Patents

Literature

160 results about "Insertion angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

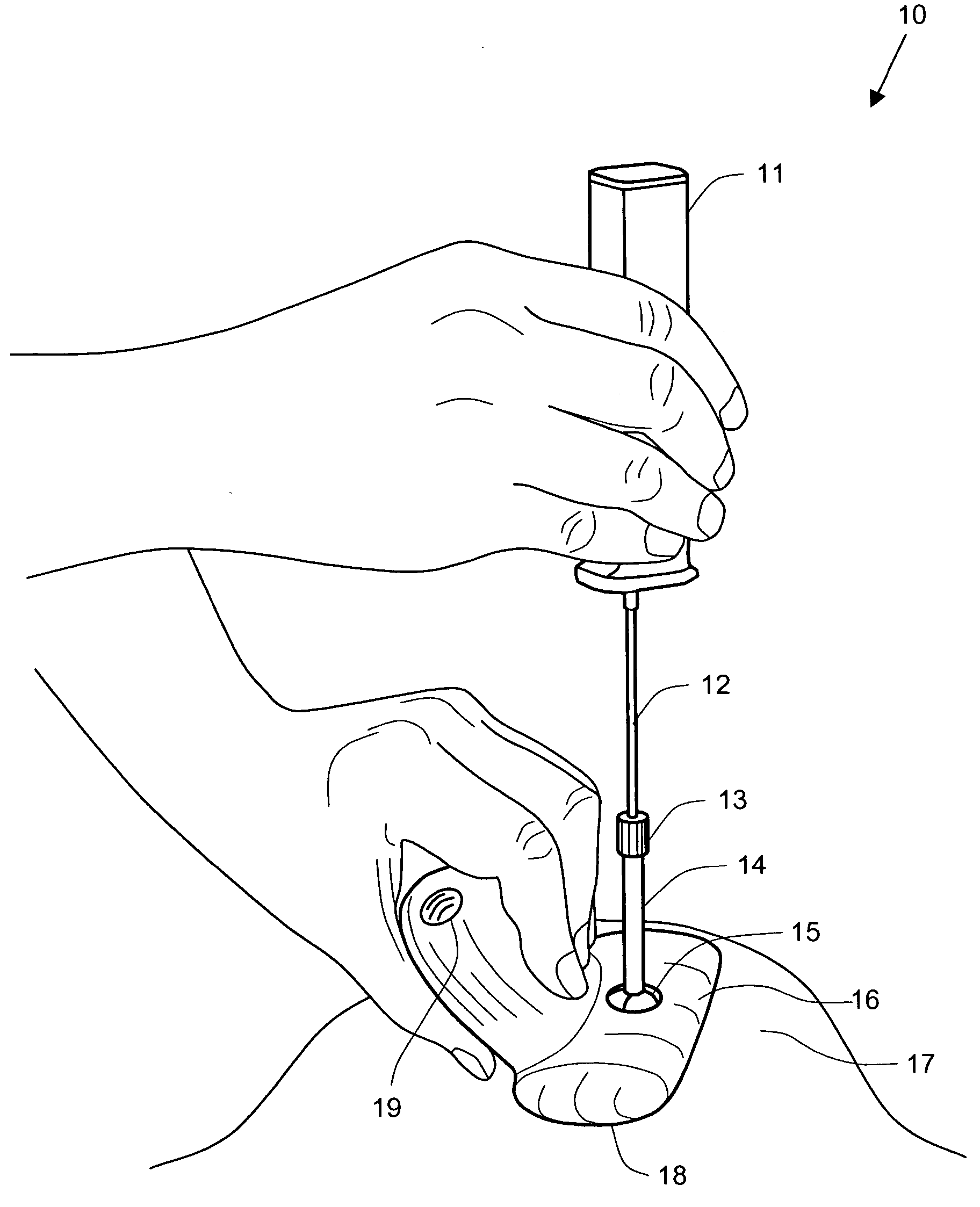

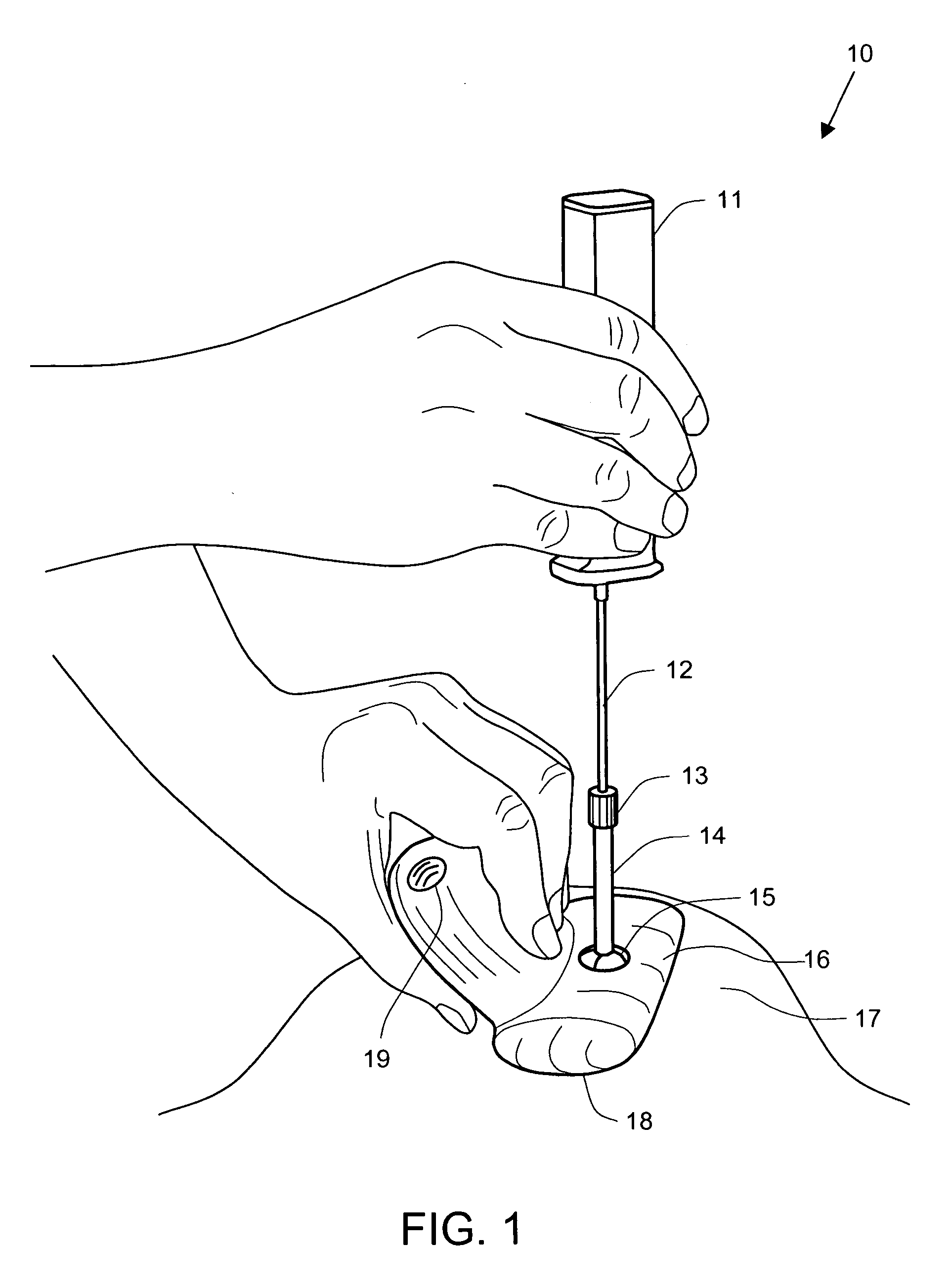

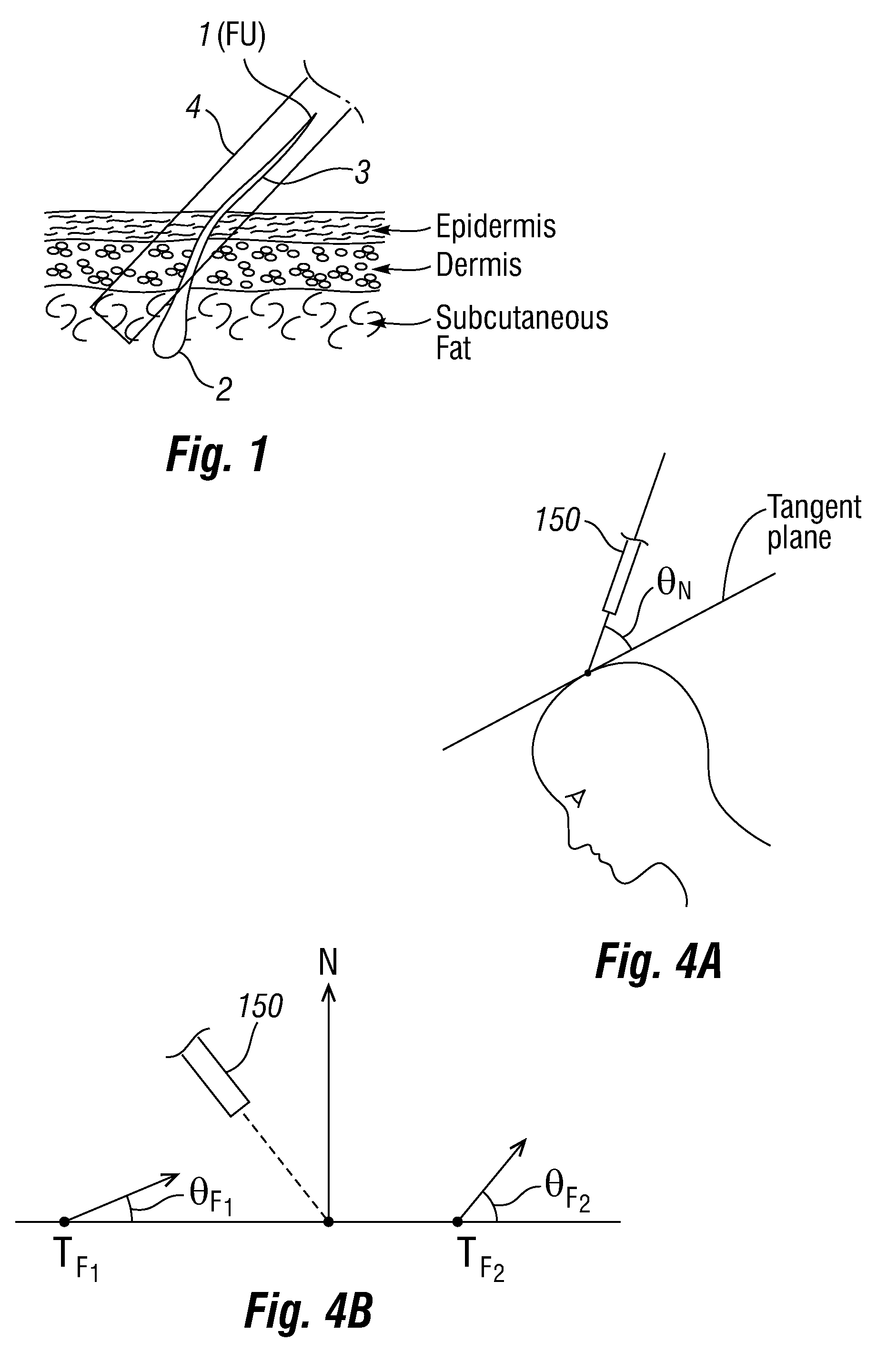

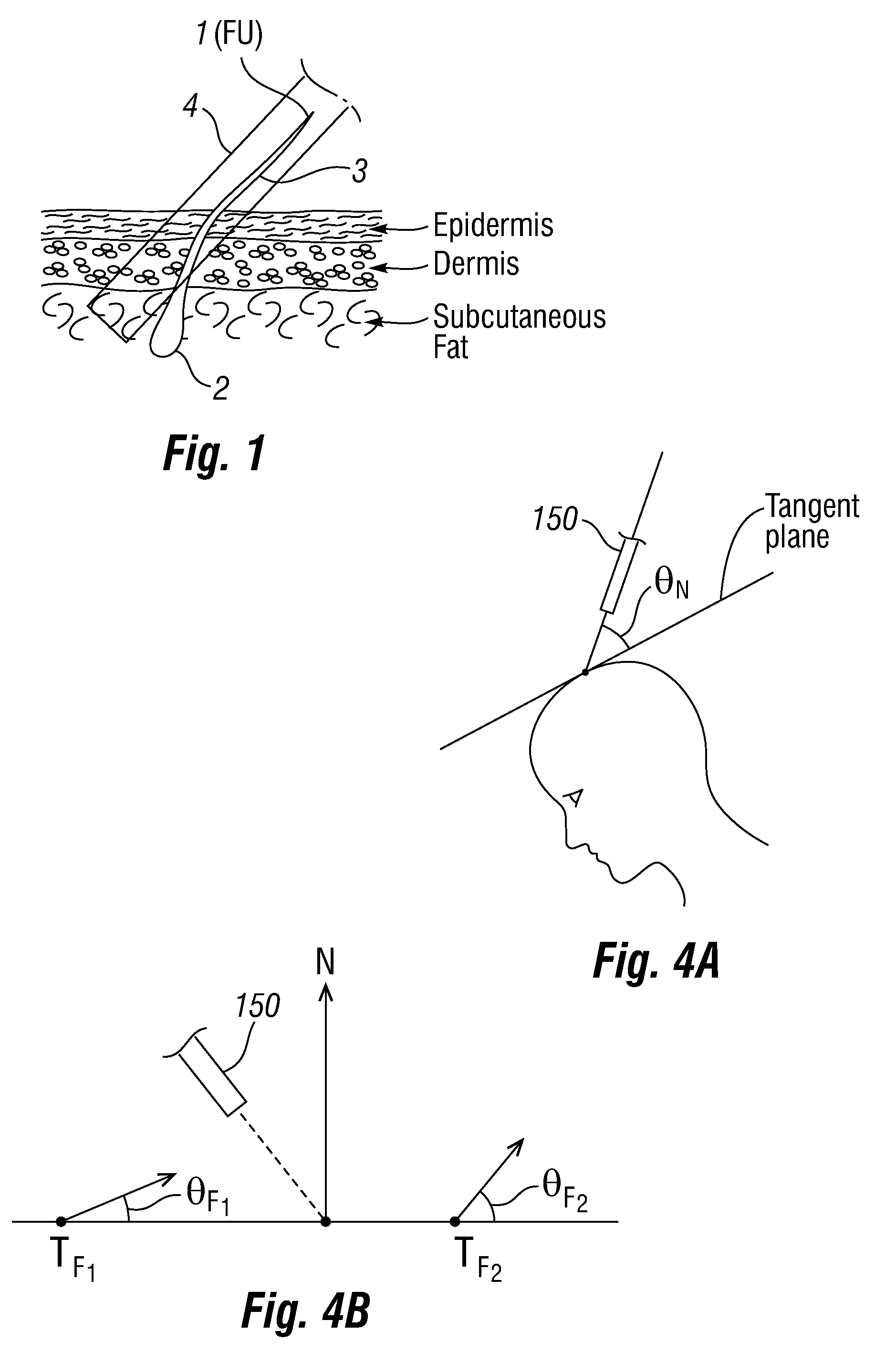

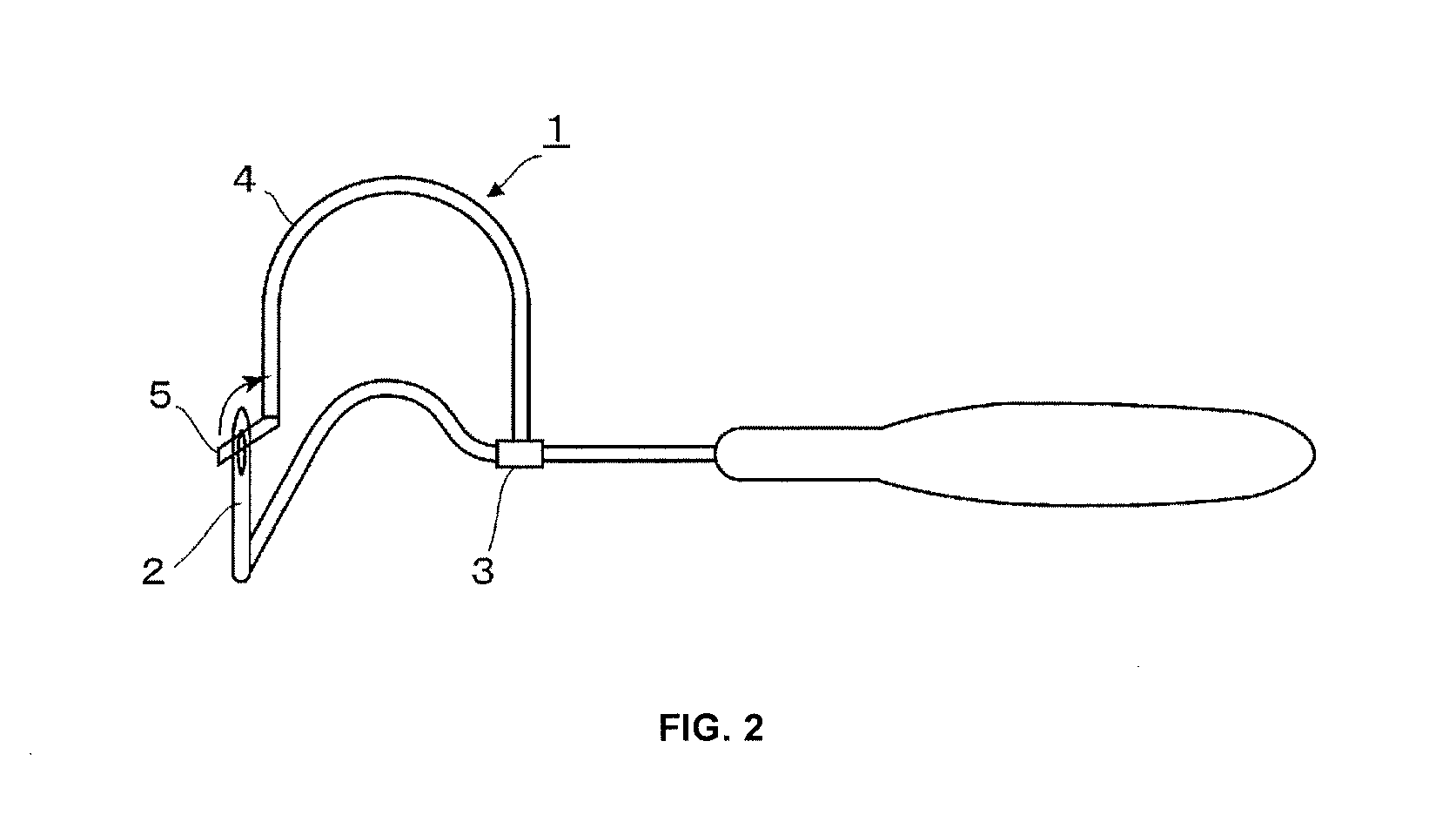

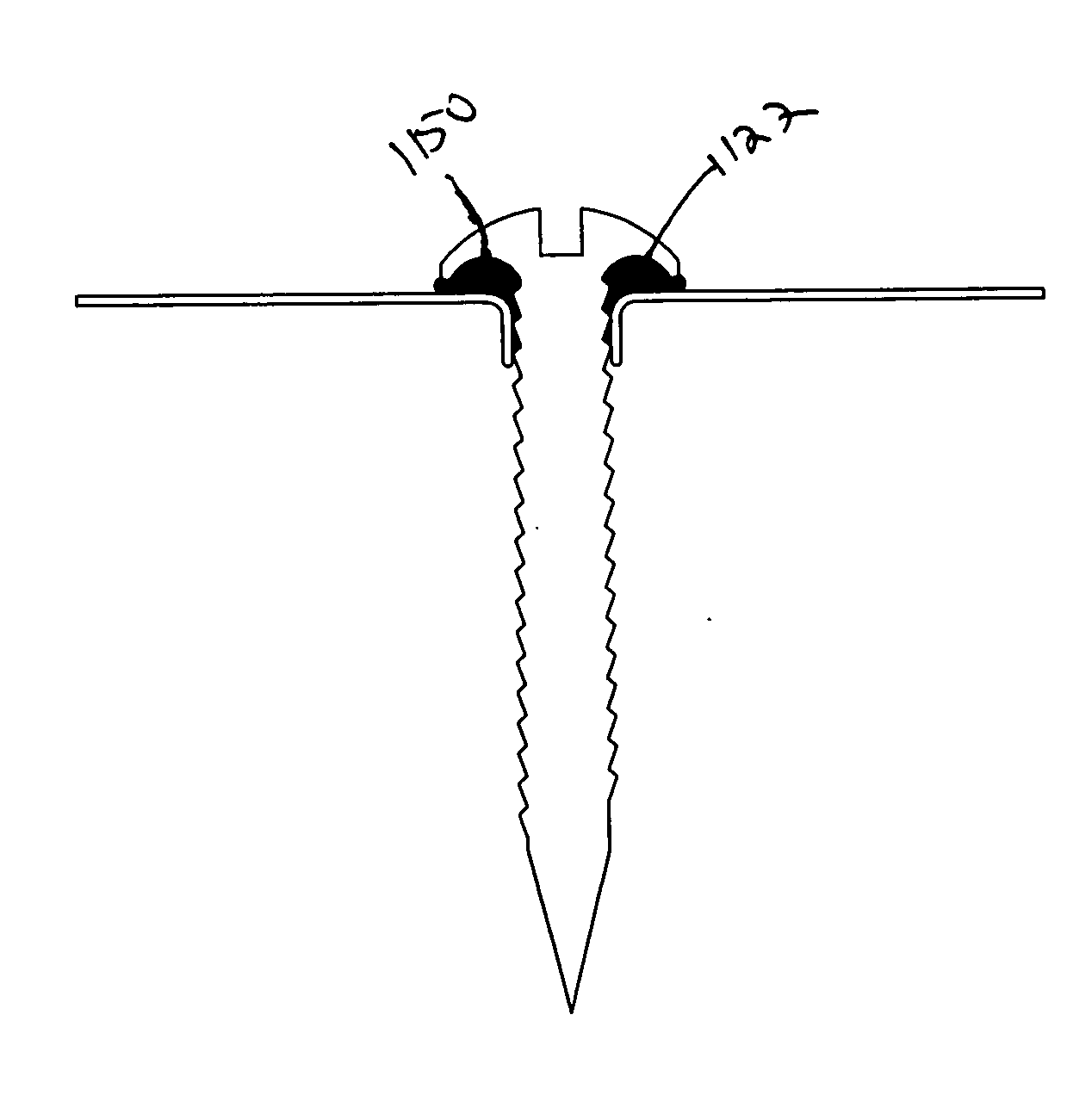

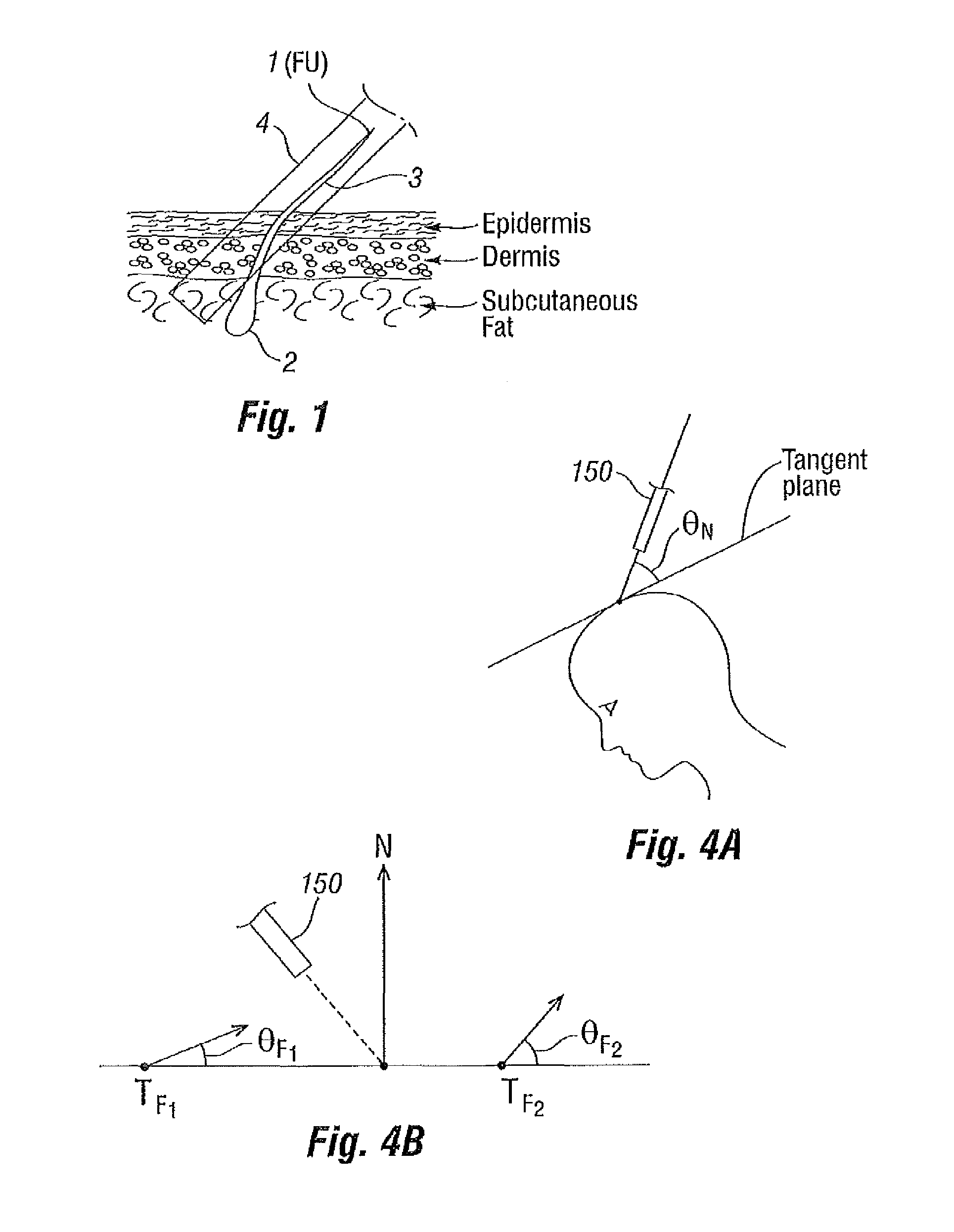

ANGLE OF NEEDLE INSERTION. The angle of insertion could be : Perpendicular (Image 1) : in which the needle is inserted perpendicularly forming a 90 degree angle with the skin surface.Most points on the body can be punctured perpendicularly. Oblique (Image 2) : in which the needle is inserted obliquely forming a 45 degree angle with the skin surface.

