Pavement method for anti-movement composite structure of large-span steel box beam bridge deck

A technology of combined structure and steel box girder, applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of poor wear resistance, strict high temperature resistance, poor interface bonding performance, etc., to improve work performance and Mechanical properties, reducing special requirements for high temperature resistance, and enhancing synergistic deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

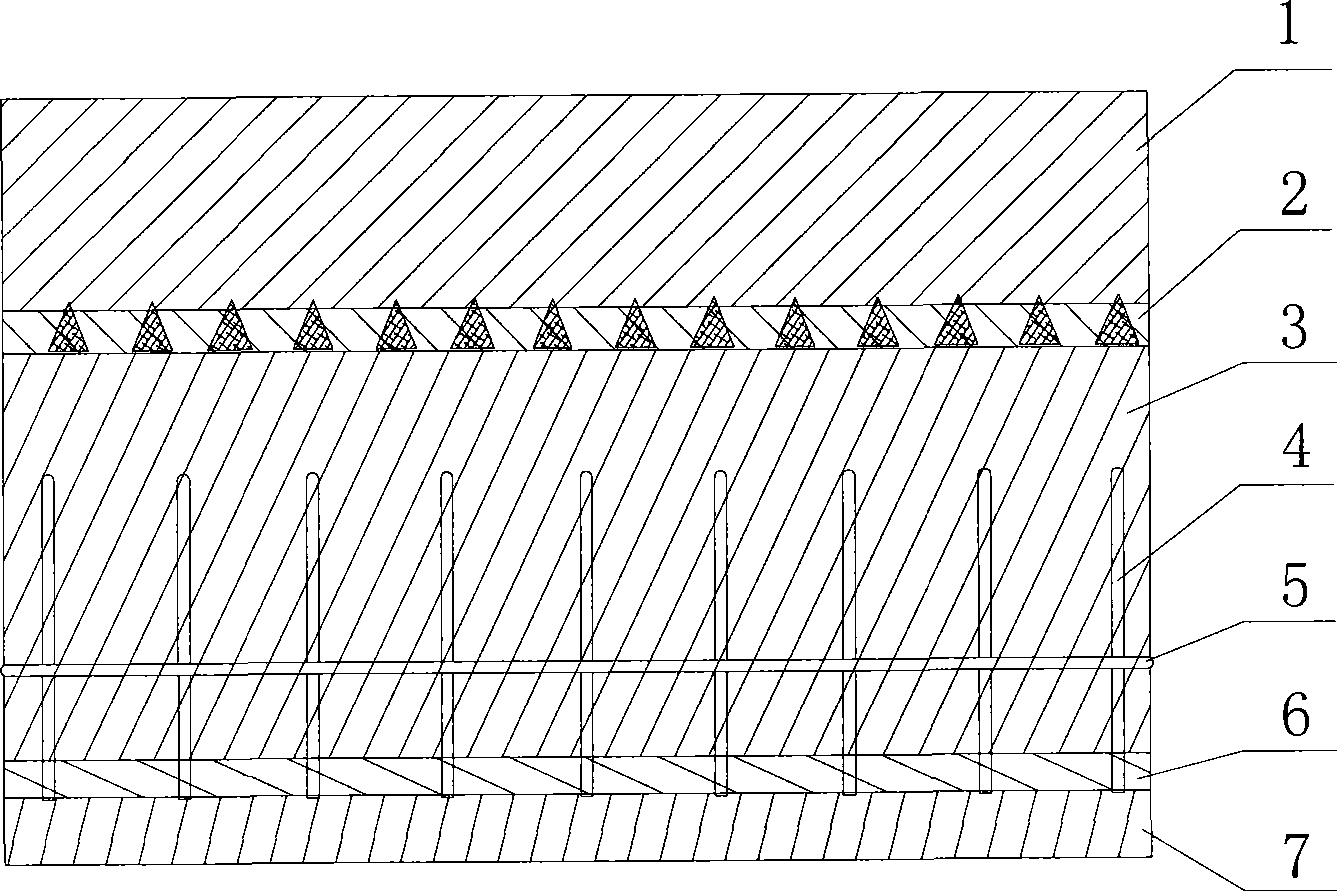

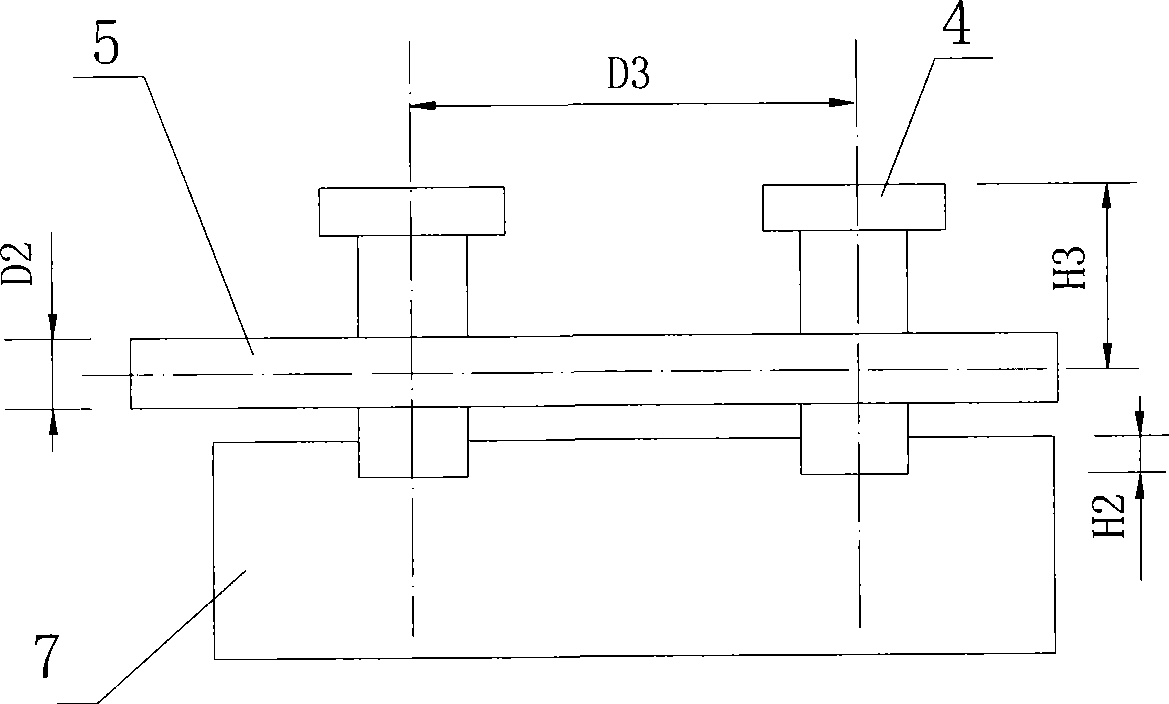

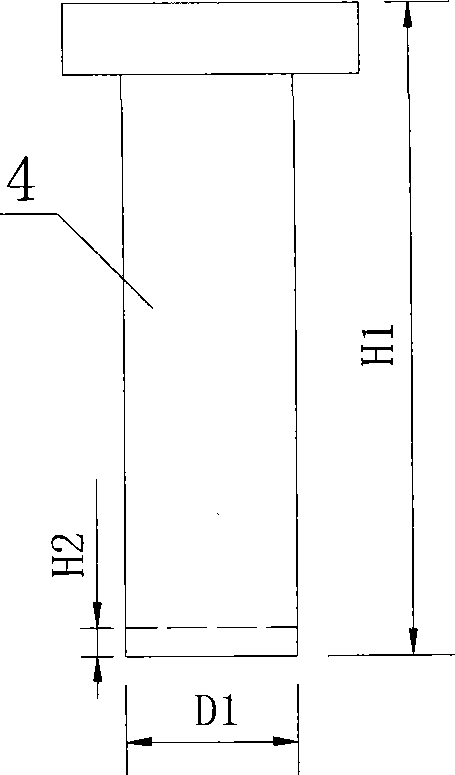

[0056] Such as figure 1 , figure 2 , image 3 As shown, a method for paving a long-span steel box girder deck anti-movement composite structure includes the following steps:

[0057] 1) Pretreatment of steel box girder deck steel plate:

[0058] ①Sand blasting and rust removal:

[0059] Firstly, check the appearance of the steel box girder deck (steel deck for short). If there is welding slag, spatter and burrs, it should be removed by polishing; secondly, the steel box girder deck steel plate that has been sandblasted and derusted should be pre-cleaned Treatment, use a high-pressure water gun or surface cleaner to clean the surface to remove the dust, oil and grease on the surface of the steel box girder bridge deck steel plate caused by a process; finally, after the surface of the steel box girder bridge deck steel plate is dry, start spraying For sand rust removal, the operating temperature should be strictly controlled to be 3°C higher than the dew point, and the relative hum...

Embodiment 2

[0083] A method for paving a long-span steel box girder bridge deck anti-movement composite structure, which includes the following steps:

[0084] 1) Pretreatment of steel box girder deck steel plate:

