Patents

Literature

53results about How to "Meet drainage requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Design method and design system for roof rainwater drainage systems and drainage system

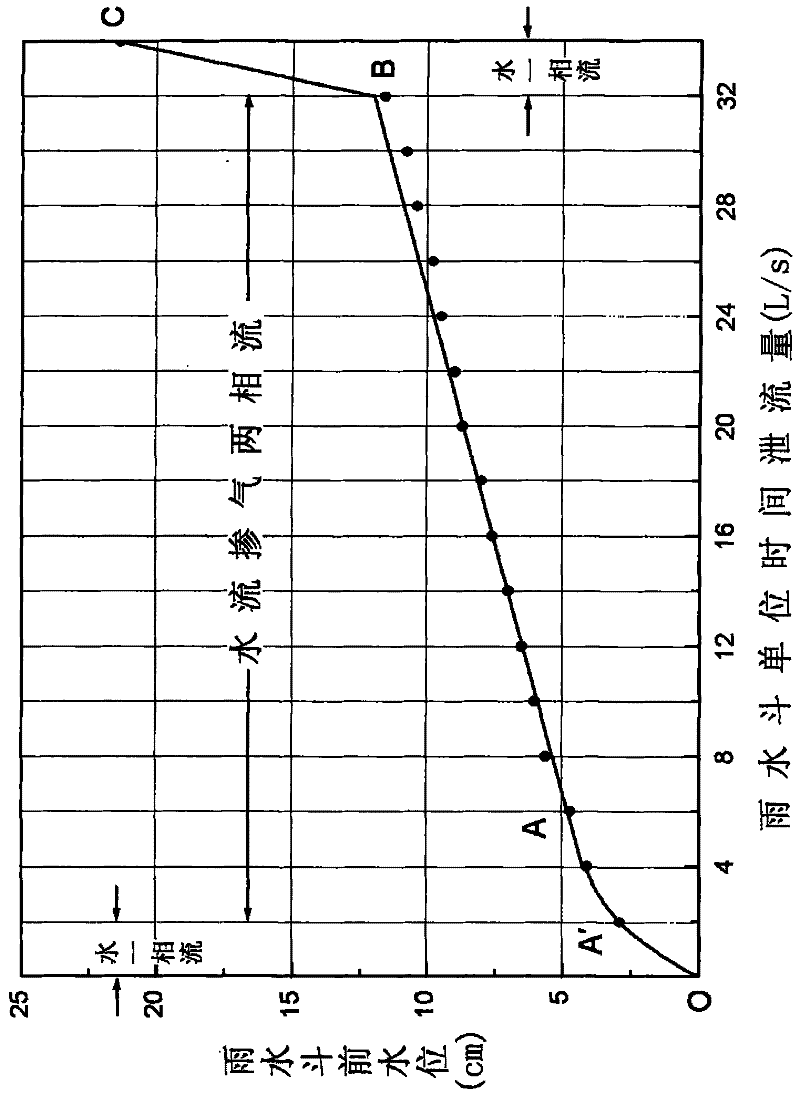

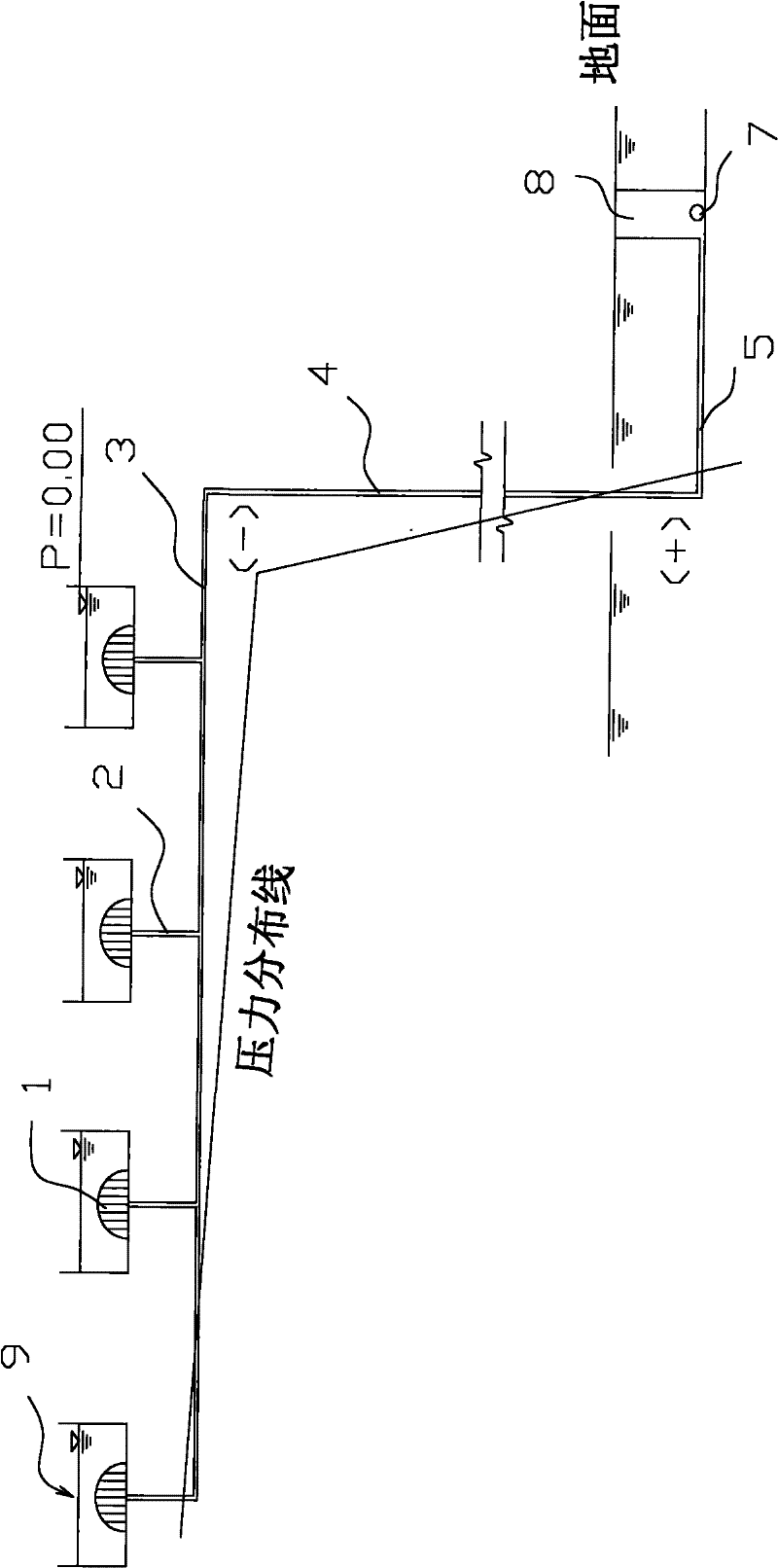

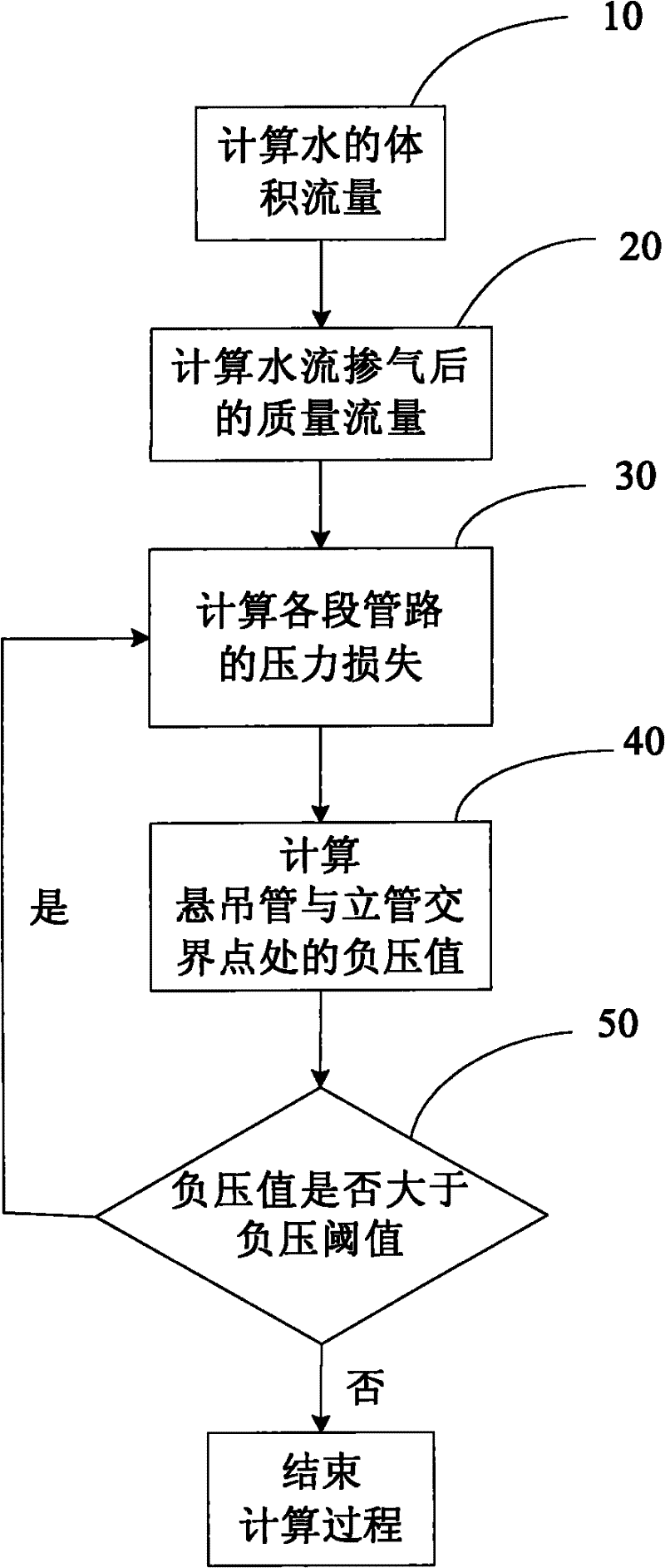

The invention provides a design method for roof rainwater drainage systems, which comprises the following steps of: calculating the volumetric flow rate of water flowing through a rainwater hopper; calculating the mass flow rate of an aerified water flow; calculating the pressure loss of each pipeline section based on the mass flow rate of the aerified water flow; calculating the values of negative pressures on a hanged pipe and a stand pipe at the junction point of the tail end of the hanged pipe and the top end of the stand pipe; judging whether the values of negative pressures on the hanged pipe and the stand pipe at the junction point satisfy the design requirements of a pipe system or not, if so, completing the design process; and otherwise, designing the value of each pipe diameter again, and then calculating again. Therefore, in the drainage system designed according to the design method for roof rainwater drainage systems provided by the invention, the pipes of the drainage system are thin and short in length, so that the application quantity and construction quantity of the pipes can be reduced, thereby reducing the cost of the whole drainage system. Meanwhile, the drainage system is additionally provided with an exhaust device, therefore, the hidden troubles such as roof rainwater ponding and leakage as well as manhole sweating can be avoided.

