Non-dismantling die cast-in-place lightweight thermal insulation wall formboard, thermal insulation wall and construction method thereof

A technology for insulating walls without removing formwork, applied to walls, building components, buildings, etc., can solve the problems of complex wall construction and low efficiency, and achieve the effect of ensuring wall thickness consistency, high strength, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

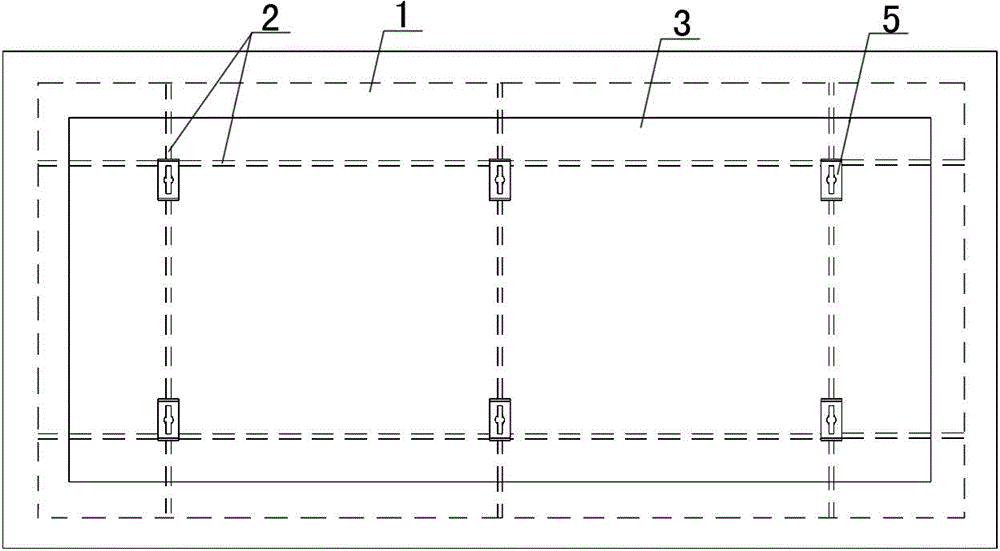

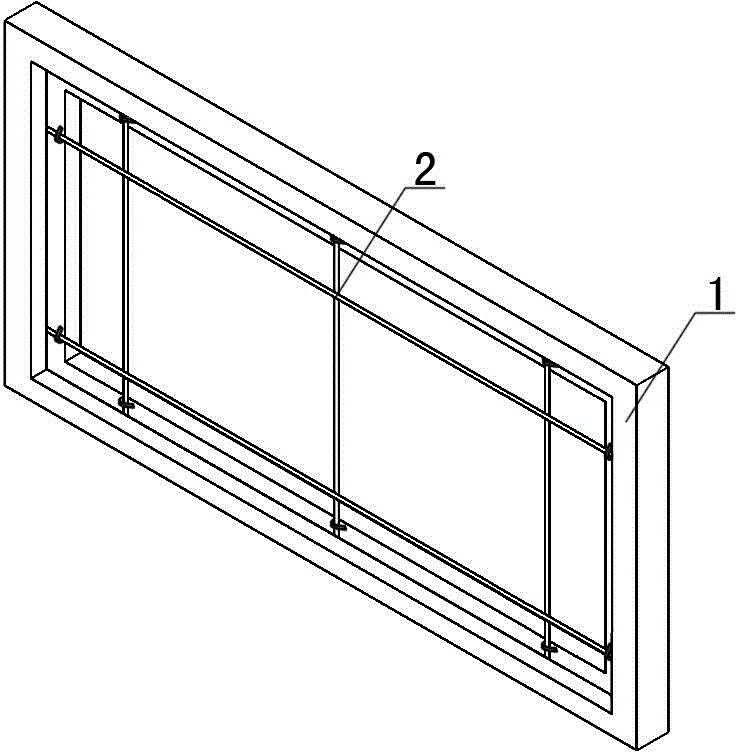

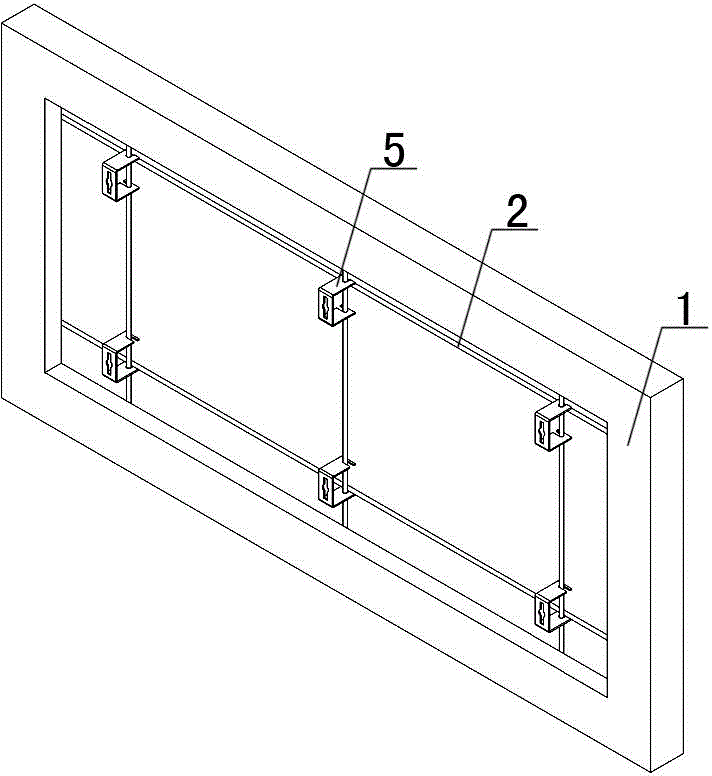

[0044] Examples see Figure 4 As shown, this formwork-free cast-in-place light-weight thermal insulation wall formwork includes an inner formwork, an outer formwork, and a pair of tension connectors 4 connecting the two formworks, see figure 1As shown, the inner template includes a template frame 1, a steel mesh skeleton 2 connected between the inner rings of the template frame, a steel bar clip 5 connected at the intersection node of the reinforcement in the steel mesh skeleton 2, and filled in the template frame The inner template core 3, the outer ring of the template core 3 and the inner ring of the template frame 1 are attached to each other; the template frame 1 and the template core 3 are both made of rubber powder polystyrene particle insulation mortar, so The strength of the rubber powder polystyrene particle insulation mortar is greater than 0.5Mpa, and the thermal conductivity is 0.05W / m·K~0.07W / m·K; the steel grid skeleton 2 is poured inside the formwork core 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com