Patents

Literature

245results about How to "Improve mechanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comprehensive treating system for domestic wastes

InactiveCN102527701AIncrease productionImprove qualityBio-organic fraction processingWaste processingSludgeOrganic manure

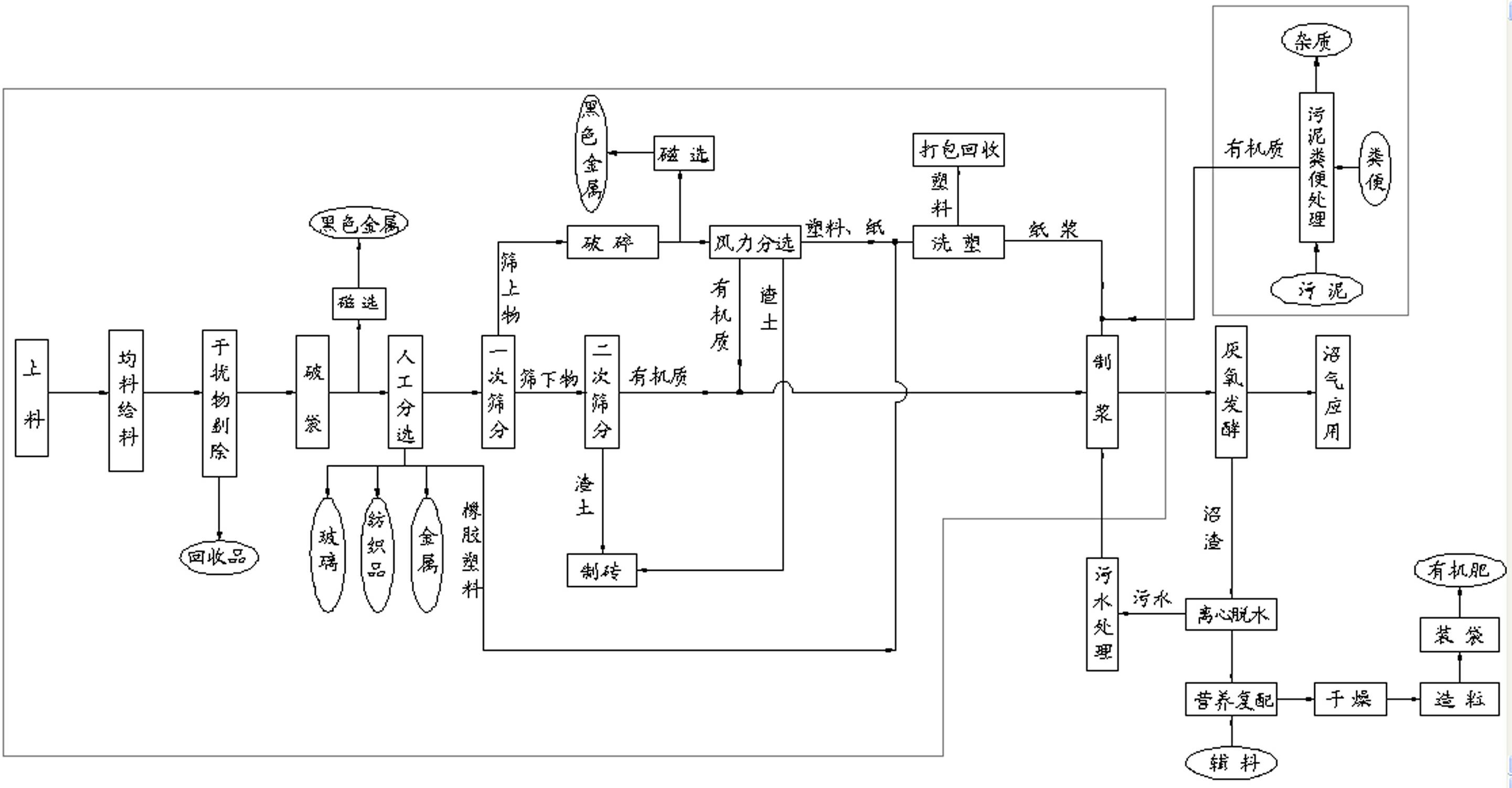

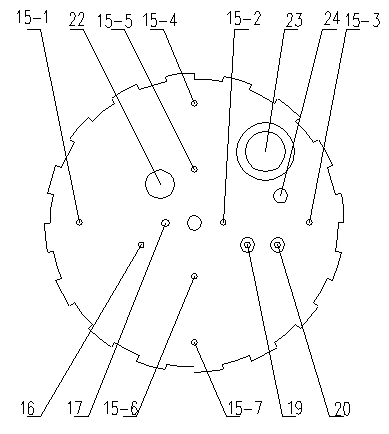

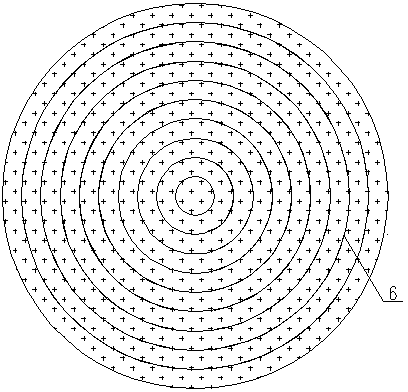

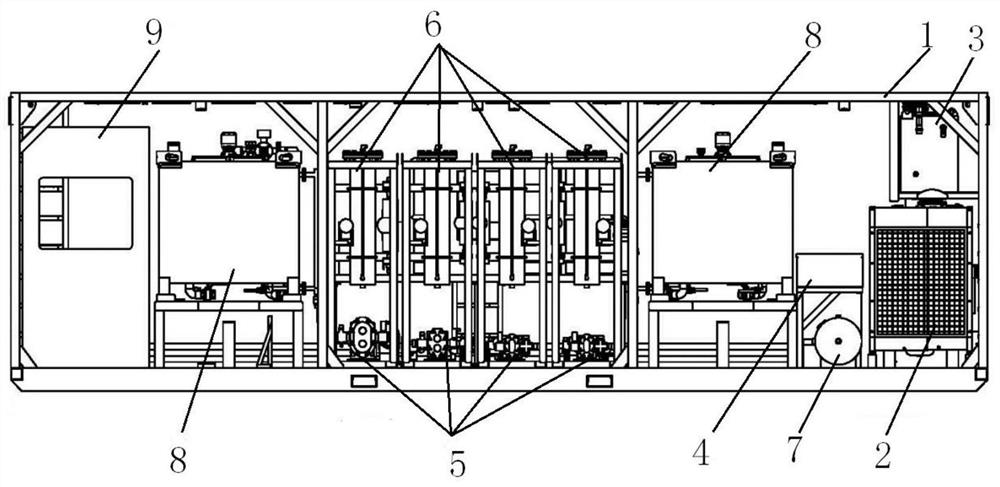

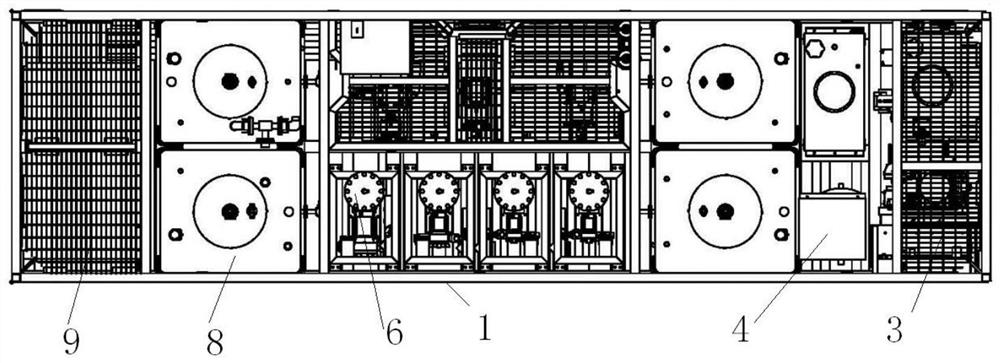

The invention discloses a comprehensive treating system for domestic wastes. Reutilizing comprehensive treatment for mixed wastes is realized by the system according to a comprehensive sorting technology and a combined anaerobic fermentation technology, wherein the advanced sorting techniques, such as, crushing, magnetic separating, sieving, air classifying, and the like, are adopted in the comprehensive sorting technology; reutilized products, such as metal, plastics, organic matters, and the like, are screened out; the screened organic matters are prepared into slurry together with sludge and excrements and are then subjected to the combined anaerobic fermentation; the reutilized products, such as methane, organic fertilizer, and the like, can be produced under the action of anaerobic fermentation; and after the methane is purified, the methane is used for generating power, domestic fuel or vehicle-mounted fuel. According to the technology, the intensified treatment for organic wastes, such as domestic wastes, sludge, excrements, kitchen wastes, and the like, can be realized. The comprehensive treating system is high in mechanical and automated degree. Compared with the prior art, the comprehensive treating system has the advantages of simplification, effectiveness, less labor power, and the like.

Owner:BEIJING HAOHAI TIANJI TECH +1

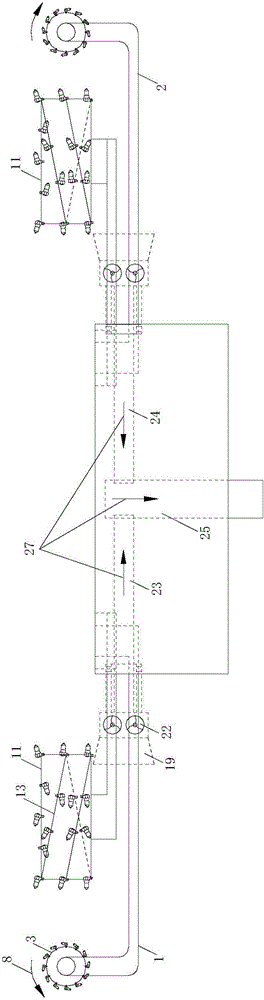

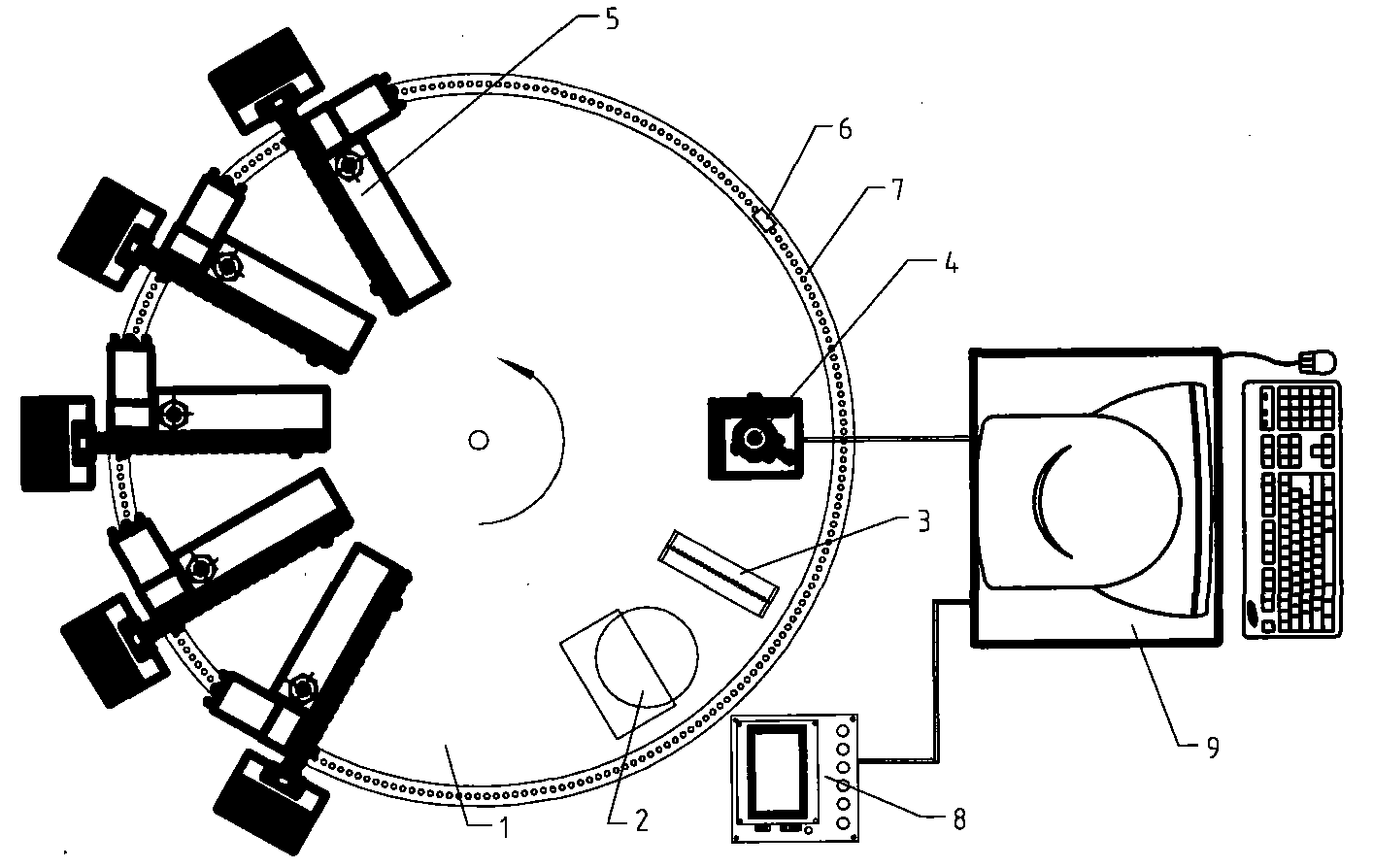

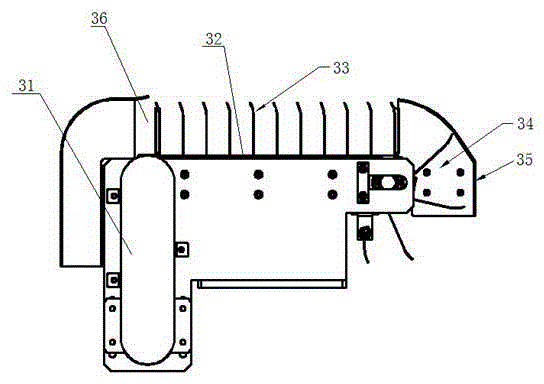

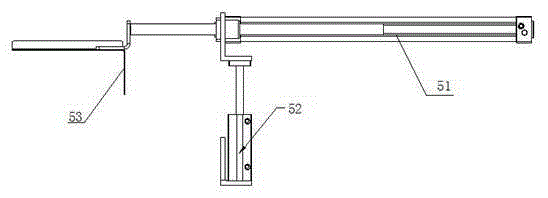

Corn-seed image carefully-choosing apparatus and usage method for apparatus

InactiveCN104084379AGuaranteed accuracyContinuous and even double row feedingSortingMachine visionImage detection

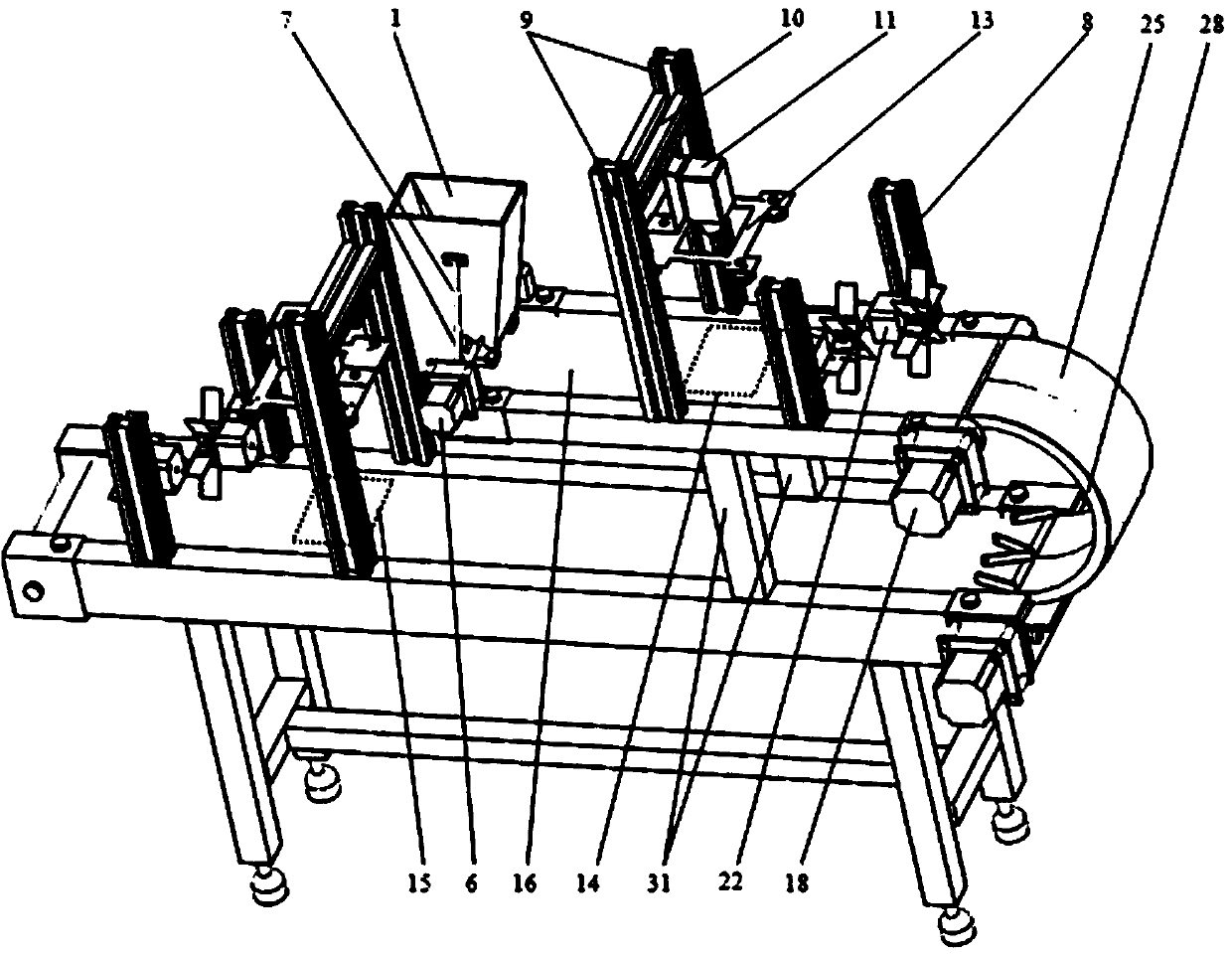

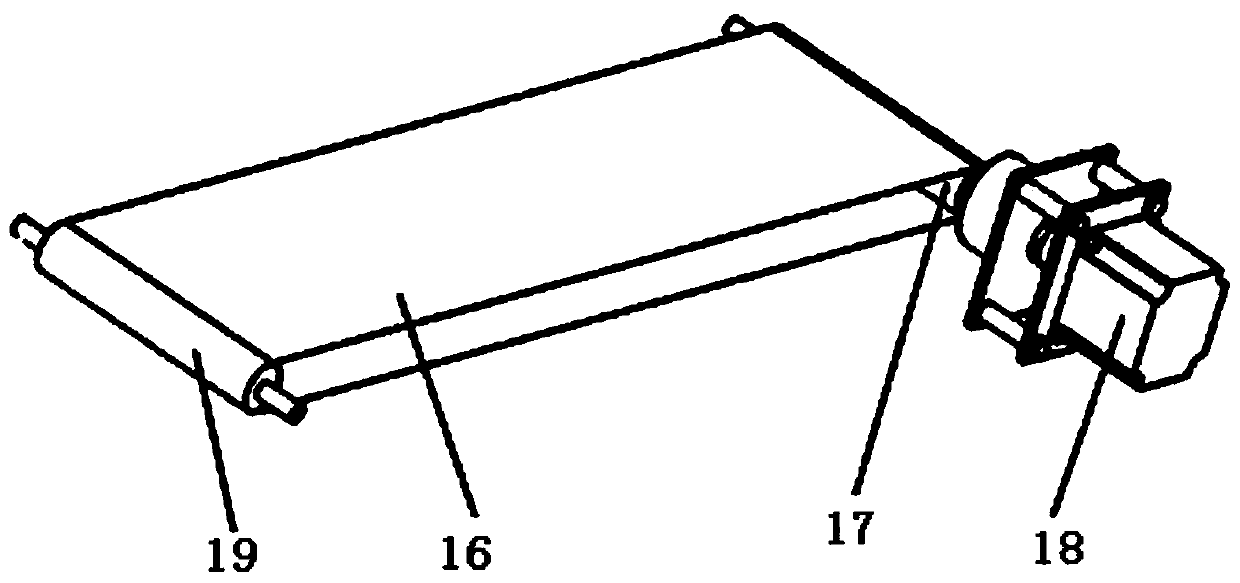

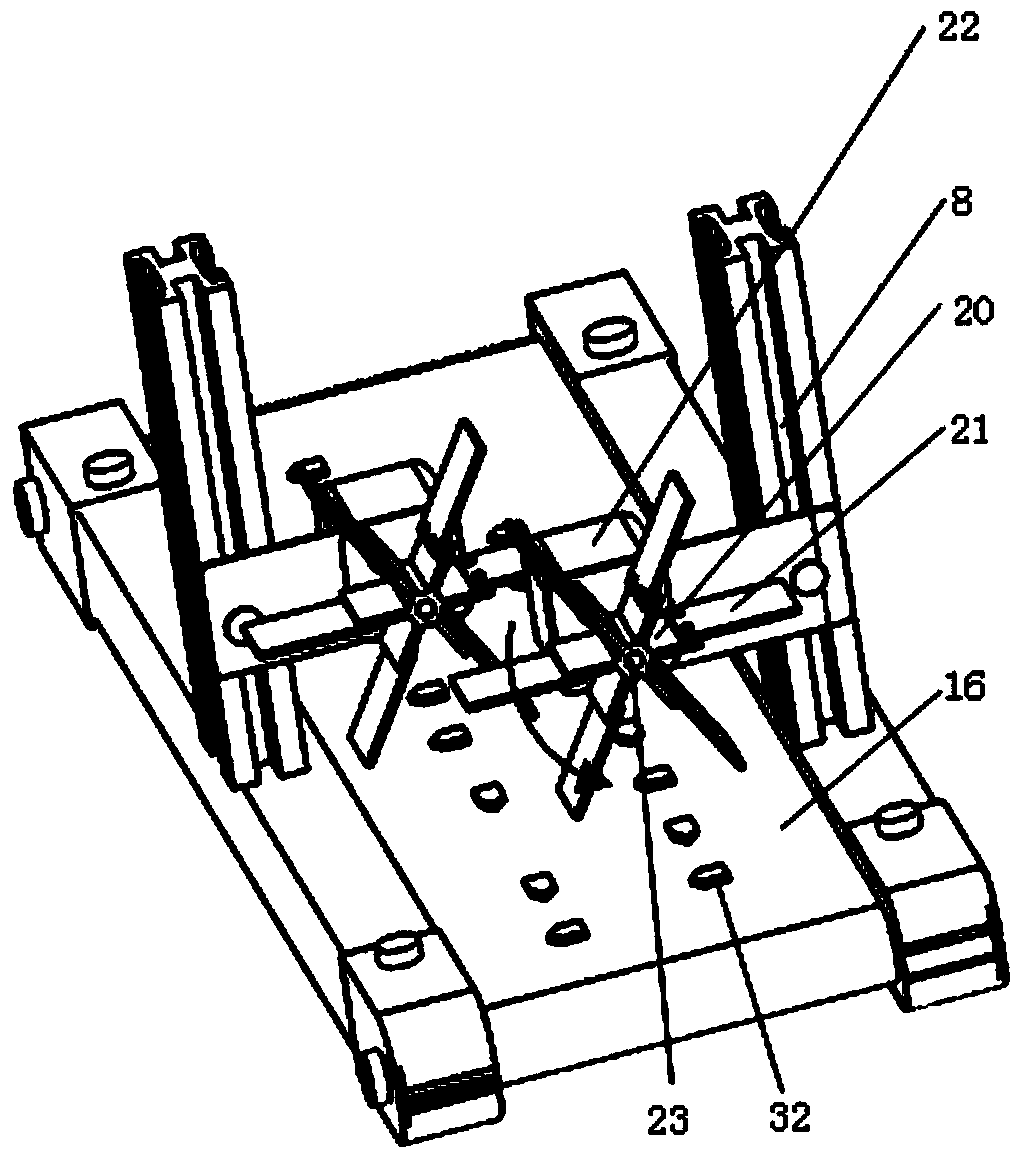

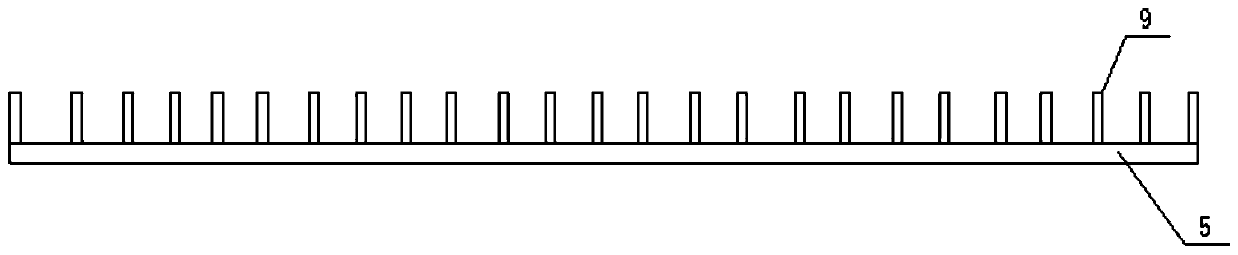

The invention relates to the technical field of visual inspection by using a machine, and concretely relates to an corn-seed image carefully-choosing apparatus and a usage method for the apparatus. The technical scheme is characterized in that the a practical efficient on-line carefully-choosing image detection algorithm for corn seeds is provided; a corn-seed turning-over mechanism is designed, which is capable of performing image detection determination on the front side and the reverse side of a corn seed and helps to guarantee accuracy of a detection result; an electromechanical sorting execution mechanism with simple structure is designed; and a novel double-row feeding mechanism is designed, which is capable of continuously uniformly performing double-row feeding on corn seeds. The corn-seed image carefully-choosing apparatus is simple in structure, precise and efficient, and is significant in guaranteeing enforcement of orientated precise sowing of corn, realizing careful choosing of corn seeds before sowing, promoting high quality, high yield and stable development of corn industry in our country and mechanization, automation and intelligentization level of agricultural-product detection.