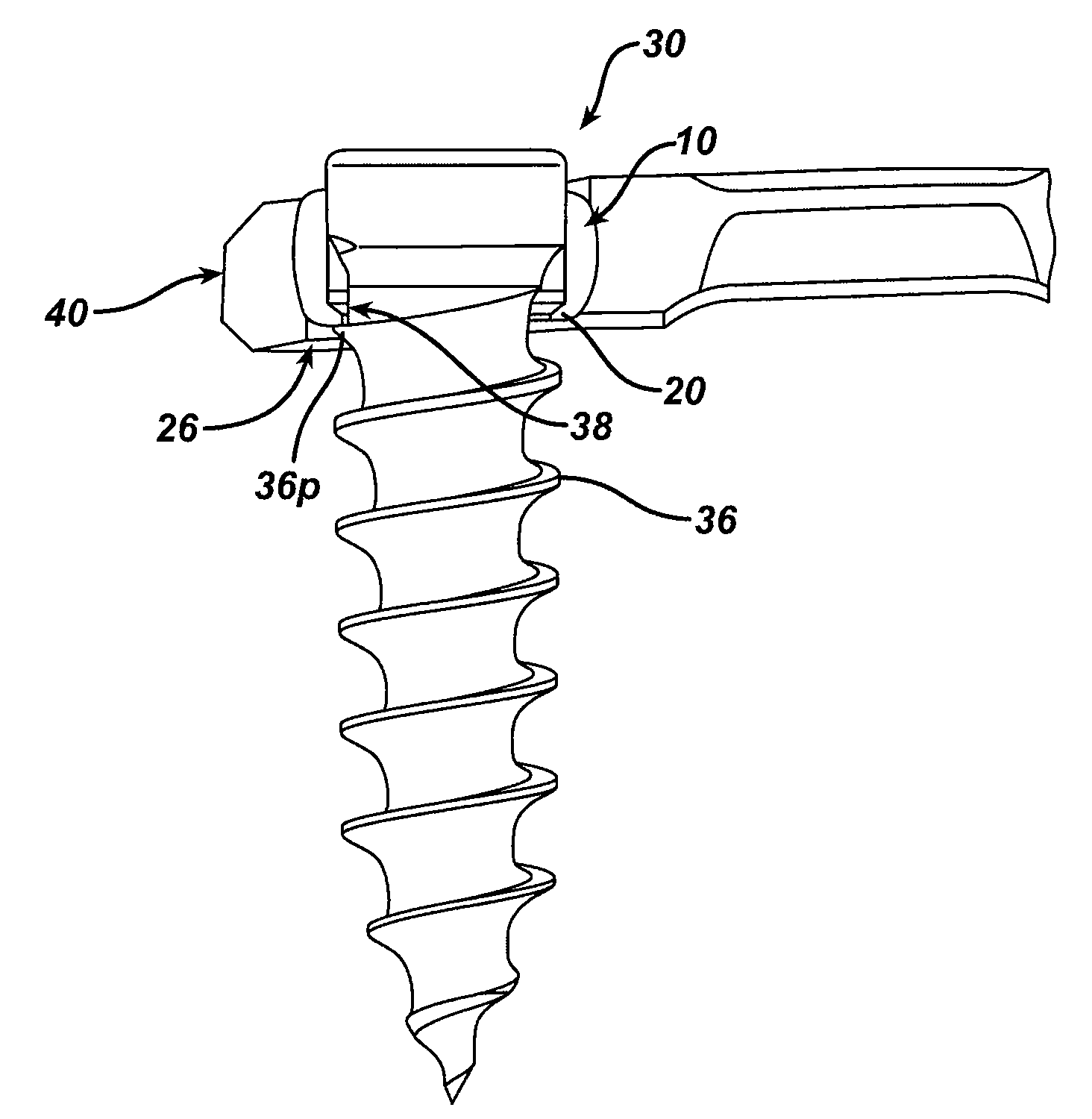

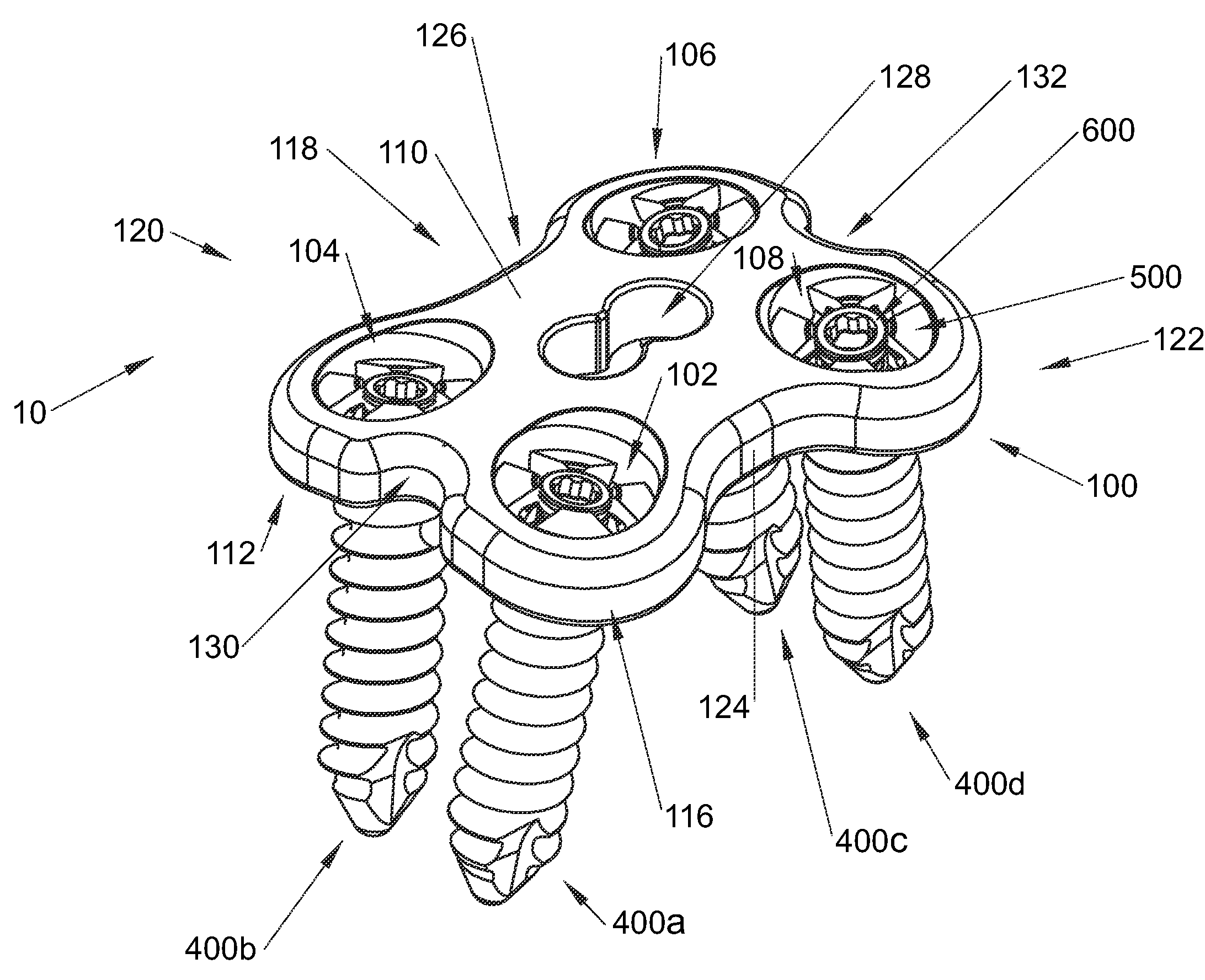

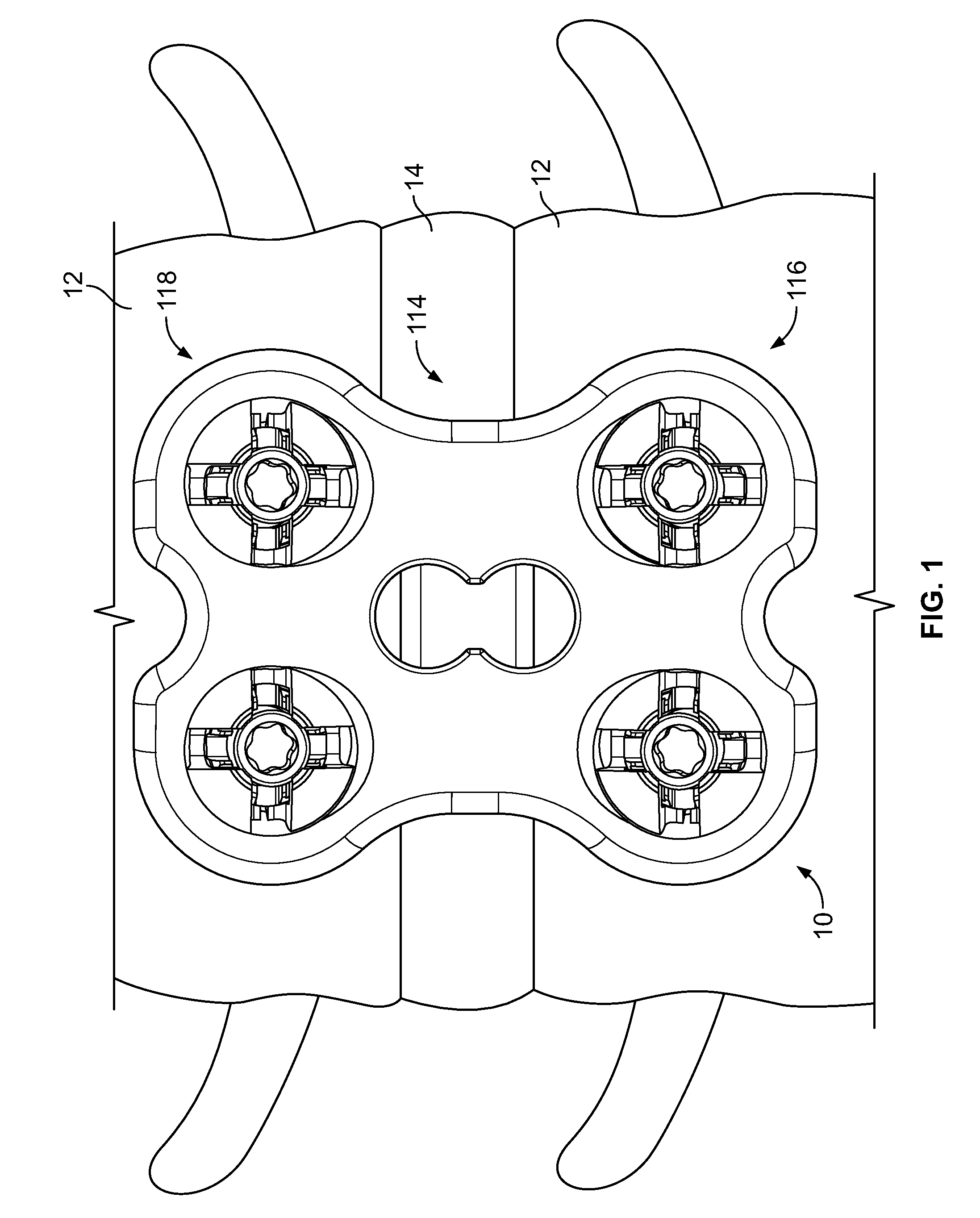

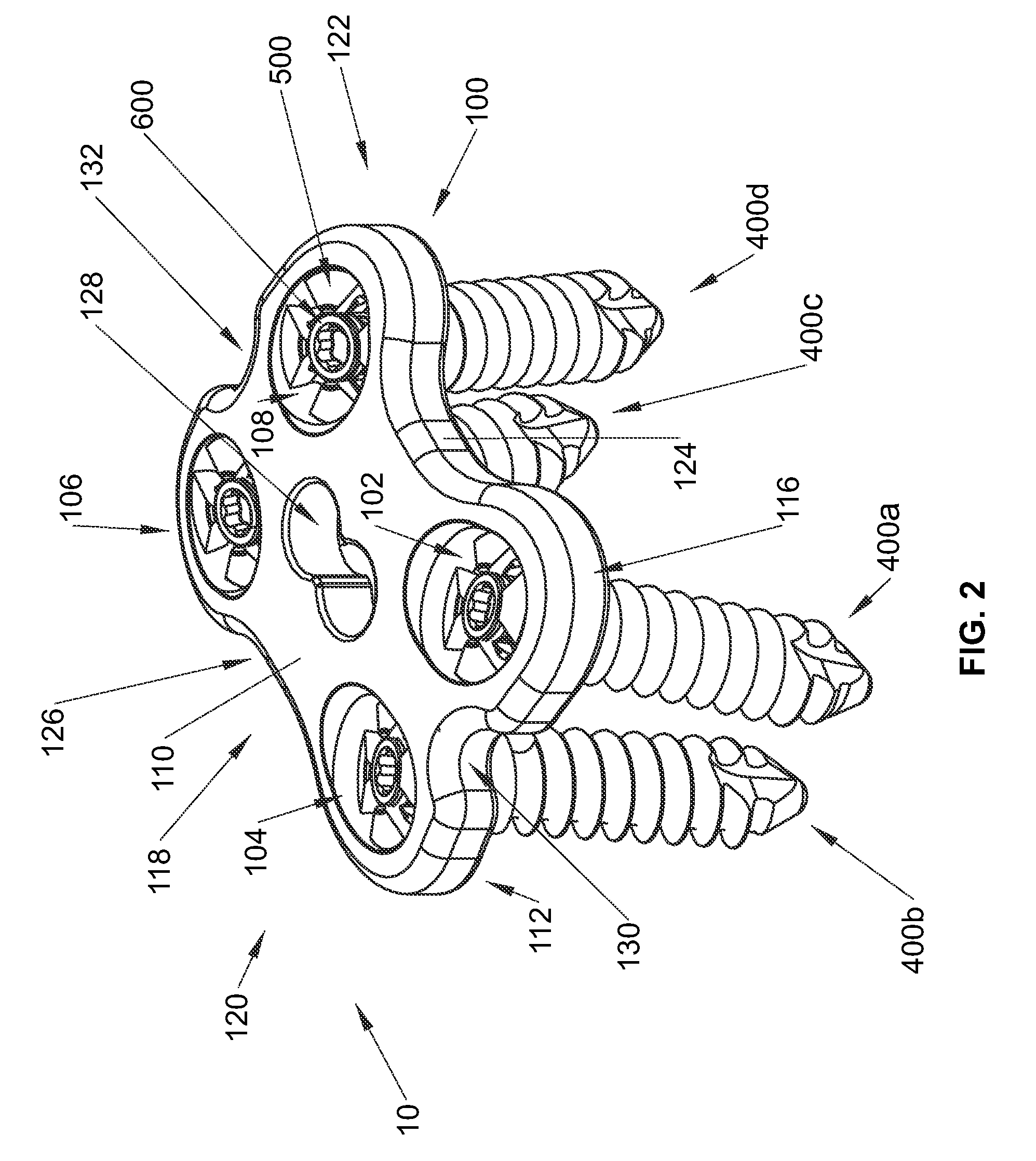

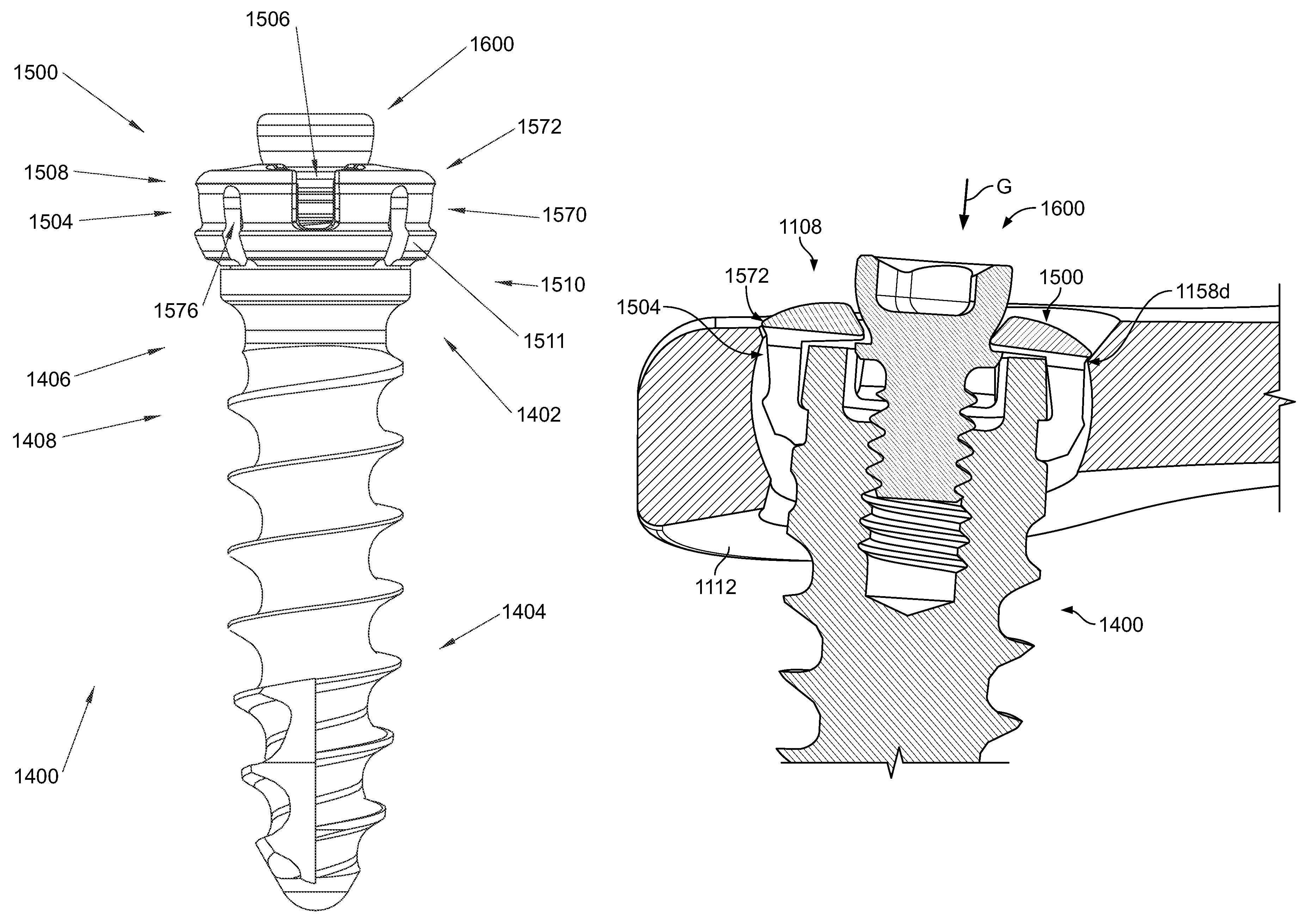

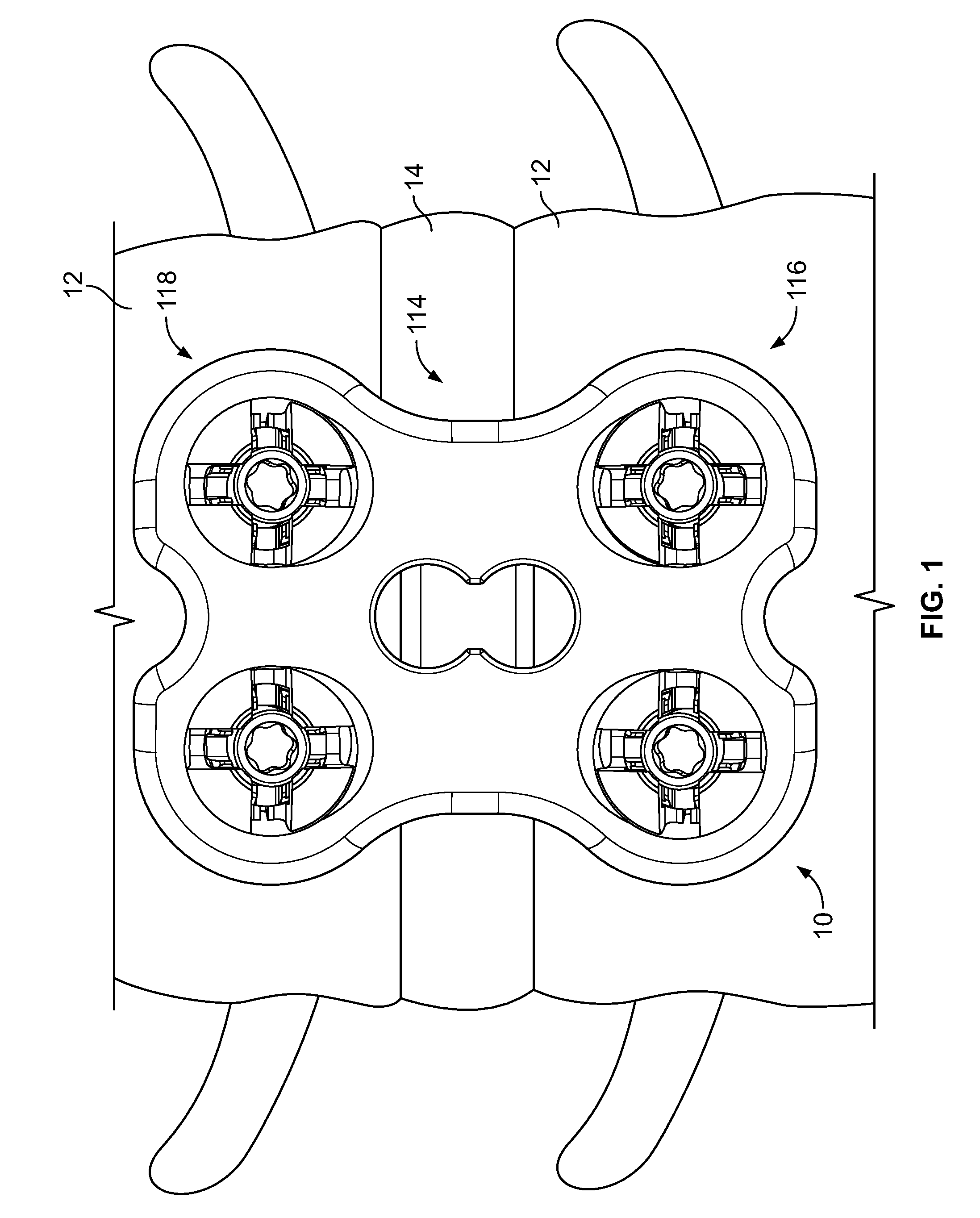

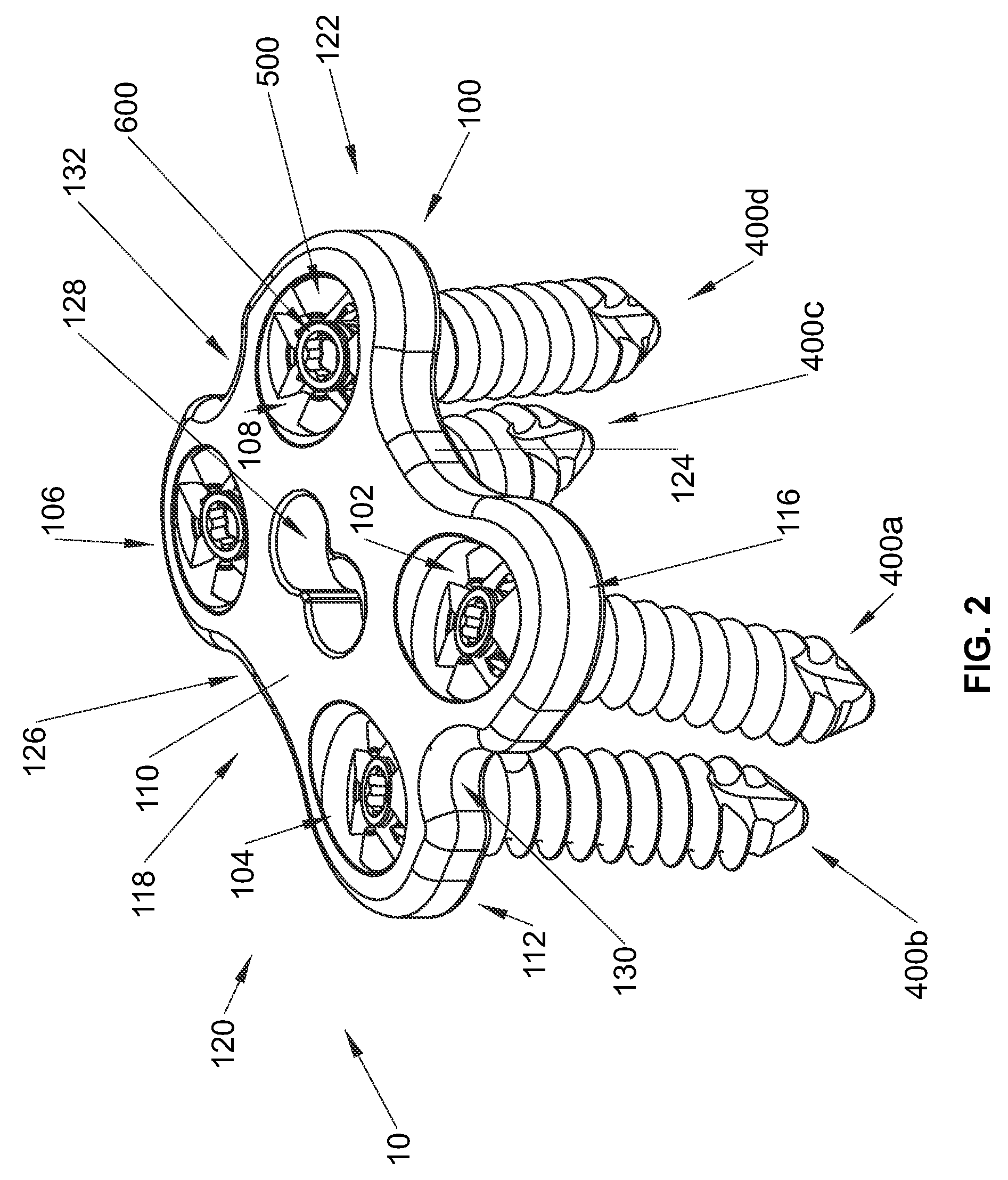

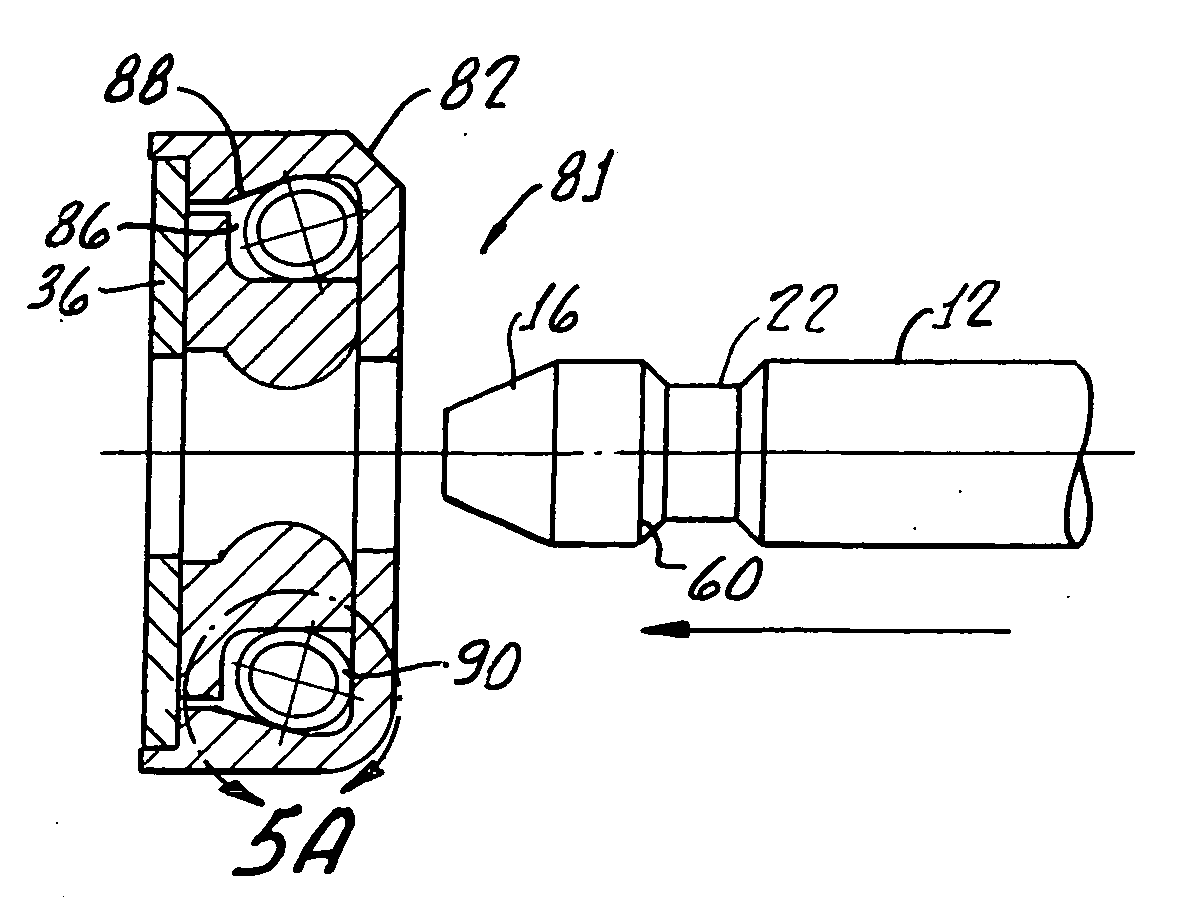

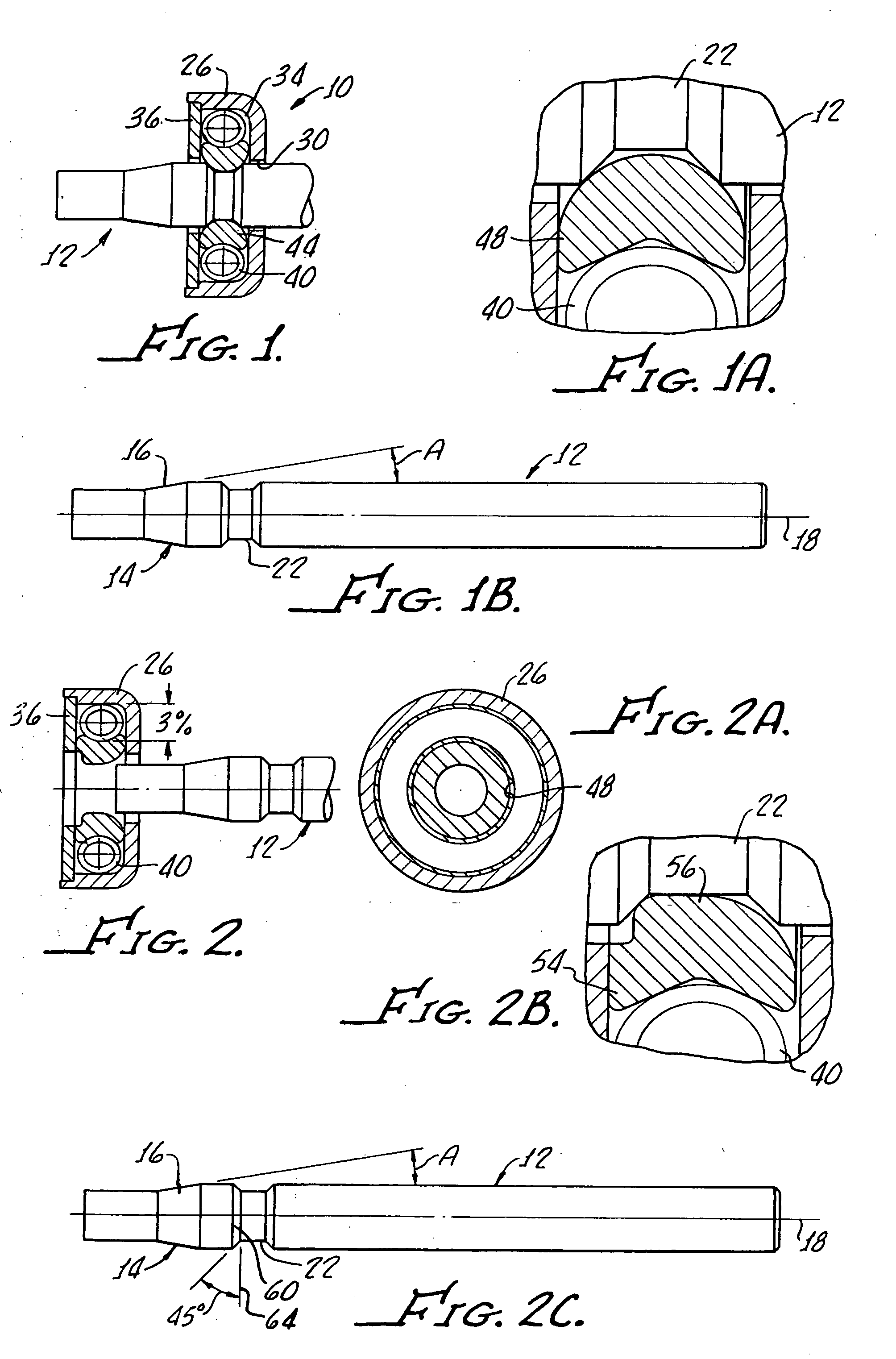

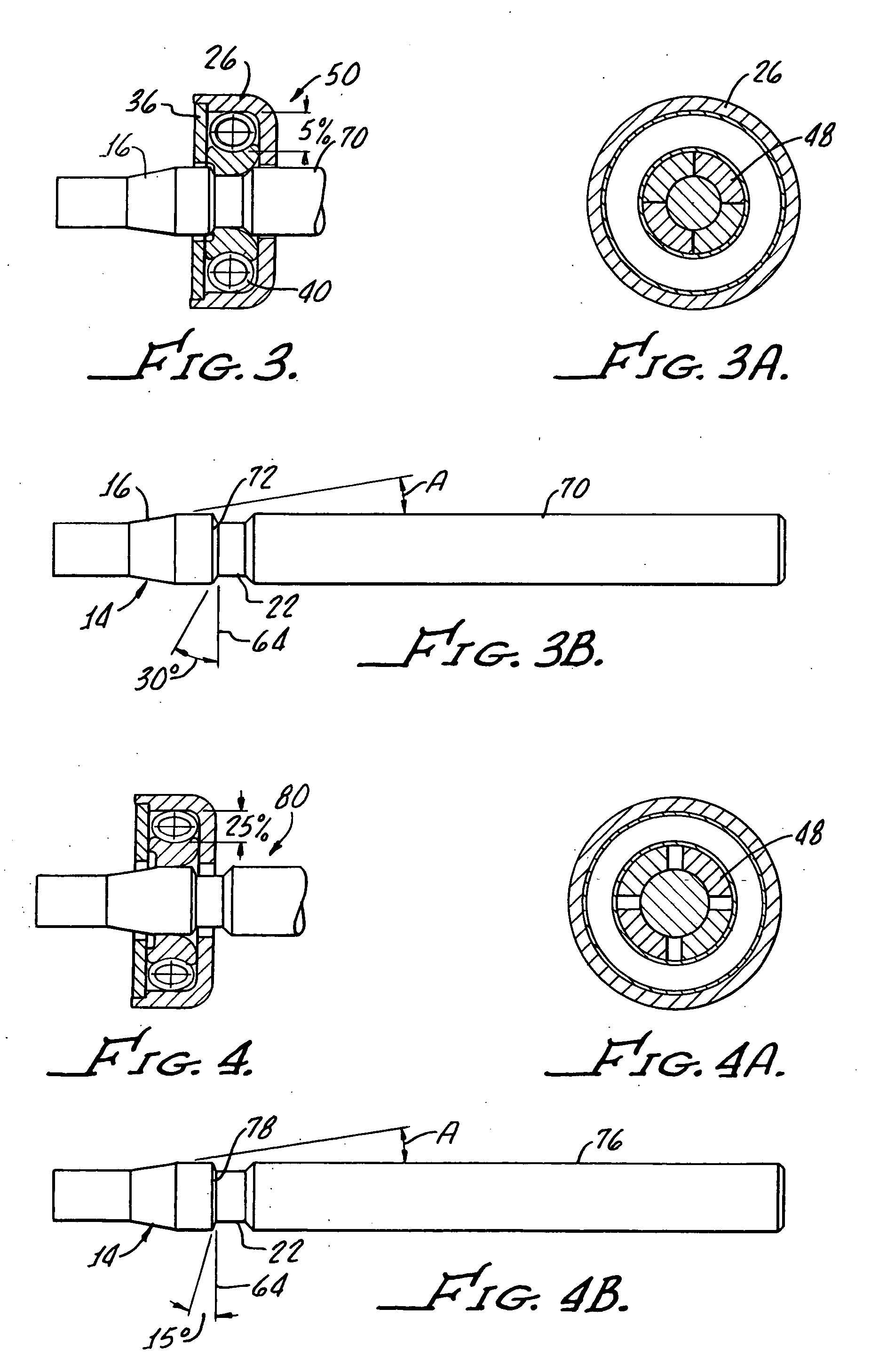

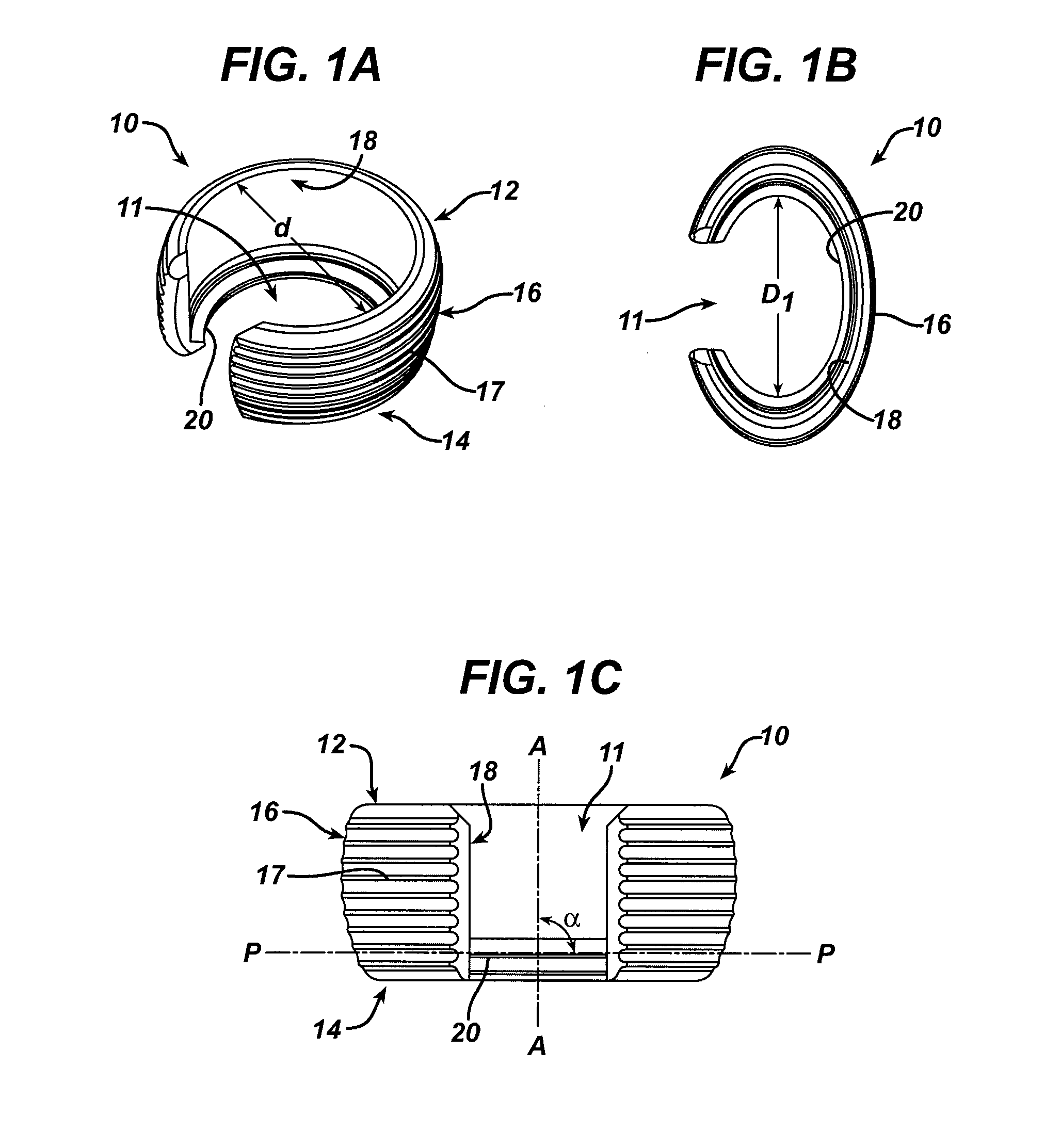

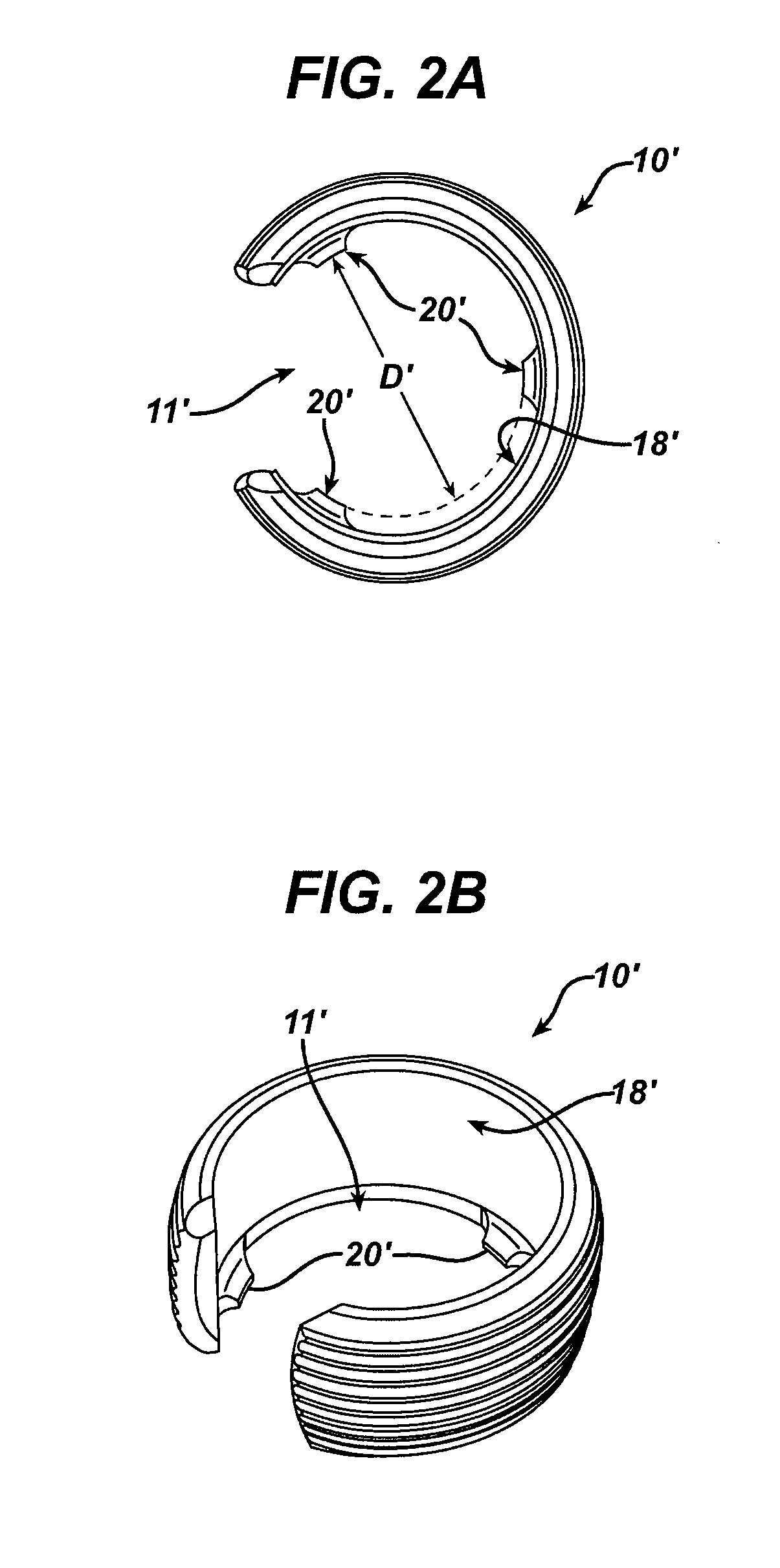

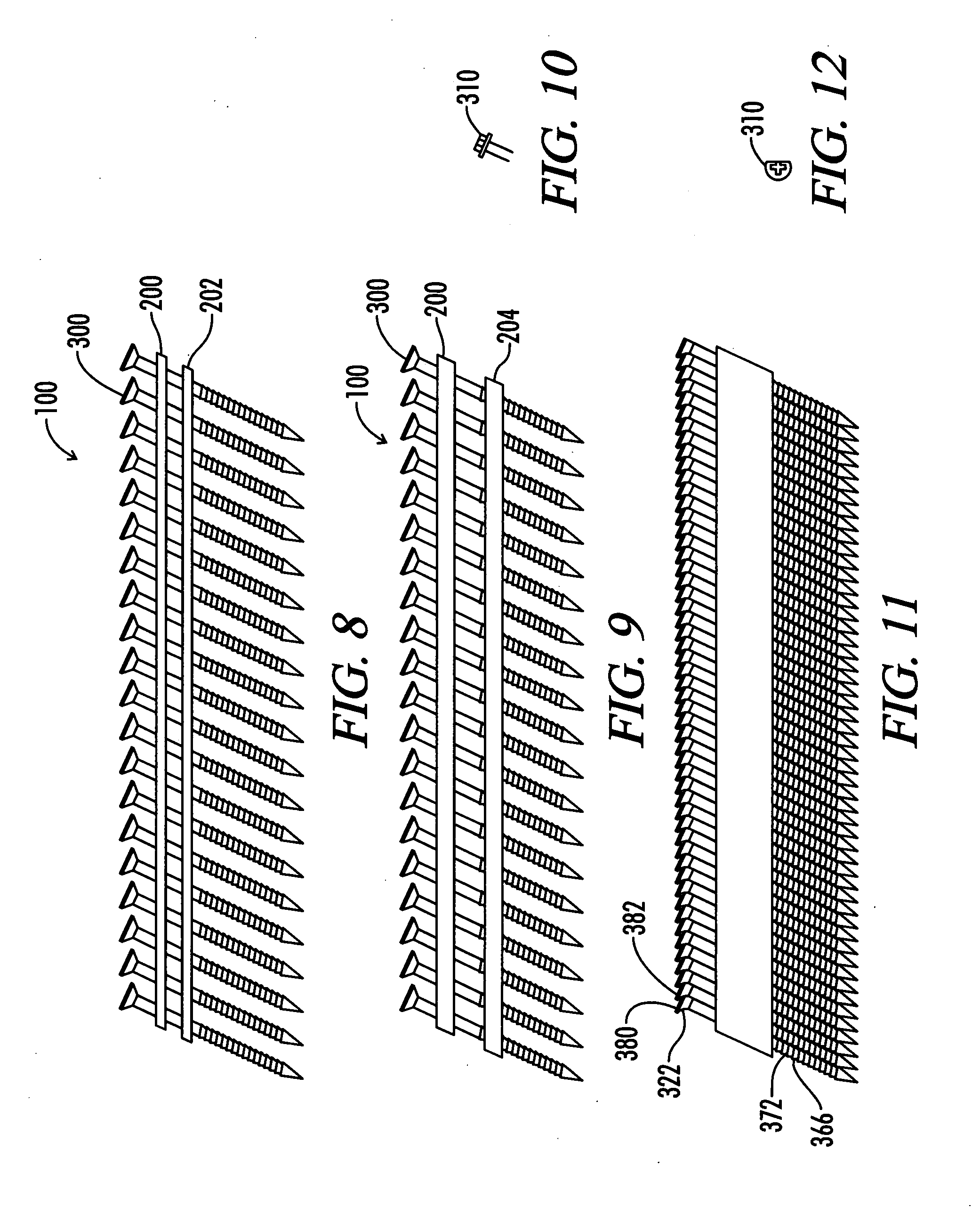

Multi-angular fastening apparatus and method for surgical bone screw/plate systems

InactiveUS6955677B2Maximum flexibilityWide rangeSuture equipmentsInternal osteosythesisFiberEngineering

