Cutting tool and method of using same

A technology of cutting tools and cutting elements, applied in the fields of picks, saws and drills, it can solve the problems such as the falling off of the cutter head, and achieve the effect of excellent cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] In the following detailed description of the preferred embodiment as shown in the accompanying drawings, like reference numerals refer to like parts.

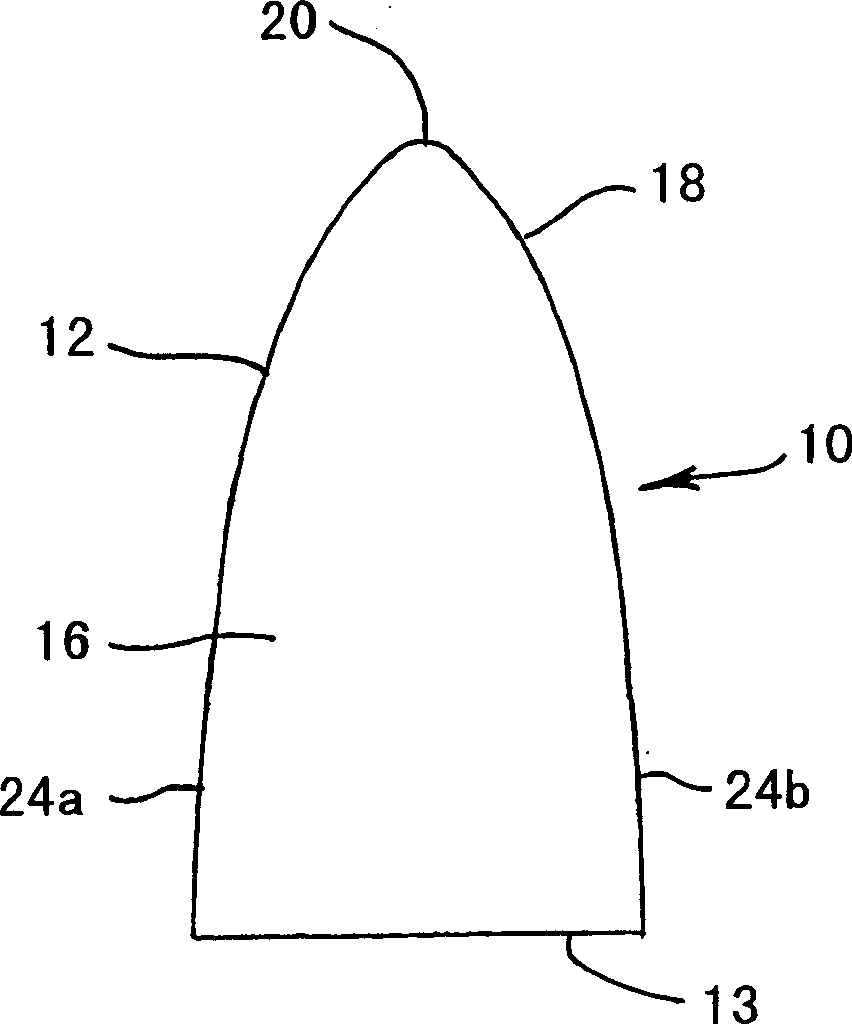

[0094] figure 1 A cross-section of a cutting element 10 is shown that includes a pointed body 12 formed from ADC. The cutting element 10 includes a base 13, an elongated mounting portion 16 adapted to be received on a support substrate of a tool body (not shown), and a cutting portion 18 having a cutting face or point 20 formed thereon. . The cutting tip 18 is oval, or bullet-shaped, while the sides 24a, 24b of the mounting portion 16 taper inwardly from the base 13 to the cutting portion 18 .

