Offline automatic brick stacking assembly line and brick stacking method

An assembly line and automatic technology, applied in the stacking, transportation and packaging of objects, destacking of objects, etc., can solve the problems of mechanization, insufficient automation, narrow range of brick and brick forming machines, and rough structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

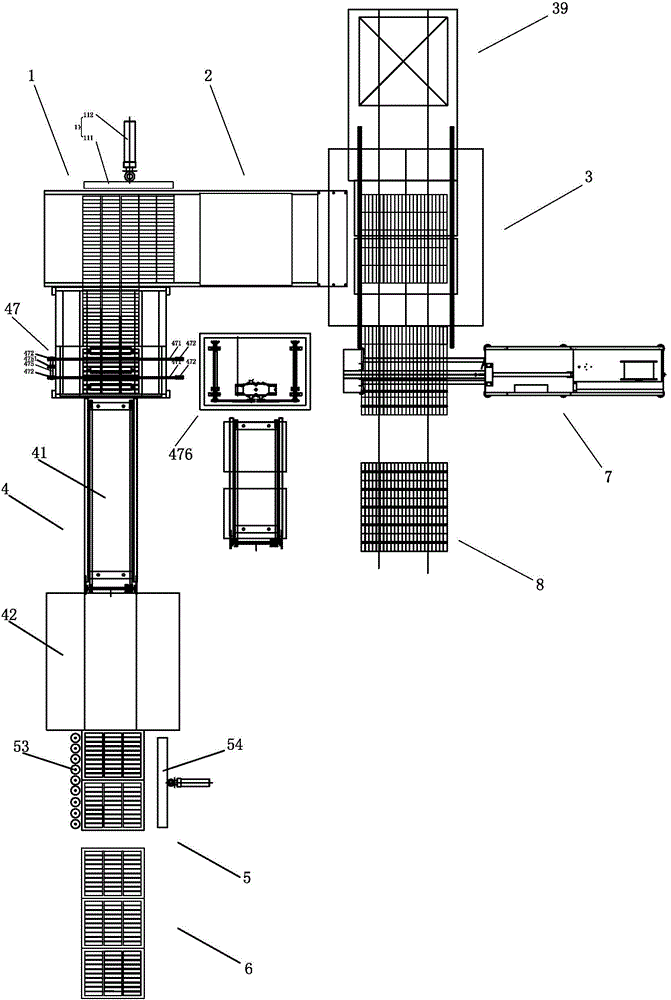

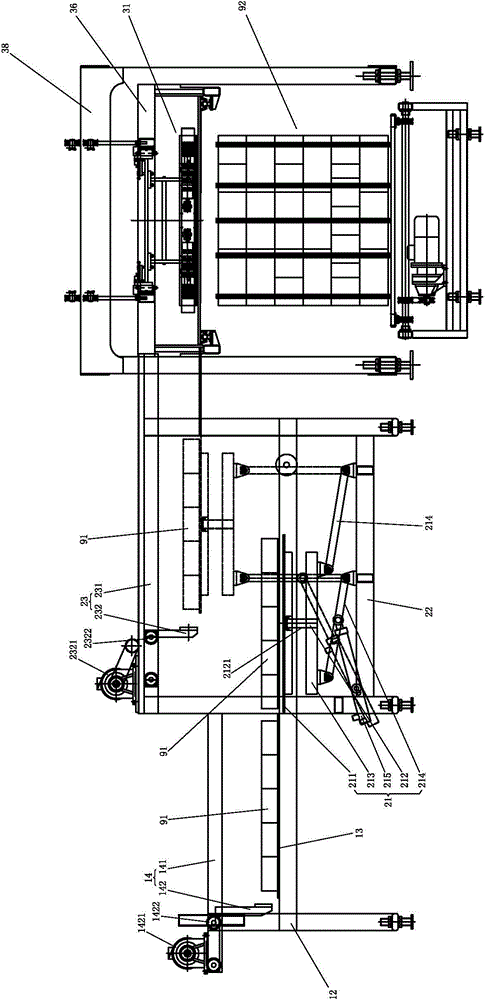

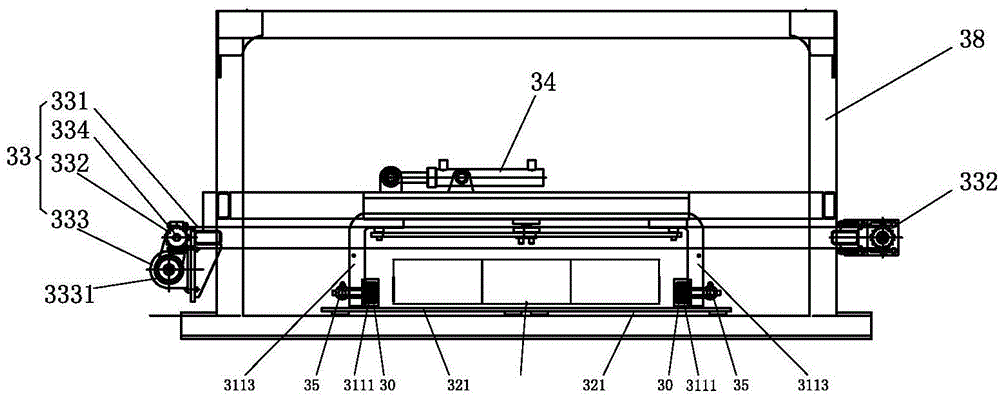

[0084] The off-line automatic code brick assembly line of the present invention, as Figure 1-18 As shown, it includes a brick arrangement device 1, a brick running device 2 and a code brick device 3.

[0085] Brick arranging device 1, brick running device 2 and brick stacking device 3 are arranged sequentially along the assembly line; brick arranging device 1 arranges brick piles 9 into a stackable brick layer 91; brick running device 2 transports the brick layer delivered by brick arranging device 1 91 continues to be conveyed forward; The stacking brick device 3 codes each brick layer 91 layer by layer into a forming brick stack 92; The brick reducing device 11 of a row; The brick running device 2 includes the brick turning device 21 that turns the brick layer 91 at a predetermined angle relative to the upper or lower brick layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com