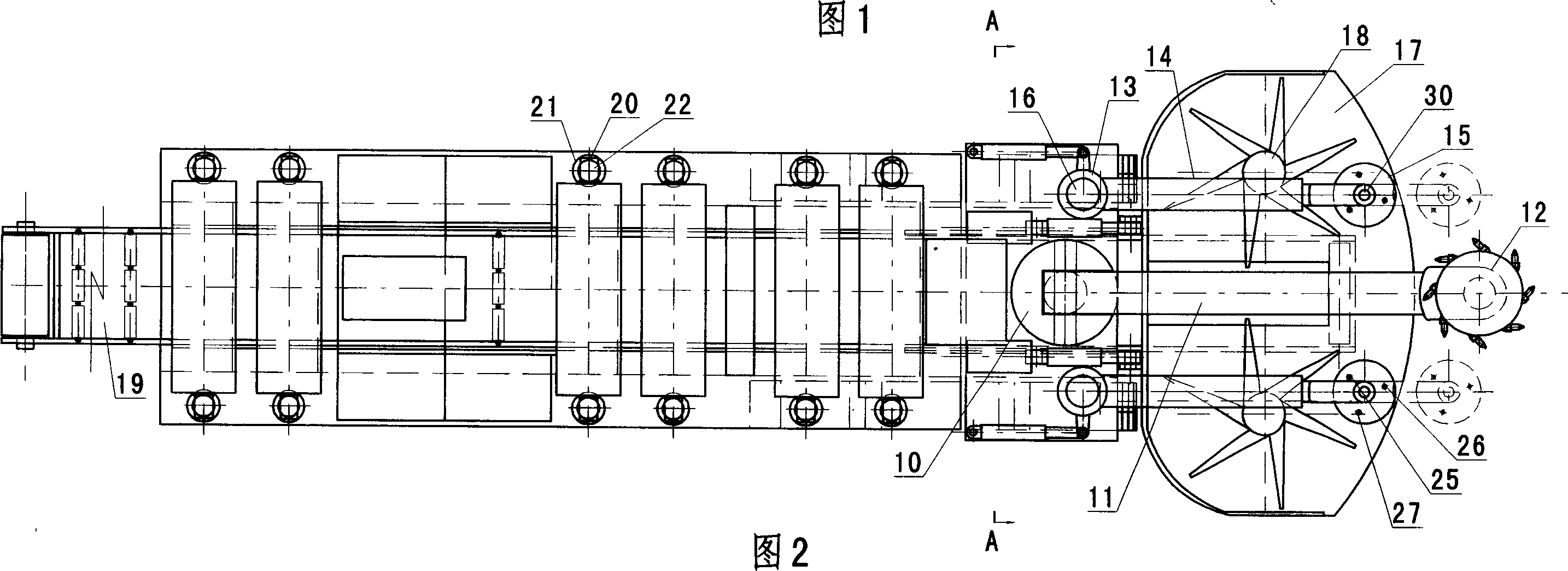

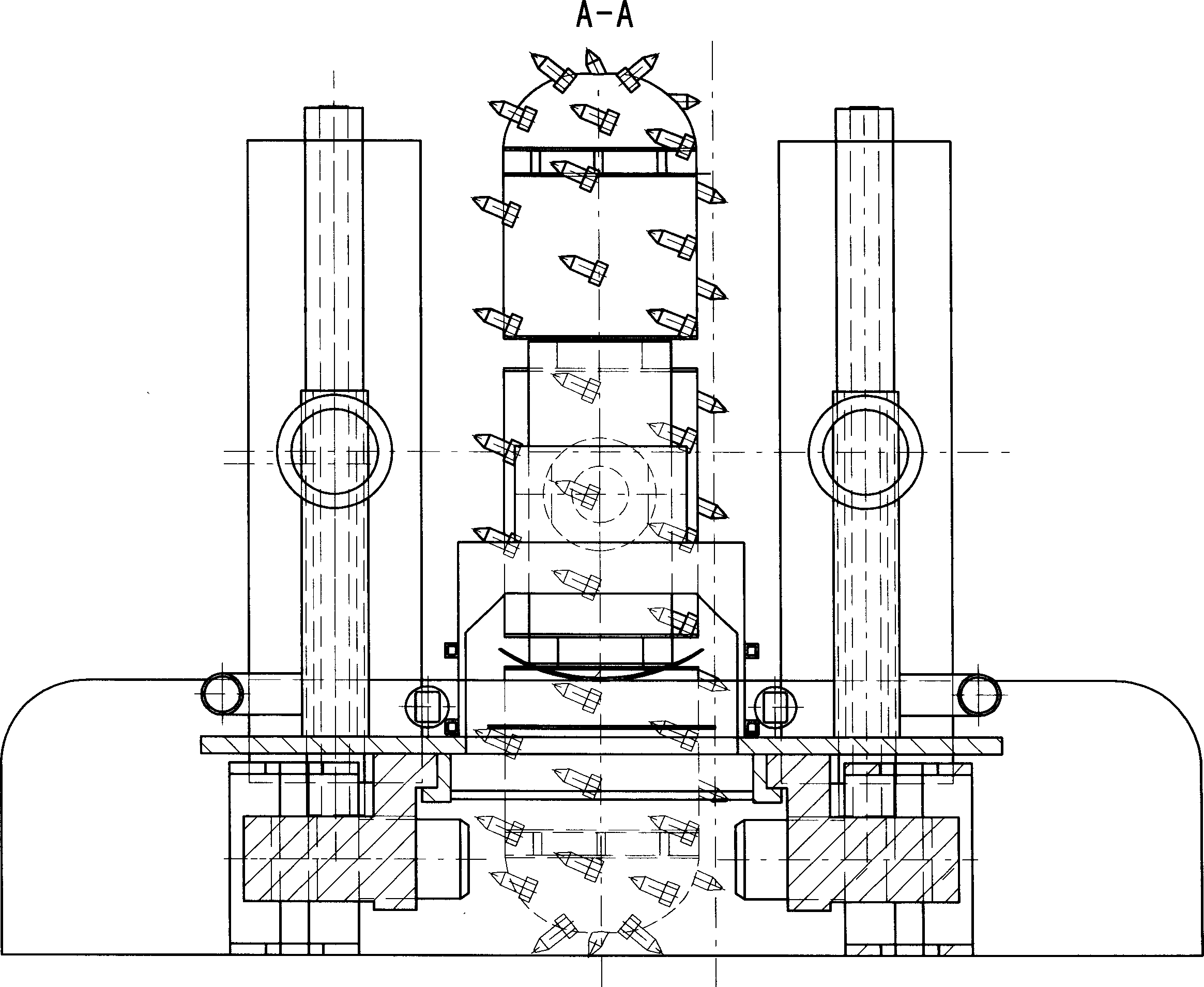

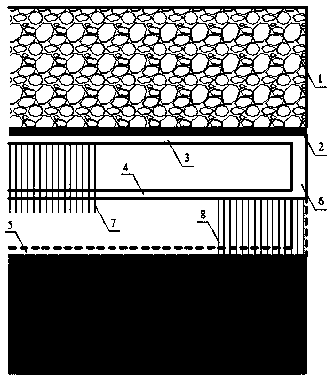

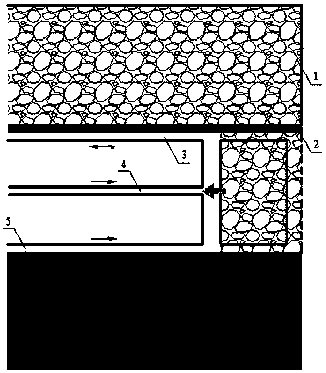

Fast and highly-efficient tunneling method for large section of hard-rock tunnel in coal mine by combination of fully-mechanized tunneling and blasting driving