Owner:CHINA AGRI UNIV

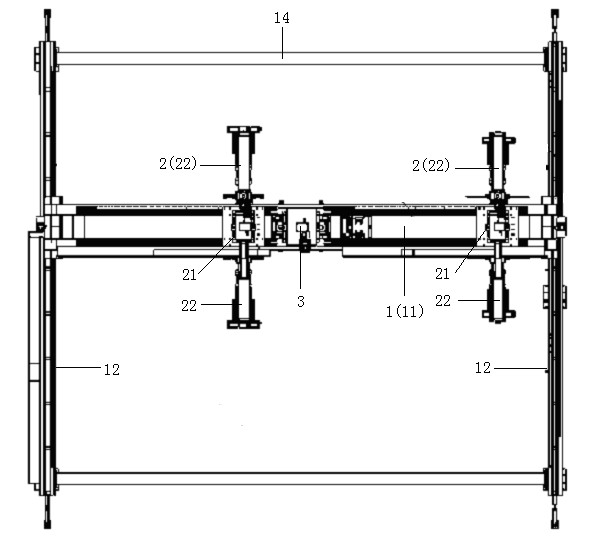

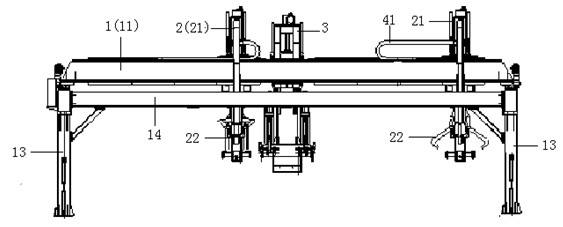

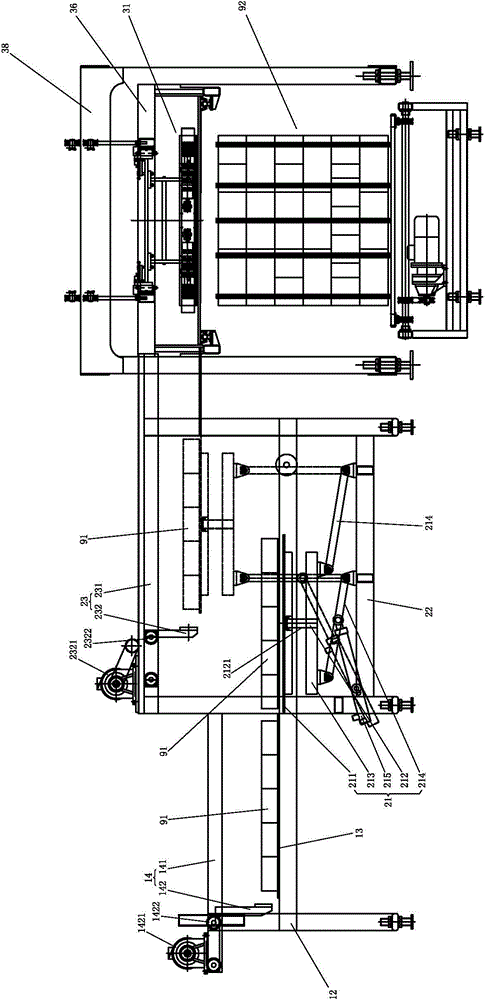

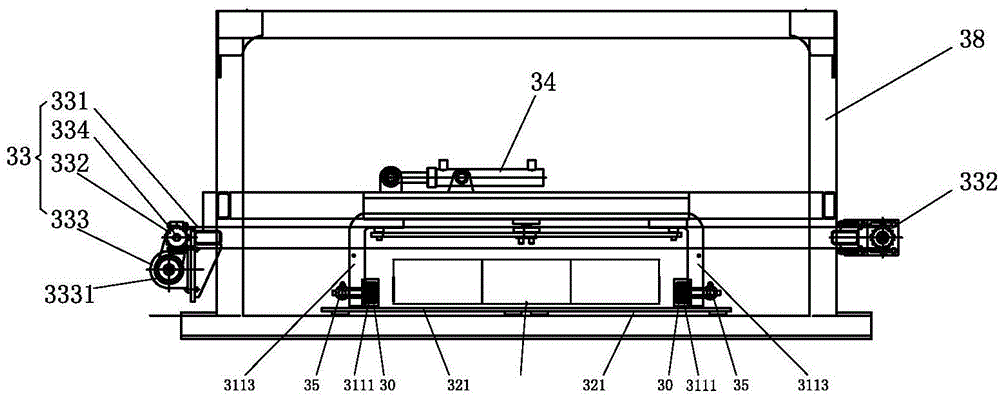

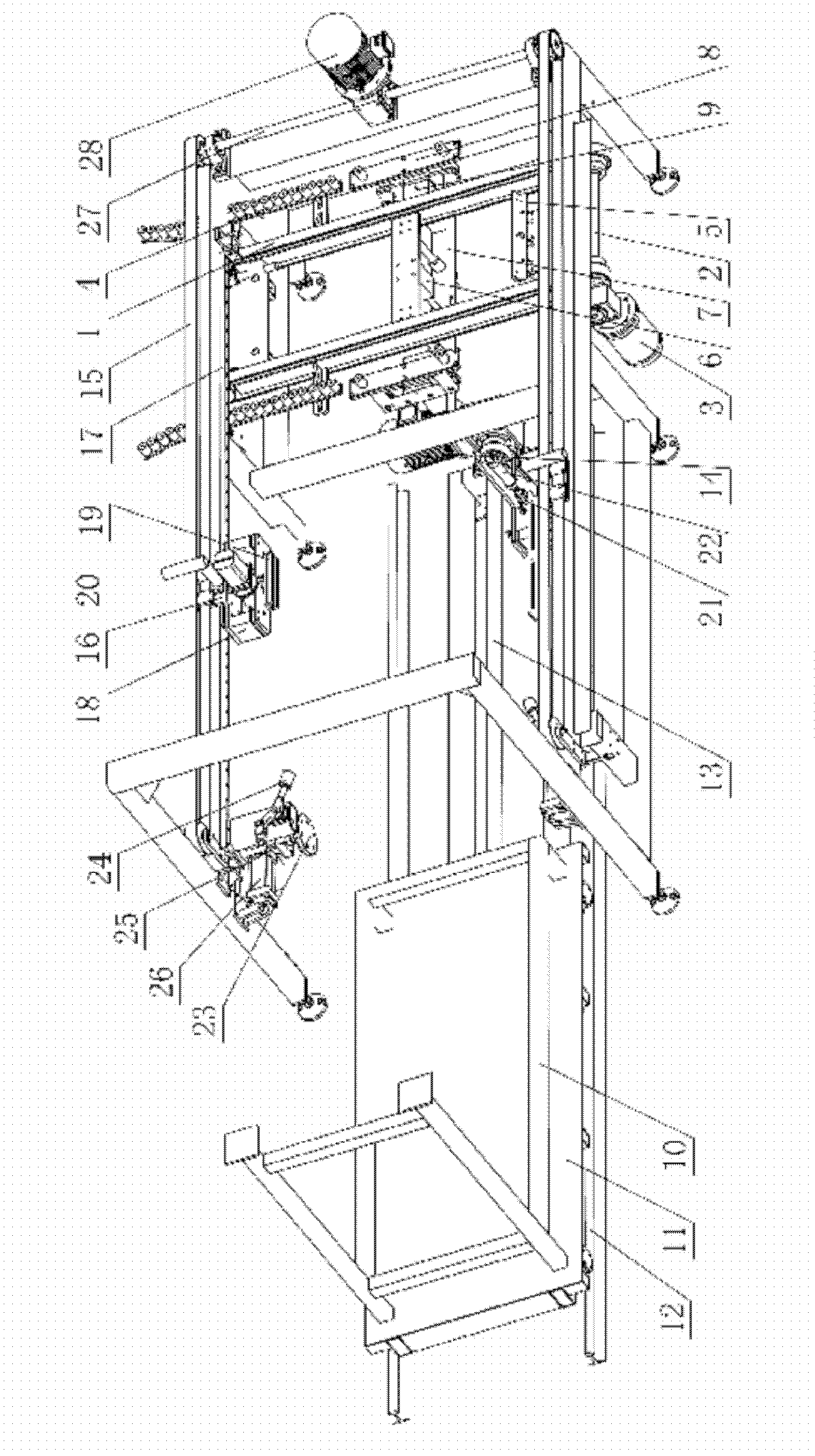

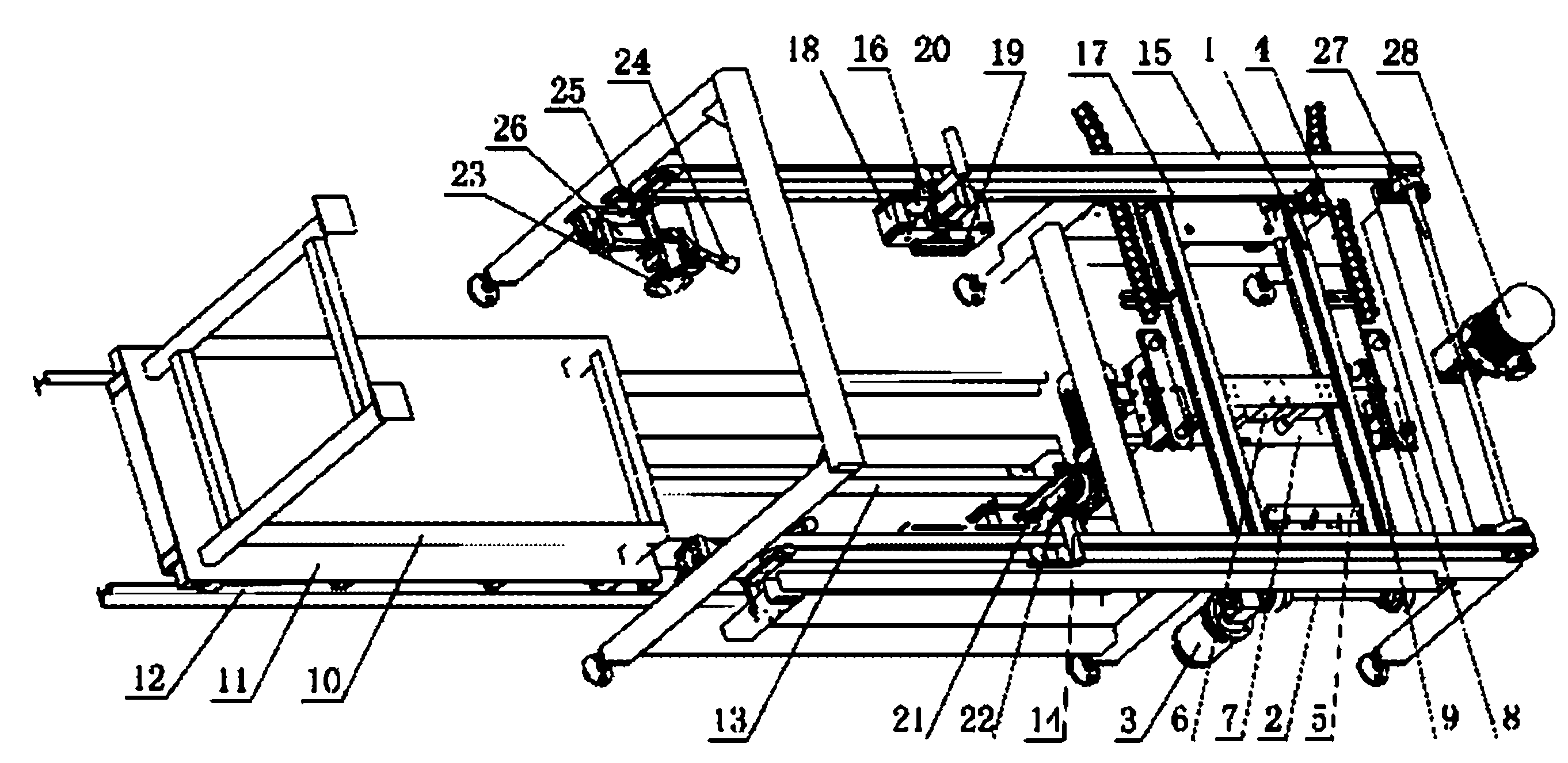

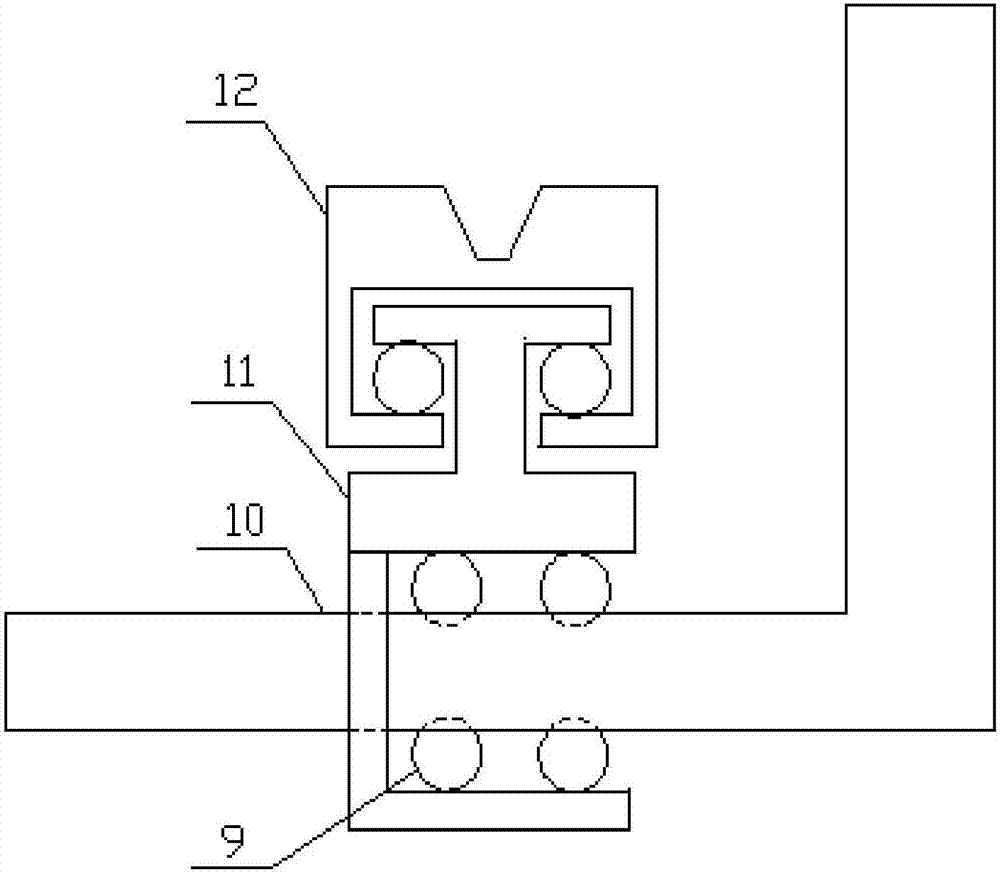

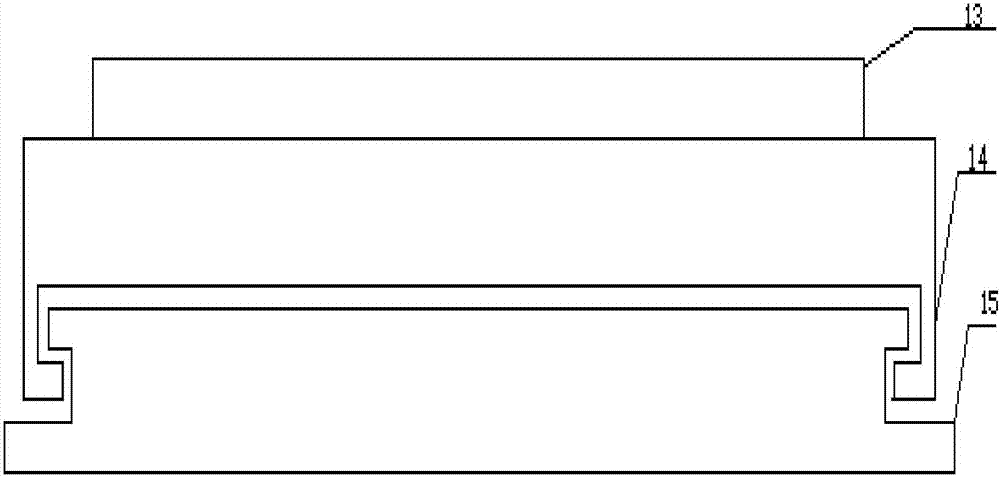

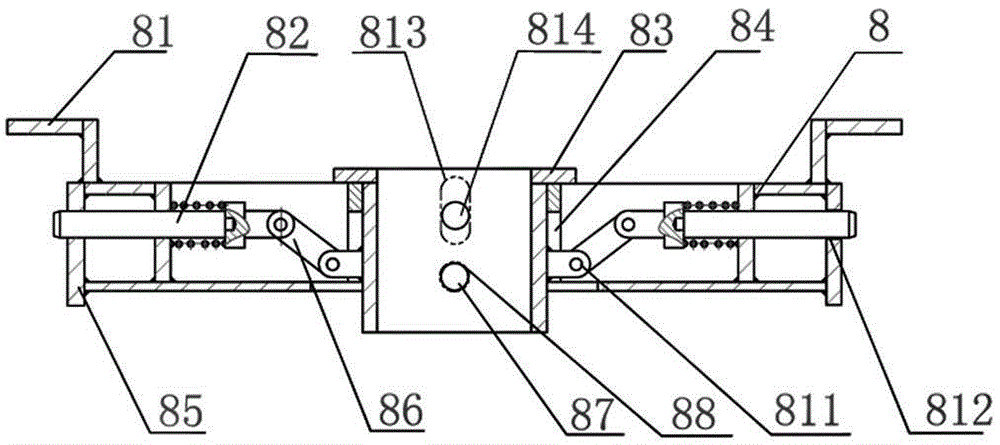

Special portal-type bolster frame assembly manipulator for truck bogie production line

ActiveCN102430906AEliminate potential safety hazardsImprove assembly qualityProgramme-controlled manipulatorMetal working apparatusBogieProduction line

The invention provides a special portal-type bolster frame assembly manipulator for a truck bogie production line, which is mainly composed of a frame, two side frame manipulators, a swing bolster manipulator and an electric control unit, wherein the side frame manipulators, swing bolster manipulator and electric control unit are installed on the frame; the frame is mainly composed of a cross beam, a support beam, a vertical support and a traveling beam which are connected with each other; the two side frame manipulators are installed on the cross beam, and each side frame manipulator is composed of a side frame transverse operating / vertical lifting unit and a side frame grabbing / clamping / turning unit; and the swing bolster manipulator is installed on the cross beam and positioned betweenthe two side frame manipulator. The invention provides an indispensable important apparatus of the key position bolster frame assembly for a truck bogie production line; the side frame manipulators can operate leftward and rightward or forward and backward to grab and lift the side frames transported by the transport vehicle, and smoothly align and assemble the side frame with the swing bolster grabbed by the swing bolster manipulator, and thus, the degree of mechanization and automation is high; and the invention has the advantages of labor saving, time saving and high assembly quality, and eliminates the potential safety hazard in the craning process.