Owner:CHINA IPPR INT ENG

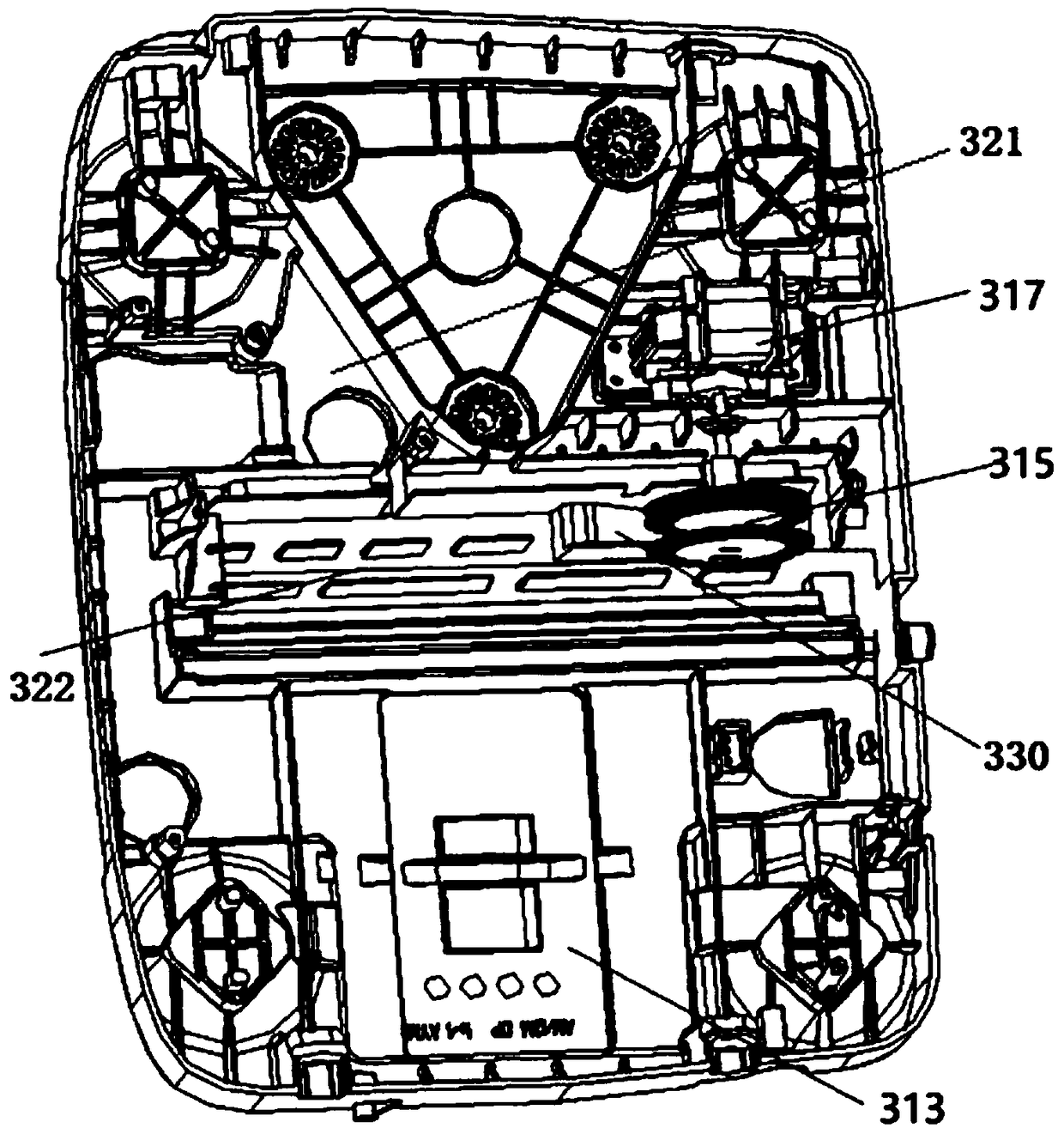

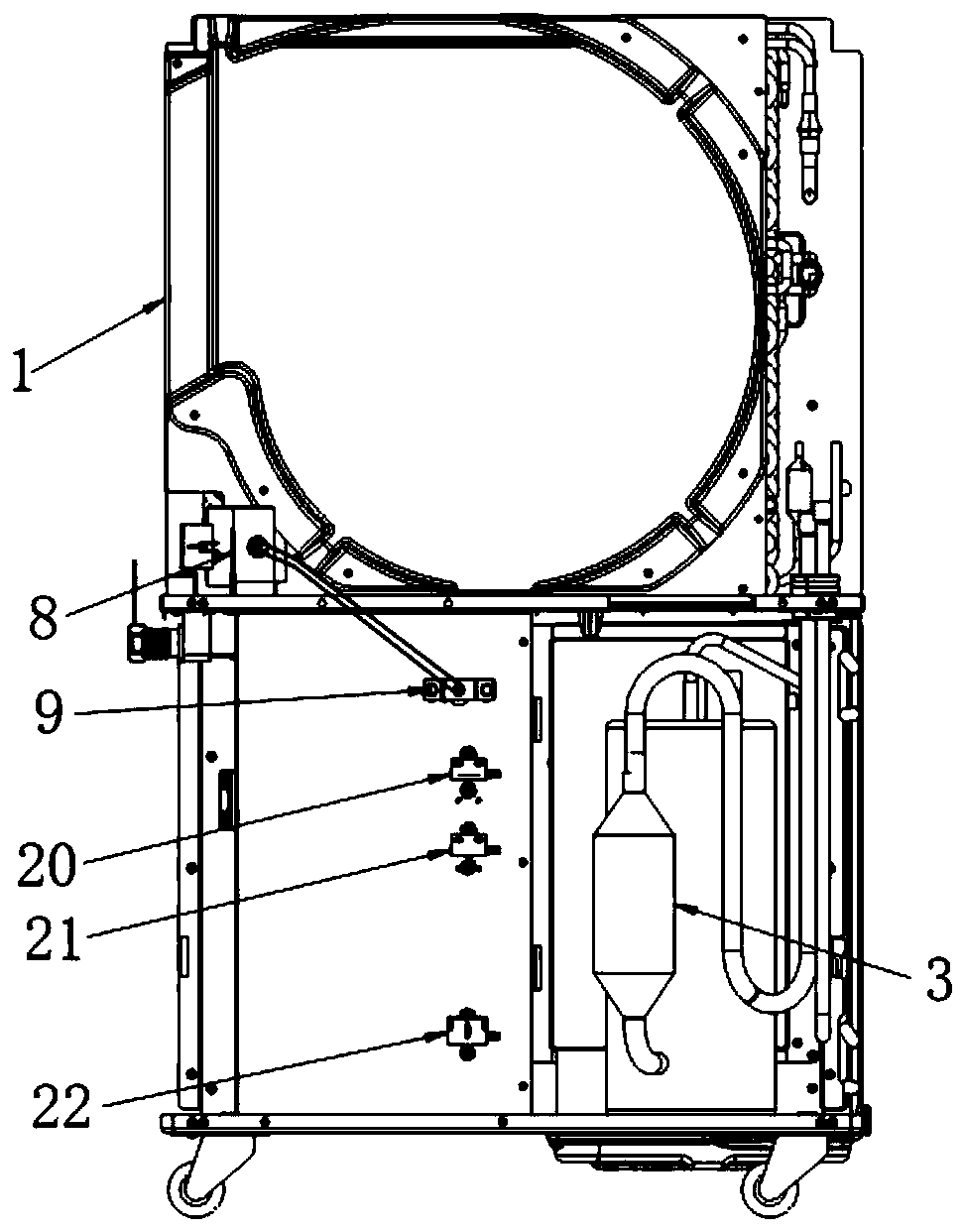

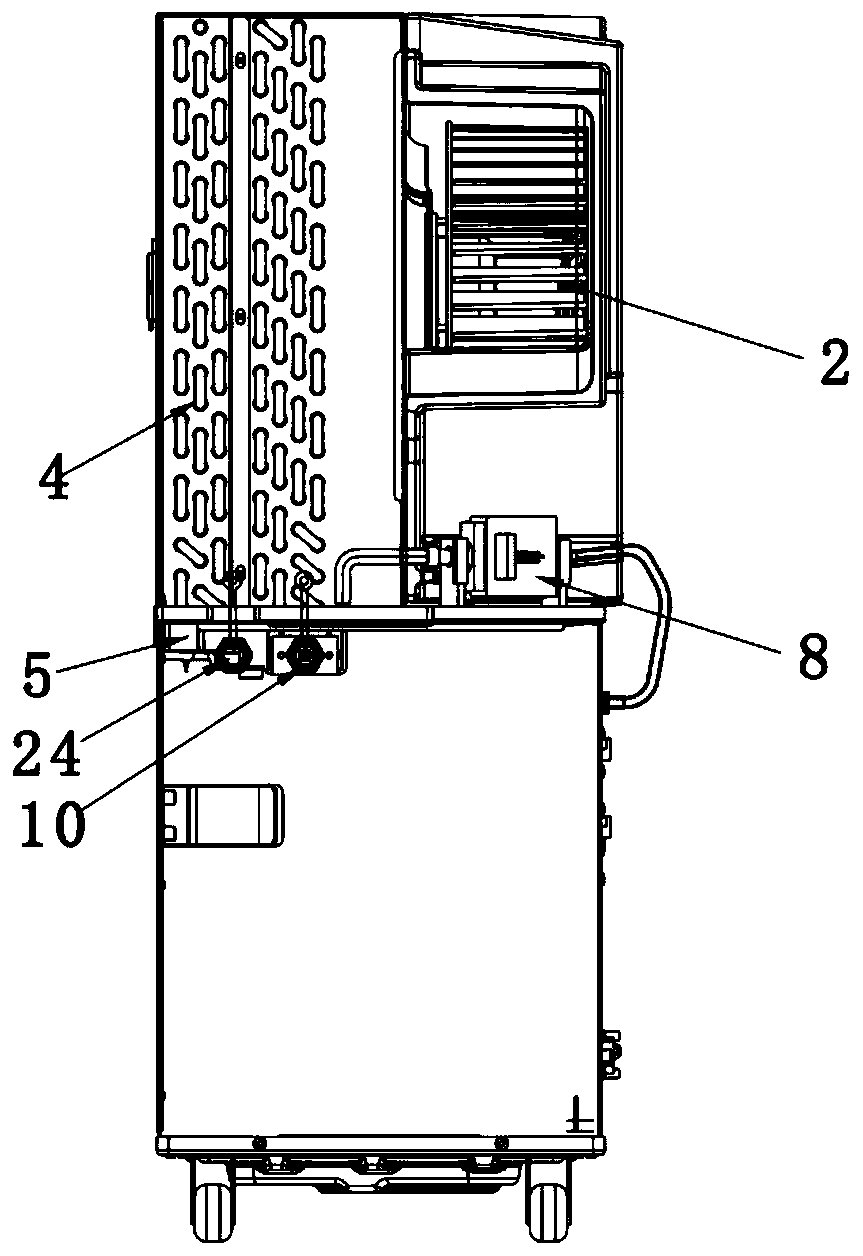

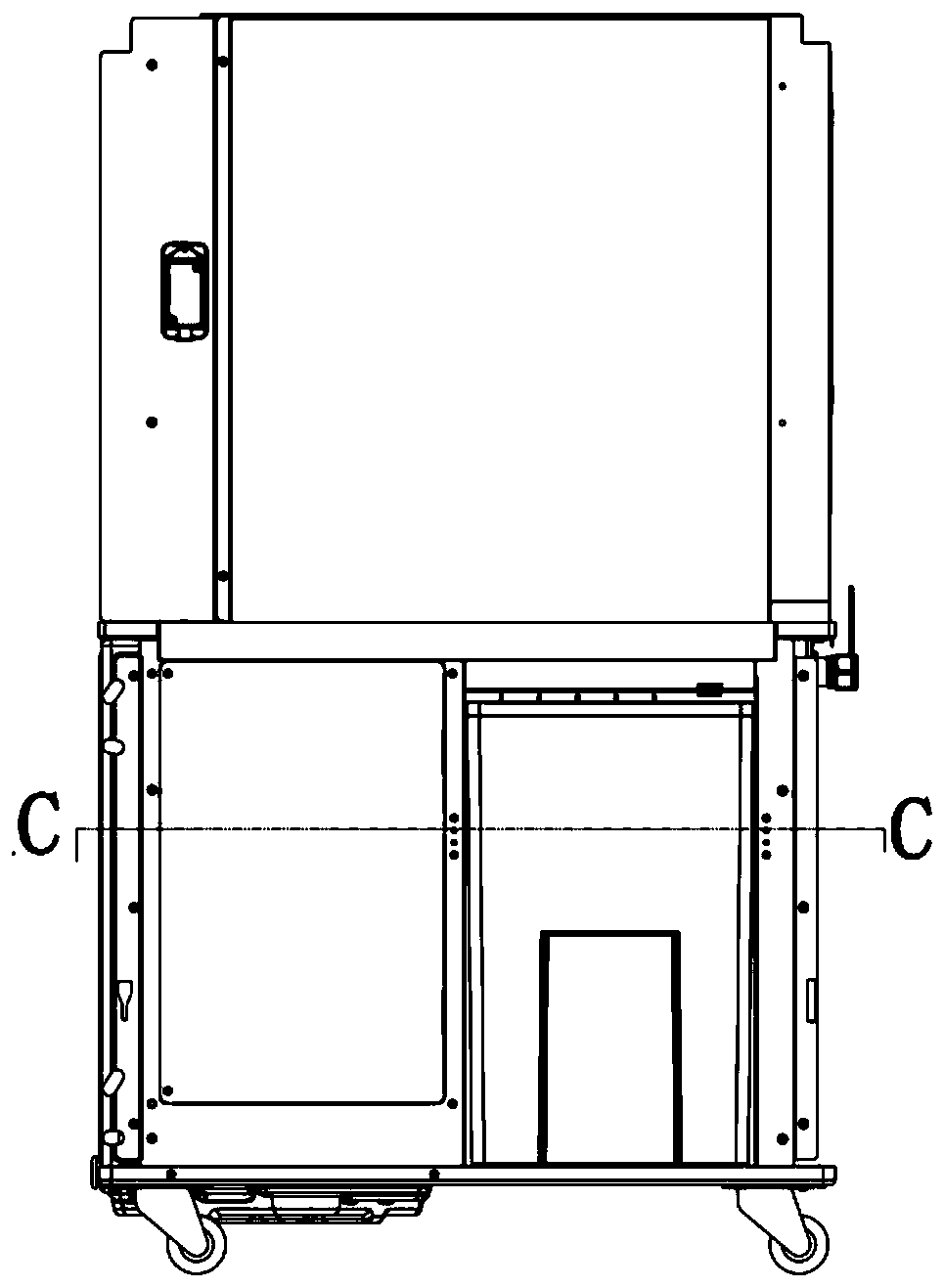

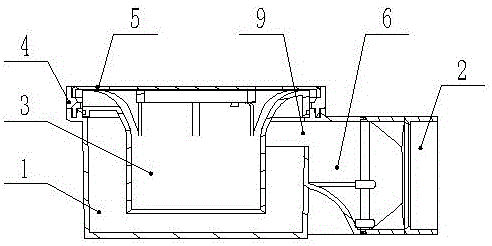

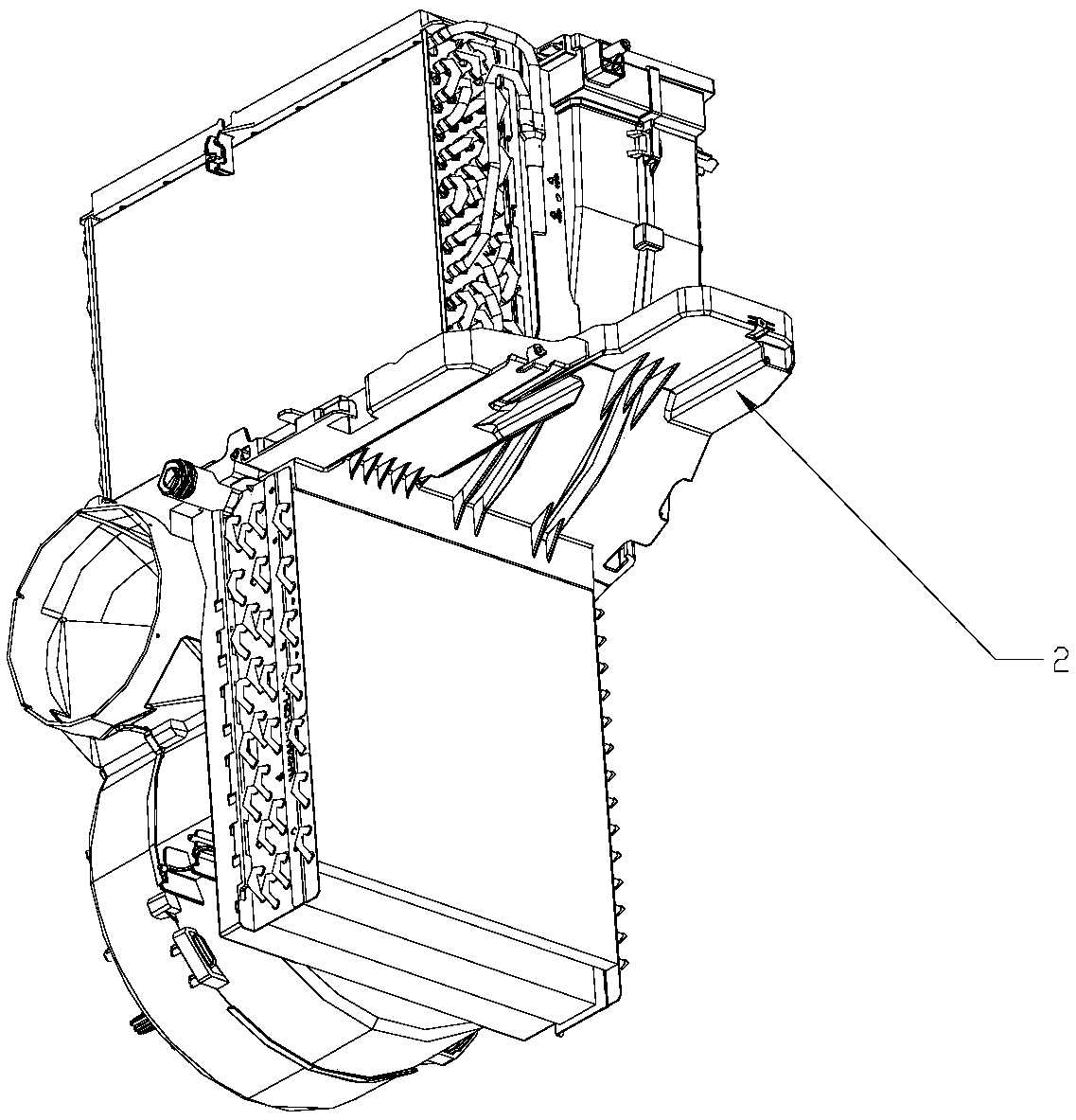

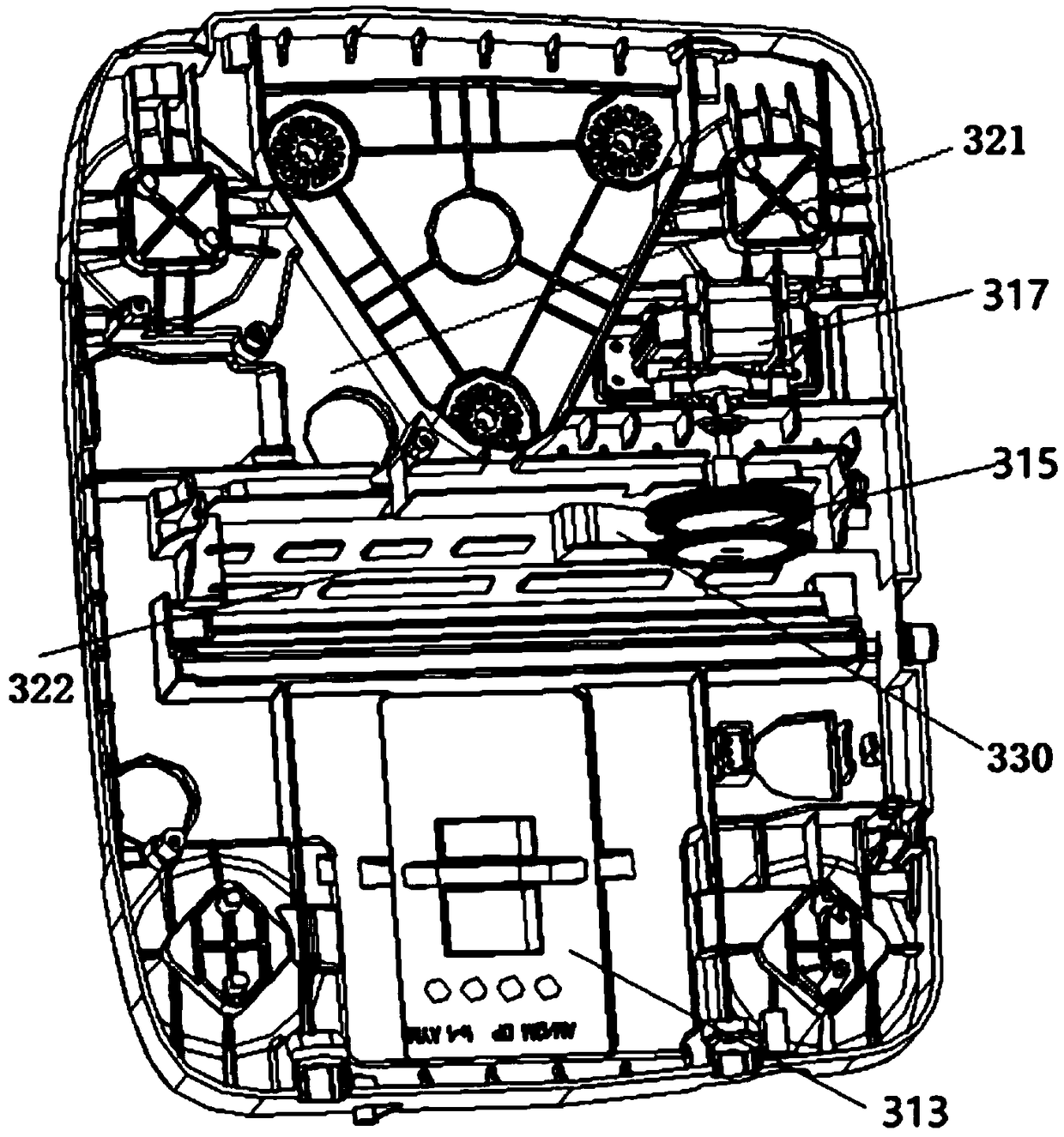

Mobile air conditioner

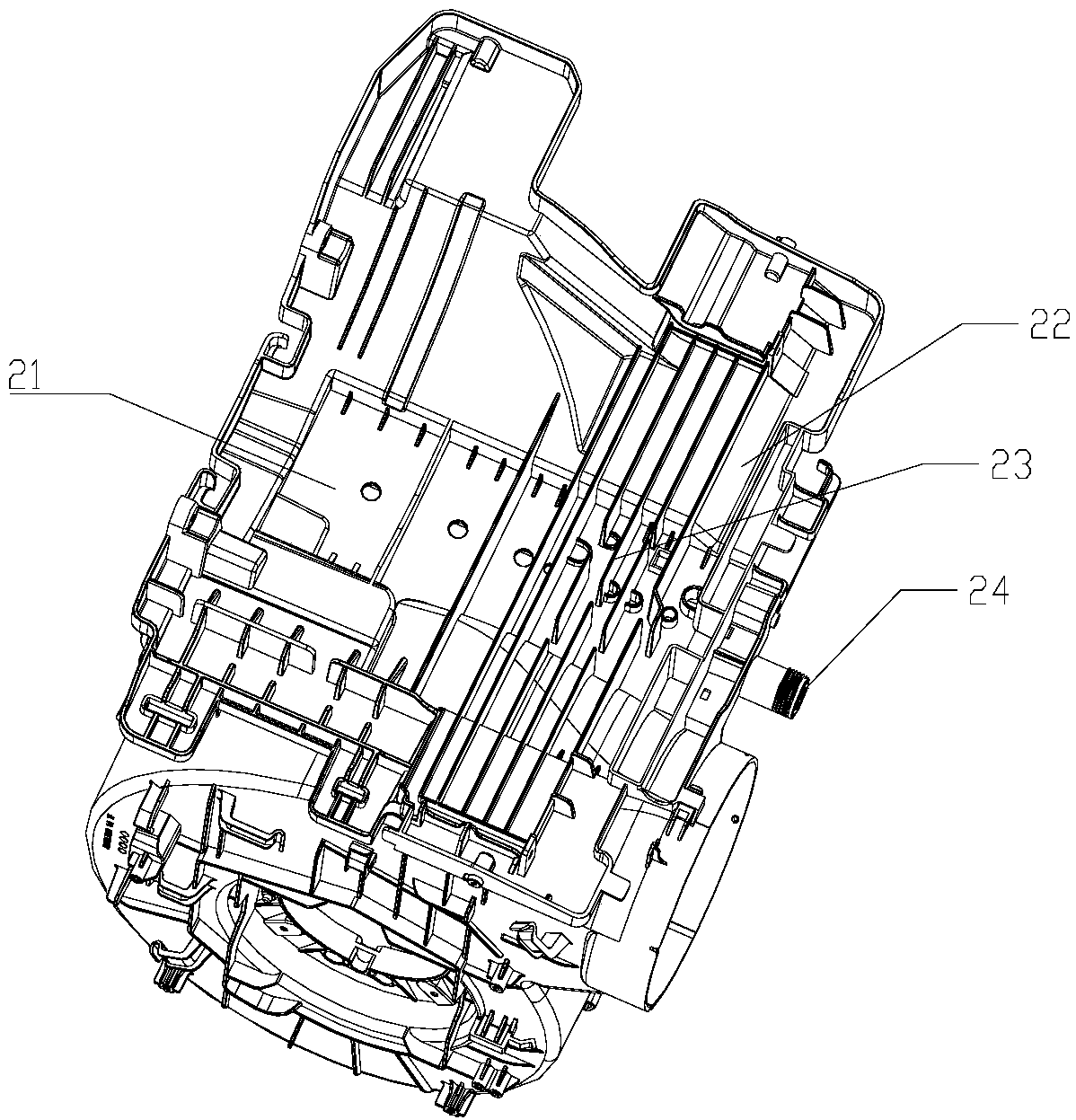

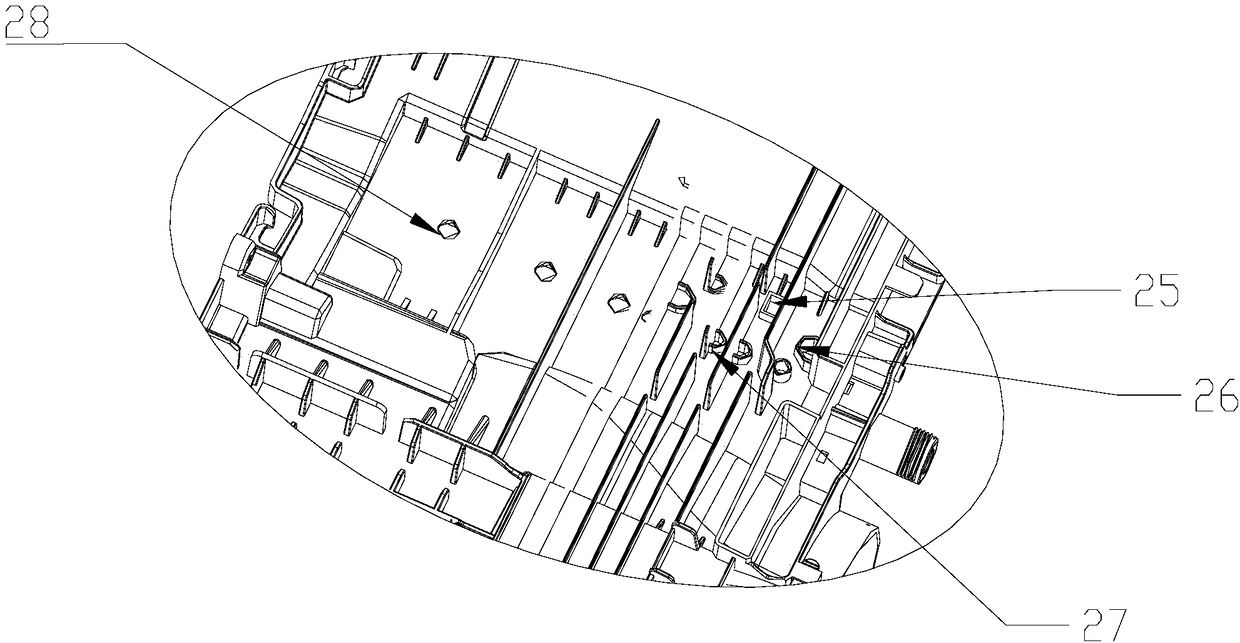

PendingCN108870552AExtended use timeReduce downtimeCondensate preventionLighting and heating apparatusWater circulationEngineering