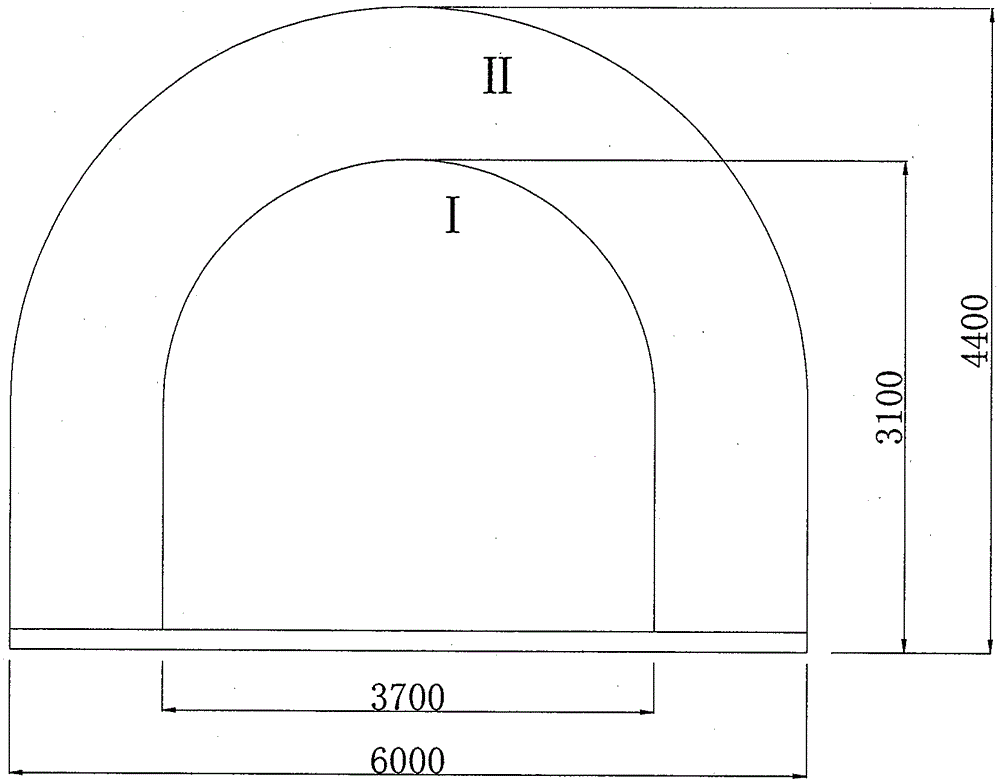

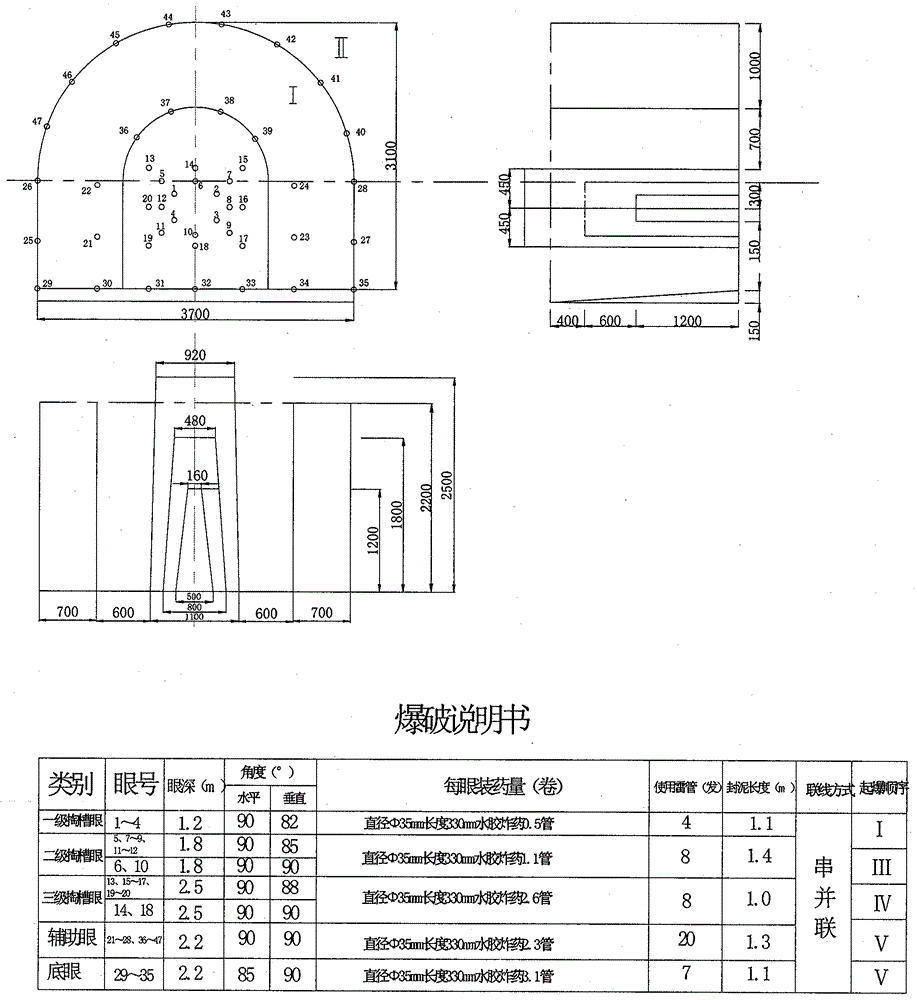

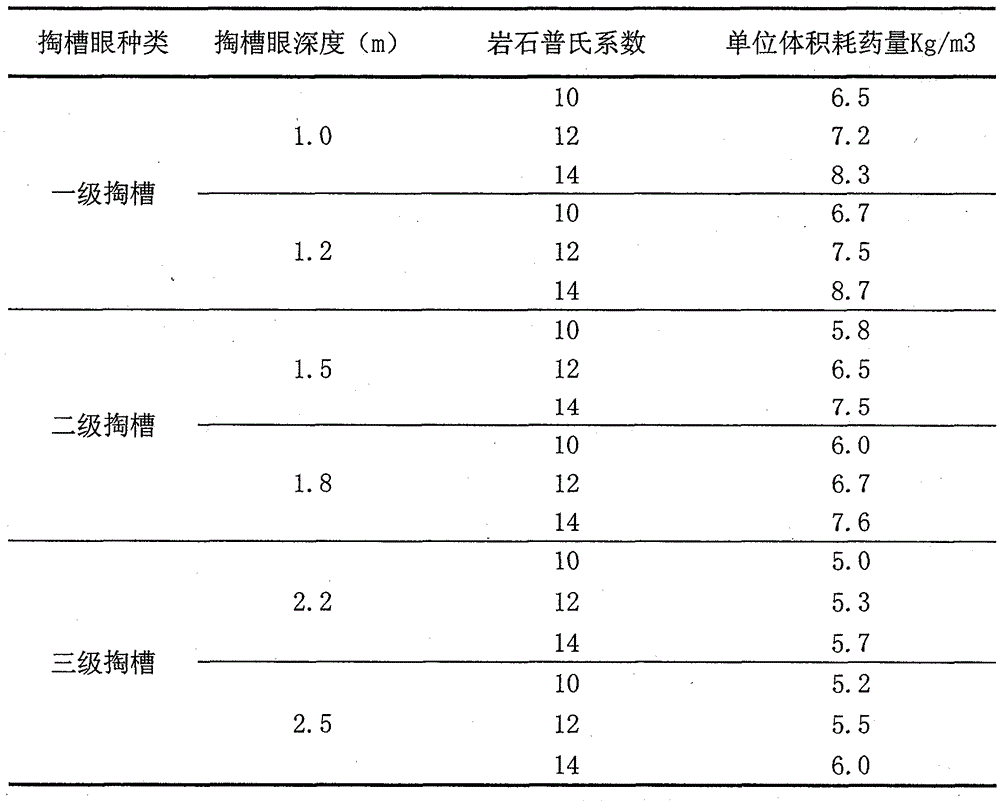

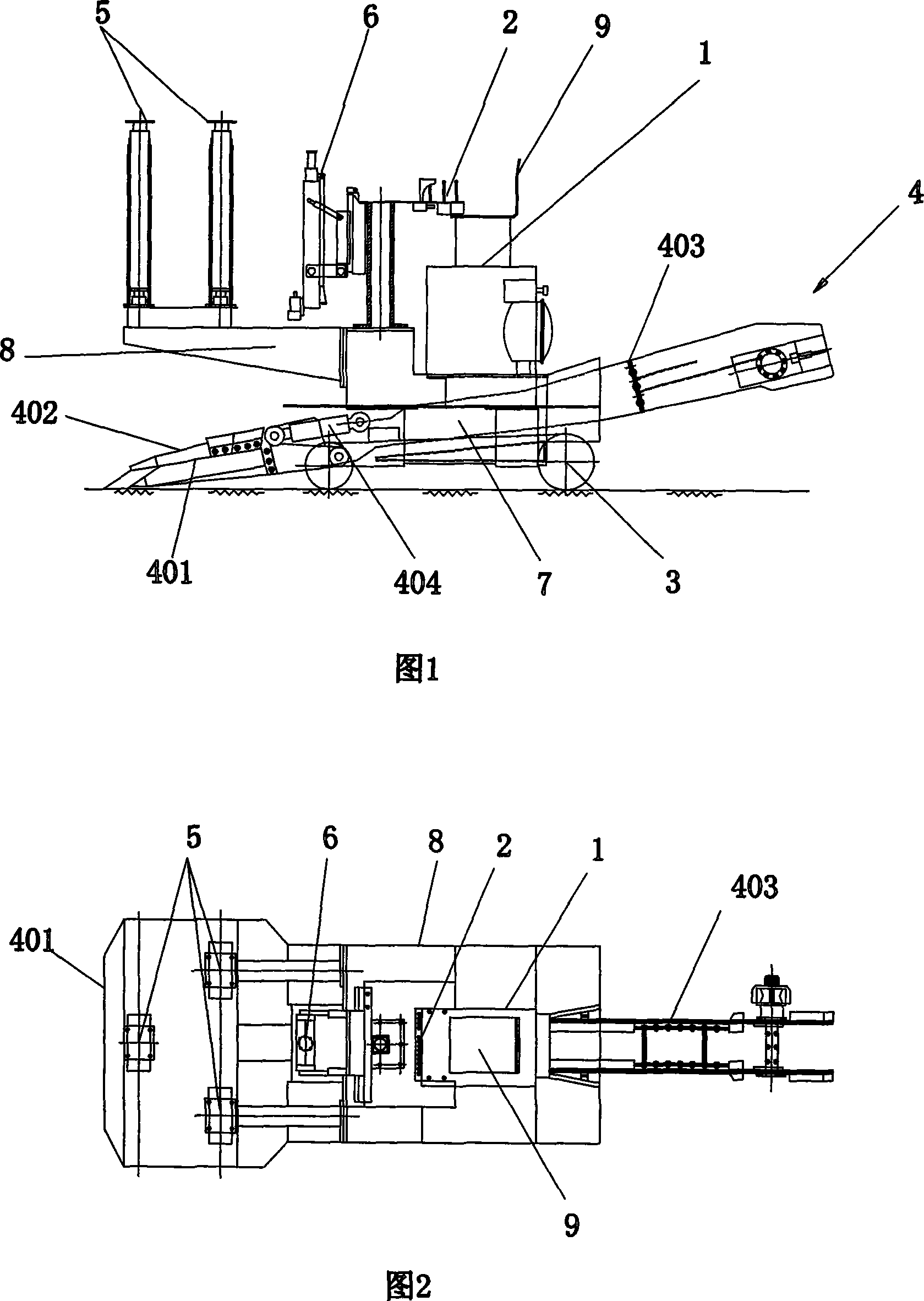

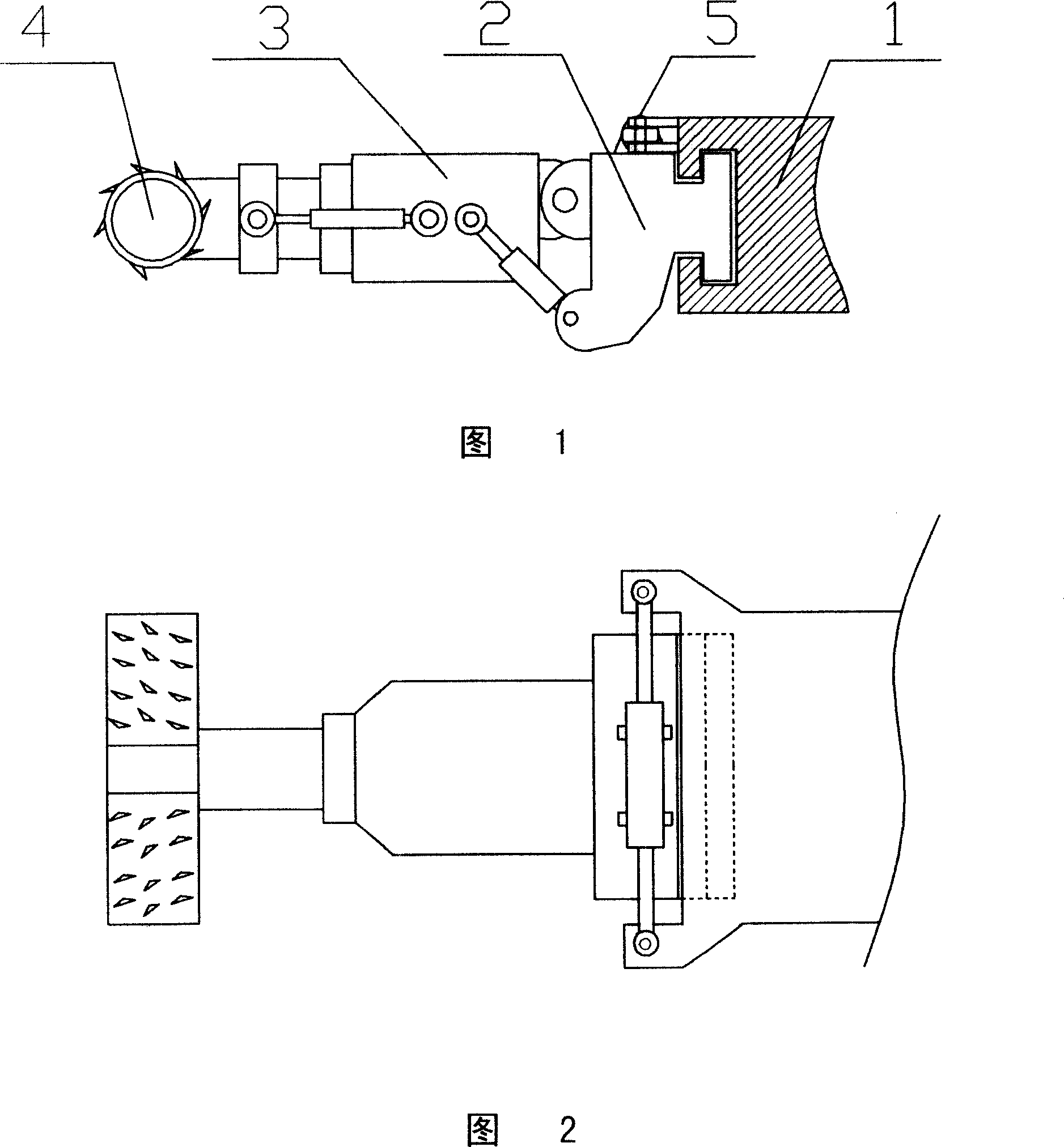

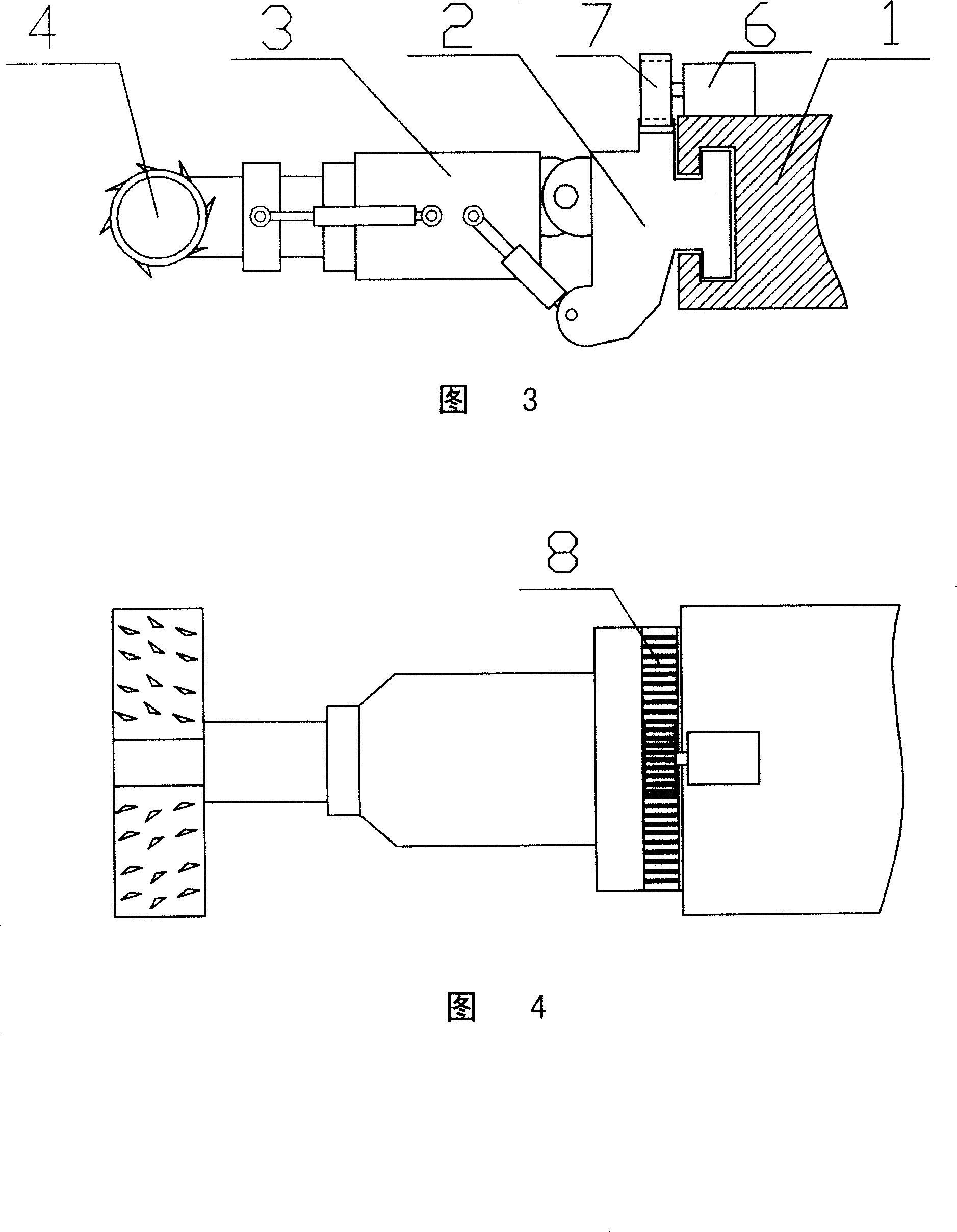

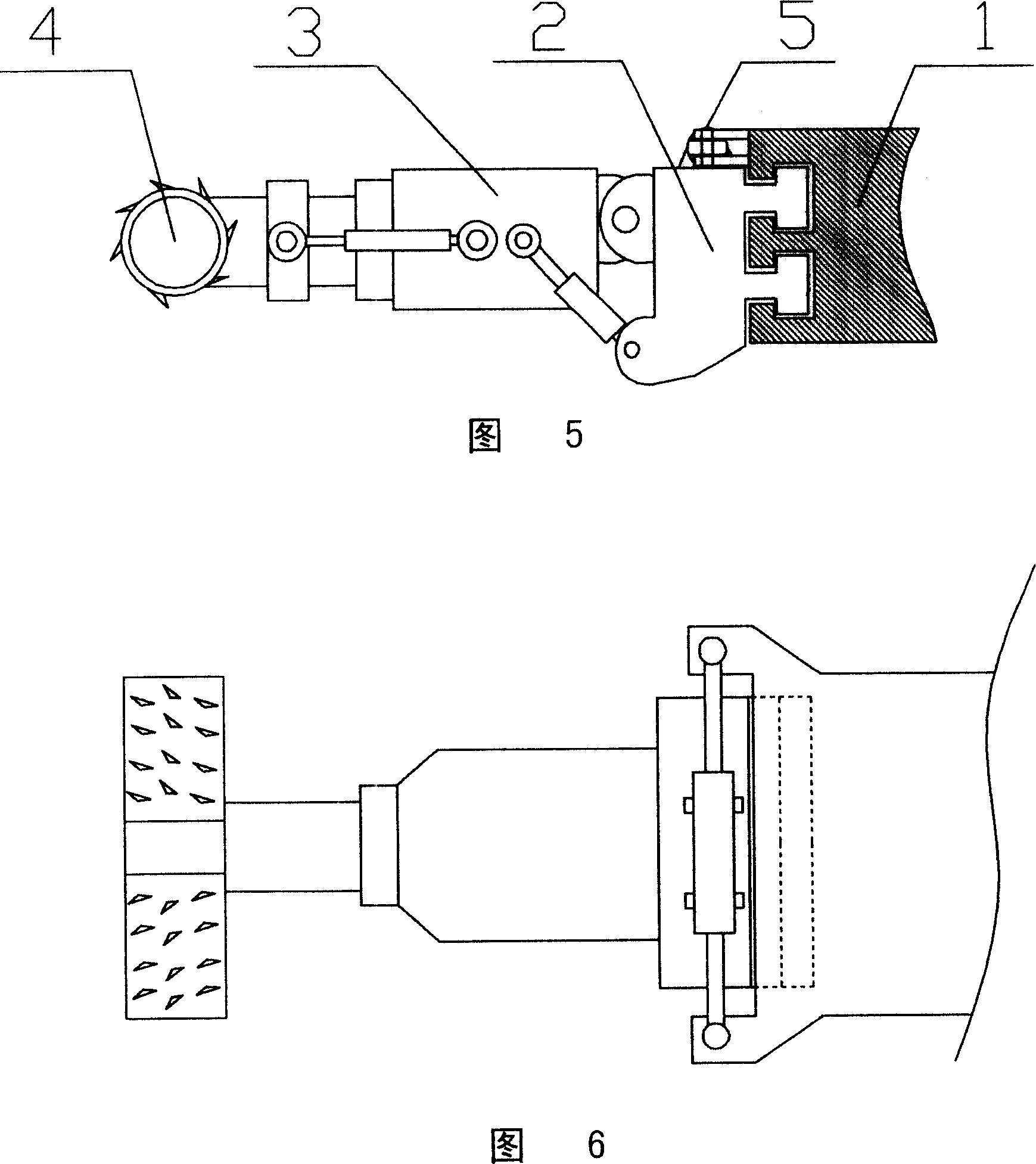

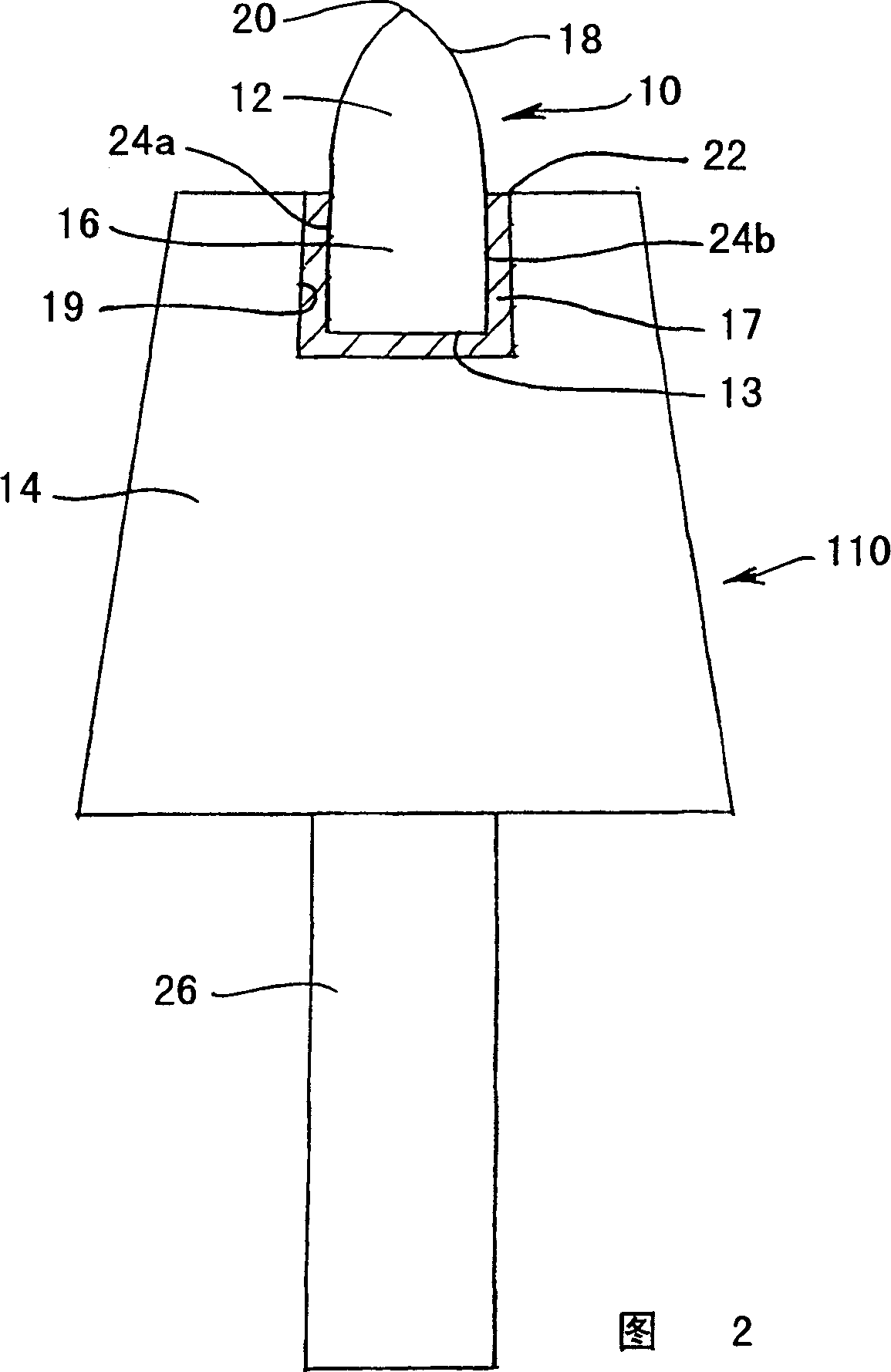

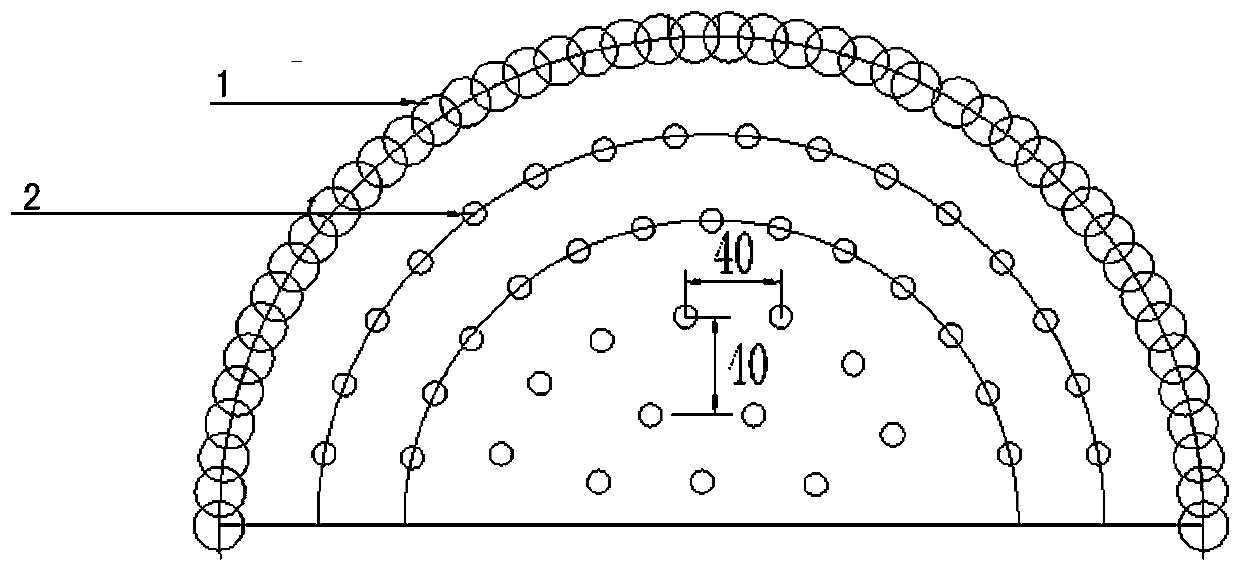

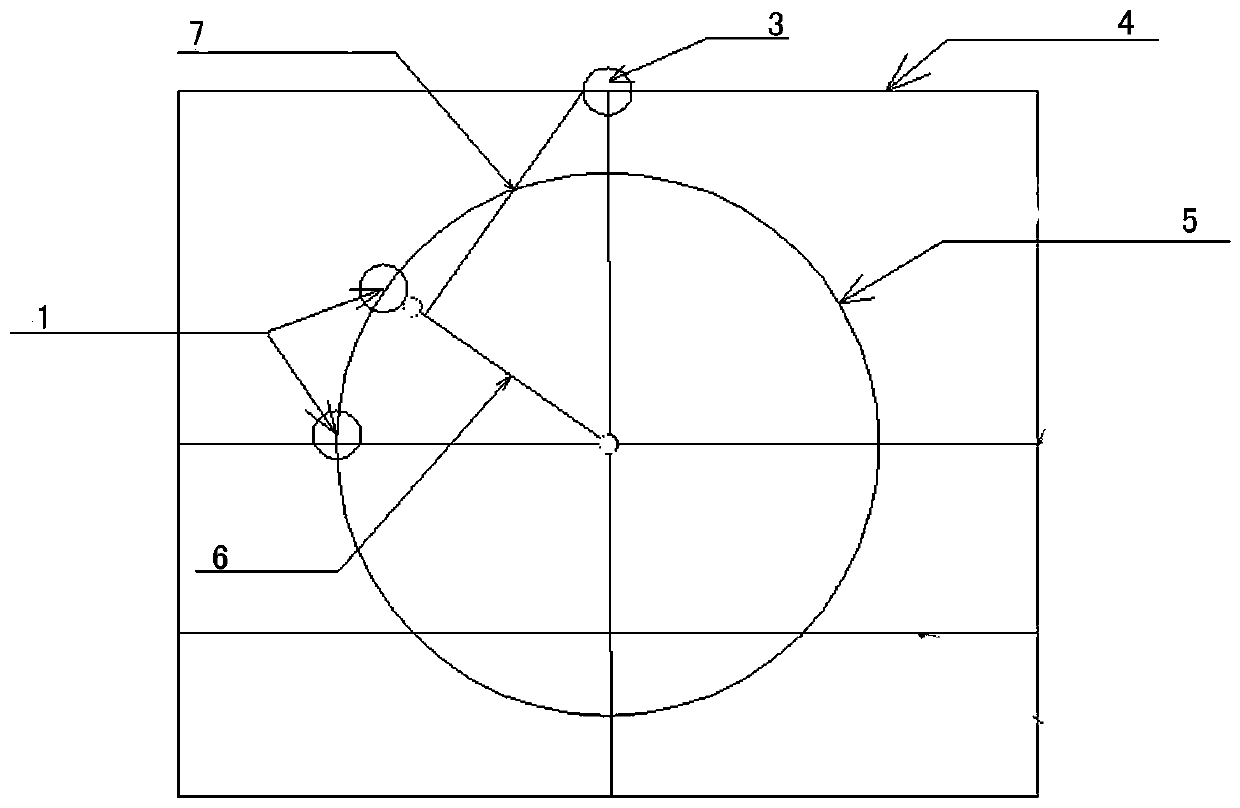

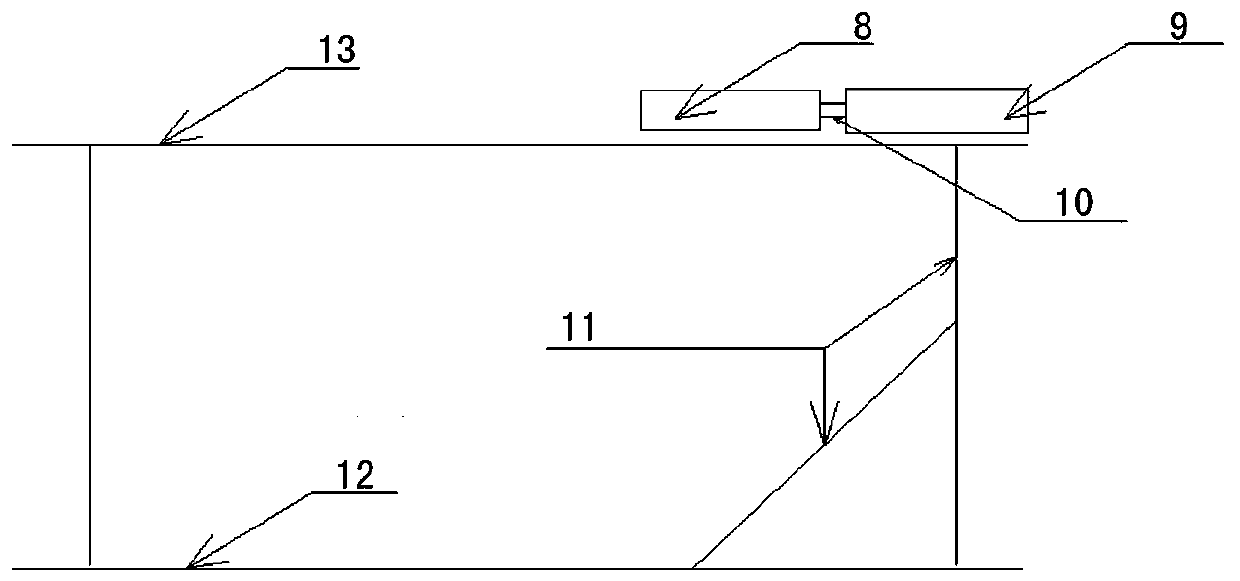

The invention relates to a fast and highly-efficient tunneling method for a large section of a hard-rock tunnel in a coal mine by combination of fully-mechanized tunneling and blasting driving. As shown in the figure 1, a cut hole with the borehole diameter of Phi 40.0 mm and a reliever hole with the charge diameter of Phi 35.0 mm are arranged in the section of the hard-rock tunnel with the protodyakonov coefficient f larger than 10.0 for digging out a groove cavity with s approximately equal to 14.0 m<2>. As shown in the figure 2, the cut hole adopts a three-stage oblique cut with stages deepening and angles of inclination increasing stage by stage. The consumption of charge in unit volume is determined based on the hard-rock protodyakonov coefficient and shot hole depth according to quantification of the figure 3. Three stages of oblique cuts respectively select I, III, IV-section millisecond delay detonators. A V-section millisecond delay detonator is selected by the reliever hole. The oblique cuts and the whole section of the reliever hole are detonated once with the total delay time no more than 130.0ms. After the groove cavity is formed in a blasting method. The reasonable tooth parameters are selected to rapidly expand the groove cavity to the design section and contour is finished under effect of a free surface of a fully-mechanized coal winning machine. Due to millisecond delay detonation of the oblique cut in three stages and larger borehole diameter, stemming is blocked to increase so that rocks do not affect the fully-mechanized coal winning machine after the working surface during the throwing process. The safe and efficient effect can be achieved.