Owner:江苏中创机械装备制造有限公司

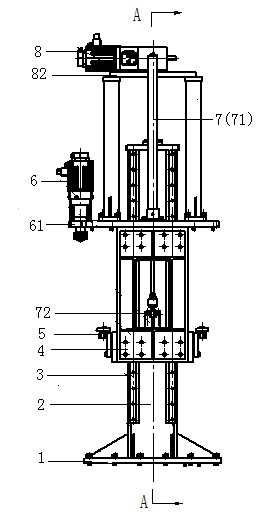

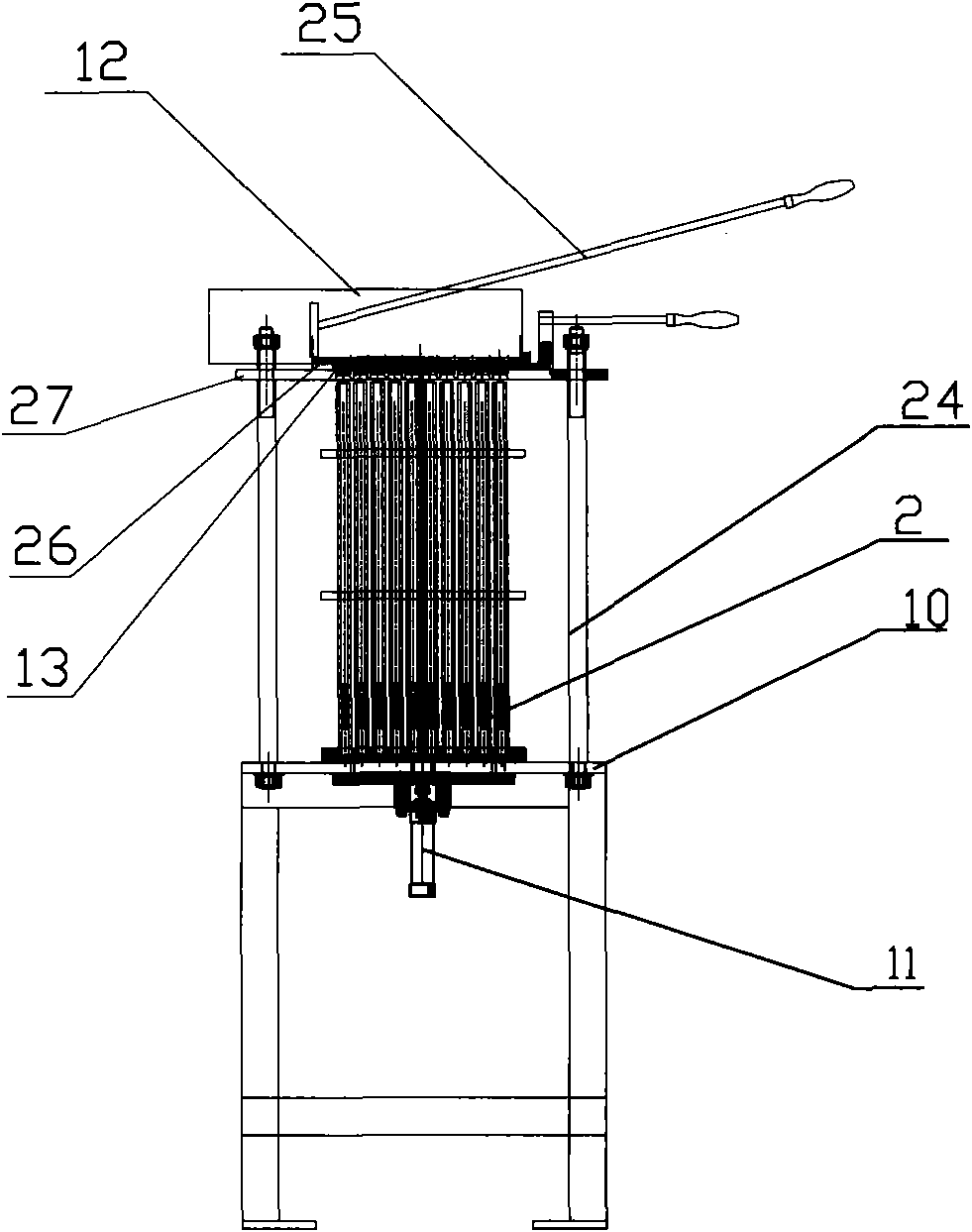

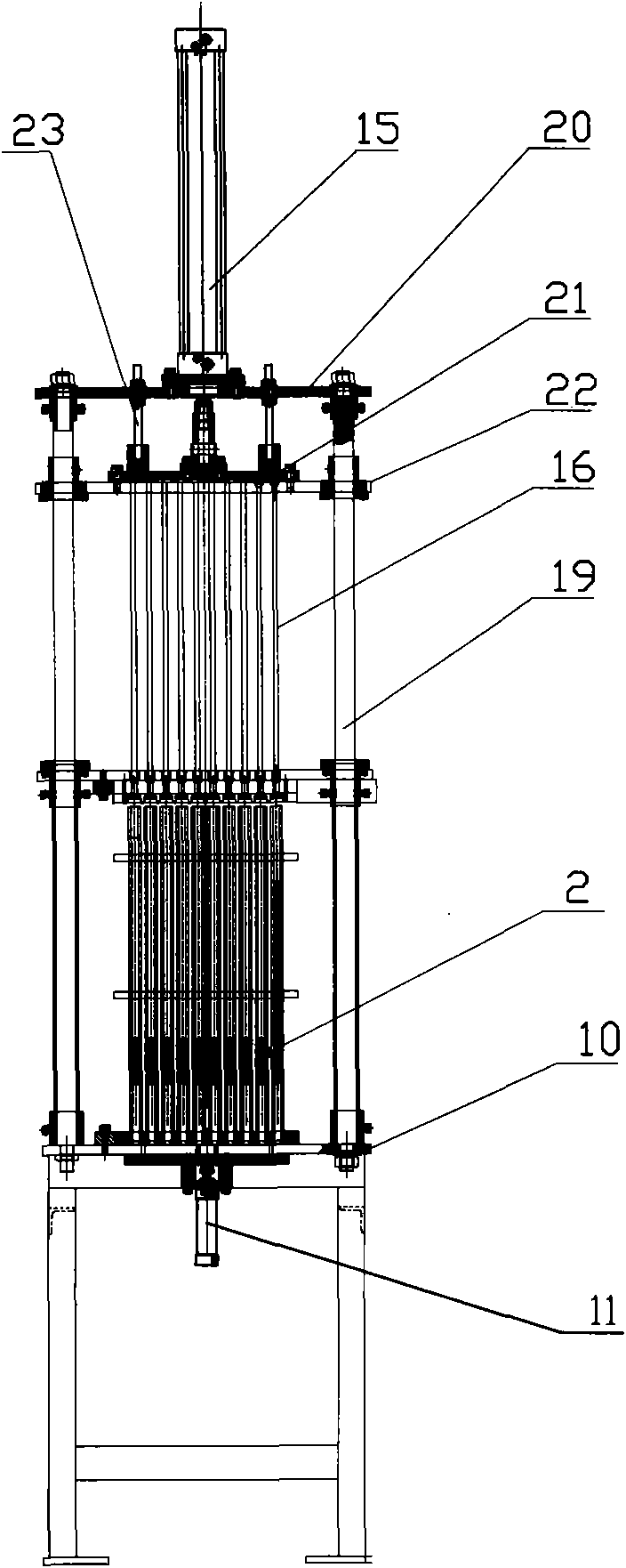

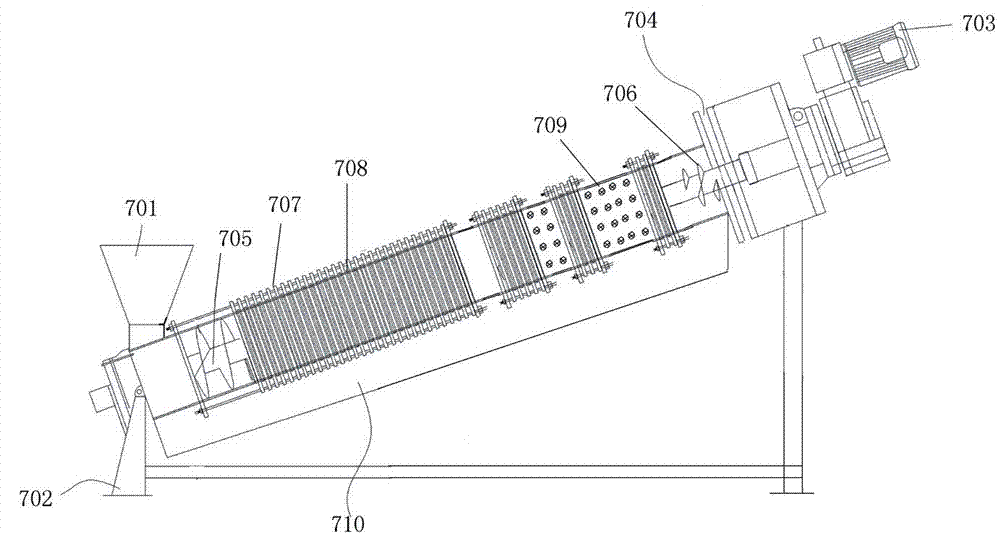

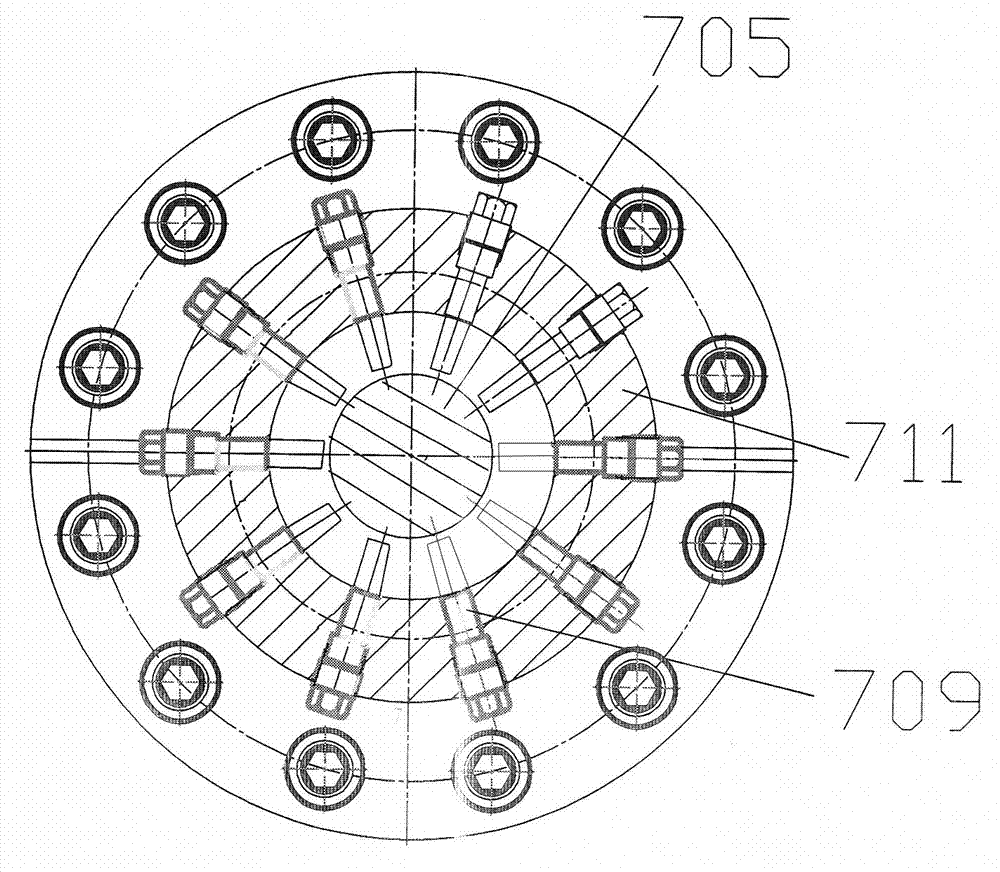

Solid state fermentation cylinder and solid state fermentation method

ActiveCN102839119AWell mixedAvoid damageBioreactor/fermenter combinationsBiological substance pretreatmentsThermal insulationEngineering

The invention discloses a solid state fermentation cylinder and a solid state fermentation method. The solid state fermentation cylinder comprises a cylinder body and a jacket provided with an upper port and a lower port, the upper end of the cylinder body is an upper end cover, a mixing system capable of lifting is arranged on the upper end cover, and according to the mixing system, a mixing frame is driven by a driving system. The mixing frame is formed by a wall surface scraper plate, a bottom surface scraper plate and mixing blades, the wall surface scraper plate and the bottom surface scraper plate form a frame-shaped structure, and the mixing blades are fixedly connected in the frame-shaped structure. The solid state fermentation cylinder and the solid state fermentation method effectively resolve the problem of low fermentation performance caused by uneven thickness and uneven heating of a feed layer. According to the solid state fermentation cylinder and the solid state fermentation method, all the processes from feeding to discharging are concentrated in the solid state fermentation cylinder, the process of transportation of materials is simplified, and the mixing system and a cooling thermal-insulation system of equipment are strengthened. Automatic bulk production of solid state fermentation can be achieved, the pure culture in the solid state fermentation process is effectively guaranteed, quality and safety of products are improved, and homogeneity property in the same bulk is guaranteed.

Owner:CHENGUANG BIOTECH GRP CO LTD

Full-automatic liquid adding device for fracturing construction and adding calibration method

PendingCN112196508AStable structureStructure, stable installationMass flow measurement devicesTransportation and packagingTransfer caseControl engineering

The invention belongs to the technical field of fracturing construction mechanization, and particularly provides a full-automatic liquid adding device for fracturing construction and an adding calibration method. The full-automatic liquid adding device comprises a prying frame, an engine, a transfer case, a hydraulic device, a liquid adding pump, a metering calibration tank, a liquid additive tank, a liquid supply pump and a control unit, wherein the input ends of the engine, the transfer case and the hydraulic device are sequentially connected; the output end of the hydraulic device is connected with the liquid supply pump and the liquid adding pump; the liquid supply pump is connected with an inlet of the liquid additive tank; an outlet of the liquid additive tank is sequentially connected with inlets of the metering calibration tank, the liquid adding pump and the liquid additive tank; the control unit is electrically connected with the engine, the transfer case, the hydraulic device, the liquid adding pump, the metering calibration tank, the liquid supply pump and the liquid additive tank; and the current situation that in the fracturing construction process, the liquid additive adding precision is large in adding difficulty and discontinuous is avoided, the mechanization and automation degree of fracturing construction is improved, meanwhile, the construction quality and potential safety hazards are effectively eliminated, and the construction success rate is increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

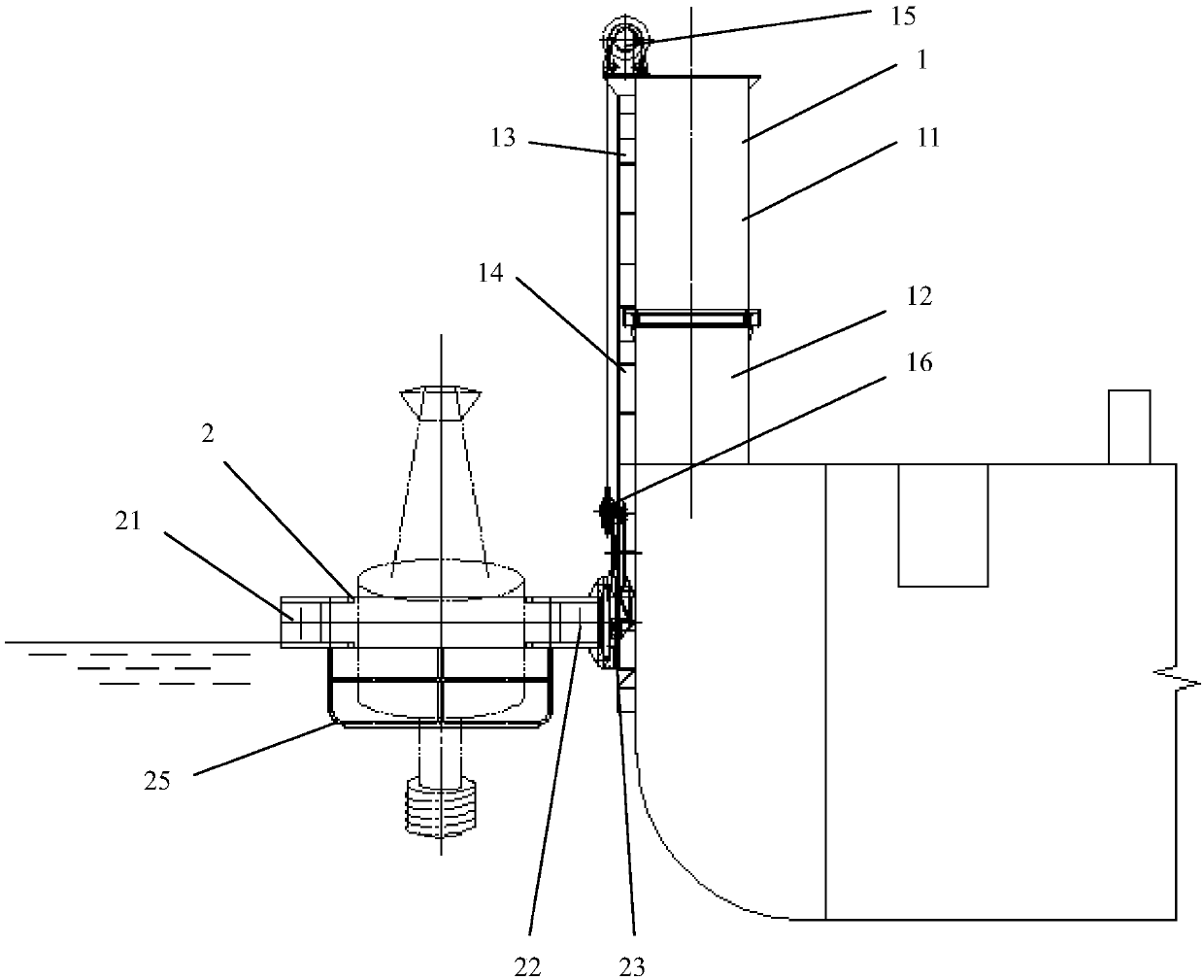

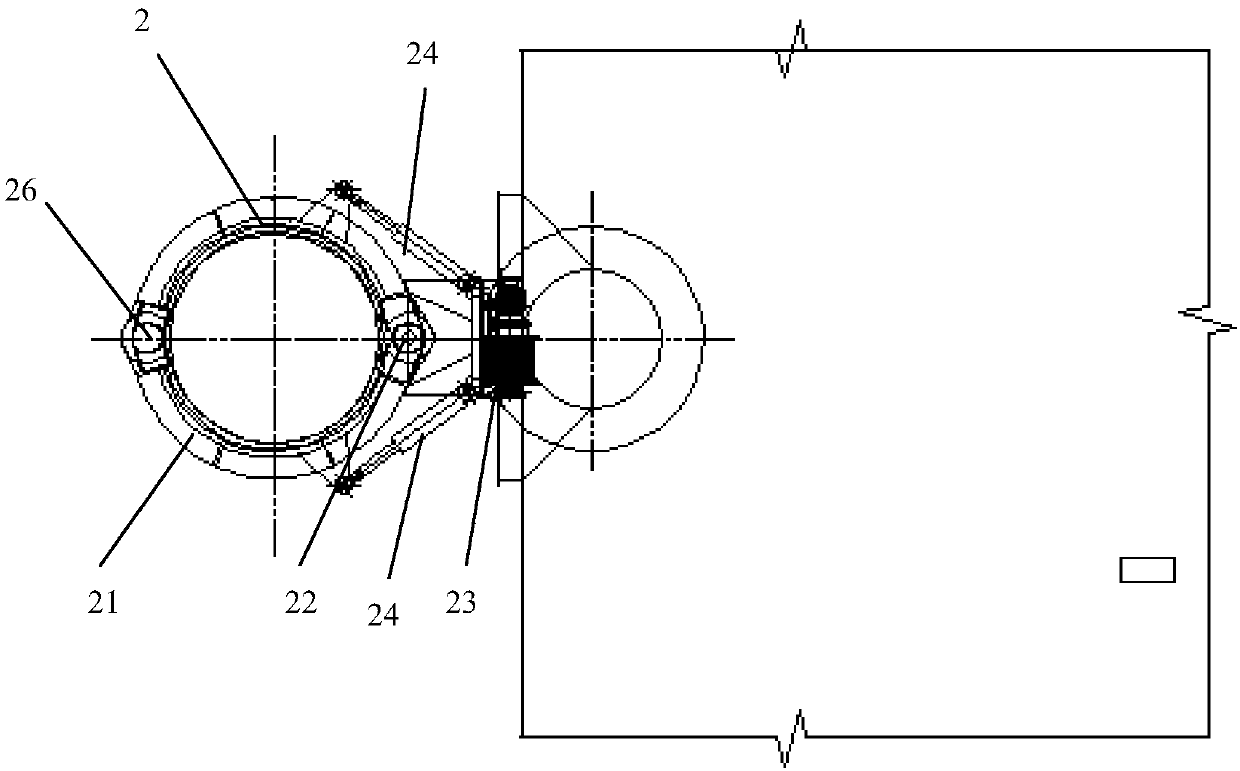

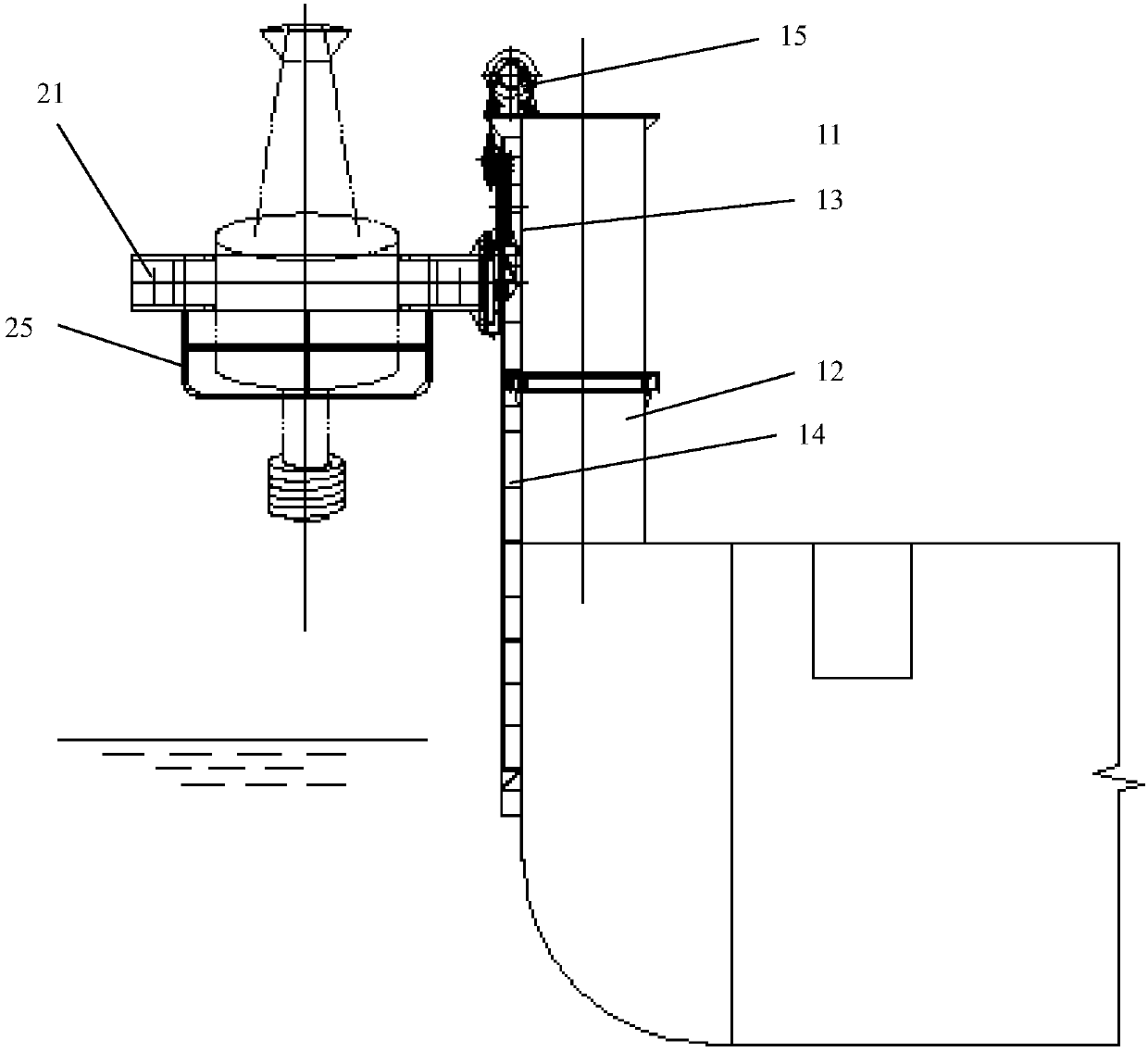

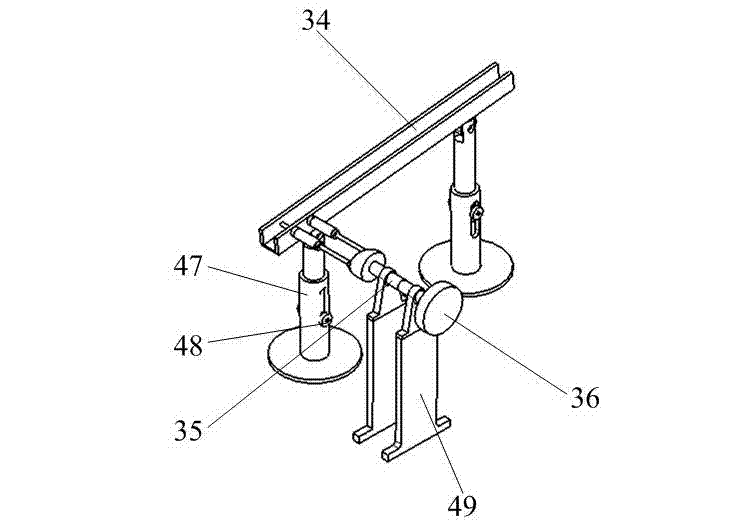

Automated buoy recycling and laying device

ActiveCN107697242AIncrease the window periodImprove work efficiencyBuoysVessel salvagingBuoyAutomated control system

The invention discloses an automated buoy recycling and laying device. The automated buoy recycling and laying device comprises a buoy hoisting and slewing device, a buoy clamping device and a power and automated control system, wherein the buoy hoisting and slewing device is used for hoisting a buoy and slewing the buoy to a deck face of a hull, a sliding chute guide rail is arranged on the buoyhoisting and slewing device, the buoy clamping device is used for clamping the buoy and slidably connected with the sliding chute guide rail, and the power and automated control system is used for providing power for the buoy hoisting and slewing device and the buoy clamping device and controlling the buoy hoisting and slewing device and the buoy clamping device. According to the automated buoy recycling and laying device, the operating efficiency is high, the safety and the reliability are better, dangerous operation of hooking and the like which need to be participated in directly by personnel is not needed, operation can be conducted under a higher sea condition, the window period of the buoy operation is prolonged, and greater benefits are obtained.