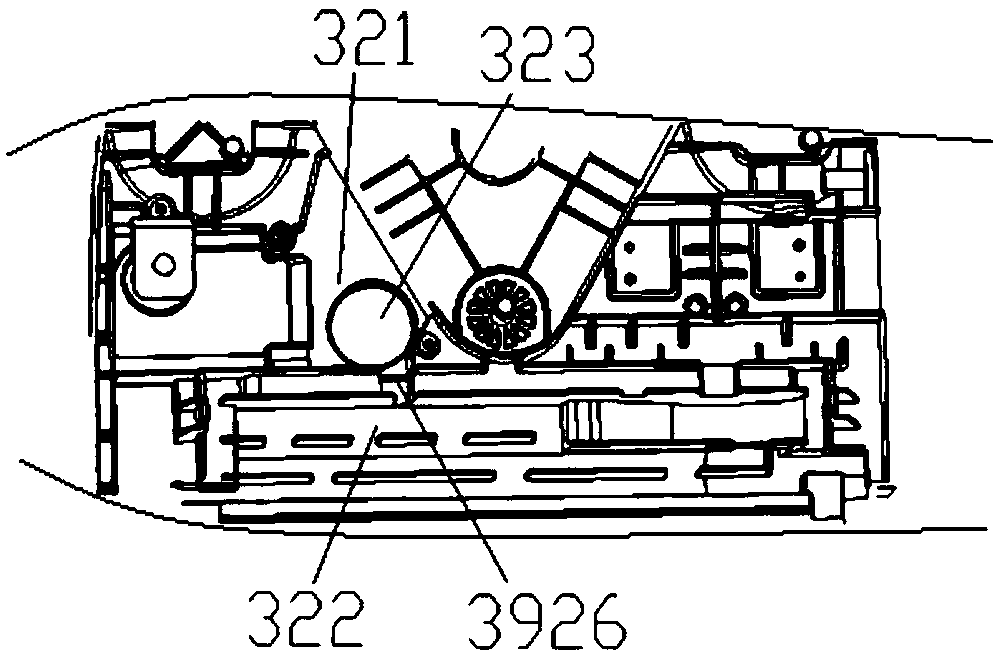

The invention provides a mobile air conditioner. The mobile air conditioner comprises an upper water receiving disc, a middle water receiving disc and a chassis structure, the chassis structure comprises a water absorption area, a water tank area, a water splashing area and a water level control area, and further comprises water retaining ribs used for isolating the water absorption area from thewater tank area and a convergence part which is positioned between the water splashing area and the water tank area and is close to a convergence port of the water splashing area, wherein the water splashing wheel is arranged in the convergence part. According to the mobile air conditioner, the cooperation among the upper water receiving disc, the middle water receiving disc and a chassis is adopted, therefore, water correspondingly in the upper water receiving disc, the middle water receiving disc and the chassis in the air conditioner can be reasonably distributed, the water is preferentially supplied to the water splashing area, moreover, the water in the upper layer and the water in the middle layer can be directly supplied to the water splashing area, the water circulation step is reduced, and the water splashing efficiency is improved.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

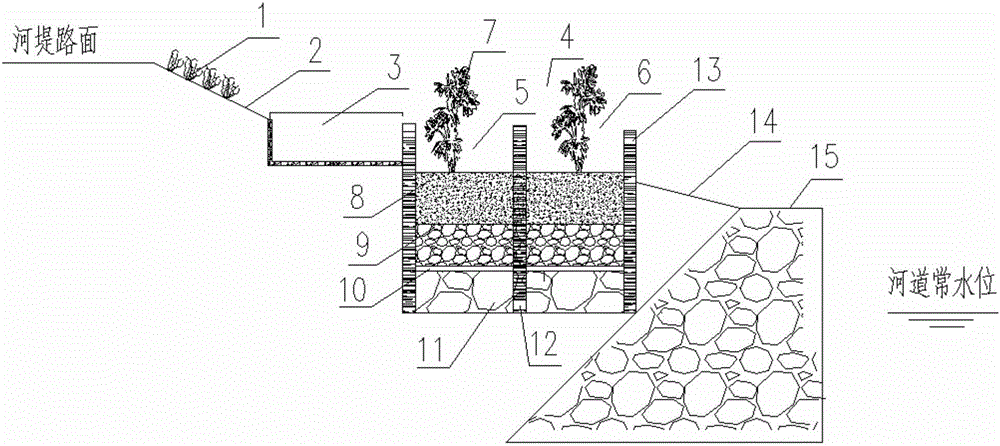

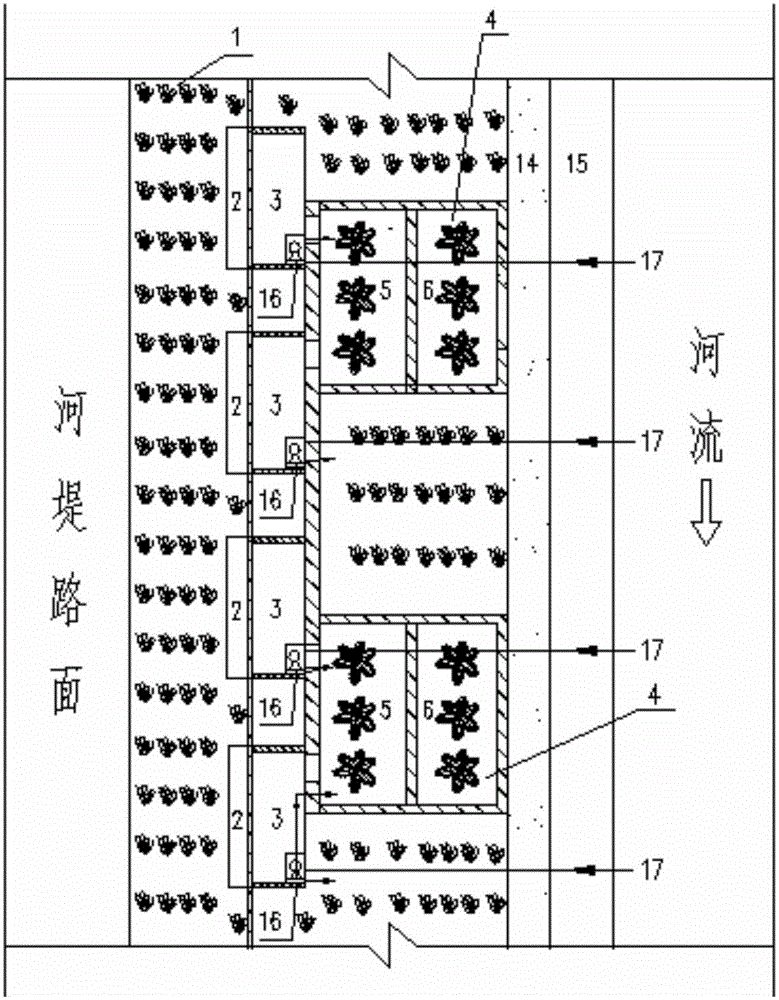

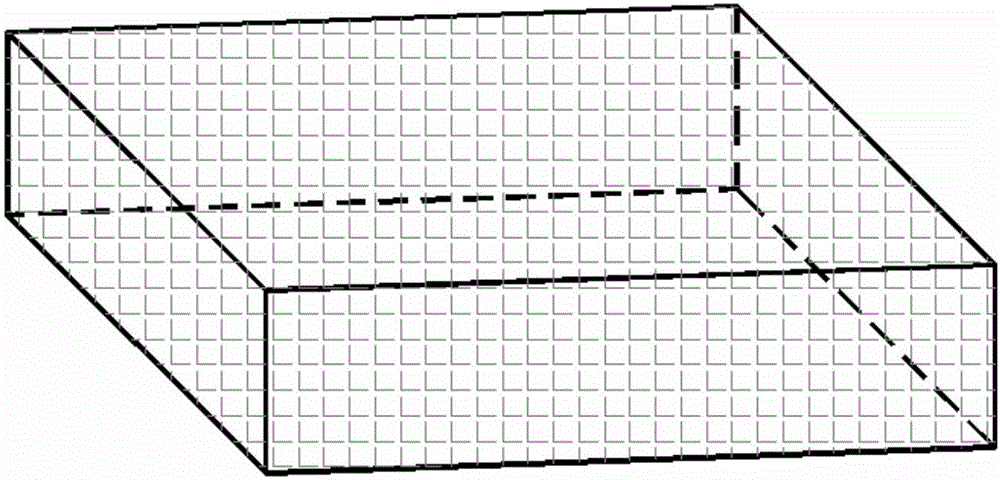

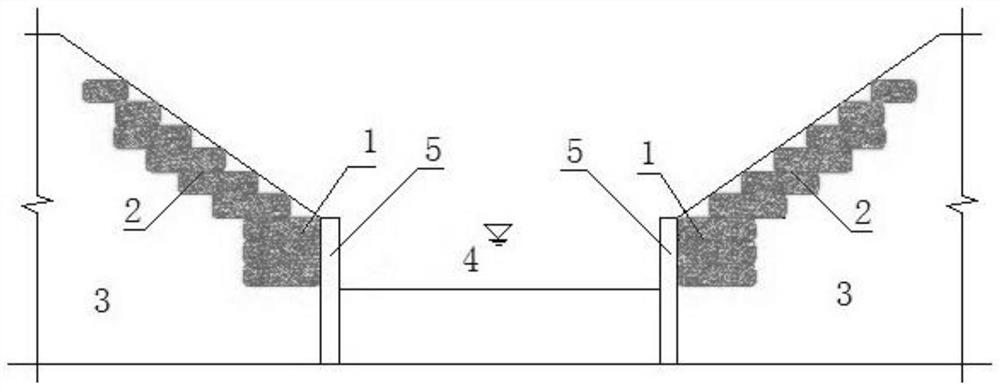

Controllable slow flow pollutant interception circulating module system based on sponge city construction

ActiveCN105839582AMeet drainage requirementsAchieve intelligent comprehensive managementBreakwatersQuaysWater storageDry season

The invention discloses a controllable slow flow pollutant interception circulating module system based on sponge city construction. The system is arranged at the river facing side of a riverbank; a vegetation buffer zone is arranged downwards along the slope of the bank, then, water collecting and guiding zones are arranged downwards, and next, controllable water storage modules are arranged downwards, vertically and correspondingly, wherein each controllable water storage module is of a box structure built by using unit cuboids made of a polypropylene material and is respectively 100-120m long, 1-1.2m wide and 0.5-0.6m deep, and the length and amount of the controllable water storage modules are consistent with those of the water collecting and guiding zones; and the side, close to a river channel, of each controllable water storage module is vertically and downwards provided with a miniature slow flow wetland system which is sequentially provided with a planting soil layer, a packing layer and a supporting layer from top to bottom. The invention embodies a rainy-season runoff pollutant interception control and dry-season landscape water quality maintenance method which provides reference and guide effects for city non-point source pollution control, landscape water quality maintenance, new-built municipal rain discharging hole design and sponge city construction.

Owner:科瑞斯众(天津)科技有限公司

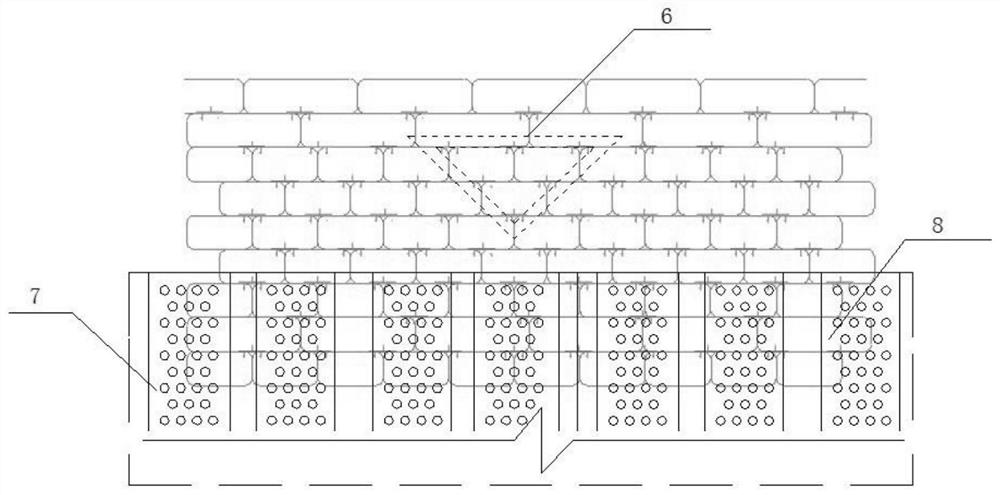

Road drainage structure

InactiveCN104988821ABearing strength has no effectGood drainageGround-workSingle unit pavingsChipsealWater collection

The invention discloses a road drainage structure which comprises a concrete board. A flow guide pipe is transversely installed on the concrete board. The two ends of the flow guide pipe penetrate the concrete board and connected with pipe plugs. The pipe plugs are hinged to the flow guide pipe. A water collection piece is transversely arranged above the flow guide pipe and located in the concrete board. Drainage joints are vertically arranged on the water collection piece and communicated with the water collection piece. Water penetration layers are connected to the tops of the drainage joints. Each water penetration layer is of a reversed-triangle structure. The upper surface of each water penetration layer is located on a road foundation layer. Connecting pipes are arranged in the water penetration layers and vertically arranged on the water penetration layer. The road drainage structure is good in drainage effect and is used for municipal road drainage, a drainage device can be prefabricated, a construction period is shortened, labor intensity is relieved, cost is reduced, and road load bearing strength is not affected; meanwhile, the drainage requirements of different regions and different rainfall volumes can be met by adjusting the diameter of laid drainage pipes and the void ratio of graded broken stone.