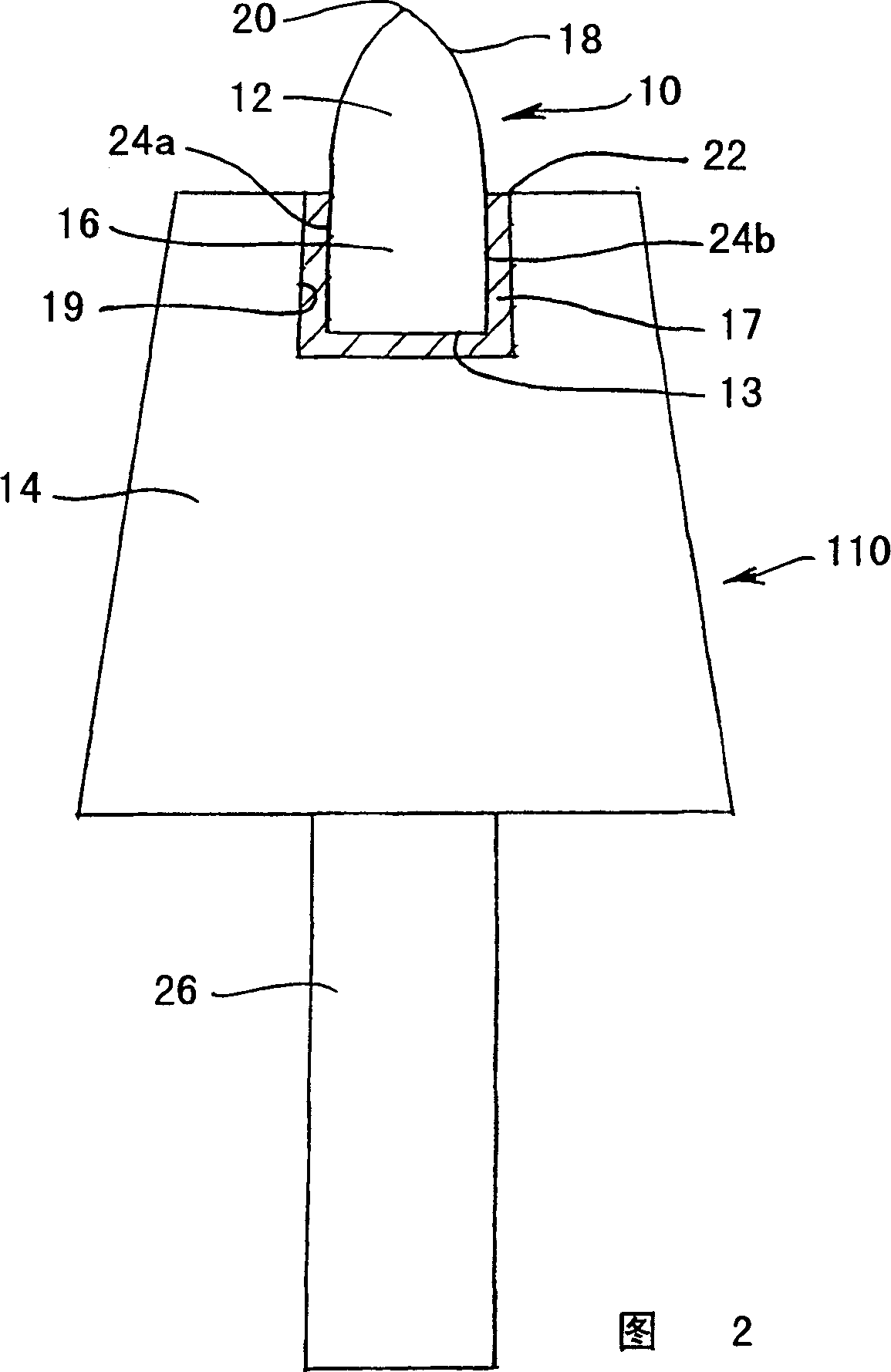

[0095] In FIG. 2 , a pick 110 is shown comprising a cutting element 10 comprising a pointed body 12 formed from ADC mounted on a pick body 14 made of steel. The cutting element 12 is included in the figure 1 The structure shown in , will not be repeated here. An elongated mounting portion 16 fits in a recess 17 on the pick b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com