Owner:708TH RES INST OF CSSC

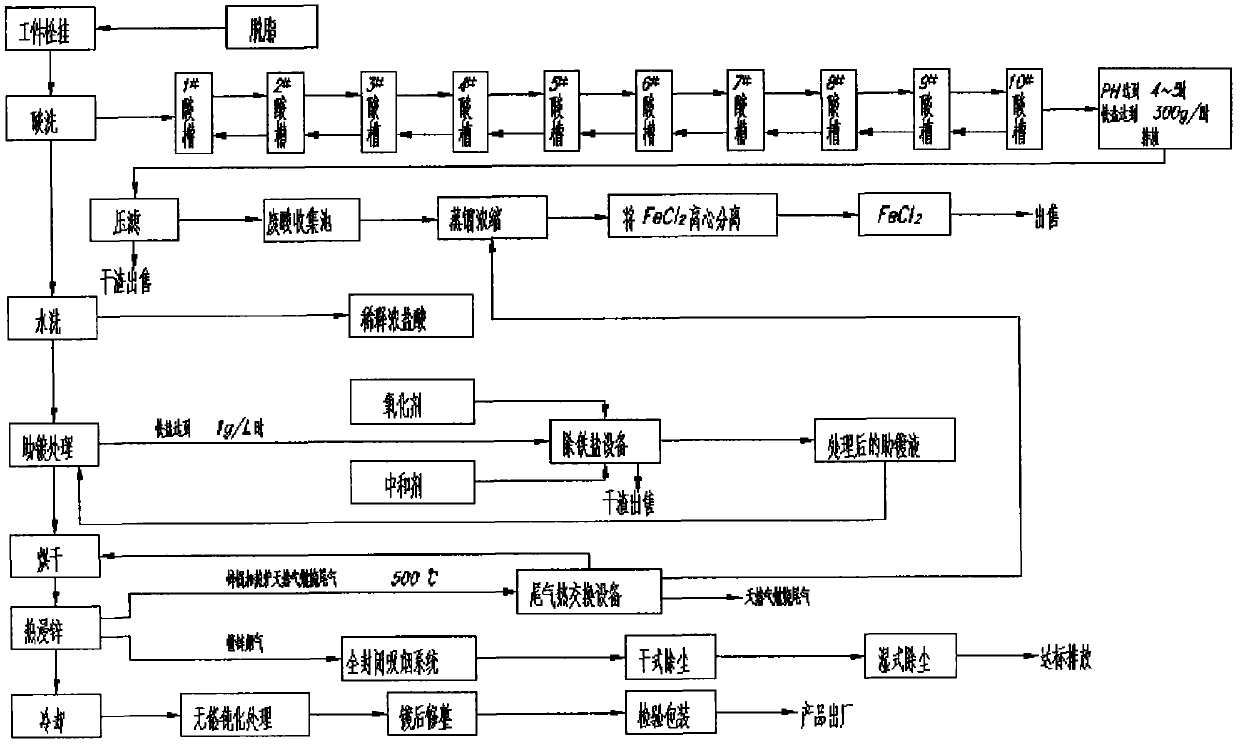

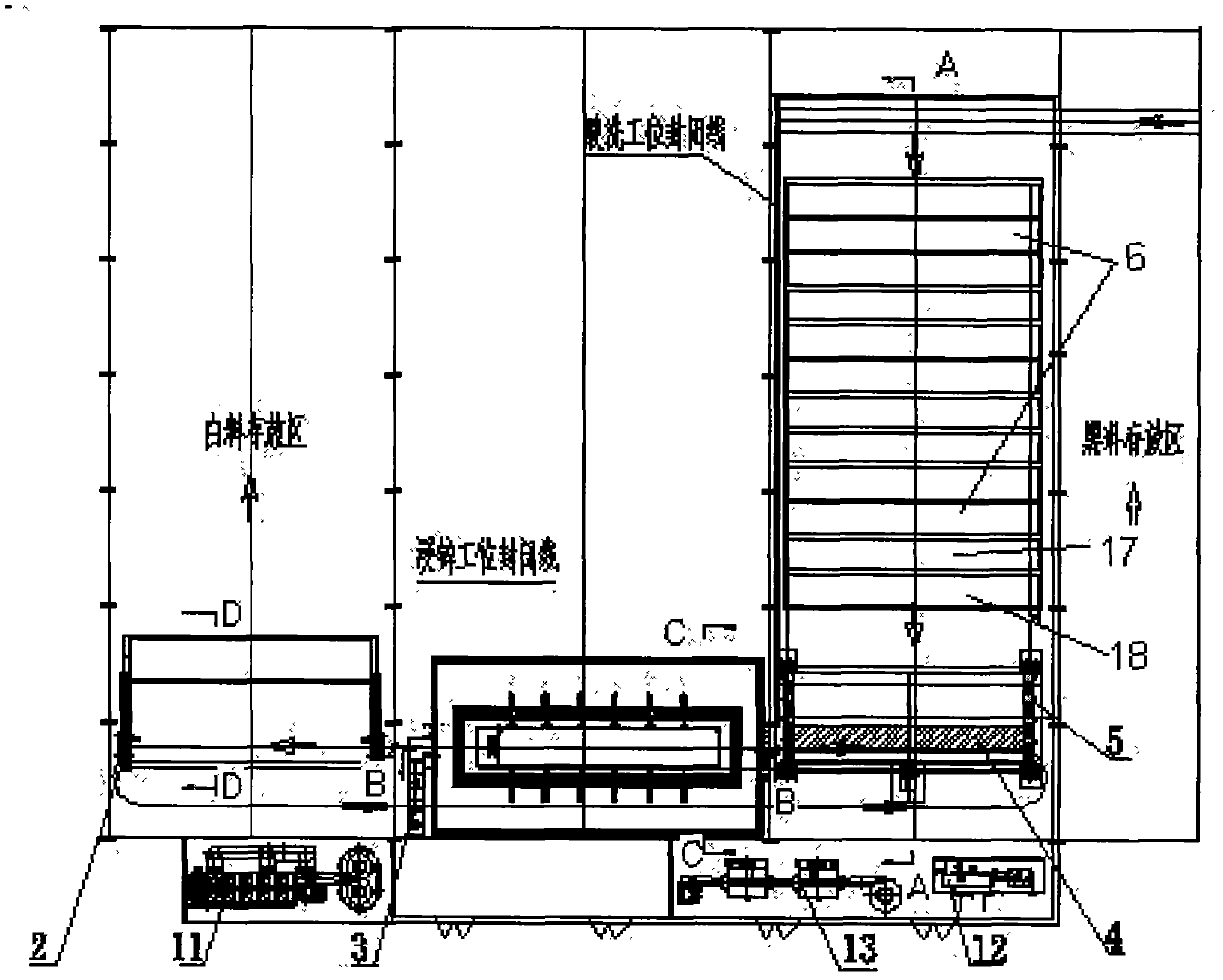

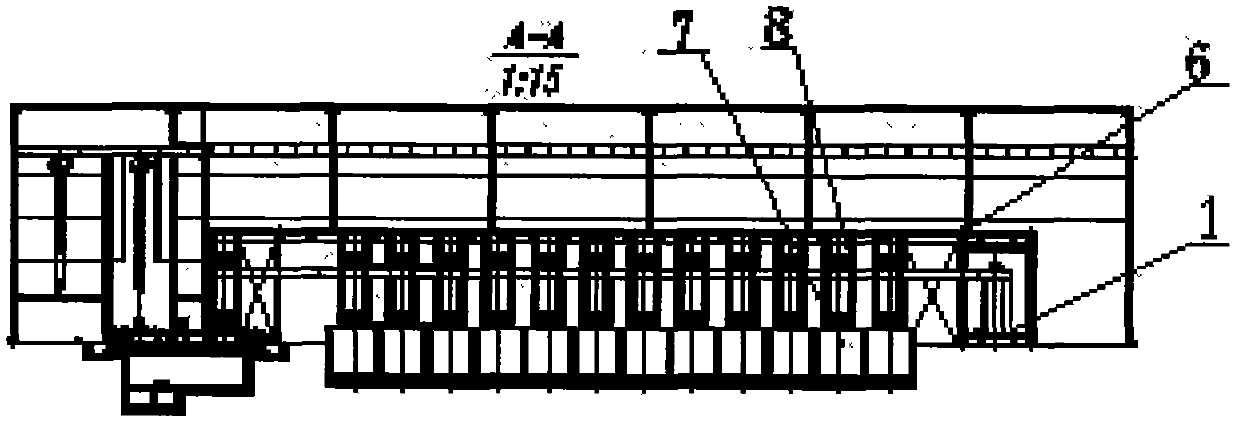

L-shaped full-closed environment-friendly hot galvanizing production equipment and method

InactiveCN102400075ADiffusion space is smallConvenient smokingHot-dipping/immersion processesAcid washingProcess engineering

The invention discloses an L-shaped full-closed environment-friendly hot galvanizing production method. The method is characterized in that: acid washing step-by-step automatic operation is implemented by adopting a mechanical hydraulic transmission manner, namely an acid washing workpiece automatic conveying system horizontally or vertically lifts to automatically convey workpieces to be galvanized to specified anti-collision acid washing tanks for acid washing and dust removing treatment step by step according to the multi-tank acid washing technological requirements, and the whole acid washing process is sequentially, progressively and automatically finished according to the technological requirements. The L-shaped full-closed environment-friendly hot galvanizing production method is pollution-free, environment-friendly, low in energy consumption, mechanical and automatic, and has the characteristics of full closure and integration of reclamation and treatment; and by the method, acid washing automation is realized, the labor intensity is furthest lightened, the production efficiency is improved, and the problem of pollution is solved.

Owner:张志红

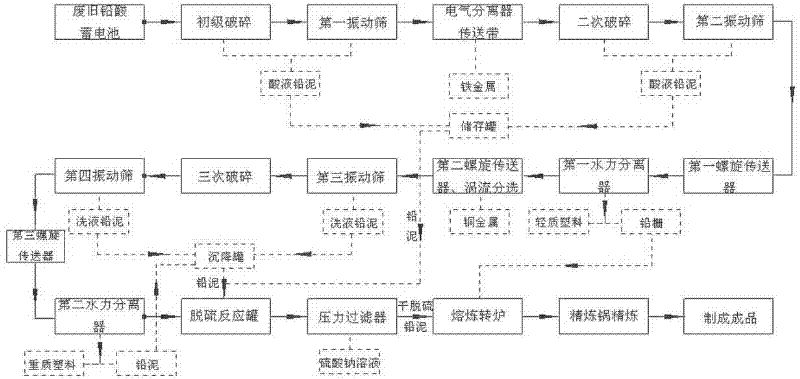

Closed circulating and recycling method of waste lead-acid accumulator

ActiveCN102534220ARealize pollution-free productionMethod environmentally friendlyProcess efficiency improvementFiltrationIngot

The invention relates to a closed circulating and recycling method of a waste lead-acid accumulator, and is used for solving the problem of low recovery efficiency, severe pollution and the like in the existing recycling aspect of the waste lead-acid accumulator due to lagging processing equipment, technical process production scale and the like. The method comprises the steps of: separating materials in the waste accumulator by crushing, oscillating screen sorting, magnetic separation, hydraulic sorting, vortex sorting and other methods, then carrying out desulfurization and pressure filtration treatment on obtained lead mud, then sequentially conveying obtained dried desulfurized lead mud and lead grid to a convertor and a refining kettle for smelting and refining, finally processing the refined molten lead into lead powder, lead grid or lead ingot, and storing for later use or selling as a finished product. The method has the advantages that the mechanical automation degree is high, pollution-free measures are adopted, the materials are thoroughly separated, the recovery rates of the materials are greatly improved, the total recovery rate of lead achieves 98%, the recovery rateof plastic achieves 95%, and the comprehensive utilization rate of resources achieves 98%.