Owner:CHENGDU KECHUANG JIASI TECH

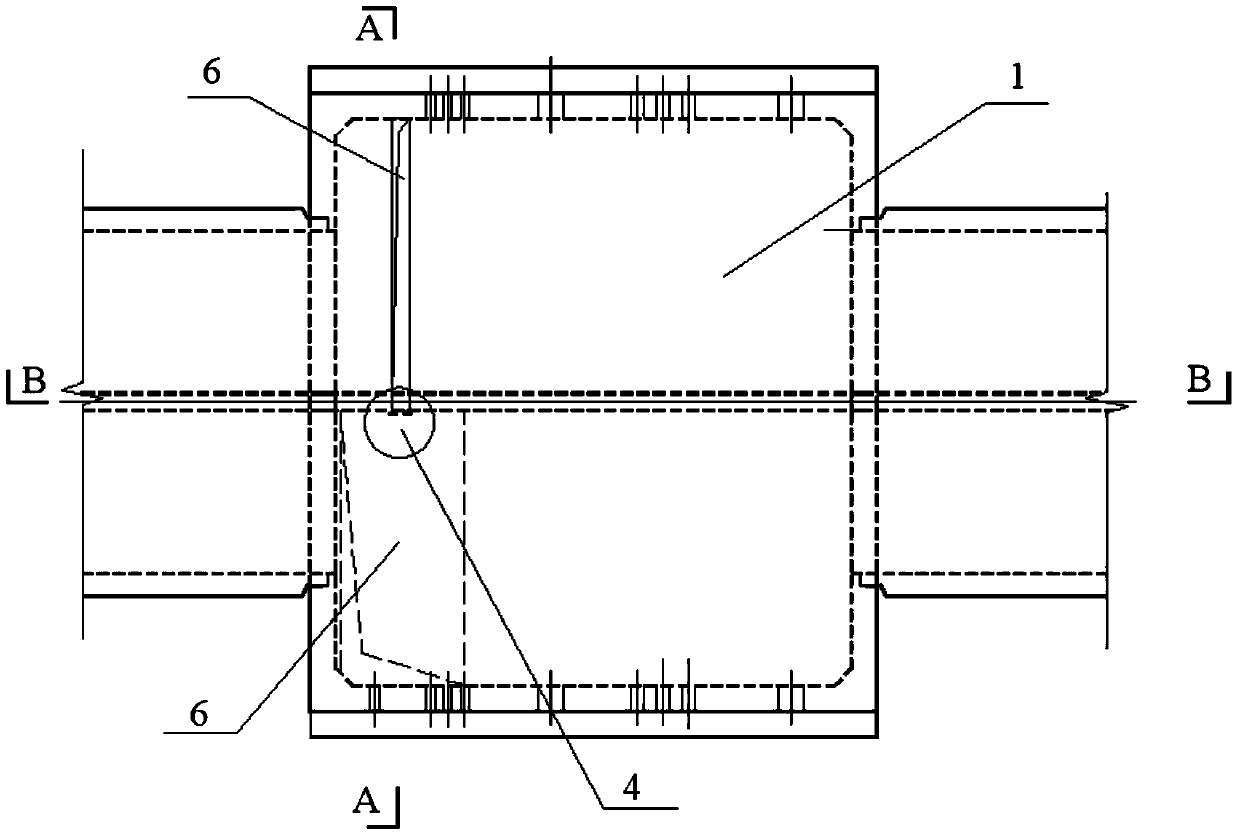

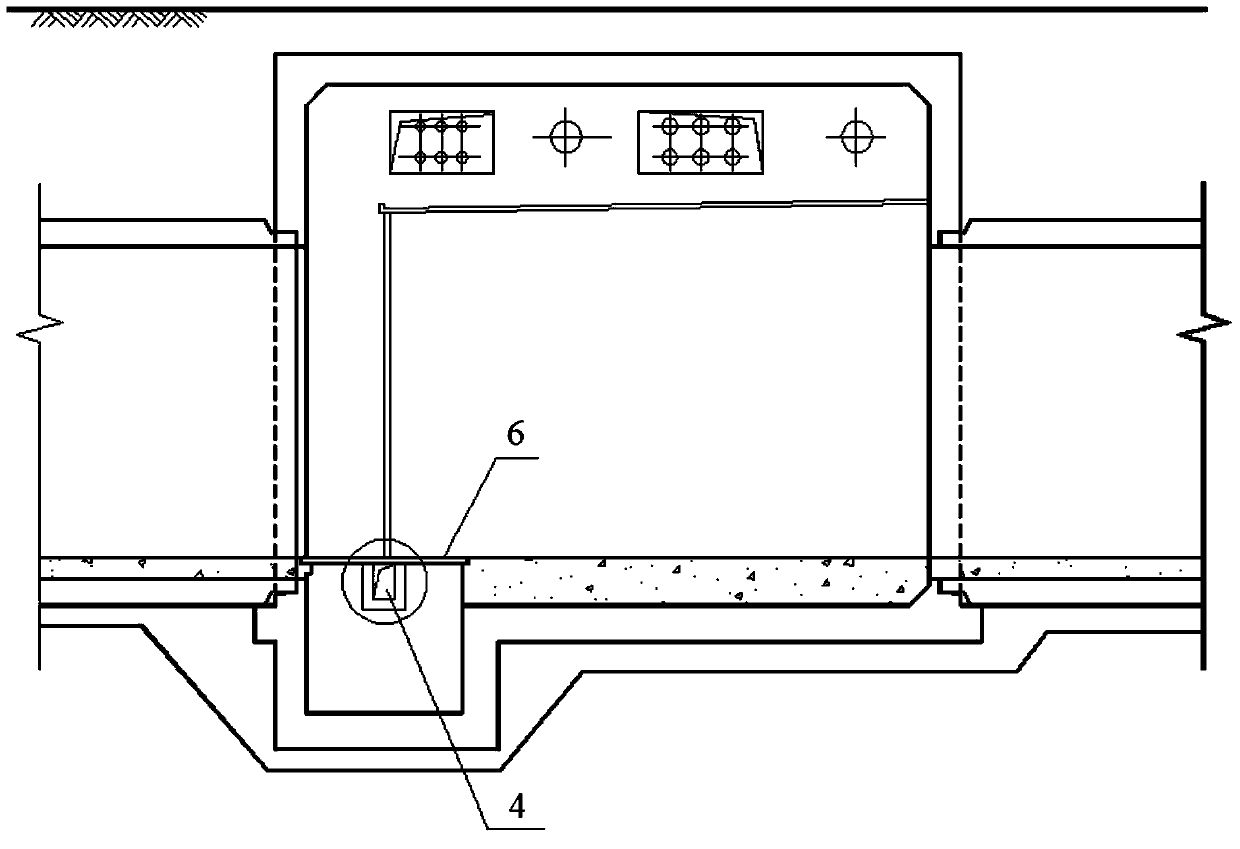

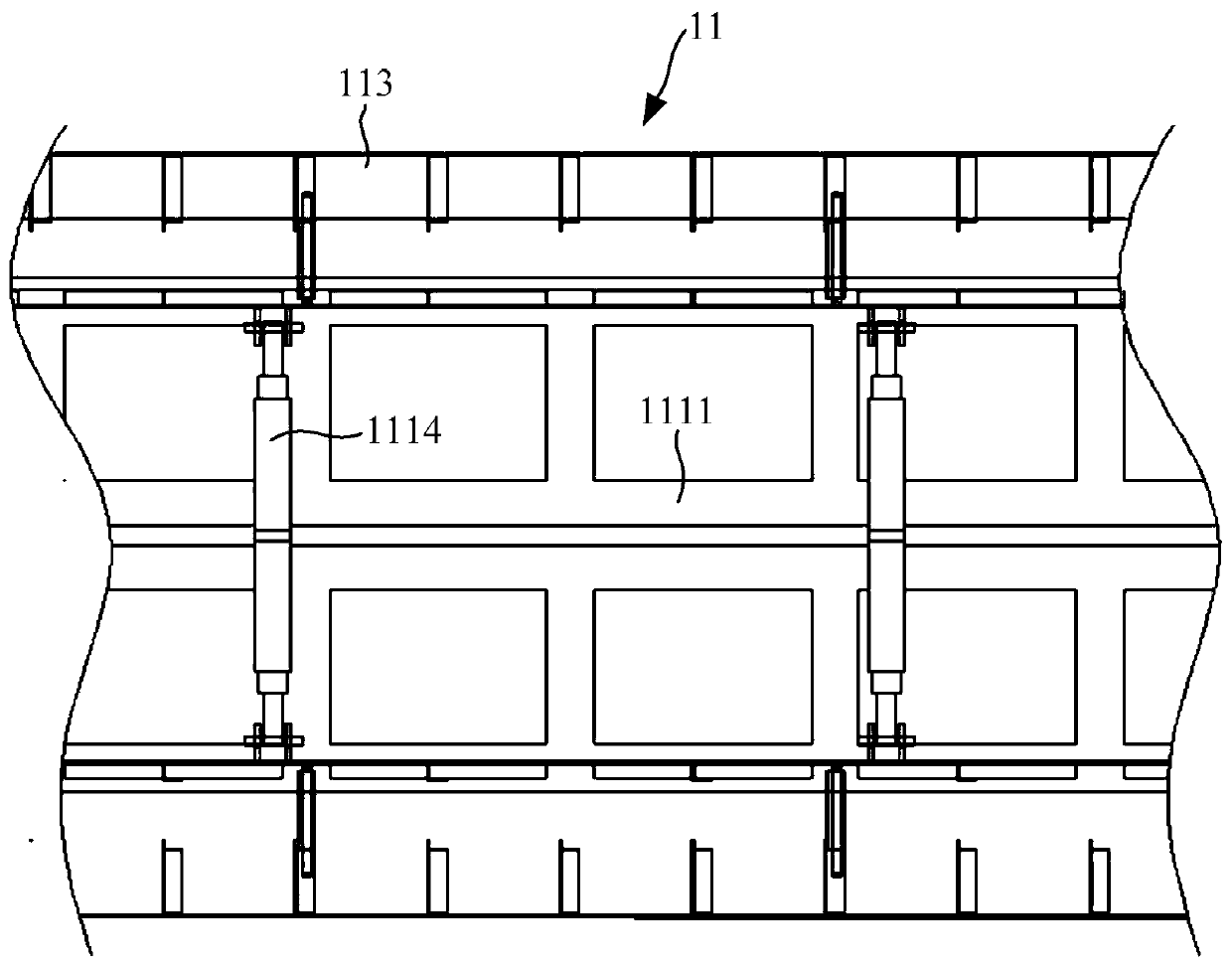

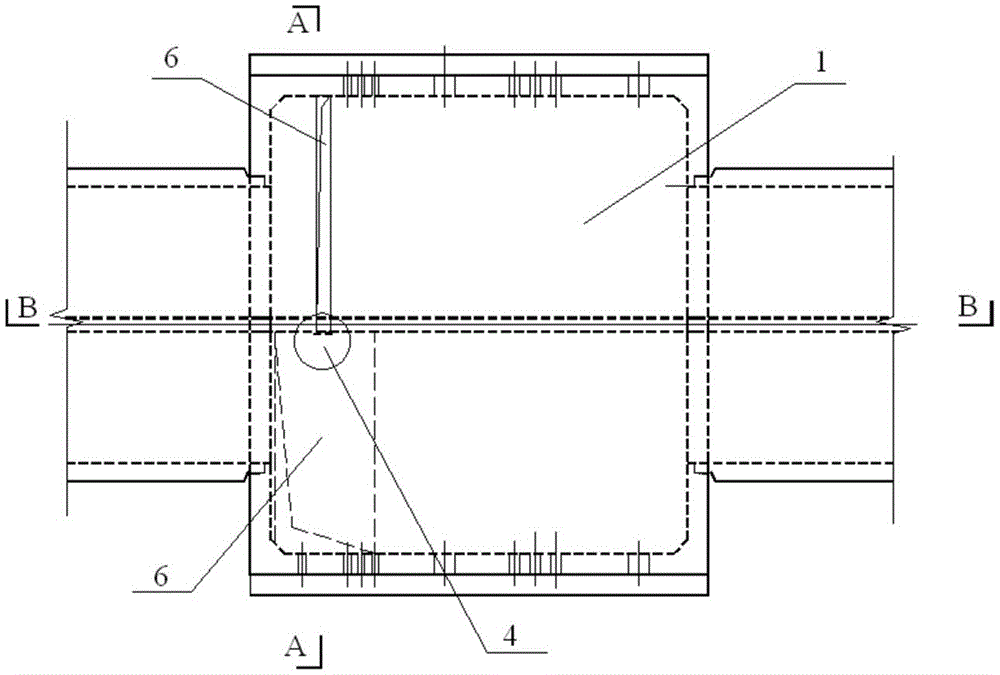

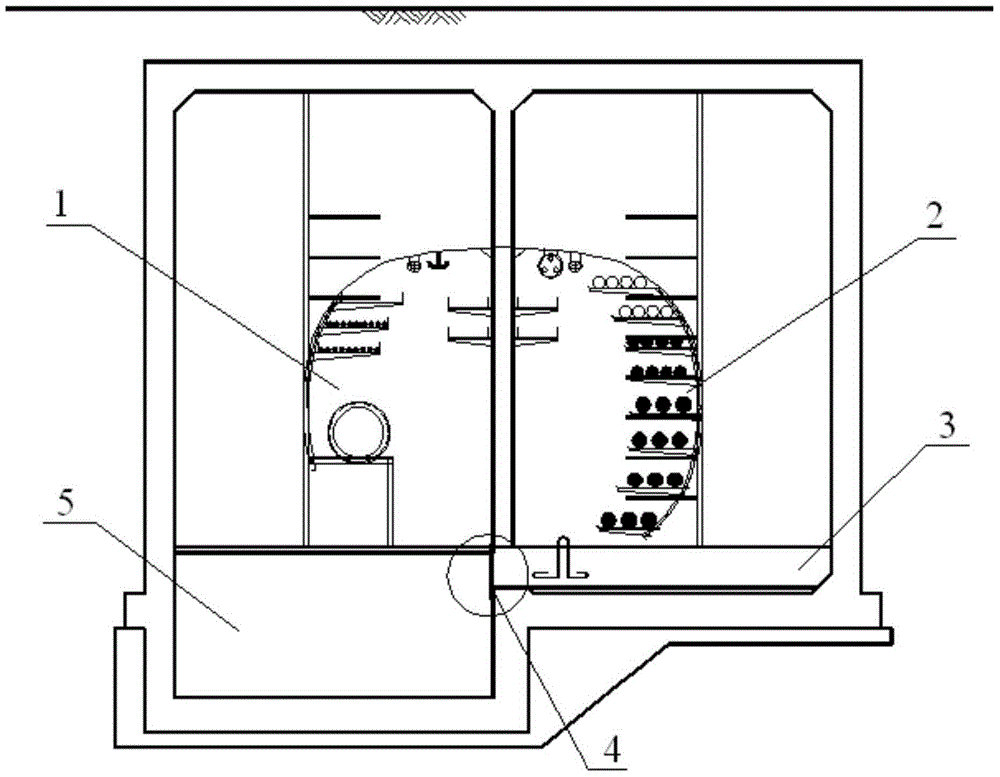

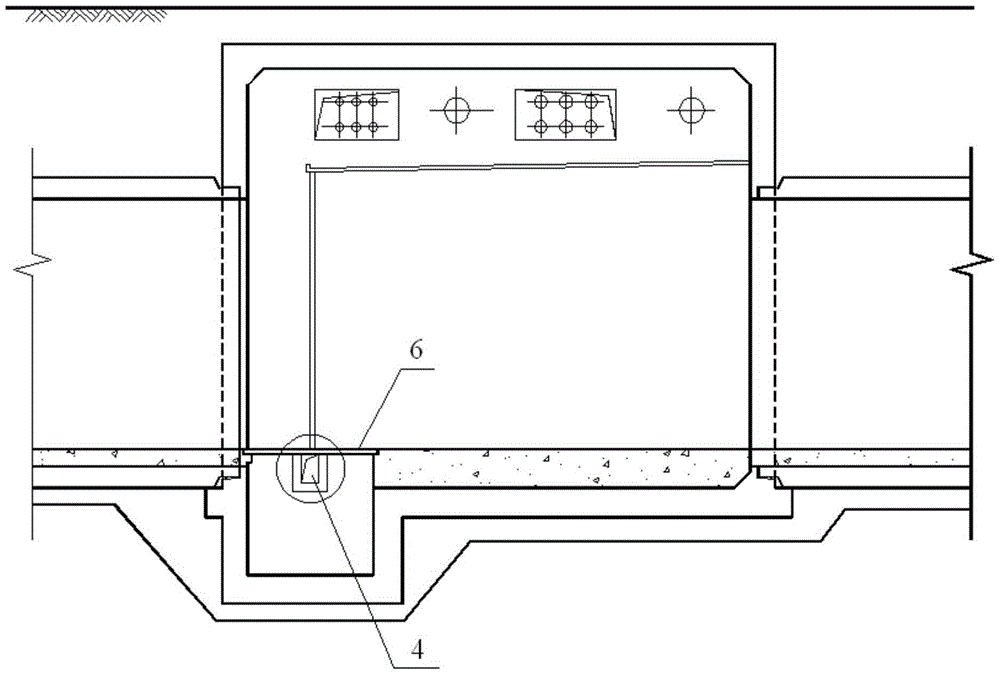

Underground integrated pipe gallery structure

InactiveCN103953068AUnderstand the purposeLearn about featuresArtificial islandsSewerage structuresWater dischargeUtility tunnel

The invention discloses an underground integrated pipe gallery structure, which comprises a pipeline cabin and a cable cabin, wherein the pipeline cabin and the cable cabin are respectively arranged in a pipe gallery, the bottom of the pipeline cabin is provided with a grid cover plate, a water collecting pit is arranged under the pipeline cabin, the bottom of the cable cabin is also provided with a grid cover plate, a water discharge open trench is arranged under the cable cabin, the depth of the water discharge open trench is smaller than the depth of the water collecting pit, the water discharge open trench is communicated with the water collecting pit, and a one-way baffle sheet is arranged at a communicating part of the water discharge open trench and the water collecting pit and is in a one-way conduction state in the direction towards the water collecting pit along the water discharge open trench. The underground integrated pipe gallery structure has the advantages that the water discharge requirements of each function cabin met, the water collecting pit is not increased, the water seeping water in the cable cabin and the like can be discharged in time through the one-way baffle sheet, and the water in the water collecting pit of the pipeline cabin cannot enter the cable cabin.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

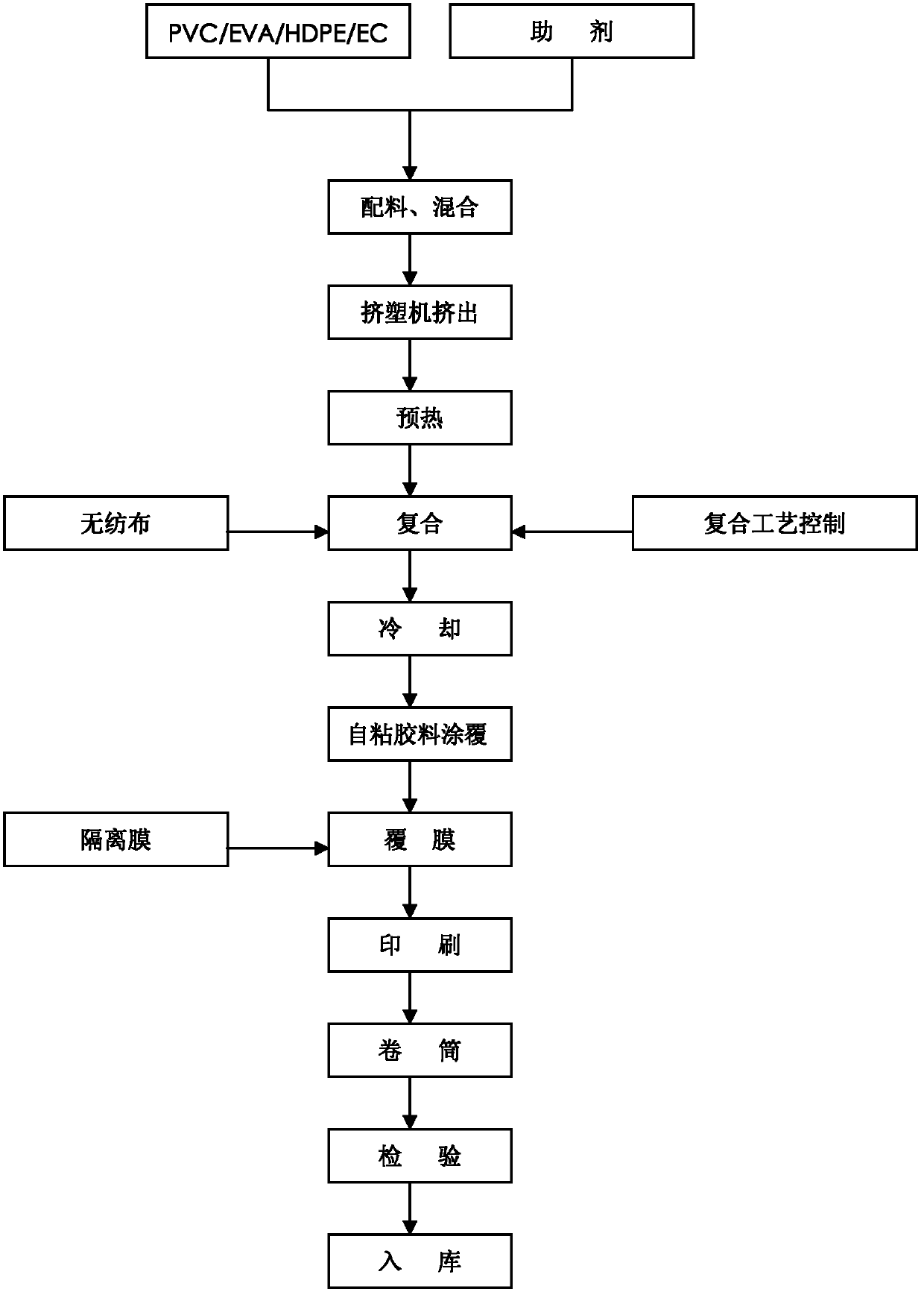

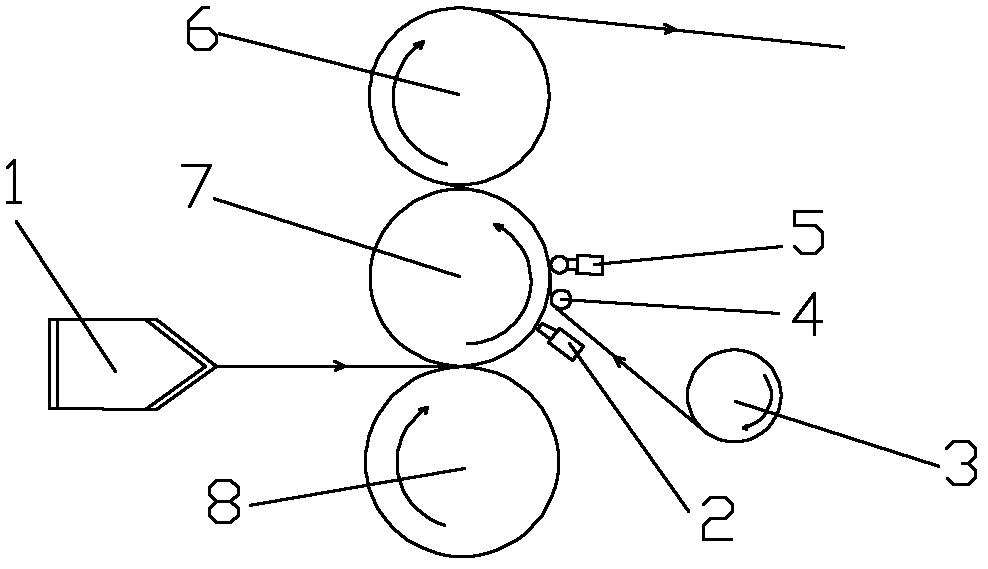

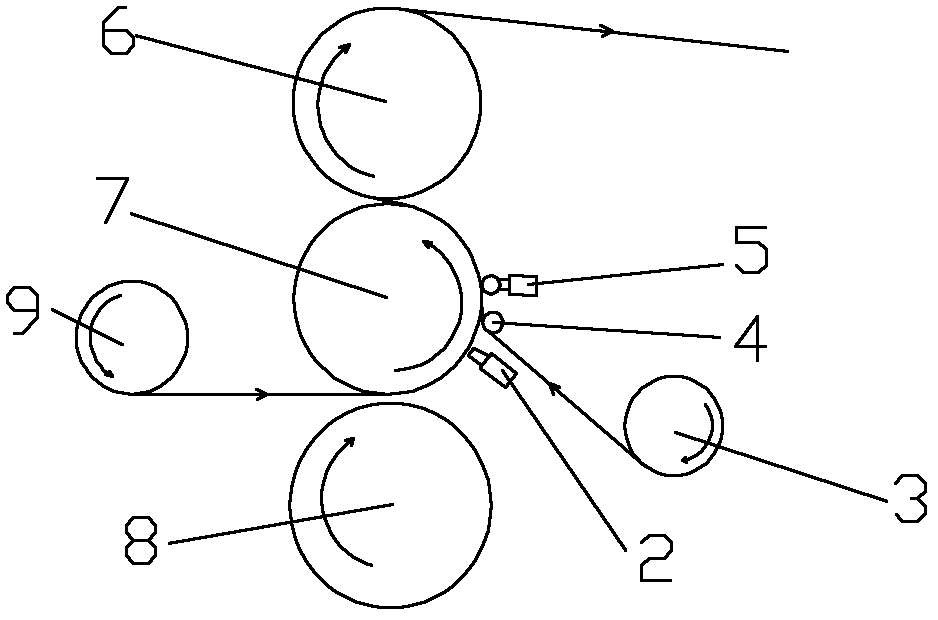

Composite waterproof board and production technology thereof

InactiveCN102434177AEasy to fixPrevent water channelingUnderground chambersSynthetic resin layered productsGeotextileExtrusion moulding

