Excavation construction method for ultra-hard rock tunnel through hydraulic dilling matched with hydraulic splitting

A construction method and tunnel excavation technology, which is applied to tunnels, earthwork drilling, mining equipment, etc., can solve problems such as high construction cost, low tunnel excavation efficiency, and large impact on surrounding buildings and structures, and improve construction efficiency. Improve work efficiency, reduce construction risk, and increase tunneling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

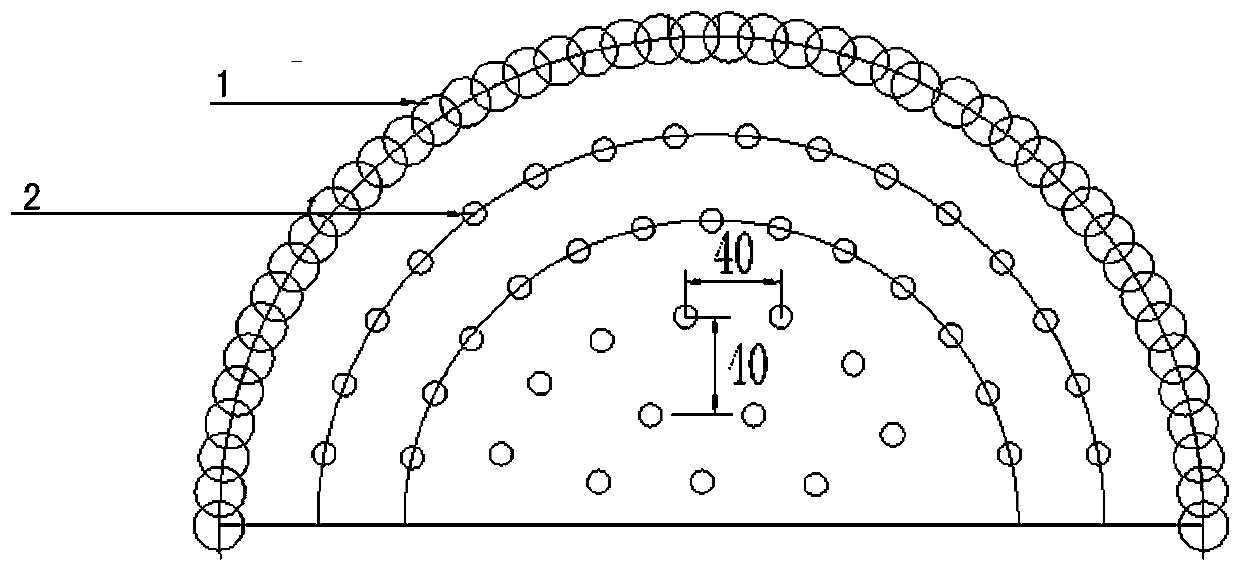

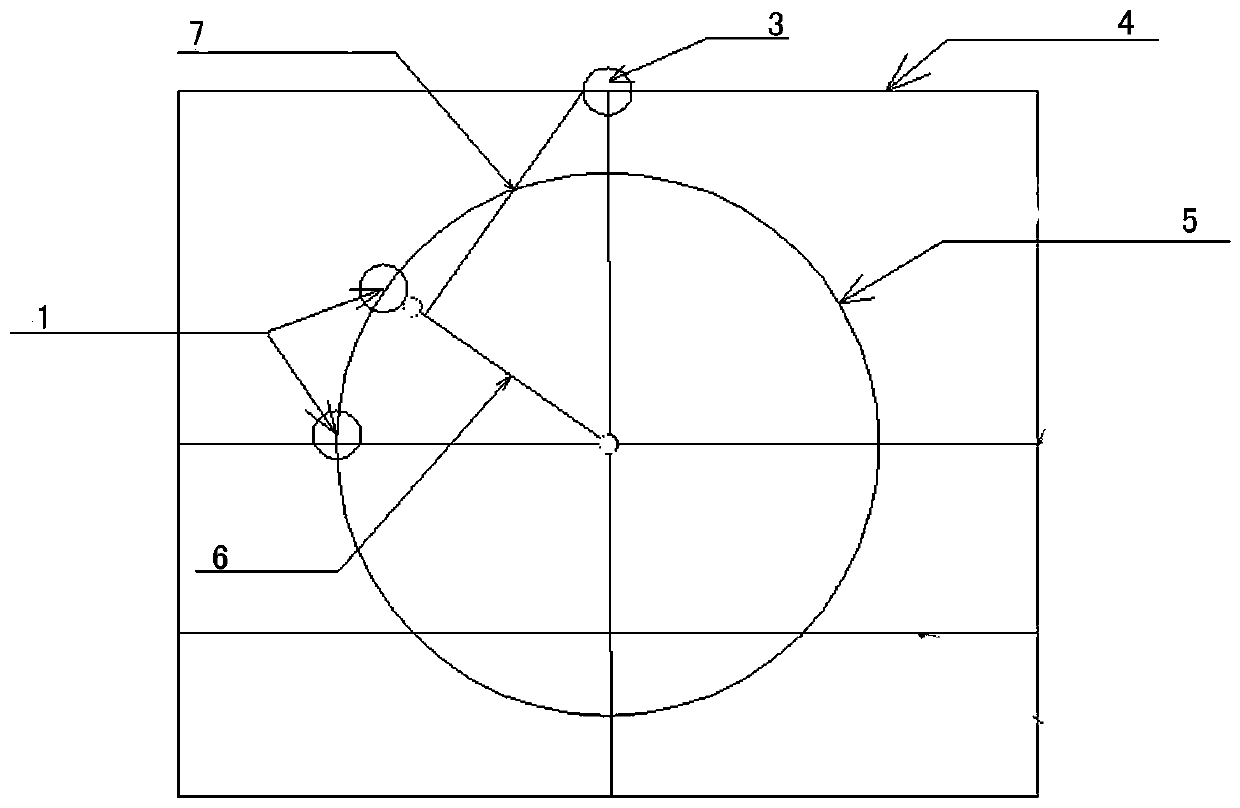

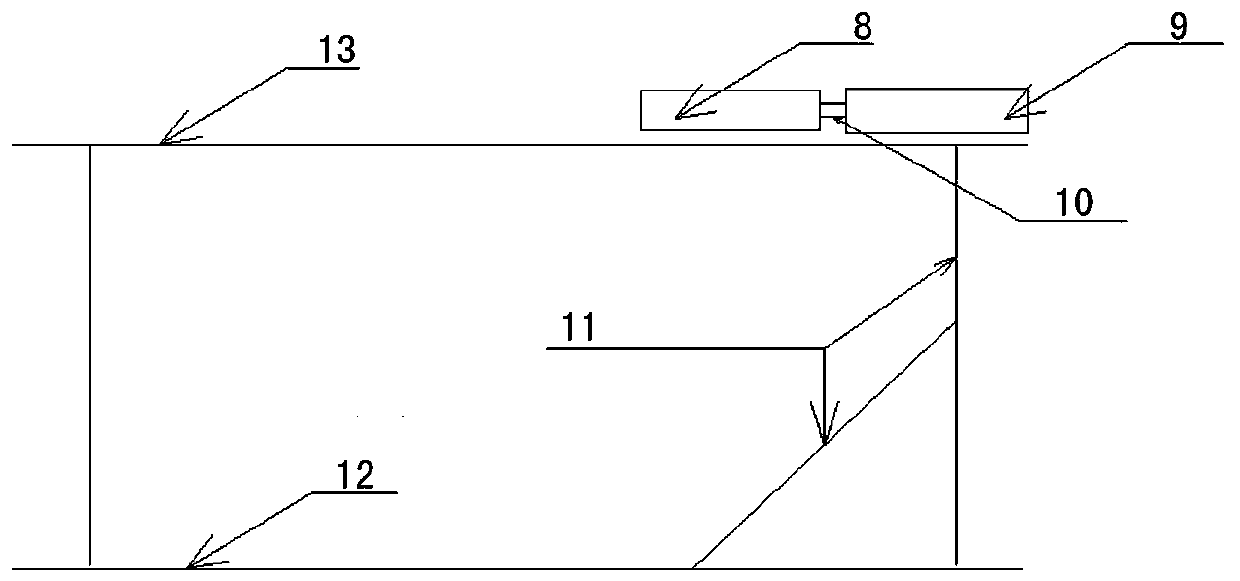

[0019] The construction principle of the present invention is: water drilling + hydraulic splitting to excavate the upper section, and rock cutting saw to excavate the lower section. Tunnel excavation is carried out by the method of "cutting the lower section surface by section drawing groove". Water-milling drills are used to drill and core horizontally along the excavation contour in an adjacent circle, forming continuous channels around the periphery to provide a free surface for the excavation of the upper section rock mass. In the rock mass excavation area of the upper section, the pneumatic drill is used to drill splitting holes in the horizontal direction at a certain interval, and the rock mass is split from the periphery to the inside with a hydraulic splitting machine using the free surface formed by the excavation of the surrounding channels. After the excavation of the upper section is completed, the rock mass of the lower section is excavated using a rock cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com