Owner:阳煤集团山西吉天利科技有限公司

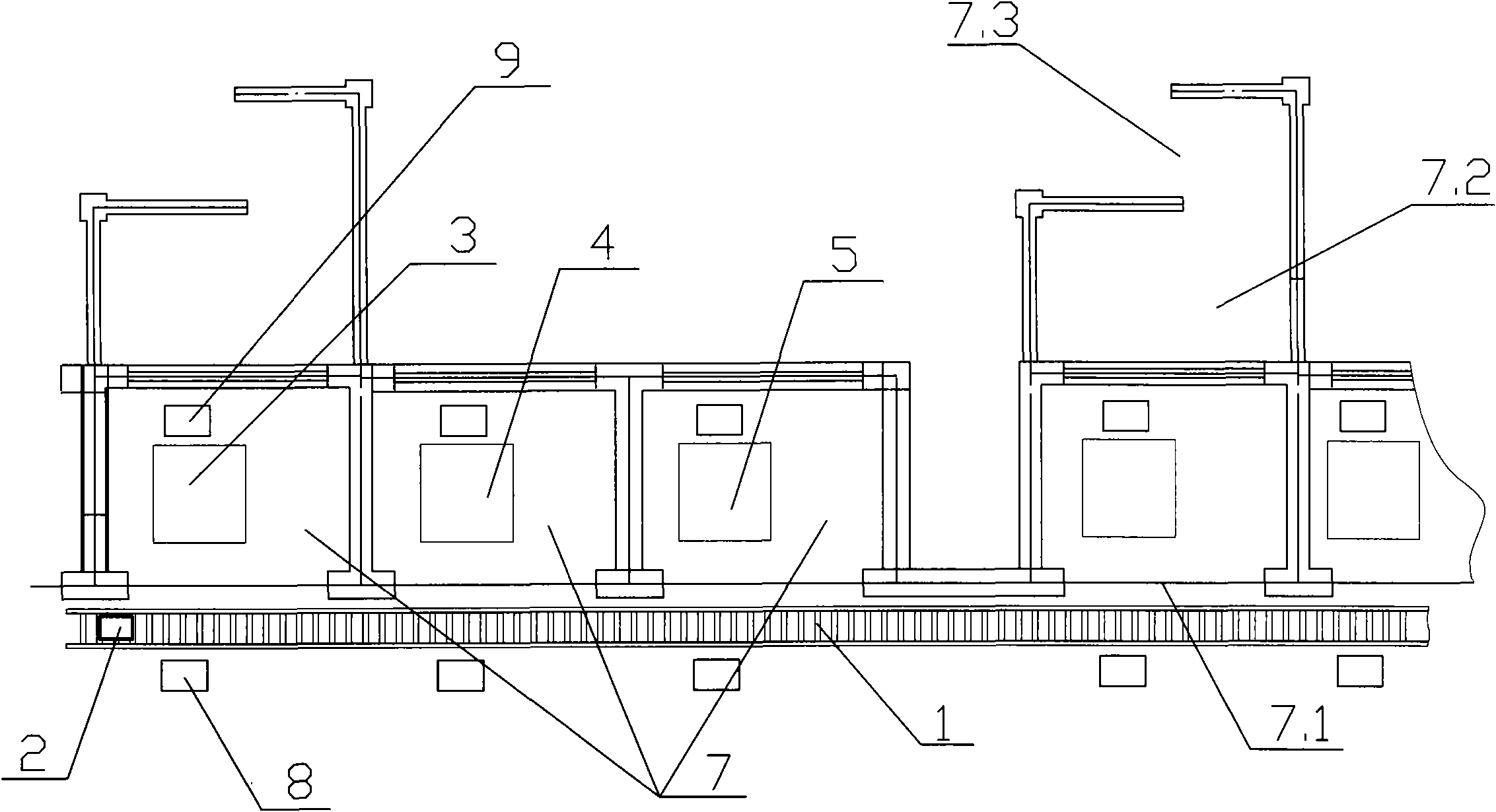

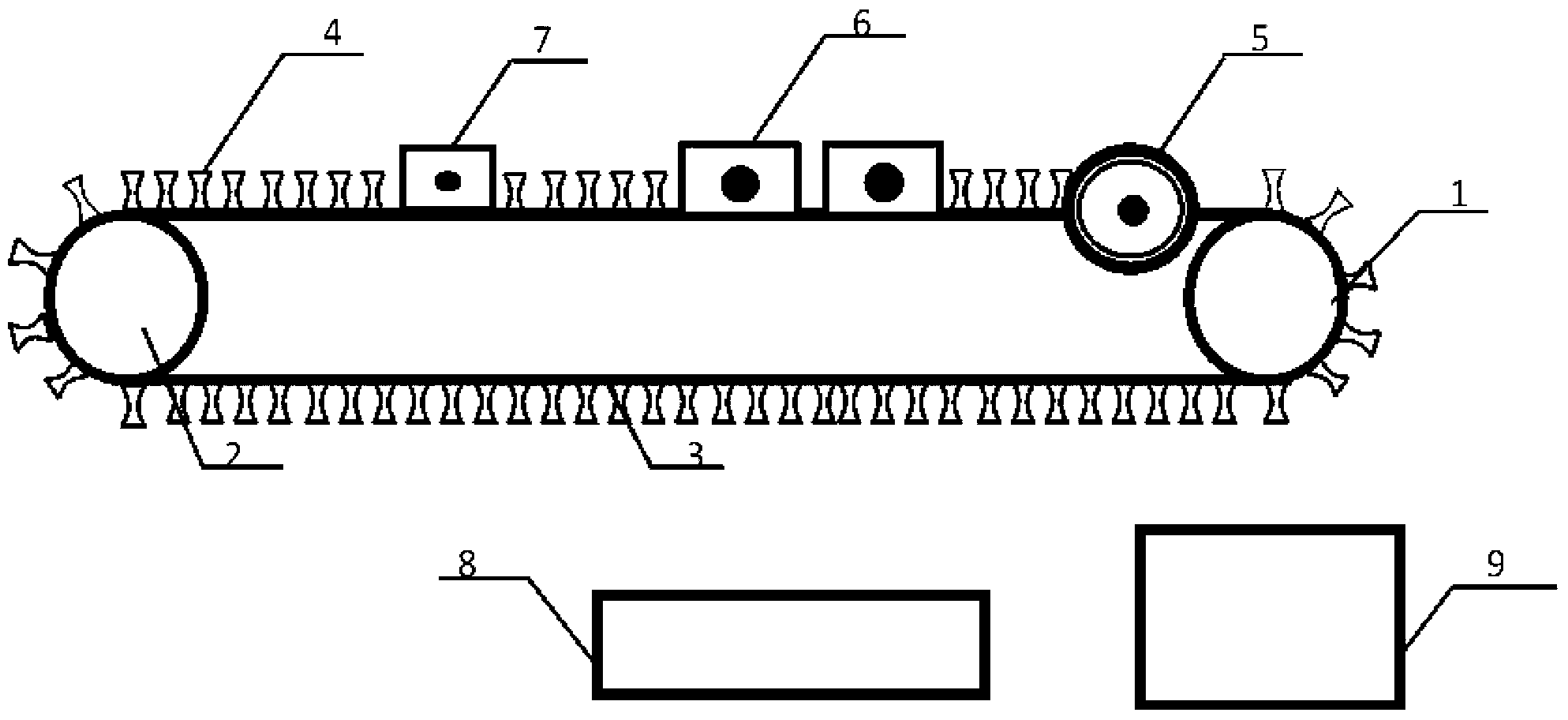

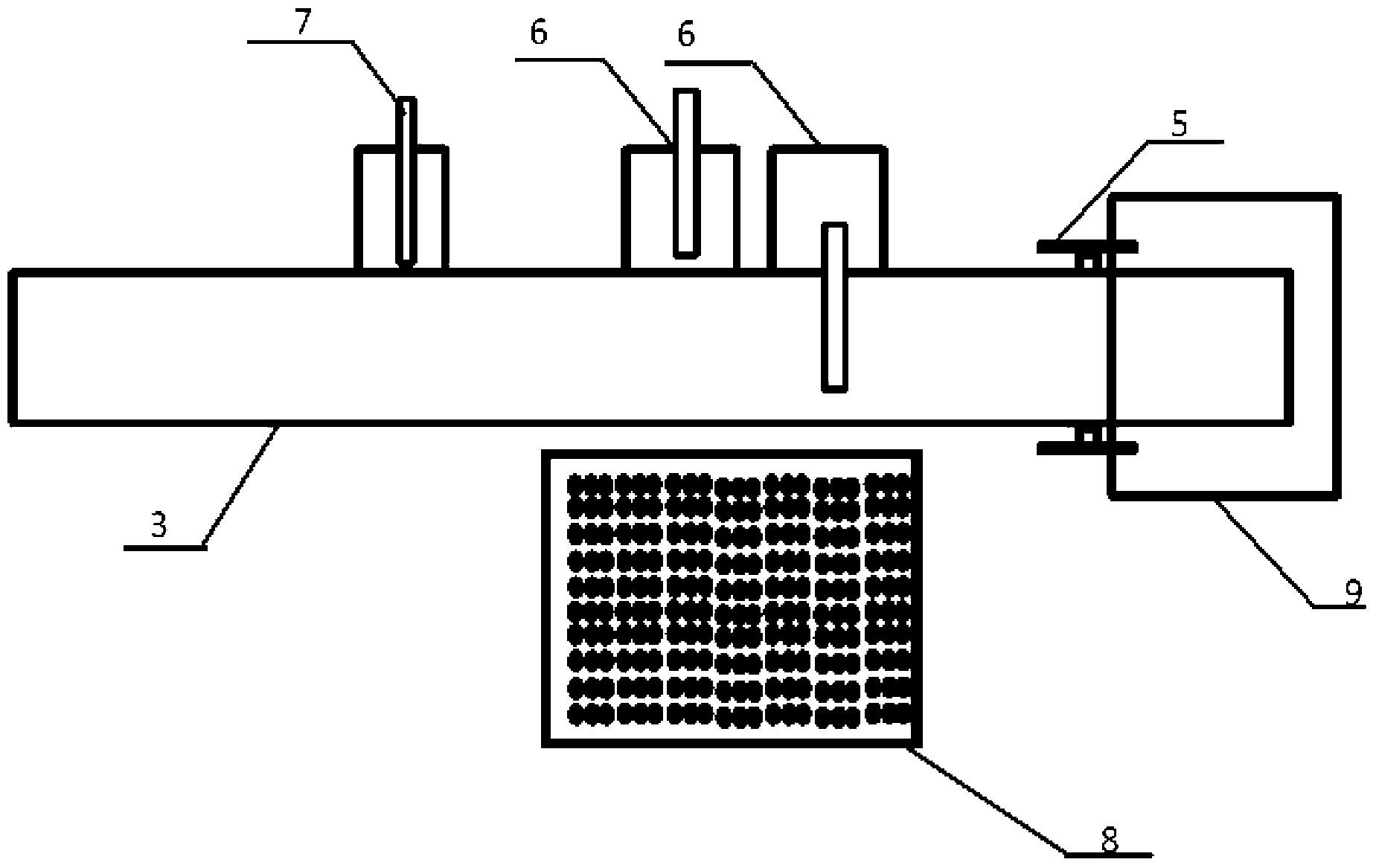

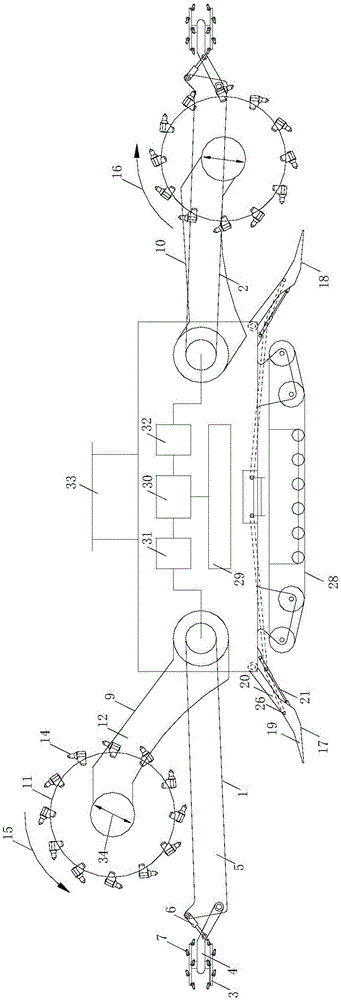

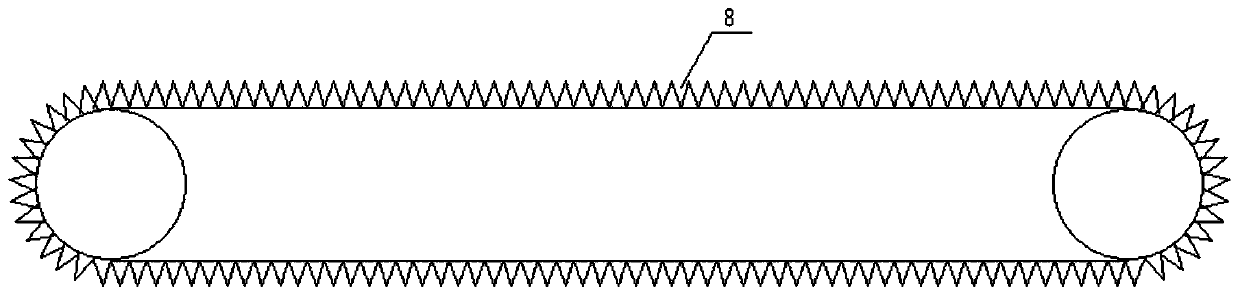

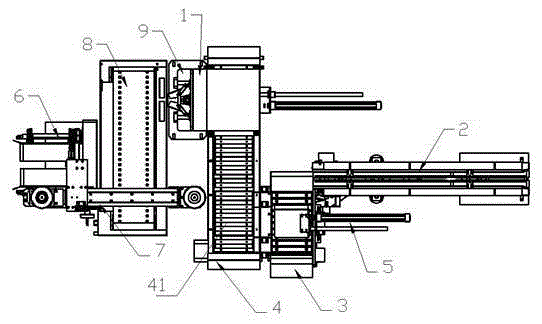

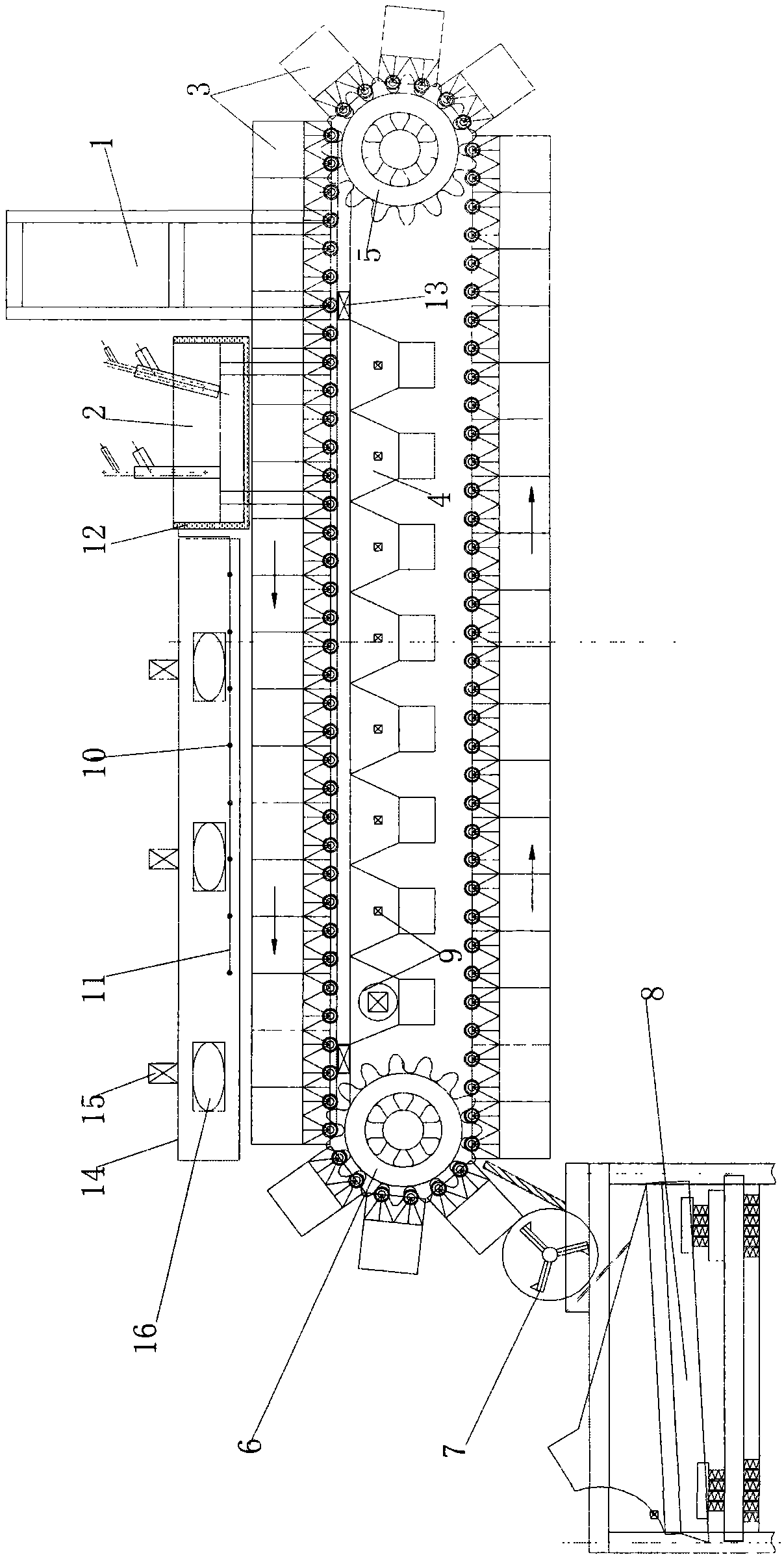

Method for automatically assembling and producing fireworks

The invention discloses a method for automatically assembling and producing fireworks. A conveyor belt (1) is adopted to convey a tube mold frame (2) to an automatic powder charging machine (3) for charging powder, to an automatic bead charging machine (4) for charging beads and to an automatic soil loader (5) for loading soil, and the one-bang loading process is finished. The load for the tube body (6) in the tube mold frame (2) is at least over one bang load, and the equipment for each bang load is positioned in each explosion-proof chamber (7) arranged in turn on one side of the conveyor belt. An input push device (8) of the tube mold frame is arranged outside the conveyor belt (1) outside the door of each explosion-proof chamber (7), and an output push device (9) of the tube mold frame is arranged in each explosion-proof chamber (7) corresponding to each input push device (8). The method for automatically assembling and producing fireworks can assemble 100 flash bangs totally, and provides convenient labor-saving high-production efficiency equipment for the firecracker industry; and the equipment has the advantages of novel design, simple structure, convenient maintenance, low cost and high production efficiency, and ends manual work for assembling flash bangs and beads.

Owner:林红斌

Offline automatic brick stacking assembly line and brick stacking method

The invention provides an offline automatic brick stacking assembly line. The offline automatic brick stacking assembly line comprises a brick arranging device, a brick transferring device and a brick stacking device, wherein brick layers can be reduced by at least one row or one line relative to the upper layer or the lower layer through the brick arranging device, the corresponding brick layer can be rotated by a predetermined angle relative to the upper layer or the lower layer through the brick transferring device, so that a formed brick stack is more stable, the brick layers in the reduced row or line can be pulled to be separated while the brick layers in the non-reduced rows or lines are stacked, so that a gap is formed between every two adjacent rows or lines, then stacking is conducted, after the formed brick stack is packaged, a transporter can be inserted into the gaps conveniently for grabbing, and when two gaps exist, the two insertion angles of a forklift can be inserted for transportation. In this way, the offline automatic brick stacking assembly line has the advantages that brick stacking quality is high, efficiency is high, the formed brick stack can be transported by the transporter such as the forklift conveniently, the degree of mechanization and the degree of automation are high, the assembly line can be adapted to various types of bricks and various brick forming machines, and practicability is high. The invention further provides a brick stacking method. All the functions can be achieved effectively by the adoption of the brick stacking method.

Owner:泉州市万昌机械制造有限公司

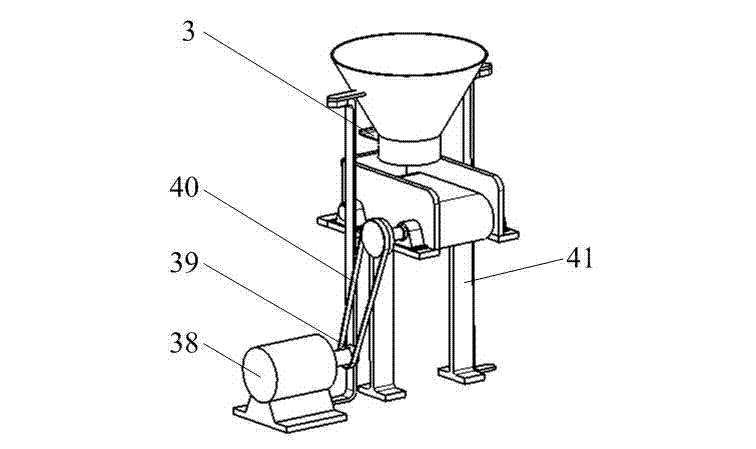

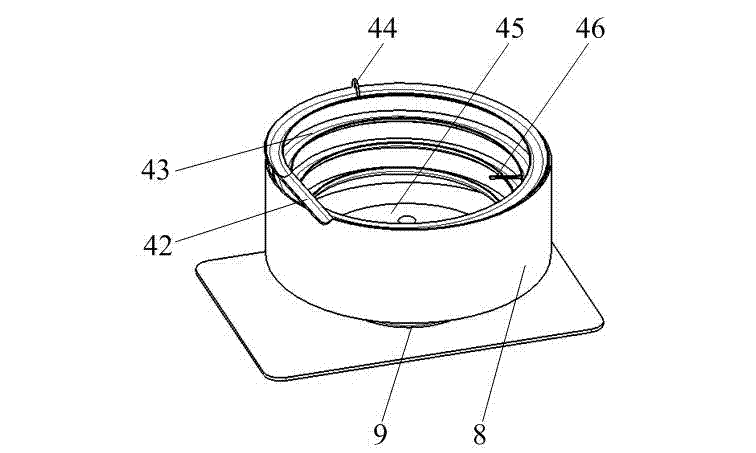

Walnut feeding, conveying, isolating and shelling all-in-one machine

The invention discloses a walnut feeding, conveying, isolating and shelling all-in-one machine which consists of a main machine seat, a feeding and conveying device, a vibrating and conveying device, an isolating device, a shelling device and a power transmission. The feeding and conveying device, the vibrating and conveying device, the isolating device, the shelling device and the power transmission are mounted on the main machine seat. Compared with the prior art, the walnut feeding, conveying, isolating and shelling all-in-one machine has the following advantages that an integrated design method integrating feeding, conveying, isolating and shelling is adopted, and mechanization, automation and integration degrees of the total machine are high; walnuts are supplied by the aid of a conveying belt, a vibrating disc, an isolating device and a conveying disc, so that supplying speed is flexible and adjustable, labor cost is effectively reduced, and processing efficiency is improved; and the linear reciprocating latch type isolating device and the cylindrical cam indexing type conveying disc are adopted, so that coordinated, orderly and efficient running is realized in a walnut shelling process, and the walnut feeding, conveying, isolating and shelling all-in-one machine is applicable to industrialized, standard and large-scale production. In addition, a work mode is reliable, shelling efficiency is high, and accordingly the walnut feeding, conveying, isolating and shelling all-in-one machine is popularized and applied conveniently.

Owner:SHANDONG UNIV OF TECH

Automatic dismantling and separating device for waste dry cell and dismantling and separating method

InactiveCN103296294AAvoid processing inefficienciesSolve follow-up processing difficultiesSolid waste disposalReclaiming serviceable partsProcess engineeringConveyor belt

The invention discloses an automatic dismantling and separating device for a waste dry cell and a dismantling and separating method, The automatic dismantling and separating device comprises a roller, a belt, a grinding wheel group, a firing pin, a cutter and a vibrating screen, wherein the conveyor belt is provided with a plurality of rubber partition plates; the grinding wheel group is arranged on the conveyor belt; the first side of the conveyor belt is provided with the cutter and the firing pin; the second side of the conveyor belt is provided with the vibrating screen. A first roller, a grinding wheel, the cutter and the firing pin are powered on; the waste dry cells are fixedly arranged between two adjacent partition plates of the belt one by one. Along with the movement of the belt, two ends of each waste dry cell are cut off by the grinding wheel rotating at high speed, paste and a carbon bar of the dry cell are pushed out of a shell of the dry cell through the firing pin, and a zinc skin is separated from a plastic skin through the cutter. The automatic dismantling and separating device and dismantling and separating method for the waste dry cell have the advantages that a paste electrolyte, a zinc drum and the carbon bar can be comprehensively recycled, and the processing working efficiency and a separation effect of the waste dry cell can be improved.

Owner:ANHUI UNIV OF SCI & TECH

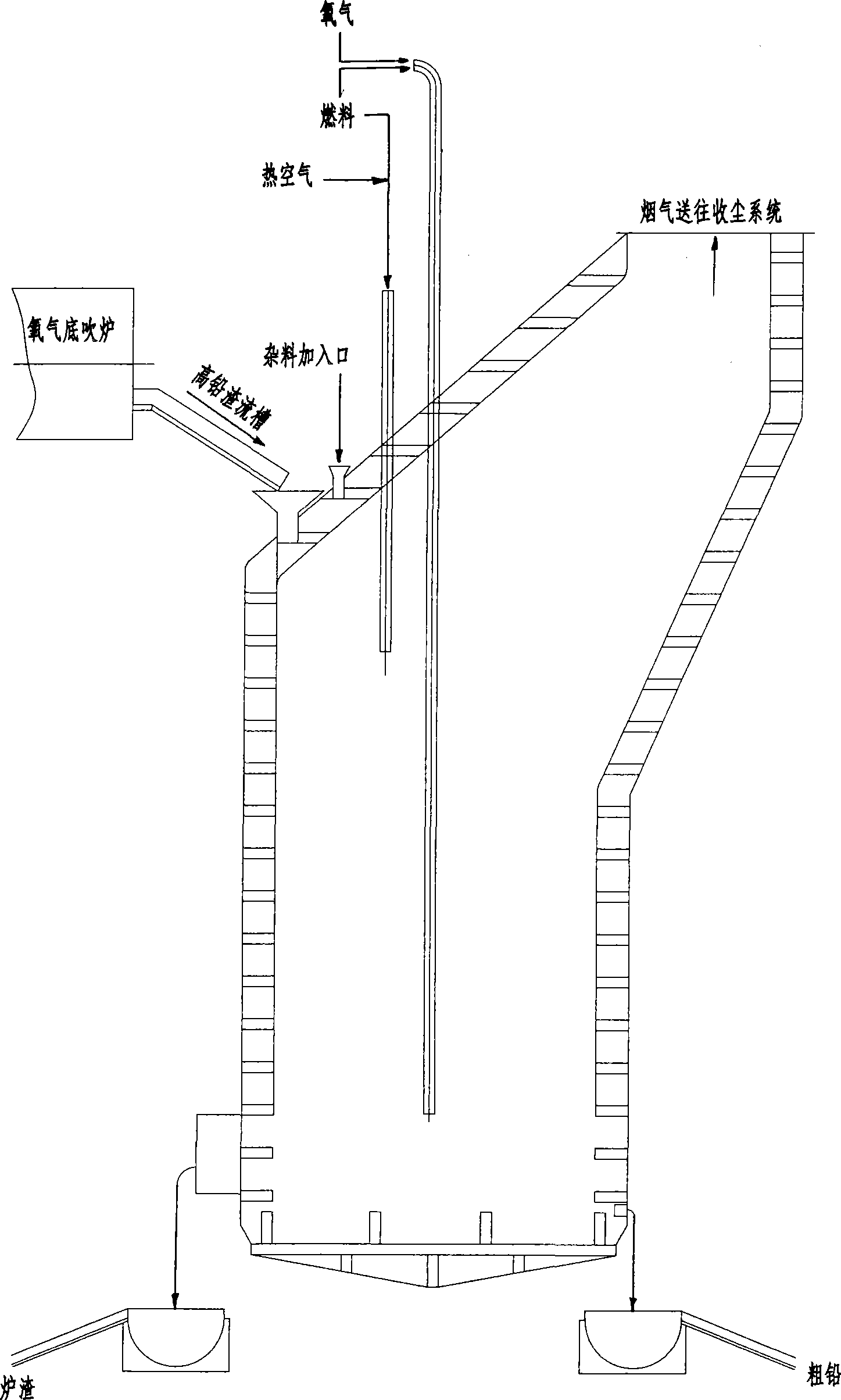

Process for direct reduction of liquid high-lead skim with reduction furnace

The invention discloses a process of directly reducing liquid high lead slag in reducing furnace, secondary lead-containing materials such as the liquid high lead slag, lead concentrate, scrap leads, waste accumulators and the like generated from the oxygen bottom blowing smelting furnace or zinc leaching residues are used as raw materials and are added from the top end of the reducing furnace; coal powder and natural gas used as fuel and oxygen-enriched air used as combustion improver are continuously led in from the top of the reducing furnace to carry out combustion reaction; the temperature in the reducing furnace is kept at 1000-1500 DEG C; the coal powder and natural gas can be simultaneously used as reducing agents and fall into the reaction tank at the bottom of the reducing furnace after being fully mixed with the raw materials; the lead oxides in the raw materials are reduced to crude lead and the addition of the reducing agents is subject to full reduction of the lead oxides in the raw materials. The process of the invention directly reduces the liquid high lead slag, fully utilizes the thermal energy of the high lead slag and further reduces the coke consumption and flue gas volume, thereby dramatically reducing the smoke dust rate and the smelting cost.