The invention discloses a composite waterproof board and a production technology thereof. The composite waterproof board comprises a geotextile arranged on a surface of a waterproof board, wherein the geotextile and the waterproof board have a uniformly distributed and discontinuous adhesive part, the adhesive part is provided with a uniformly distributed and suspended fixed part; and the other surface is provided with a self-stick layer prepared through clading and a surface isolation membrane of the self-stick layer. The production technology comprises the following steps of: preparing raw materials, performing extrusion moulding; preheating and bonding; coating a self-stick rubber material and laminating; and rolling to obtain the finished product, wherein in the preheating and bonding step, a program is utilized to control a retractable compression roller to laminate the preheated waterproof board which is overlapped with the geotextile and form the discontinuous adhesive part. The adhesive part of the geotextile and the waterproof board is uniformly distributed, a uniform draining channel is reserved to meet the further drainage requirement; and the composite waterproof board can be embedded in the existing waterproof board production line, waterproof boards with different structures can be conveniently produced according to needs, preheating and bonding are performed continuously on the surface of the compression roller, the product has high quality and is more stable, and energy is saved.

Owner:SICHUAN WEIDUN JIANGXIN CONSTR CO LTD

Dehumidifier with multifunctional drainage function and drainage method

PendingCN111059649AExtended service lifeEasy to cleanMechanical apparatusCondensate preventionOutfallDrainage tubes

The invention discloses a dehumidifier with a multifunctional drainage function and a drainage method. The dehumidifier comprises a box body and a drainage device, wherein the drainage device comprises a water receiving tray and a water tank, a first drainage opening of the water receiving tray directly face a water inlet of the water tank, the dehumidifier further comprises a water pump, a firstconnecting piece and a second connecting piece, the water pump is arranged in the middle of the box body, the first connecting piece and the second connecting piece are arranged on the box body, a water inlet of the water pump is connected with the first connecting piece through a pipeline, a water outlet of the water pump is connected with the second connecting piece, the water tank is provided with a drainage pipe, one end of the drainage pipe extends into the bottom of the water tank, the other end of the drainage pipe is connected with a third connecting piece arranged on the water tank, the third connecting piece is in tight butt joint with the first connecting piece, and a dehumidification device and the water pump are electrically connected with an electric cabinet assembly. According to the dehumidifier and the method, the dehumidifier separates the water pump from the water tank, the water pump is prevented from being eroded by water or acid and alkali, the service life of thewater pump is prolonged, the drainage method comprises an automatic drainage mode, a manual drainage mode and a direct drainage mode, and good applicability is achieved.

Owner:广东百奥电气有限公司

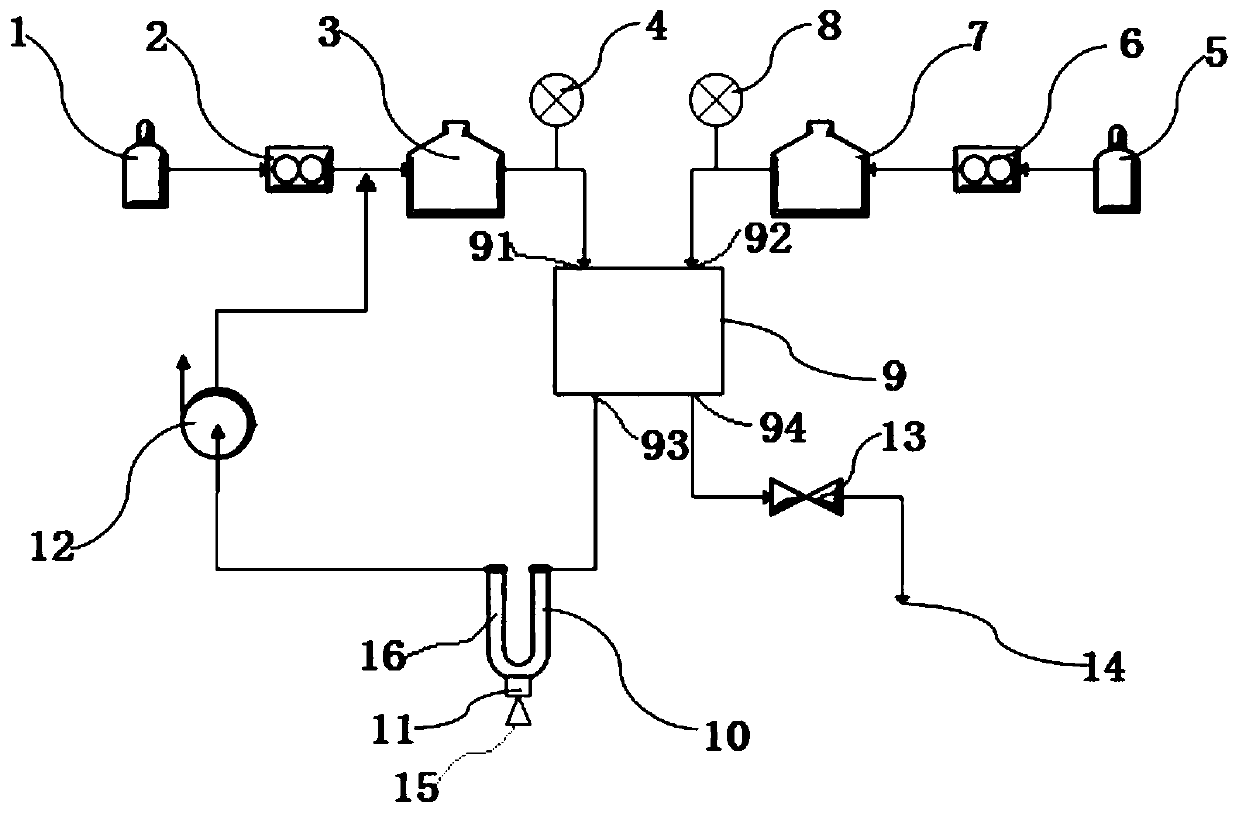

Anode water discharge control method and water discharge system of hydrogen fuel cell

InactiveCN110364753AEasy to judgeMeet drainage requirementsFuel cellsWater dischargeHydrogen fuel cell

The invention discloses an anode water discharge control method and a water discharge system of a hydrogen fuel cell. The method comprises the steps of separating hydrogen-containing waste water generated by the anode by using a hydrogen circulating pump, collecting the separated waste water into a container, monitoring the power of the hydrogen circulating pump in real time, and discharging the waste water in the container when the power of the hydrogen circulating pump is greater than or equal to a set threshold P0. According to the invention, real-time monitoring is carried out according tothe water accumulation condition, intelligent water discharge is realized, the equipment damage caused by frequent water discharge when the amount of waste water is small is avoided, the water blockage caused by untimely water discharge when the amount is waste water is large is also avoided, the operation is simple, manpower is liberated, the cost is reduced, and the system efficiency is improved.

Owner:DONGFENG MOTOR CORP HUBEI

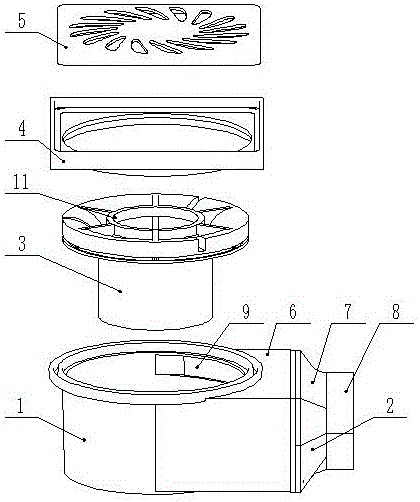

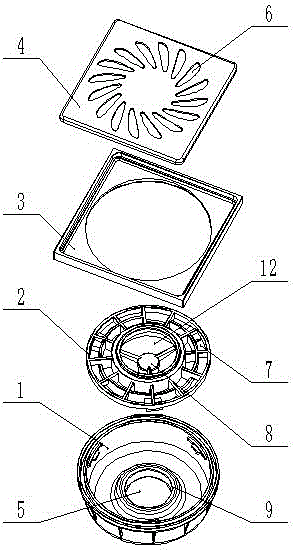

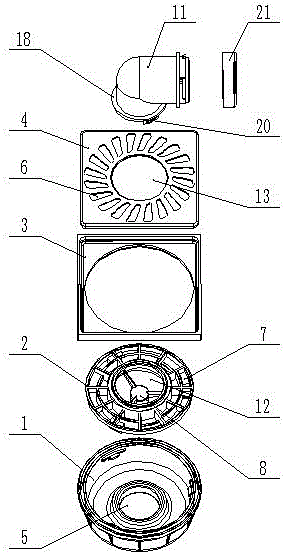

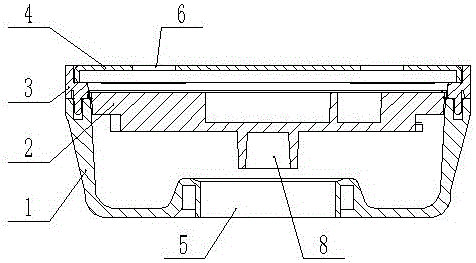

High-flow cross-draining water-sealing floor drain

PendingCN106759810ASimple structureIncrease drainage flowSewerage structuresClimate change adaptationEngineeringStreamflow

The invention relates to a high-flow cross-draining water-sealing floor drain, belongs to the technical field of floor drains and provides a cross-draining floor drain small in size, high in flow capacity and compatible with washing machine drainage; according to the technical scheme, a floor drain body is a container with a top opening, a water-sealing cover is in the shape of a ring having the inner cylindrical face extended down to form a barrel, the water-sealing cover is arranged inside the floor drain body, the bottom of the barrel hangs in the air, the ring of the upper portion of the water-sealing cover adapts to the upper portion of the floor drain body in shape and is locked to the upper portion of the floor drain body, a water seal is formed between the water-sealing cover and the floor drain body, a frame is mounted above the water-sealing cover and the floor drain body, and a grate is mounted in the frame; the outer side of the floor drain body is connected with a water outgoing pipe, the water outgoing pipe includes a square tube segment, a transition segment and a circular tube segment, the square tube segment is connected to the outer wall of the floor drain body, and the upper portion of the sidewall of the floor drain body inside the square tube segment is provided with a horizontal water outlet; the high-flow cross-draining water-sealing floor drain is suitable for cross-draining pipelines.

