Solid state fermentation cylinder and solid state fermentation method

A solid-state fermentation tank and tank technology, which is applied in biochemical equipment and methods, solid-phase fermentation bioreactors, fermentation and other directions, can solve the problem that the fermentation effect is difficult to guarantee, the preventive measures for bacterial contamination in the sampling method are not specified, and the fermentation quality is affected. and other problems, to achieve the effect of purebred culture and efficient and safe large-scale production, preventing the control of product microbial indicators, and simplifying the material conveying process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

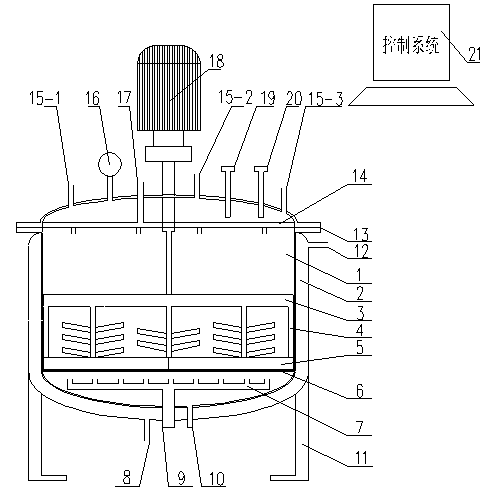

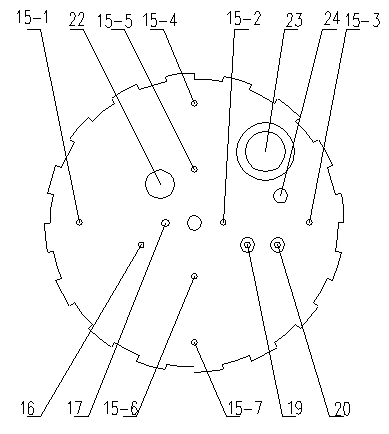

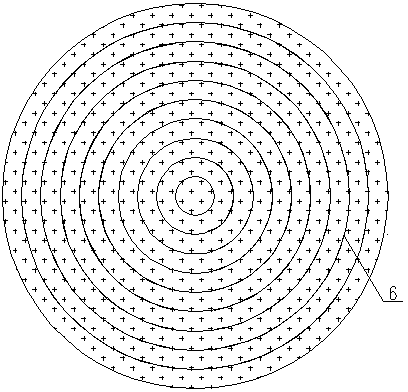

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the solid-state fermenter includes a fermenter tank body 1 supported by a tank body bracket 11 , and a jacket 2 is coated on the outside of the tank body 1 for heating and cooling. The top of the tank body 1 is an upper end cover, and a quick-opening door connection structure is realized between the upper end cover and the tank body 1 through a quick-connect flange 13, figure 1 , figure 2As shown, the upper end cover is provided with a pressure gauge 16, a humidity probe 19, and a temperature probe 20 for monitoring the condition in the tank, a mirror lamp 22, a sight glass and an opening 23 for real-time observation of the fermentation status of the material in the fermentation tank, and Flame sampling port 24 for aseptic sampling. figure 1 As shown, the solid-state fermentation tank is also provided with a stirring system, and the stirring system is driven by a drive system 18 through a hydraulic shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com