Large-span steel box beam bridge deck pavement layer material gradient structure pavement construction method

A bridge deck paving and gradient structure technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of adverse social impact, poor high temperature resistance of asphalt concrete, complicated construction, etc., and achieve excellent anti-rutting and anti-skid performance. , Improve the effect of low interface bond strength and improve driving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0075] The present invention is suitable for pavement construction of gradient structure of bridge deck materials with a single-span span of steel box girder of various urban bridges within 150 meters (including 150 meters), and the design load is checked according to the vehicle-super 20 level and the trailer-120 level.

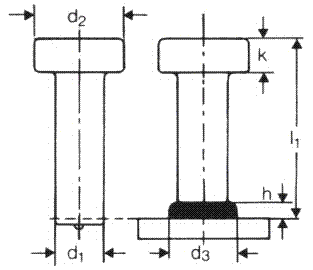

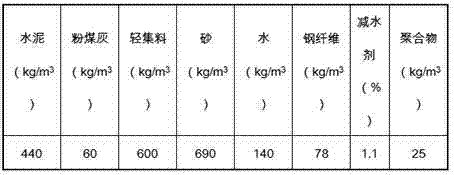

[0076] The process principle of the present invention is based on the principle of material gradient design, utilizes the maximum tensile stress of the pavement layer, the maximum shear stress between the pavement layer and the steel plate layer, and the elastic modulus ratio n (n=E pavement layer) of the bridge deck pavement system. / E steel plate) increases and gradually decreases, it is proposed to weld shear members on the steel plate (elastic modulus 210GPa), bind the steel mesh, and pour the lower layer of high-toughness lightwei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com