Owner:安徽铜冠有色金属(池州)有限责任公司

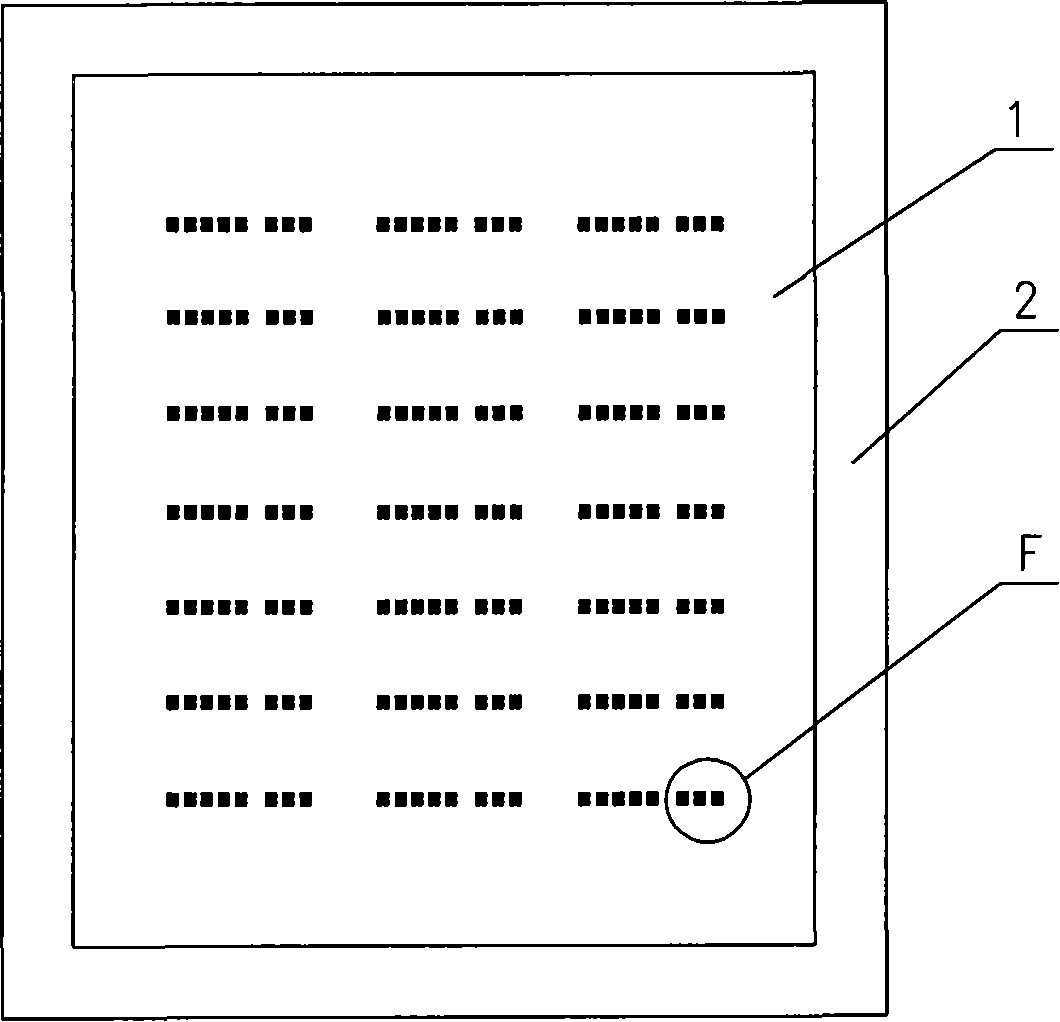

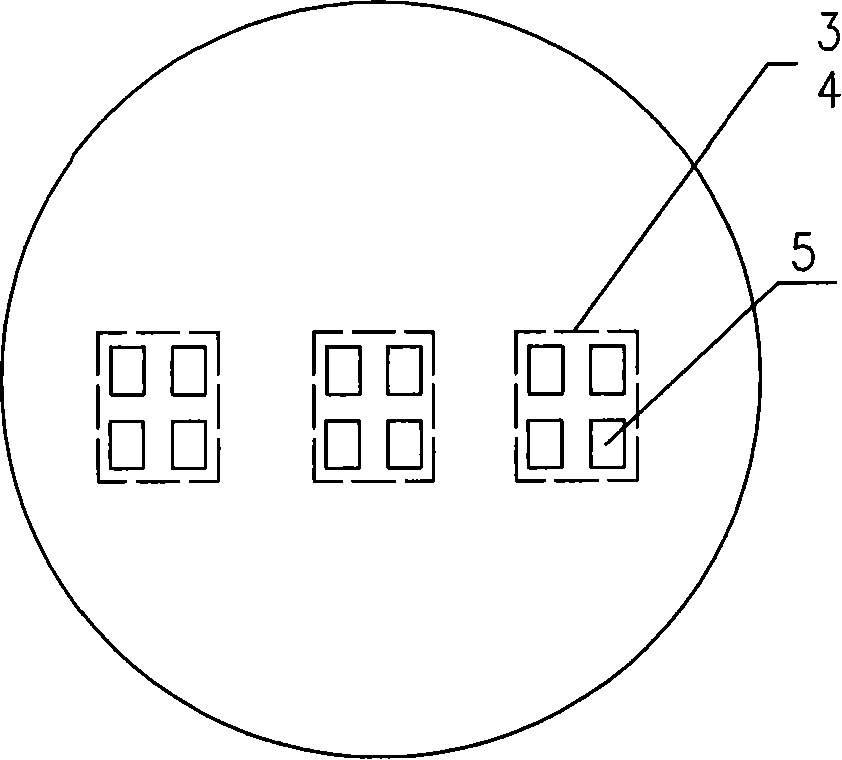

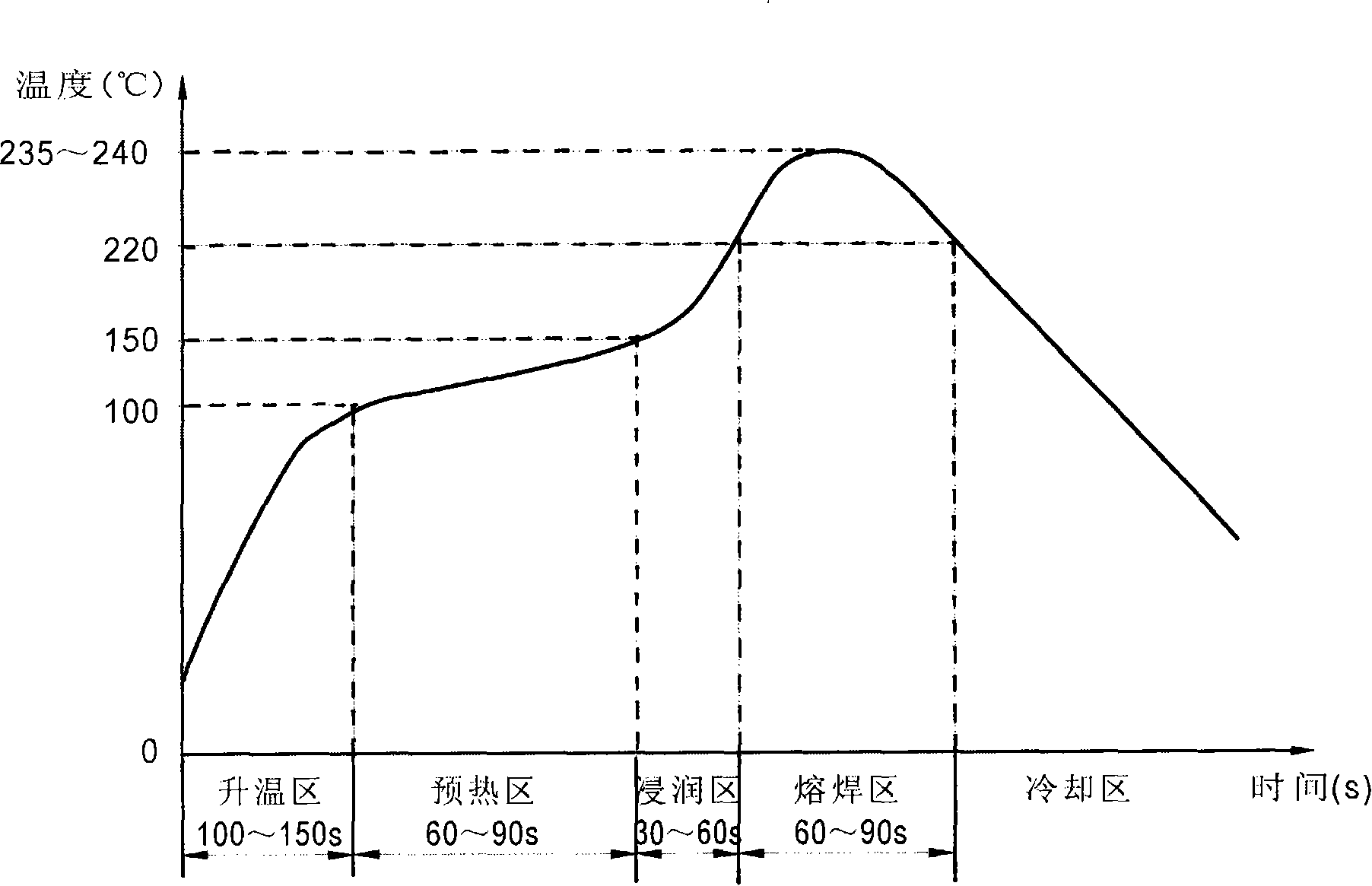

Solder tray local tin plating method on circuit board

InactiveCN101252815AImprove mechanizationReduce manufacturing costPrinted circuit assemblingTinningEngineering

The invention discloses a method for local tinning to the bonding pad on a circuit substrate, which enables lead-free tin plasma to be brushed to the spot welding position bonding pad of the circuit substrate through a steel mesh; the circuit substrate brushed with the lead-free tin plasma passes through the five areas of a reflow soldering machine for operating parameters in sequence, to form liquid tin coating covered in the entire spot welding position bonding pad, and after the circuit substrate cools, solid tin coating is formed in the spot welding position bonding pad. The invention utilizes the steel mesh to brush the lead-free tin plasma to the bonding pad of a common substrate, and utilizes the reflow soldering machine and depends on the wetting property of soldering flux, and the diffusion and the self positioning effect of the tin plasma to accomplish the tinning process of the bonding pad, the tin coating meets the process requirements of the thickness and the smoothness, and provides good basic conditions for the subsequent spot welding working procedure, and the manufacturer does not require to purchase special substrates for the substrate supplier, therefore, the production efficiency can be greatly improved, the qualified rate of the product can be increased, and the production cost of the enterprise can be reduced.

Owner:MORNSUN GUANGZHOU SCI & TECH

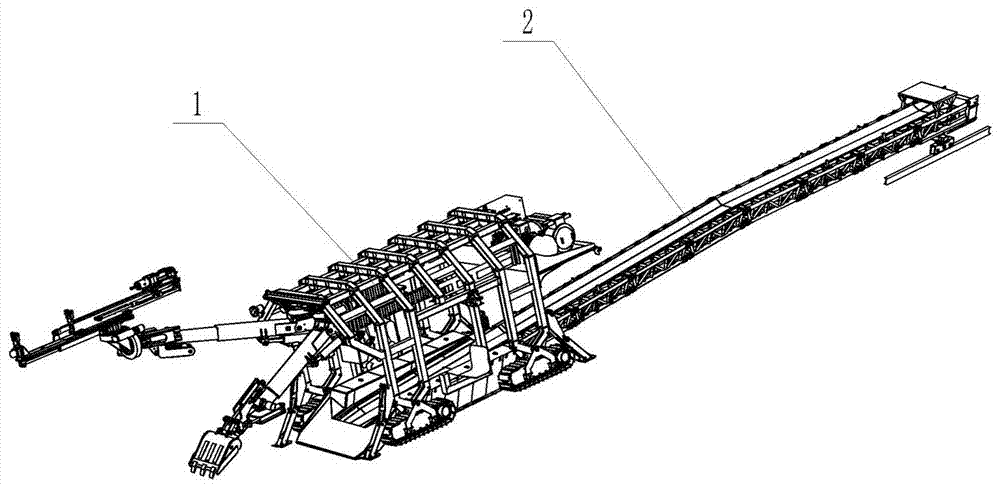

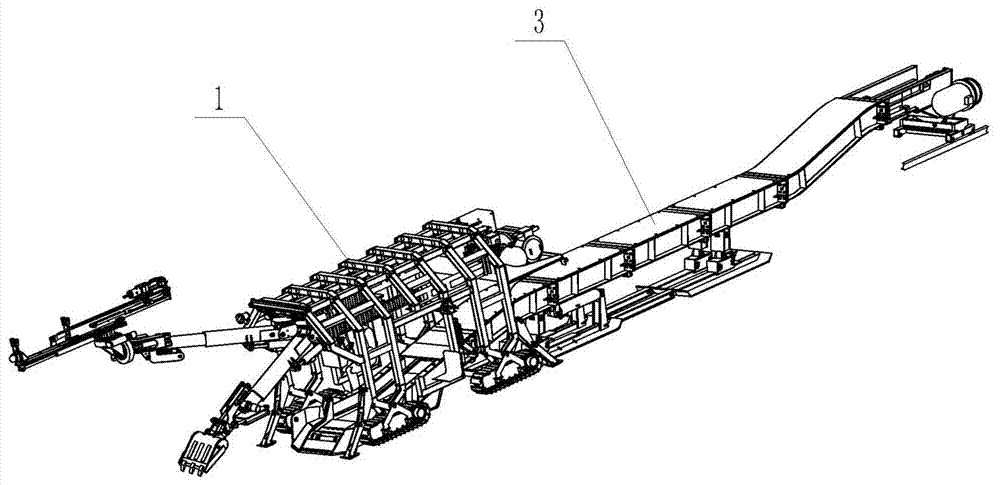

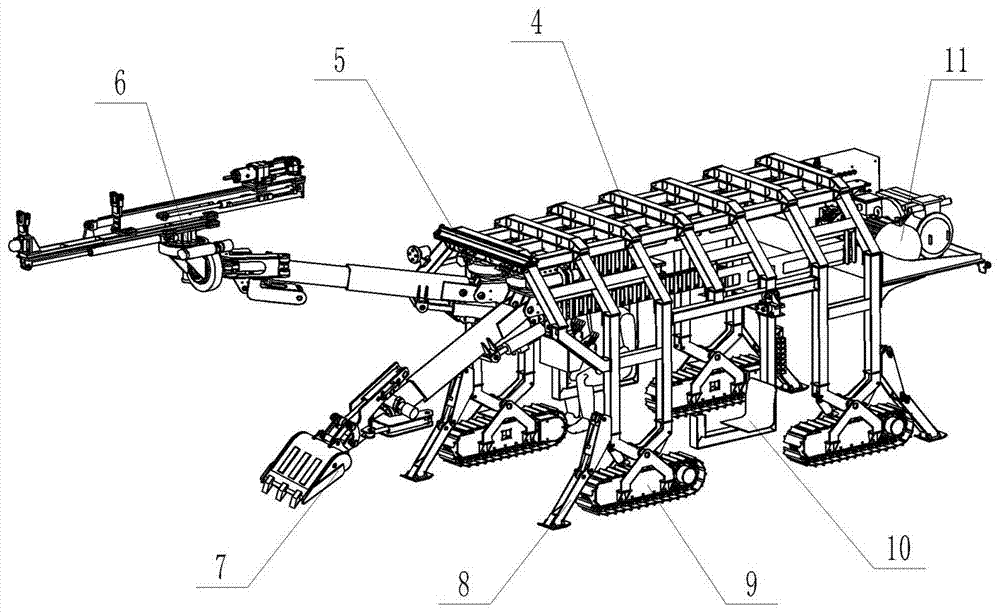

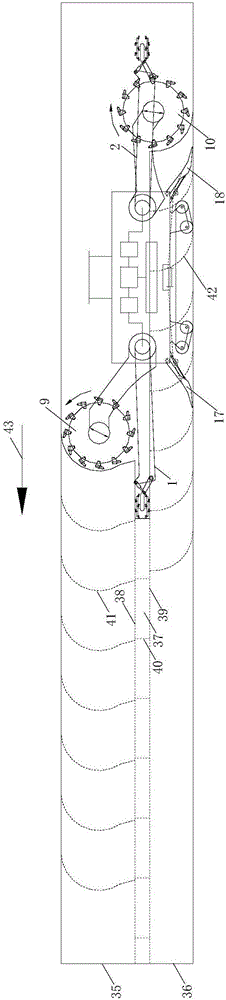

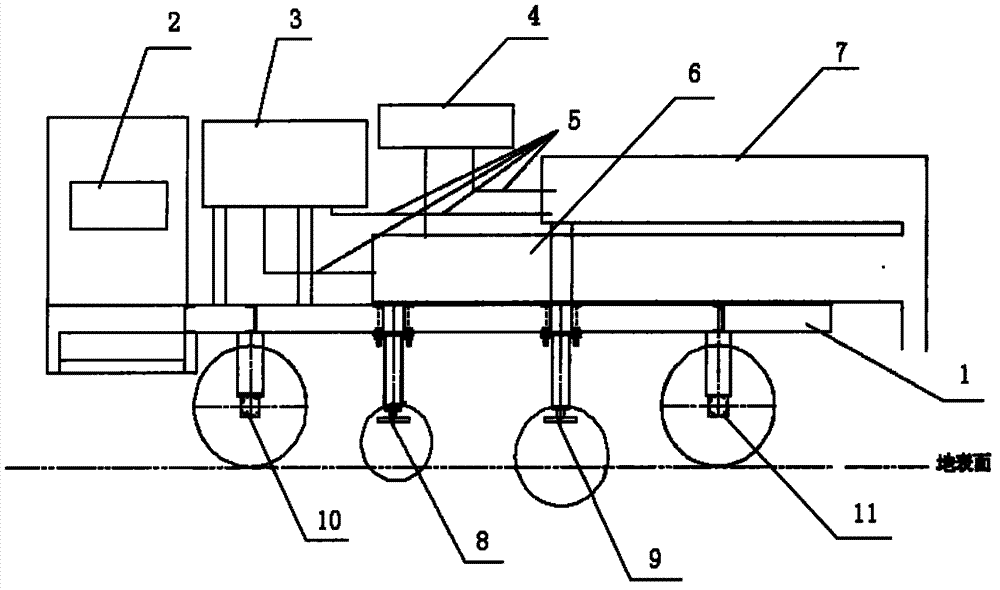

Drilling and loading and transporting complete equipment for stone drift blasting driving

PendingCN107060802AImprove walking adaptabilityImprove stabilityDerricks/mastsMine roof supportsEngineeringDriving mode

Drilling and loading and transporting complete equipment for stone drift blasting driving is disclosed. The problems that existing blasting driving modes and material transporting equipment are low in degree of mechanization and automation, high in labor intensity and poor in safety, and the working efficiency is influenced are solved. The drilling and loading and transporting complete equipment comprises a crawler-type frame drill loader and a material transloading and conveying device, and is characterized in that the front portion of a frame type support of the crawler-type frame drill loader is provided with a drilling machine assembly and a bucket assembly correspondingly; track walking mechanisms are arranged at the lower portions of the two sides of the frame type support correspondingly; a cannon curtain is arranged at the front end of the frame type support; and the material transloading and conveying device is provided with a spading plate, an automatic-moving mechanism and a protective structure and arranged in a transporting space at the inner sides of the crawler-type frame drill loader. According to the drilling and loading and transporting complete equipment for stone drift blasting driving, the design is reasonable, the structure is compact, the occupied roadway space is small, and the drilling and loading and transporting complete equipment can be applied to hole drilling, broken stone loading and material continuous transporting of a blasting driving face; and a roadway roof can be supported temporarily, the damage to the equipment can be reduced, movement is stable, the adaptability is high, and the working efficiency and the safety of the blasting driving face are enhanced obviously.

Owner:SHENYANG TIAN AN TECH CO LTD

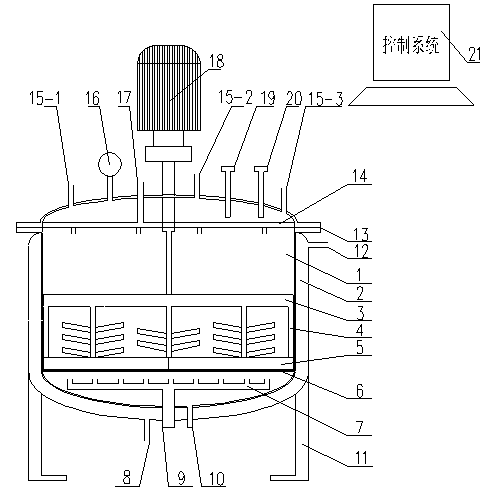

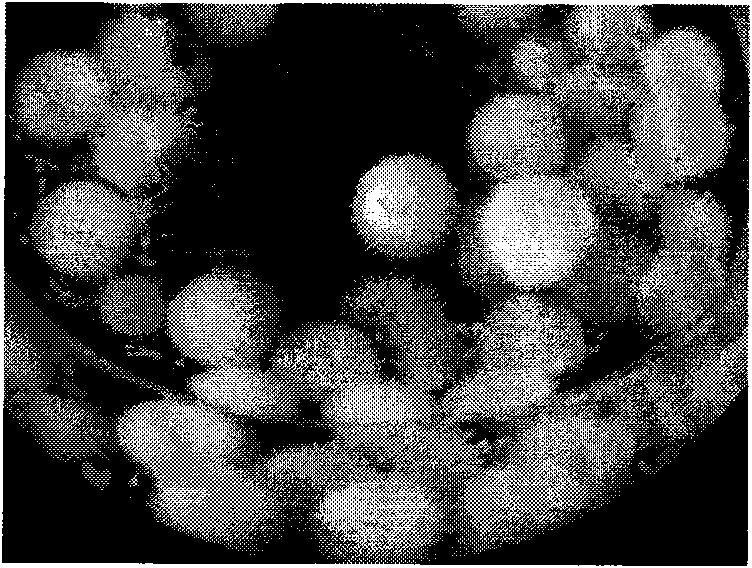

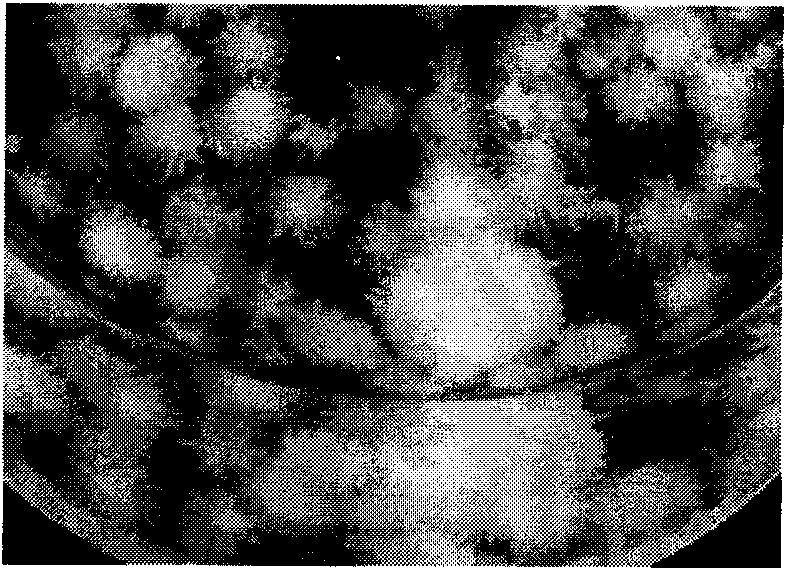

Spherical granule bacteria cellulose and preparing method thereof and special culture medium

InactiveCN101586134AImprove mechanizationHigh degree of automationMicroorganism based processesFermentationPollutionCulture mediums

The invention discloses a spherical granule bacteria cellulose and preparing method thereof and special culture medium. The culture medium provided by the invention comprises carbon, nitrogen source, inorganic salt and growth factor, also comprises coconut water with percentage by volume 0%-80% and carbon source concentration 1-30g / L. The preparing method of spherical bacteria cellulose provided by the invention is to place the production bacterium of bacteria cellulose in the culture medium to oscillate for fermenting or in the fermentation cylinder to ventilate for cultivating. The spherical bacteria cellulose of the invention can be directly applied to the food processing without the cutting operations. The oscillation fermentation needs less nutrition, and is suitable for fermentation cylinder ventilated cultivation, the pollution probability is small, the product yield rate is high, the cellulose product is not traditional film sheets-shaped, and is a bran-new spherical granule-shaped, stabbed spherical or star flower-shaped, the harvesting and the rinsing are easy, especially without extra cutting operations, the spherical granule sizes can be regulated according to the fermentation condition and time.

Owner:HAINAN UNIVERSITY

Continuous rotating and vibrating cutting equipment realizing pregrooving and used for hard rock ore body and construction process of equipment

ActiveCN105804743AReduce lossesReduce depletion rateUnderground miningSurface miningControl systemHydraulic pump

The invention discloses continuous rotating and vibrating cutting equipment realizing pregrooving and used for a hard rock ore body and a construction process of the equipment. The equipment comprises ore body grooving mechanisms, ore body cutting mechanisms, ore shoveling and transportation mechanisms, a walking mechanism, a hydraulic pump station, a hydraulic rationing and control system, hydraulic vibration exciters and an operation room, wherein the ore body grooving mechanisms cut the ore body from inside to outside, so that pre-grooves are formed, stress is eliminated, crack development is promoted, and free surfaces of the ore body are increased; the ore body cutting mechanisms cut the ore body in a rotating and vibrating manner, the cutting directs of the front and rear cutting mechanisms both face the pre-grooves, and rock and ore breaking is realized mainly in a diagonal tension failure manner. Batten type reciprocating cutting is performed on the ore body, while the equipment reciprocates, the grooving mechanisms continuously pre-groove the ore body, the cutting mechanisms cut the ore body in a rotating and vibrating manner, and the shoveling and transportation mechanisms continuously shovel and transport ore which is cut off; the mining work is synergistic and continuous, the equipment does not need to turn around, and the low ore loss rate and the low dilution ratio can be guaranteed.