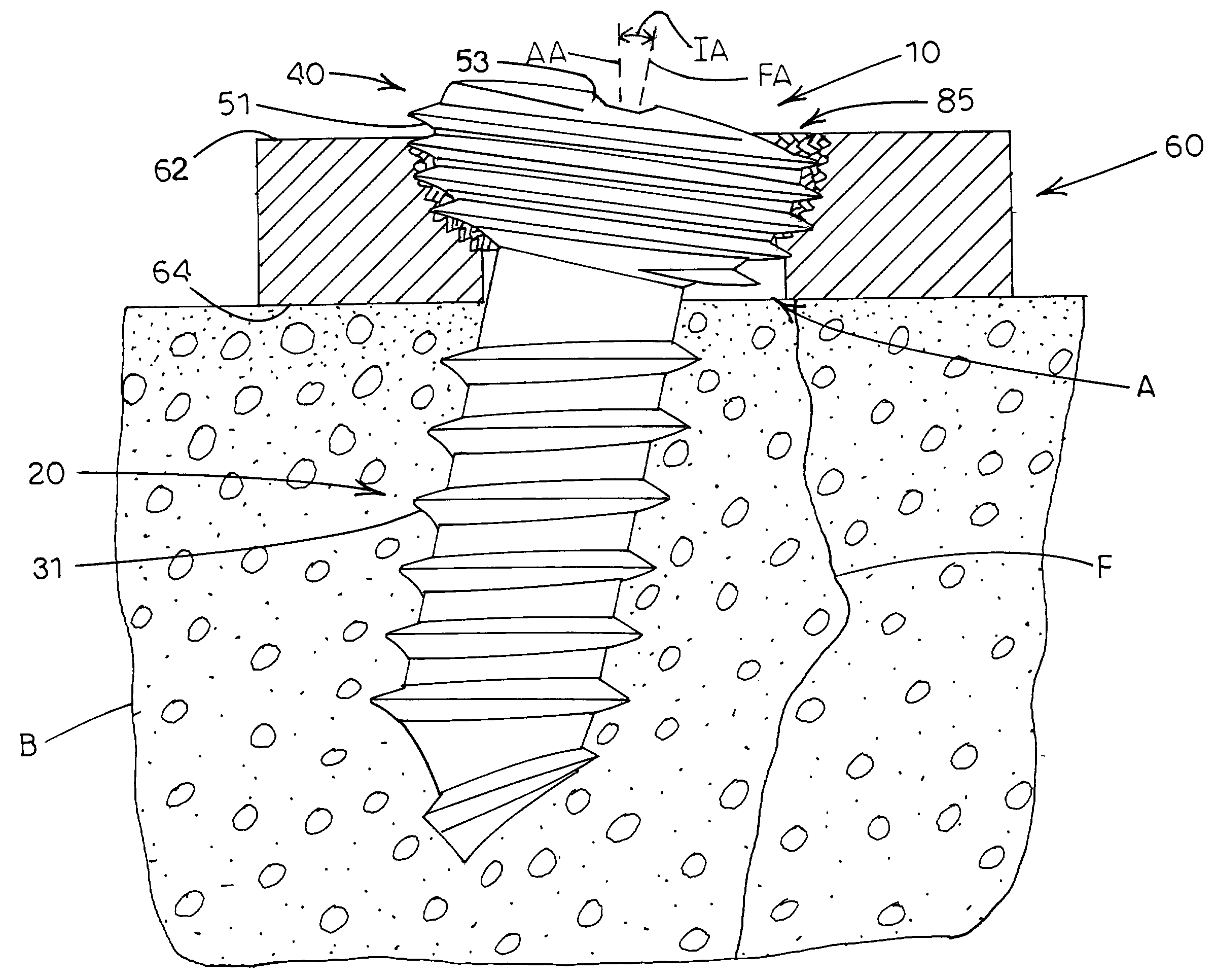

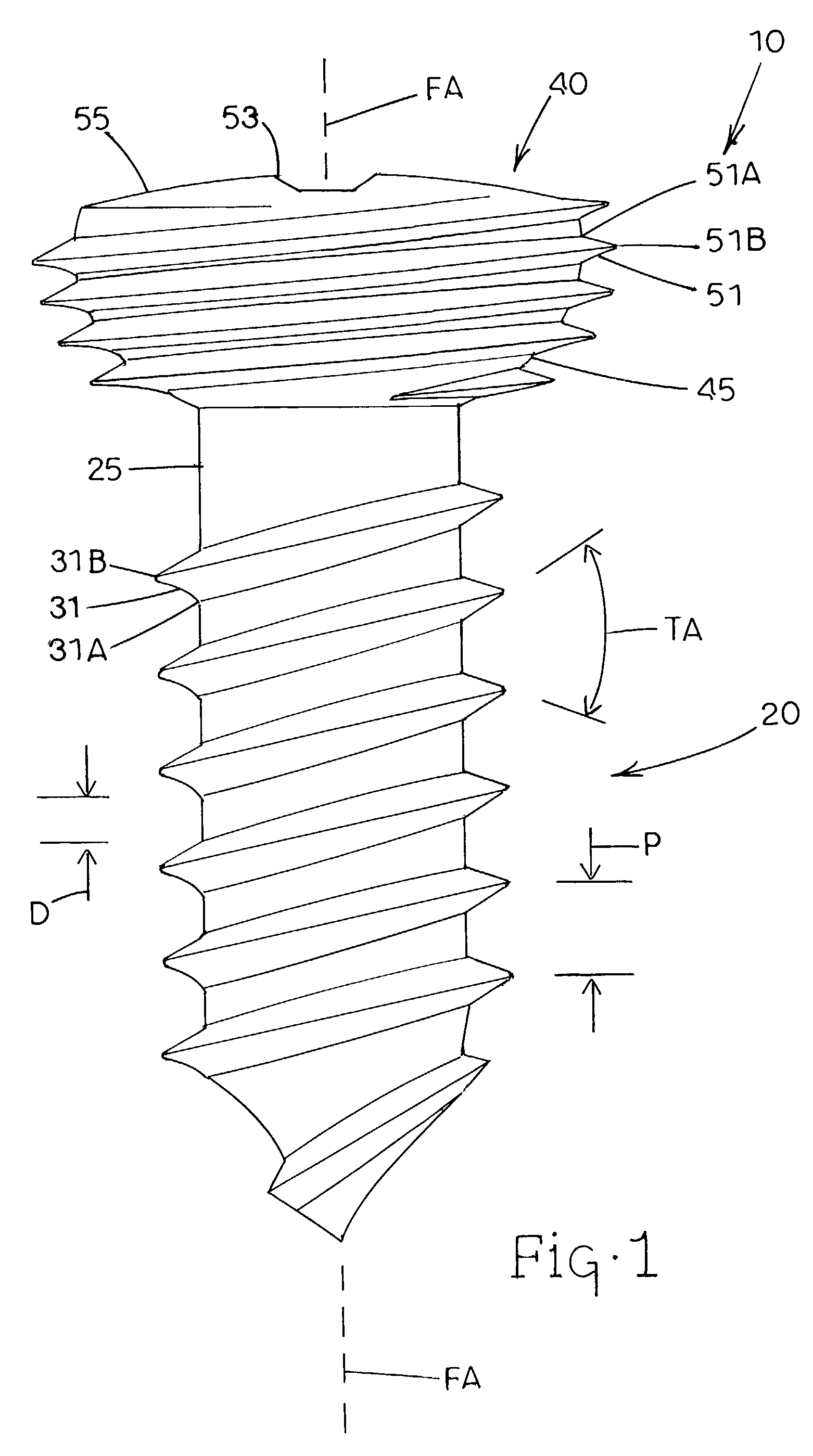

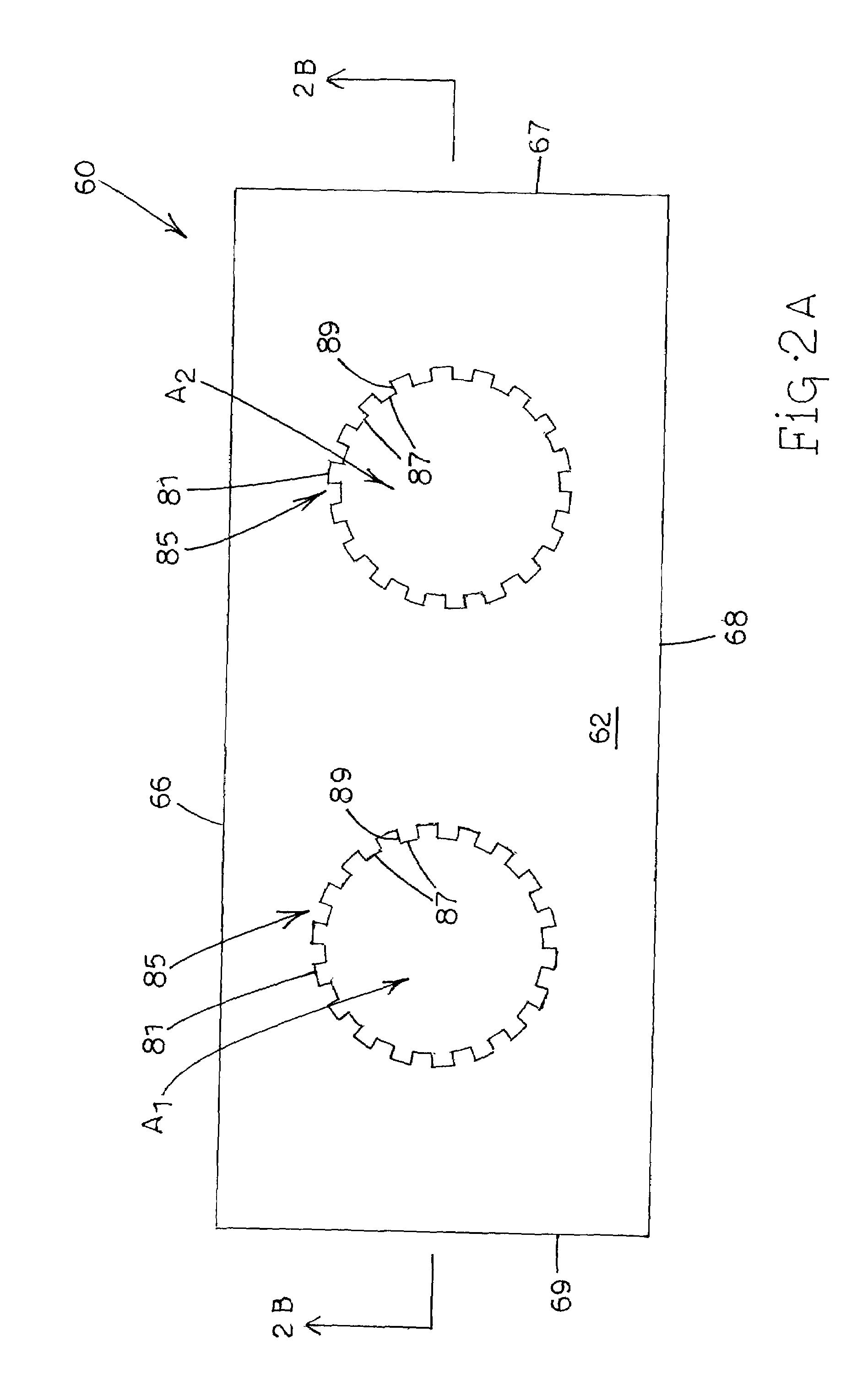

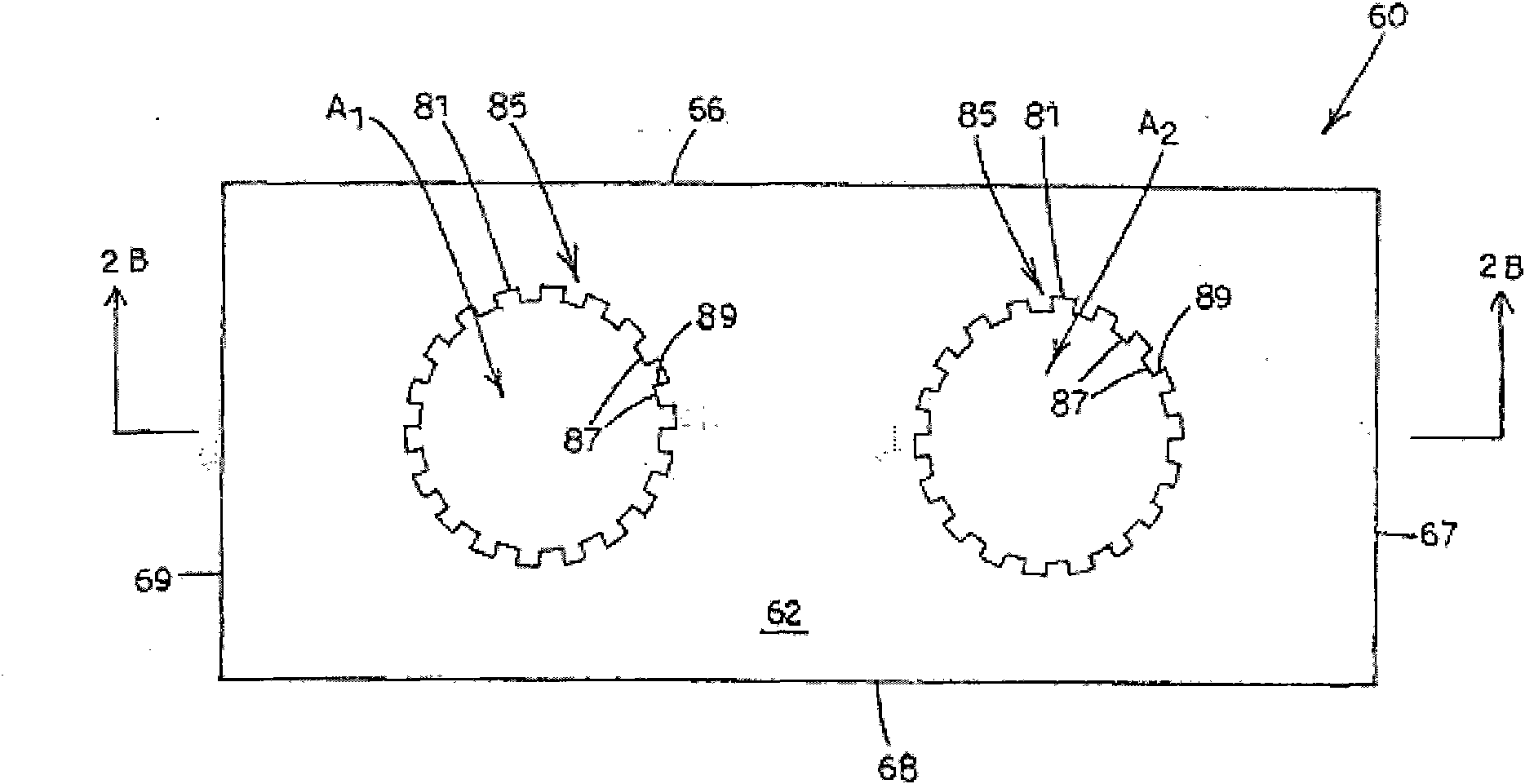

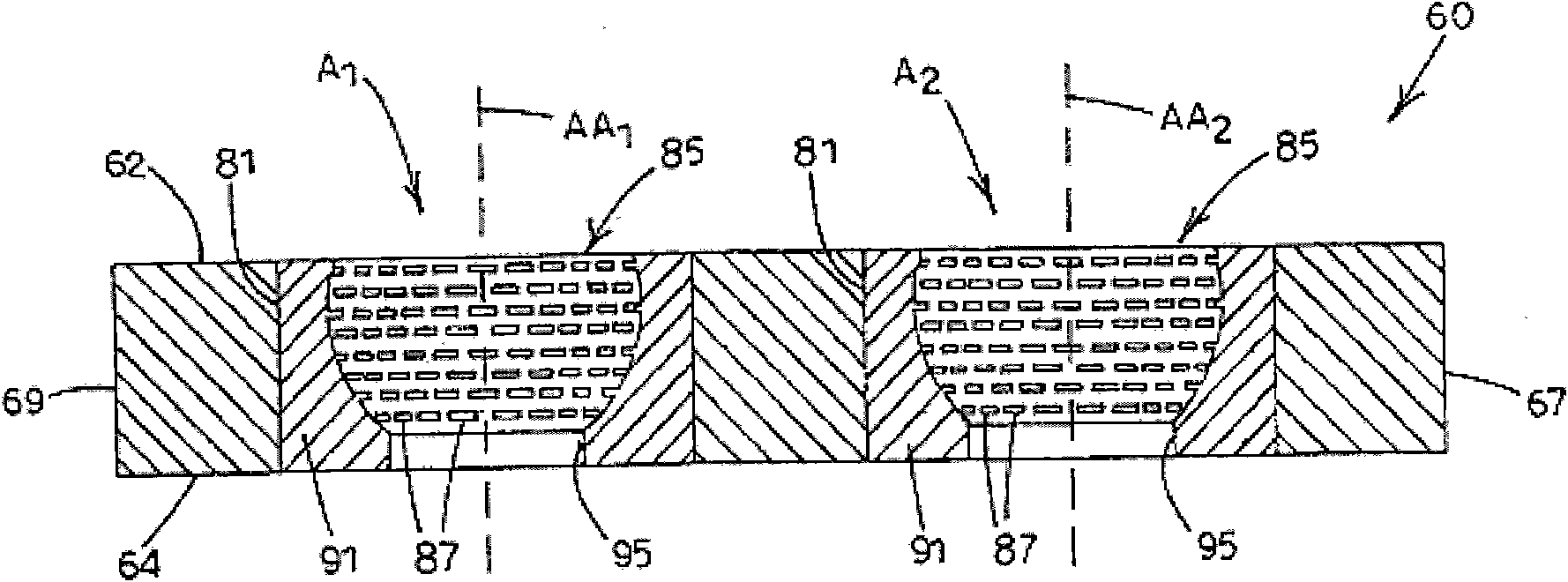

A fastening apparatus includes a fastener and a fastener receiving member. The apparatus enables the fastener to be affixed to the fastener receiving member at a variable insertion angle selected by the user. The fastener includes an elongate section and an adjoining head section. Both the elongate section and the head section are threaded. The fastener receiving member includes one or more apertures through which one or more corresponding fasteners can be inserted. Each aperture includes a contact region formed or disposed on an inside surface defining the aperture. The contact region includes a porous matrix of protrusions or fiber metal having a density and strength sufficient to render contact region tappable by the thread of the head section of the fastener. The thread on the head section is driven into the contact region at the selected insertion angle. As a result, the thread of the head section taps into the material of the contact region such that the fastener is affixed to the fastener receiving member and maintained at the insertion angle.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

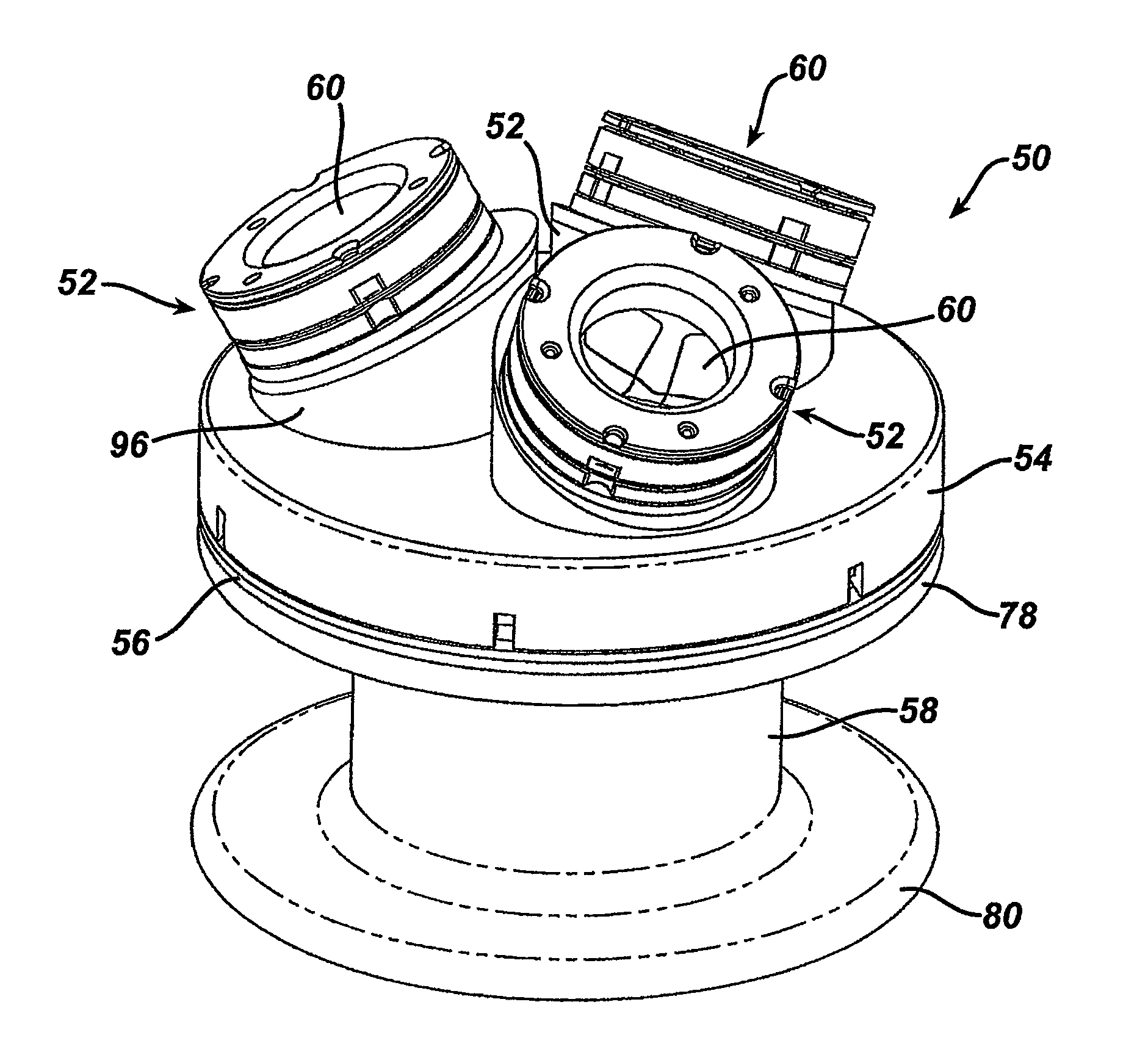

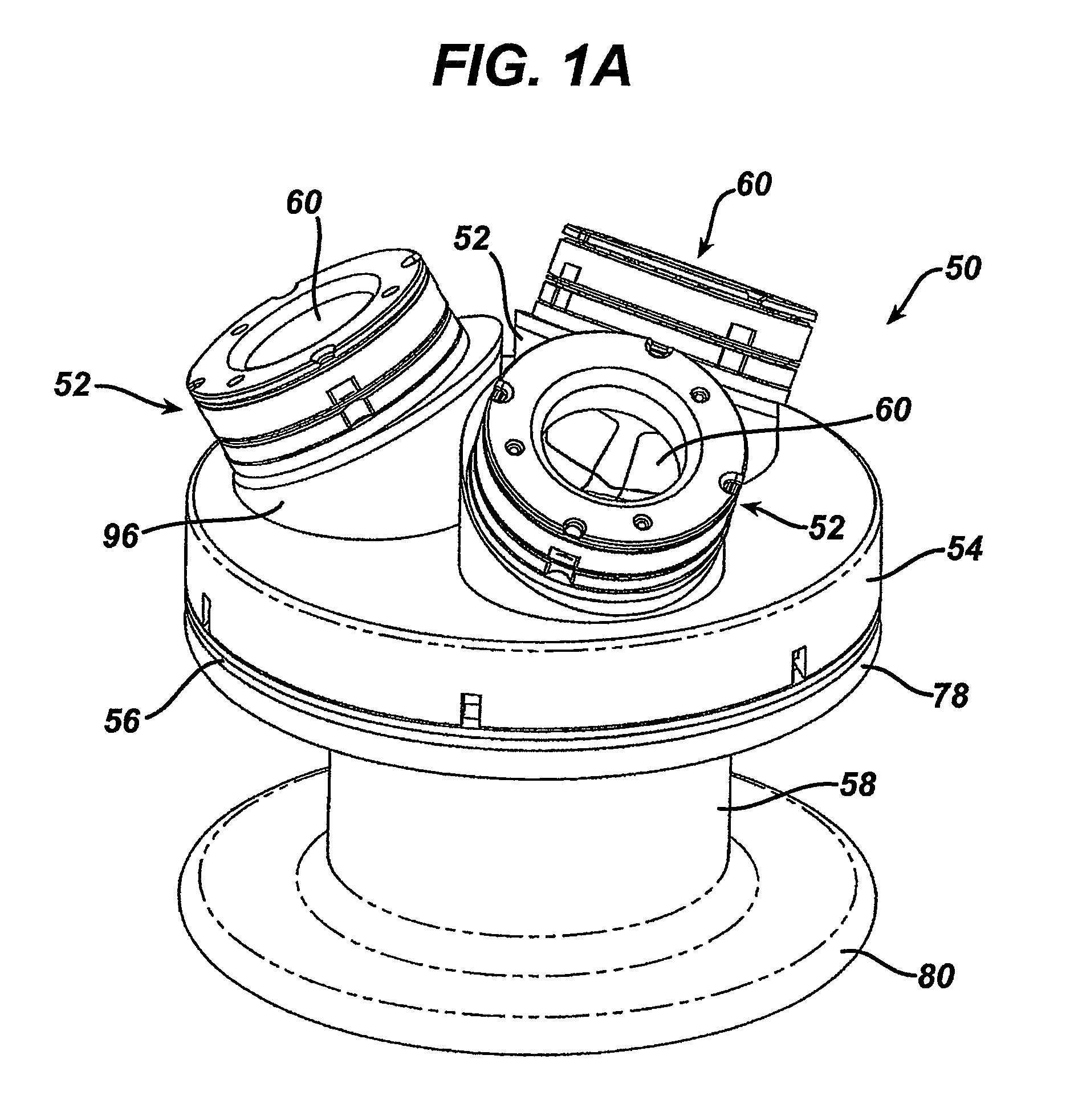

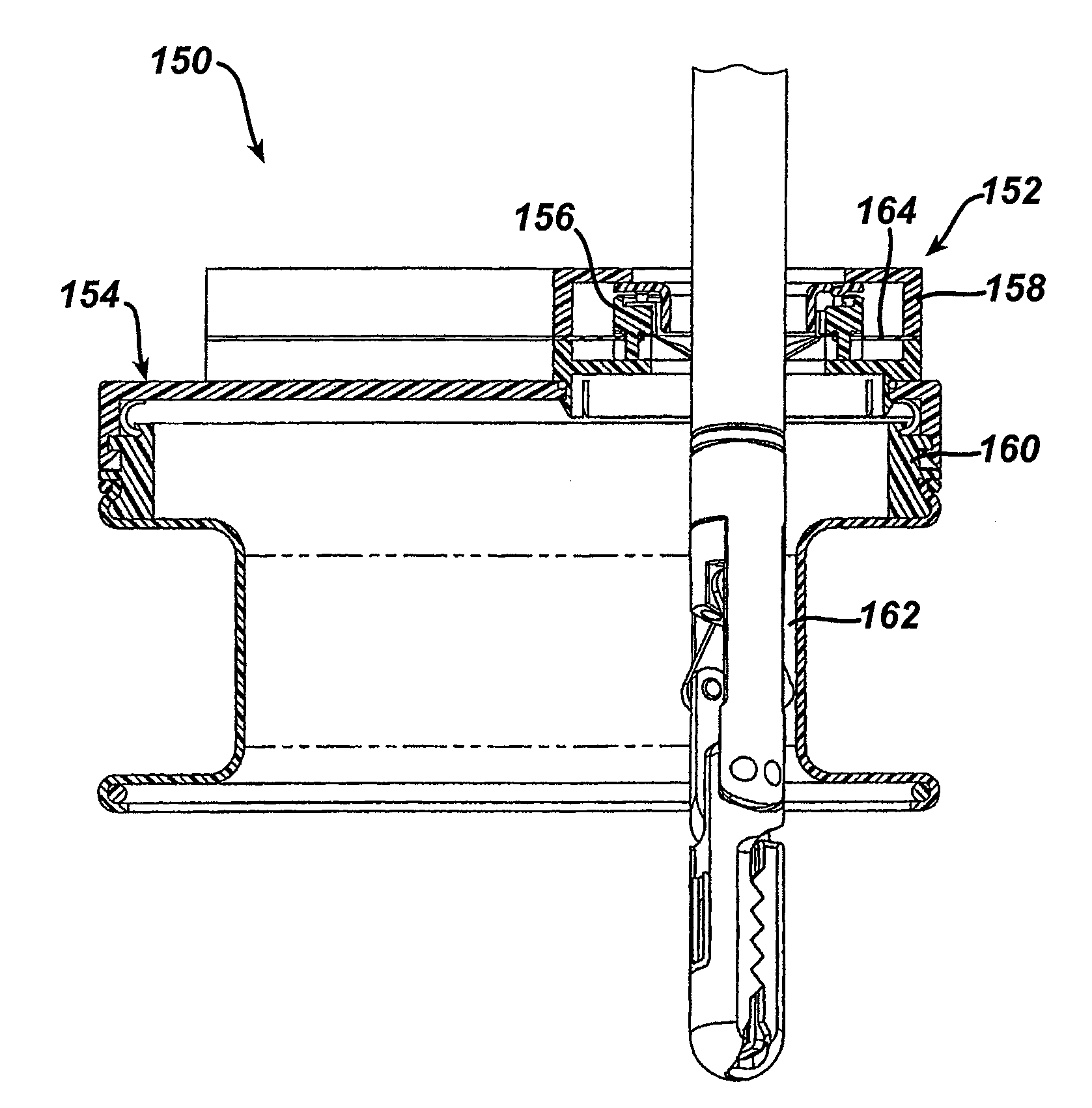

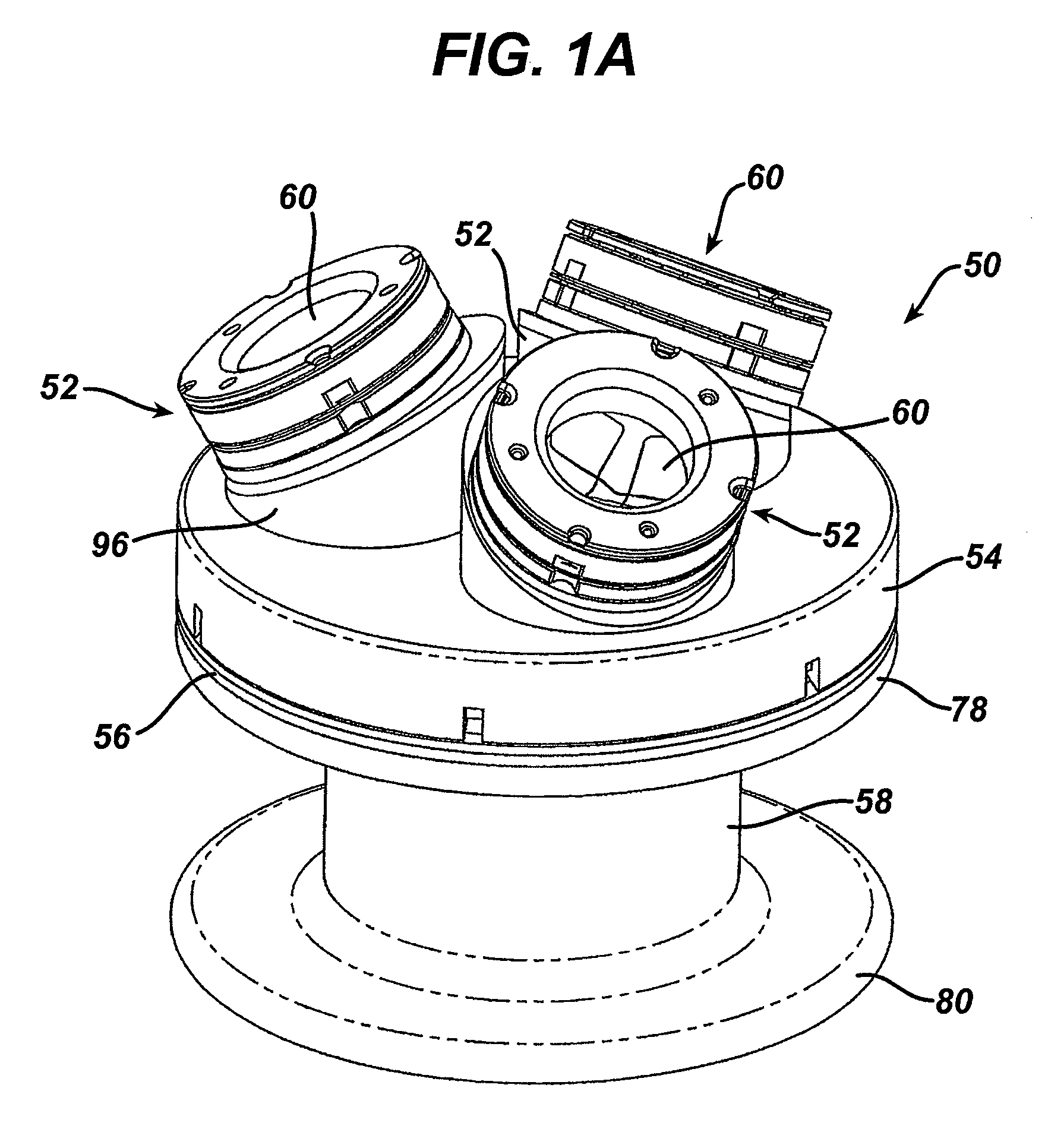

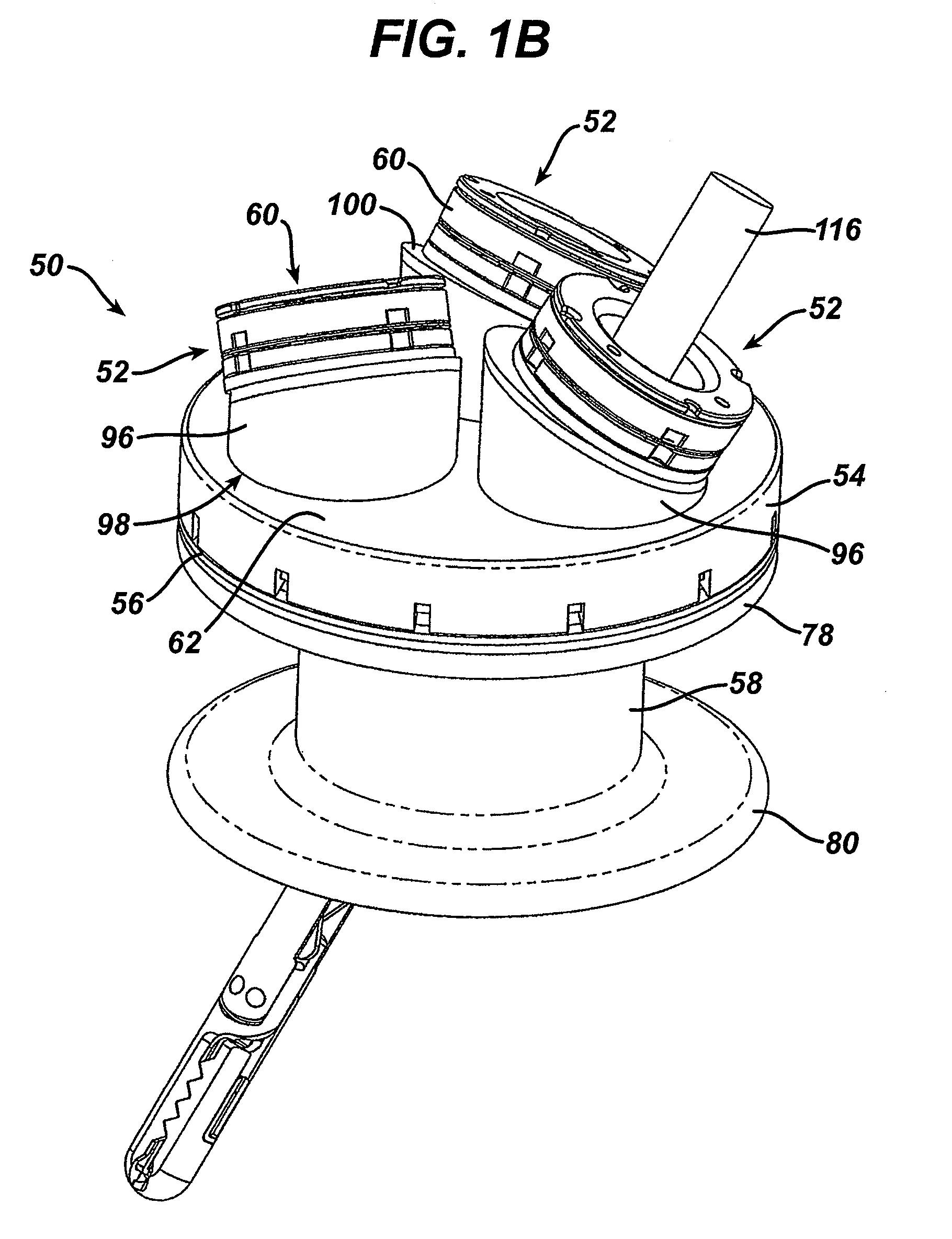

Multiple port surgical access device

Various devices are provided for allowing multiple surgical instruments to be inserted through a single surgical access device at variable angles of insertion, allowing for ease of manipulation within a patient's body while maintaining insufflation. Safety shields and release mechanisms are also provided for use with various surgical access devices.