Owner:湖南省煤业集团红卫矿业有限公司

Explosion coal-falling, coal-loading, coal-conveying and anchor-rod supporting mechanism integration operation method and apparatus

InactiveCN101025086AIncrease the speed of excavationExcavation section is largeUnderground miningSurface miningResource recoveryEngineering

The invention provides a blast-winning, coal loading, coal conveying and anchor rod-timbering mechanical integrated operating method and device. And the device mainly comprises: hydraulic system, hydraulic control table, track walking part, coal loading and conveying part, timbering part, and hydraulic anchor rod machine, and the method uses integrated device, scraper conveyor and gate coal conveyor; and its drivage circulating speed is 1m to 1.5 m, blast-winning and after the fumes have settled, making the integrated device enter into the operating site, and after completing coal loading and conveying, making anchor rod timbering; after completing the anchor rod timbering operation, making the integrated device exit the operating site and over 20 meters distant from the operating site, and then making drilling and blasting operation. And it improves explosion level of blast winning and resources recovery, and reduces operators.

Owner:闫振东

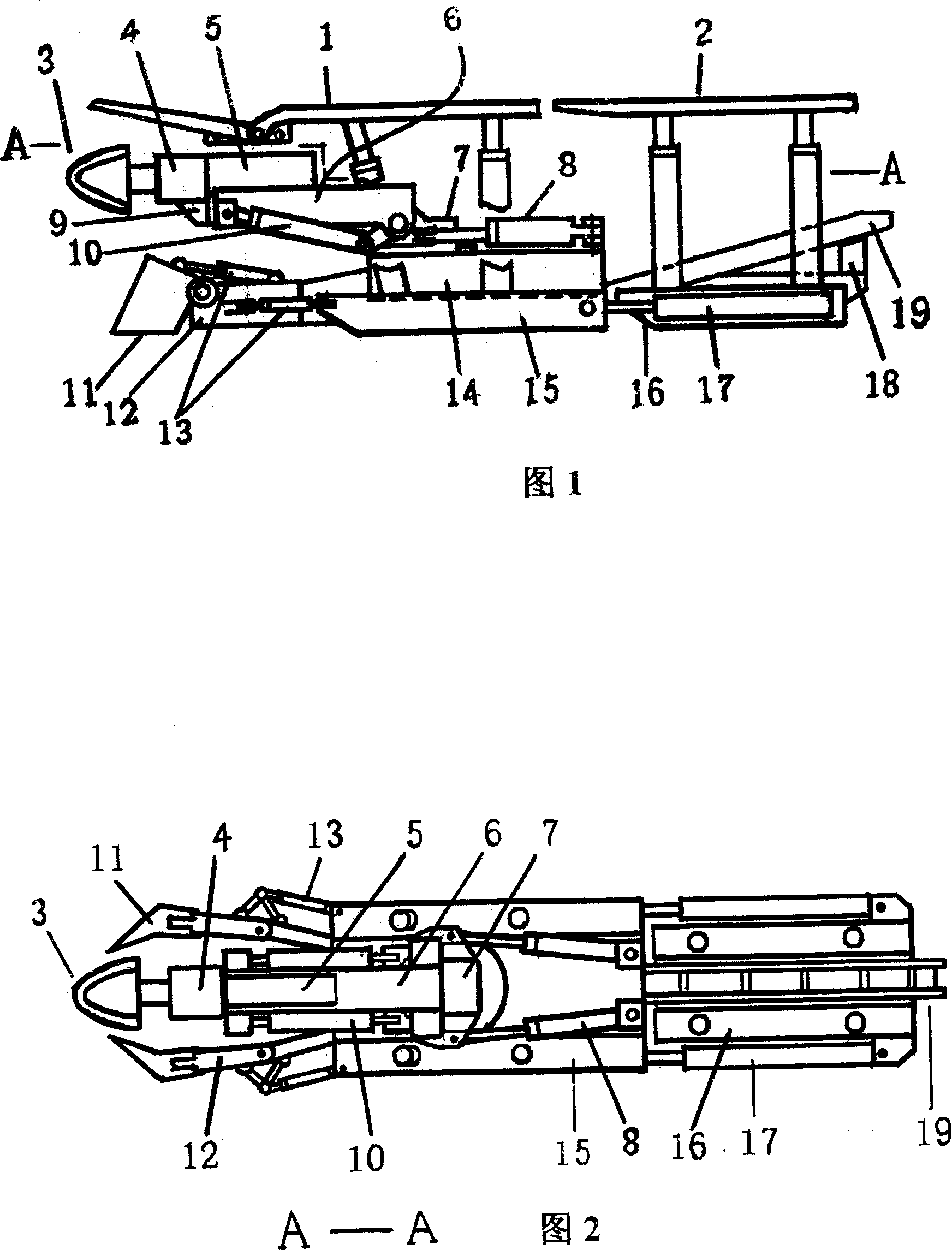

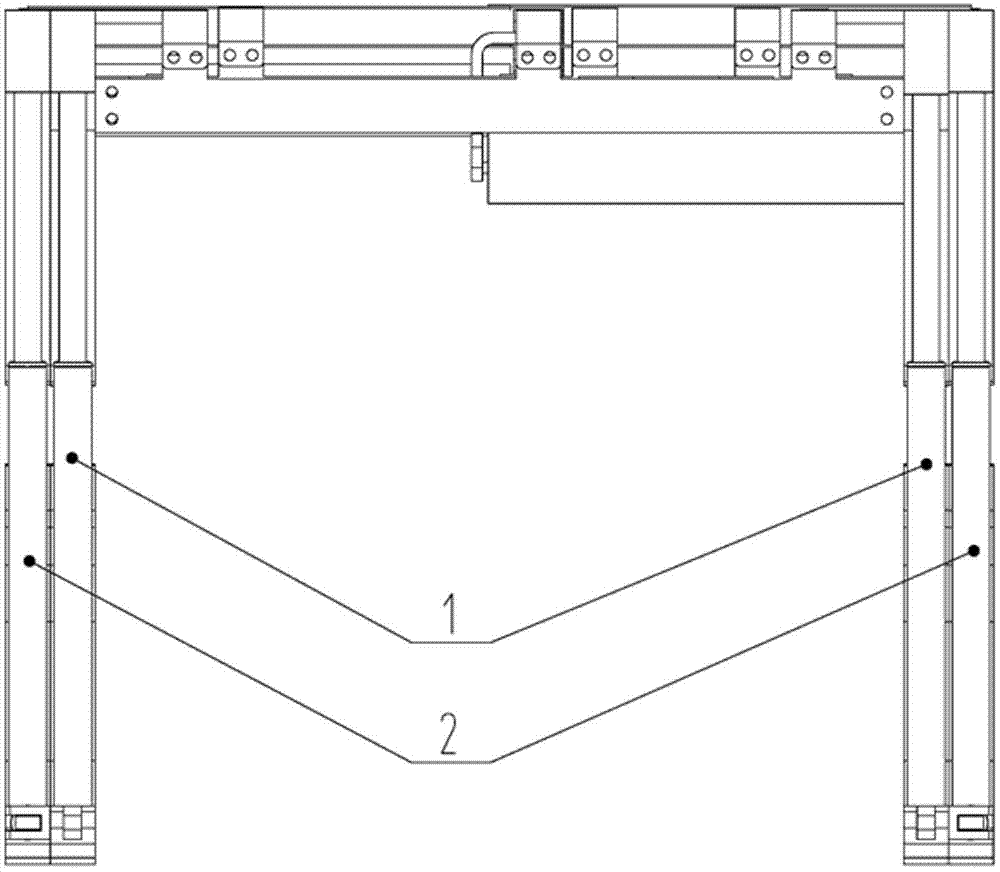

Roadheader

InactiveCN101153540AAdd supportImprove support efficiencyDriving meansCutting machinesEngineeringCantilever

A tunneling machine for tunneling gross section coal drift consists of a cutting unit, a body, a travel unit, a blade, a conveyor and a hydraulic system, etc. The cutting unit consists of a cutting head (4), a cantilever (3), a cutting motor, a cutting reduction gearbox and a telescopic part, etc. The cantilever (3) is connected with the body through a side slip guide mechanism namely a crosshead (2) is hinged onto the rear end of the cantilever (3); a guide body is arranged on the rear end of the crosshead; a guide holder (1) is fixed on the body; a guide groove is arranged on the front end of the guide holder, and the guide body is embedded in the guide groove and is in slide fit with the guide groove; or the two parts are arranged in a reverse way. A driving element or mechanism for driving the crosshead and the cantilever to make lateral movement is arranged between the guide holder and the crosshead. A cantilever tilt cylinder is hinged between the cantilever (3) and the crosshead (2). The wall of the coal drift cut by the tunneling machine is smooth, flat and easy in supporting, thereby improving supporting efficiency and effect. The cutting unit makes a large range of lateral movement, thereby realizing gross section fixed point cutting in a wider coal drift without lateral movement of the whole machine, shortening cycle time, improving tunneling speed and efficiency with great adaptability.

Owner:贾民

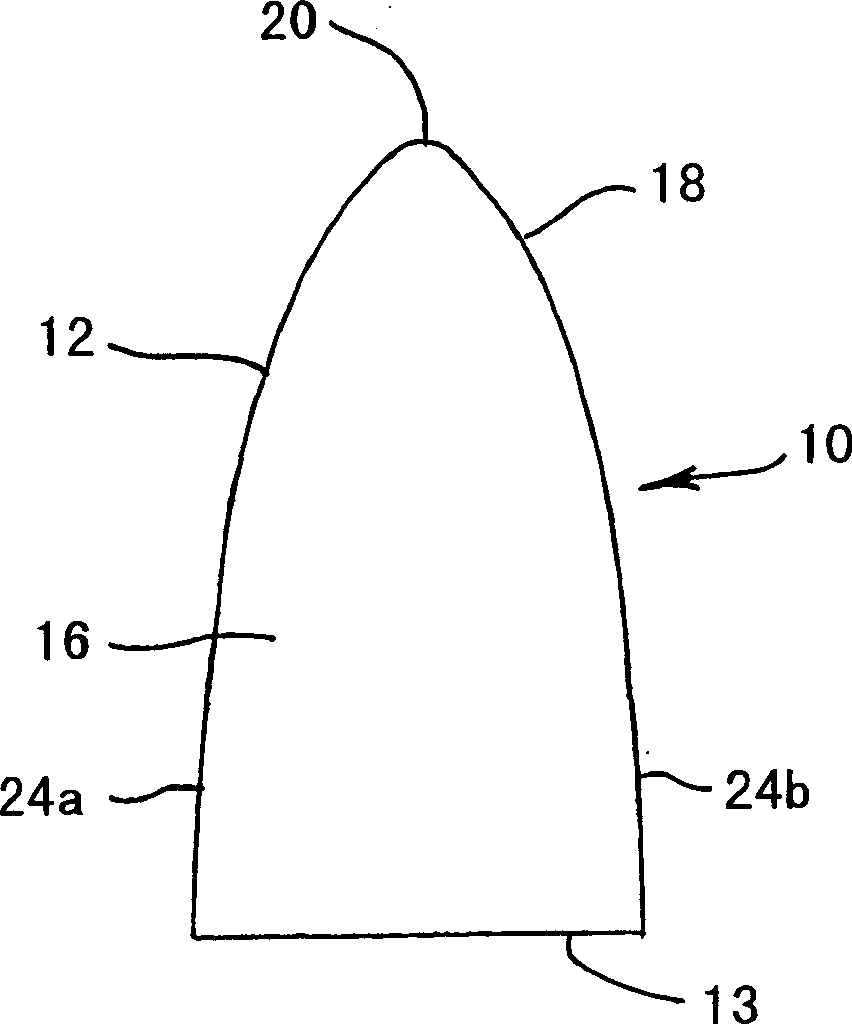

Cutting tool and method of using same

A cutting tool for cutting hard rock, which includes one or more cutting elements (10), each cutting element includes a pointed or chisel-shaped body (12), the body includes a diamond composite material, the diamond composite material Comprising diamond crystals bonded together by a silicon carbide matrix, the cutting element is mounted in a support matrix comprising a metal matrix composite material such that the tip or chisel edge of the cutting element protrudes from the matrix.

