Food packaging technology

A food packaging and packer technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low packaging efficiency, not fully automated mechanical packaging, and high labor costs, to improve packaging efficiency, save manpower and material resources, and facilitate Effects of storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

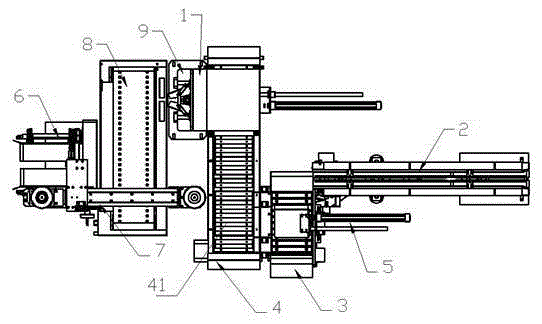

[0036] As a preferred embodiment of the present invention, this embodiment discloses:

[0037] A food packaging process, comprising the steps of:

[0038] Material conveying step: convey the bagged food materials that have been packaged by the outer packaging machine to

[0039] Material turning and discharging step: turn the delivered bagged food materials 90°, arrange the turned bagged food materials according to the set quantity, and push the bagged food materials arranged in the set quantity to

[0040] Material sorting step: sort and arrange the pushed bagged food materials according to the set quantity and set number of layers, and then transport the sorted bagged food materials to packing station 1;

[0041] At the same time, it also includes a bag taking step: taking out a single packaging bag and transporting it to the rear of packaging station 1;

[0042] Bag opening step: open the mouth of the single packaging bag delivered to packing station 1;

[0043] Packing ...

Embodiment 2

[0045] As another preferred embodiment of the present invention, this embodiment discloses:

[0046] A food packaging process, comprising the steps of:

[0047] Material conveying step: the bagged food materials that have undergone outer packaging and outer packaging are conveyed to

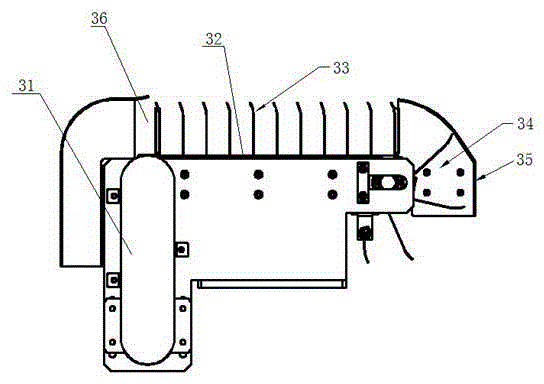

[0048] Material turning and discharging step: when the bagged food materials are conveyed from the outer packaging machine, the bagged food materials are placed flat on the material conveying device 2, which is not conducive to the arrangement and arrangement of the bagged food materials. The material conveying device 2 will pack the bags When the food material is transported to the turning and arranging device, it enters from one end, and under the action of the discharge plate 33, the bagged food material is turned over 90°, that is, the bagged food material is erected and arranged, instead of manual alignment. The arrangement of bagged food materials facilitates the subsequent packaging of ba...

Embodiment 3

[0055] As another preferred embodiment of the present invention, this embodiment discloses:

[0056] A food packaging process, comprising the steps of:

[0057] Material conveying step: the bagged food materials that have undergone outer packaging and outer packaging are conveyed to

[0058] Material turning and discharging step: when the bagged food materials are conveyed from the outer packaging machine, the bagged food materials are placed flat on the material conveying device 2, which is not conducive to the arrangement and arrangement of the bagged food materials. The material conveying device 2 will pack the bags When the food material is transported to the turning and arranging device, it enters from one end, and under the action of the discharge plate 33, the bagged food material is turned over 90°, that is, the bagged food material is erected and arranged, instead of manual alignment. The arrangement of bagged food materials facilitates the subsequent packaging of ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com