Owner:CILAG GMBH INT

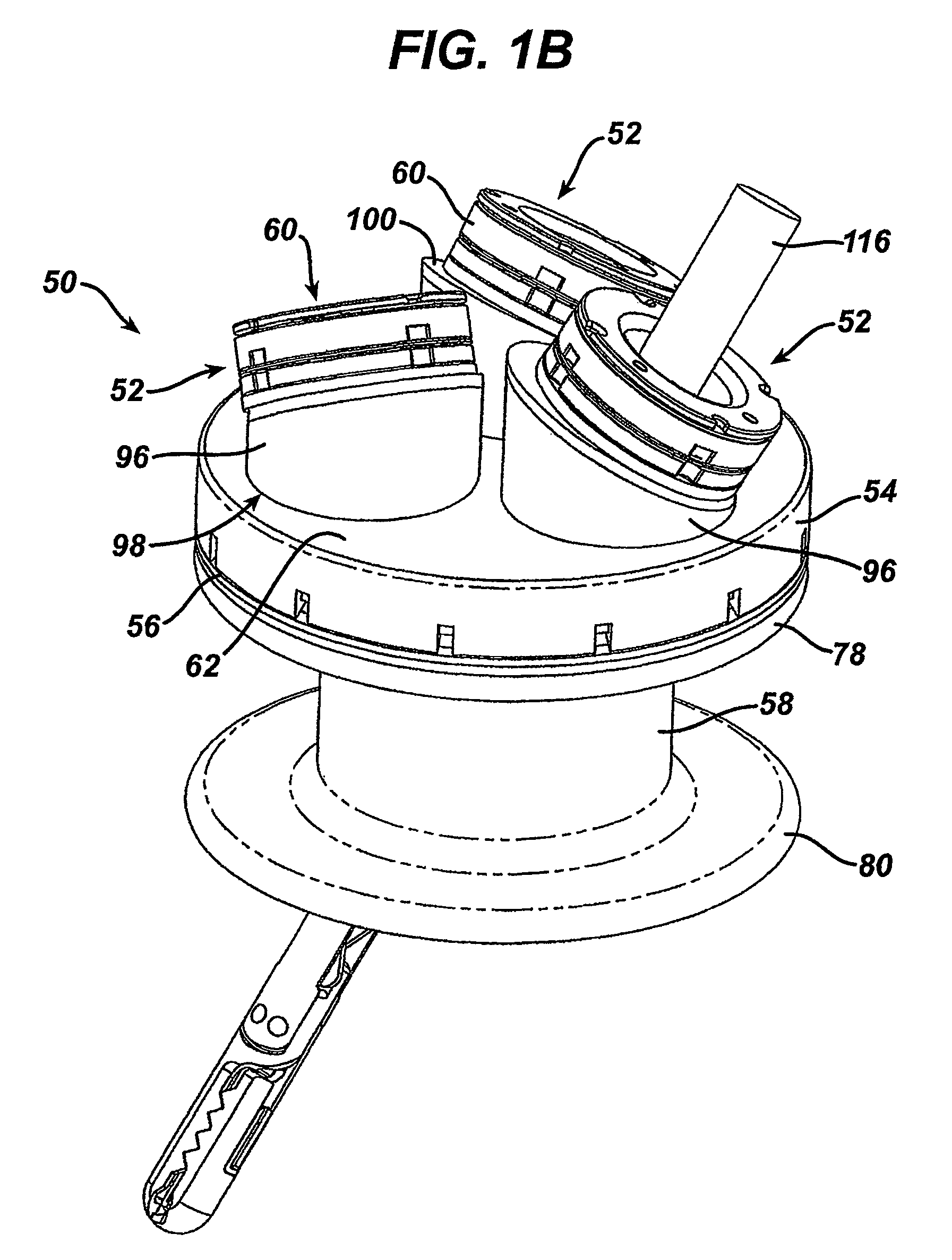

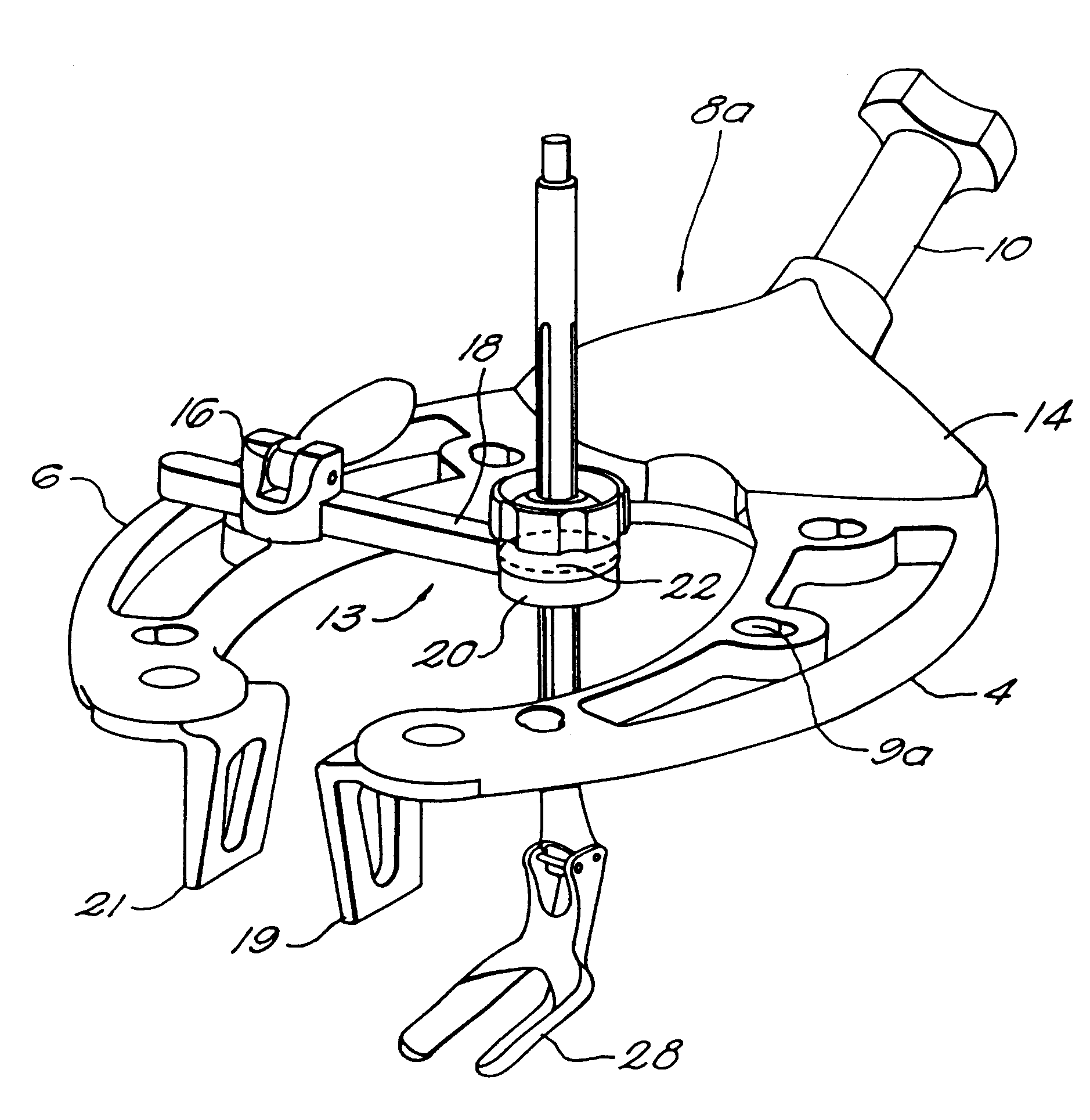

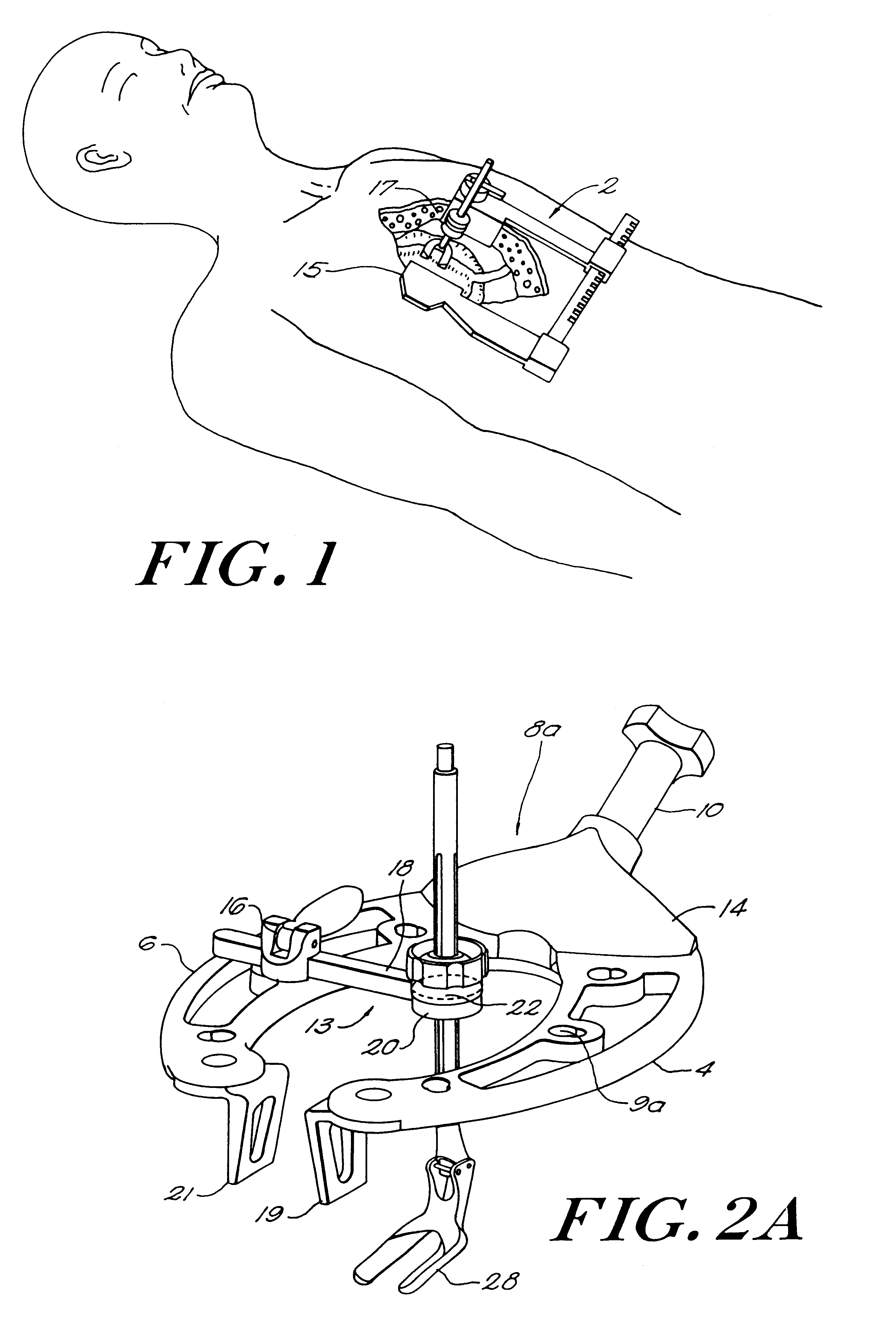

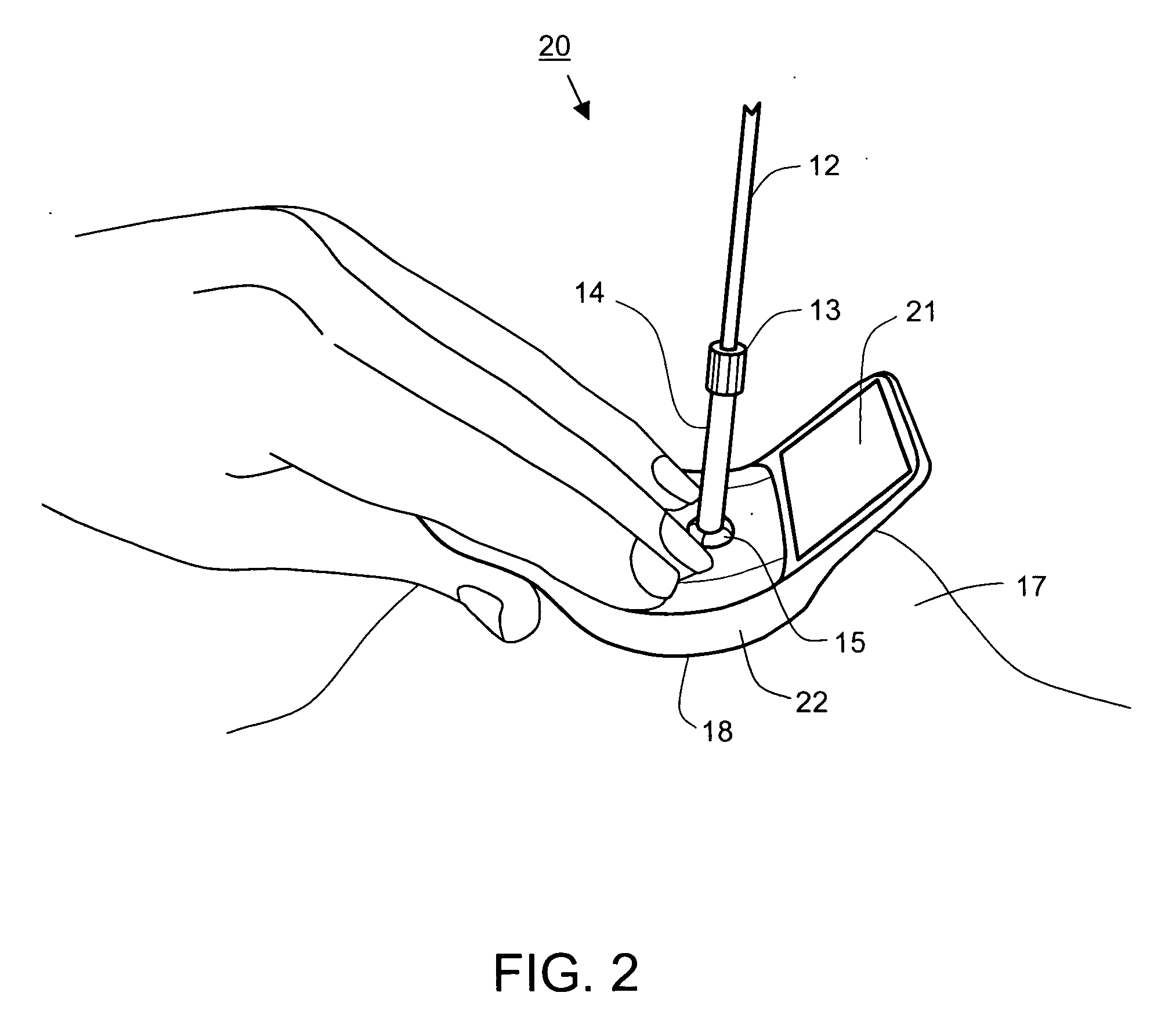

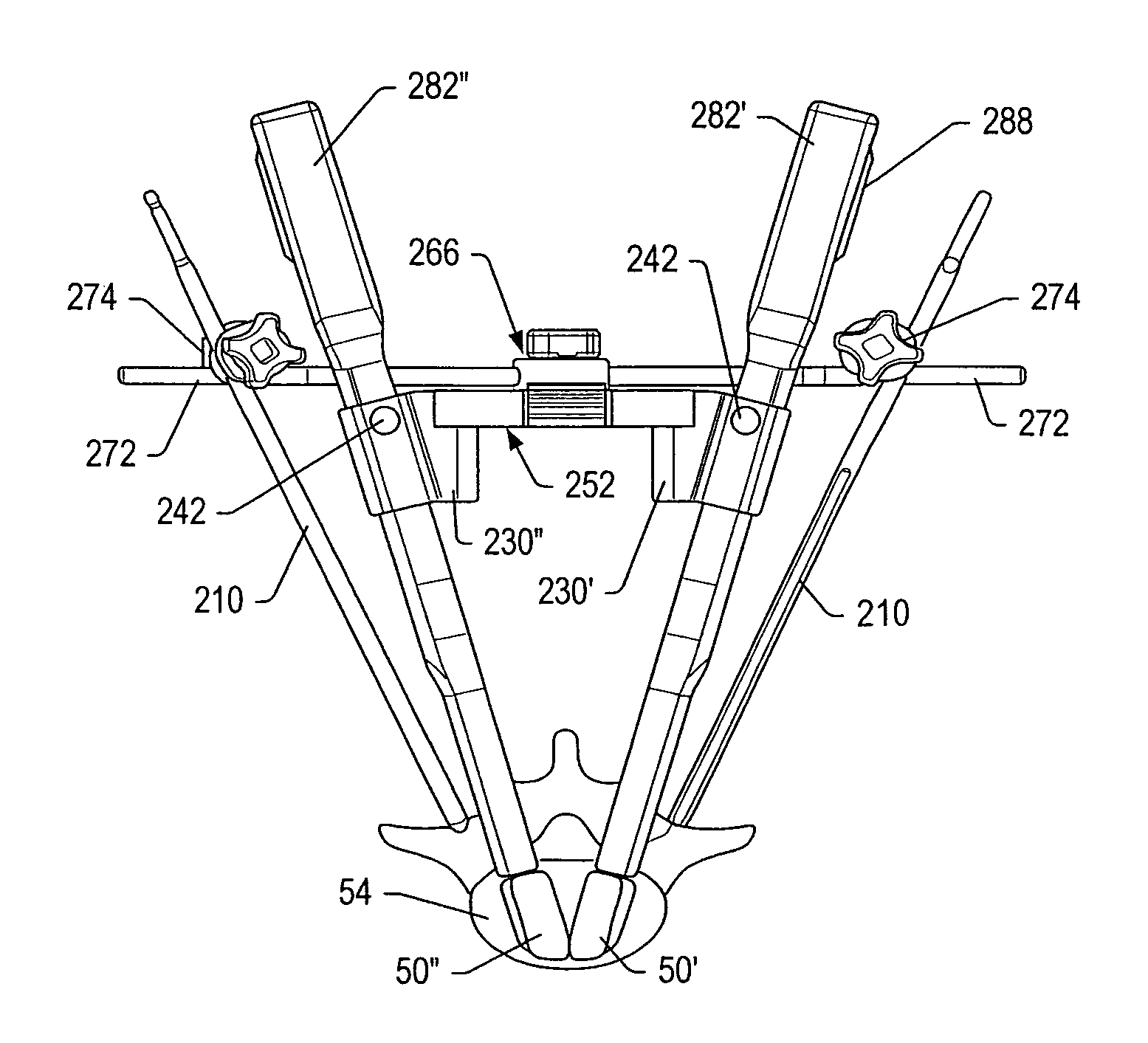

Minimally invasive surgical apparatus

The present invention encompasses tools and a tool-holding retractor assembly. The retractor assembly spreads an incision and holds the incision open. At least one extension device, having a tool holder on one end, attaches to the assembly. The holder includes a selectively locking multi-axis adjustable mounting element adapted to grip a tool shaft. The mounting element acts as a universal mounting providing rotational and sliding movement of the tool shaft. The extension device adjusts to position the tool holder peripherally of the surgical field. Once the retractor is placed, the extension device provides full access to regions below the incision. The extension device allows the surgeon to chose the insertion point and insertion angle of the tool shaft.

Owner:SMITH & NEPHEW INC +1

Multiple Port Surgical Access Device

ActiveUS20100081882A1Protection from damageCannulasInfusion syringesInsertion angleSurgical department

Various devices are provided for allowing multiple surgical instruments to be inserted through a single surgical access device at variable angles of insertion, allowing for ease of manipulation within a patient's body while maintaining insufflation. Safety shields and release mechanisms are also provided for use with various surgical access devices.

Owner:CILAG GMBH INT

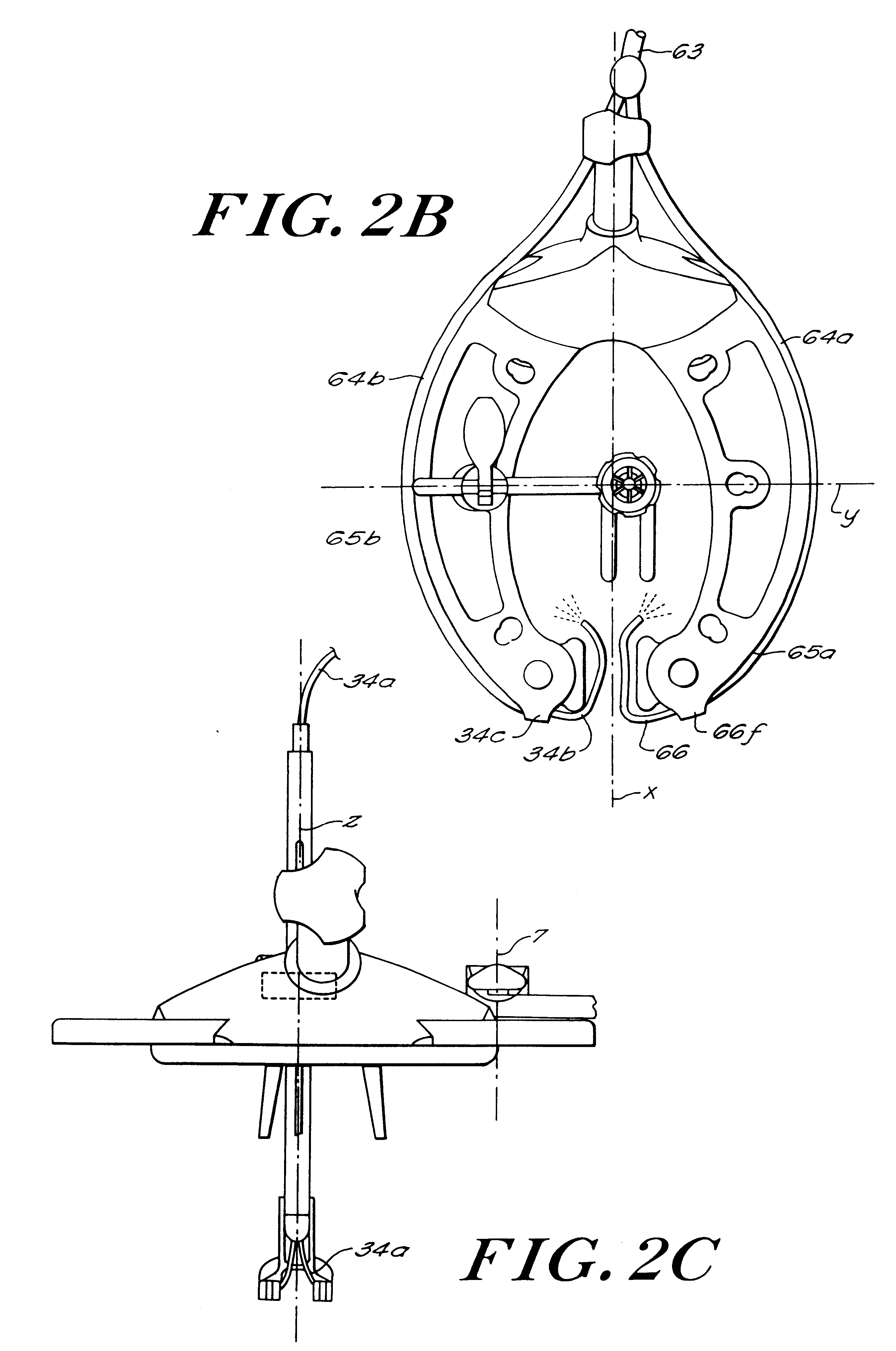

Device and method for biopsy guidance using a tactile breast imager

InactiveUS20040267121A1Provide real-timeIncreased sensitivity and repeatability and accuracyUltrasonic/sonic/infrasonic diagnosticsSurgical needlesBiopsy procedurePressure sense

A biopsy guidance device is enclosed based on a tactile imaging probe adapted to accept a biopsy gun. The tactile imaging probe includes a pressure sensing surface providing real-time 2-D images of the underlying tissue structures allowing to detect a lesion. A cannula is provided supported at a center point by a ball and socket joint. The joint is equipped with linear and angular sensors and supports the cannula with the ability to rotate thereof about the center point. The position, linear and angular displacement and direction of the needle tip of a biopsy needle placed inside the cannula is therefore known at all times and provided as a feedback signal to a physician. Also provided to a physician is a position of the target site at a lesion, as well as a linear and angular deviation of the needle tip away from the target site. Such audio, light, or visual feedback allows the physician to correct the insertion angle and depth to confidently reach the target site to perform a biopsy. Method is also disclosed to guide the biopsy procedure.

Owner:ARTANN LAB

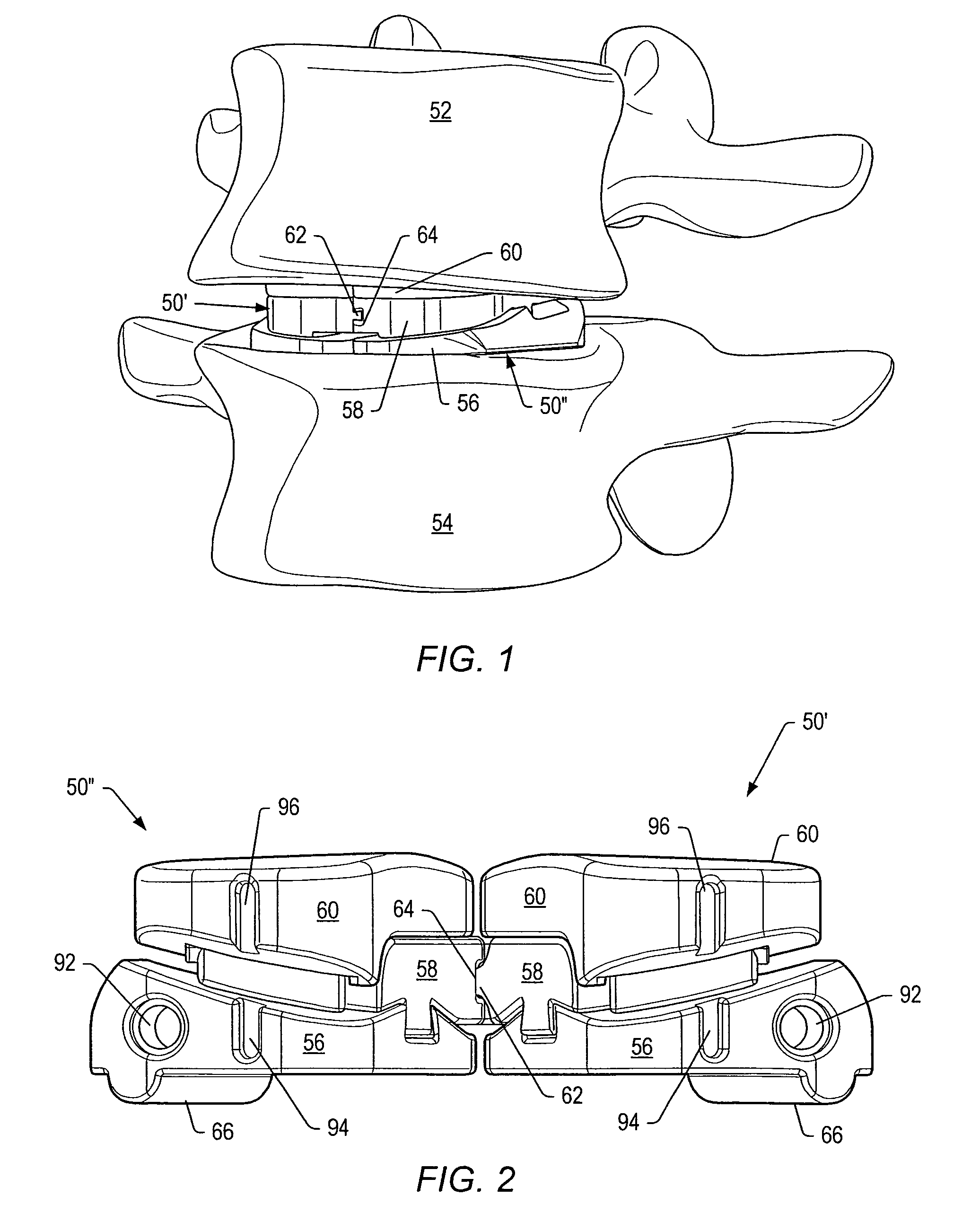

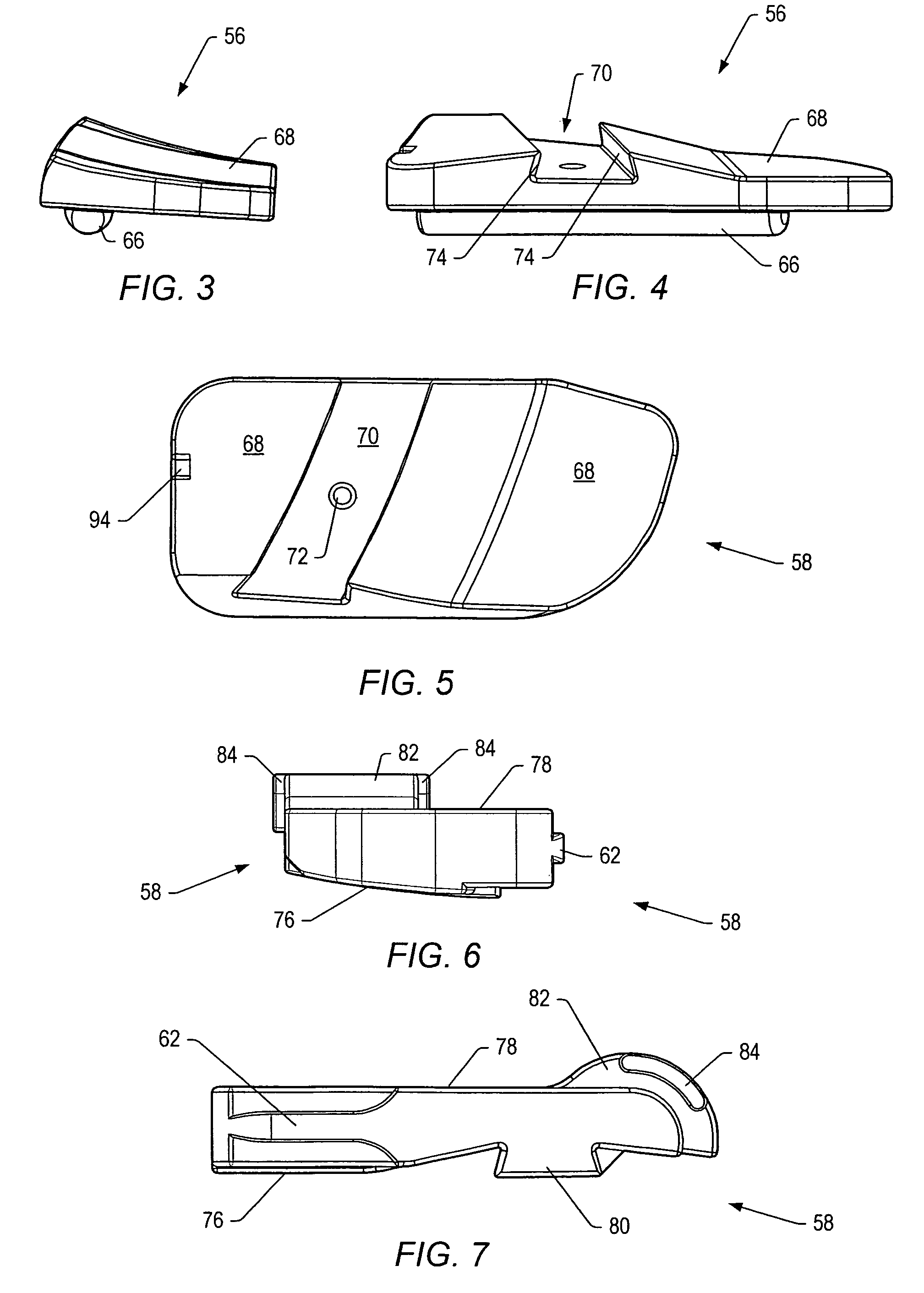

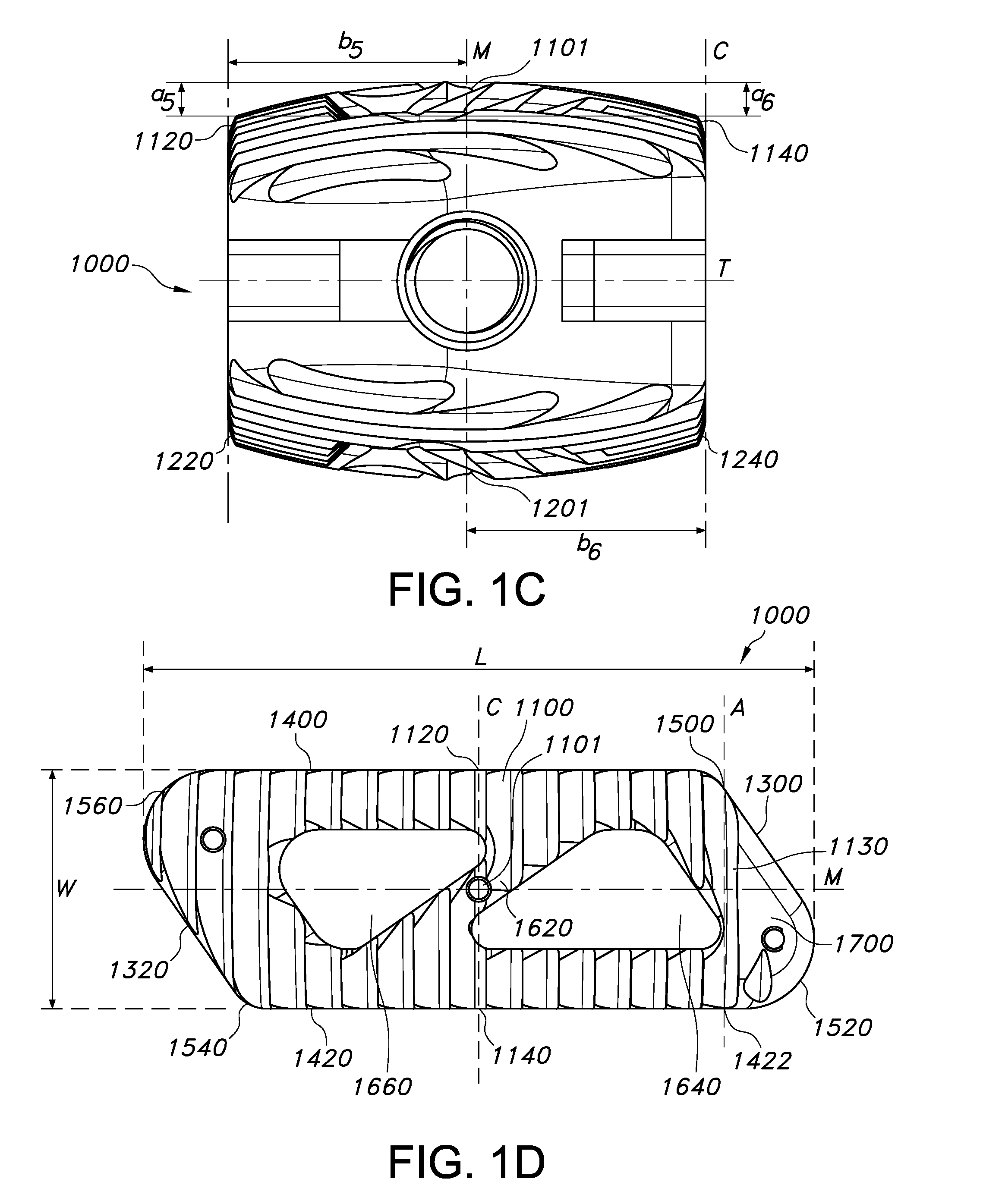

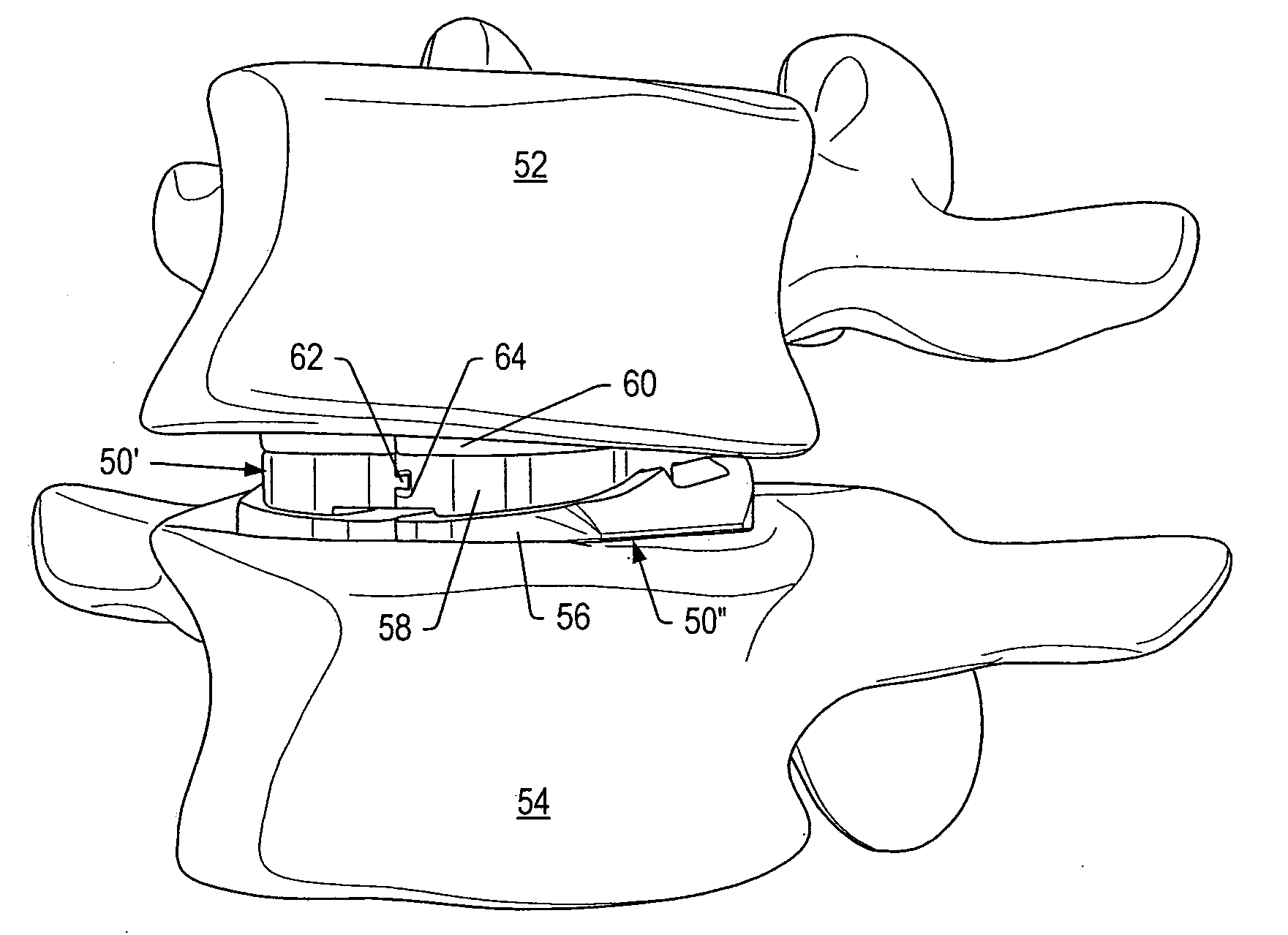

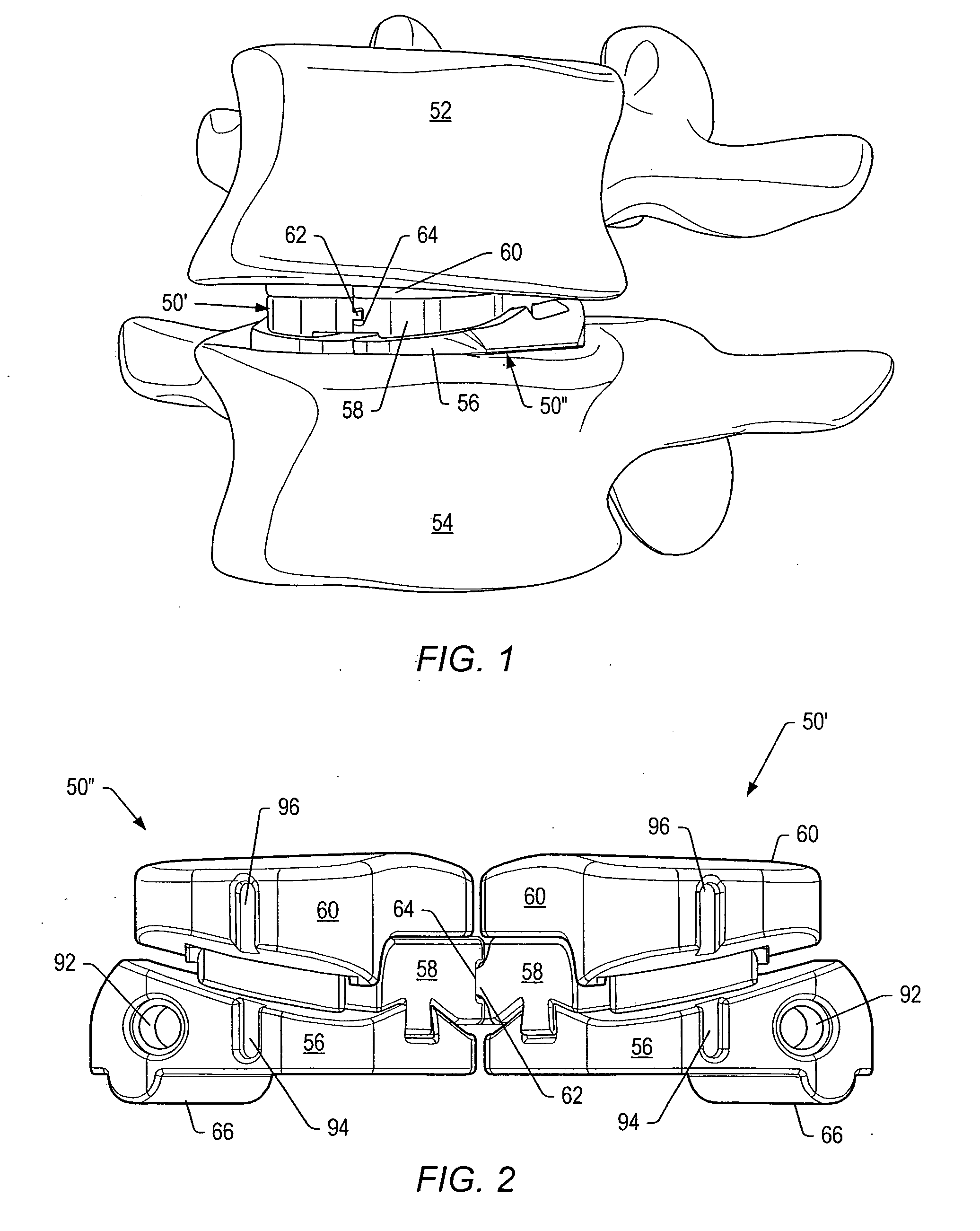

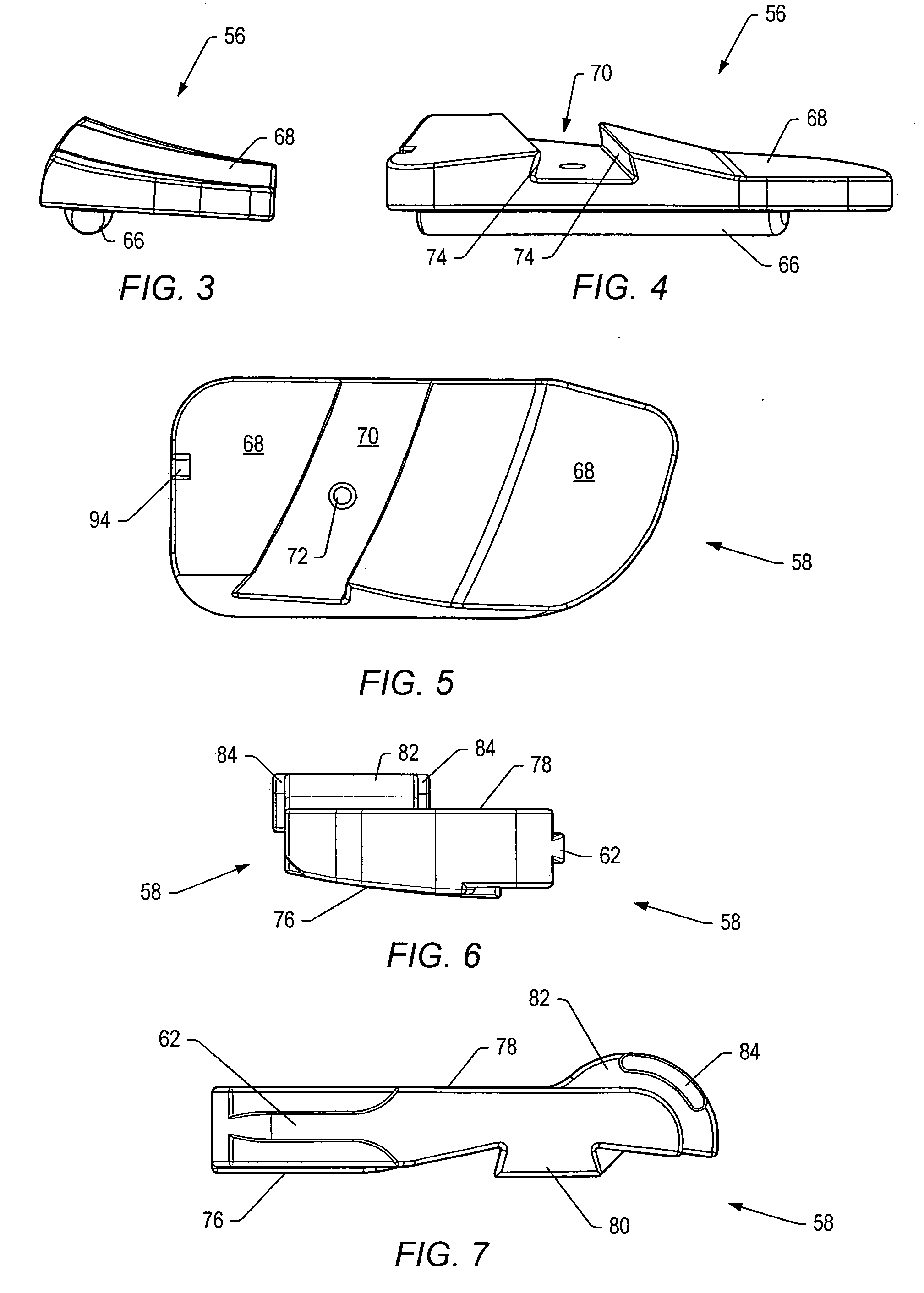

Artificial functional spinal unit system and method for use

Insertion methods for placing dynamic interbody devices between a first vertebra and a second vertebra using a posterior approach are provided. In an embodiment, the insertion method may be based on the first vertebra. A bridge assembly may be attached to tap shafts positioned in the first vertebra. The bridge assembly may establish an insertion angle of implants into a disc space between the vertebrae. In an embodiment, the insertion method may be based on the position of expandable trials positioned between the vertebrae. The trials may be positioned and a bridge assembly may be coupled to the expandable trials and taps positioned in the first vertebra. One or more posterior stabilization systems may be coupled to the vertebrae after insertion of the dynamic interbody devices between the vertebrae.

