Supporting method of laneway under multiple goafs in ultra-close coal seam group

A very short-distance, coal seam group technology, applied in the support field of roadways under multi-goaf areas in extremely short-distance coal seam groups, can solve problems such as imperfect roadway support under multi-mined-out areas, and achieve good safety and economic effects. The effect of alleviating the tension of excavation and reducing the excavation construction team

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

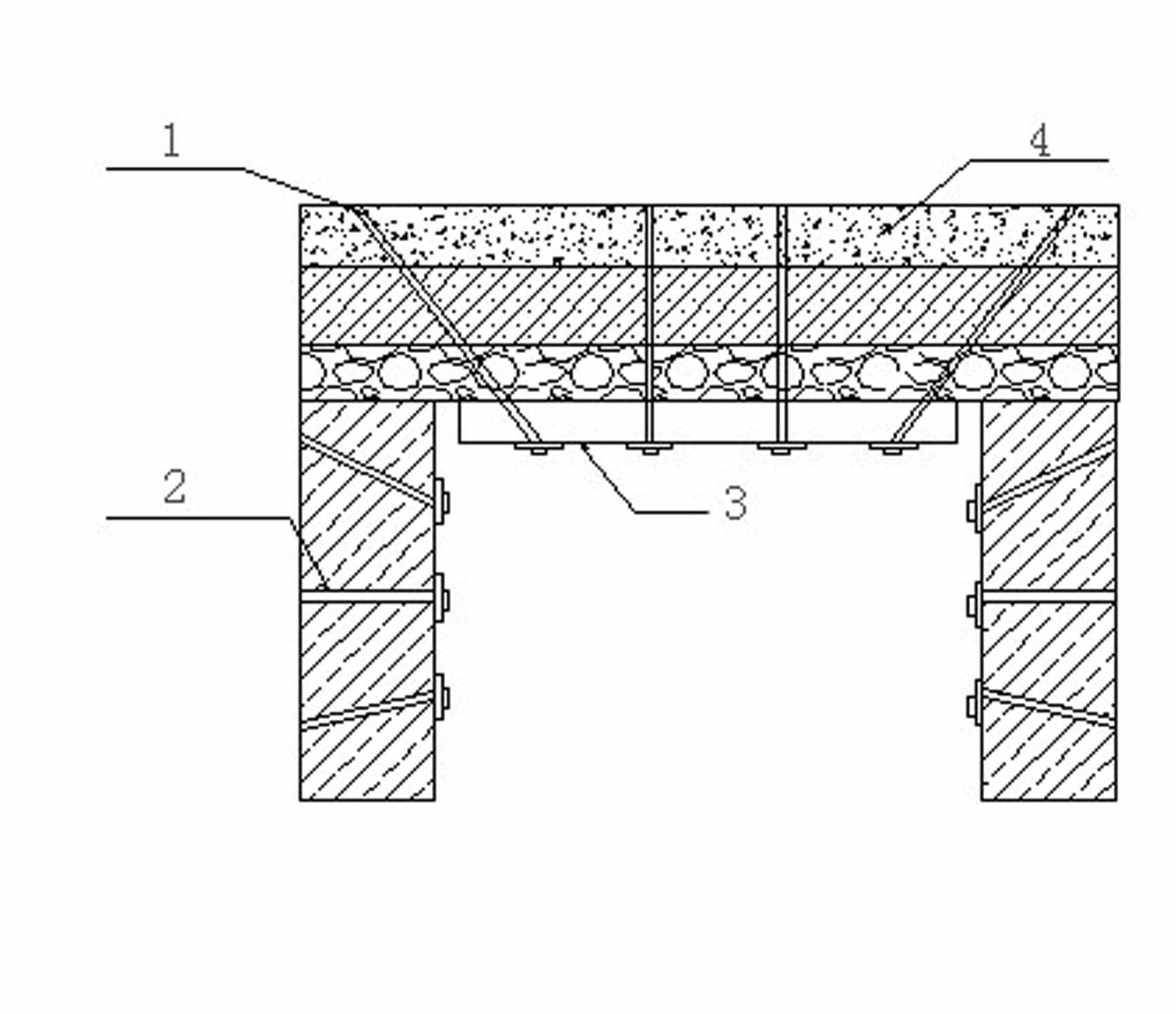

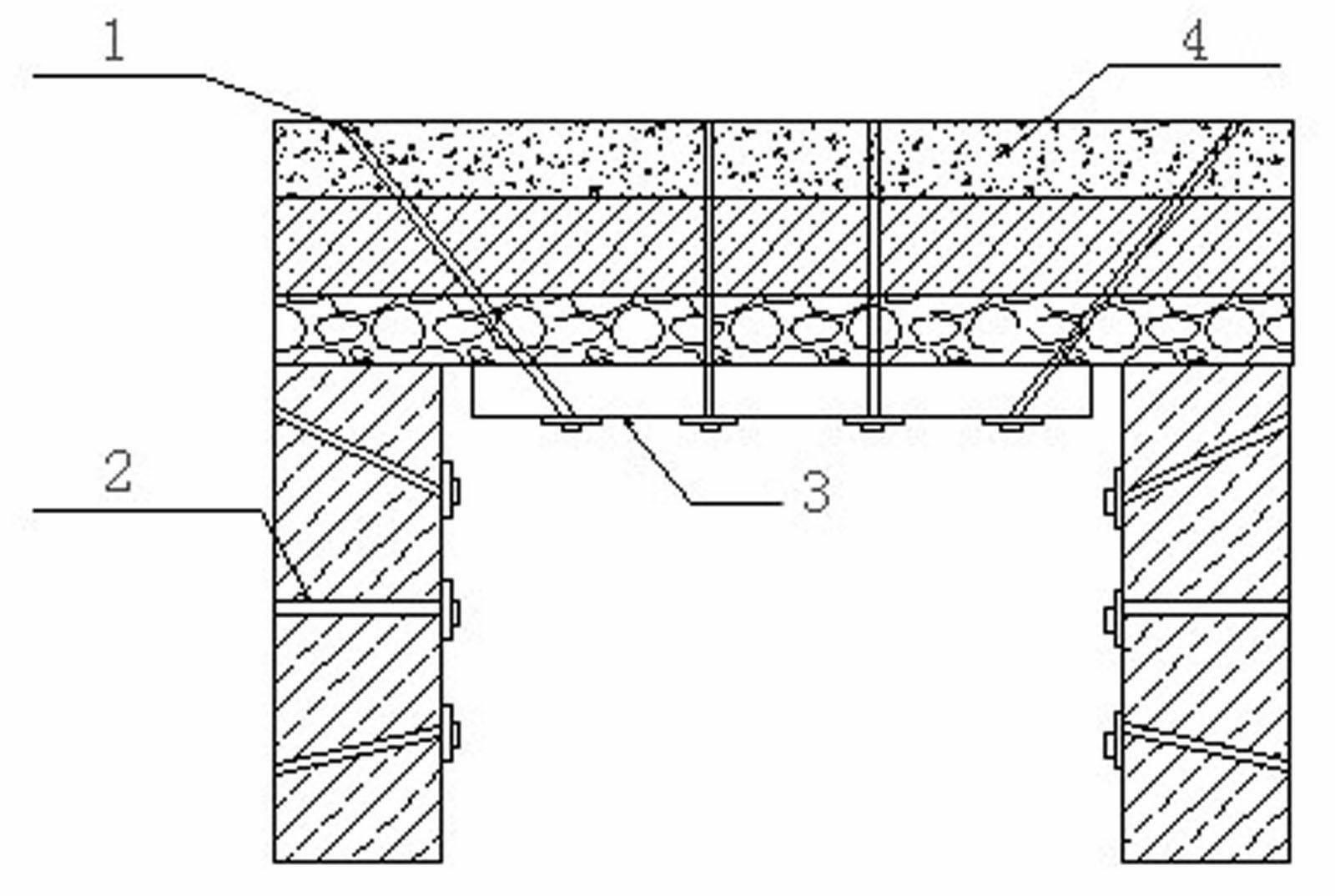

[0031] The support method for the roadway under the multi-mined-out area of the extremely close coal seam group includes the following steps:

[0032] Preparatory work, the steps include: use hand picks to construct the section, reserve 500mm for the two sides of the roadway, and finally use hand picks to plan and dig into shape; perform temporary support, lay steel wire mesh, and upper steel beams 3;

[0033] To install the roof anchor 1, the steps include: use a single anchor drill to drill the anchor holes according to the 3 holes of the steel beam; put two sections of resin medicine coils into the anchor holes through the 3 holes of the steel beam, and use the assembled anchor 1 Slowly push the resin medicine roll to the bottom of the hole; use the stirring joint to connect the drilling rig with the anchor pin nut, then raise the drilling rig to push the anchor rod, start stirring when it is close to the roof rock surface 300~500mm, slowly raise the drilling rig and Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com