Owner:TAIYUAN KINDER SANITARY WARE & EQUIP CO LTD

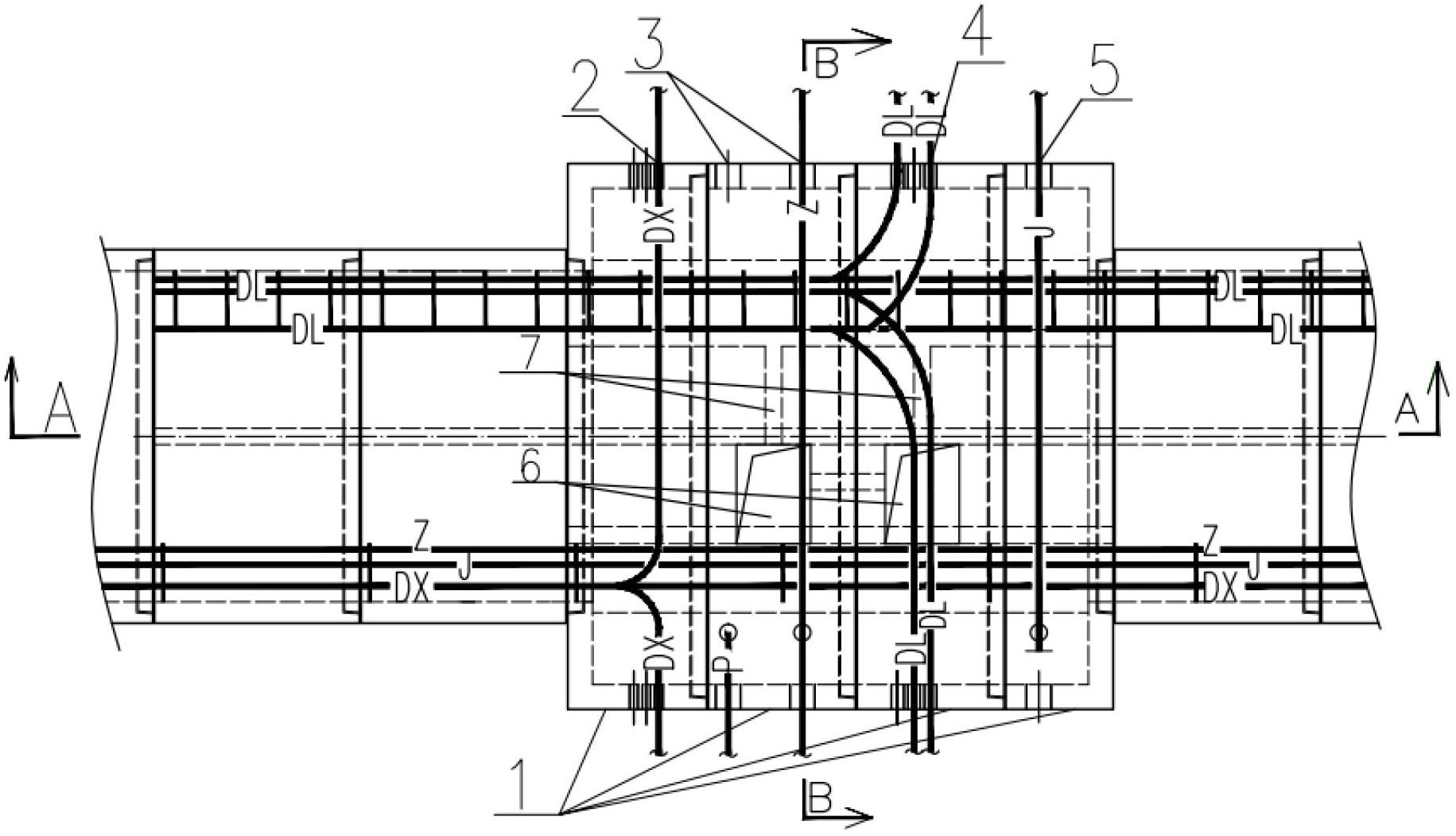

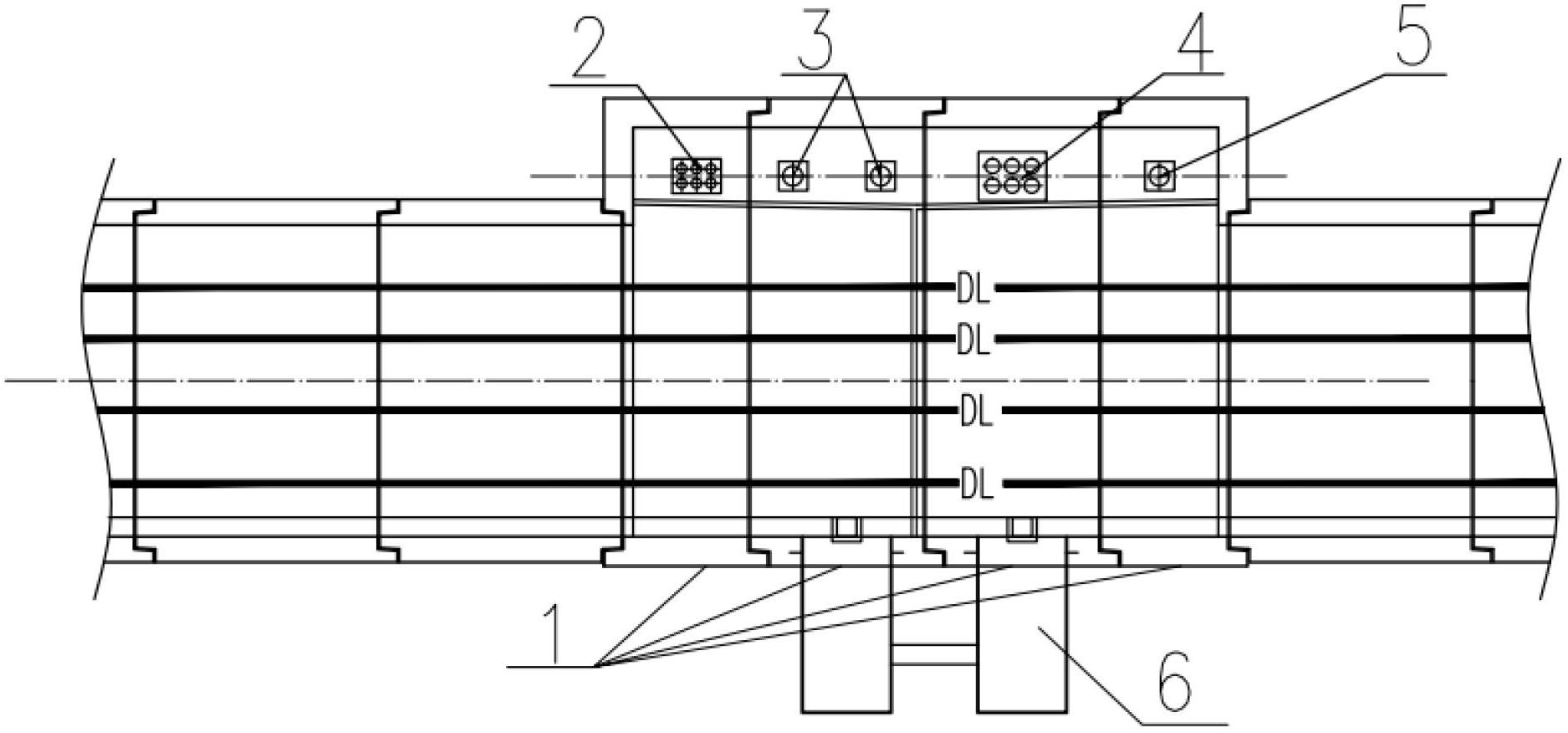

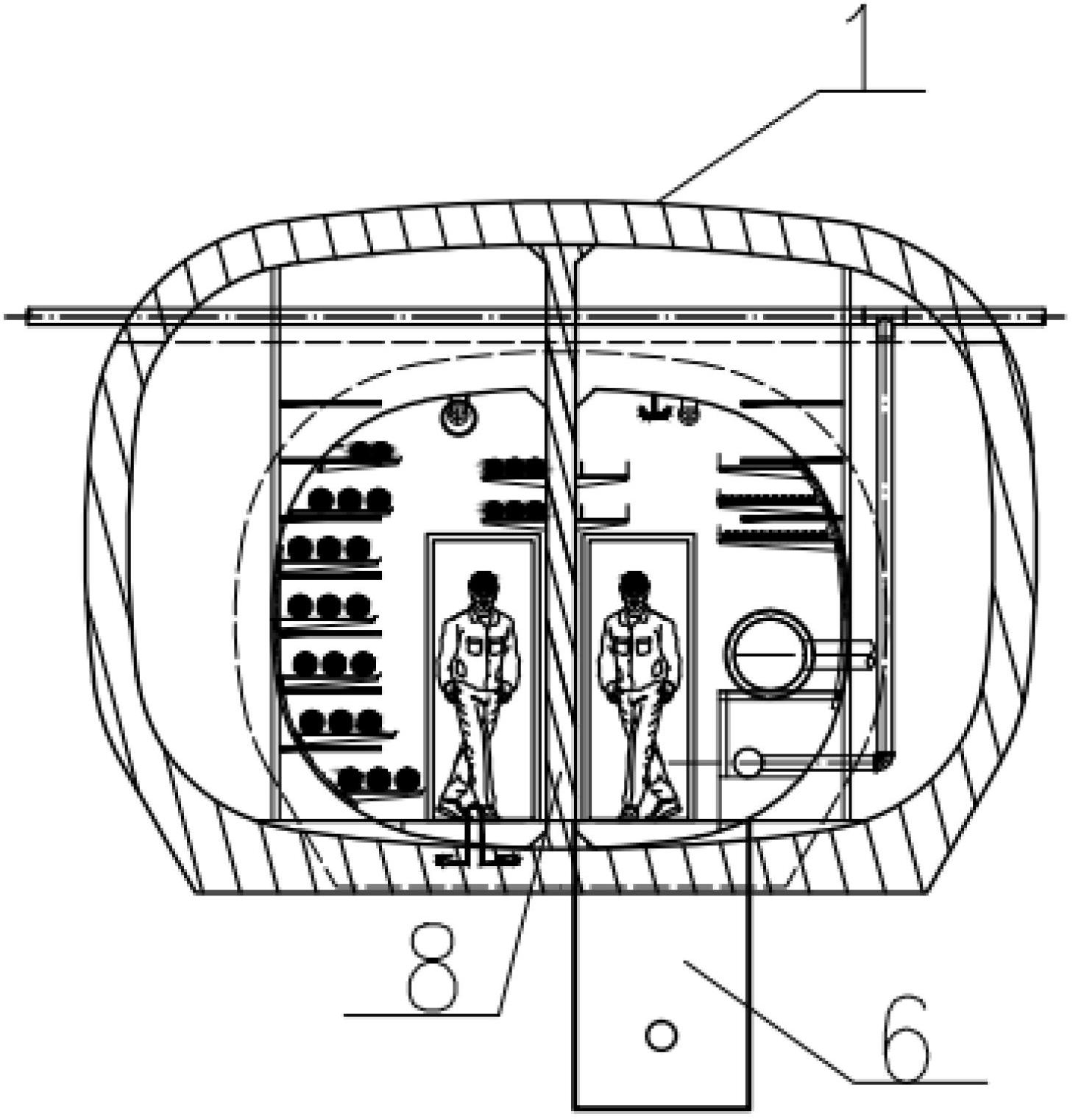

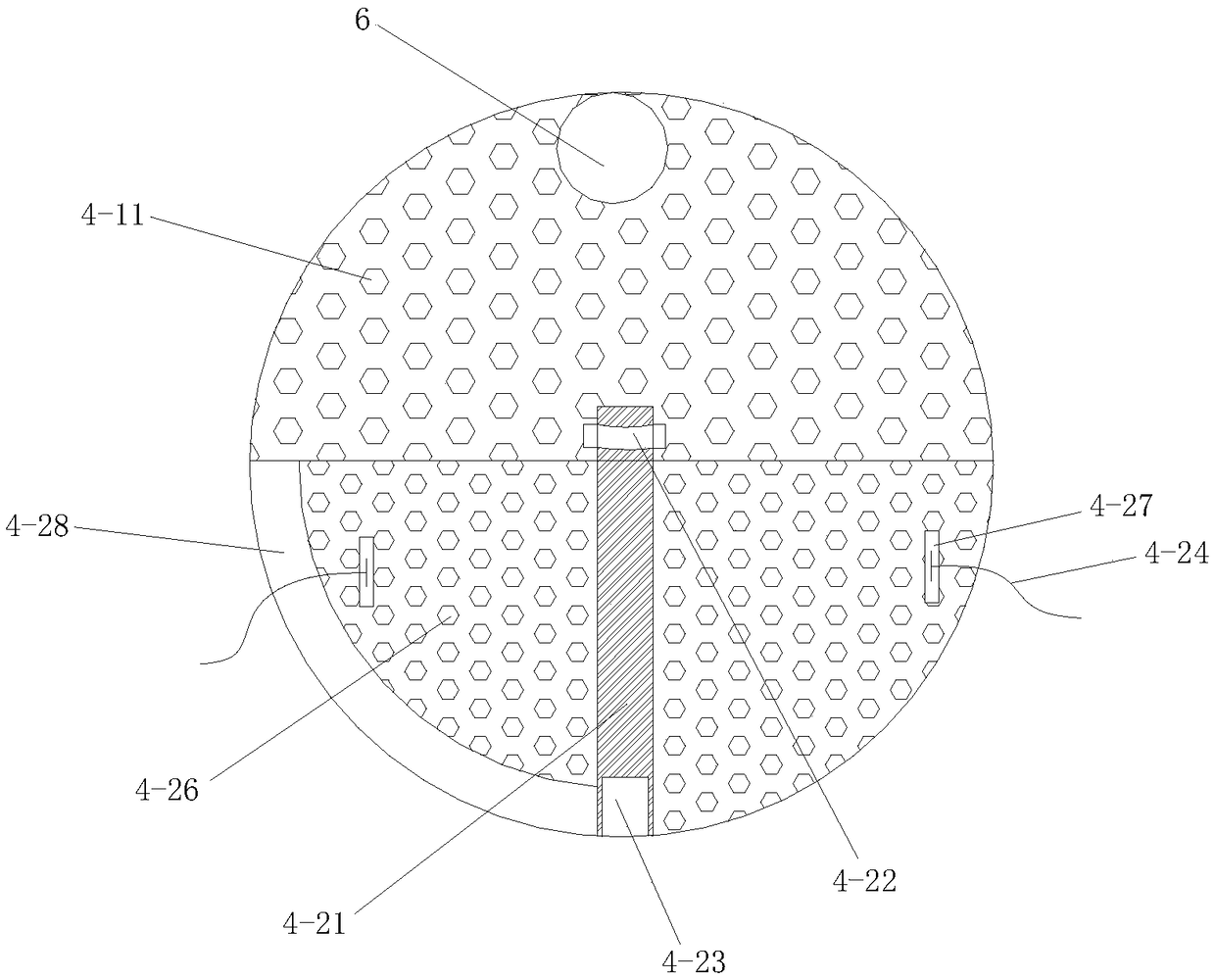

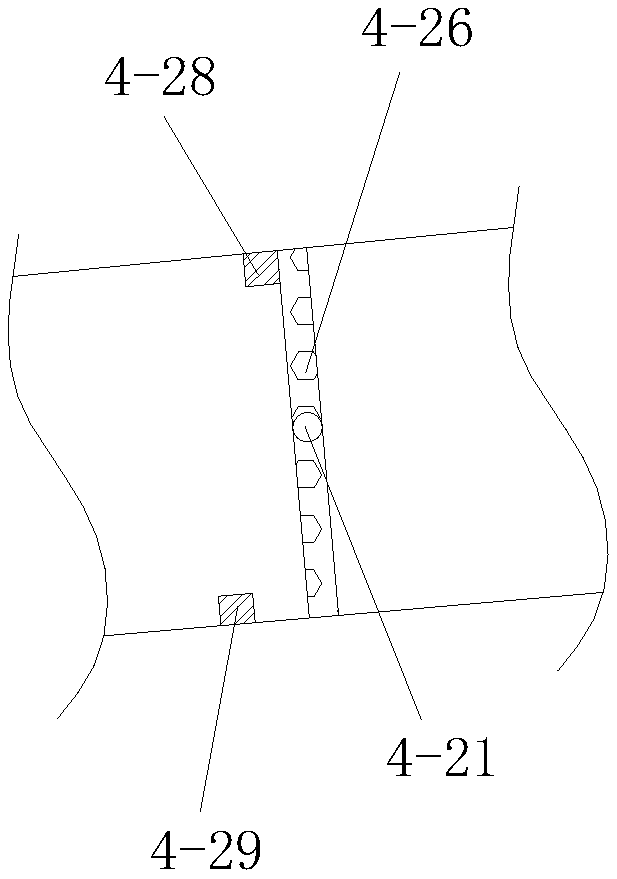

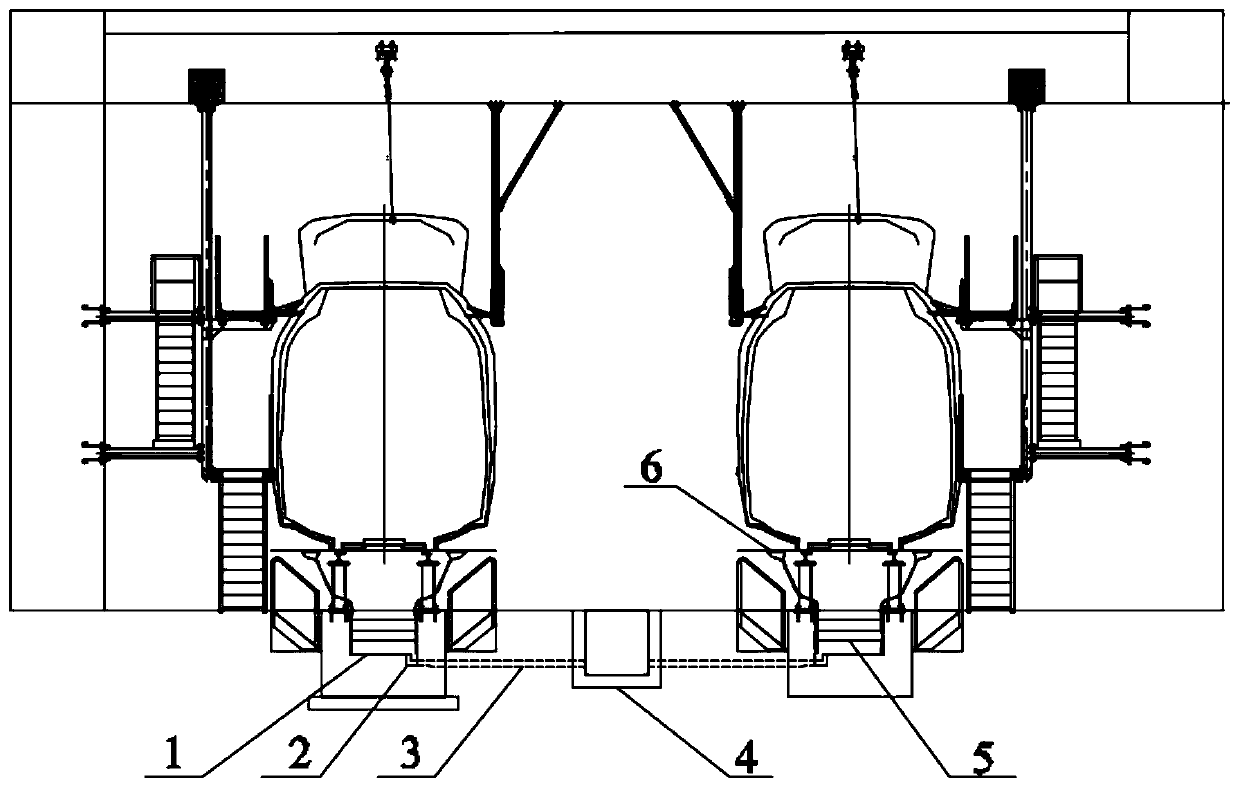

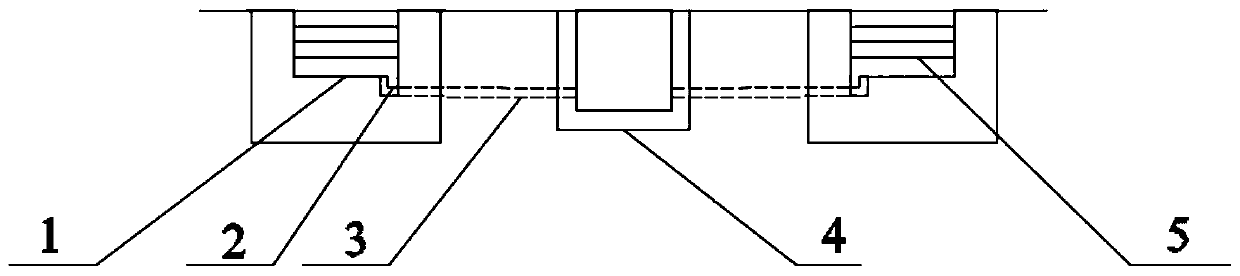

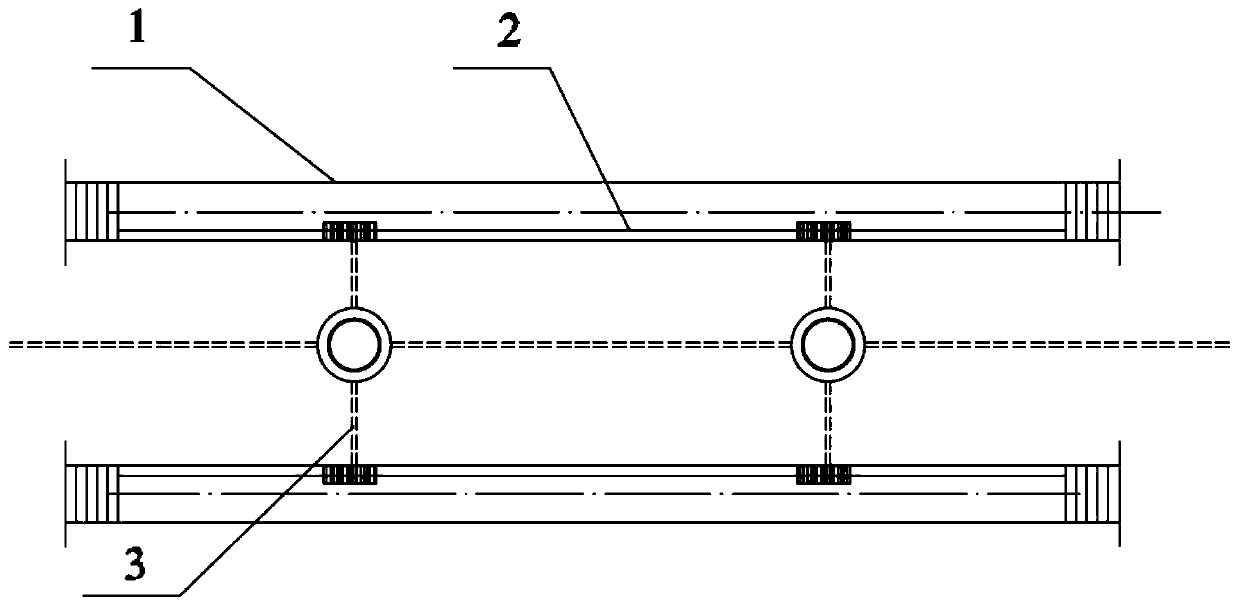

Precast assembled pipeline combined shaft

InactiveCN102691312AGood sealing effectImprove the sealing effectArtificial islandsUnderwater structuresLine tubingUtilization rate

The invention discloses a precast assembled pipeline combined shaft, which comprises at least two precast pipe sections, wherein a sealing element is arranged at the joint of the adjacent precast pipe sections; the cross section of each precast pipe section is elliptic; a steel water collecting pit and a drainage ditch are arranged at the bottom of the precast pipe sections; each precast pipe section comprises a partition wall for partitioning a passage into a first passage and a second passage; and each precast pipe section is provided with a prepared hole through which a pipeline and a cable get in and out. The precast pipe sections are assembled into the pipeline combined shaft, so that the quality of the pipeline combined shaft is ensured, and the pipeline combined shaft is high in non-uniform settling resistance and quick in construction. By adopting the precast pipe sections of which the cross sections are elliptic, the sealing effect between the adjacent precast pipe sections is good, and the utilization rate of the internal space of each precast pipe section can also be improved.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

