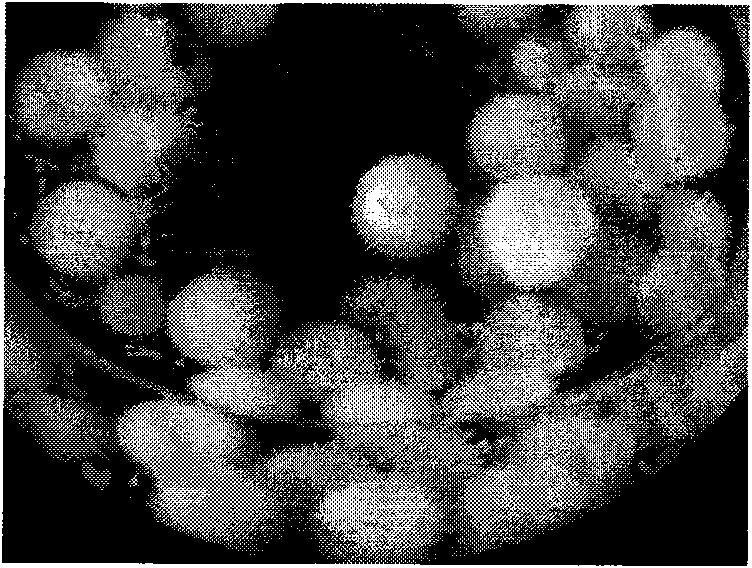

Spherical granule bacteria cellulose and preparing method thereof and special culture medium

A technology of bacterial cellulose and spherical particles, applied in biochemical equipment and methods, methods based on microorganisms, fermentation, etc., can solve the problems of gel cellulose without spherical particles, achieve novel and unique appearance, save man-hours, and produce products The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

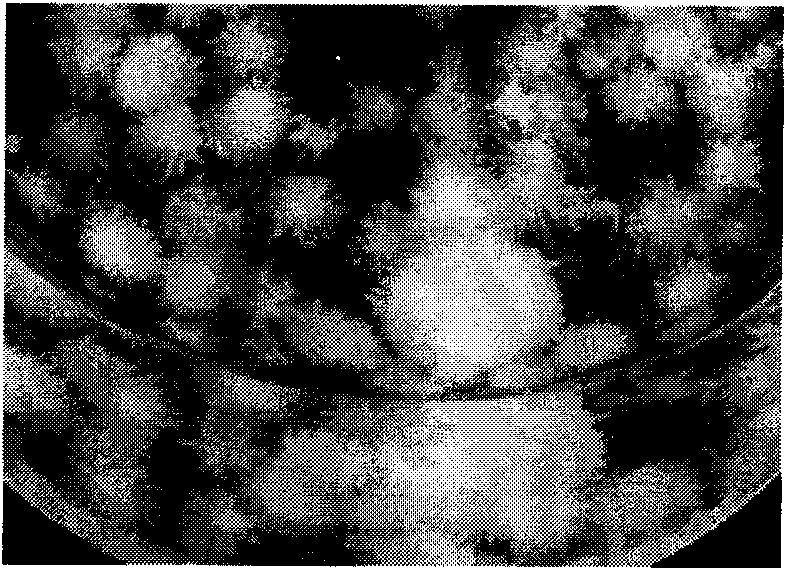

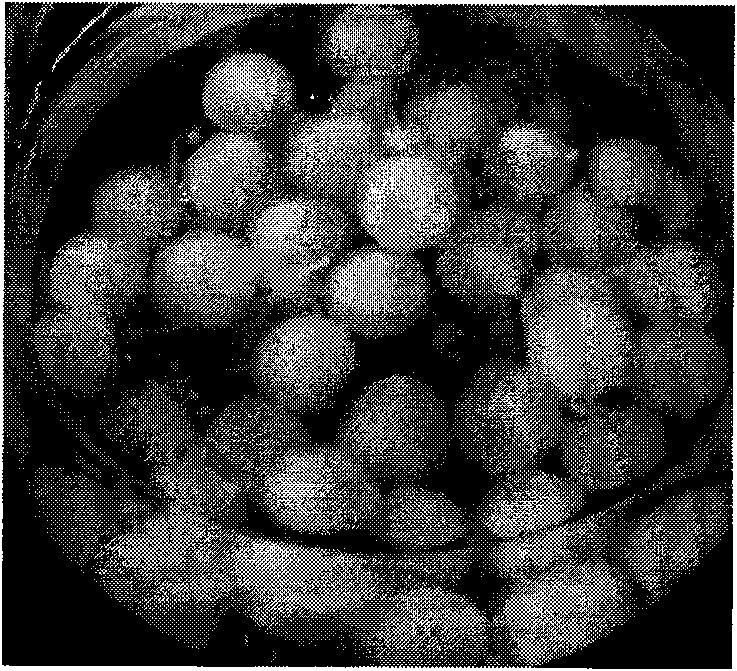

[0043] Embodiment 1, the preparation of spherical particle bacterial cellulose

[0044] 1. Determination of the optimal components and content of the fermentation medium

[0045] The preserved strain CGMCC1.1812 on the slant medium was activated for 1-2 generations on the fresh slant medium. Since the bacterial cells are easily wrapped by cellulose products when cultured on a slant, the lawn sticks into sheets, so it is advisable to streak inoculate intermittently when transferring to a slope, and do not streak continuously to prevent the lawn from sticking and making it difficult to transfer. Then insert a small piece of bacterial lawn into 20ml liquid seed culture medium (100ml Erlenmeyer flask, sealed with air-permeable sealing film), vibrate and culture at 30°C and 120r / min for 20-24h to make seed culture solution.

[0046] Then the seed liquid is inserted into the liquid fermentation medium by 4%-5% (to avoid inserting fiber filaments) and carried out various condition t...

Embodiment 2

[0081] Embodiment 2, the preparation of spherical particle bacterial cellulose

[0082] The difference between this example and Example 1 is that the bacterial strain used was replaced by the bacterial strain accc10215, and the rest of the test conditions were completely the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com