Owner:FLEXUSPINE INC

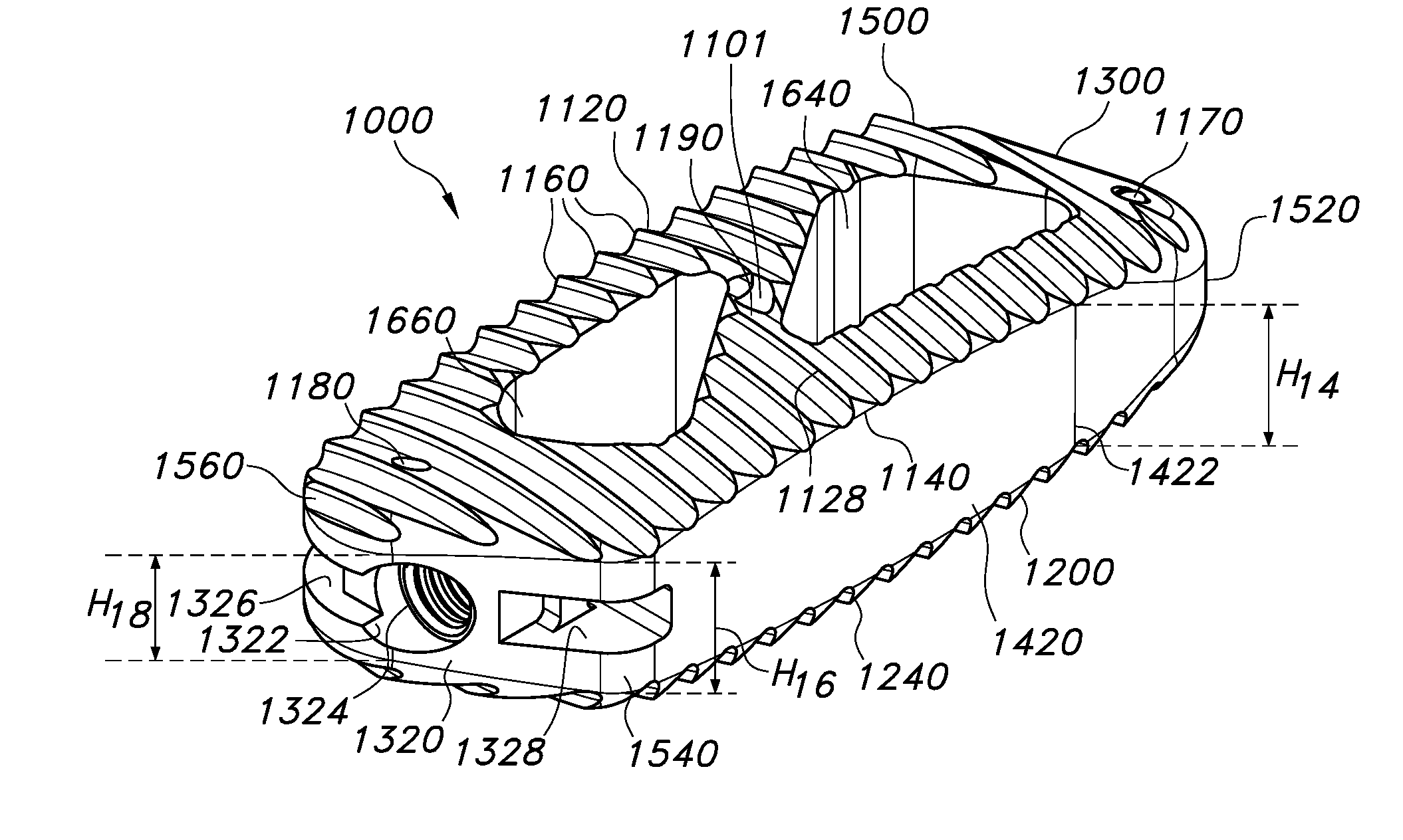

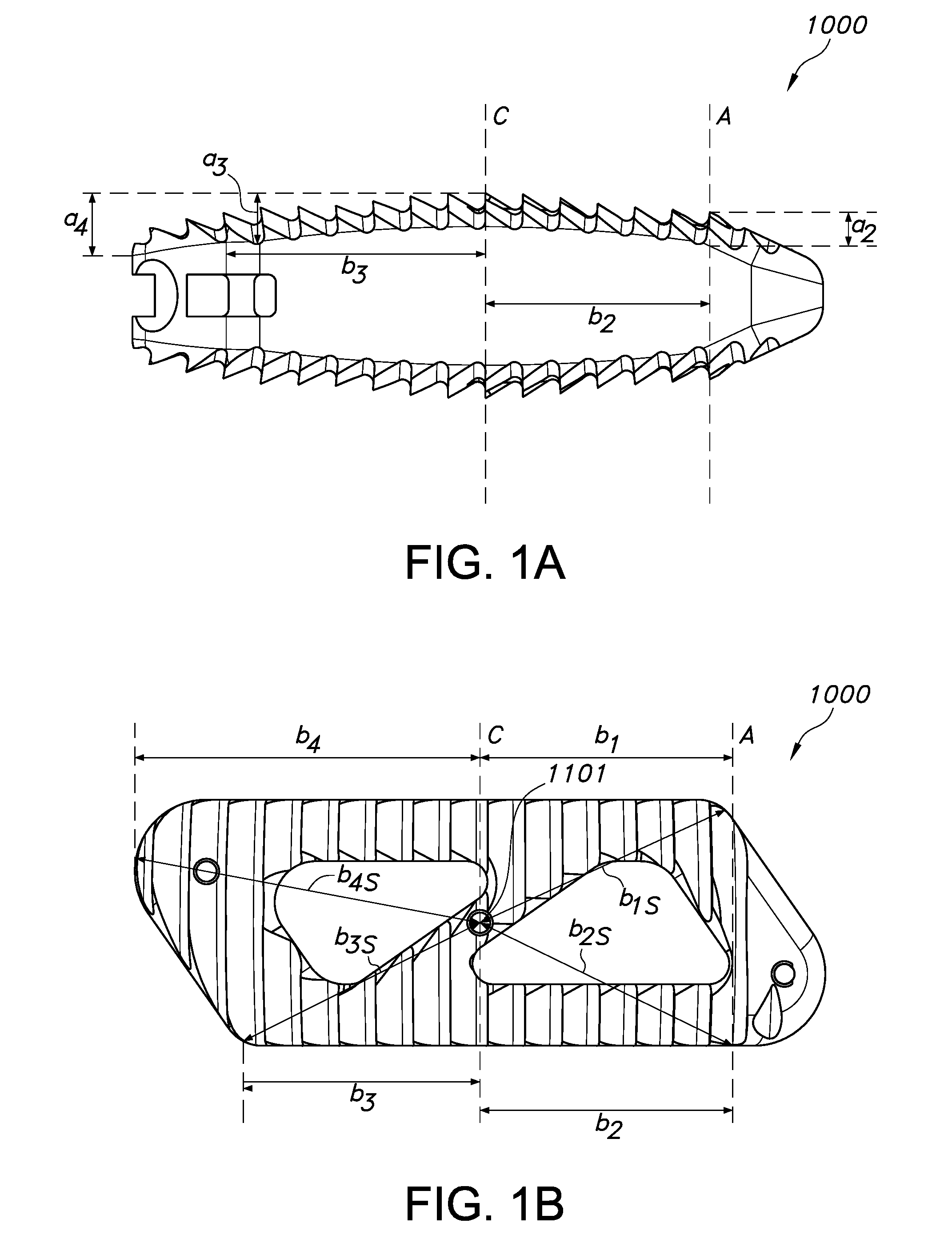

Spinal fusion implant for oblique insertion

Intervertebral spinal fusion implants for interbody fusion of the anterior column of the spine are described. The implants have a substantially bi-convex or a substantially offset bi-convex shape. The implants are placed through a transforaminal or posterior approach at an oblique insertion angle. The implants have an outermost point on the superior convex surface and an outermost point on the inferior convex surface and four edges of differing heights. The outermost superior and inferior points of the implants are connected with the four edges with convex surfaces of different curvatures. The curvatures of the convex surfaces of the implants are designed to match the curvatures of concave vertebral surfaces when the implants are inserted at an oblique insertion angle.

Owner:CAMBER SPINE TECH

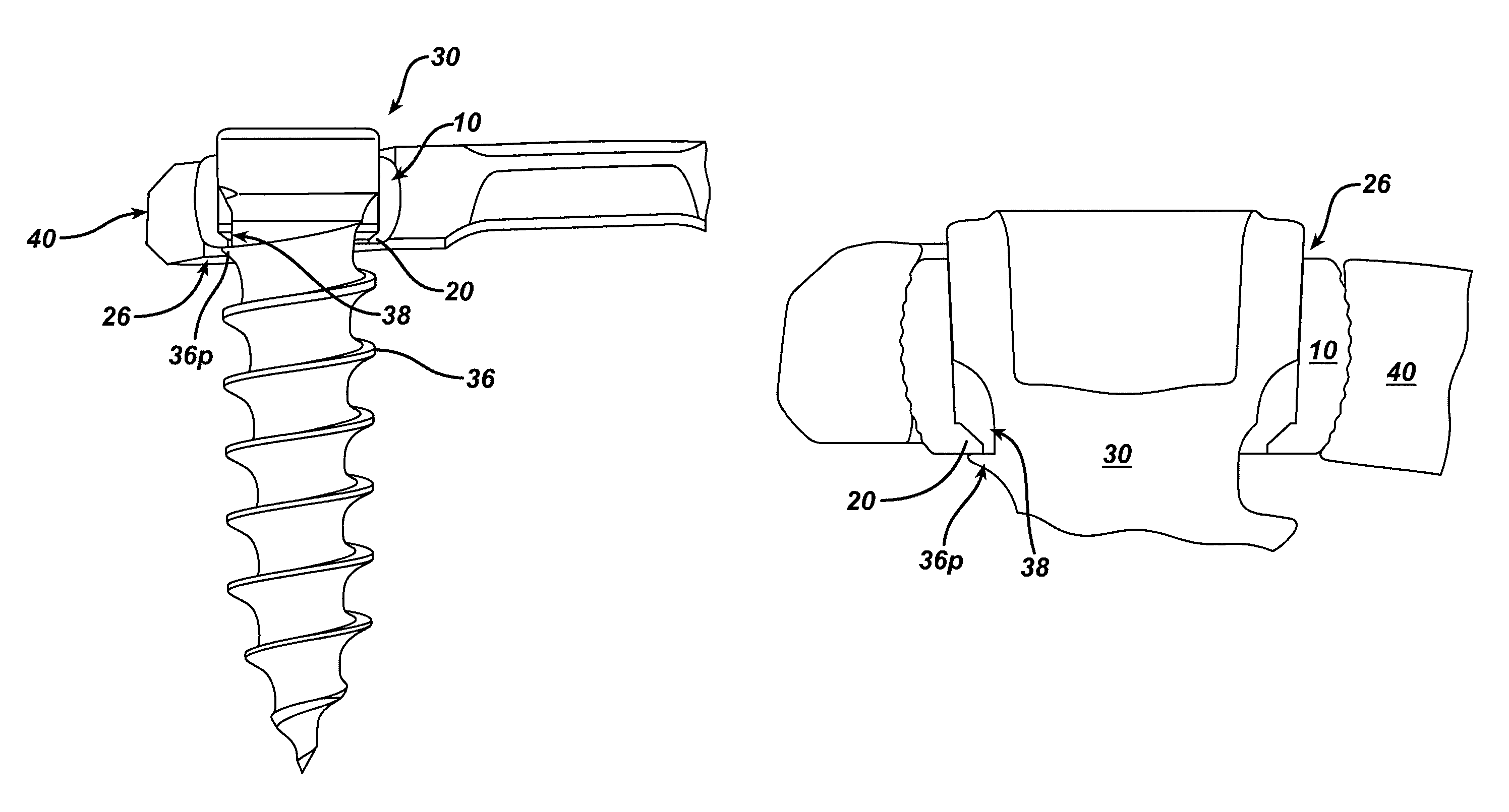

Passive Screw Locking Mechanism

ActiveUS20080243192A1Prevent exitSuture equipmentsInternal osteosythesisLocking mechanismEngineering

Methods and devices are provided for passively locking a bone screw within a bone plate. In particular, the methods and devices allow a bone screw to be locked within a thru-hole in a bone plate without requiring any additional locking steps. In an exemplary embodiment, an annular feature is provided in a thru-hole of a bone plate, or in a bushing that is disposed within a thru-hole of a bone plate, for engaging a bone screw. The annular feature can be configured such that it allows the bone screw to be inserted through the thru-hole at various insertion angles while still being effective to prevent back-out of the bone screw, thereby locking the screw to the plate.

Owner:DEPUY SYNTHES PROD INC

Bone Plate System

A bone plate system is provided that includes bone plates and bone anchor assemblies for being inserted into bone plate bores to secure the bone plates to one or more bones. In one aspect, the bone plate system includes a bone anchor assembly having a locking cap and a locking fastener connected to a head portion of a bone anchor. The bone anchor assembly is driven into a bone plate bore before the locking fastener is shifted to expand the locking cap and fix the bone anchor assembly within the bore. In another aspect, the bone plate system includes a bone anchor assembly having a locking cap that deflects radially inward due to contact with the bone plate at large bone anchor assembly insertion angles. In addition, a bone anchor assembly having a preassembled condition with a locking cap resisting back out of a locking fastener.

Owner:PIONEER SURGICAL TECH INC

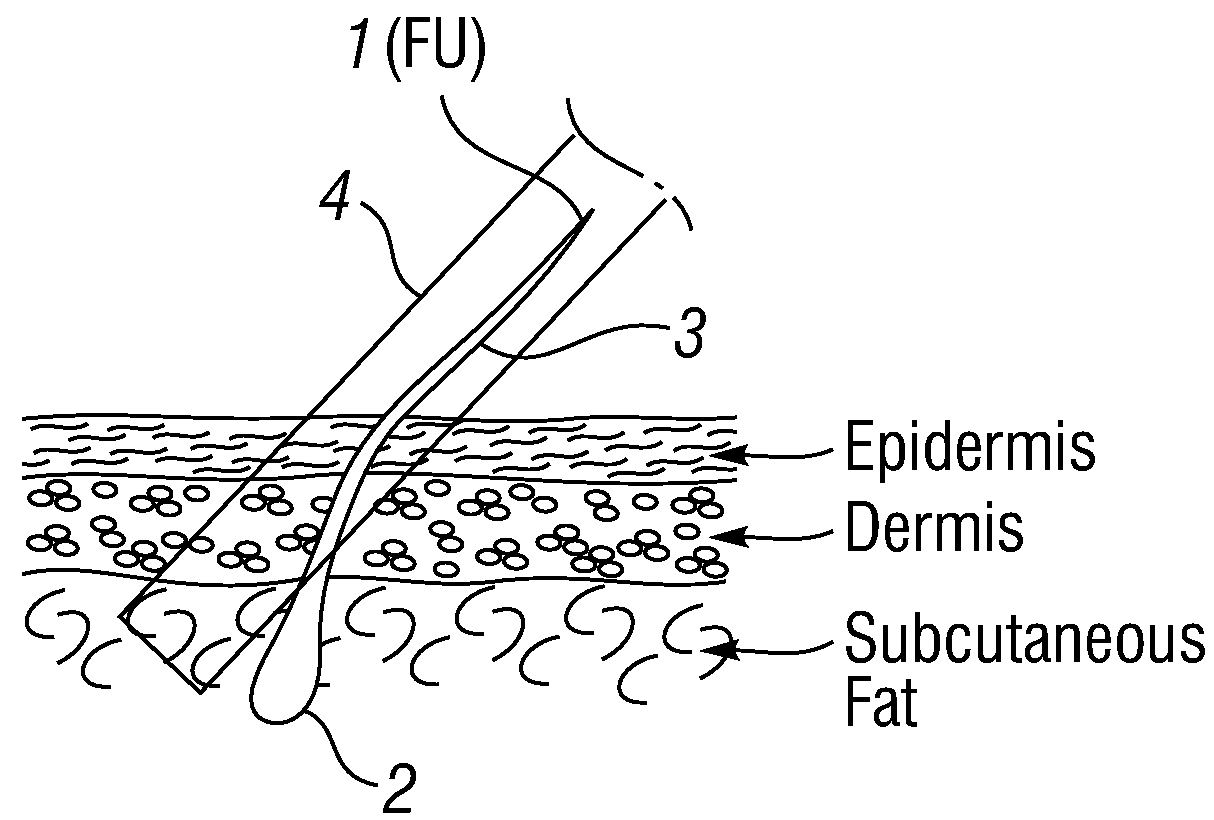

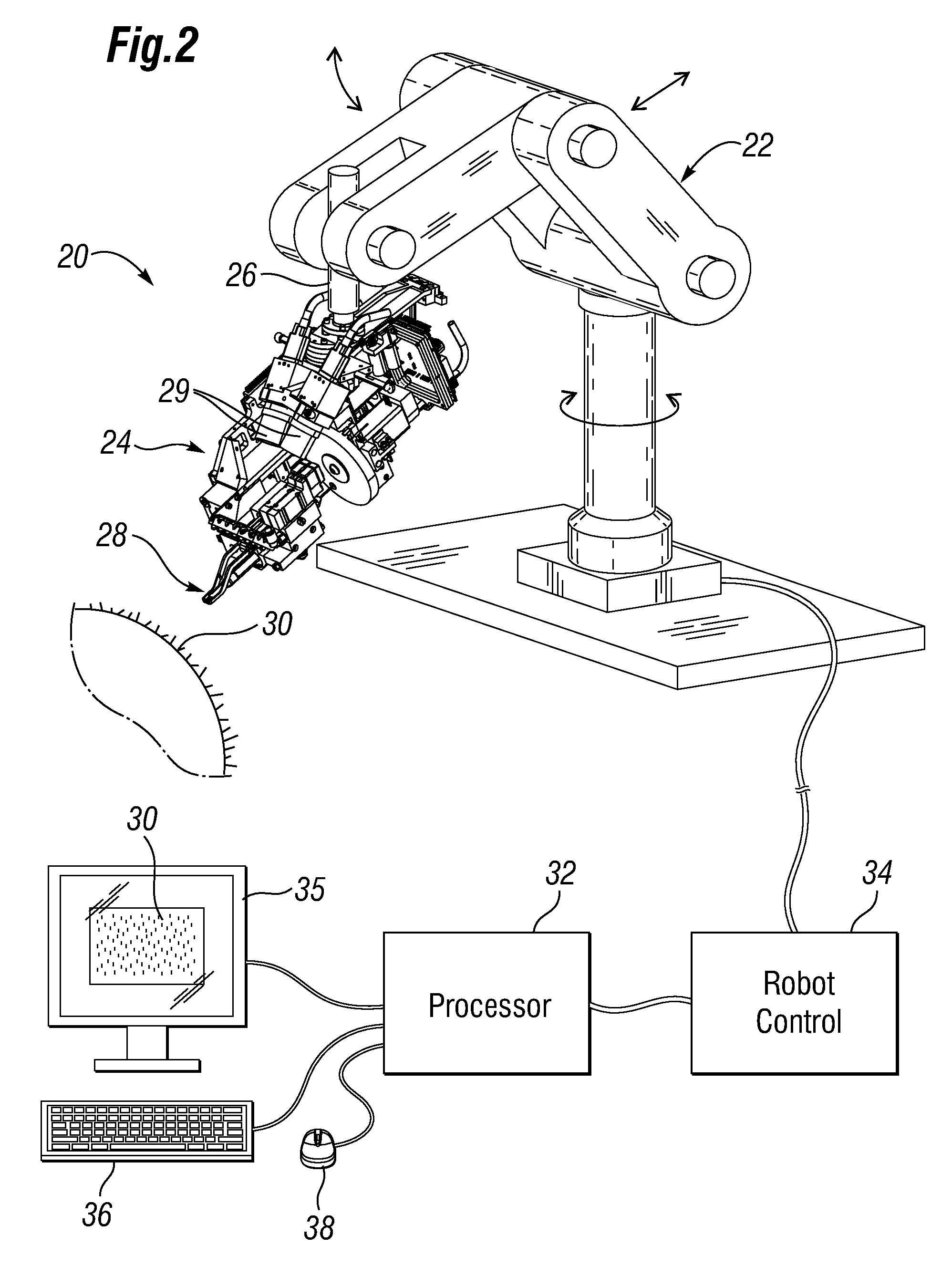

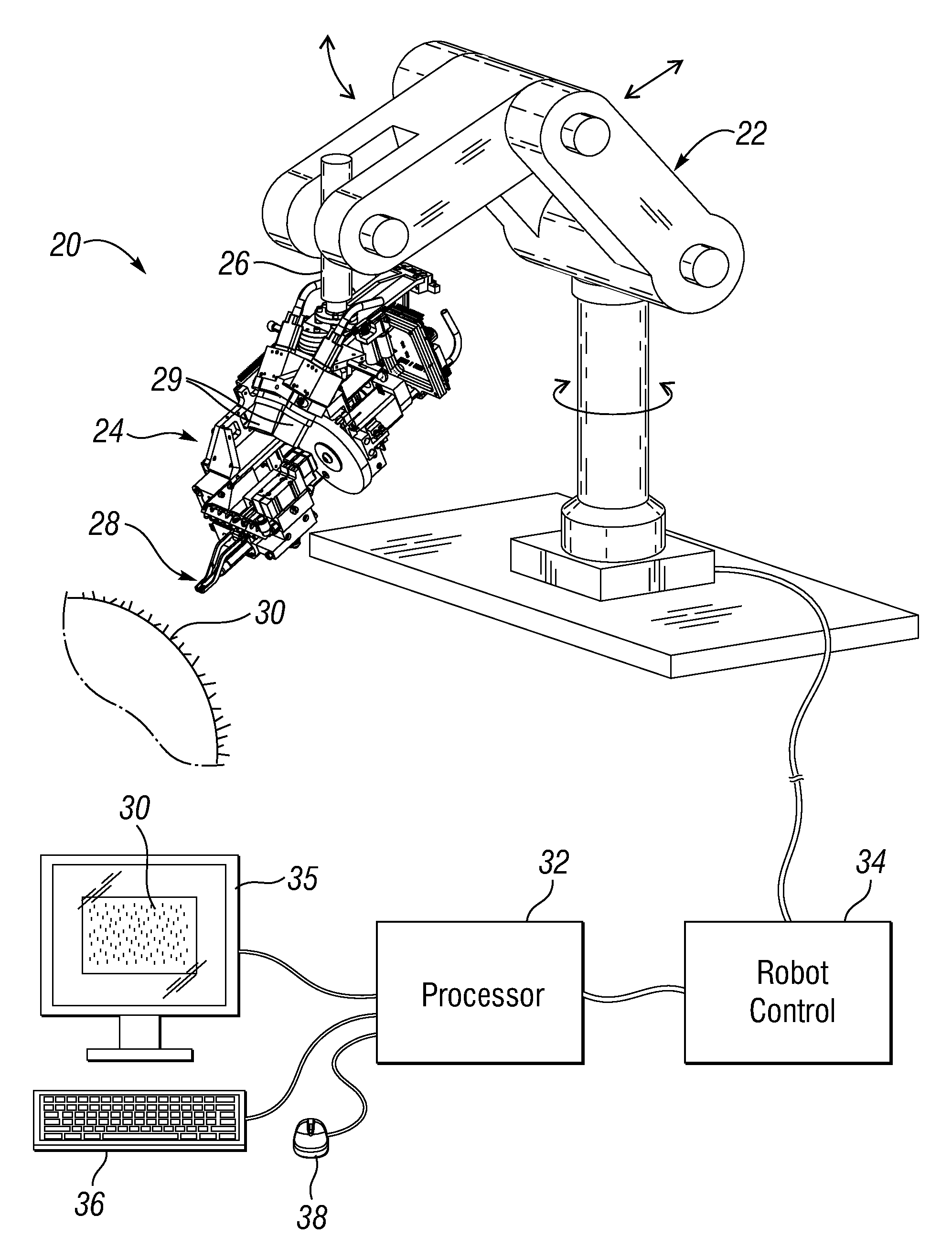

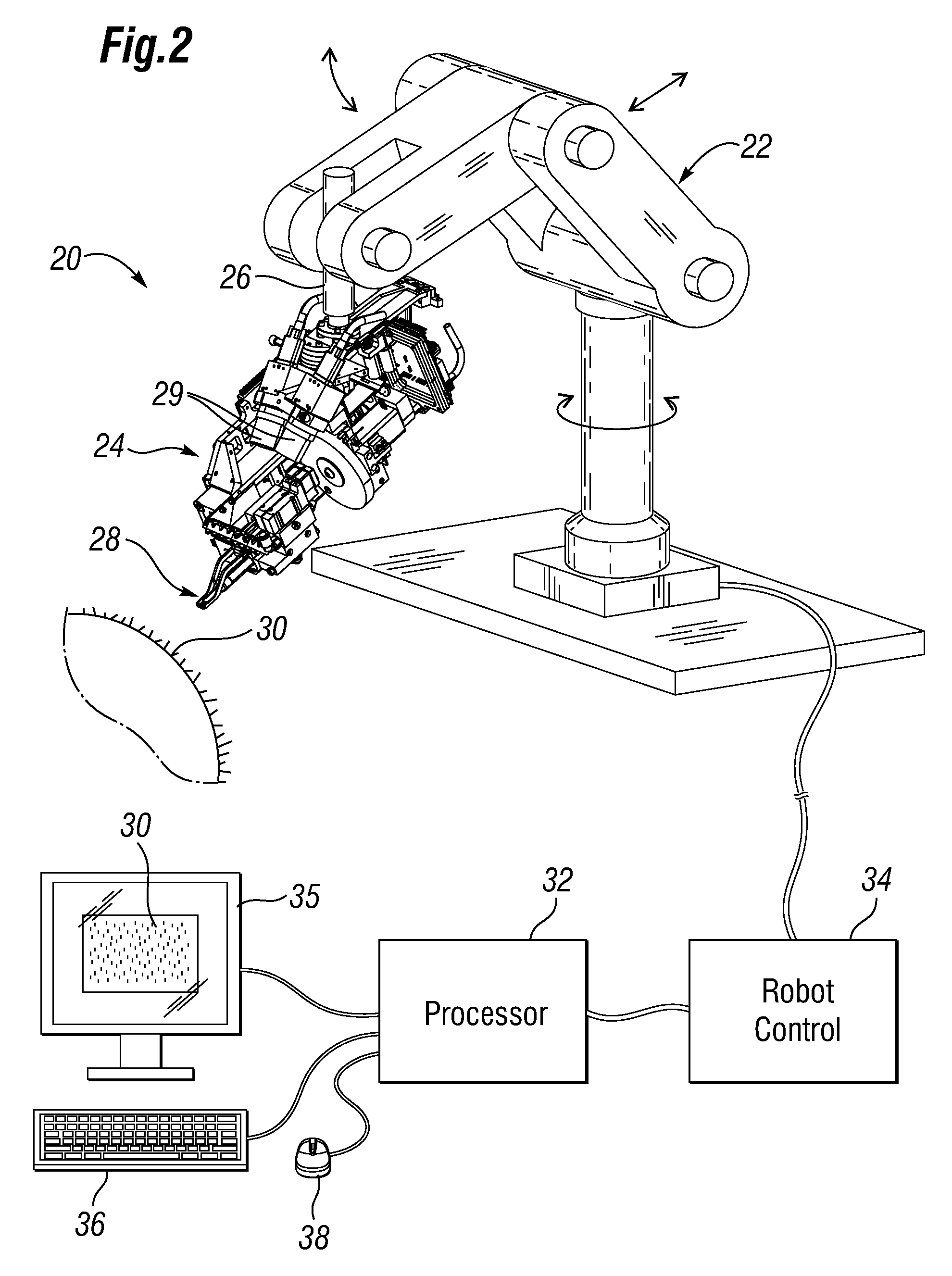

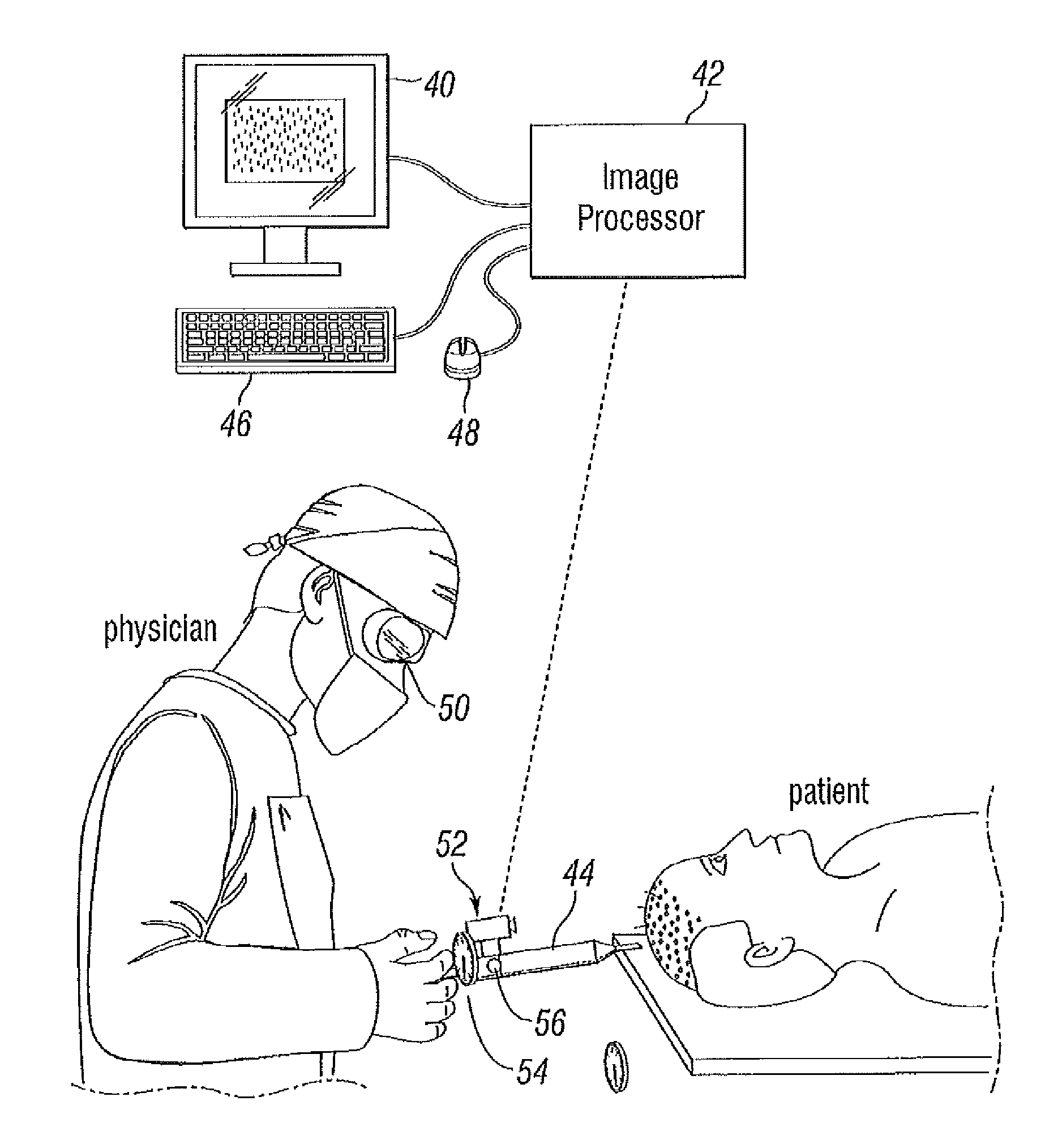

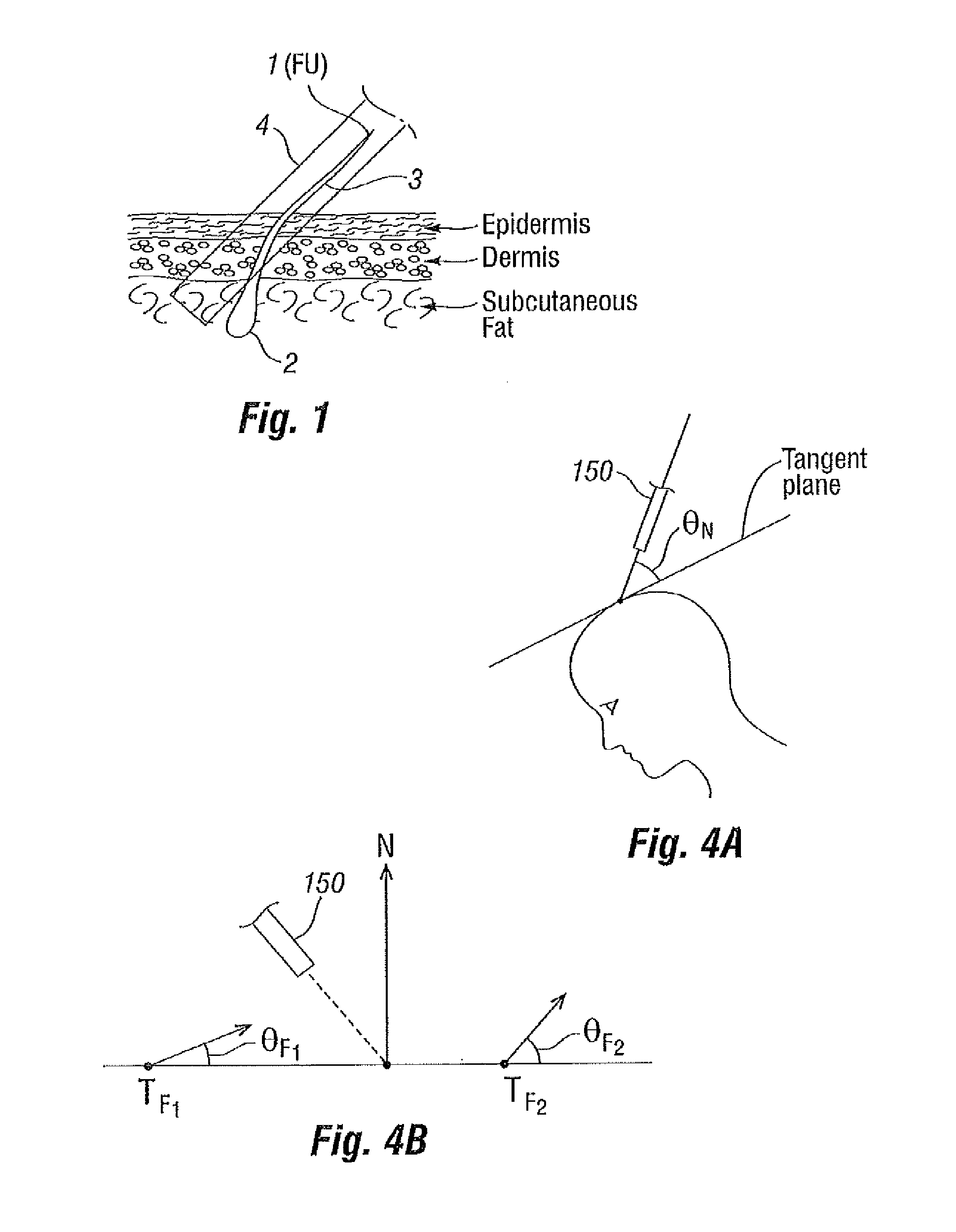

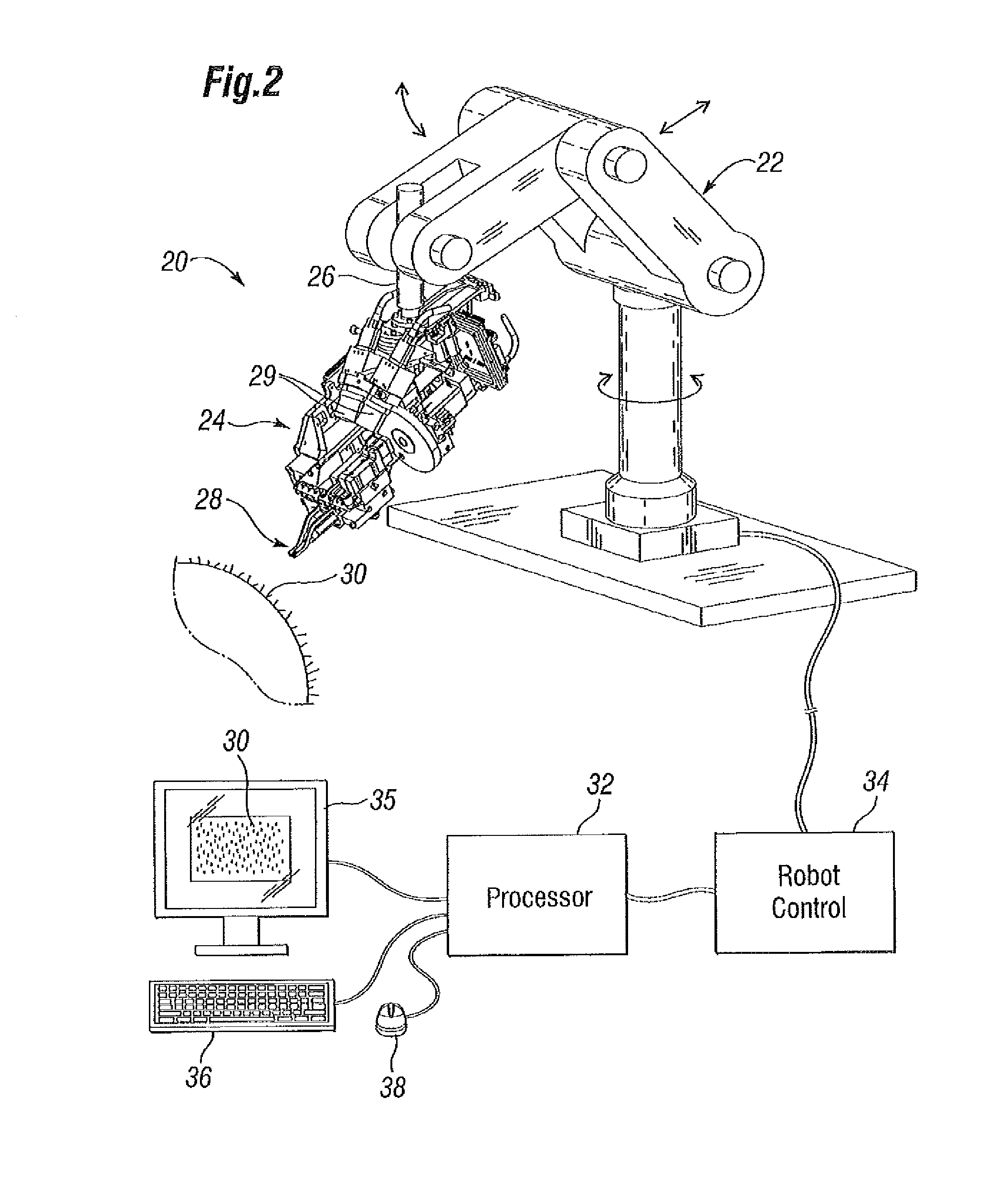

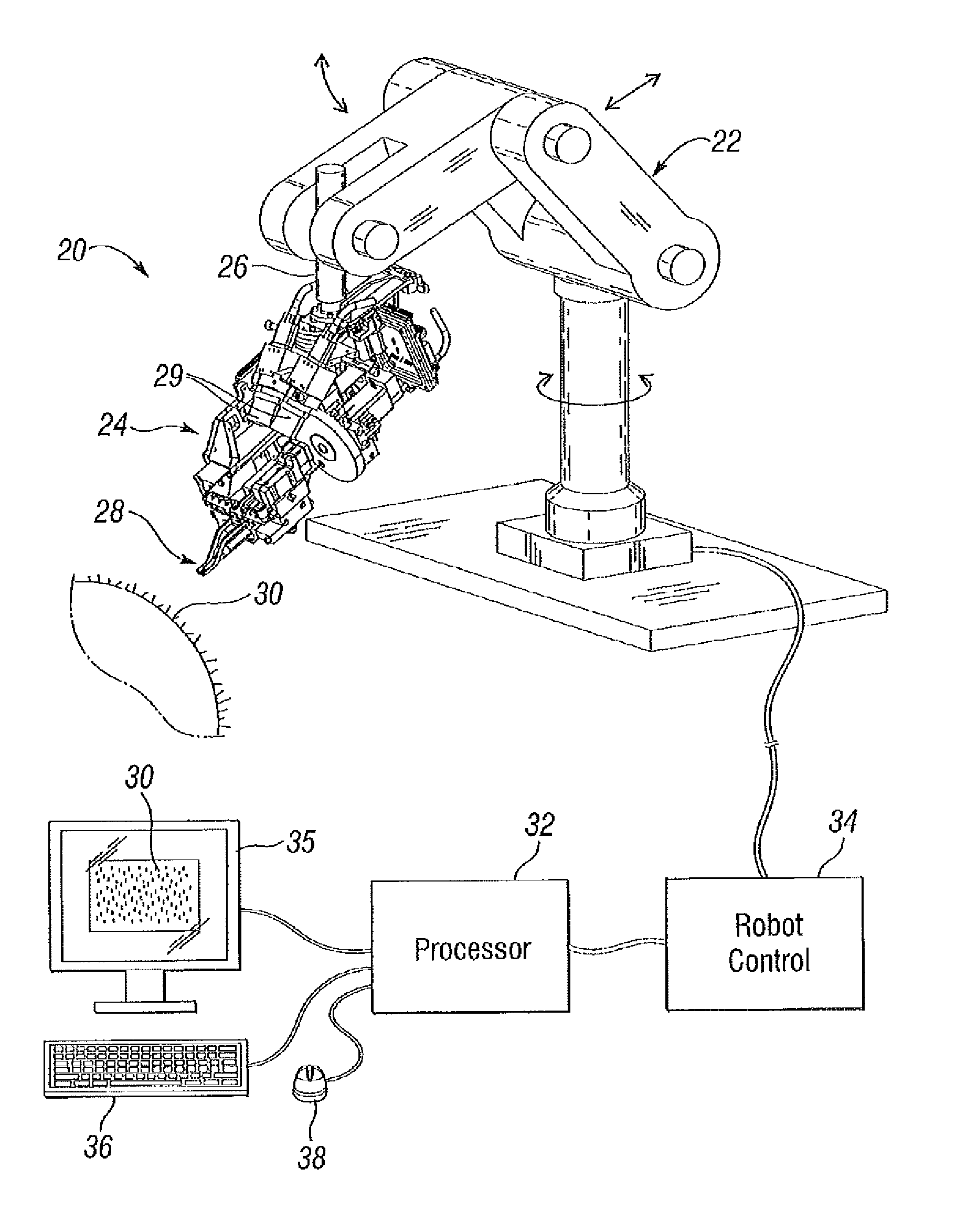

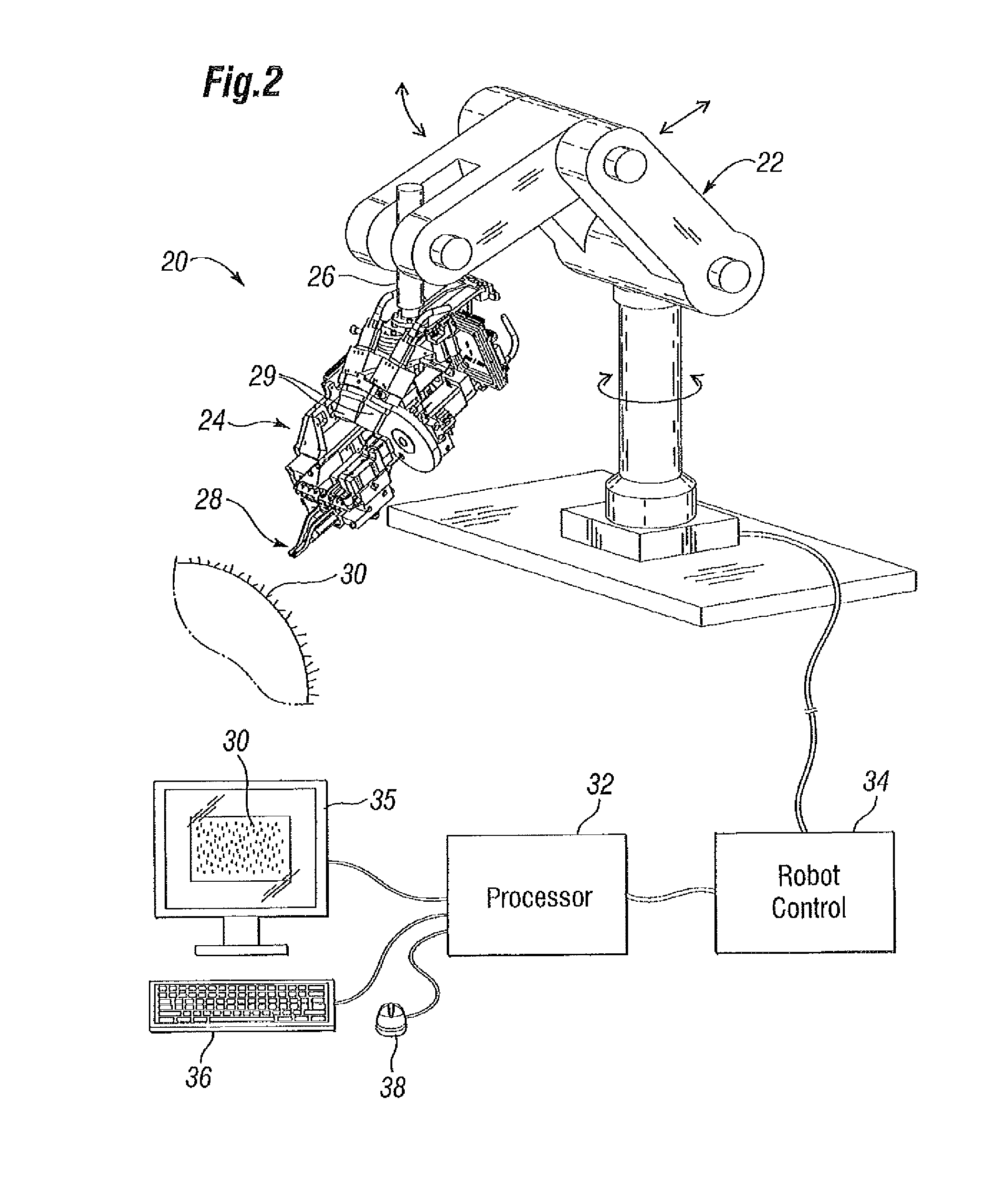

System and method for harvesting and implanting hair using image-generated topological skin models

Systems and methods are provided for orienting a hair harvesting tool relative to a follicular unit to be harvested. Further, systems and methods of implanting follicular units are provided, which are based on the orientation of the existing follicular units or based on pre-determined insertion angle. The provided systems and methods use image processing and image-generated topological skill models. In some embodiments surface fit is performed using, for example, a planar fit, quadric fit, cubic fit, mesh fit and parametric fit.

