Anchor rod drill machine propulsion and rotation system and cooperative self-adaptation control method thereof

A technology of self-adaptive control and slewing system, applied in drilling equipment and methods, automatic control system of drilling, installation of bolts, etc., can solve the problem of lack of setting basis for the given value of drilling rig speed and propulsion force, and the drilling process. Can't run etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

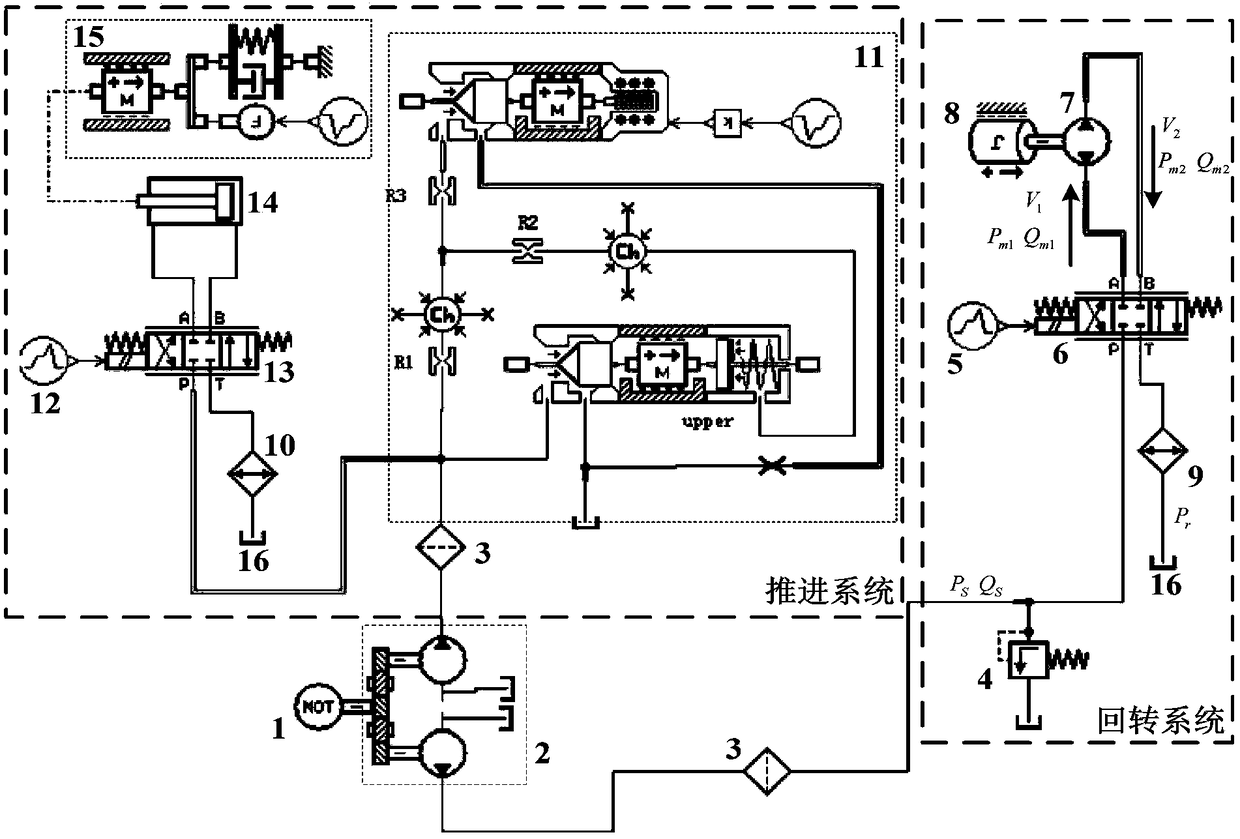

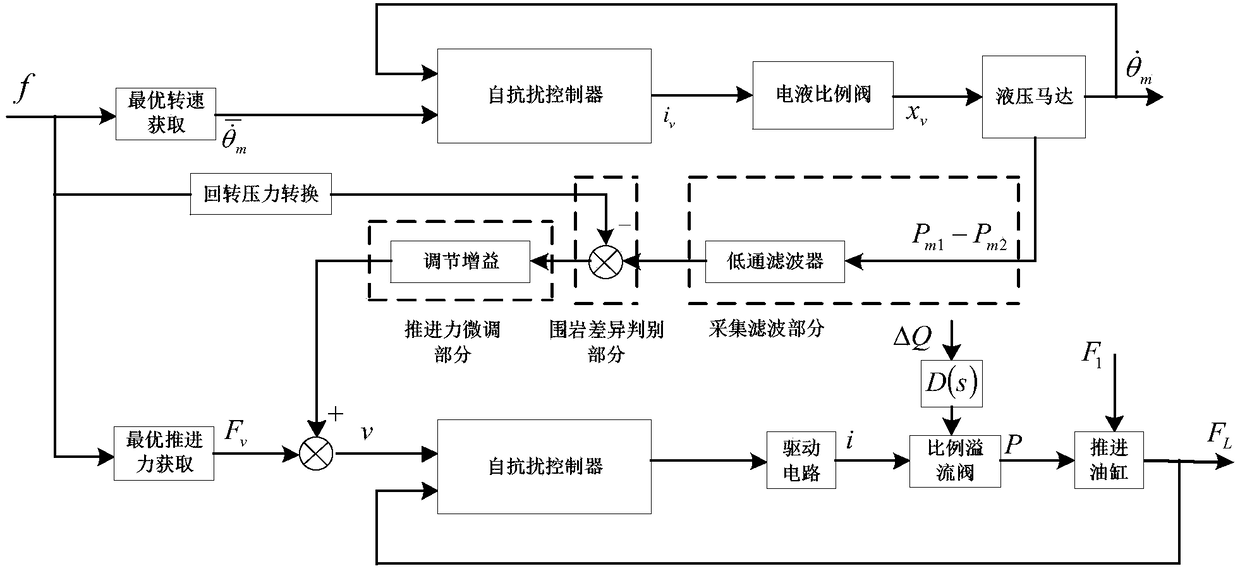

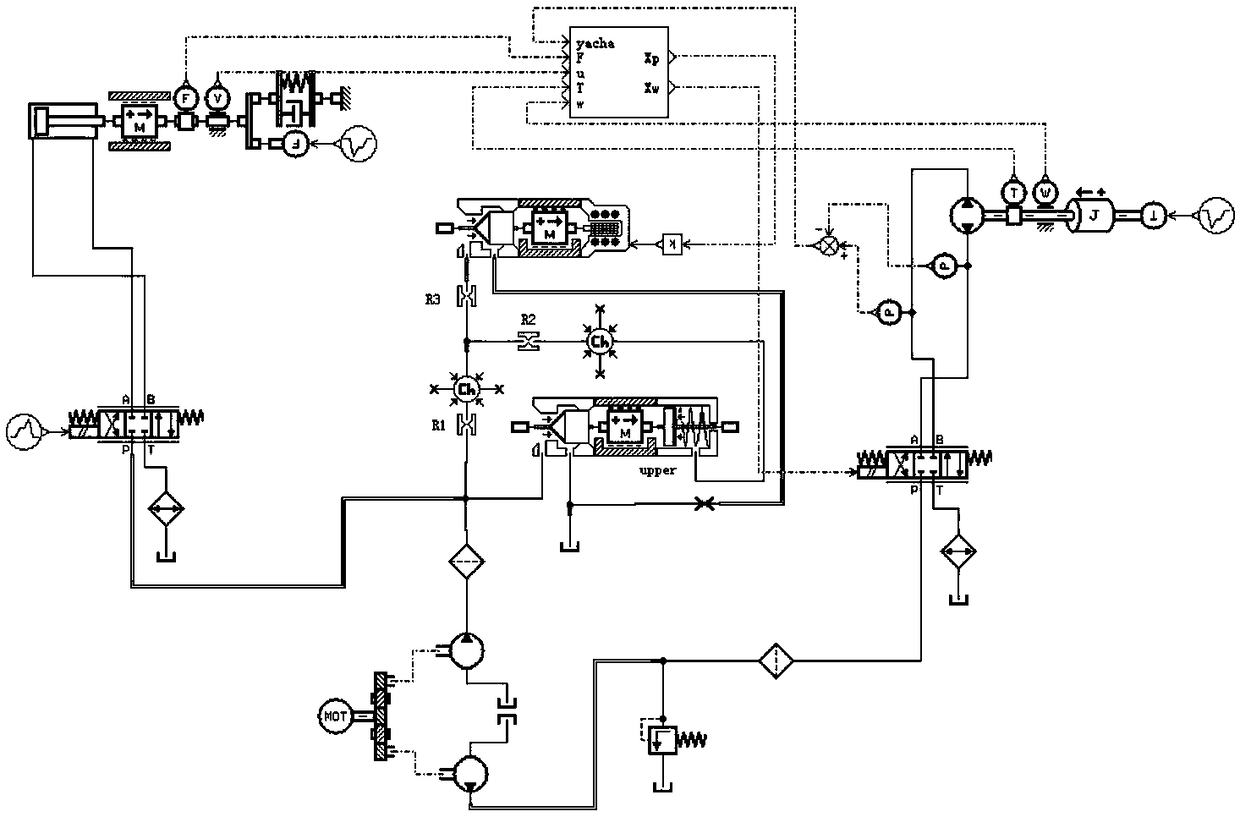

[0066] This patent sets the optimal propulsion force and optimal speed according to the properties of the surrounding rock, adopts a composite method to coordinate the drilling rig’s propulsion and slewing system, and considers the non-linear and multi-interference characteristics of the hydraulic system of the rock bolter, adopts an active disturbance rejection controller to realize Independent control of rig propulsion and slewing systems.

[0067] The cooperative adaptive control of the propulsion and rotation of the rock bolter is an important part of the automation and robotization of the whole machine of the rock bolter, and it has far-reaching significance for the implementation of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com