Owner:COMMONWEALTH SCI & IND RES ORG

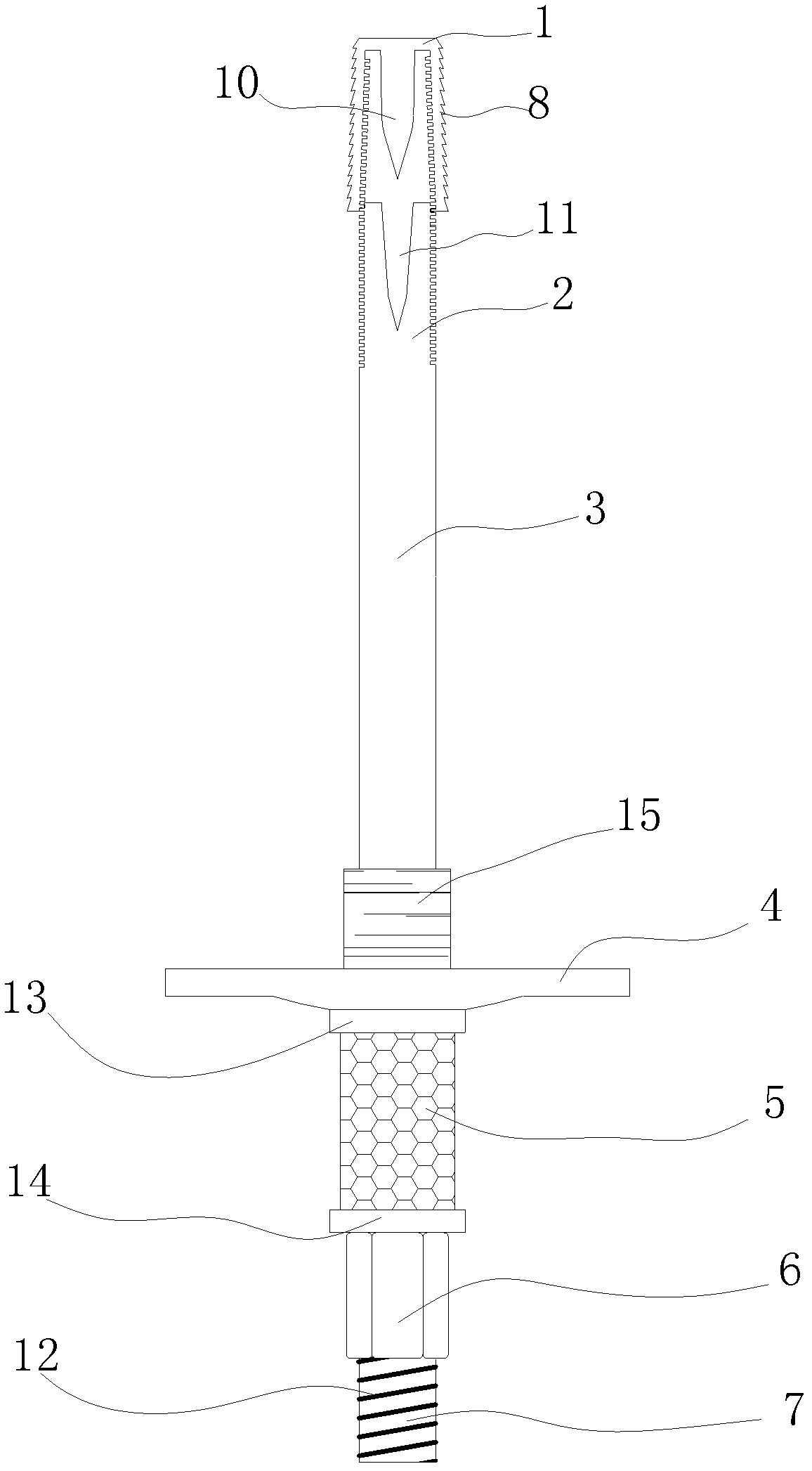

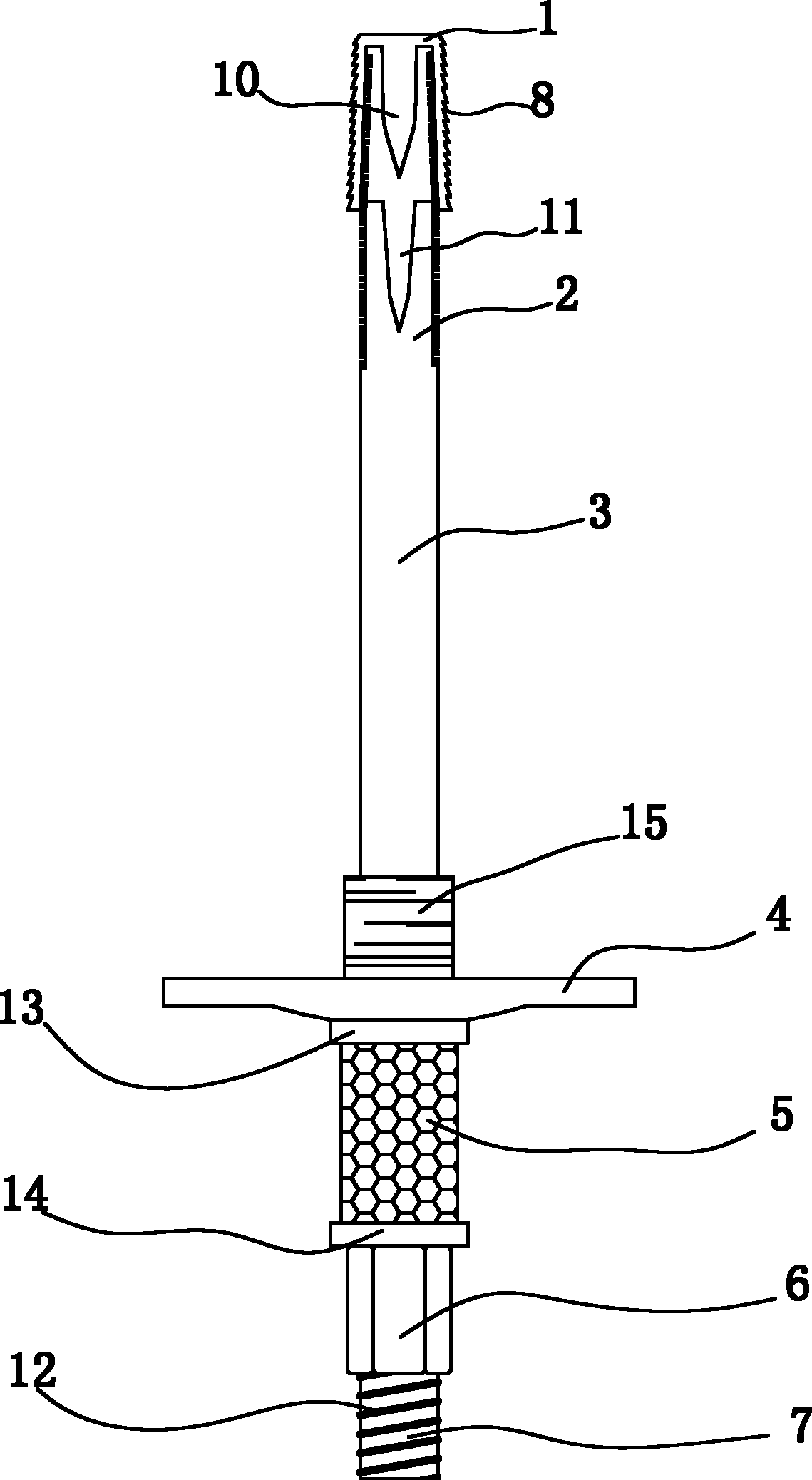

Quickly mounted efficient energy-absorbing mining anchor rod

The invention discloses a quickly mounted efficient energy-absorbing mining anchor rod which comprises an expansion shell, a rod head, a rod body, a tray, an anti-seismic buffering material, a nut and a rod tail, wherein a tooth-shaped bulge is arranged on the outer surface of the expansion shell; matched threads are respectively arranged on the inner surface of the expansion shell and the outer surface of the rod head; a tapered bulge is arranged in the expansion shell; a tapered groove is arranged at the top of the rod head; a vertex angle of the tapered bulge is more than the vertex angle of the tapered groove; the thread is arranged on the rod tail; and the tray and the anti-seismic buffering material are respectively sleeved on the rod tail and are positioned and pre-tensioned by the nut. According to the invention, quick loading is realized by the anchor rod; mounting process is simplified; mounting time is shortened; driving speed is increased; the anti-seismic buffering material has a compressing buffering function when rock is burst, so as to effectively resist the dynamic loading effect at rock bursting moment; a certain anchoring force is kept by the anchor rod; and the anchor rod is prevented from being broken and invalid. Besides, the quickly mounted efficient energy-absorbing mining anchor rod has the beneficial effects of simple structure, convenience in mounting, high operability, and the like, and is widely applied to underground supporting for deep well.

Owner:CENT SOUTH UNIV

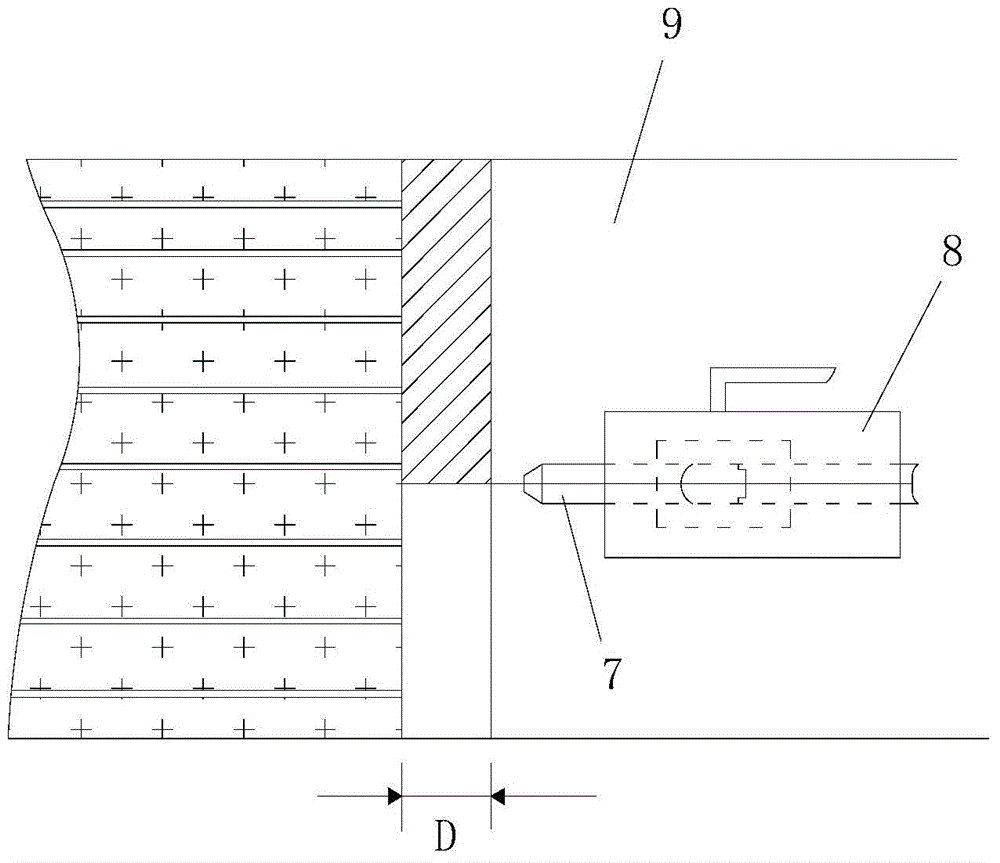

Excavation construction method for ultra-hard rock tunnel through hydraulic dilling matched with hydraulic splitting

The invention belongs to the technical field of construction of overline large bridges, and provides an excavation construction method for an ultra-shallow-buried hard rock tunnel penetrating througha sensitive building area in order to solve the problems that an existing side span cast-in-place section and an existing closure section are large in interference with a business line, high in construction risk and the like. The overline bridge beam is constructed by adopting a construction method of using a parallel line direction cantilever method or a bracket cast-in-place method to pour a beam body and then conducting rotating in place. A conventional rotating body is cancelled and a side span cast-in-place section and a closure section are arranged, so that the problem of high construction risk above the line or adjacent to an existing line is avoided; and before the beam body rotates, the whole beam body is poured with a support, a side pier is provided with high and low bearing platforms, pouring construction is carried out after the high bearing platform and the like rotate in place, pouring of the low bearing platform is completed before rotation construction, but pouring construction is conducted after support cushion stone rotates in place, so that with the construction method ,the problems that construction is conducted above an existing line or adjacent to the existing line are solved, the operation safety of a business line is guaranteed, the construction risk is reduced, the construction safety is guaranteed, and the construction efficiency is improved.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

