Pipe-dredging vehicle

A technology for dredging pipes and carriages, applied in waterway systems, water supply devices, buildings, etc., can solve problems such as complex swing boards, large three gears of hoist, and slow handwheel screwing speed, so as to reduce the labor intensity of workers and the degree of automation High, good dredging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

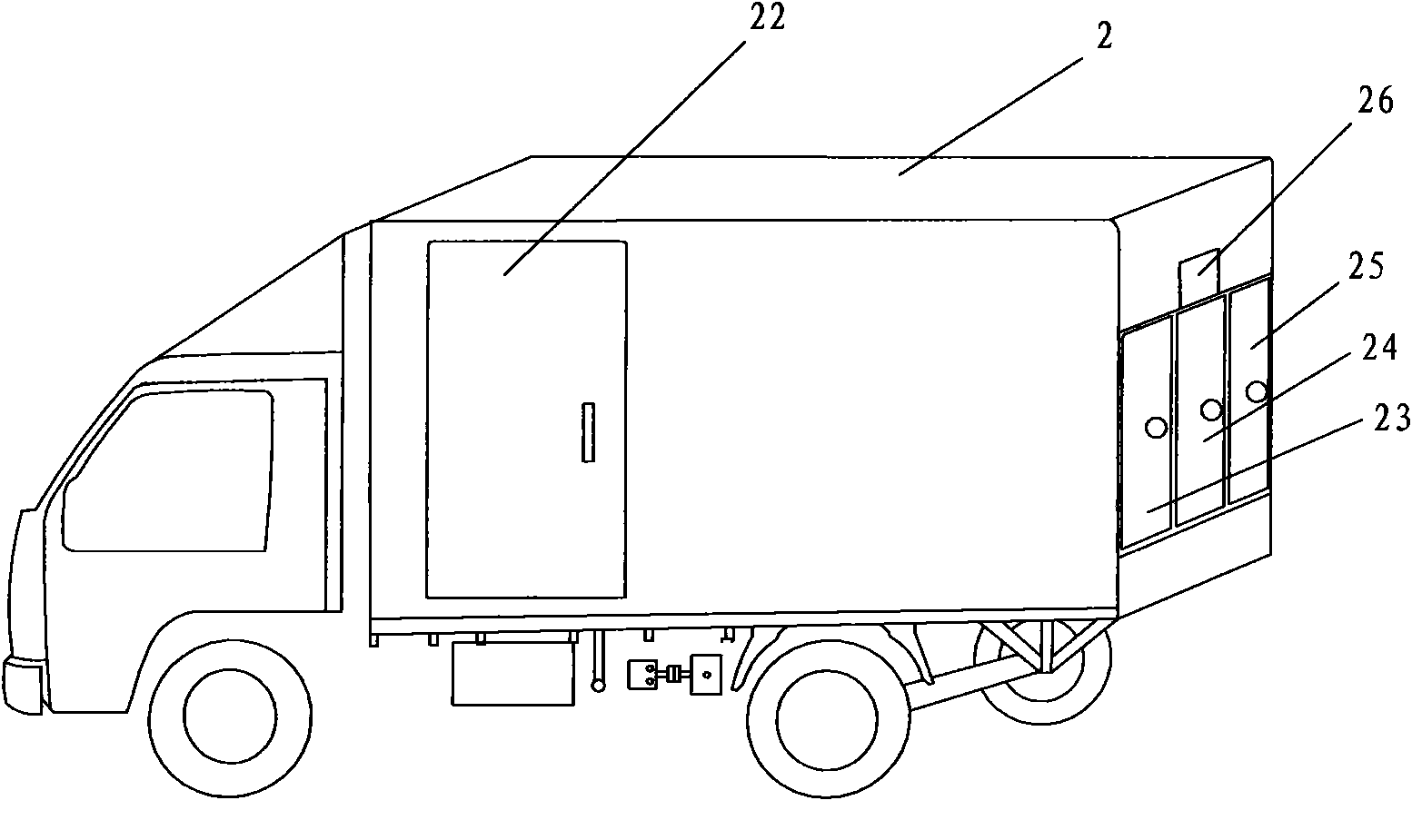

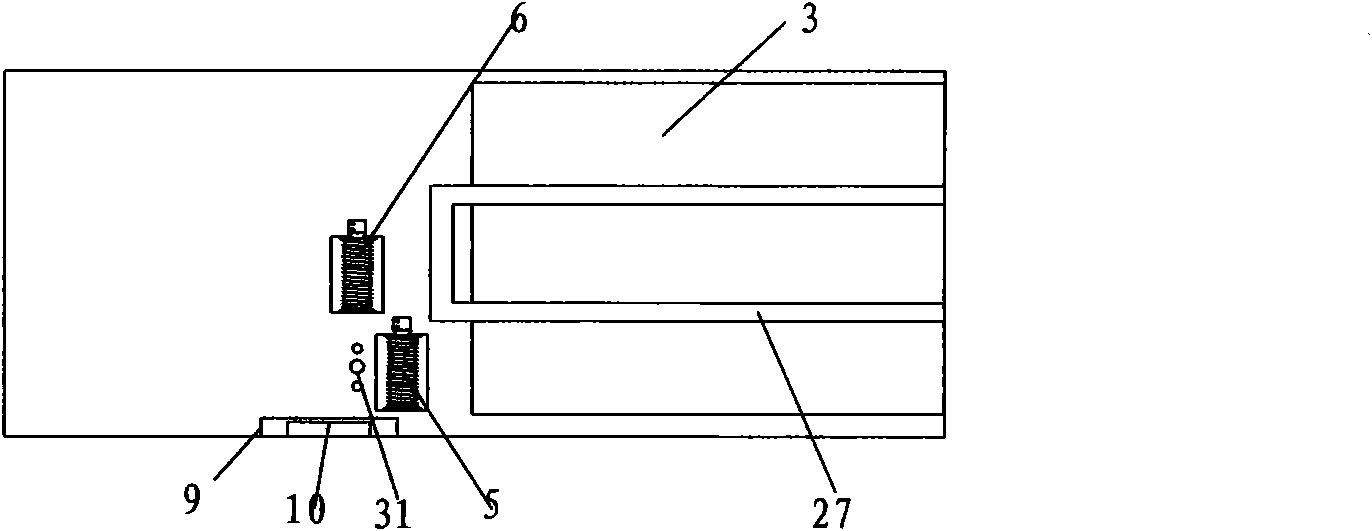

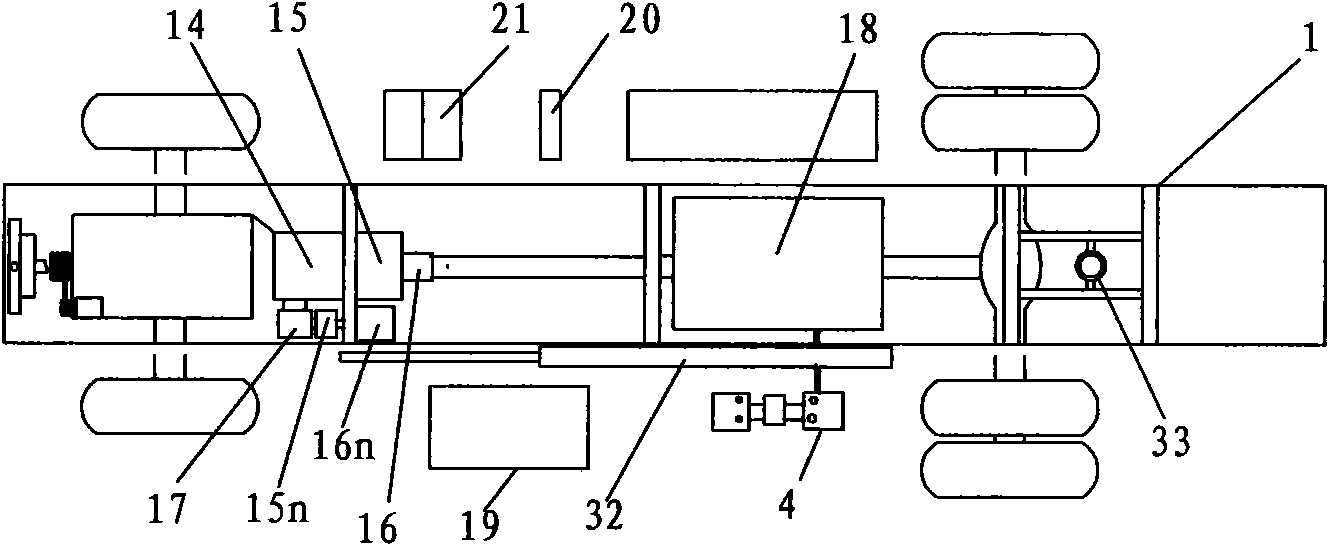

[0063] ginseng Figure 1-Figure 5 , a pipe dredging vehicle, which includes a car chassis 1, a carriage 2 arranged on the chassis 1, a dump bucket 3, and also includes a cleaning machine 4, hydraulic winches (5, 6), hoist 7, telescopic machine 8, hydraulic valve group 9. Oil cylinder, CPU controller 10, guide 11, pulley 12 and dredge 13.

[0064] An auxiliary gearbox 15 is provided between the gearbox 14 on the chassis of the automobile and the drive shaft, and the auxiliary gearbox 15 is provided with a gear oil pump 16. The setting of the inner gear of the auxiliary gearbox can make the rotating speed of the gear oil pump 16 equal to Or slightly faster than the rotational speed of the automobile engine; an auxiliary gearbox 15n can also be set up in addition, the power take-off 17 is connected with the auxiliary gearbox 15n through the shaft, the auxiliary gearbox 15n is connected with the gear oil pump 16n through the shaft, and the inner gear of the auxiliary gearbox 15n ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com