[0085] ①Sand blasting and rust removal:

[0086] First check the appearance of the steel box girder deck steel plate. If there is welding slag, spatter and burrs, it should be removed by polishing; secondly, the steel box girder deck steel plate that has been sandblasted and derusted should be pre-cleaned with a high-pressure water gun or The surface cleaner is used to clean the surface to remove dust, oil and grease on the surface of the steel box girder and bridge deck steel plate caused by a process; finally, after the surface of the steel box girder and bridge deck steel plate is dry, start sandblasting and rust removal, and the operating temperature Strictly control 3℃ higher than the dew point, and the relative humidity should be lower than 80%. In case of rain or snow, rust...

Embodiment 3

[0110] A method for paving a long-span steel box girder bridge deck anti-movement composite structure, which includes the following steps:

[0111] 1) Pretreatment of steel box girder and bridge deck steel plate:

[0112] ①Sand blasting and rust removal:

[0113] First check the appearance of the steel box girder deck steel plate. If there is welding slag, spatter and burrs, it should be removed by polishing; secondly, the steel box girder deck steel plate that has been sandblasted and derusted should be pre-cleaned with a high-pressure water gun or The surface cleaner cleans the surface to remove the dust, oil and grease on the surface of the steel box girder and bridge deck due to a process. Finally, after the surface of the steel box girder and bridge deck is dry, start sandblasting and rust removal, and the operating temperature Strictly control 3℃ higher than the dew point, and the relative humidity should be lower than 80%, in case of rain or snow, etc., rust removal operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com