Accurate leveling device for cast-in-situ concrete flooring formed in one step and construction method

A technology for concrete and floor, applied in construction, building structure, processing of building materials, etc., can solve the problems of low efficiency, complicated process and high cost, and achieve the effect of simple operation, improved flatness standard and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

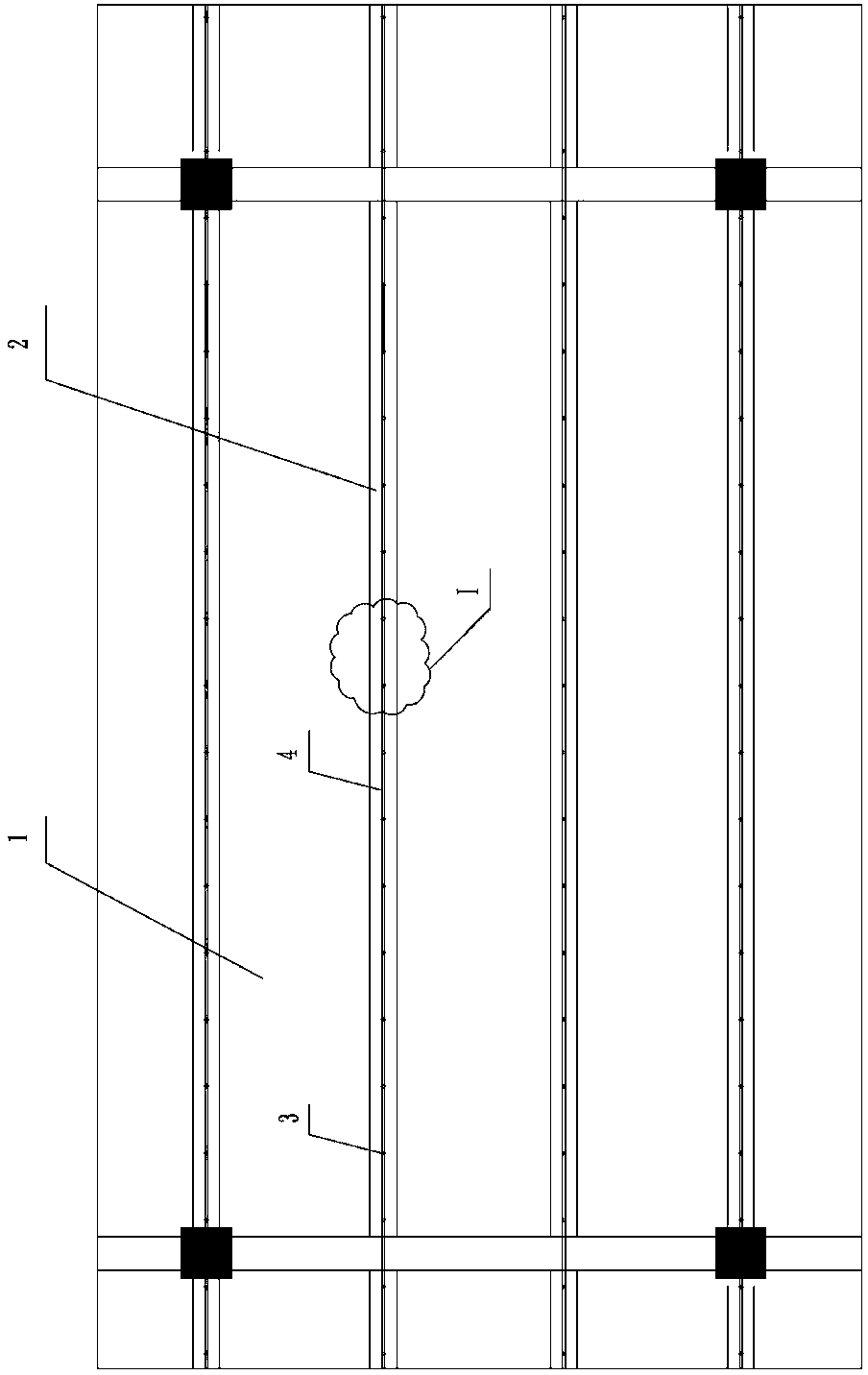

[0023] like figure 1 As shown, the precise leveling device for the cast-in-place once-formed concrete floor of the present invention includes the structural floor formwork 1 and all the longitudinal steel skeletons 2 in the beams. In the present invention, each longitudinal steel skeleton 2 is welded with a number of leveling plates corresponding to each other and evenly distributed. Adjustment frame 3. Steel pipe guide rails 4 are supported longitudinally on all leveling adjustment frames 3 on each longitudinal steel bar skeleton 2 . All the longitudinal reinforcement frame 2, the leveling adjustment frame 3 welded on the longitudinal reinforcement frame 2, and the steel pipe guide rail 4 supported by the leveling adjustment frame 3 jointly constitute a precise leveling device for the cast-in-situ once-formed concrete floor.

