Auxiliary device of sintering machine

An auxiliary device and sintering machine technology, applied in the metallurgical industry, can solve the problems of sand blowing, poor mechanization, low economic benefits, etc., and achieve the effects of reducing labor intensity, improving mechanization, environmental protection and energy saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The principle is to add an appropriate amount of water vapor to the air of the burning sinter, and a water gas reaction will occur on the combustion layer to generate hydrogen and carbon monoxide, which will strengthen the reducing atmosphere of the combustion layer, which is more conducive to the reduction of iron, thereby reducing the sintering rate. iron oxide. At the same time, because the water-gas reaction is an endothermic reaction, the burned sinter is cooled rapidly, and the thermal conductivity of water vapor is dozens of times that of air, which naturally facilitates the cooling of sinter.

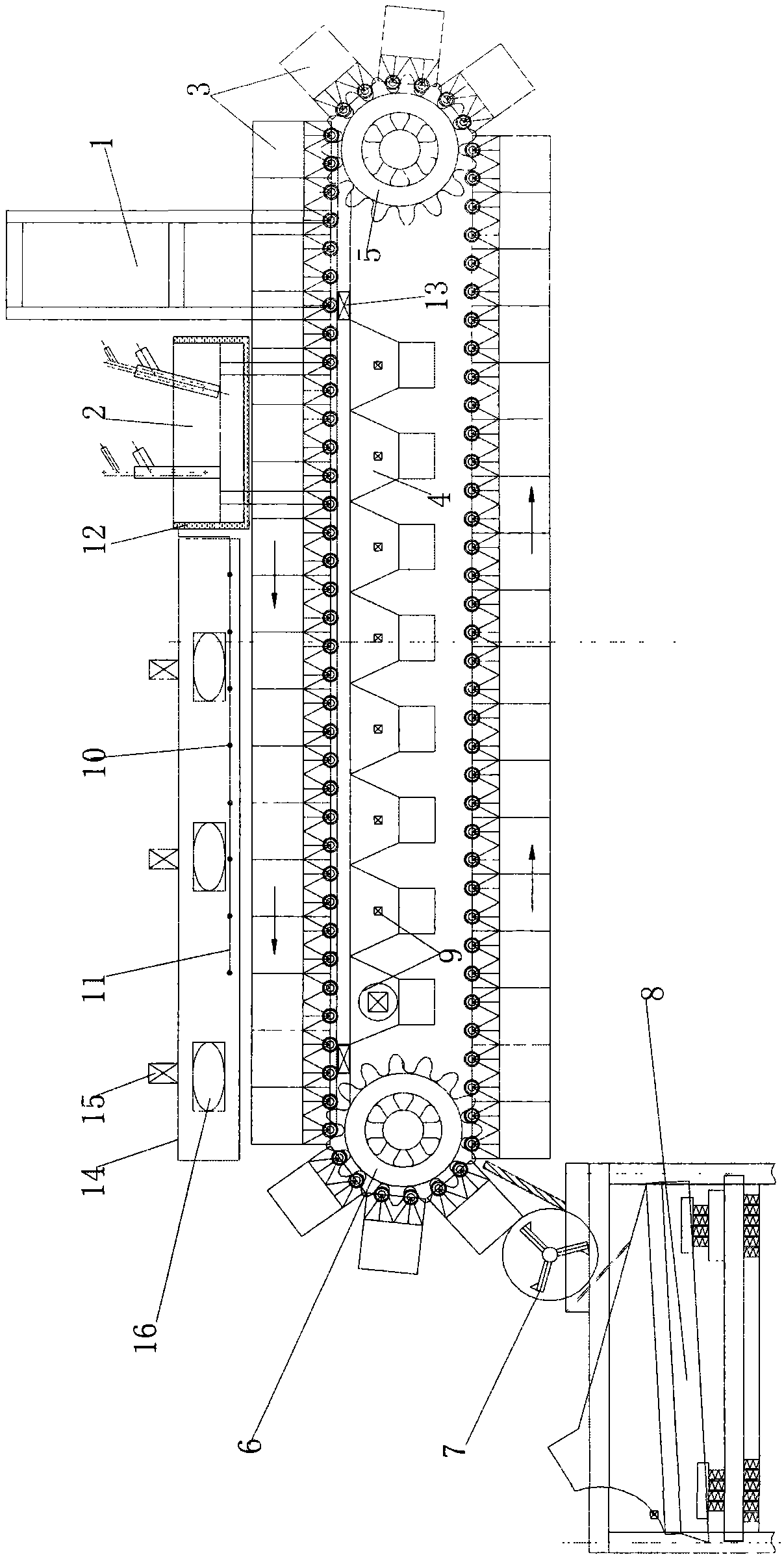

[0011] by figure 1 (Exhaust type) belt-type sintering machine is taken as an example. In the figure, a protective cover (14) and a blast control device (15) are installed from the igniter (2). The atomizing nozzle (10) and the electric atomizing nozzle (10) are adjusted by the thermal sensor (9) to control the switch. Under normal conditions, the temperature of the therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com