Owner:CENT SOUTH UNIV

Preparation method for local ceramic reinforced aluminum matrix composite wear-resistant part

A preparation method for a local ceramic reinforced aluminum matrix composite wear-resistant part includes: firstly, preparing a zirconia toughened alumina (ZTA) preformed part; secondly, fixing the ZTA preformed part in a die forging die and vacuumizing the interior of the die forging die; and finally, injecting aluminum liquid into a runner of the die forging die, squeezing the aluminum liquid into a cavity of the die forging die under high pressure first, then using the forging die for forging and stamping until the aluminum liquid completely solidifies, and separating a male die from a female die so as to fetch the composite wear-resistant part out from the forging die when composite materials completely solidify. By using the preparation method, not only wear-resistant performance of the surface of the composite wear-resistant part is improved, but also effects of the character of high toughness of ZTA particles are simultaneously brought into full play, and probability of internal fragmentation of ceramic is greatly reduced, overall impact resistance of the composite wear-resistant part is improved, and furthermore due to the fact that the composite wear-resistant part is prepared through a method of combining low vacuum die forging with extrusion die forging, the aluminum liquid can be fully composited with the ZTA particles, and the number of internal interstices of the wear-resistant part is decreased. Accordingly, overall intensity of the composite wear-resistant part is improved, and service life of the composite wear-resistant part is prolonged.

Owner:GUANGDONG INST OF NEW MATERIALS

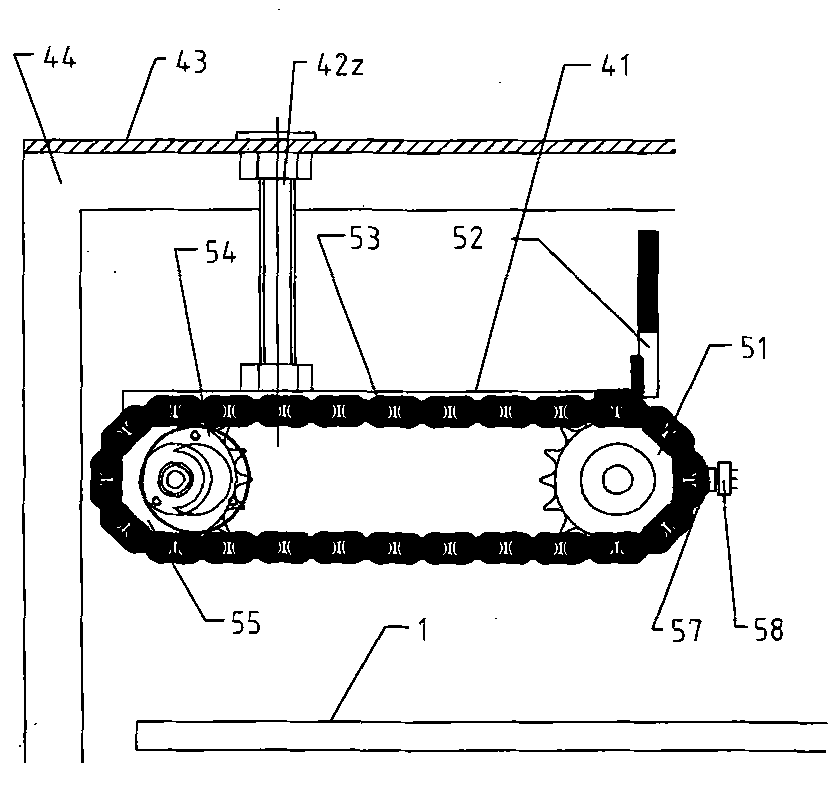

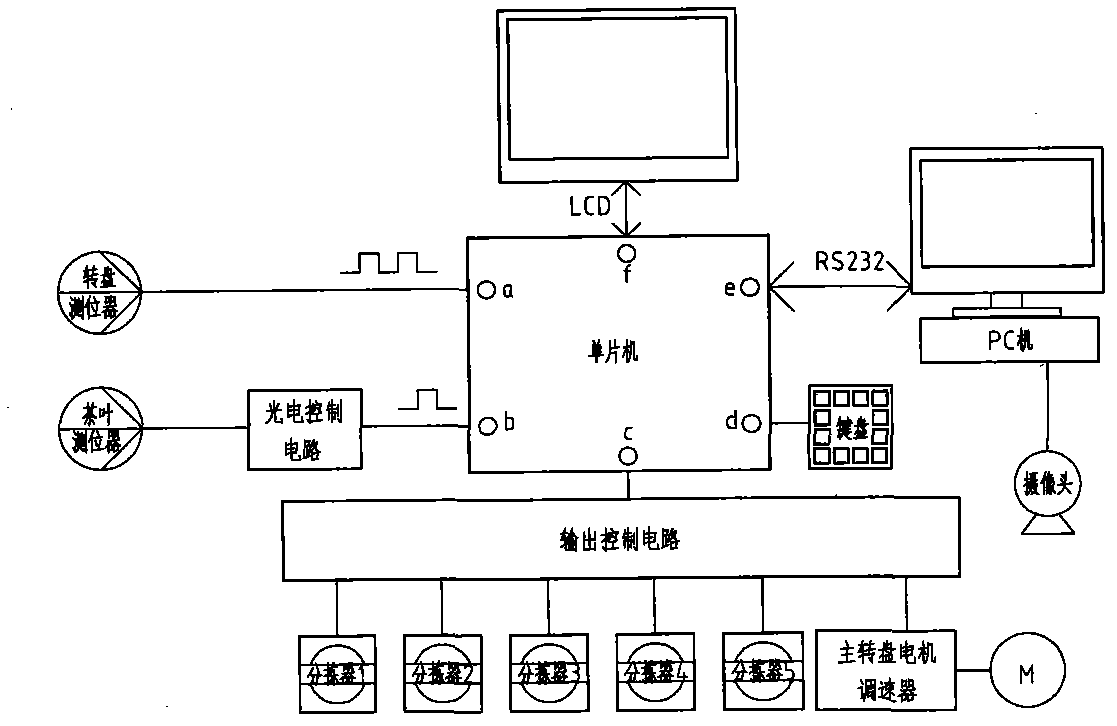

Intelligent classification device for machine-picked fresh tea

InactiveCN102166571AImprove level qualityReduce labor intensitySortingMicrocontrollerMicrocomputer control

The present invention relates to an intelligent classification device for machine-picked fresh tea, and belongs to the agriculture and forestry mechanical technology field. The device comprises a control portion and a rotating disk, the periphery of which is orderly provided with a feeding device, a tea position finder, a camera, and a set of sorters in a circumferential direction. Each sorter comprises a chain driving mechanism arranged on a frame, with a hairbrush, which is capable of brushing with a chain in a direction from the central part to the edge of the rotating disk, being arrangedoutside of a driving chain of the chain driving mechanism, and a hairbrush in-position induction device for controlling a hairbrush stop position being arranged in the driving chain. The signal output end of the tea position finder is connected with a corresponding signal input end of an one-chip microcomputer control circuit, the signal output end of the camera is connected with an image signal input end of a PC, and the control output ends of the one-chip microcomputer control circuit are respectively connected with the controlled ends of chain driving mechanisms. The device can high-effectively and automatically finish the whole process of tea classification.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Sorting and stacking device for ceramic bricks

The invention discloses a sorting and stacking device for ceramic bricks. The sorting and stacking device comprises a conveying mechanism for conveying the ceramic bricks, a brick blocking mechanism used for blocking conveying of the ceramic bricks, a brick jacking mechanism used for jacking the ceramic bricks blocked by the brick blocking mechanism from the conveying mechanism, a pile retreat mechanism capable of moving in a reciprocating manner, a turnover and conveying mechanism used for conveying the ceramic bricks on a position above the pile retreat mechanism and overturning the ceramic bricks to be vertically stacked and propped against a bracket, and a brick tidying and protecting device used for tidying the ceramic bricks stacked on the bracket and allowing the ceramic bricks to move towards the pile retreat direction so as to be stacked on the bracket in a protection way. In practical production process, according to the sorting and stacking device, the ceramic bricks can be arranged side by side in the ceramic brick conveying direction, and the ceramic bricks of different levels can be respectively sorted and stacked, a transitional way of manually sorting and stacking the ceramic bricks is replaced. Therefore, the sorting and stacking device has the advantages of high mechanization and automation degree, improved production efficiency, and reduced enterprises management cost.

Owner:崔永凤

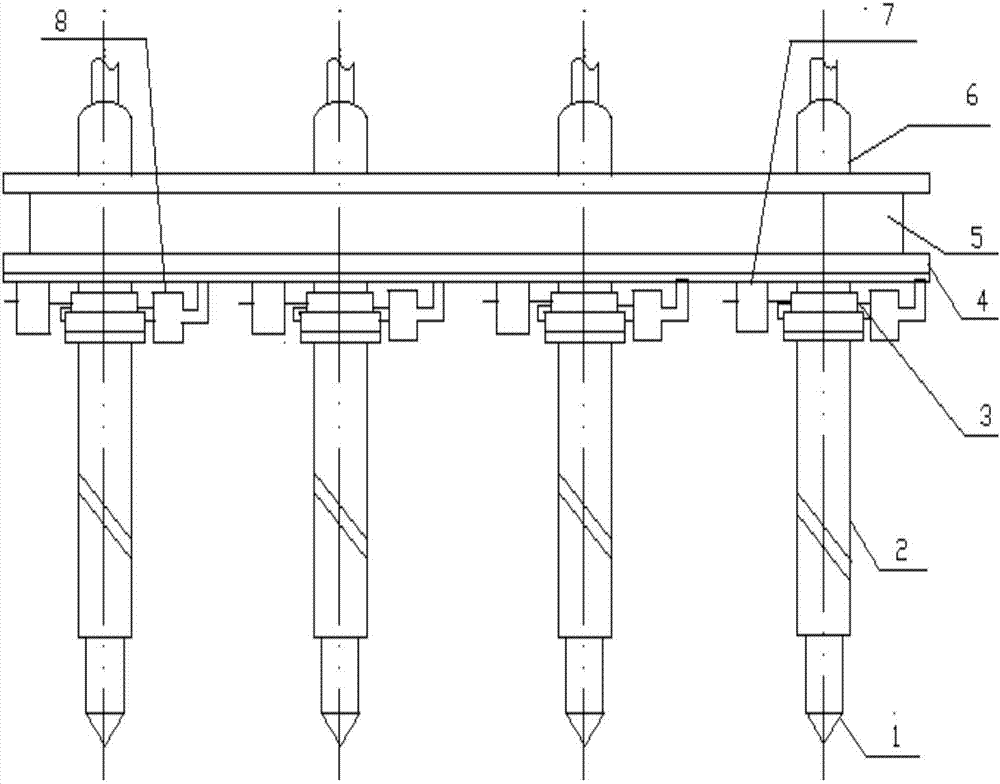

Multi-shaft hydraulic drill with drill bit intervals being adjustable and work method thereof

InactiveCN107052392AReduce volumeGreat driving forcePositioning apparatusMetal-working holdersHydraulic motorMotor drive

The invention discloses a multi-shaft hydraulic drill with the drill bit intervals being adjustable and a work method of the multi-shaft hydraulic drill with the drill bit intervals being adjustable. Drill bits can slide in sliding grooves and are hydraulically driven by valve-controlled cylinders, and therefore the distance between every two adjacent drill bits can be adjusted. The drill bits are clamped through drill rod fixing devices, so that the drill bits keep dynamic balance when the drill bits drilling holes. Compared with traditional motor drive, hydraulic motor drive has the advantages that the size is small, the weight is light, the drive force is large, stepless speed change can be conducted, and drill bit screw taps can be quite conveniently protected. The power ratio of the hydraulic motors is large, large holes can be drilled in the manner that one hydraulic motor drives the corresponding drill bit, the drill bits can be detached, the application range of a drilling machine is expanded, and the drilling efficiency is improved.

Owner:陕西速力机电科技有限公司

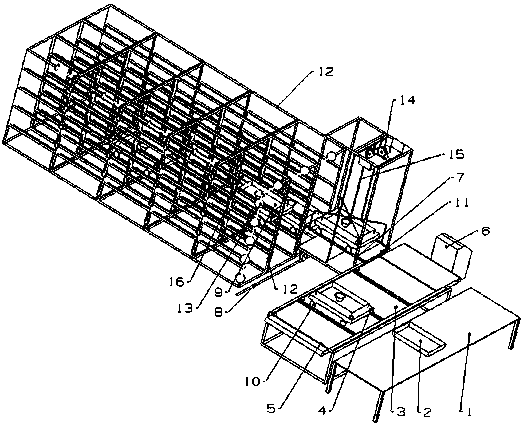

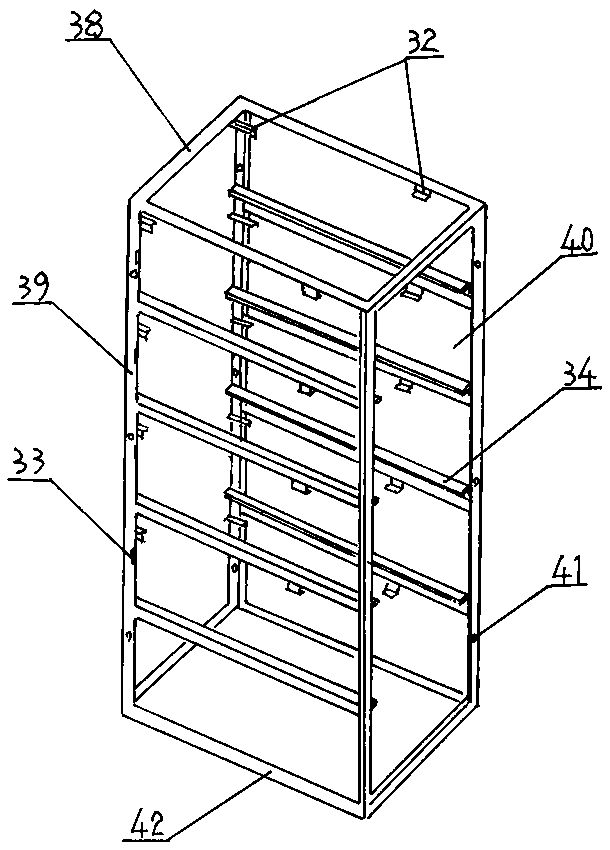

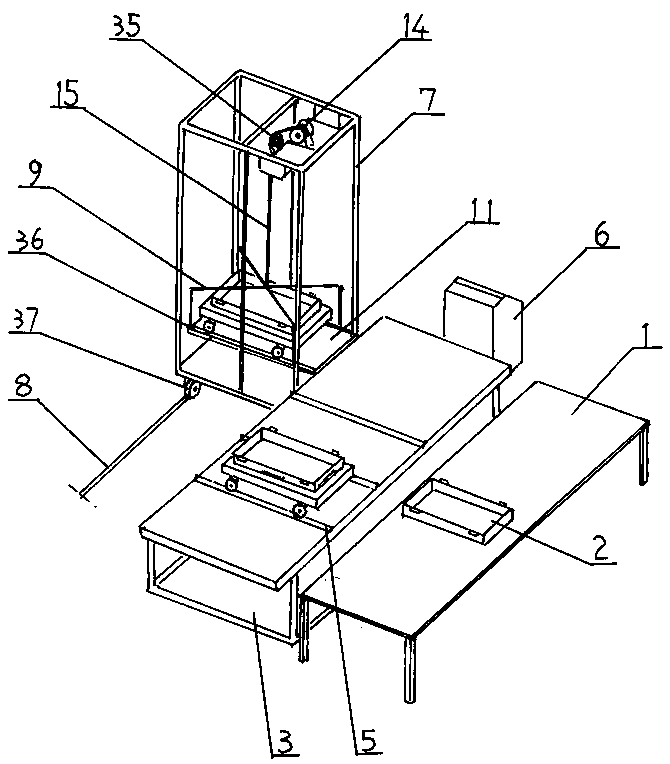

Three-dimensional cultivation device with cultivation tray automatic feeding and discharging function

PendingCN107758189AImprove mechanizationIncrease productivityReceptacle cultivationStorage devicesEngineeringRational design

The invention belongs to a three-dimensional cultivation device with a cultivation tray automatic feeding and discharging function. The device is composed of cultivation trays, a control table and anoperation table; a lifting locomotive runs on a locomotive track; a cultivation frame array which is formed by connecting a plurality of cultivation frames in parallel and in series is arranged on oneside perpendicular to the locomotive track; a temporary storage table and the operation table are sequentially arranged on the other side perpendicular to the locomotive track; and a transport cart is used for carrying the various cultivation trays to move back and forth between the temporary storage table and corresponding tray clamping lugs in the cultivation frame array. According to the three-dimensional cultivation device with the cultivation tray automatic feeding and discharging function, a sidewalk between traditional three-dimensional cultivation frames is omitted, and people do notneed to pass through between the three-dimensional cultivation frames to place or take down the cultivation trays, thus the height and the width of the vertical frames can be greatly extended, and thedevice has the advantages that the structural design is simple and reasonable, the mechanization degree is high, labor is saved, time and labor are saved, use cost is low, the stability is good, operation is simple and convenient, the production efficiency is high and the use effect is good.

Owner:北京市农业机械研究所有限公司

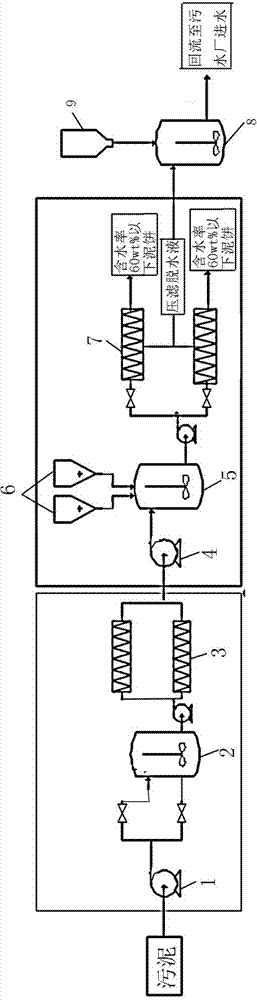

Inorganic conditioning based integrated sludge deep dehydration treatment process

InactiveCN103482844AReduce the ratioReach the smellSludge treatment by de-watering/drying/thickeningThermal energySocial benefits

The invention relates to an inorganic conditioning and pin screw machine based integrated sludge deep dehydration treatment process. The process comprises the steps such as primary dehydration, deep dehydration, dehydrated sludge delivery and the like; the moisture content in the sludge is reduced from 99.7% to less than 60% once in two stages by only adopting medication modifying and pin screw machine filter pressing ways instead of depending on any external conditions such as thermal energy and the like. In the whole operation process, no smoke, odor and noise are generated, no external thermal sources are needed, no secondary pollution is caused, the clean production can be realized, and more importantly, an operable approach is provided for waste sludge recycling, so that the process has very important significance in handling a large-area and large-quantity sludge treatment situation on both economic and social benefits.

Owner:孙阳 +1

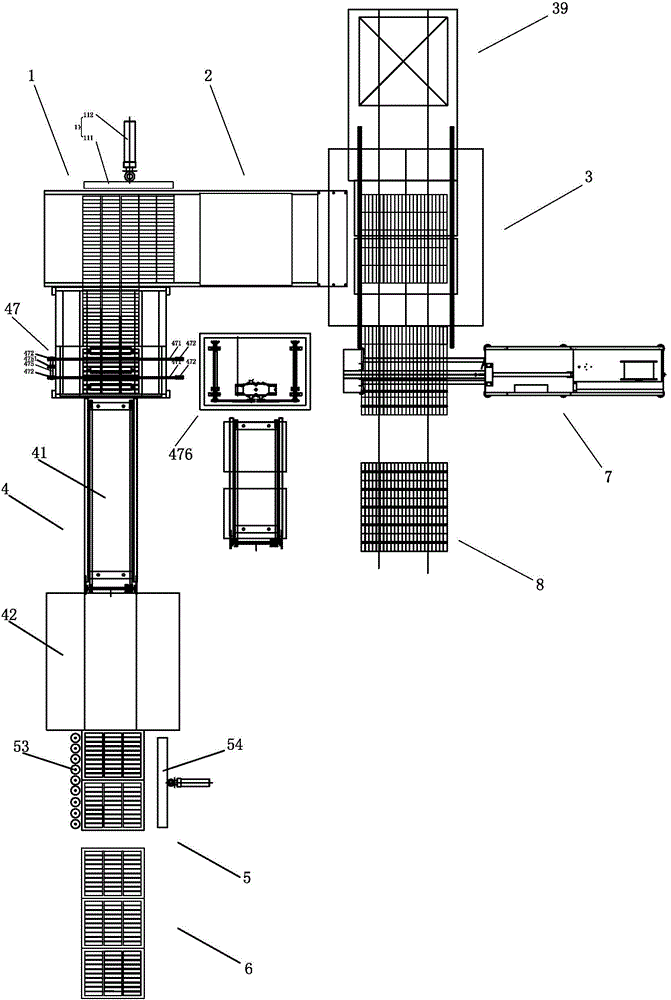

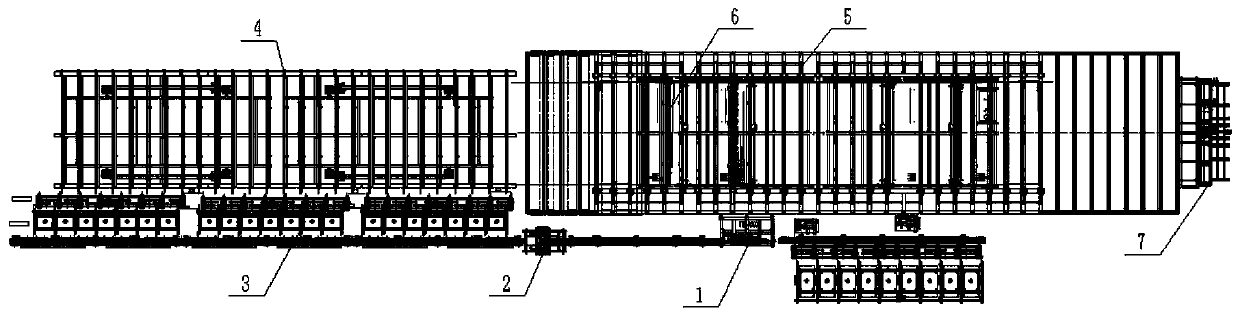

Flexible production line and process for spatial three-dimensional reinforcing mes

PendingCN110918838ALow plane bending accuracyHigh precision of plane bendingMetal-working apparatusWire networkMesh reinforcementStirrup

The invention discloses a flexible production line for a spatial three-dimensional reinforcing mesh, which comprises a stirrup cloth production line, a bending production line, a main reinforcement cloth production line, and a gantry production line. The present invention also discloses a flexible production process for the spatial three-dimensional reinforcing mesh, which includes the following steps: S1, preparing stirrups and completing plane distribution; S2, pulling the stirrups onto a bending platform; S3, horizontally moving a guide beam in the same longitudinal direction so that the stirrups are planarly bent according to a set bending angle; S4, sequentially distributing main reinforcement; S5: welding and binding to form a mesh; S6, successively performing operations from an outside three-dimensional bending mechanisms to bend the mesh twice from the two sides of the production line to its centerline to achieve three-dimensional bending forming of the mesh; and S7, after themesh is formed, lifting the mesh out of the production line. The production line and the production process of the invention can improve the industrialization, mechanization, automation, and assemblylevel of the bridge tower spatial three-dimensional reinforcing mesh construction .