Owner:VENUS CONCEPT INC

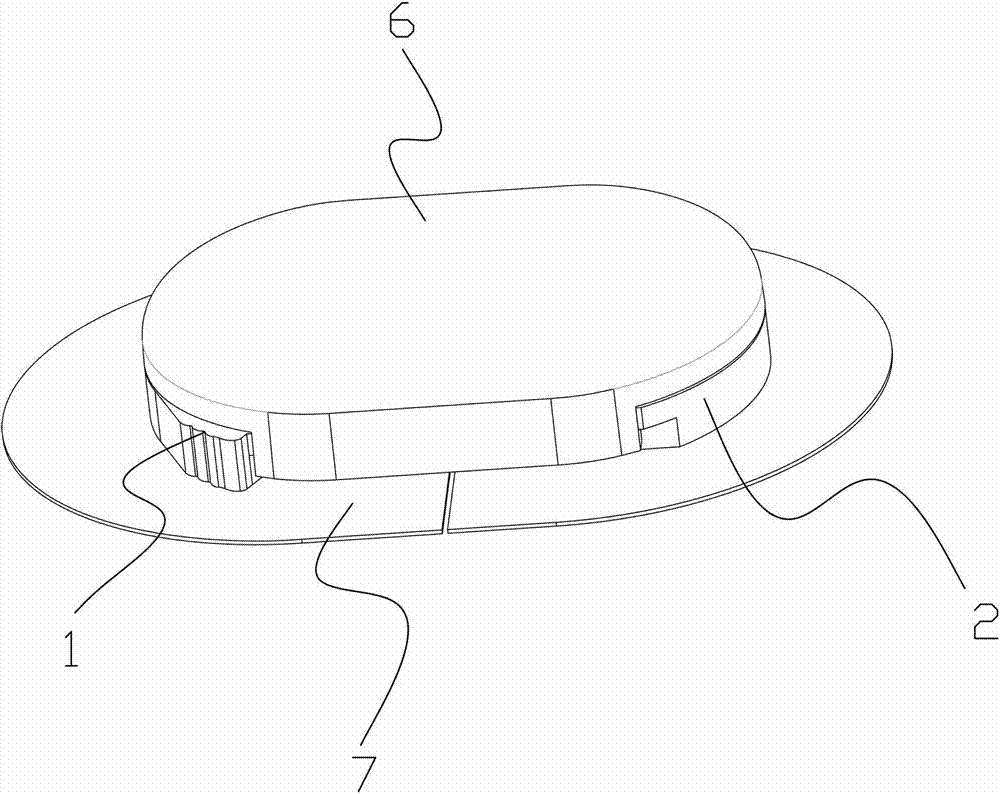

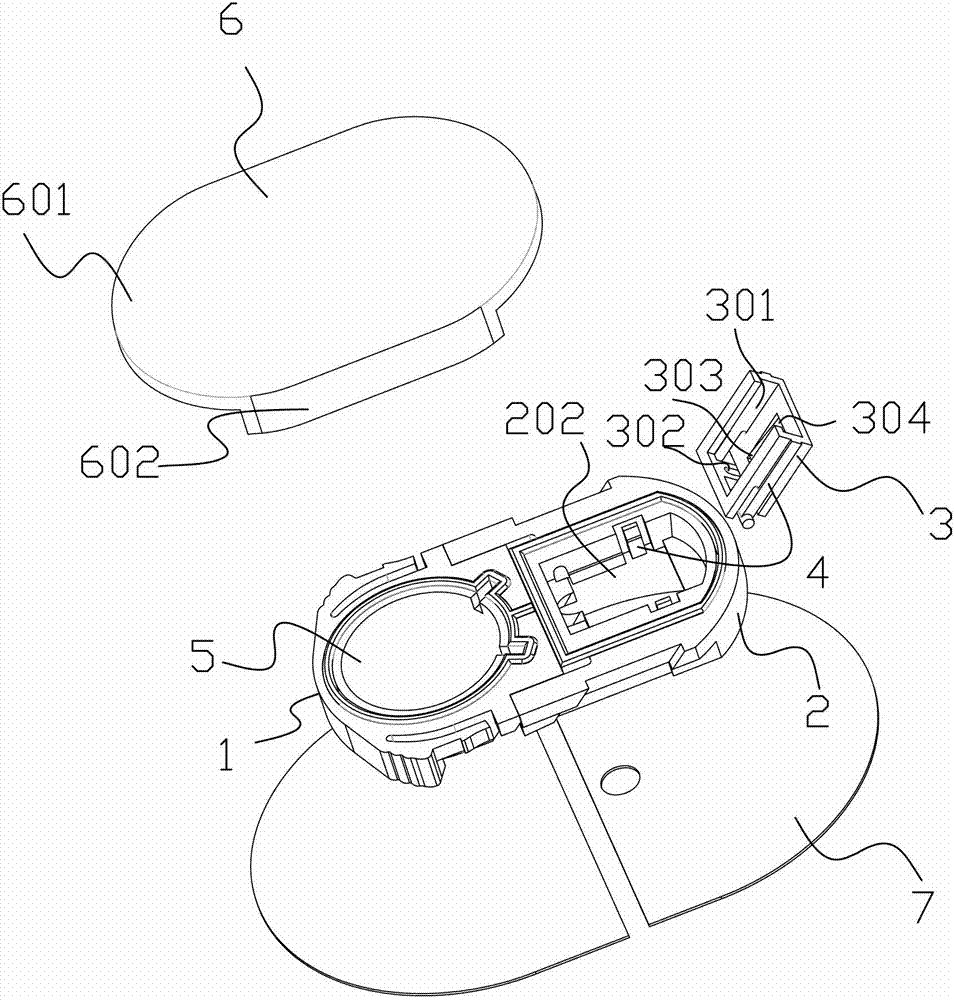

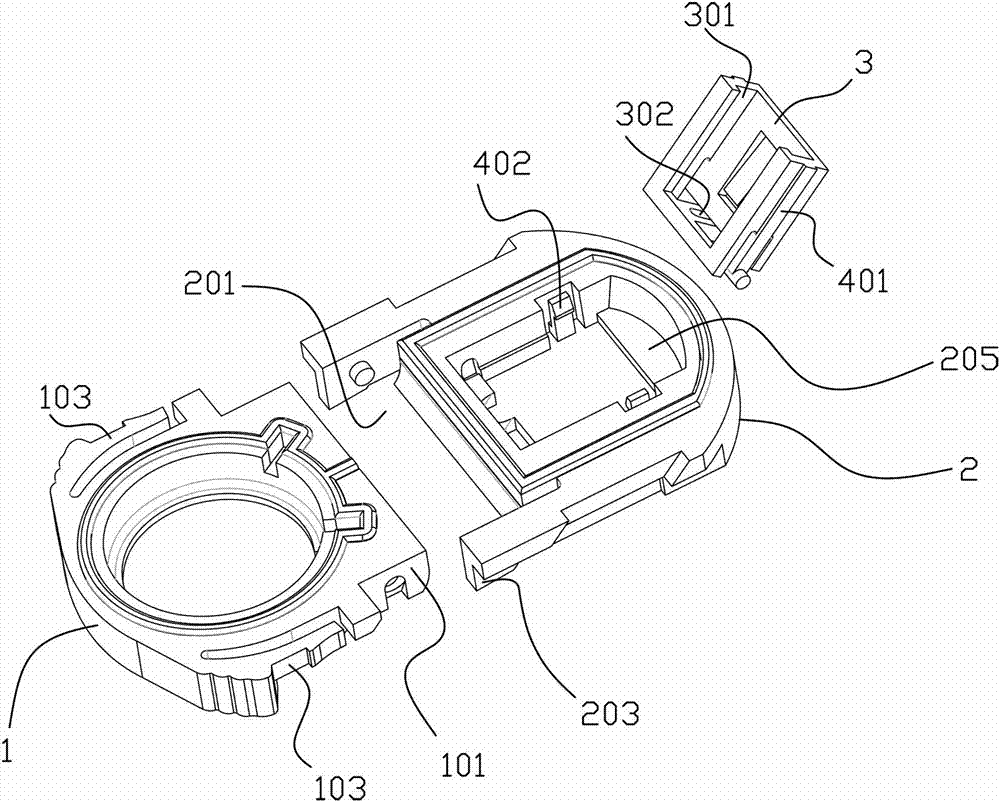

Sensor device capable of controlling insertion angle in subcutaneous tissue

ActiveCN103750819AFast implantReturn quicklyDiagnostic recording/measuringSensorsMedicineEffective length

The invention discloses a sensor device capable of controlling insertion angle in subcutaneous tissue, the sensor device comprises a fixing base and an inserting base provided with a hard needle tubing through hole and rotatably connected to the fixing base. The sensor device capable of controlling insertion angle in subcutaneous tissue has the advantages that it is convenient to insert the insertion type biosensor into the subcutaneous tissue and adjust the insertion angle of the insertion type biosensor in the skin tissue, so that the insertion type biosensor can have longer effective length in the subcutaneous tissue; the measured data is more accurate and near to the actual data.

Owner:ZHEJIANG POCTECH

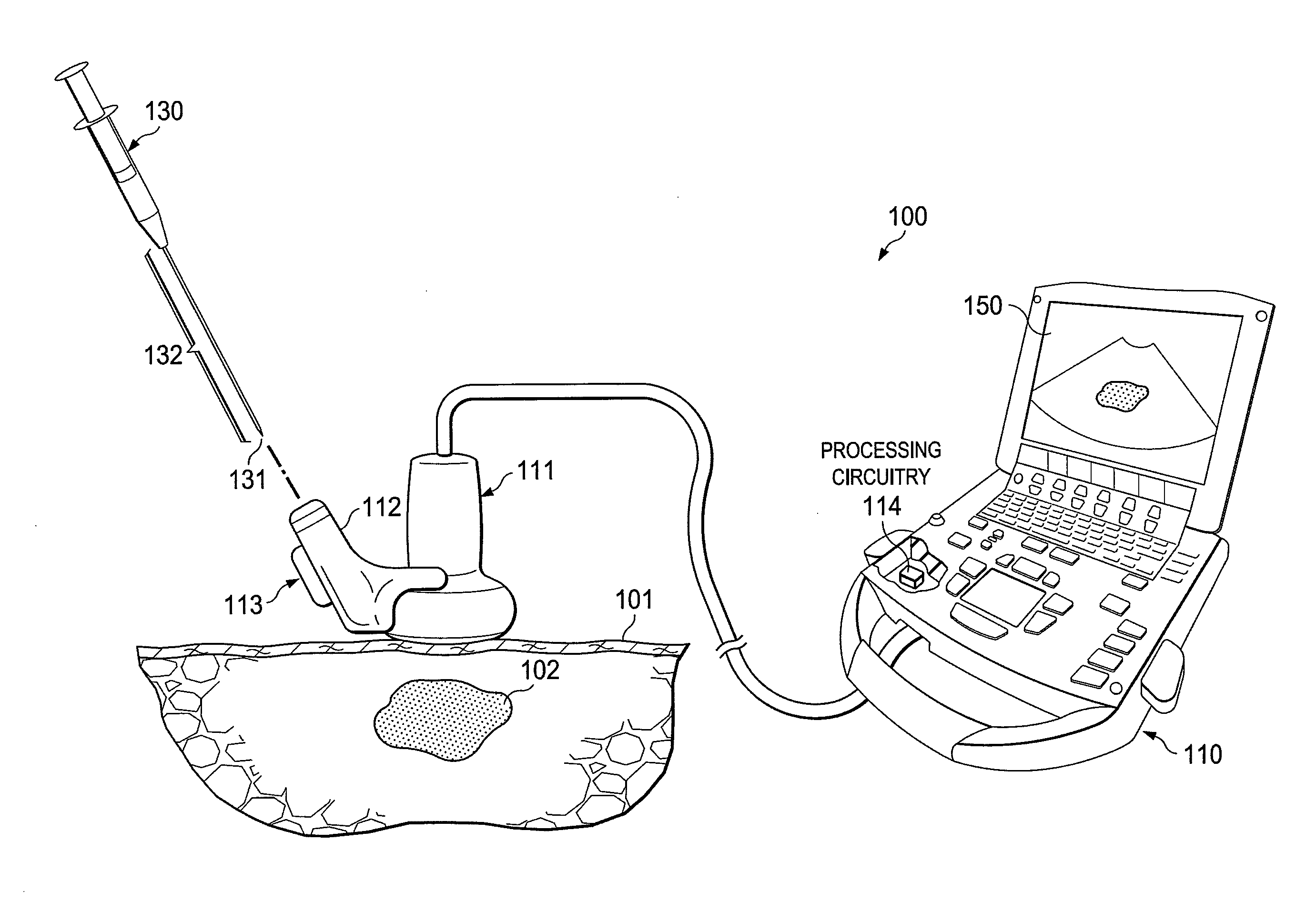

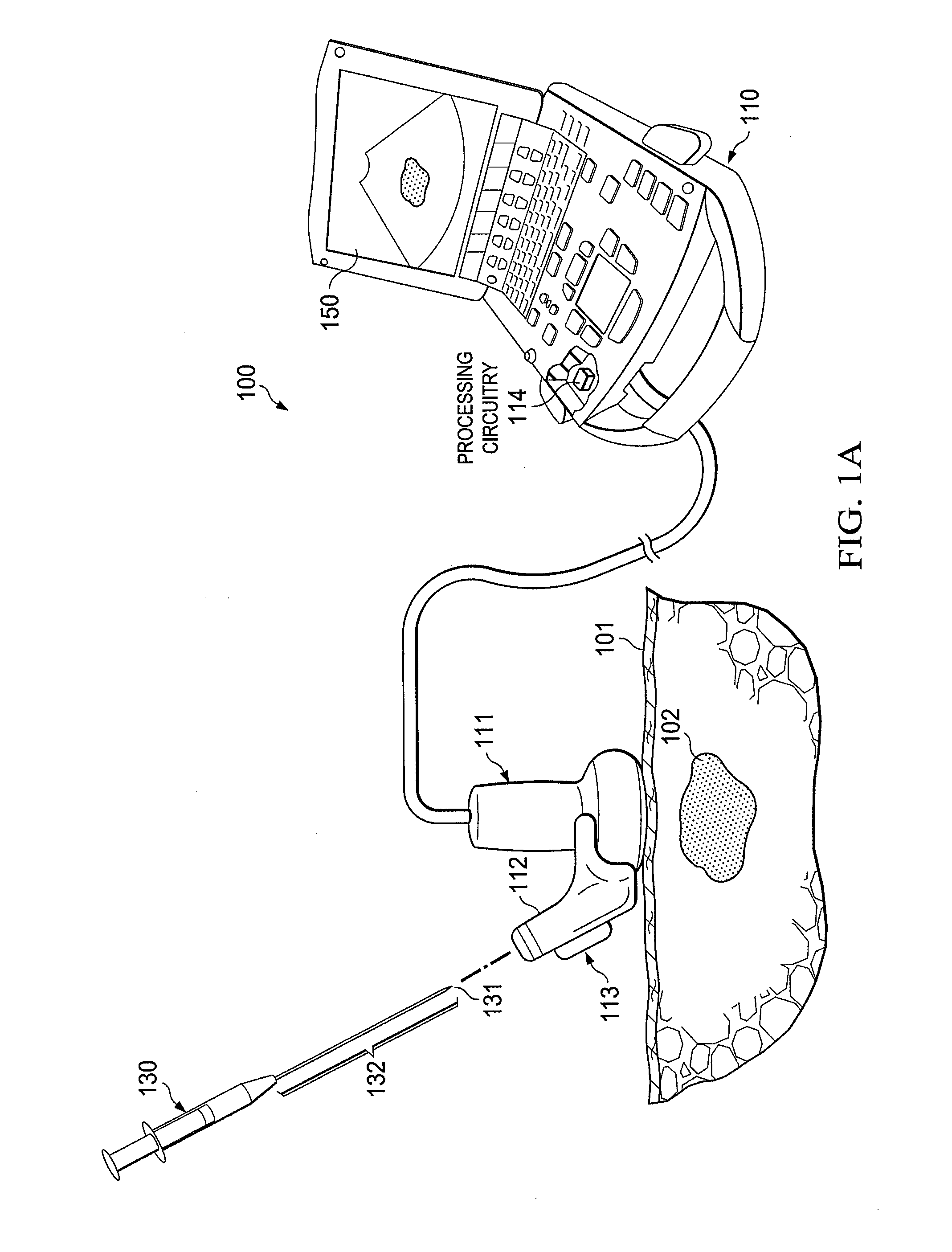

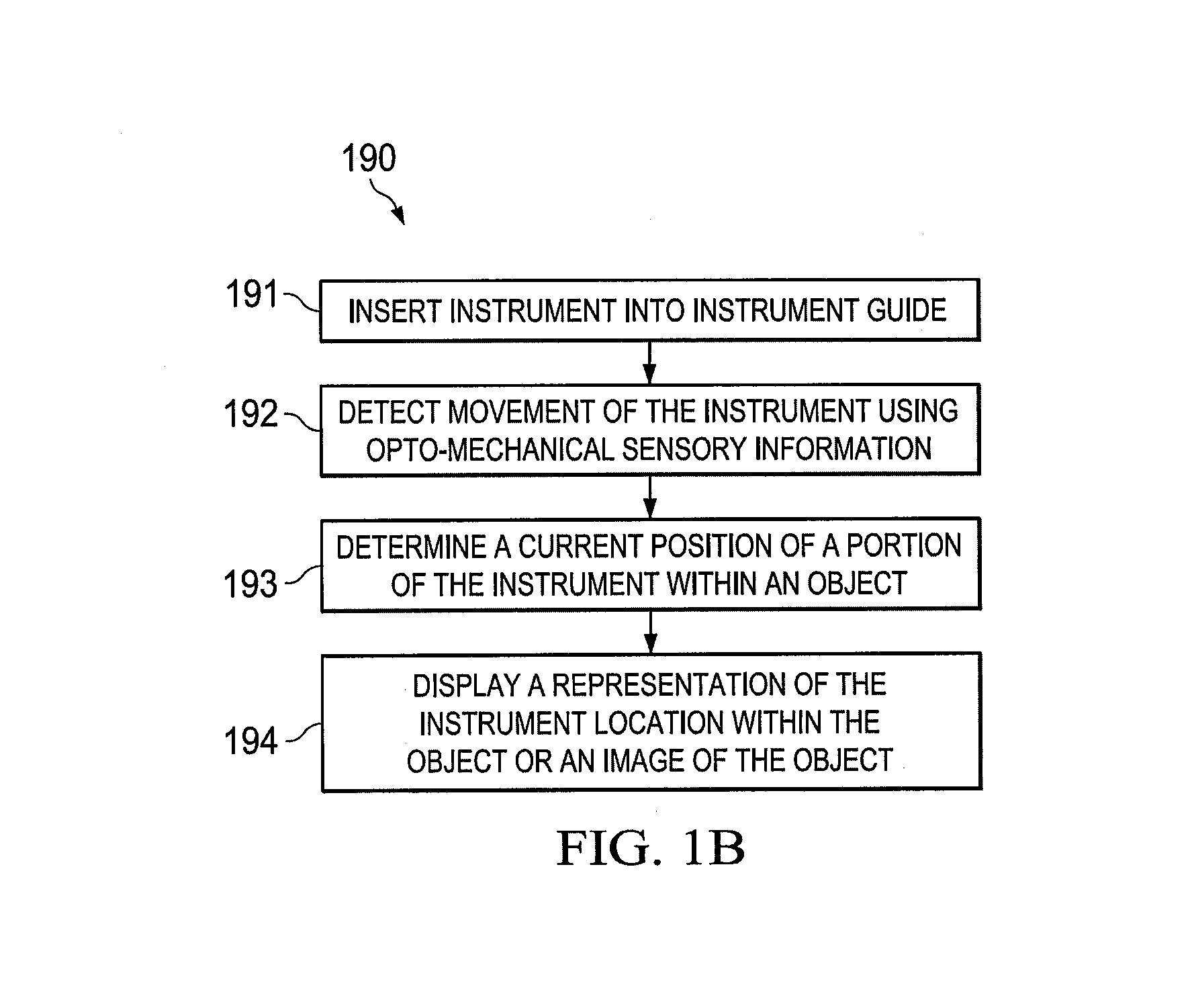

Systems and methods for assisting with internal positioning of instruments

ActiveUS8527033B1Easy to operateEasy to detectUltrasonic/sonic/infrasonic diagnosticsSurgical needlesEngineeringInsertion angle

Systems and methods which determine the position of an instrument internal to an object using an opto-mechanical sensor are shown. Embodiments utilize an opto-mechanical sensor system in which a mechanical instrument interface provides instrument movement information to a corresponding optical sensor system to determine instrument movement. Determinations of instrument movement preferably provide information regarding movement direction and speed. Such information, when used in combination with other information such as starting position or starting position offset, insertion angle or angle of attack, and / or insertion plane, is utilized by embodiments of the invention to determine the position of an instrument or portion thereof. Embodiments are adapted to accommodate different instrument configurations. Position information may be utilized in combination with an ultrasound image to display a visual representation of the instrument, or portion thereof, within a object being imaged.

Owner:FUJIFILM SONOSITE

System and method for harvesting and implanting hair using image-generated topological skin models

Systems and methods are provided for orienting a hair harvesting tool relative to a follicular unit to be harvested. Further, systems and methods of implanting follicular units are provided, which are based on the orientation of the existing follicular units or based on pre-determined insertion angle. The provided systems and methods use image processing and image-generated topological skill models. In some embodiments surface fit is performed using, for example, a planar fit, quadric fit, cubic fit, mesh fit and parametric fit.

Owner:VENUS CONCEPT INC

Bone plate system

A bone plate system is provided that includes bone plates and bone anchor assemblies for being inserted into bone plate bores to secure the bone plates to one or more bones. In one aspect, the bone plate system includes a bone anchor assembly having a locking cap and a locking fastener connected to a head portion of a bone anchor. The bone anchor assembly is driven into a bone plate bore before the locking fastener is shifted to expand the locking cap and fix the bone anchor assembly within the bore. In another aspect, the bone plate system includes a bone anchor assembly having a locking cap that deflects radially inward due to contact with the bone plate at large bone anchor assembly insertion angles. In addition, a bone anchor assembly having a preassembled condition with a locking cap resisting back out of a locking fastener.

Owner:XTANT MEDICAL HLDG INC

Systems and Methods for Harvesting and Implanting Hair Using Image-Generated Topological Skin Models

Systems and methods are provided for determining the need to change and / or changing orientation of a tool relative to an object on a body in at least partially automated procedure. Also, systems and methods are provided for orienting a hair harvesting tool relative to a follicular unit to be harvested. Further, systems and methods of implanting follicular units are provided, which are based on the orientation of the existing follicular units or based on pre-determined insertion angle. The provided systems and methods use image processing and image-generated topological skin models. In some embodiments surface fit is performed using, for example, a planar fit, quadric fit, cubic fit, mesh fit and parametric fit.

Owner:VENUS CONCEPT INC

Artificial functional spinal unit system and method for use

Insertion methods for placing dynamic interbody devices between a first vertebra and a second vertebra using a posterior approach are provided. In an embodiment, the insertion method may be based on the first vertebra. A bridge assembly may be attached to tap shafts positioned in the first vertebra. The bridge assembly may establish an insertion angle of implants into a disc space between the vertebrae. In an embodiment, the insertion method may be based on the position of expandable trials positioned between the vertebrae. The trials may be positioned and a bridge assembly may be coupled to the expandable trials and taps positioned in the first vertebra. One or more posterior stabilization systems may be coupled to the vertebrae after insertion of the dynamic interbody devices between the vertebrae.

Owner:FLEXUSPINE

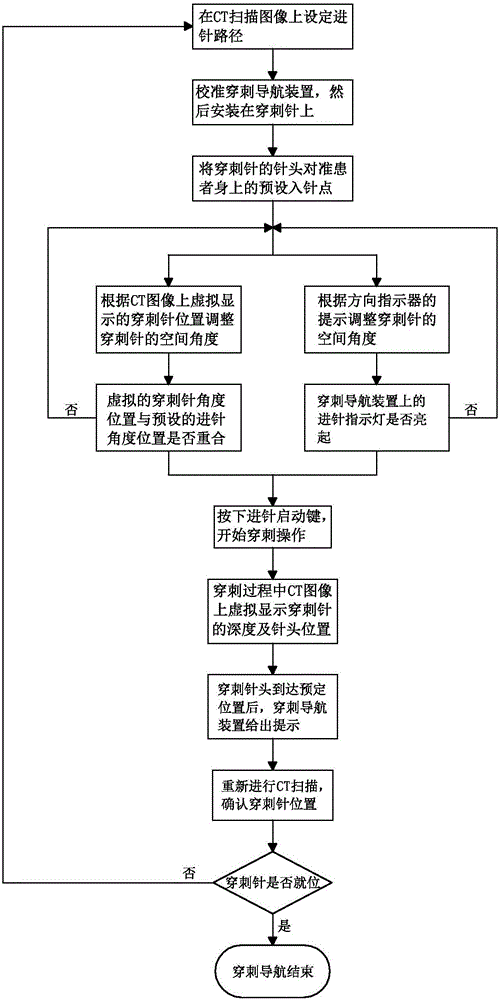

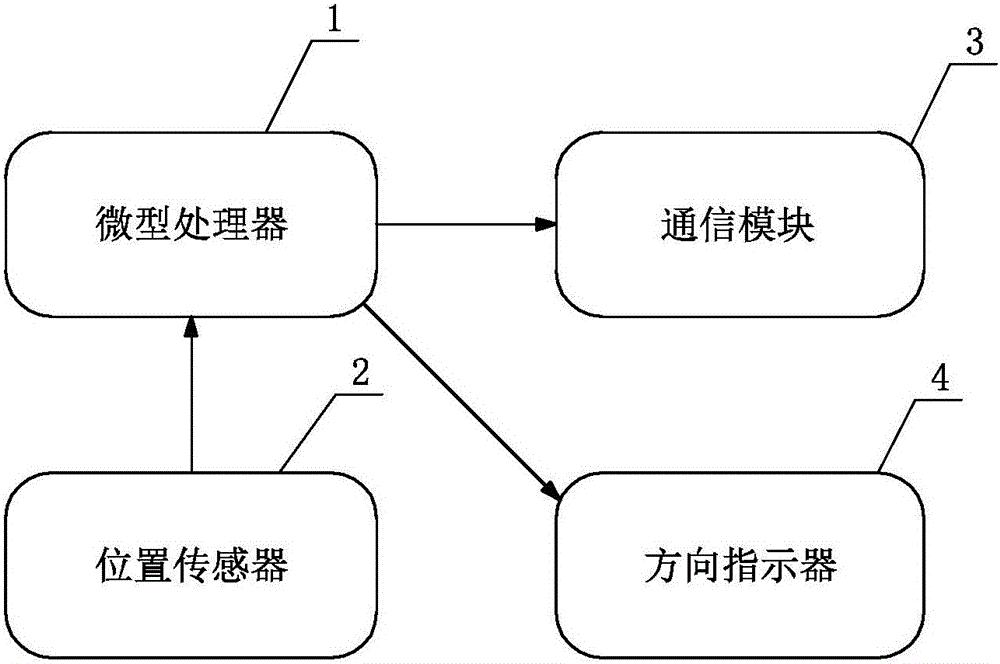

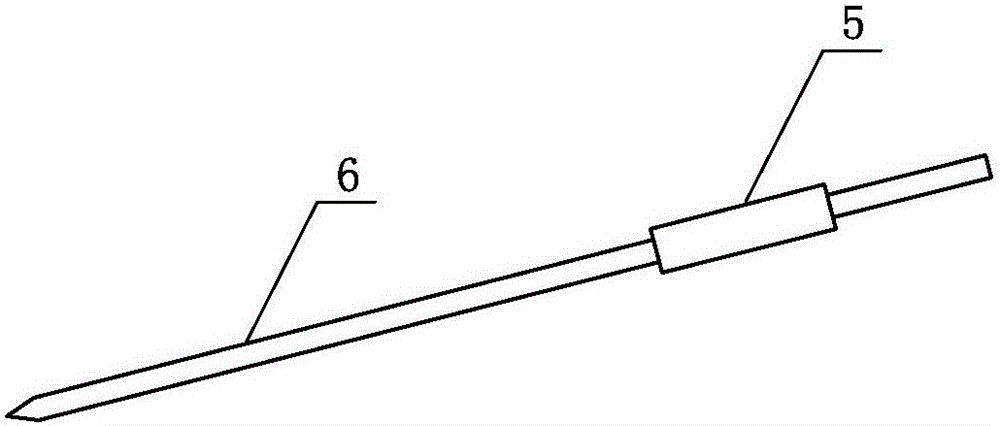

Method for conducting puncture navigation in CT interventional therapy and puncture navigation device

InactiveCN105796161AHigh precisionReduce complexitySurgical needlesTrocarComputed tomographyInterventional therapy

The invention relates to a method for conducting puncture navigation in a CT interventional therapy and a puncture navigation device. The puncture navigation device comprises a microprocessor, a position sensor, a communication module and a direction indicator, and the puncture navigation device is connected with a CT scanning system; the puncture navigation method comprises the steps that the CT scanning system plans a preset needling insertion angle on a CT image and transmits the preset needling insertion angle to the puncture navigation device; the puncture navigation device transmits space angle information of a puncture needle to the CT scanning system and virtually displays the space angel information on the CT image; a space angle of the puncture needle is adjusted by observing the CT image or according to a hint of the direction indicator to enable the space angle of the puncture needle to be overlapped with the preset needling insertion angle; needle insertion is started, and when the needle head of the puncture needle reaches a puncture target point, the CT scanning system conducts scanning again to confirm whether the puncture needle is in position or not. According to the method for conducting puncture navigation in the CT interventional therapy and the puncture navigation device, the puncture accuracy is improved, the puncture complexity is reduced, the number of insertion of the needle is decreased, and pain borne by a patient is reduced.

Owner:SAINUO WEISHENG SCI & TECH BEIJING

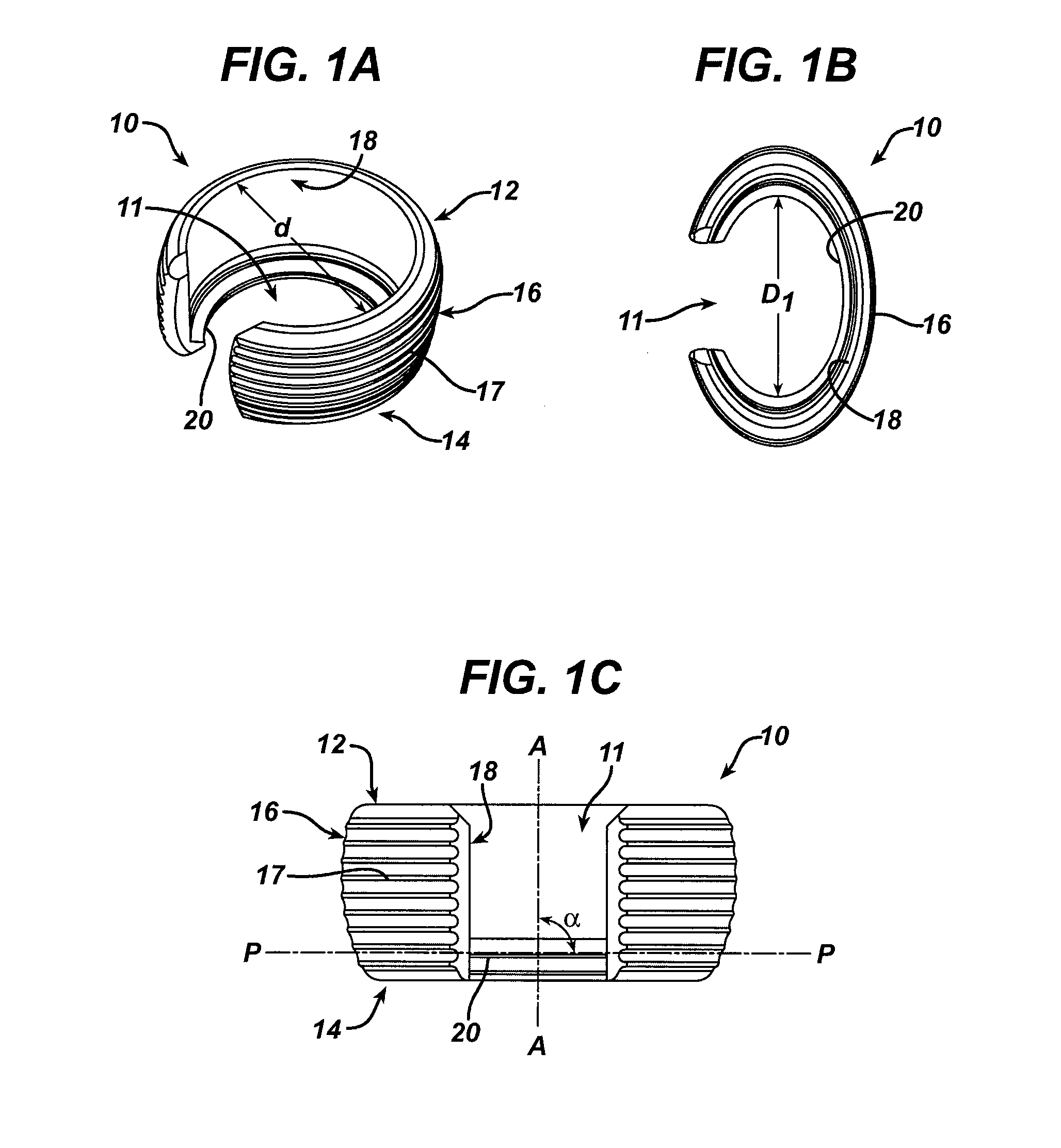

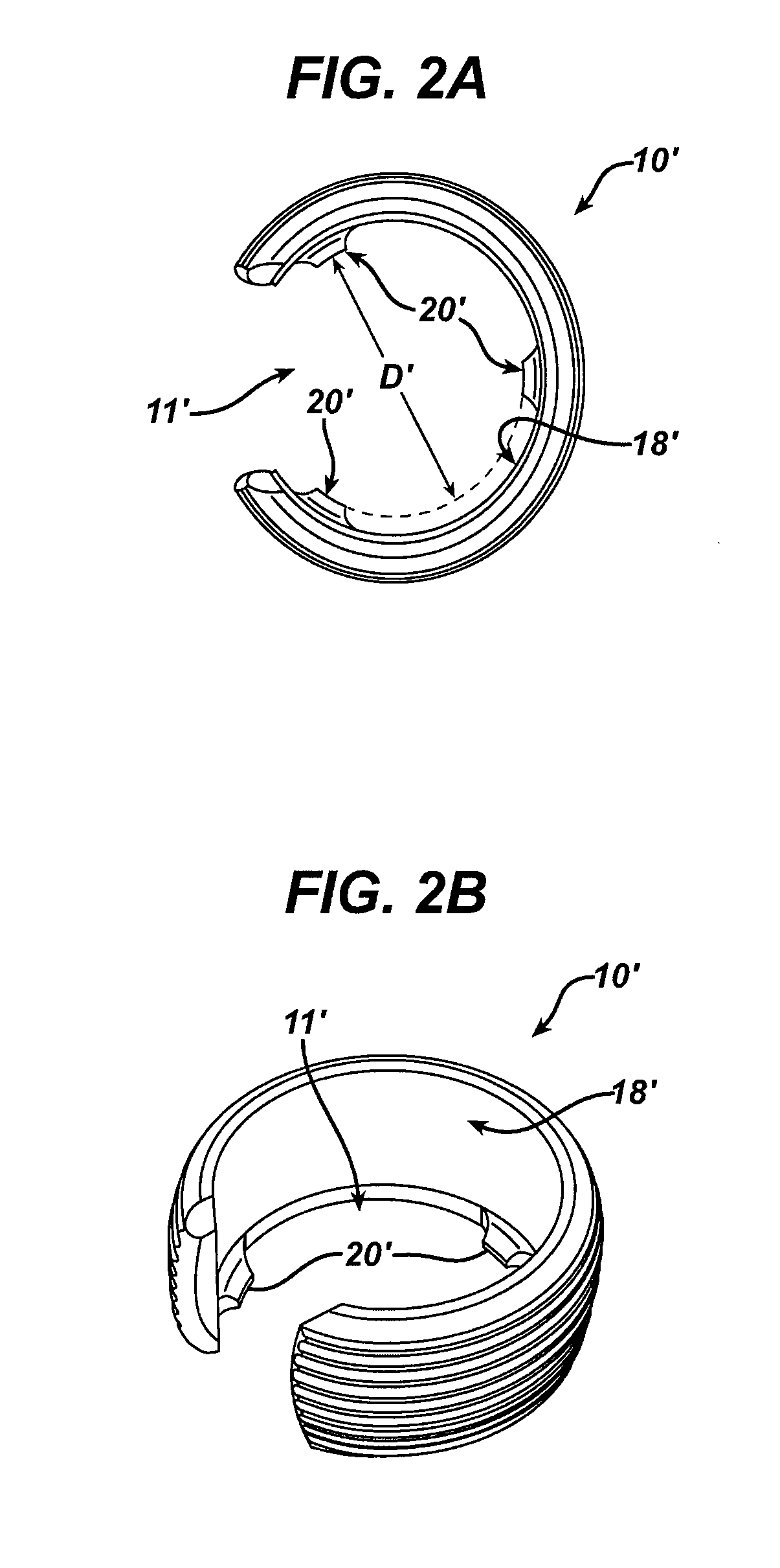

Spring energized segmented-ring latch

A latch device includes a shaft having a surface of revolution defining an insertion surface disposed at an insertion angle along with a circumferential groove. A housing is provided which includes a shaft receiving bore therethrough and a torroidal cavity with a spring disposed therein. A segmented ring is provided which includes a plurality of separate sound producing dogs circumferentially disposed about the housing bore for latching between the housing and the shaft.

