Flexible production line and process for spatial three-dimensional reinforcing mes

A technology for reinforced mesh and flexible manufacturing, which is applied in the field of spatial three-dimensional reinforced mesh flexible manufacturing production line and its production process, can solve the problems of a large number of manual binding and low degree of automation, achieve a high degree of factoryization, and improve production efficiency and precision. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

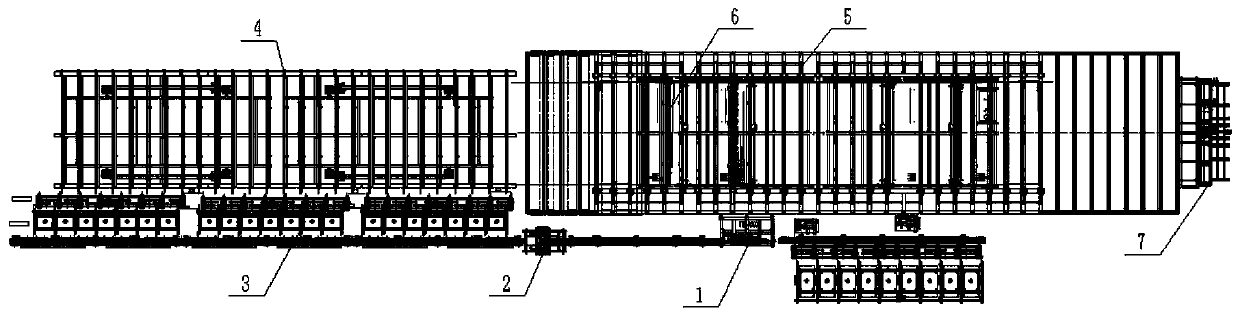

[0053] The present invention mainly comprises the following several steps to complete the production of steel mesh sheet:

[0054] (1) Stirrup fabric:

[0055] The three-dimensional mesh is formed by one plane bending and two three-dimensional bending. In order to ensure the control of the butt joint accuracy in the later construction, the reinforcement and positioning before plane bending are particularly critical.

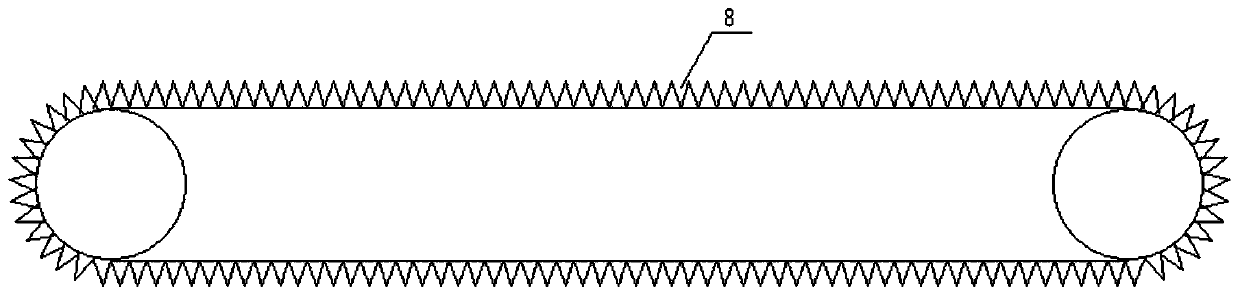

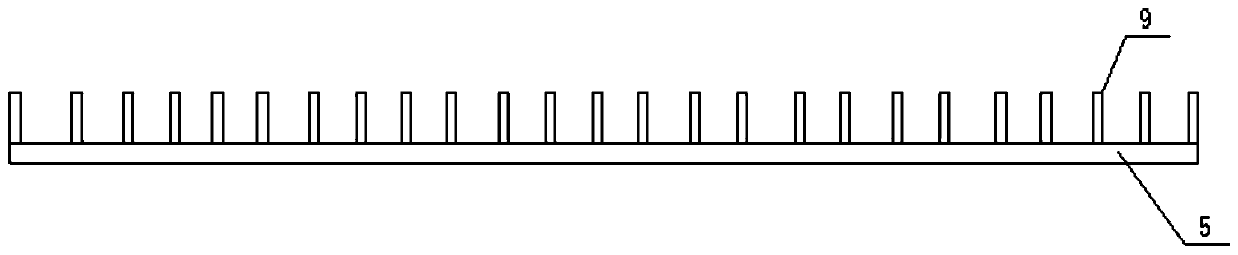

[0056] The stirrups are loaded onto the cloth table in sequence, and the positioning grooves 8 of the multiple positioning mechanisms 4 correspond to each other in the transverse direction, so that all the stirrups constituting the mesh are evenly distributed in the positioning grooves 8 according to the set spacing. On the distributing table, the stirrups take 50mm as the interval modulus (that is, the stirrup spacing can be set to 100mm, 150mm, 200mm, etc.) to complete the plane distribution. A kind of specific structure of the positioning groove 8 of the pre...

Embodiment 2

[0072] Also includes stirrup stock before stirrup cloth:

[0073] Due to the variable cross-section design of the bridge tower, the length of each stirrup is different. In order to achieve fast and accurate cutting, the production line is equipped with a special intelligent bar shearing mechanism 2, which cooperates with a dedicated automatic conveying The roller table completes the fully automatic butt welding of the steel bars on the line, and then completes the rapid sizing and cutting on the production line according to the production needs. The characteristics of joint processing, fast welding speed and reliable quality.

[0074] After the stirrup blanking and butt welding are completed, it will be automatically transported to the stirrup waiting platform until all the stirrups required for the entire mesh are ready, and the transfer process of the stirrup adopts the stirrup stepped feeding mechanism 3 Automatically, this mechanism can realize unmanned transfer and autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com