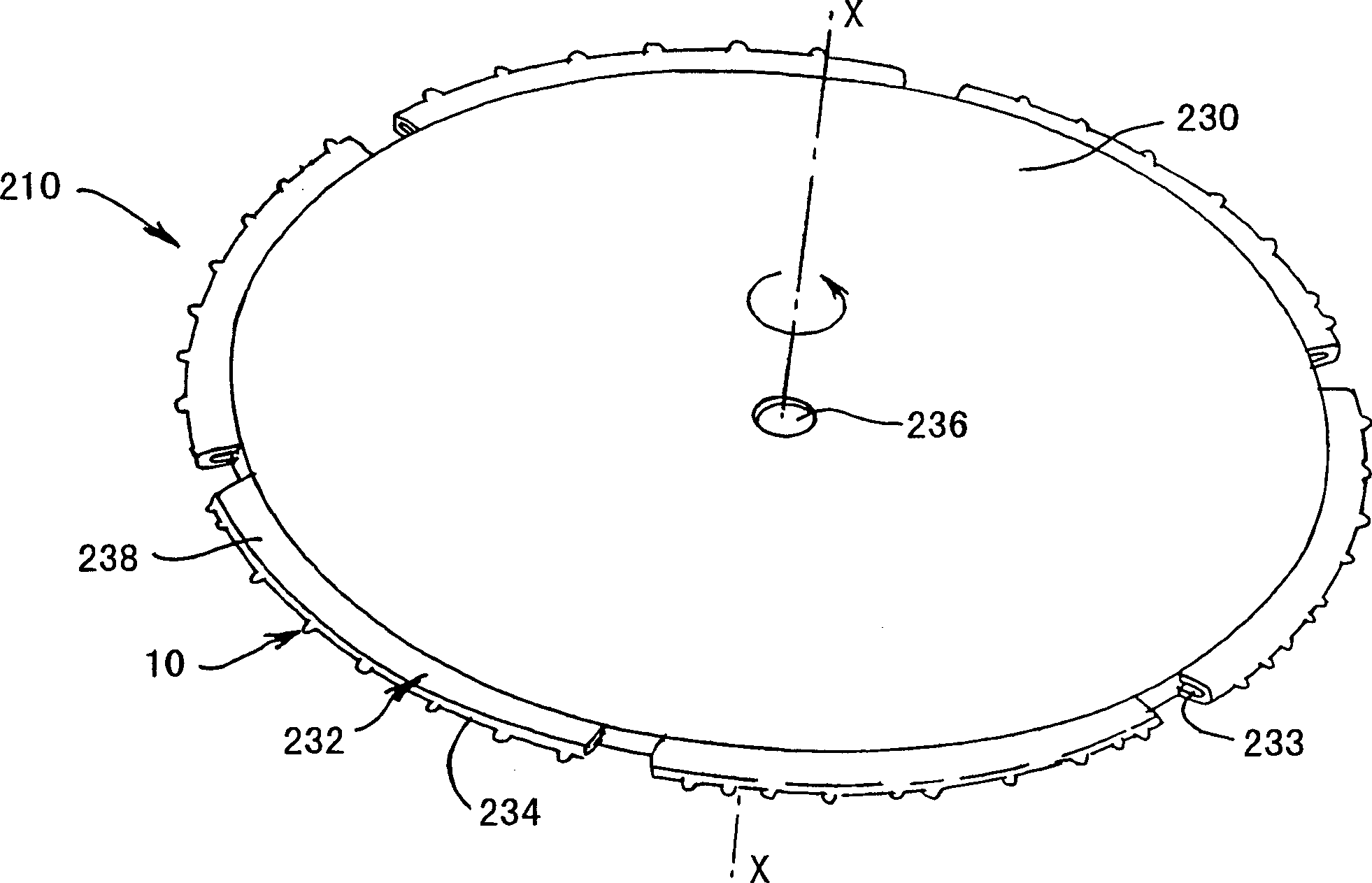

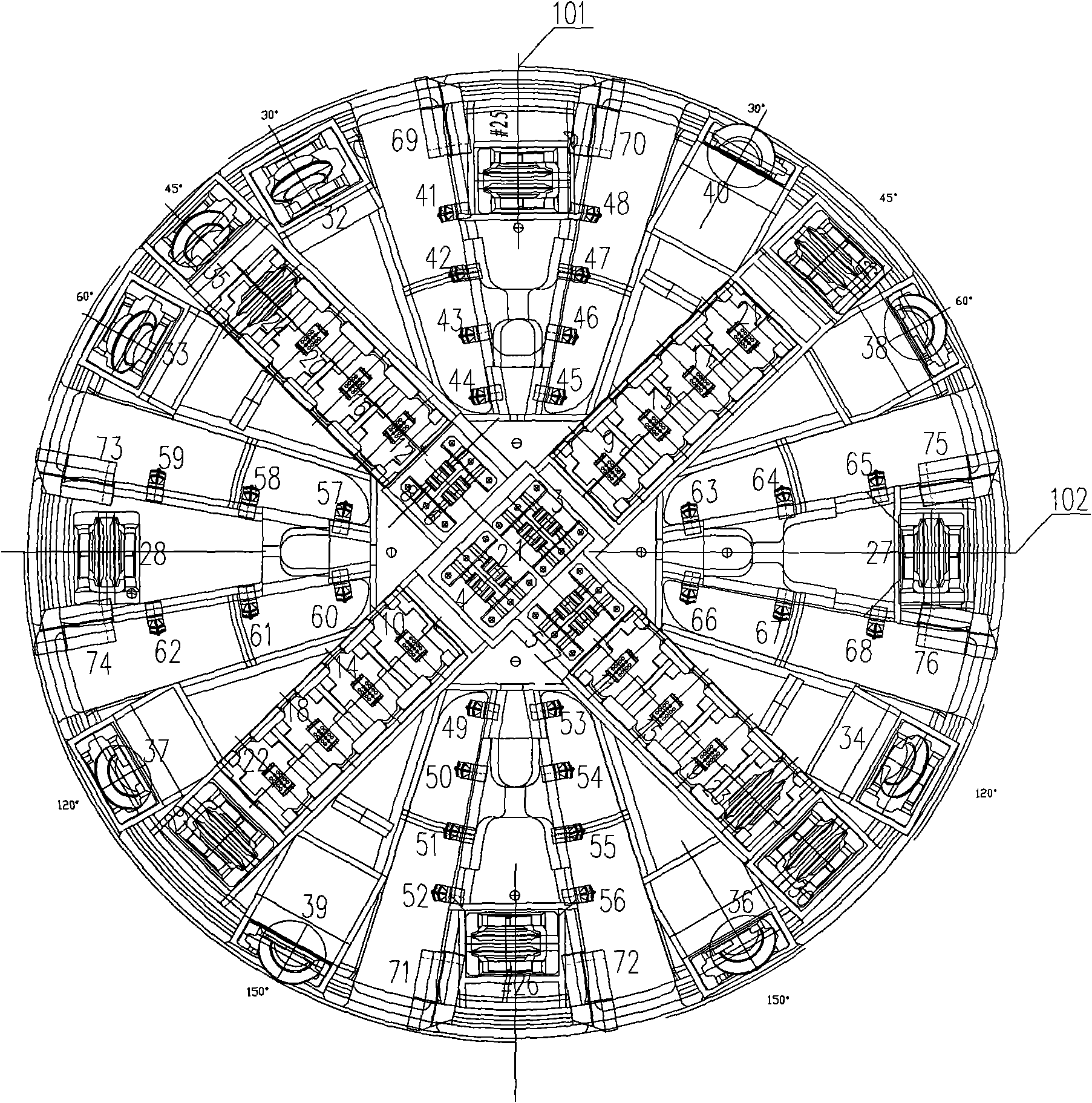

Earth pressure balance shield machine cutterhead

The invention discloses an earth pressure balance shield machine cutterhead. The surface of the cutterhead comprises a central area, a facial area and a marginal area, wherein each two-edged serrated cutter arranged on No. 1 to No. 8 cutter seats comprises two cutter bodies and two cutter heads fixedly connected on the cutter bodies, wherein the top face of each cutter head adopts the higher-middle and lower-side structure by gradually raising areas from both sides to the middle parts; the upper part of each side face of the cutter head is an externally expanded inclined face; the middle part of the top face is fixedly connected with a strip-shaped hard alloy, and the top faces of both sides of the strip-shaped hard alloy are fixedly connected with four rows of symmetrically distributed hard alloy column teeth; height differences are respectively formed between the tops of the hard alloy column teeth and the top of the strip-shaped hard alloy; and abrasion proof overlaying welding layers are fixedly connected with the peripheral top faces and the side faces of the strip-shaped hard alloy and the hard alloy column teeth. The cutterhead provided with the structure of the invention can increase advance rate, reduce abrasion and prolong service lives of the cutters, and reduce advancing cost under the circumstance of water-rich sandy cobble strata.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

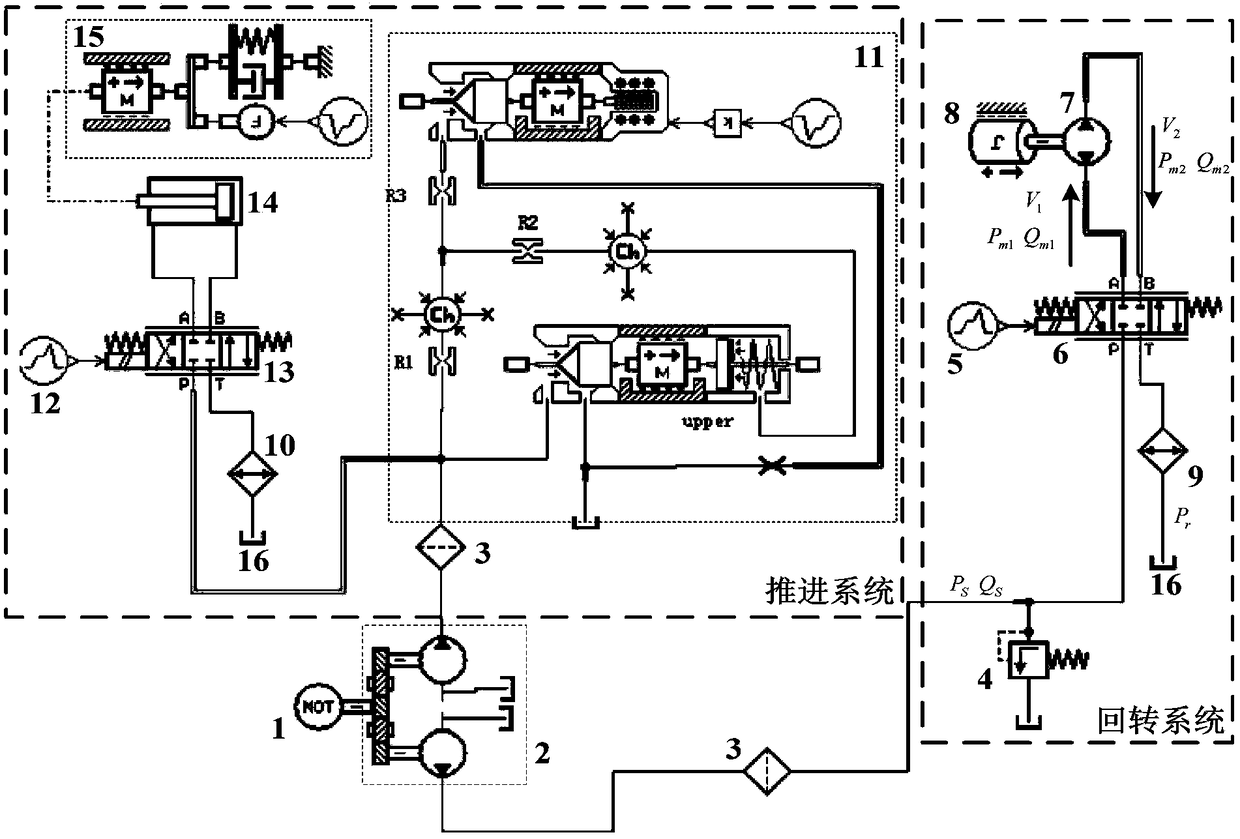

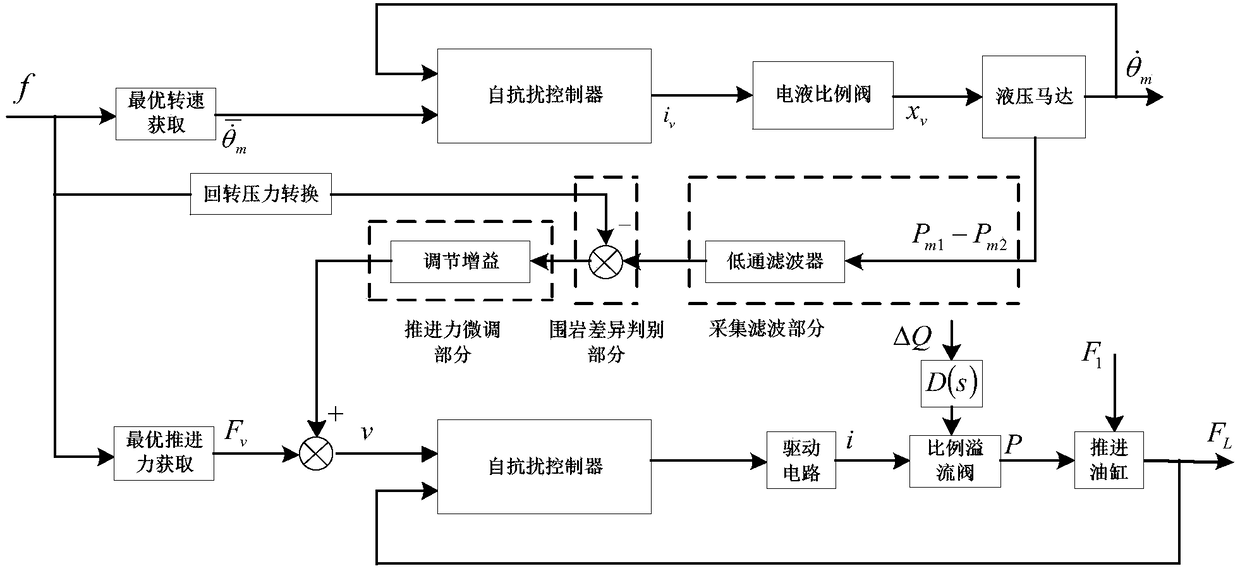

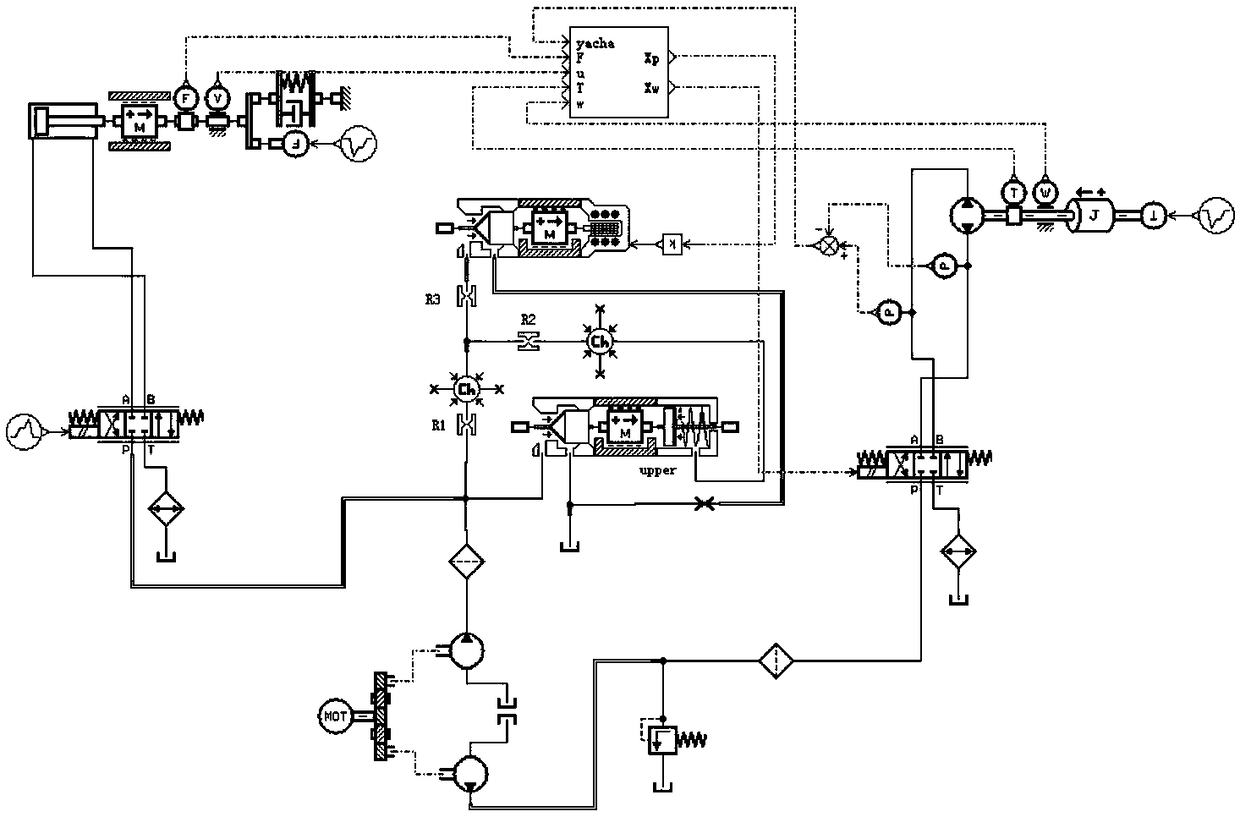

Anchor rod drill machine propulsion and rotation system and cooperative self-adaptation control method thereof

ActiveCN108643884ASolve the problem of large dependence on work experienceImprove work efficiencyConstructionsRotary drillingActive disturbance rejection controlEngineering

The invention discloses an anchor rod drill machine propulsion and rotation system and a cooperative self-adaptation control method thereof to increase the anchor protection speed and improve the drilling quality. Firstly, in order to restrain nonlinearity of a drill machine system and improve robustness of the drilling process, active disturbance rejection control is implemented for single loopsof a propulsion system and a rotation system; secondly, a rock hardness coefficient obtaining method based on drill machine while-drilling information is given; finally, a composite control mode is adopted, according to the estimated rock hardness coefficient, the optimal propulsion force and the optimal rotation speed of drilling of a drilling machine of this time are determined, and accordinglycooperative action of the anchor rod rotation and propulsion systems is achieved; and when the estimated rock hardness coefficient differs from the actual value, according to the low-frequency filtering value of the rotation pressure, the optimal propulsion force is adjusted in a self-adaptation mode, and the self-adaptation capacity of an anchor rod drill machine is improved.