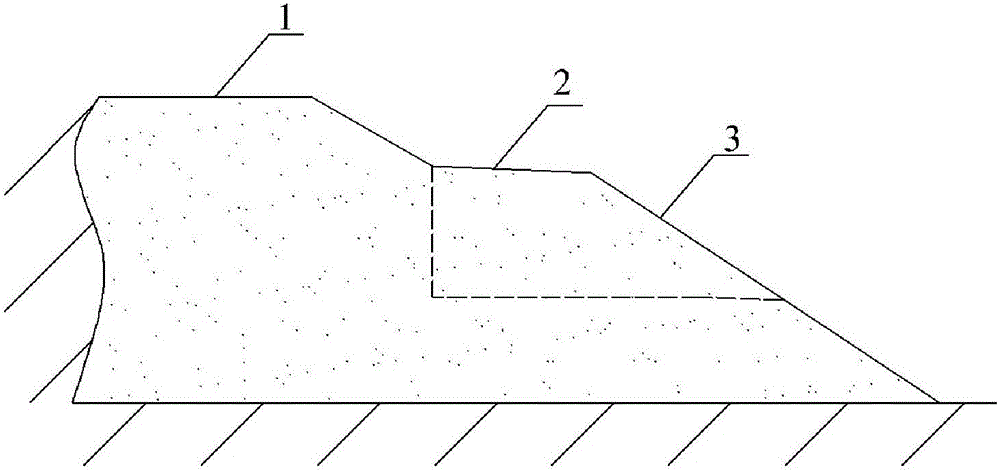

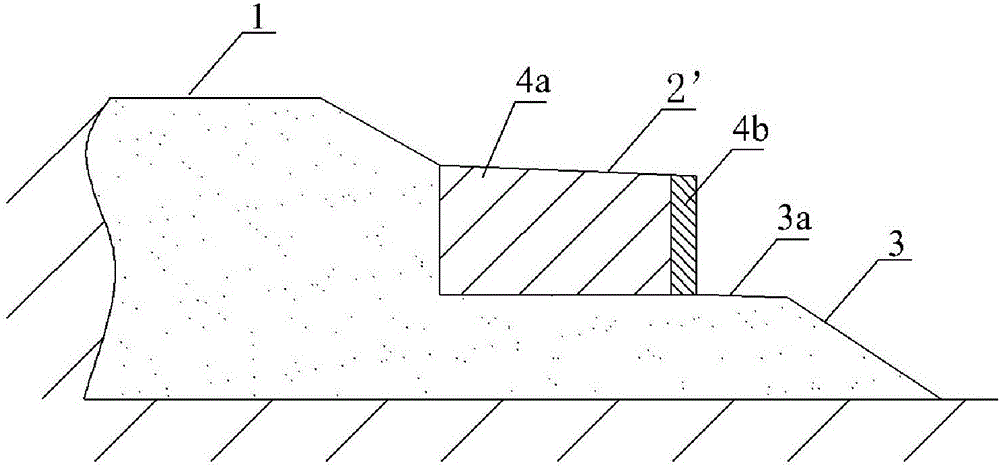

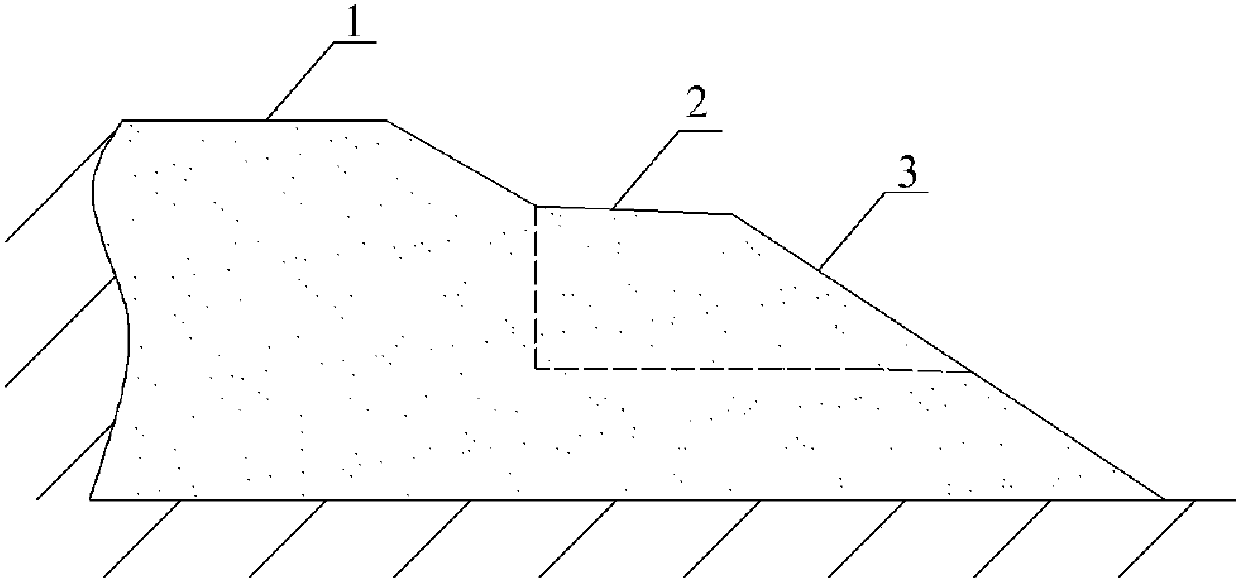

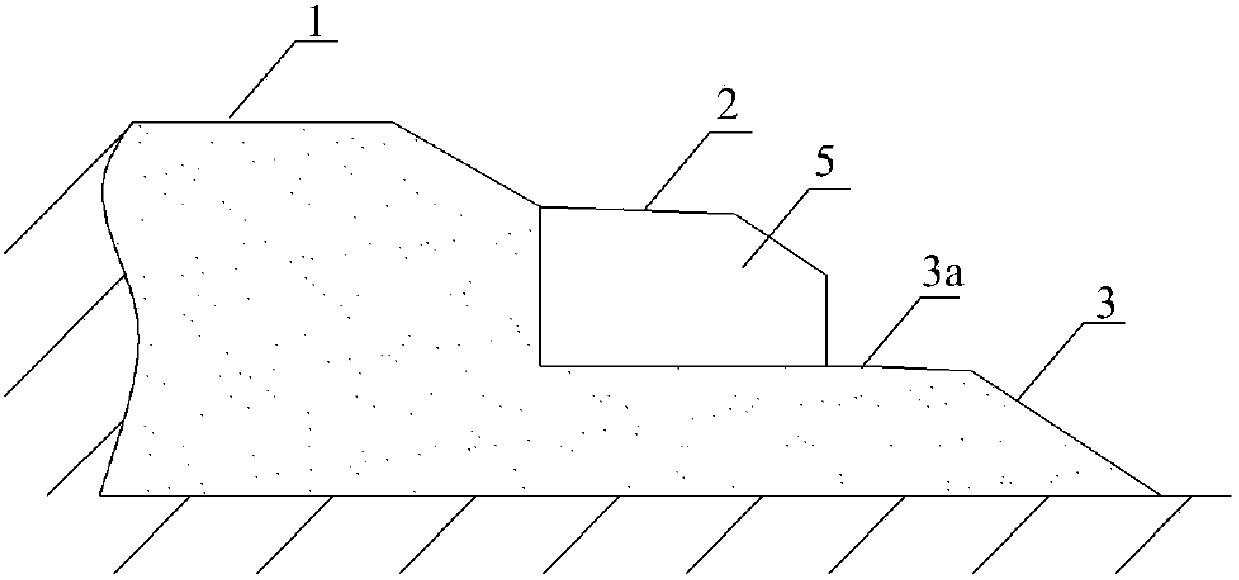

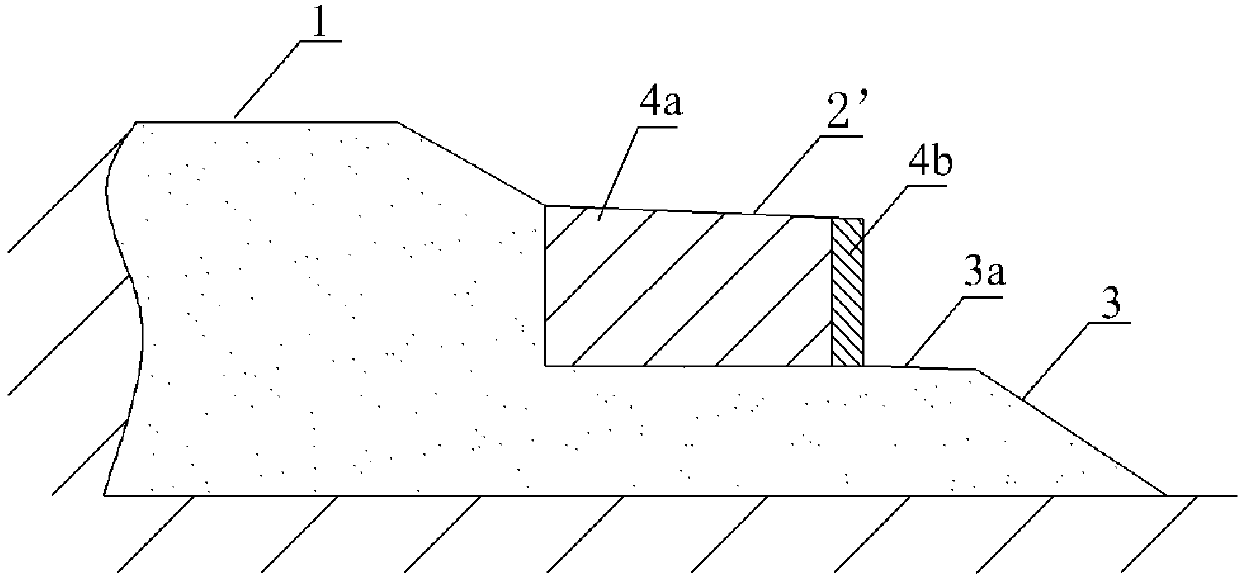

Method for widening shoulder of existing railway subgrade

A method for widening a shoulder of an existing railway subgrade comprises the steps: A, digging on a shoulder of a railway subgrade and a subgrade slope outside the shoulder, transverse troughs at equal intervals longitudinally along a line, the transverse troughs being used for receiving transverse ribs of unitary T-shaped members, inner ends of the transverse troughs being positioned at a junction of the shoulder and a bed, and the length of the transverse ribs being equal to the width of a widened new shoulder; B, cutting the subgrade slope longitudinally along the line to form a slope platform for placing vertical panels of the unitary T-shaped members; C, placing the transverse ribs of the unitary T-shaped members in the transverse troughs, with the vertical panels placed on the sloe platform; D, on the inner side of the vertical panels and two sides of the transverse ribs, backfilling soil layer by layer and compacting until the soil is flush with the shoulder to form the widened new shoulder. In widening the shoulder by the method, subgrade soil is highly stable, low disturbances are caused to the soil, masonry quantity is low, construction period is short, and the cost is low.

Owner:SOUTHWEST JIAOTONG UNIV

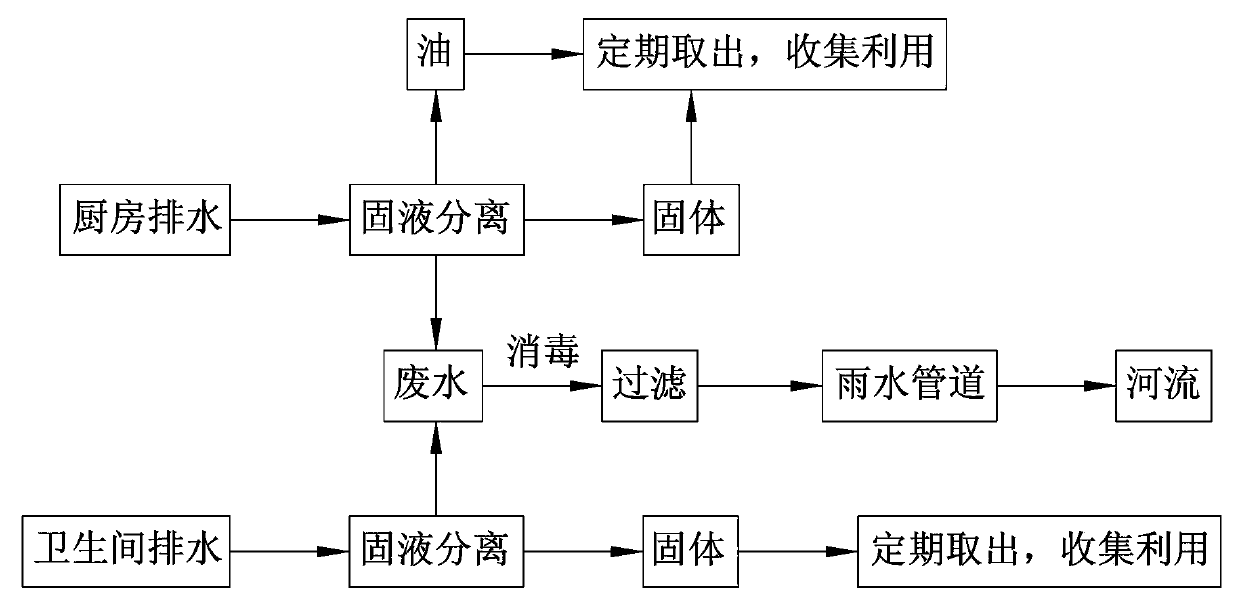

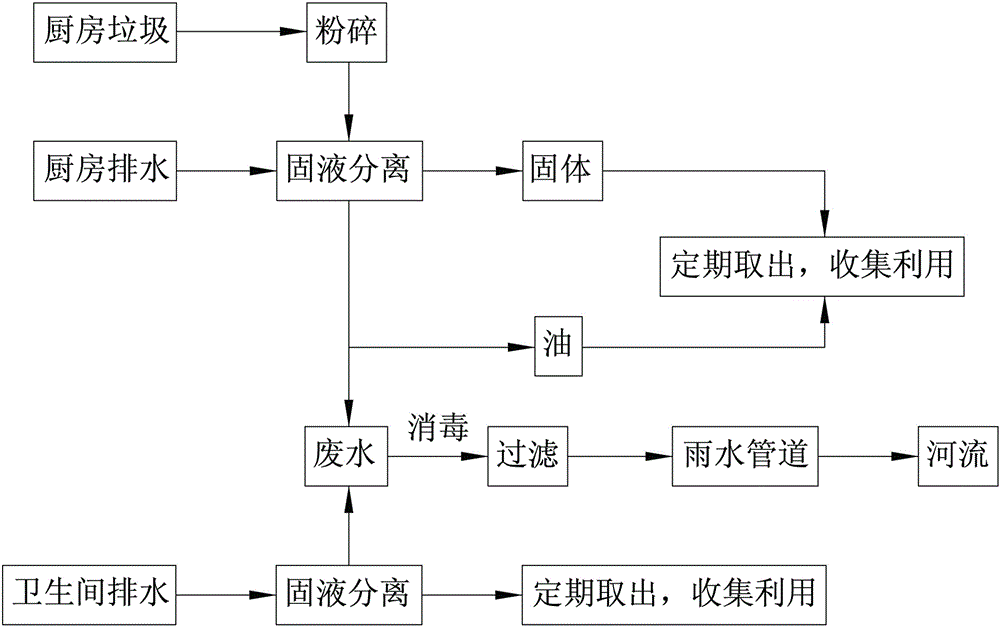

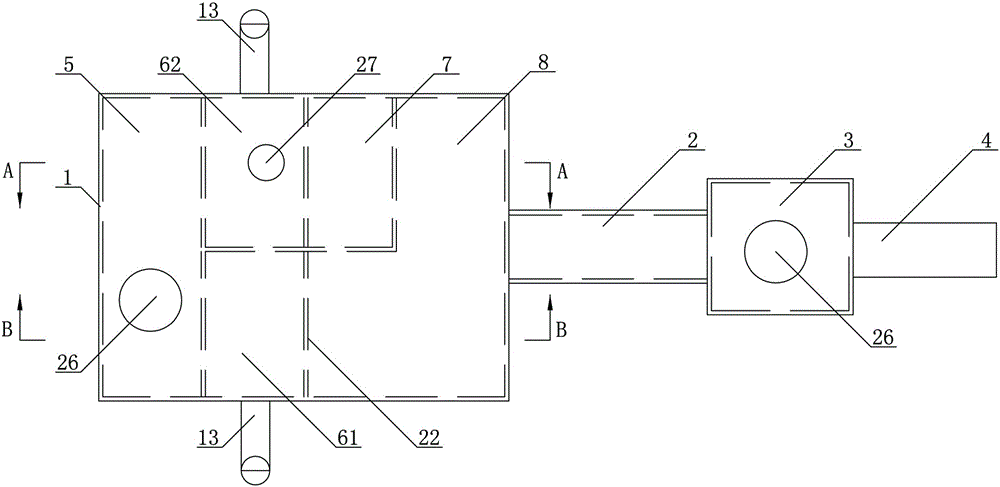

Method and device for treating water drained from kitchens and bathrooms

InactiveCN103739166AAvoid new pollution problemsSolve pollutionMultistage water/sewage treatmentWater storageWastewater

The invention relates to a method and a device for treating water drained from kitchens and bathrooms. A method for treating water drained from kitchens and bathrooms comprises the following steps: 1) immediately filtering sewage drained from kitchens so as to realize solid-liquid separation; 2) carrying out oil-water separation on liquid sewage; 3) immediately disinfecting sewage drained from bathrooms, and then filtering the sewage so as to realize solid-liquid separation; 4) disinfecting the wastewater subjected to oil-water separation, mixing the obtained water with the sewage subjected to solid-liquid separation in the 3), and further filtering the obtained mixture; 5) after the obtained water is subjected to further depth processing and reaches the standards, discharging or reusing the obtained product. A device for treating water drained from kitchens and bathrooms is provided with a solid-liquid separation chamber and a water storage chamber arranged in a sewage tank, the solid-liquid separation chamber is divided into a solid-liquid separation chamber for water drained from kitchens and a solid-liquid separation chamber for water drained from bathrooms, an oil storage tank communicated with the solid-liquid separation chamber for water drained from kitchens is arranged in the sewage tank, and sewage in the water storage chamber enters a filter pipe. According to the invention, the discharge of sanitary sewage and the cyclic utilization of wastes in communities are realized.

Owner:王凤蕊

Straight-through type mass flow siphon floor drain compatible with water drainage of washing machine

The invention relates to a straight-through type mass flow siphon floor drain compatible with water drainage of a washing machine and belongs to the technical field of floor drains. The straight-through type mass flow siphon floor drain provided by the invention can produce a siphon effect, has quick water drainage speed and is also compatible with the water drainage of the washing machine. According to the adopted technical scheme, a water outlet connected with a sewer line is arranged below a main shell, a water flowing screen is detachably connected to the inner wall of the main shell by a buckle, a frame is arranged on the main shell, and a grate is arranged in the frame; a water flowing hole is formed in the part of the water flowing screen arranged below a water inlet hole, a first through hole is formed in the middle part of the water flowing screen, a siphon piece is connected to the inner wall of the first through hole by multiple ribs, a water distributing piece with buffering and flow dividing effects is arranged at the top of the siphon piece, a washing machine joint can be also comprised, a second through hole is formed in the middle part of the grate, and the washing machine joint is detachably connected with the first through hole at the middle part of the water flowing screen. The straight-through type mass flow siphon floor drain is applicable to a sewer line with a trap.