Owner:CCCC SECOND HARBOR ENG

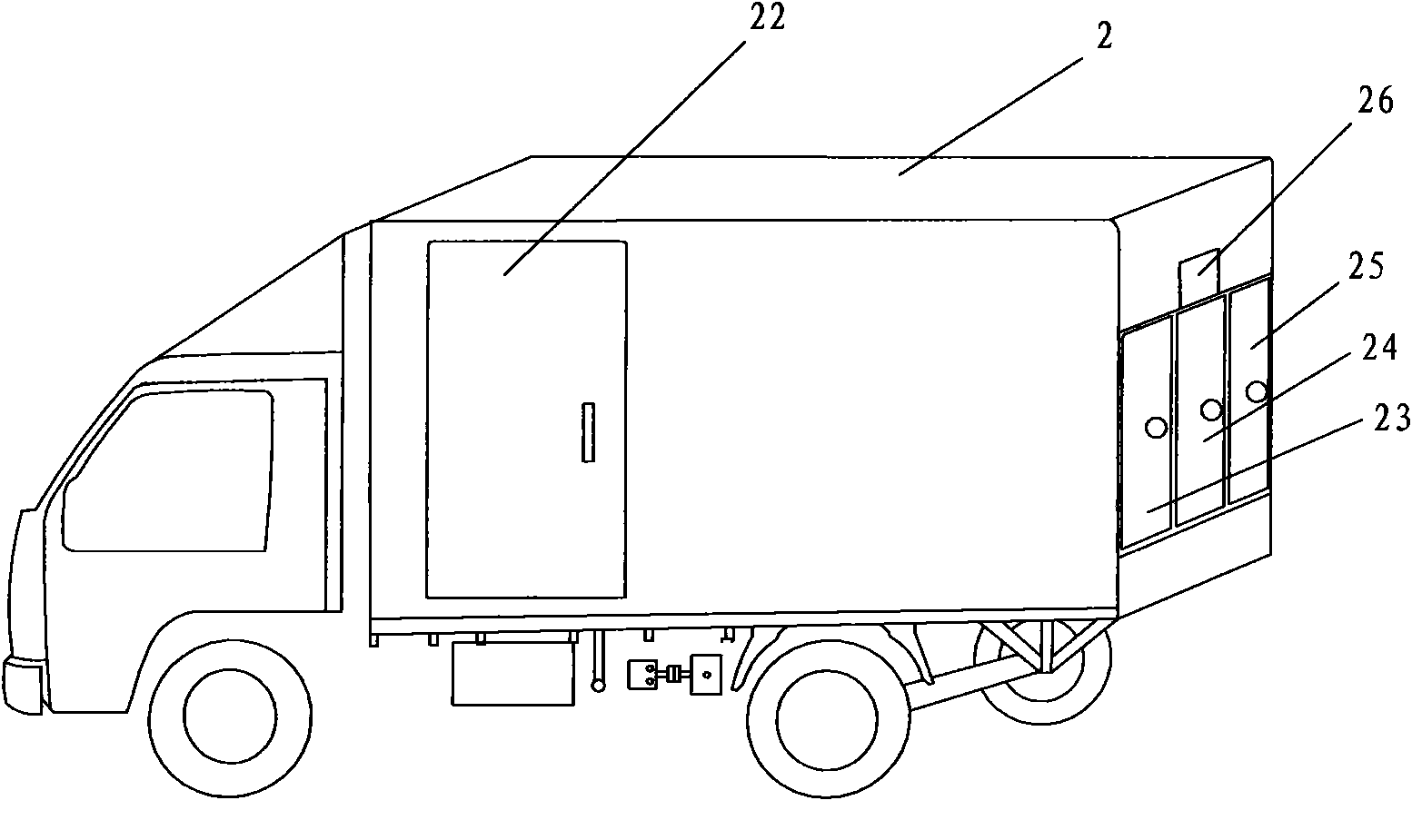

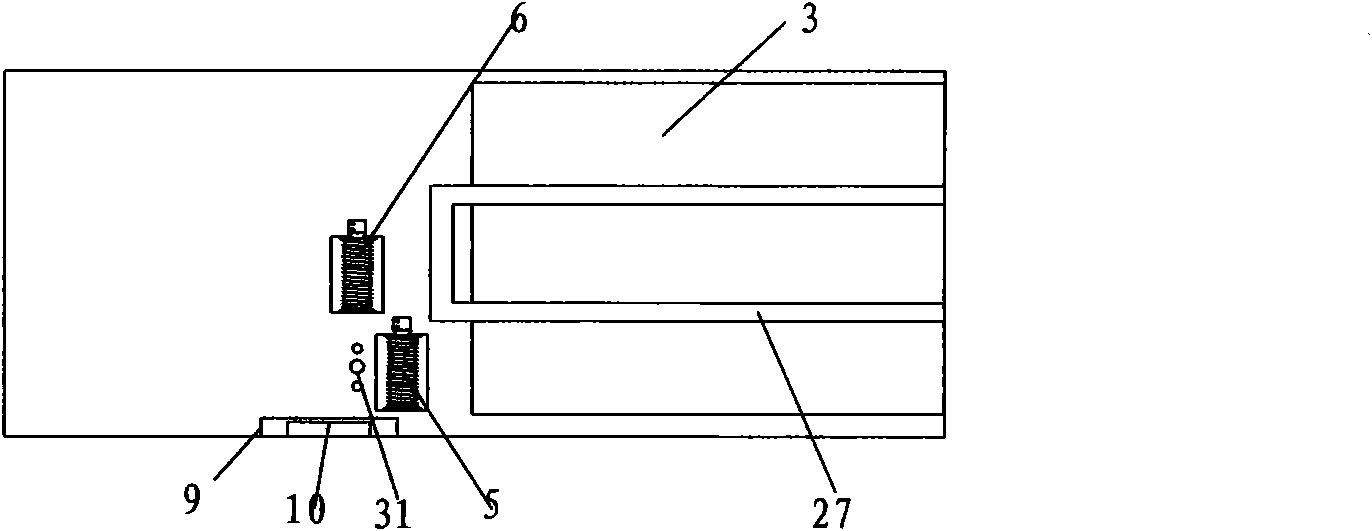

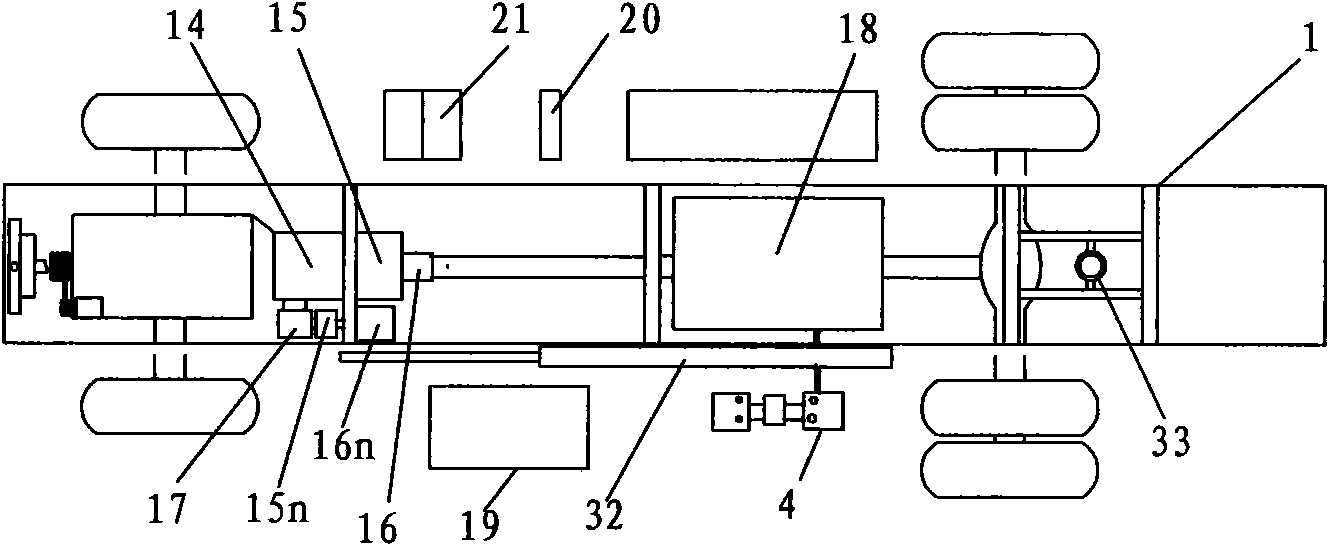

Pipe-dredging vehicle

The invention discloses a pipe-dredging vehicle, which comprises a vehicle chassis, a truck bed arranged on the vehicle chassis, a self-discharging dump bucket arranged inside the truck bed, a telescopic bracket, a windlass, a toolbox, a cleaning machine, a hydraulic block, a CPU controller and a remote controller arranged outside the truck bed, a conductor, and a pulley machine. The tail of the pipe-dredging vehicle is aligned with a pipeline A wellhead, while the front part is aligned with a pipeline B wellhead; a telescopic machine is pushed out, and a back wire rope passes through an excavator and is connected with an inner ring of a removable cover plate; and a front wire rope passes below the vehicle chassis, and moves forwards to get into the B wellhead and get out of the A wellhead to be connected with an outer ring of the excavator. CPU program is started to drive power; and driven by the wire rope to operate between the pipeline and the vehicle back and forth, the elevator sends dredged sludge and sandstone onto the vehicle and automatically unloads. The vehicle has high mechanization, automation level and stable performance, and can solve the problem that sanitation workers cannot solve, greatly saves the energy consumption, alleviates environment pollution, reduces the labor intensity of workers, and improves the working efficiency.

Owner:吴彪

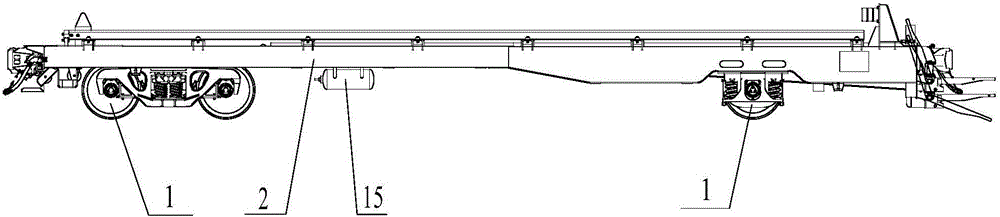

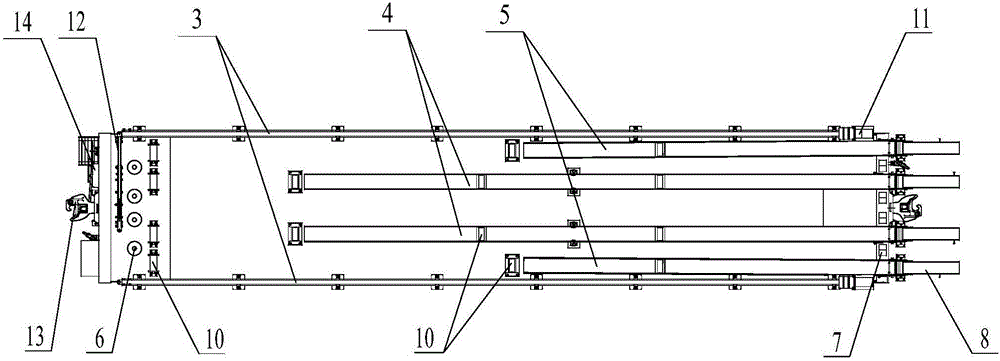

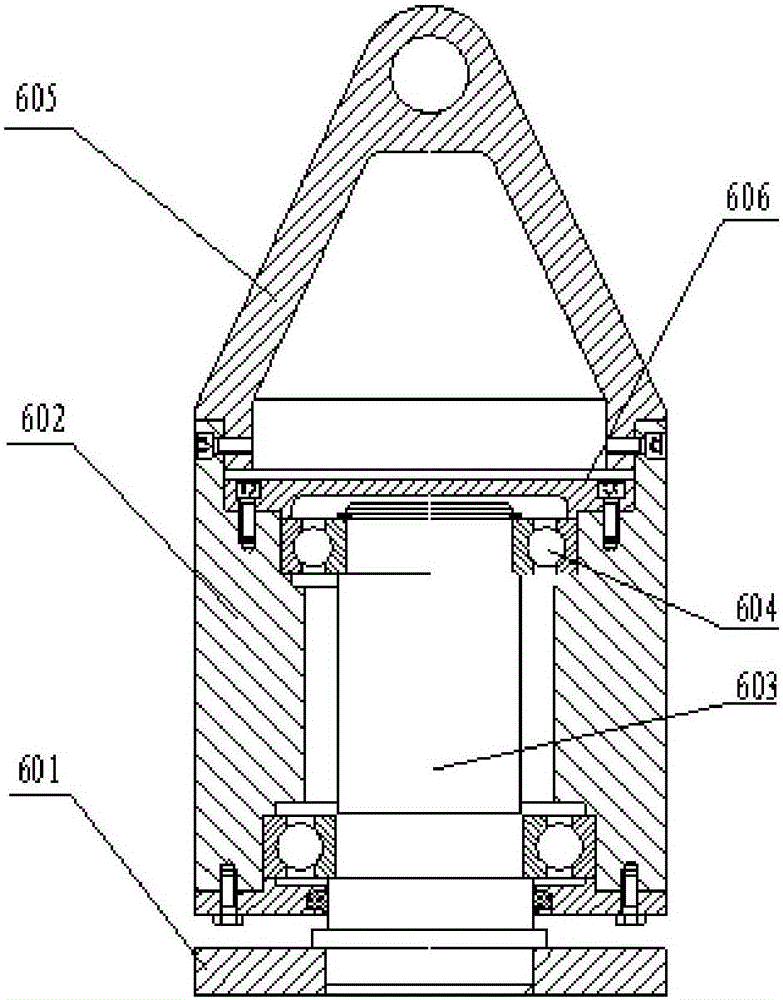

Rail-switching operation vehicle and rail-switching transport vehicle set

InactiveCN106114532AAchieve loadingRealize unloadingTrack superstructureRailway track constructionBogieUltimate tensile strength

The invention provides a rail-switching operation vehicle and a rail-switching transport vehicle set. The rail-switching operation vehicle comprises steering frames and a vehicle body underframe arranged on the steering frames, wherein running rails allowing a hoisting vehicle to travel and first steel rail guide grooves for accommodating steel rails to be switched are arranged / formed on / in the top surface of the vehicle body underframe; and the rail-switching operation vehicle further comprises a first steel rail guide device and a second steel rail guide device for guiding the steel rails to be switched to enter in or move out from the corresponding first steel rail guide grooves. The rail-switching operation vehicle provides an opening space for collecting operation and unloading operation of the steel rails for the hoisting vehicle, during steel rail unloading operation, the steel rails can be unloaded to preset unloading positions; during rail collecting operation, recovery of old steel rails is guided, so that the loading and the unloading of the steel rails to be switched are realized, the mechanized and automatic degree of the rail-switching operation is greatly increased, and the working efficiency is improved; and the labor intensity is reduced, the manning levels are reduced, the quality of rail-switching operation can also be improved, and requirements for urban construction and rail traffic development at current are met.

Owner:CRRC SHENYANG CO LTD

Food packaging technology

ActiveCN105235946AEasy to storeEasy to transportWrapper twisting/gatheringMaterial resourcesEngineering

The invention discloses a food packaging technology and relates to the technical field of the food packaging technology. The food packaging technology includes a material conveying step, a material overturning and arranging step, a material sorting step, a bag taking step, a bag opening step and a packaging step. According to the packaging technology, after food is packaged in small bags through an outer packaging machine, the small bagged food is overturned, arranged, sorted and laminated; and finally, the small bagged food is packaged into food packaged in large bags. The whole technologic process is full automatic and mechanical, manual packaging is not needed, and a large amount of manpower and material resources are saved. The packaging technology is high in automatic and mechanical degree, packaging efficiency can be improved easily, and storage and transportation of the food packaged in bags are facilitated.

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

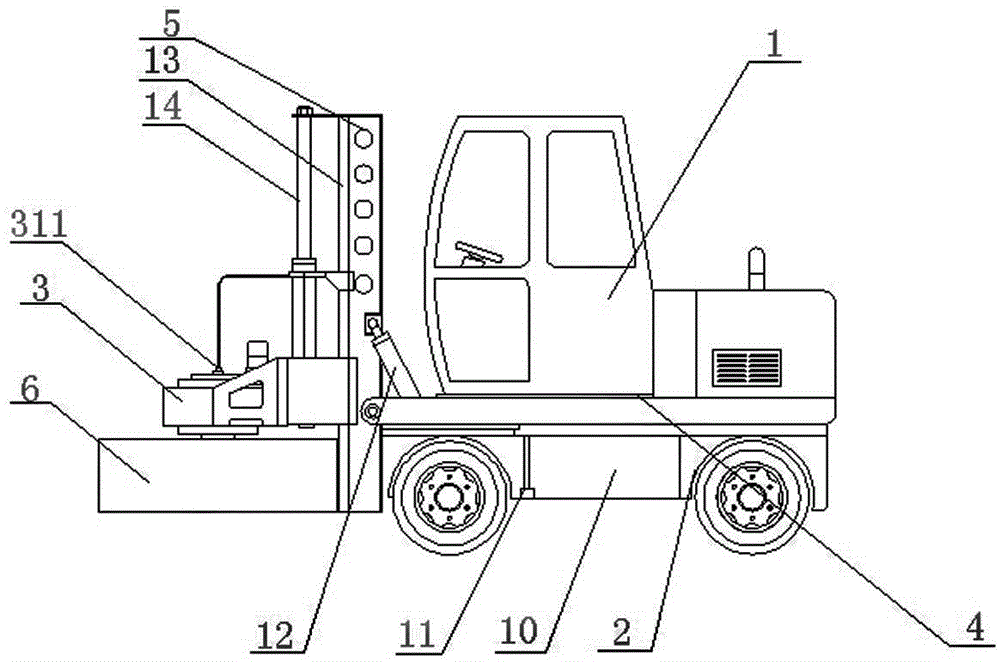

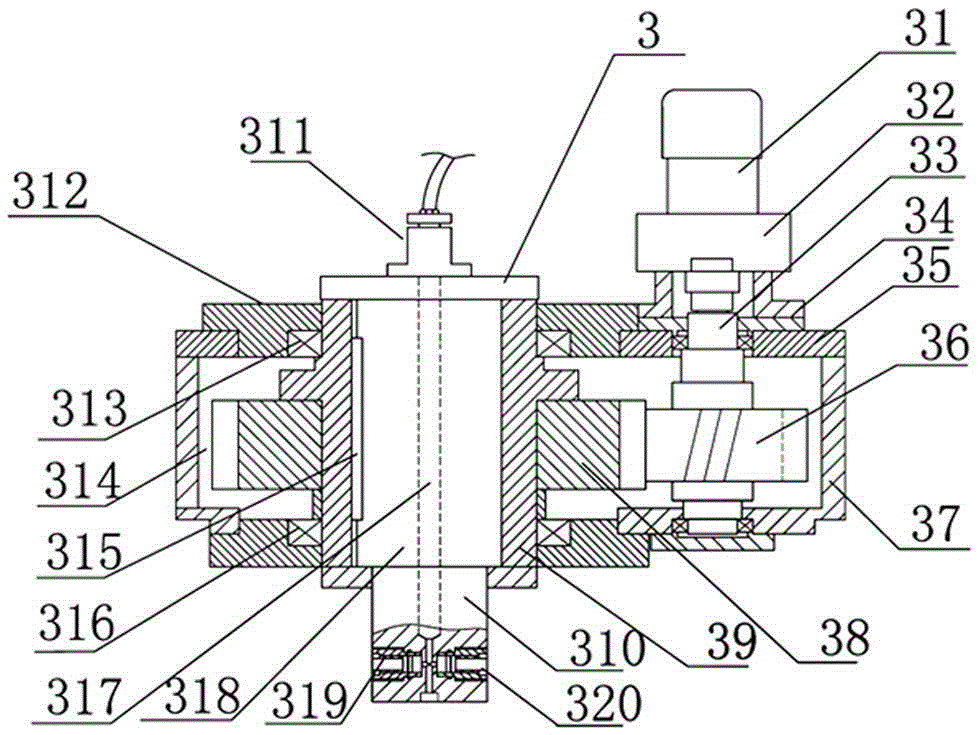

Road well lid repairing machine

InactiveCN105421204APromote repairReduce investmentArtificial islandsUnderwater structuresStructural engineeringRoad surface

The invention provides a road well lid repairing machine which is used for maintaining conditions such as damage, sinking, well ring looseness or inclining of a well lid on a road. The road well lid repairing machine comprises a walking engine and a drilling and milling head; a mast is additionally arranged, the lower portion of the mast is hinged to the front end of the walking engine, and a swing oil cylinder is arranged between the mast and the walking engine; the drilling and milling head is arranged on a vertical guide rail in a guide manner, a lifting oil cylinder is arranged between the top of the mast and the drilling and milling head, and repairing tools are connected to the lower end of the drilling and milling head; and the repairing tools are a drum driller, a well ring lifting device and a rolling device or one or two of the drum driller, the well ring lifting device and the rolling device. By means of the road well lid repairing machine, the problems that road well lid repairing construction is difficult, and time and labor are wasted are solved, and application and popularization of municipal administration paths are facilitated.

Owner:山东济宁金易德机械有限公司

Auxiliary device of sintering machine

The invention discloses an auxiliary device of a sintering machine. The auxiliary device can be a water gas generating device additionally arranged on the sintering machine. The auxiliary device is characterized in that a protective cover, an air supply control system, a pipeline, spray nozzles, valves and sensors are mounted in an area starting from an igniter of the sintering machine, steam can be distributed from the igniter of the sintering machine to the tail of the area, an appropriate amount of steam is added into air around combusting sintering ores, gas water reaction is carried out on a combustion layer, hydrogen and carbon monoxide are generated, reducing atmosphere of the combustion layer is strengthened, iron can be reduced advantageously, and accordingly iron oxide of the sintering ores is reduced. The auxiliary device of the sintering machine has the advantages that by the aid of the auxiliary device, the sintering ores can be directly cooled on the machine and can be conveyed in place, equipment (such as a belt cooler) which is high in energy consumption and investment can be omitted, the mechanization is improved, the labor intensity of workers is relieved, the auxiliary device is simple in process and is environmental friendly, energy can be saved, large quantities of resources are saved, and the like.

Owner:薛相毅

Farmland pollution remediation equipment and method

InactiveCN104707863AEasy to moveImprove mechanizationContaminated soil reclamationProcess engineeringPollution Remediation

The invention discloses farmland pollution remediation equipment and a method. The equipment comprises a rack, a control compartment, an agent box, a liquid box, a conveying device, a lifting device I, a lifting device II, a stirring device I and a stirring device II, wherein the lifting device I and the lifting device II are fixed on the rack; the control compartment, the agent box, the liquid box, the conveying device, the stirring device I and the stirring device II are arranged at the upper part of the rack; and a front wheel and a rear wheel are arranged at the bottom of the rack. The equipment achieves mechanical and automatic operation of farmland remediation to the greatest extent, so that the operation efficiency and operation precision are improved; the labor is saved; the cost is lowered; the method for farmland pollution remediation with the equipment achieve permanent settlement of pollutants in polluted soil of a farmland and ensures remediation effect and timeliness.

Owner:爱土工程环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com