Owner:CHINA UNIV OF MINING & TECH

Freezing method of frozen wall of inclined shaft

The invention provides a freezing method of a frozen wall of a frozen wall of an inclined shaft, solving the problems of difficulty in digging in the construction because an aquifer of the inclined shaft is frozen and low construction speed and meeting safe and rapid construction requirements of the aquifer of the inclined shaft. The freezing method comprises the following steps of: drilling multiple rows of freezing holes which are parallel to each other and vertically distributed, on the group, along an axial freezing range of the inclined shaft, wherein the row number of the freezing holes is determined according to the cross section size of the inclined shaft and the required freezing time, the freezing holes at the lateral part and the freezing holes at the end part respectively go deep into a water-resisting layer in the depth, water in the aquifer at the lower part is isolated by the water-resisting layer, and the freezing holes at the top go deep into the top of the inclined shaft in depth; then arranging a freezing pipe and a liquid supply pipe in each drilled freezing hole, wherein the freezing pipe and the liquid supply pipe in each drilled freezing hole are communicated with an external freezing station; and finally, starting the freezing station and enabling low-temperature saline water prepared by the freezing station to flow in the each freezing pipe to absorb heat of the stratum around each freezing pipe to form a frozen cylinder, wherein all frozen cylinders are continuously enlarged and further connected to form the frozen wall which can resist earth pressure and water pressure.

Owner:YANKUANG GRP CO LTD +1

Hydrofracturing sectional blasting fast tunnel excavation method

InactiveCN106150507AWeakened mechanical strengthLow mechanical strengthFluid removalBlastingChemical solutionEconomic benefits

The invention discloses a hydrofracturing sectional blasting fast tunnel excavation method. The method comprises the following steps: drilling in an advanced excavation surface, forming a plurality of wedge-shaped circular grooves in drill holes, communicating a water injection hole sealing device with a high-pressure water pump, sequentially pre-splitting the wedge-shaped circular grooves from the bottoms of the holes, loading the drill holes, which are arranged in a prism type, with cartridge, and then sealing the holes with stemming, connecting a blasting network for blasting, then injecting a chemical solution into the drill holes to realize fast excavation. According to the method, cracks generated by hydrofracturing provide multiple free surfaces, so that the development of the cracks are more sufficient, the chemical solution is further injected to react with rocks, so that the mechanical strength of the rocks is obviously reduced, the excavation speed of a tunneling machine is further quickened, dust is reduced during excavation, furthermore, the operation is simple, and the economic benefits are obvious.

Owner:TAIYUAN UNIV OF TECH

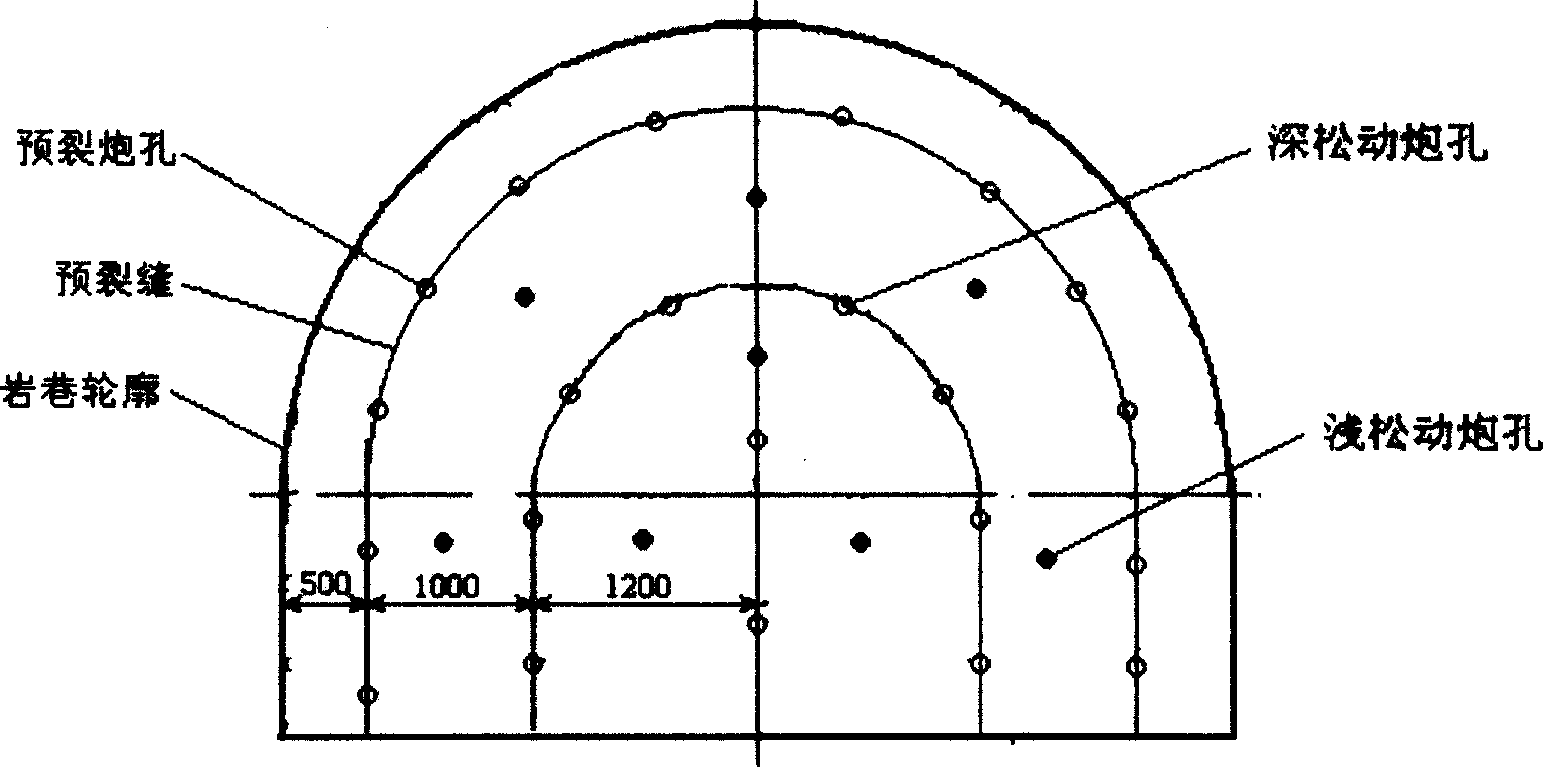

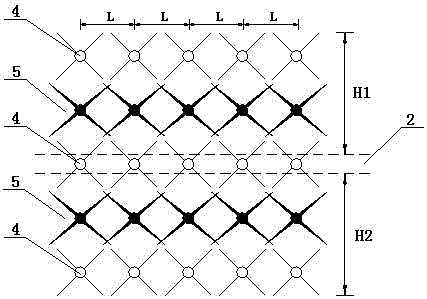

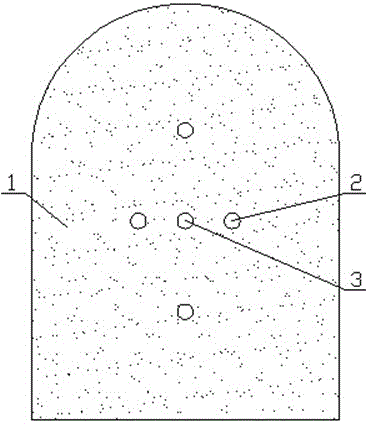

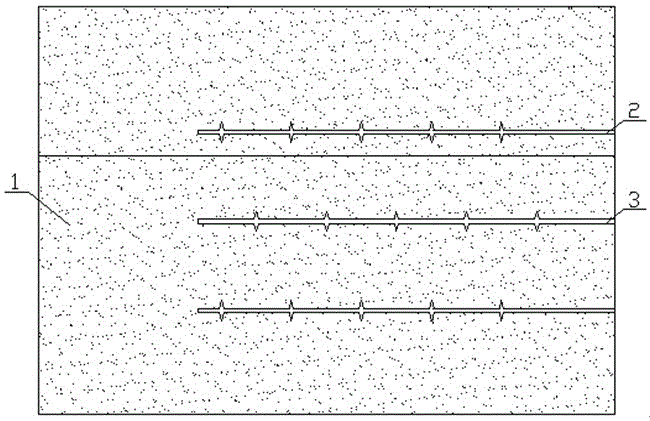

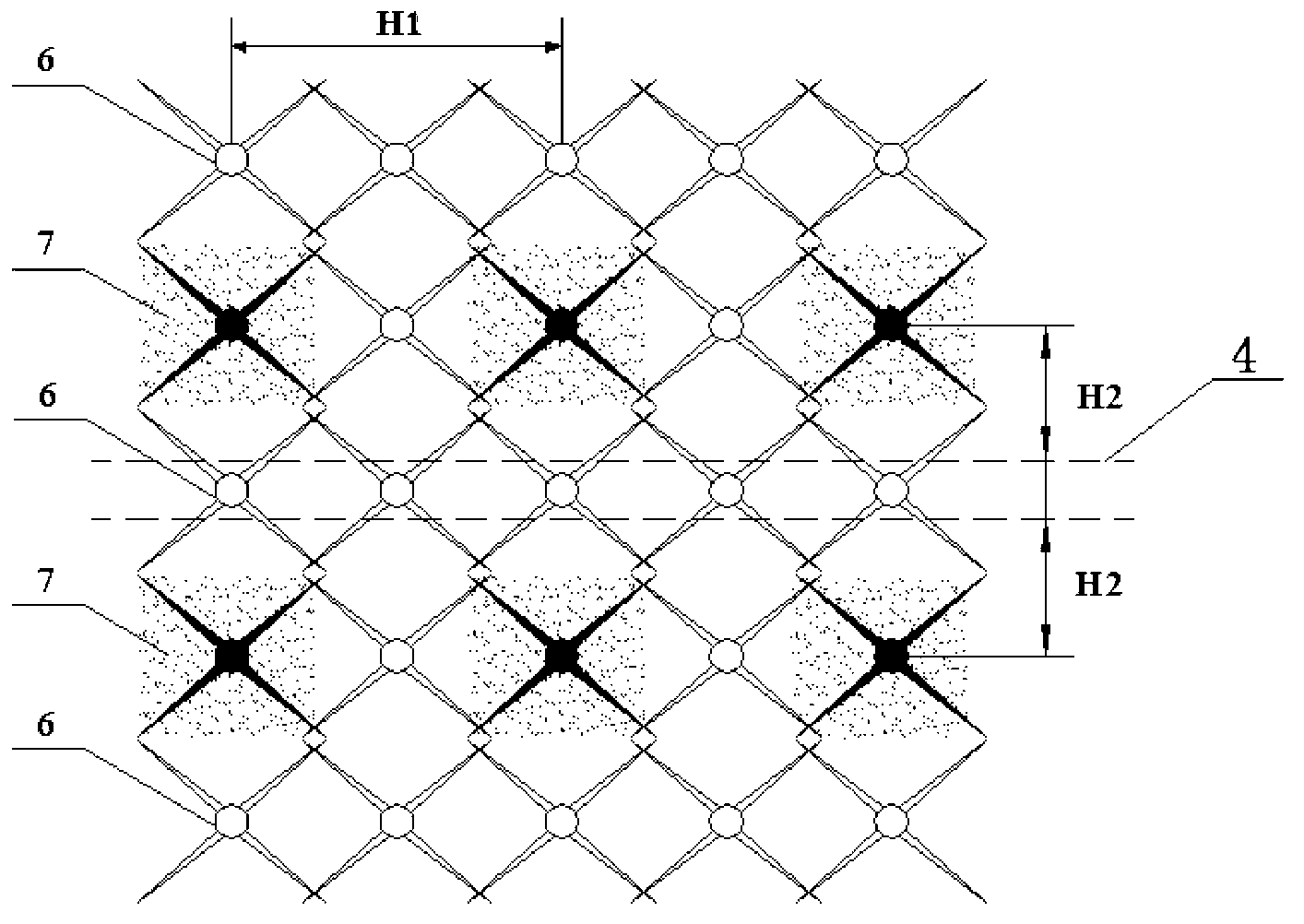

Networking reinforcement method for cross drilling holes of outburst coal seam

A networking reinforcement method for cross drilling holes of an outburst coal seam is particularly suitable for the cross drilling holes of pre-drainage coal roadway band gas in the outburst coal seam. The method comprises the following steps: about 30-60 days before the excavating of a coal roadway, stopping gas extraction from the cross drilling holes, extending outwards the distance of H2, on two sides of the pre-excavating coal roadway; injecting reinforcement material into the cross drilling holes through an injection pump, wherein the spacing distance of the cross drilling holes is H1 and the cross drilling holes are no longer subject to gas extraction; and filling the slurry into the drilling holes and allowing the slurry to penetrate into the around coal, wherein when the reinforcement material in the holes are solidified, a weak-strong-weak structure system is formed on two sides of the coal roadway, so that the strength and stress distribution of the outburst coal seam is improved, and risks during extraction process can be effectively eliminated. According to the invention, the networking reinforcement method can reduce the deformation of the two sides of the outburst coal seam by 45-65 percent, the reinforcement workload by 35-50 percent, and improves the advance speed of the coal roadway by 40-60 percent, and therefore, has a very good promotional value.

Owner:CHINA UNIV OF MINING & TECH

Automatic whole-section external rotor low-speed motor cutting rotation drum anchor driving machine

InactiveCN1707066AEliminate delaminationPut an end to arroganceAnchoring boltsCutting machinesLow speedEngineering

The cylindrical excavating and anchoring machine as one mining apparatus consists of main frame, sliding frame, walking mechanism, hydraulic system, and spraying and dust eliminating system. The sliding frame embedded on the main frame can slide horizontally back and forth under the pushing mechanism, and the cutting part, top anchoring part and the loading part on the sliding mechanism operate simultaneously while the side supporting part on the main frame anchors the side parts. The present invention realizes sync cutting, loading and anchoring in high excavating speed and accurate positioning. In addition, the leading hole prospecting machine on the main frame may be used conveniently without need of moving.