Owner:BAL SEAL ENG CO INC

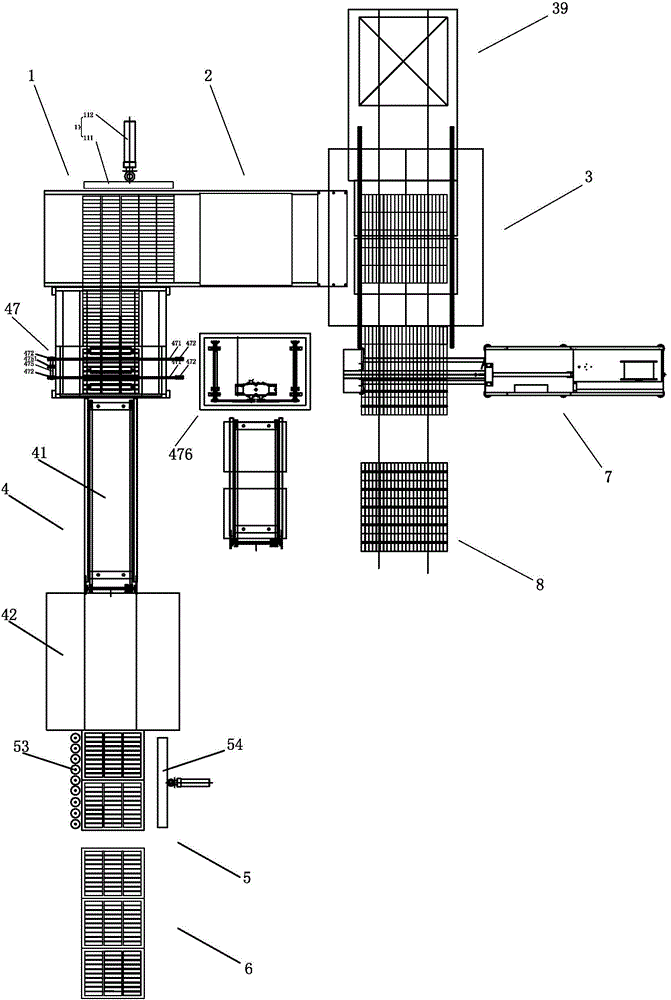

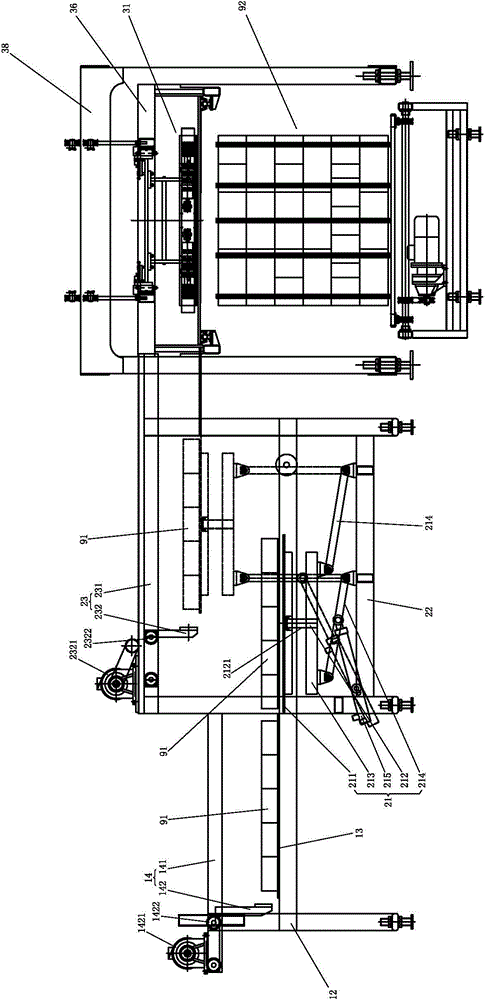

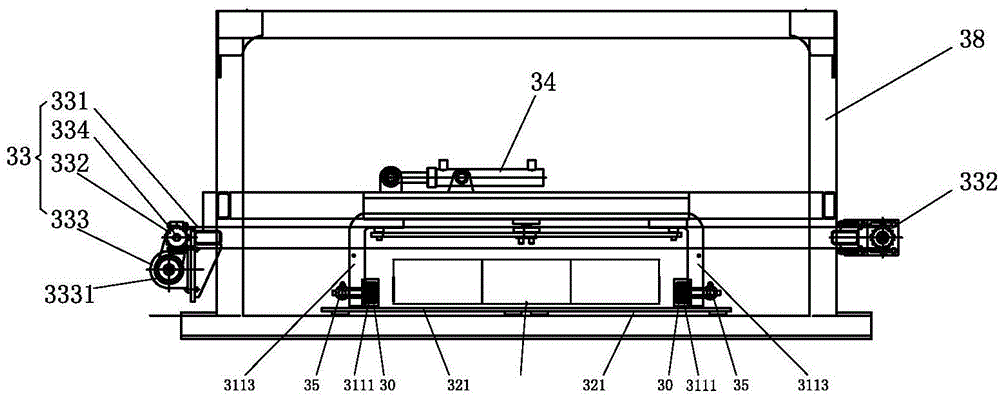

Offline automatic brick stacking assembly line and brick stacking method

The invention provides an offline automatic brick stacking assembly line. The offline automatic brick stacking assembly line comprises a brick arranging device, a brick transferring device and a brick stacking device, wherein brick layers can be reduced by at least one row or one line relative to the upper layer or the lower layer through the brick arranging device, the corresponding brick layer can be rotated by a predetermined angle relative to the upper layer or the lower layer through the brick transferring device, so that a formed brick stack is more stable, the brick layers in the reduced row or line can be pulled to be separated while the brick layers in the non-reduced rows or lines are stacked, so that a gap is formed between every two adjacent rows or lines, then stacking is conducted, after the formed brick stack is packaged, a transporter can be inserted into the gaps conveniently for grabbing, and when two gaps exist, the two insertion angles of a forklift can be inserted for transportation. In this way, the offline automatic brick stacking assembly line has the advantages that brick stacking quality is high, efficiency is high, the formed brick stack can be transported by the transporter such as the forklift conveniently, the degree of mechanization and the degree of automation are high, the assembly line can be adapted to various types of bricks and various brick forming machines, and practicability is high. The invention further provides a brick stacking method. All the functions can be achieved effectively by the adoption of the brick stacking method.

Owner:泉州市万昌机械制造有限公司

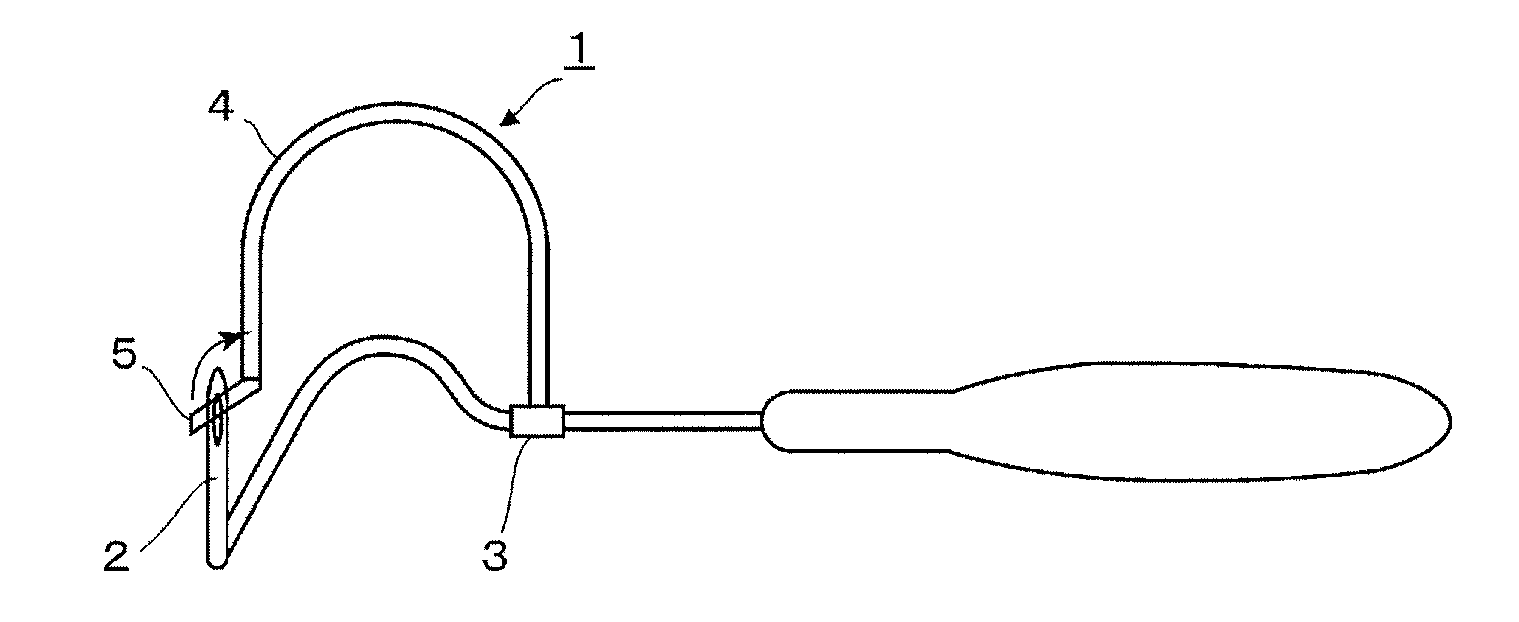

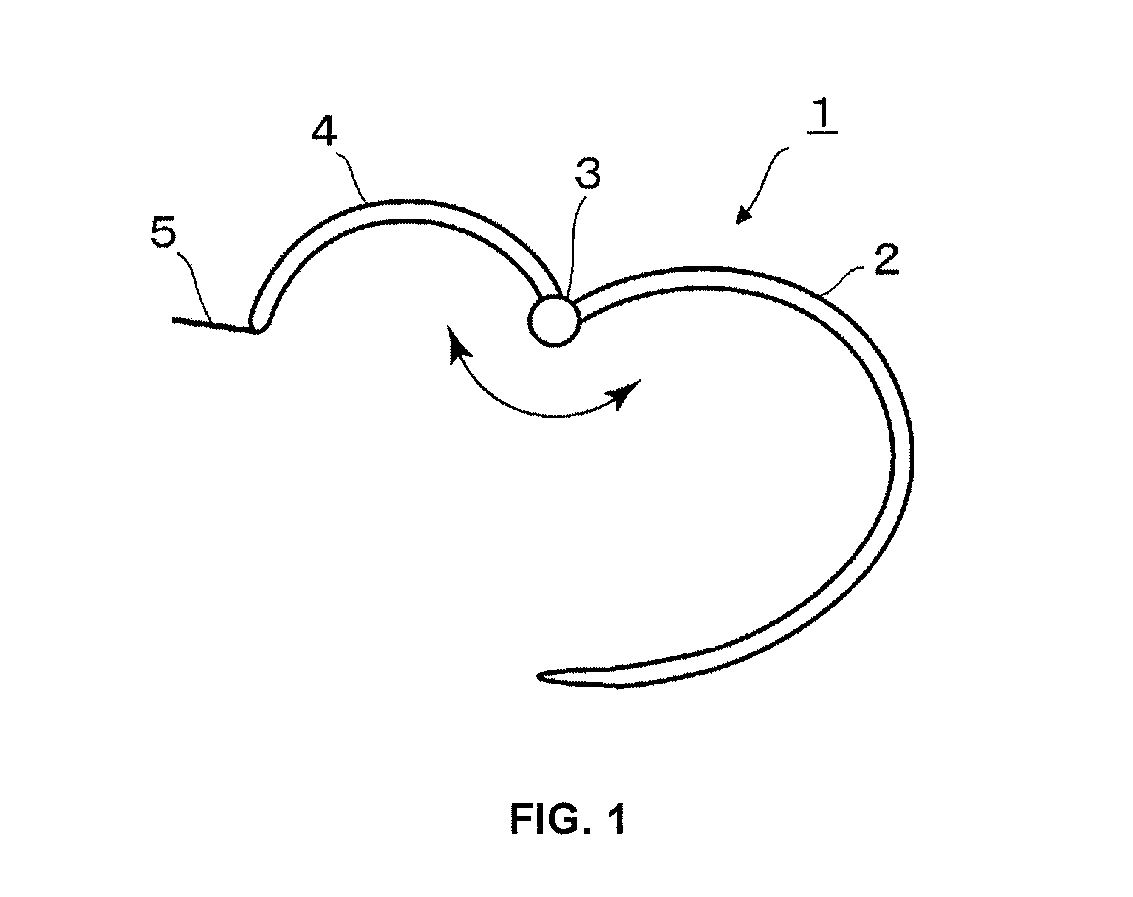

Insertion needle

InactiveUS20130023725A1Drawn reliablyShort timeSuture equipmentsSurgical needlesPelvic organsInsertion angle

An insertion needle that is turnably mounted on a handle, which holds the insertion needle, wherein the insertion needle includes a turn arm that turns so as to face the tip of the insertion needle, and a target site that guides the insertion needle provided on the tip of the turn arm, and is further provided with: through-holes in two locations that are provided separated in the longitudinal direction of the tip of the insertion needle; an indentation formed between these through-holes; and a groove in the direction from the tip of the insertion needle toward the base of the insertion needle. Furthermore, the insertion needle is suitably used in urinary incontinence surgery, pelvic organ prolapse surgery or the like.

Owner:UNIVERSITY OF MIYAZAKI

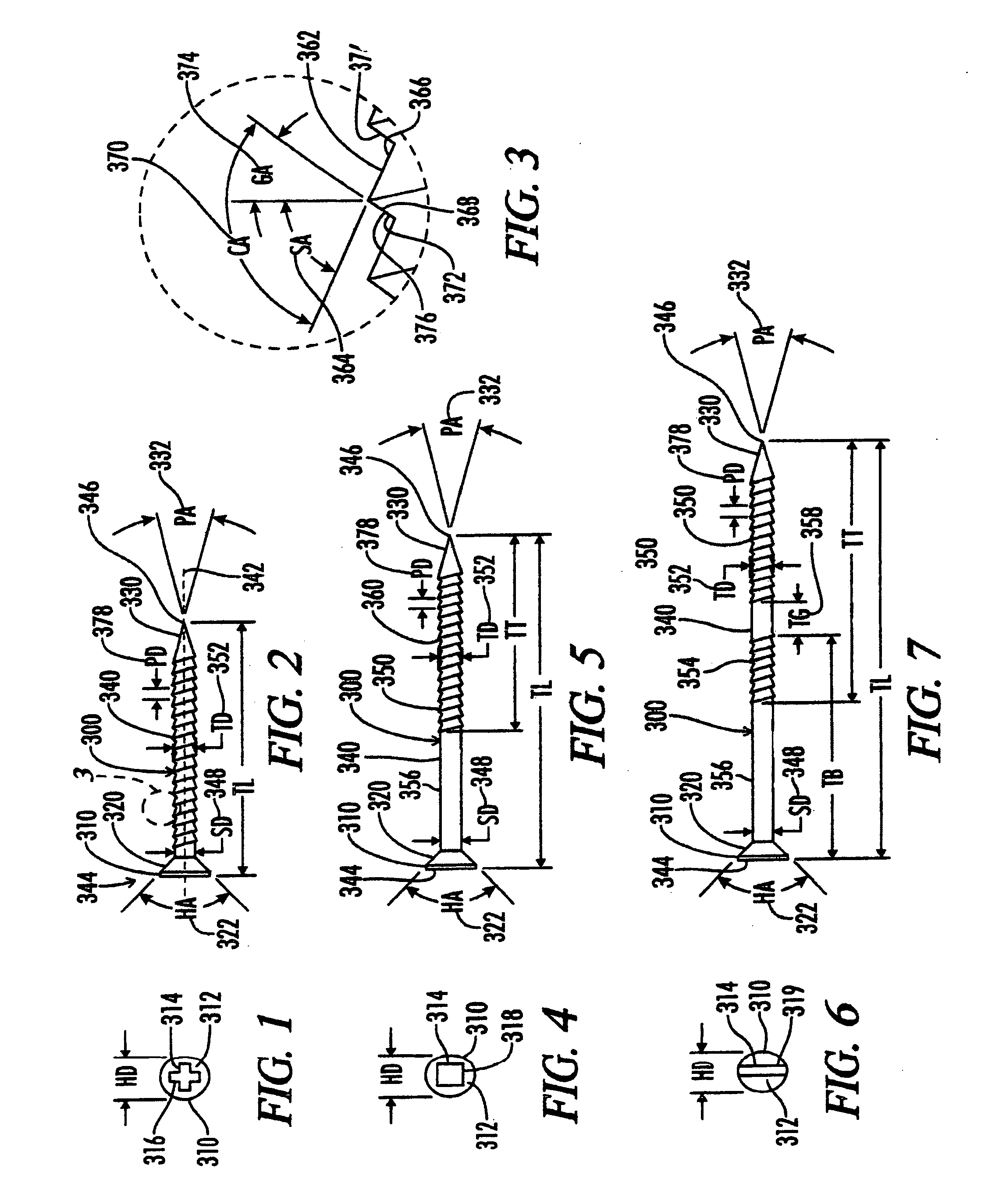

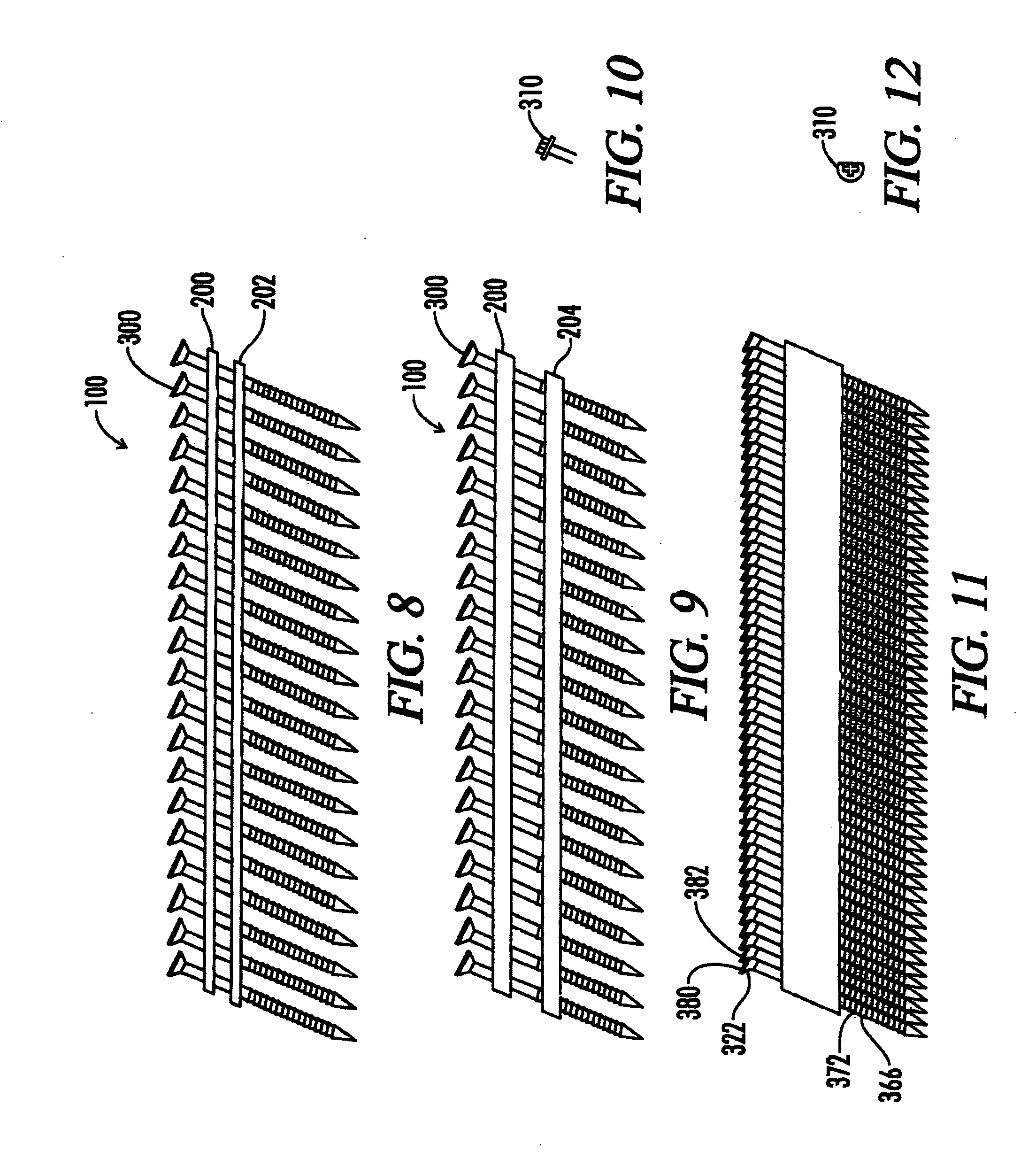

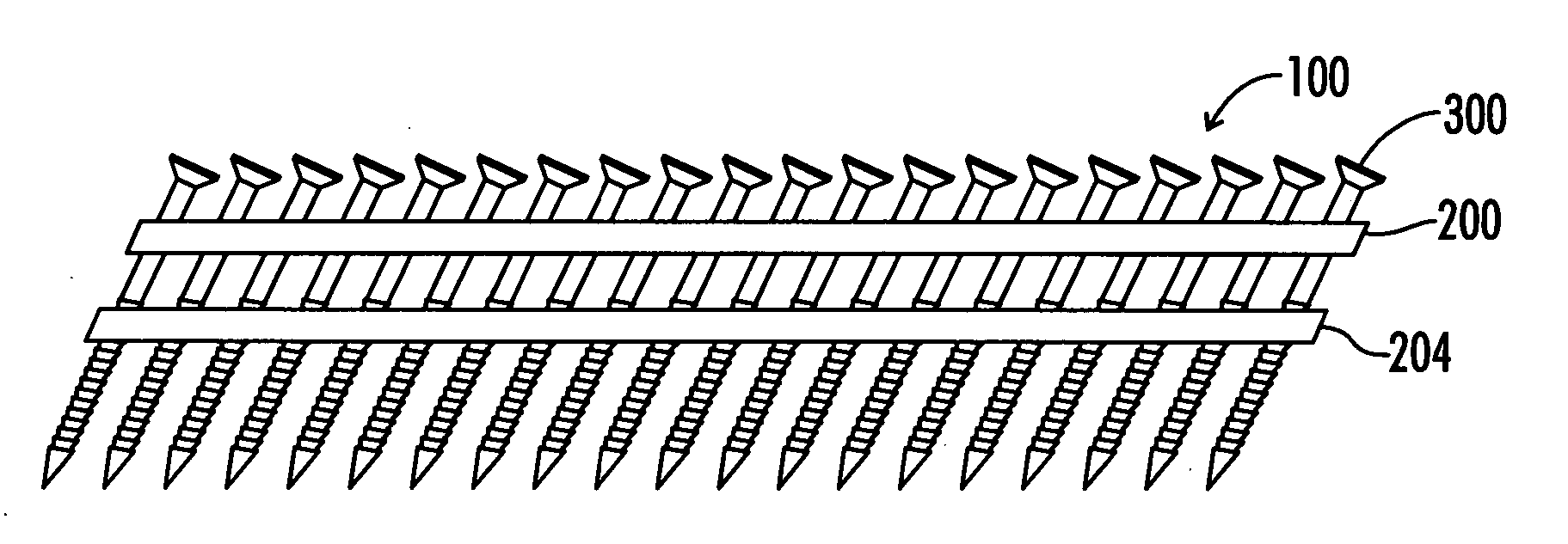

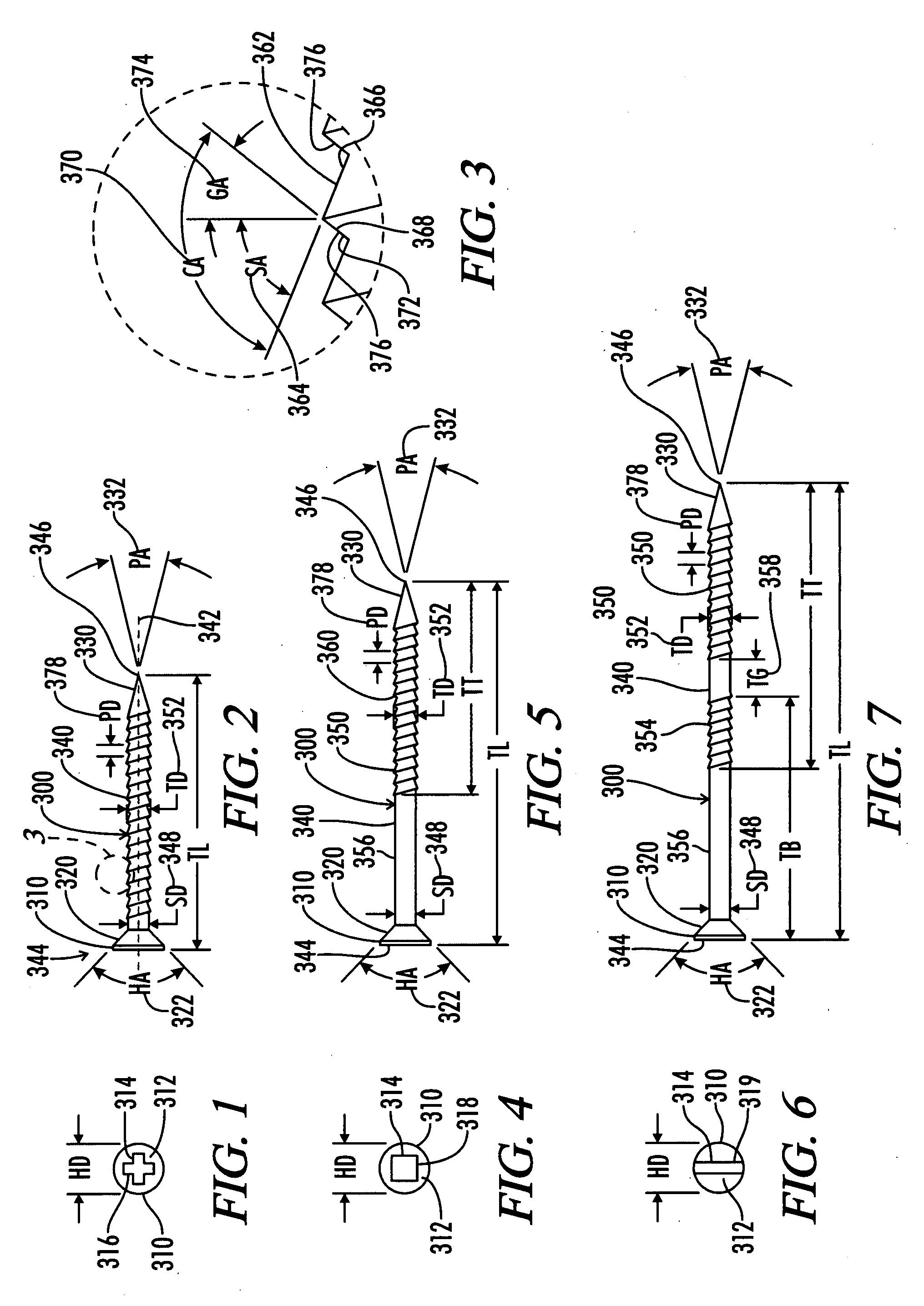

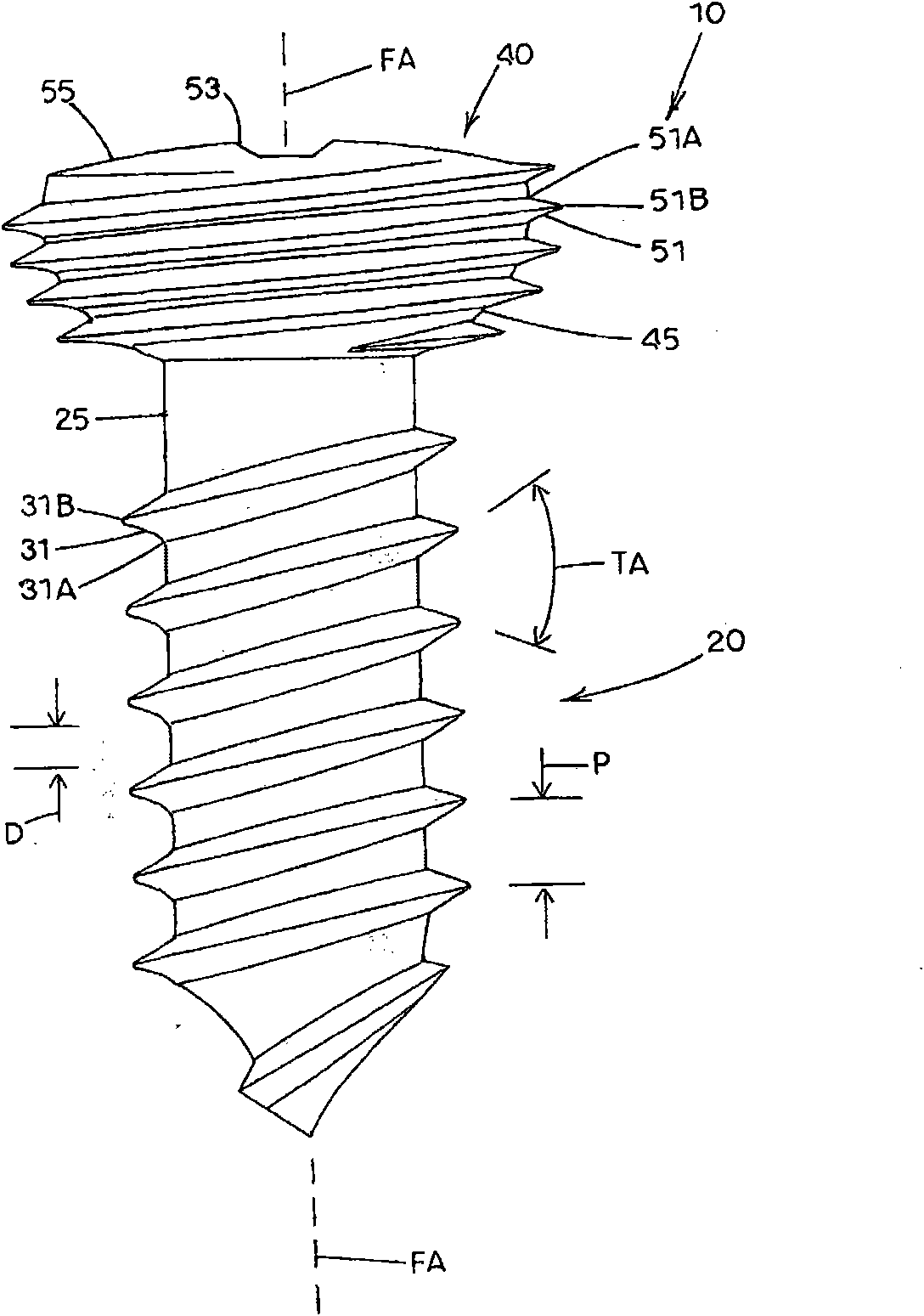

Impact-drivable screw with elastomer seal and tip highlight

An asymmetric thread impact drivable screw and clip for use with a power impact device for penetrating wood fibers while minimizing cut fibers. The screw includes an impact head and a conical shaped tip having a ballistic insertion angle at the ends of a shank. The shank defines asymmetrical threads with an insertion flank having a long side at a slide angle peaking at a crest supported by a catch flank positioned at a grip angle. Varying tool accepting recess are taught for the head along with multiple thread sections. A mushroom compaction thread section is also taught.

Owner:LITZINGER W C

Passive screw locking mechanism

Methods and devices are provided for passively locking a bone screw within a bone plate. In particular, the methods and devices allow a bone screw to be locked within a thru-hole in a bone plate without requiring any additional locking steps. In an exemplary embodiment, an annular feature is provided in a thru-hole of a bone plate, or in a bushing that is disposed within a thru-hole of a bone plate, for engaging a bone screw. The annular feature can be configured such that it allows the bone screw to be inserted through the thru-hole at various insertion angles while still being effective to prevent back-out of the bone screw, thereby locking the screw to the plate.

Owner:DEPUY SYNTHES PROD INC

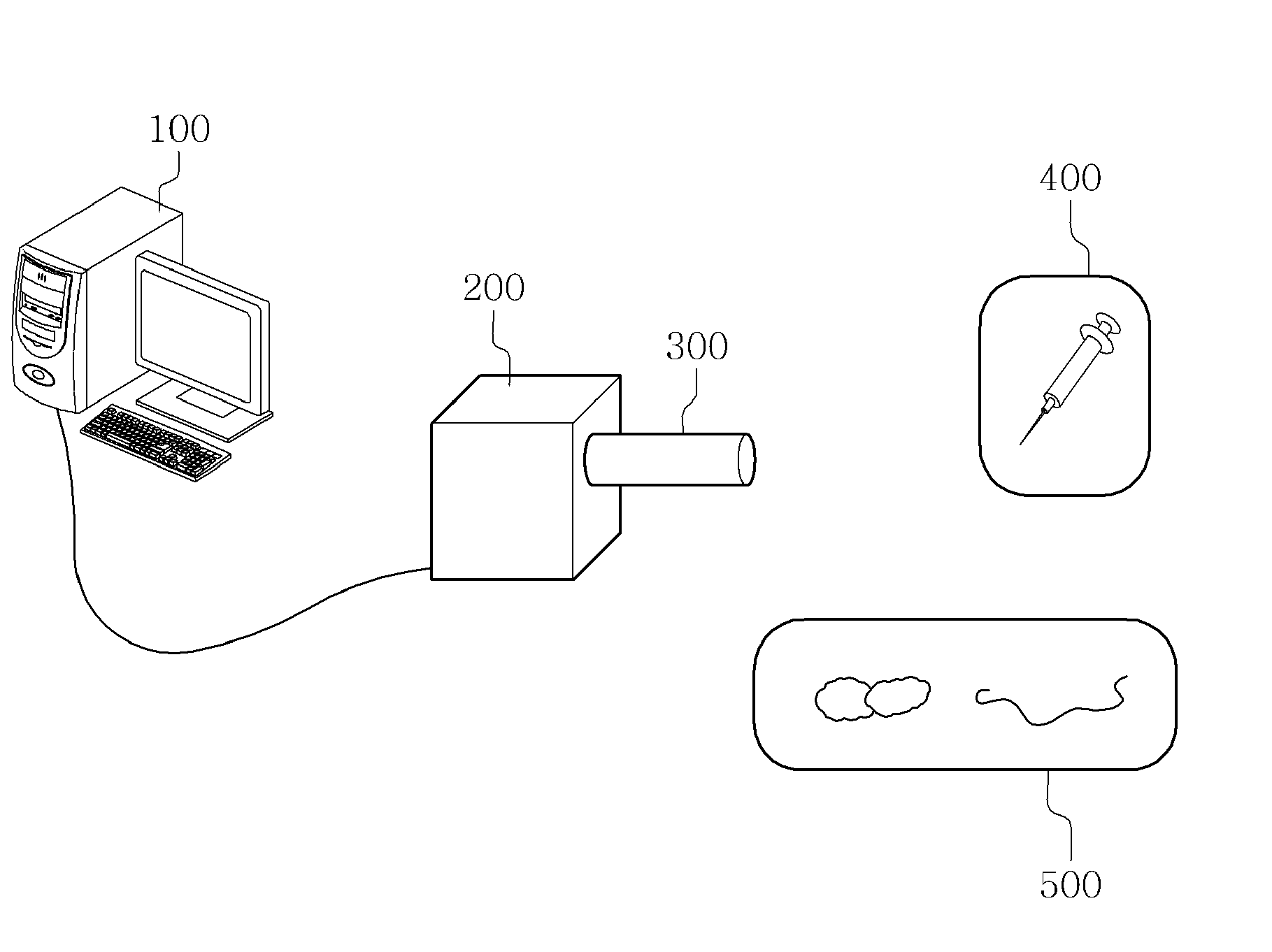

Injection simulation system and method

Provided is an injection simulation system and method. The system includes a syringe comprising an injection needle, a haptic unit which measures an insertion angle and insertion depth of the injection needle, and which comprises a motor unit that is driven by a haptic force corresponding to the measured insertion angle and insertion depth. The system also includes a control unit which calculates the haptic force corresponding to the insertion angle and the insertion depth, and transmits the calculated haptic force to the motor unit of the haptic unit.