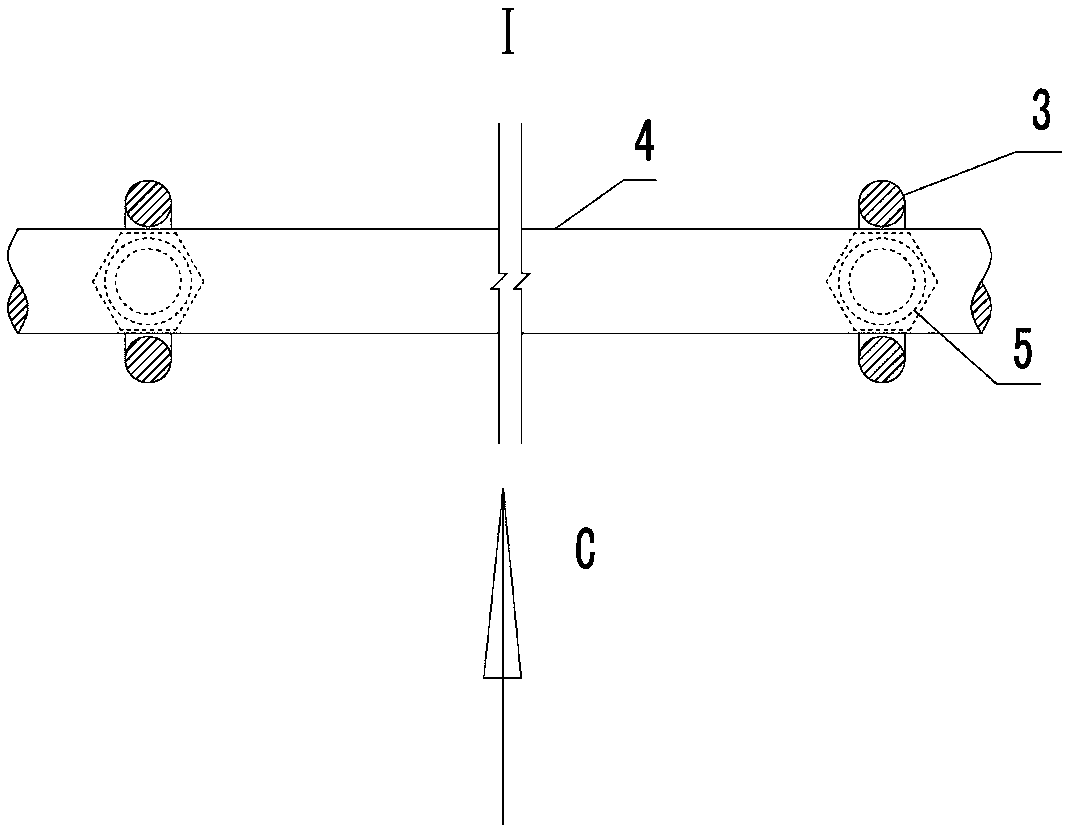

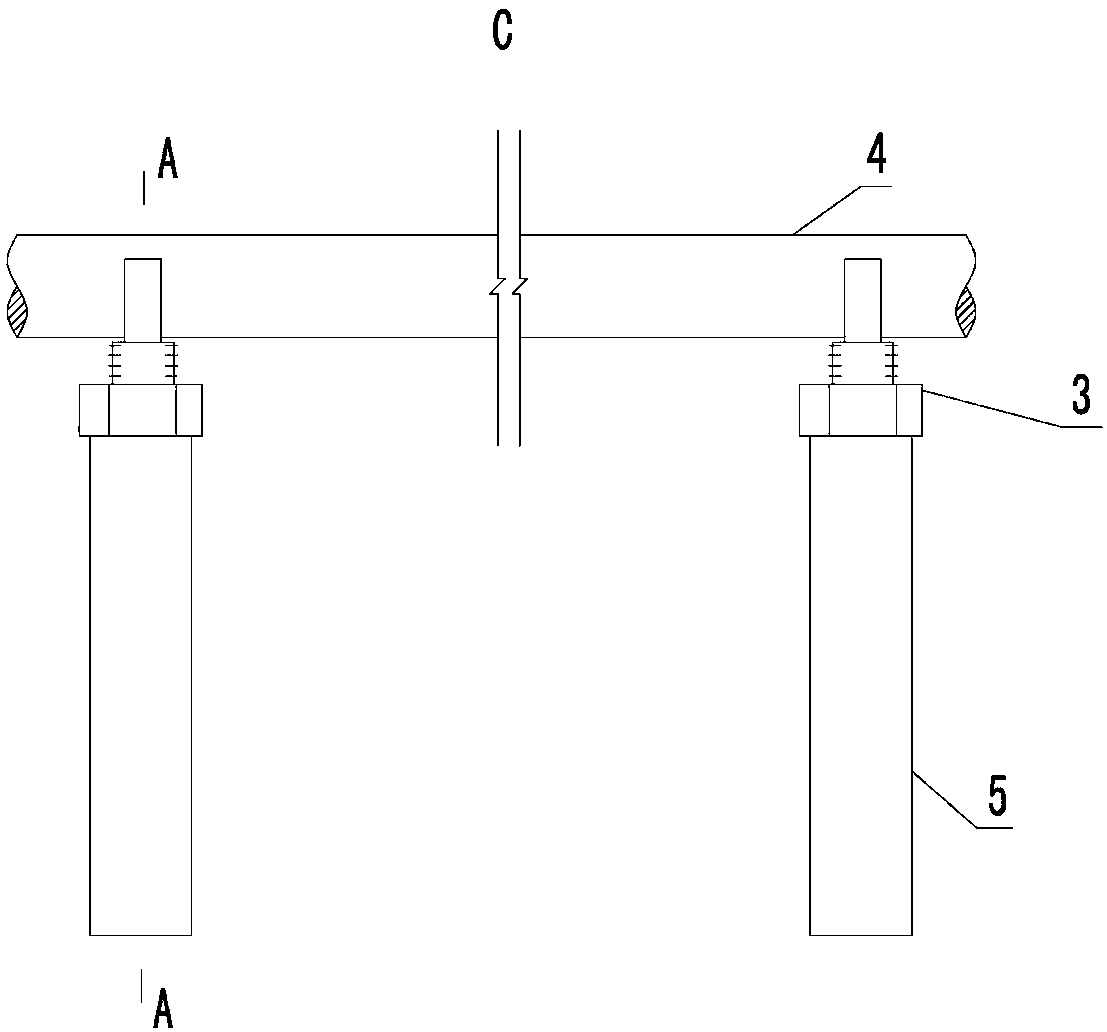

[0024] like figure 2 , image 3 , Figure 4 As shown, the leveling adjustment frame 3 is composed of a semicircular bracket 3-1, a screw rod 3-2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com