Owner:王文凯 +2

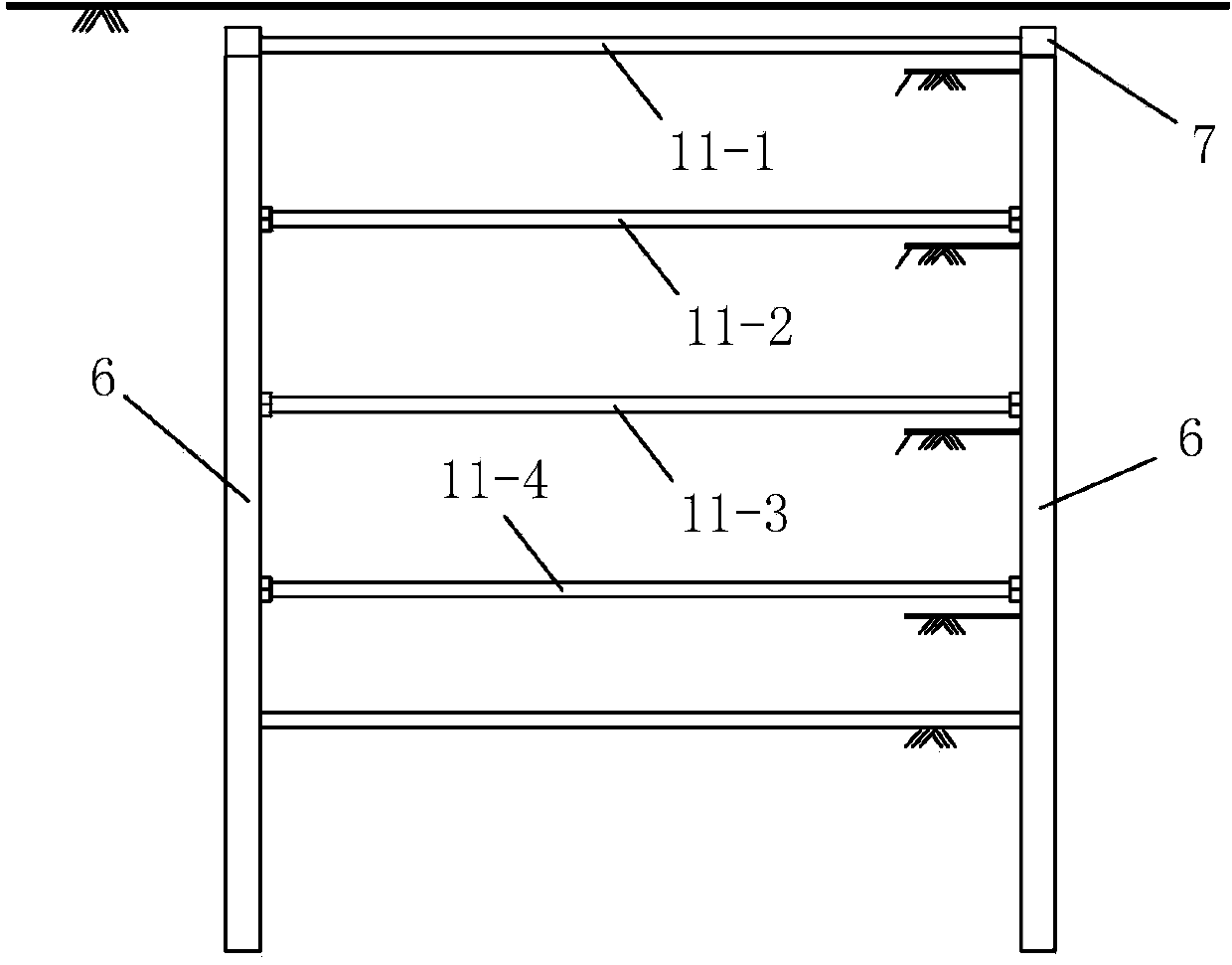

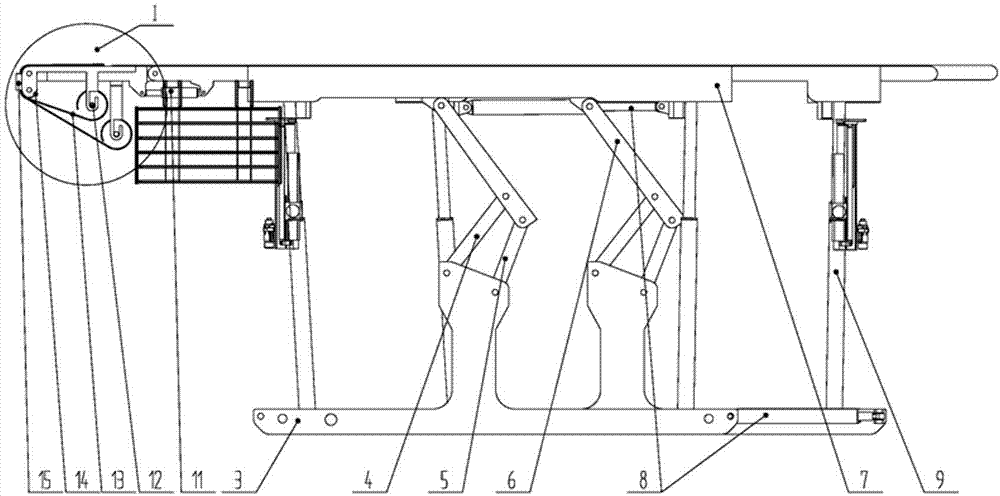

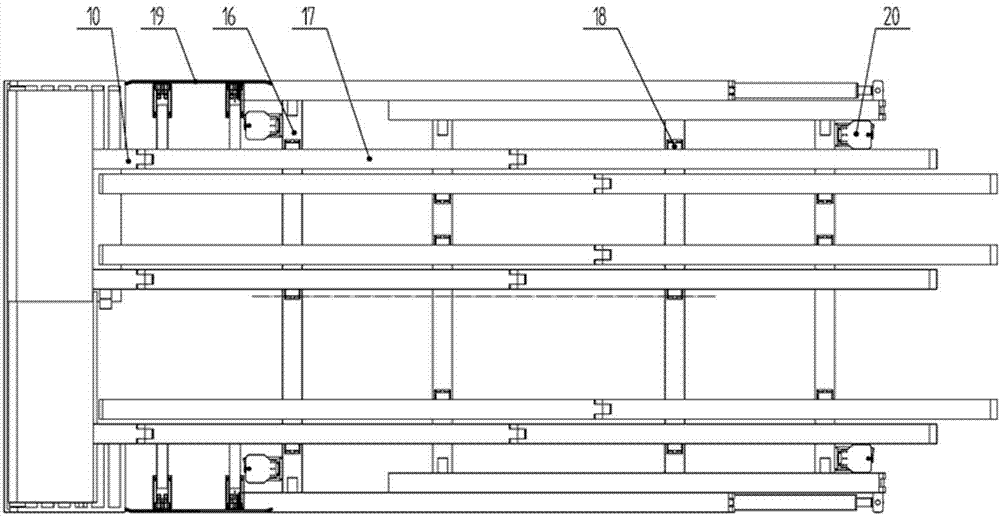

Automatic bolt mesh laying step type temporary support for fully mechanized excavation faces

ActiveCN104278999AReduce labor intensityEnsure safetyUnderground chambersMine roof supportsEngineeringHeight difference

The invention belongs to the technical field of temporary supports for underground fully mechanized excavation faces of coal mines, and particularly relates to an automatic bolt mesh laying step type temporary support for fully mechanized excavation faces, which solves the current problem that the efficiency of high-performance excavators cannot be sufficiently exerted because excavation, temporary supporting and bolting cannot be carried out synchronously. The automatic bolt mesh laying step type temporary support for fully mechanized excavation faces comprises an inner support assembly and an outer support assembly, the inner support assembly and the outer support assembly respectively comprise a left support and a right support, the left support and right support of the inner support assembly are arranged at the inner sides of the left support and right support of the outer support assembly, a height difference exists between the tops of crossbeams and the bottoms of longitudinal beams of one set of support assembly, and carrier rollers are arranged at positions where the tops of the crossbeams correspond to the bottoms of longitudinal beams of the other set of support assembly. Excavation, temporary supporting, bolt mesh laying, bolt mesh connection and bolting can be carried out synchronously, the labor intensity of workers is decreased greatly, the efficiency of excavation is increased, a working face can be supported in time, and a powerful guarantee is provided for the safety of operating personnel.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

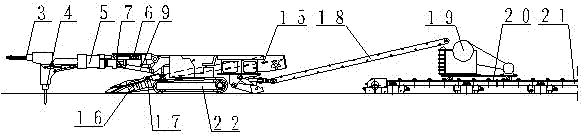

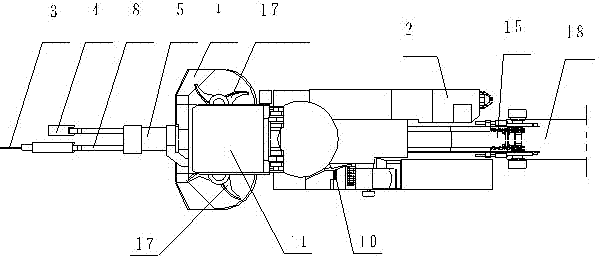

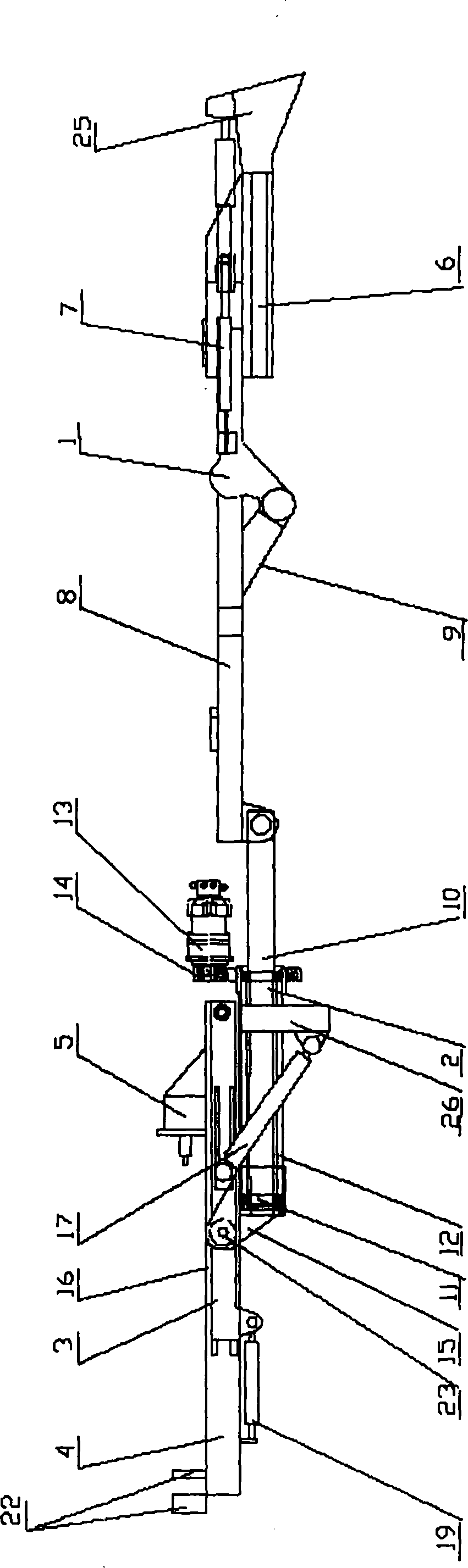

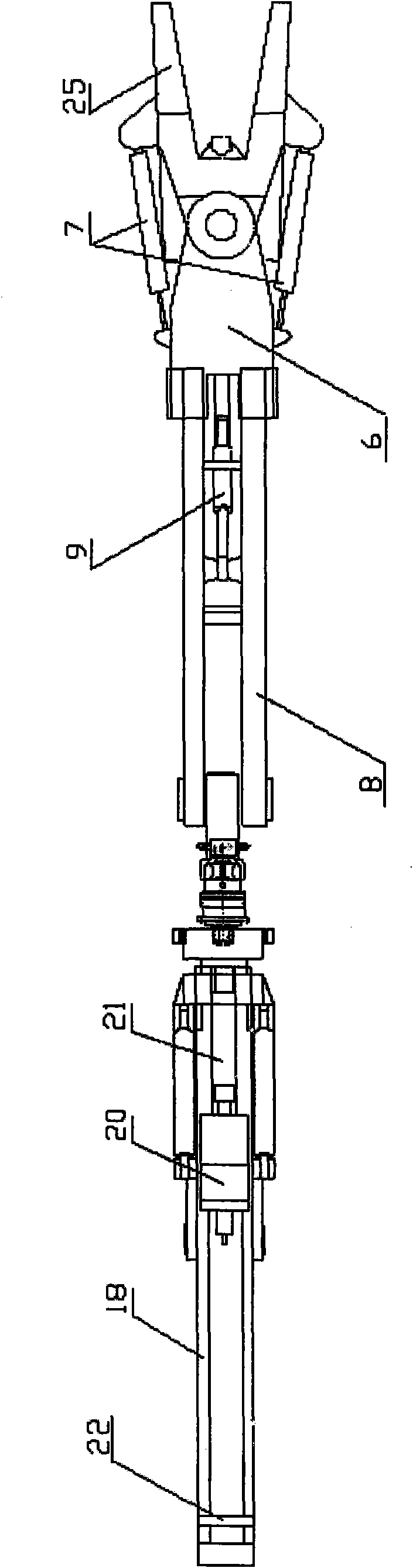

Novel omnibearing drill boom of drill loader

InactiveCN102155161AIncrease the speed of excavationReduce the number of workers and labor intensityDerricks/mastsDrilling machines and methodsDrilling machinesPetroleum engineering

The invention discloses a novel omnibearing drill boom of a drill loader. The drill boom mainly comprises a main swing arm mechanism, a slewing mechanism, a front swing arm mechanism, a drill boom regulating mechanism and a drilling hydraulic mechanism which are sequentially and movably hinged, wherein the main swing arm mechanism and a main frame are organically combined and driven by a hydraulic drilling machine. The novel omnibearing drill boom can drill the shot holes in the advancing direction as well as flank holes and top support holes, and can improve the efficiency of excavating a rock roadway and achieve the aim of saving cost.

Owner:镇江市扬虹矿用设备制造有限公司

Tendency progressive outburst elimination roadway arrangement method

InactiveCN108397227AIncrease the speed of excavationIncrease slope lengthUnderground miningSurface miningEngineeringCoal pillar

The invention discloses a tendency progressive outburst elimination roadway arrangement method, 2-5m of coal pillar or no coal pillar is reserved along a gob edge of an upper section, an air return level of the upper section is excavated; bedding drill holes are formed in the air return level to perform gas extraction on a certain area coal seam on the lower portion; after removing outburst hazards, a middle roadway is excavated; bedding drill holes are formed in the middle roadway to perform the gas extraction on a certain area coal seam on the lower portion; after removing the outburst hazards, a haulage way of the section is excavated, open-off cut communicates with the middle roadway and the air return level to form a working face to perform backstopping; and the steps above are repeated until mining of the coal seams of all the sections is completed. The tendency progressive outburst elimination roadway arrangement method has the beneficial effects that by using the gob-side entrydriving technology of the no coal pillar or narrow coal pillar and combining with the middle roadway of the working face, the purpose of effective control cover coal and gas outburst can be achieved,coal and gas outburst prevention work amount is reduced, the effective tilting length of outburst elimination of the working face is ensured, and safe and high efficient production of the working face is realized.

Owner:LIUPANSHUI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com