Owner:KOREA INST OF SCI & TECH

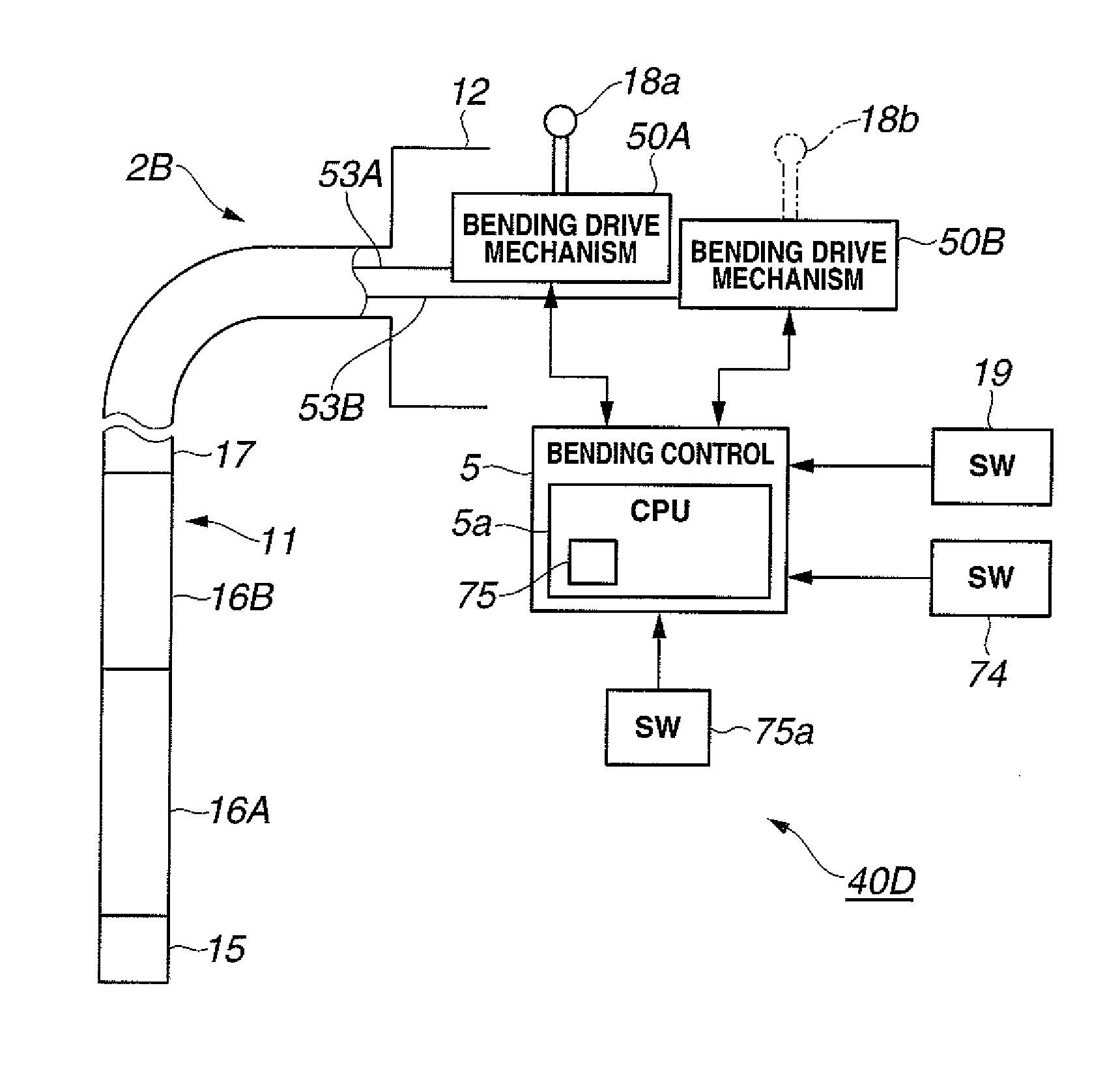

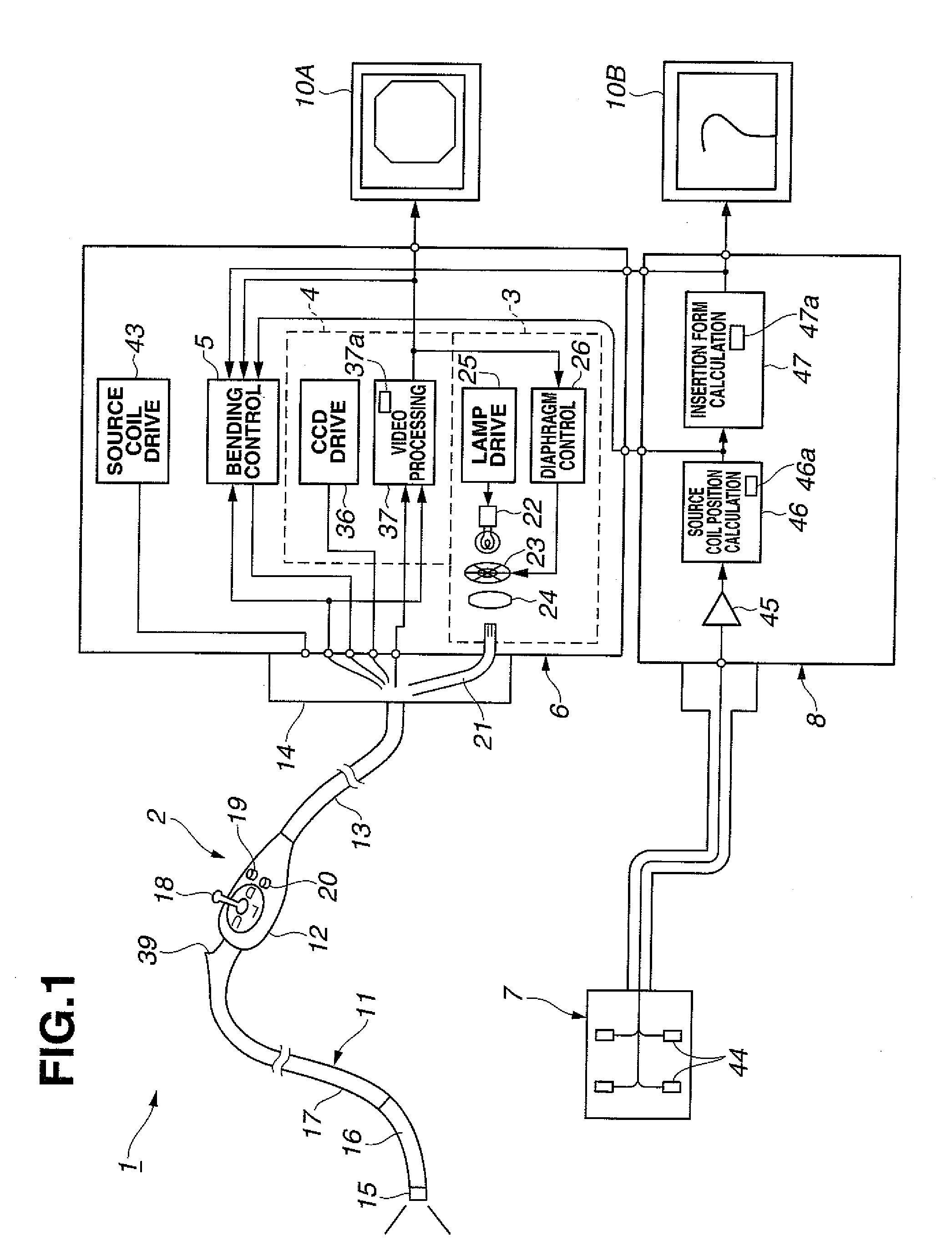

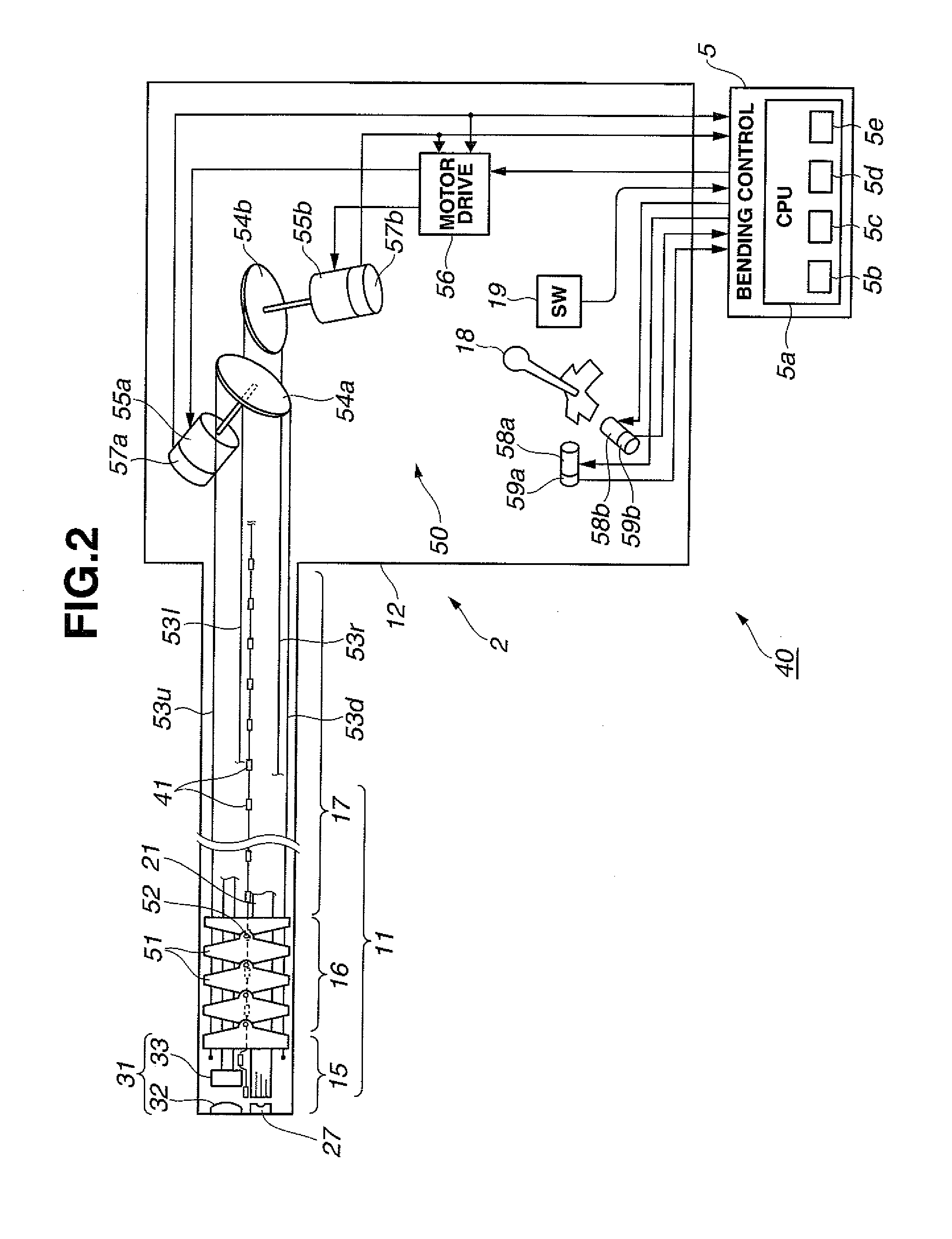

Endoscope apparatus and bending drive control method

An endoscope apparatus includes: an insertion portion including a bending portion provided on a distal end side thereof; a bending drive section that drives bending of the bending portion; an insertion shape detection section that detects an insertion shape of the distal end side of the insertion portion as insertion shape information; a curved state detection section that detects a curved state based on the insertion shape information as curve information; a plane calculation section that performs a calculation to estimate a plane for driving bending of the bending portion from the detected curve information; and a bending control section that drives bending of the bending drive section along the estimated plane.

Owner:OLYMPUS CORP

Systems and methods for harvesting and implanting hair using image-generated topological skin models

Systems and methods are provided for determining the need to change and / or changing orientation of a tool relative to an object on a body in at least partially automated procedure. Also, systems and methods are provided for orienting a hair harvesting tool relative to a follicular unit to be harvested. Further, systems and methods of implanting follicular units are provided, which are based on the orientation of the existing follicular units or based on pre-determined insertion angle. The provided systems and methods use image processing and image-generated topological skin models. In some embodiments surface fit is performed using, for example, a planar fit, quadric fit, cubic fit, mesh fit and parametric fit.

Owner:VENUS CONCEPT INC

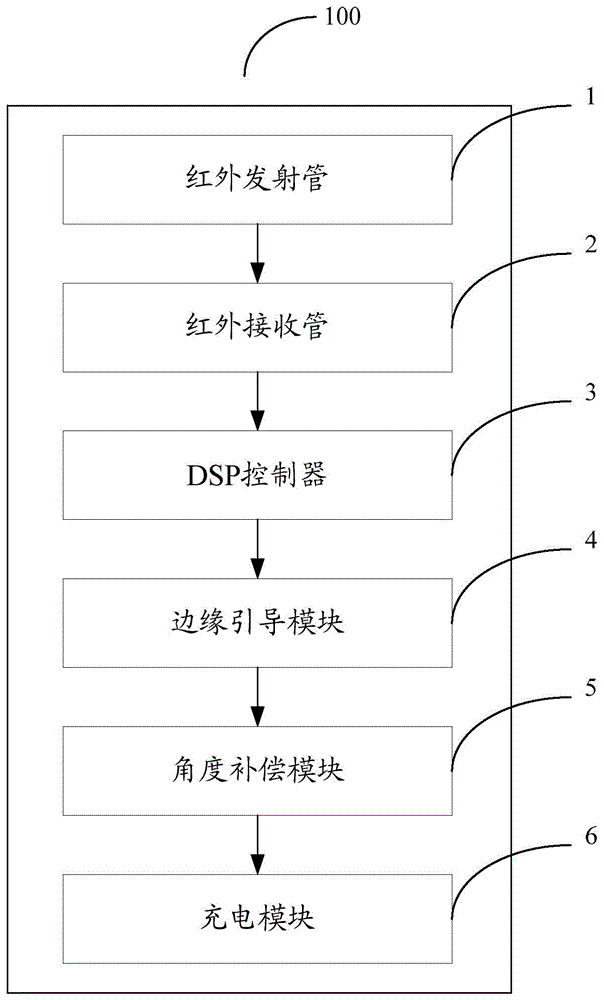

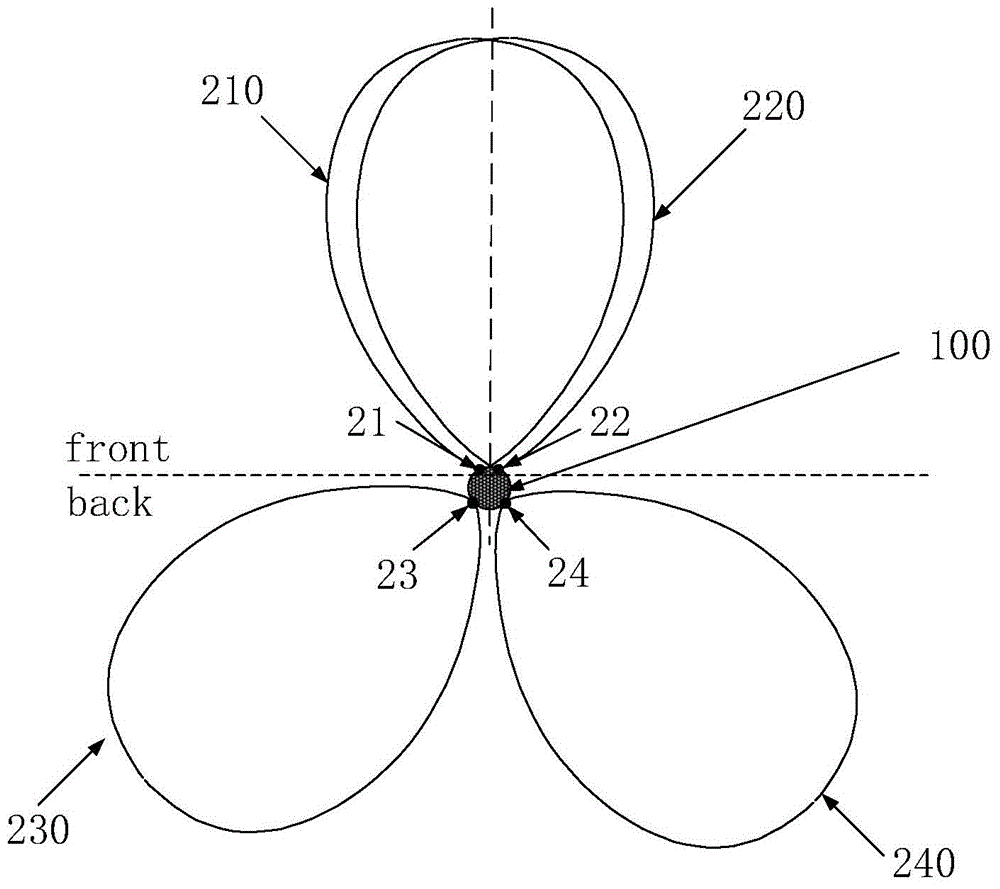

Automatic charging system and automatic charging method for robot

InactiveCN104635728ANot easy to loseAn edge-guided strategy is simple and easyPosition/course control in two dimensionsButt jointEngineering

The invention provides an automatic charging system for a robot. The automatic charging system for the robot comprises an infrared transmitting tube, infrared receiving tubes, a DSP (digital signal processor) controller, an edge guiding module, an angle compensating module and a charging module; and the infrared receiving tubes are arranged in the front of the robot and at the rear of the robot. According to the automatic charging system and an automatic charging method for the robot in an embodiment, the single infrared transmitting tube is used for transmitting infrared signals, the edge characteristics of an infrared transmitting range are skillfully used, and butt joint guidance on the robot can be implemented by an angle compensation strategy. Because edge angle characteristics of different infrared transmitting tubes are different, when the automatic charging system is used for the first time, a tangent angle of the transmitting angle at a transmitting point requires to be measured manually. Even if an approach angle has deviation due to external interferences, a charging head is within a range of a charging socket through the angle compensation strategy. Deviation of an inserting angle can be compensated through a mechanical structure of a charging station. In addition, the invention also provides an automatic charging method for the robot.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Mushroom-compaction and asymmetric-thread impact-drivable screw

An asymmetric thread impact drivable screw and clip for use with a power impact device for penetrating wood fibers while minimizing cut fibers. The screw includes an impact head and a conical shaped tip having a ballistic insertion angle at the ends of a shank. The shank defines asymmetrical threads with an insertion flank having a long side at a slide angle peaking at a crest supported by a catch flank positioned at a grip angle. Varying tool accepting recess are taught for the head along with multiple thread sections. A mushroom compaction thread section is also taught.

Owner:LITZINGER W C

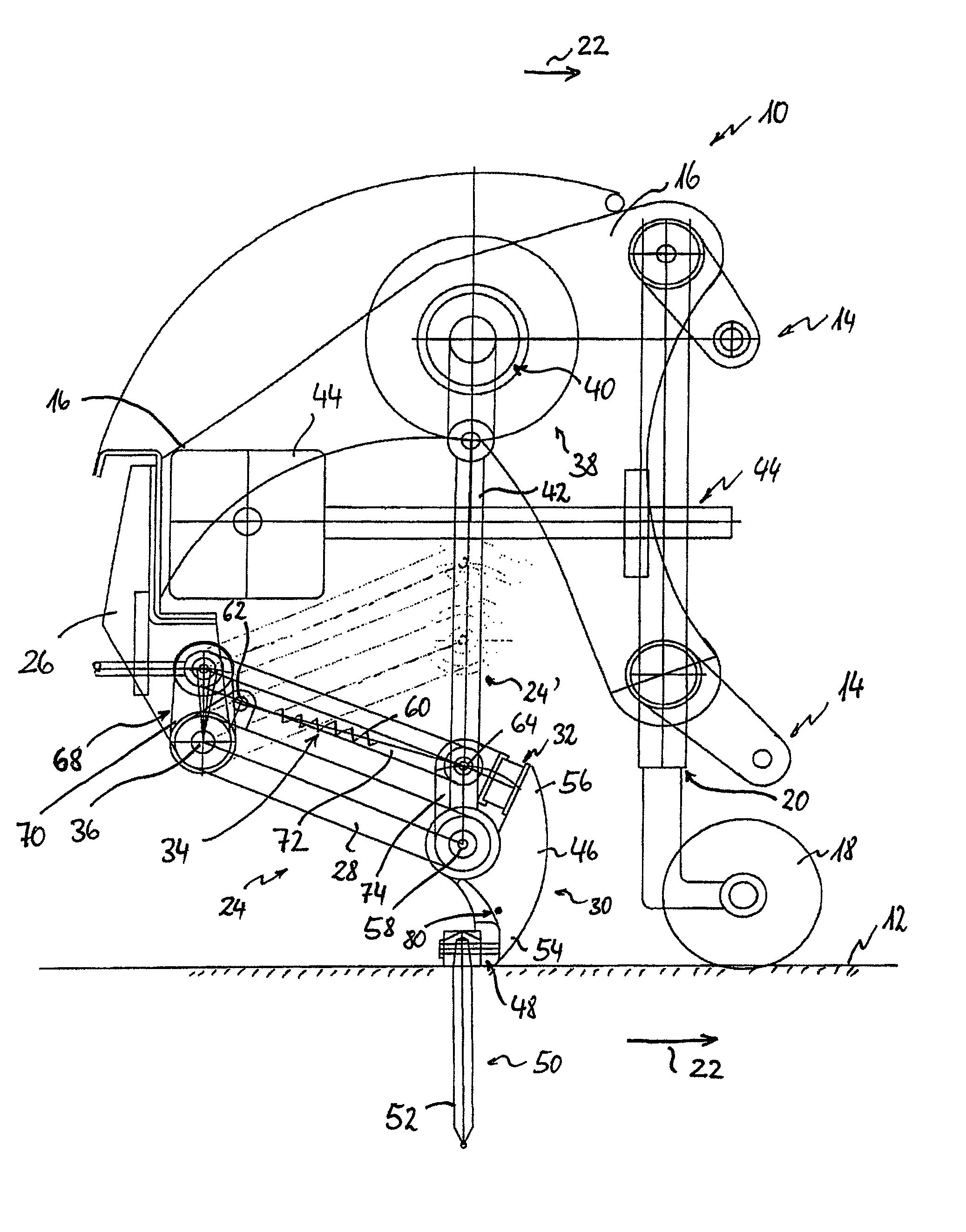

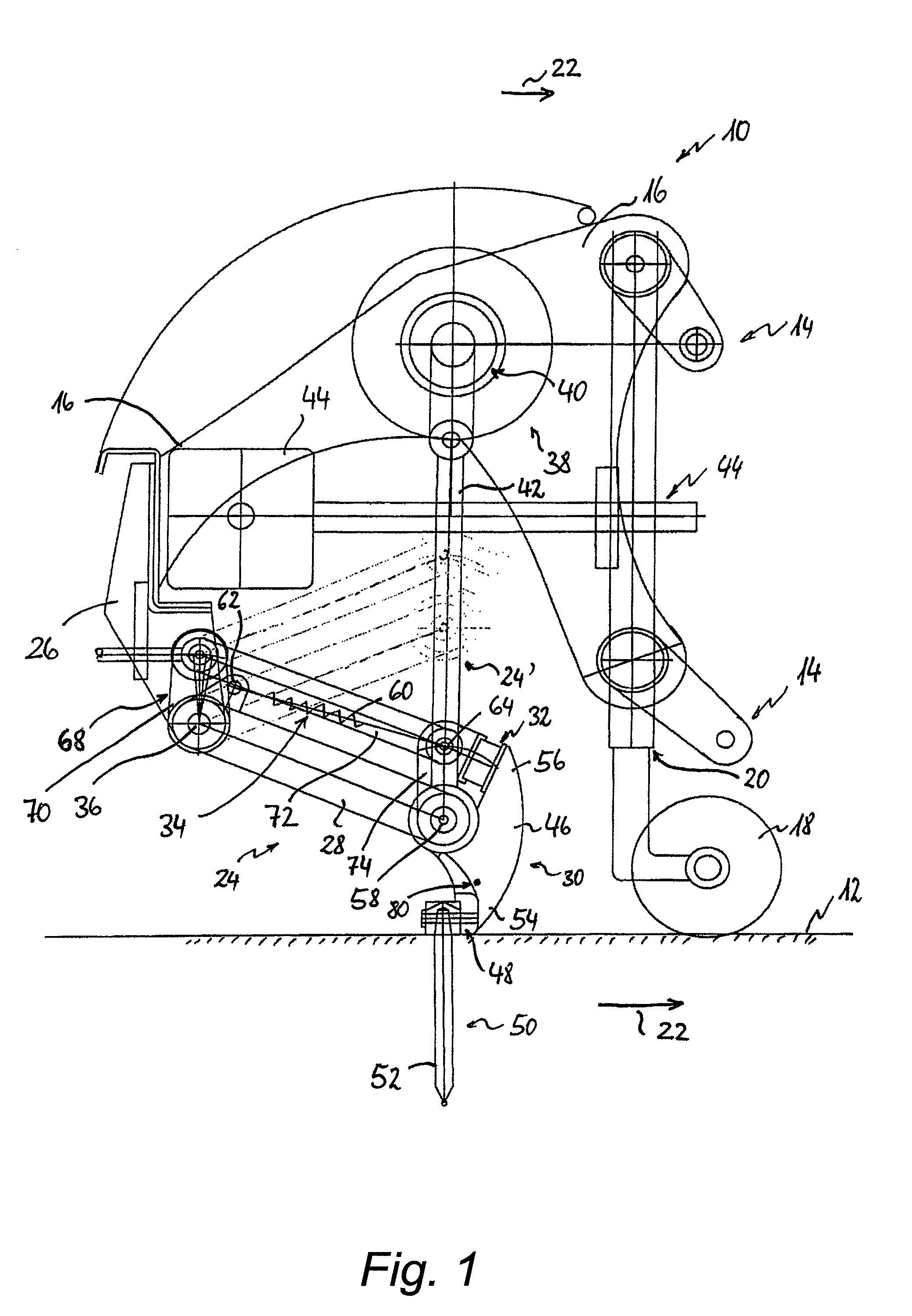

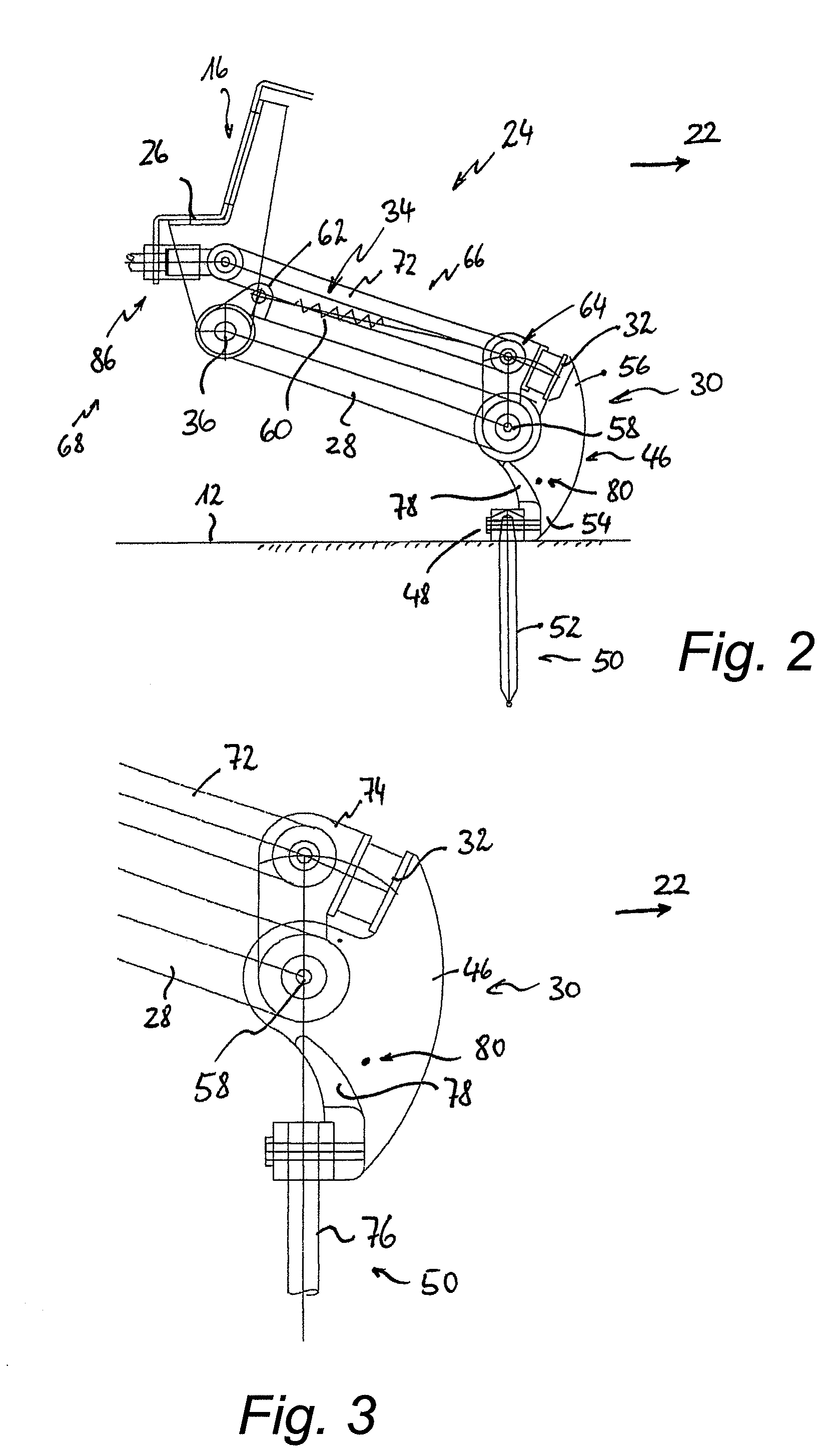

Soil treatment apparatus

InactiveUS8051917B2Avoid elevationIncrease speedSoil-working equipmentsTilling equipmentsSoil treatmentCentrifugal force

Owner:WIEDENMANN GMBH

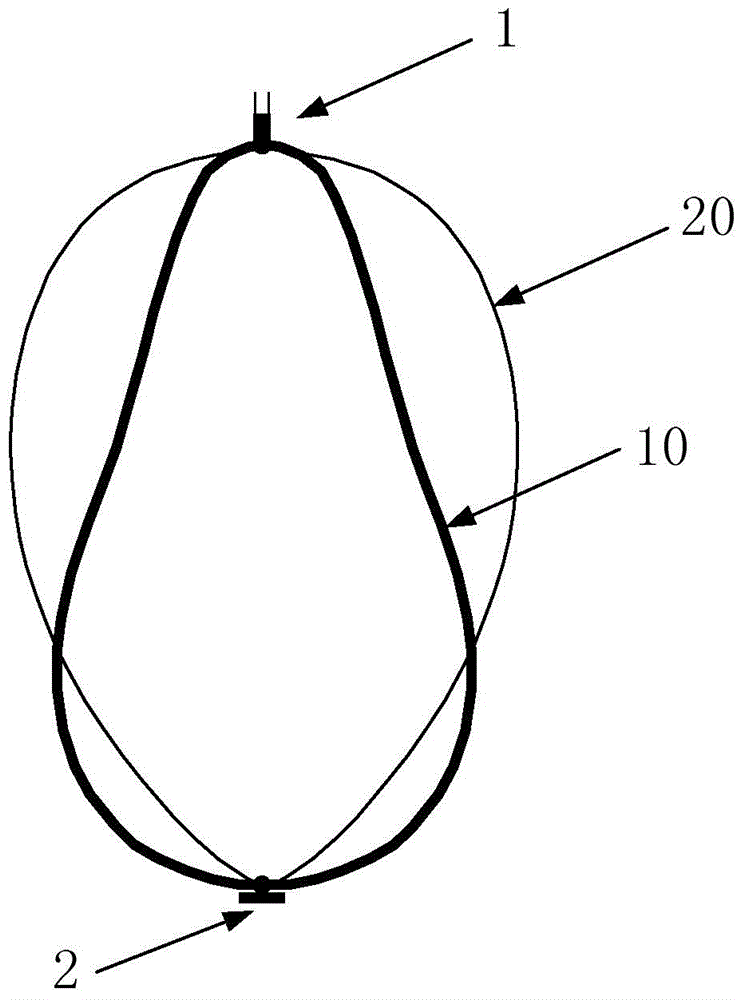

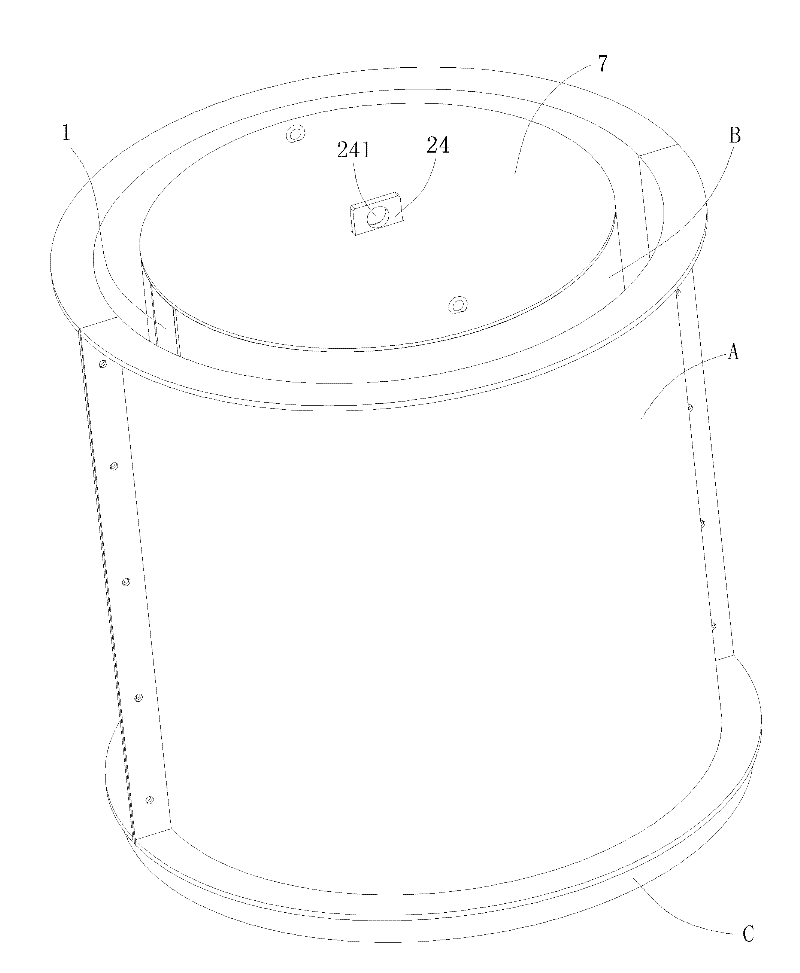

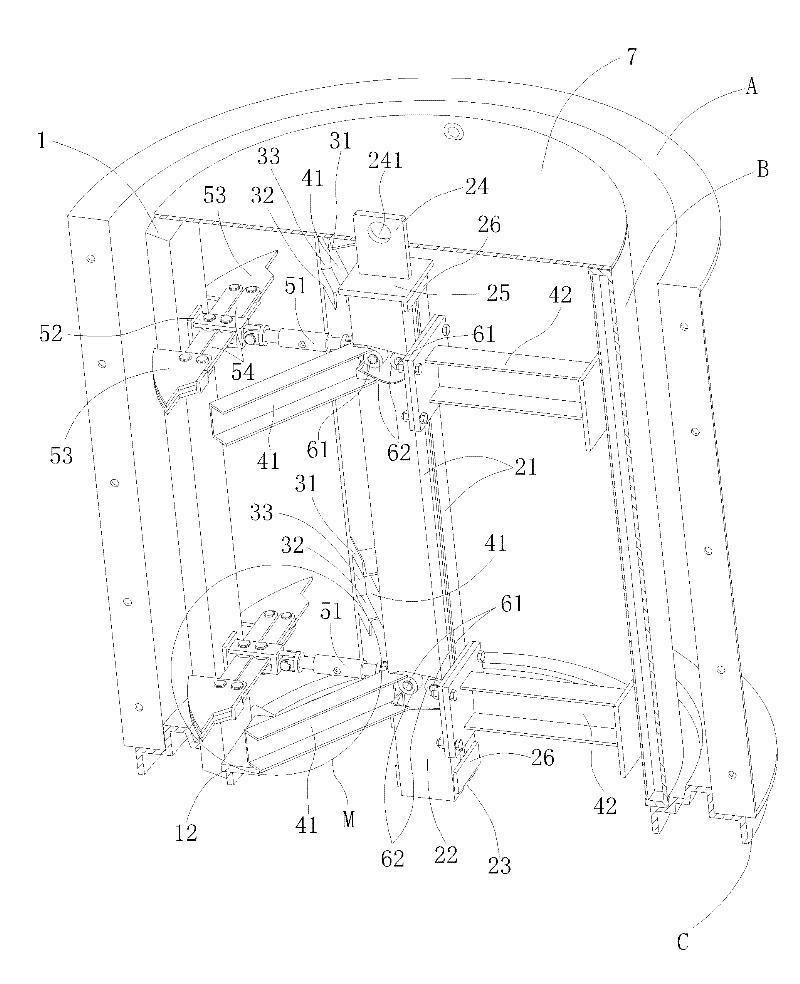

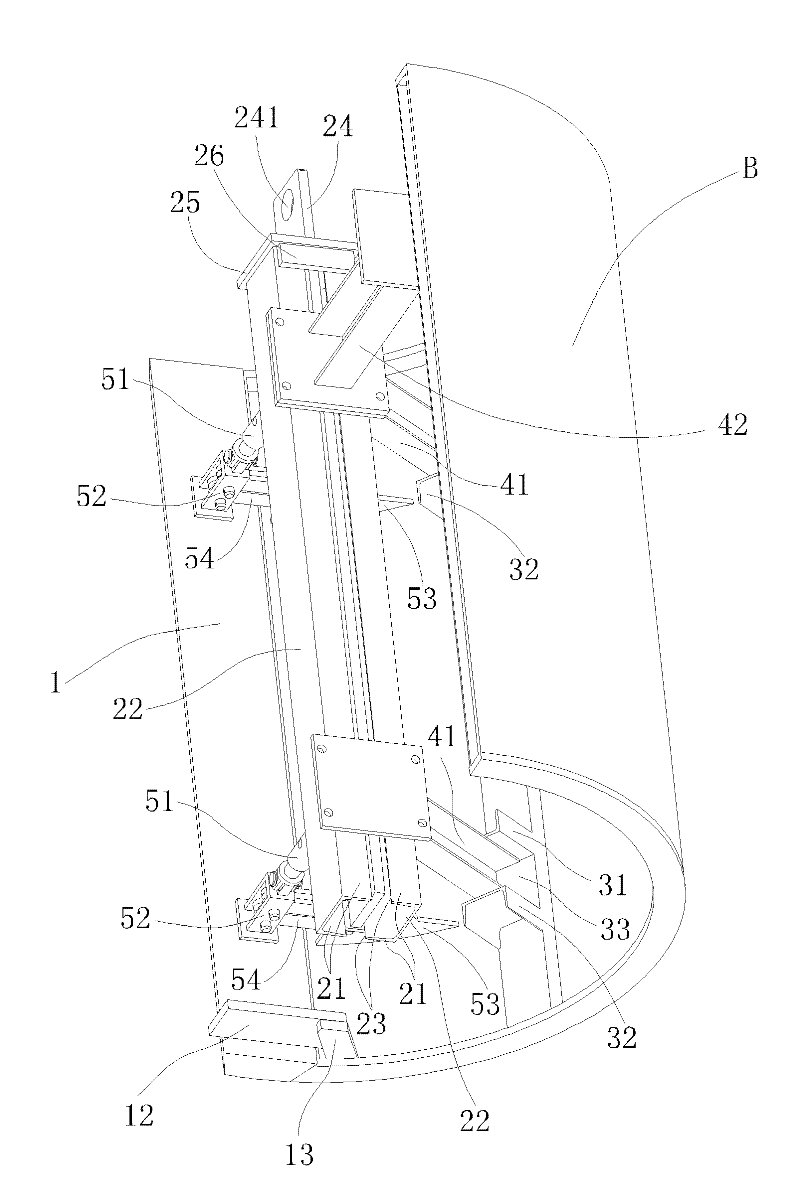

Concrete member internal mold capable of automatically stretching and contracting in radial direction

The invention provides a concrete member internal mold capable of automatically stretching and contracting in radial direction. The concrete member internal mold is characterized in that a hollow cradle is vertically arranged at the center of an internal mold cylinder, connected with the inner wall of the internal mold cylinder by a connecting assembly, and at least provided with a second vertical rabbet which is close to an insertion plate and is over against the insertion plate; a vertical core plate of which the upper part is provided with a horizontal positioning plate is inserted in the cradle and in sliding fit with the cradle, the positioning plate is arranged at the upper end of the cradle, and the thickness tendency of the core plate and the width tendency of the second rabbet are consistent; at least one group of control assemblies capable of controlling the insertion plate to move along the radial direction of the internal mold cylinder and enabling the internal mold cylinder to stretch and contract in radial direction are arranged among the internal mold cylinder, the insertion plate and the core plate, the part in the control assemblies, connected with the core plate,moves up and down along the second rabbet, and the upper limit position of the moving stroke of the part is in the cradle. During the prefabricating of a concrete member, based on the cooperation of the internal mold and a conventional hoisting device, operation personnel do not need to climb in and out of the internal mold cylinder, mold assembling and / or mold stripping can be implemented easilyand conveniently, great convenience is provided for the production of enterprises, therefore the production efficiency of the enterprises is improved and the labor intensity of the operation personnel is reduced.

Owner:ANHUI FANGDA CEMENT PROD

Anti-unscrewing and multi-angular fastening apparatuses and methods for surgical bone screw/plate systems

A fastening apparatus includes a fastener and a fastener receiving member. The apparatus enables the fastener to be affixed to the fastener receiving member at a variable insertion angle selected by the user and further provides an anti-unscrewing feature. The fastener includes an elongate section and an adjoining head section having at least one slot therein. The fastener receiving member includes one or more apertures having a contact region through which one or more corresponding fasteners can be inserted. The contact region includes a matrix of protrusions having a density and strength sufficient to render contact region tappable by the thread of the head section of the fastener. The thread on the head section is driven into the contact region at the selected insertion angle. As a result, the protrusions project into the at least one slot to prevent the fastener from backing out of the fastener receiving member. A fastener driver is also disclosed.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com