Owner:TAIYUAN KINDER SANITARY WARE & EQUIP CO LTD

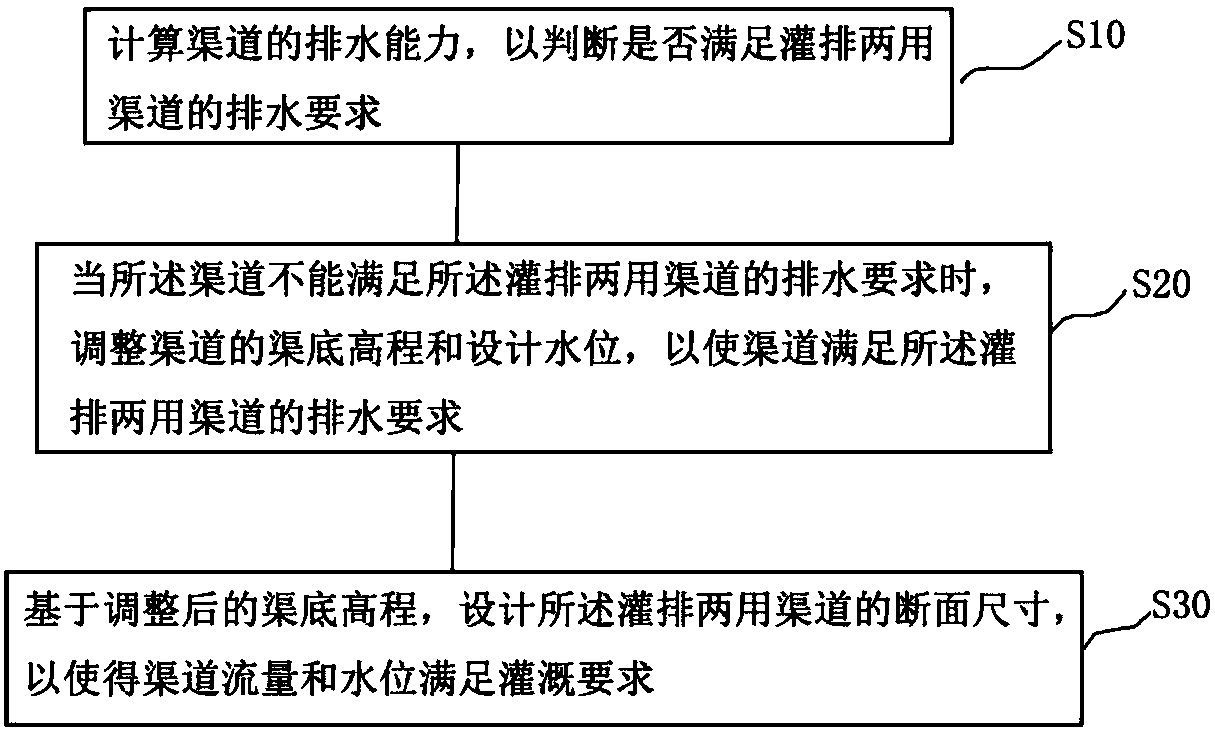

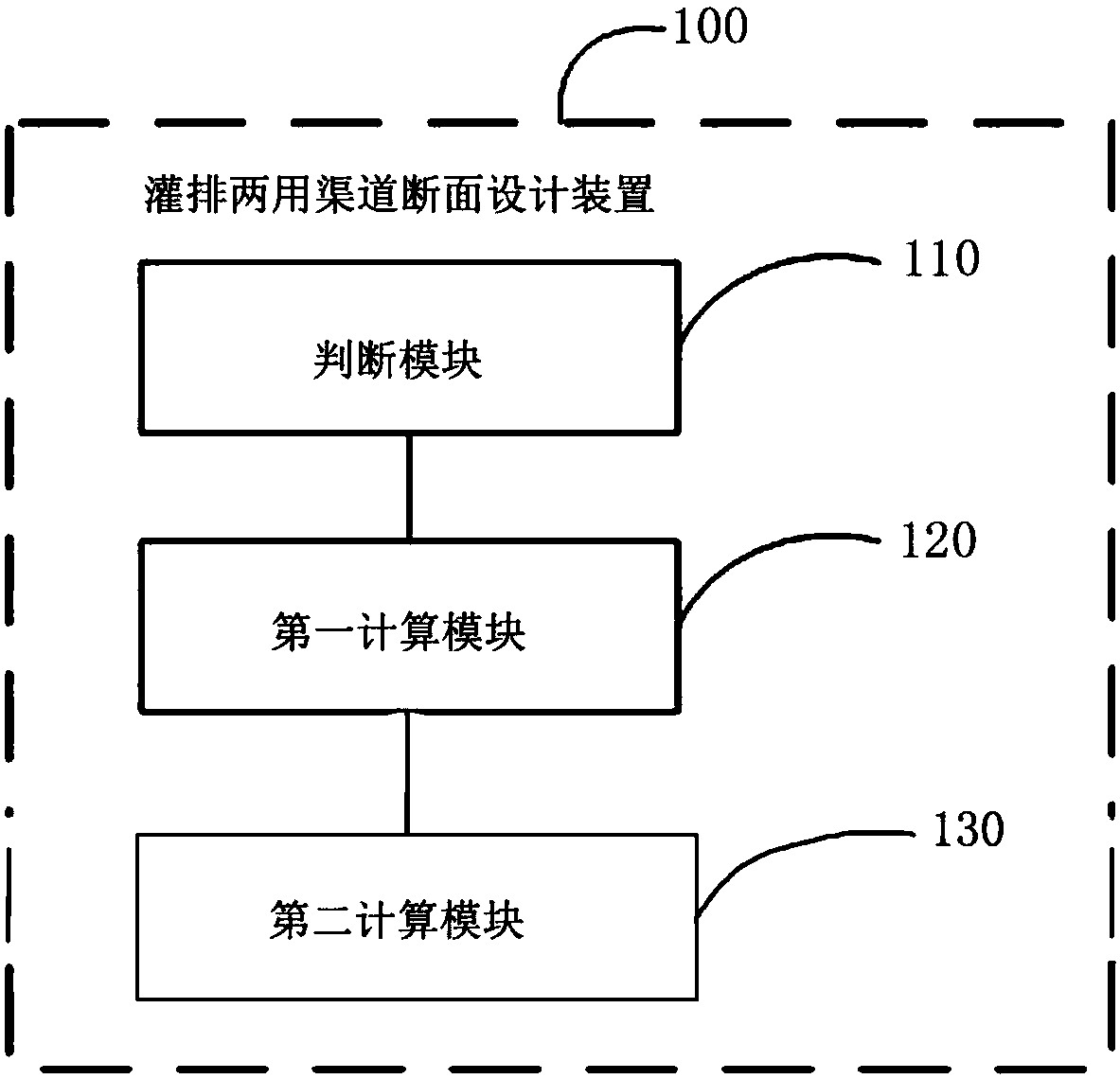

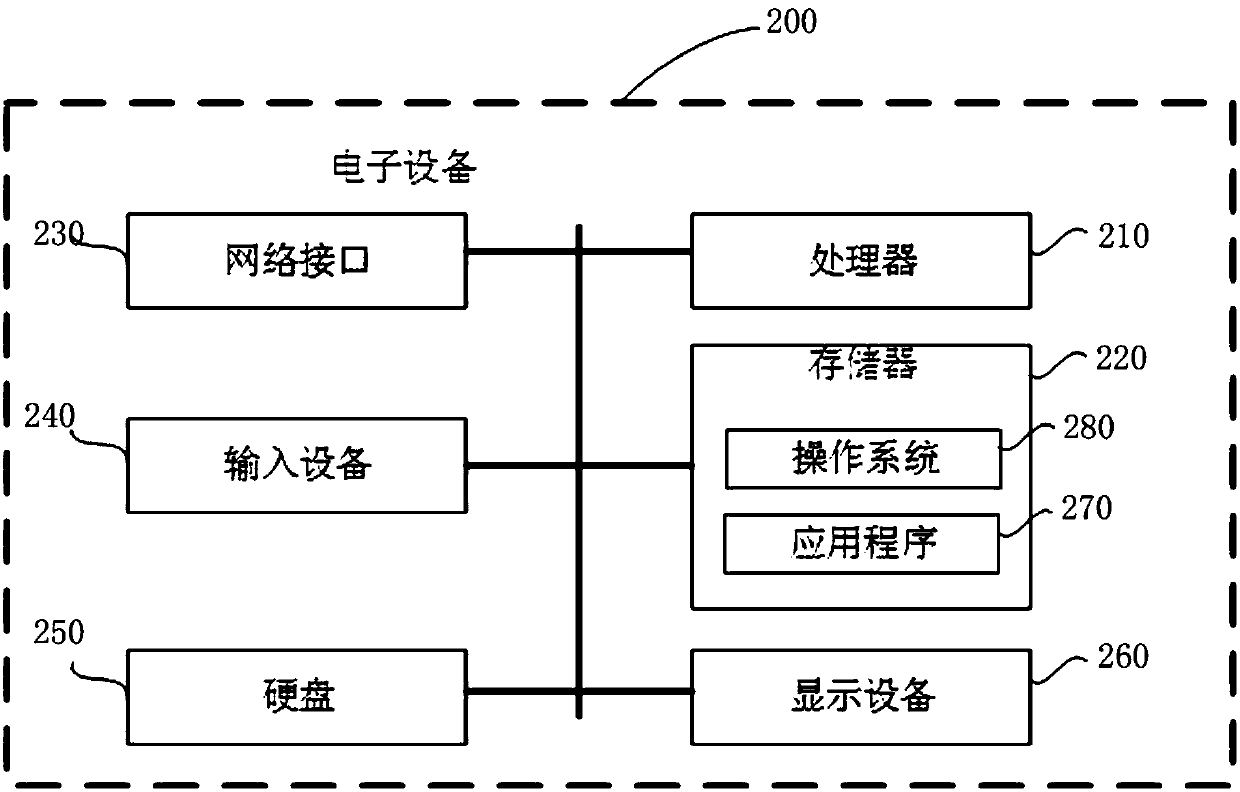

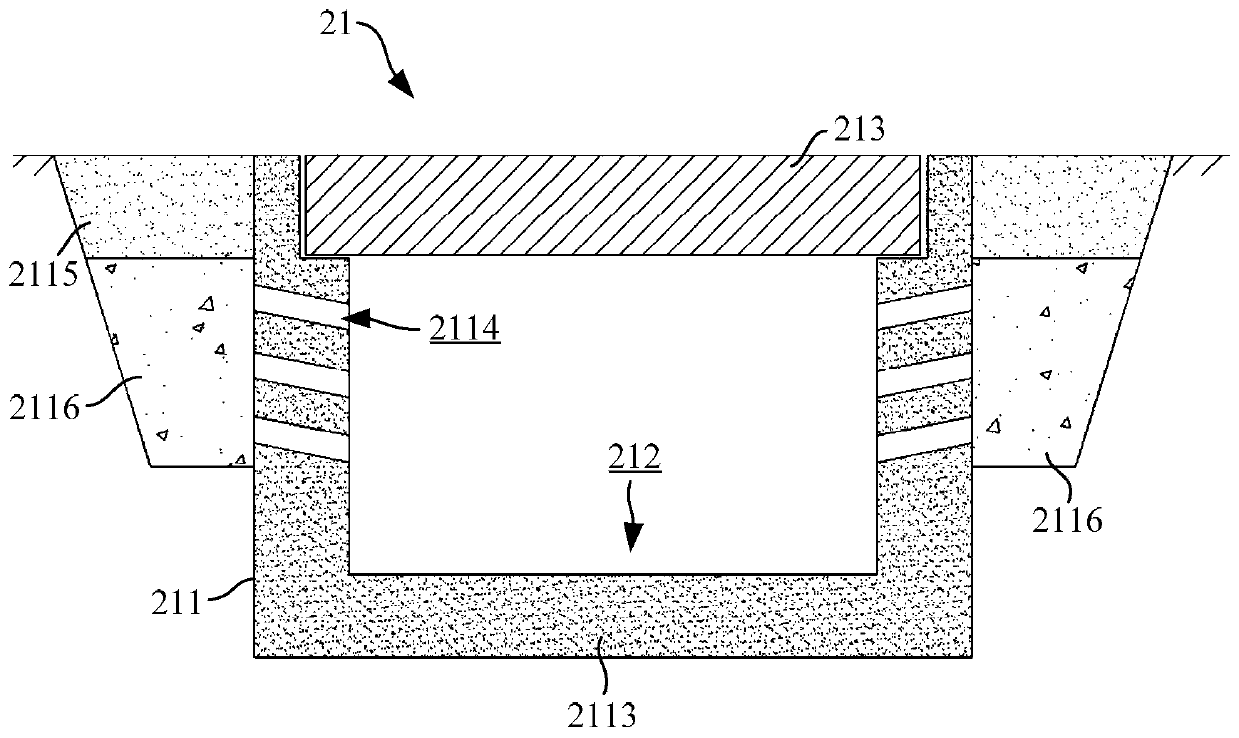

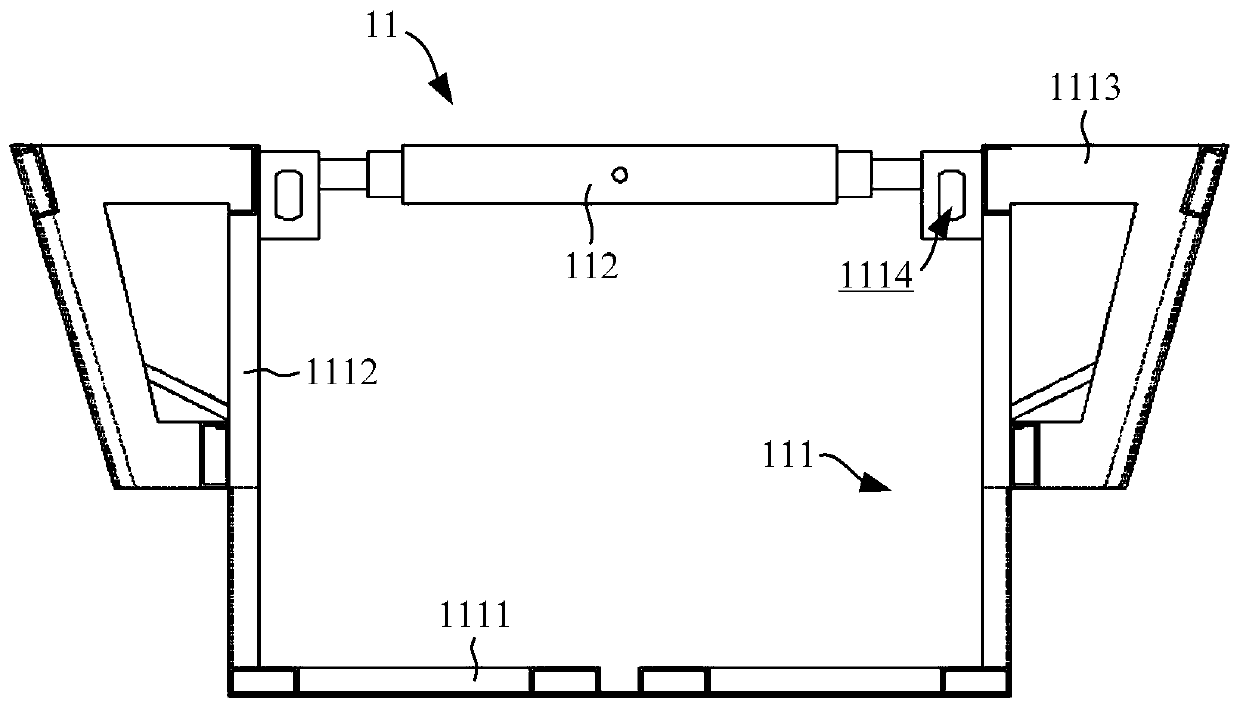

Section design method and device for irrigation and drainage dual-purpose channel, and equipment

ActiveCN107798172AGuaranteed Irrigation RequirementsMeet drainage requirementsGeometric CADSpecial data processing applicationsEngineeringDual purpose

The invention provides a section design method and device for an irrigation and drainage dual-purpose channel, and equipment. The section design method for the irrigation and drainage dual-purpose channel comprises the following steps that: S10: calculating the drainage ability of the channel so as to judge whether the drainage requirements of the irrigation and drainage dual-purpose channel are met or not; S20: when the channel can not meet the drainage requirements of the irrigation and drainage dual-purpose channel, regulating the channel bottom elevation and the design water level of the channel to enable the channel to meet the drainage requirements of the irrigation and drainage dual-purpose channel; and S30: on the basis of the regulated channel bottom elevation, designing the section dimension of the irrigation and drainage dual-purpose channel to enable the flow and the water level of the channel to meet the irrigation requirements. According to the section design method, which is disclosed by the embodiment of the invention, for the irrigation and drainage dual-purpose channel, the existing channel is transformed into the irrigation and drainage dual-purpose channel, andthe section of the irrigation and drainage dual-purpose channel is designed in a transformation process so as to guarantee the irrigation requirements of an irrigation area to a maximum degree in a most economical way.

Owner:HEILONGJIANG PROV WATER CONSERVANCY & HYDROPOWER SURVEY & DESIGN INST +1

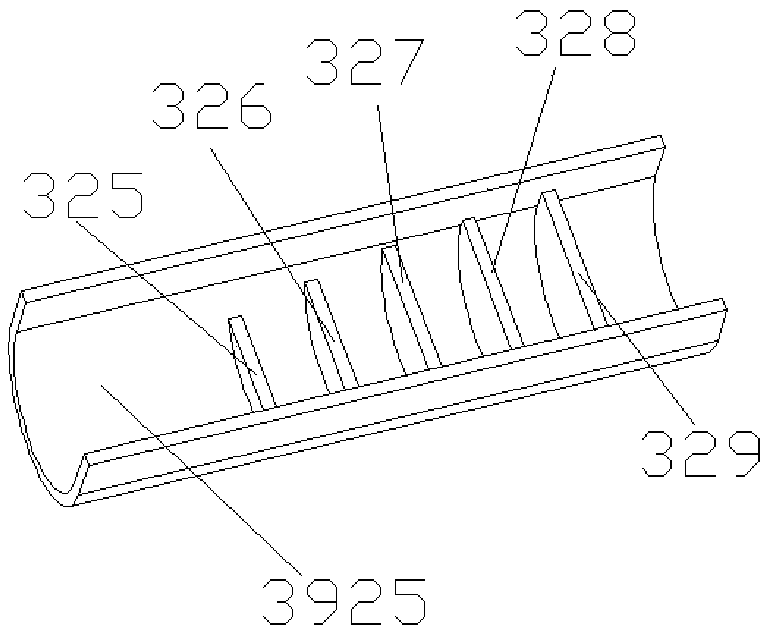

Tunnel center drainage ditch formwork assembly, drainage ditch structure and construction method of tunnel center drainage ditch formwork assembly

The invention relates to a tunnel center drainage ditch formwork assembly, a drainage ditch structure and a construction method of the tunnel center drainage ditch formwork assembly. The tunnel centerdrainage ditch formwork assembly is characterized in that an outer formwork placed in a tunnel base plate pouring space is poured to form a drainage ditch construction space, and the formed drainageditch construction space comprises a main body space and a side space communicating with the main body space; an inner formwork is placed in the main body space, the main body space and the side spaceare separated by the inner formwork, pouring is carried out in the main body space to form a main body structure, a drain ditch is formed inside the main body structure, and the side space can be poured to form a water permeable structure; and a preset flow guide pipe is placed in a main pouring space, and drainage holes which enable the water permeable structure to communicate with the drainageditch are formed. According to the tunnel center drainage ditch formwork assembly, the drainage ditch structure and the construction method of the tunnel center drainage ditch formwork assembly, the problems of single pouring material of the drainage ditch and easy leakage of a joint of the drainage ditch are effectively solved, so that parts, made of different materials, of the drainage ditch have different performances, water leaking from the joint is merged into the drainage ditch through the permeable structure, and the tunnel drainage requirements under complex conditions are met.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

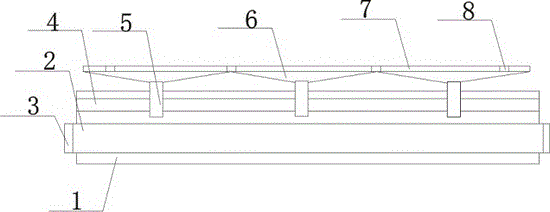

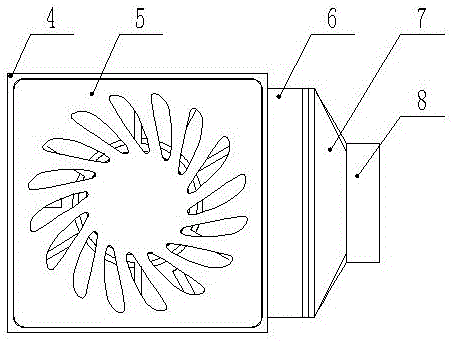

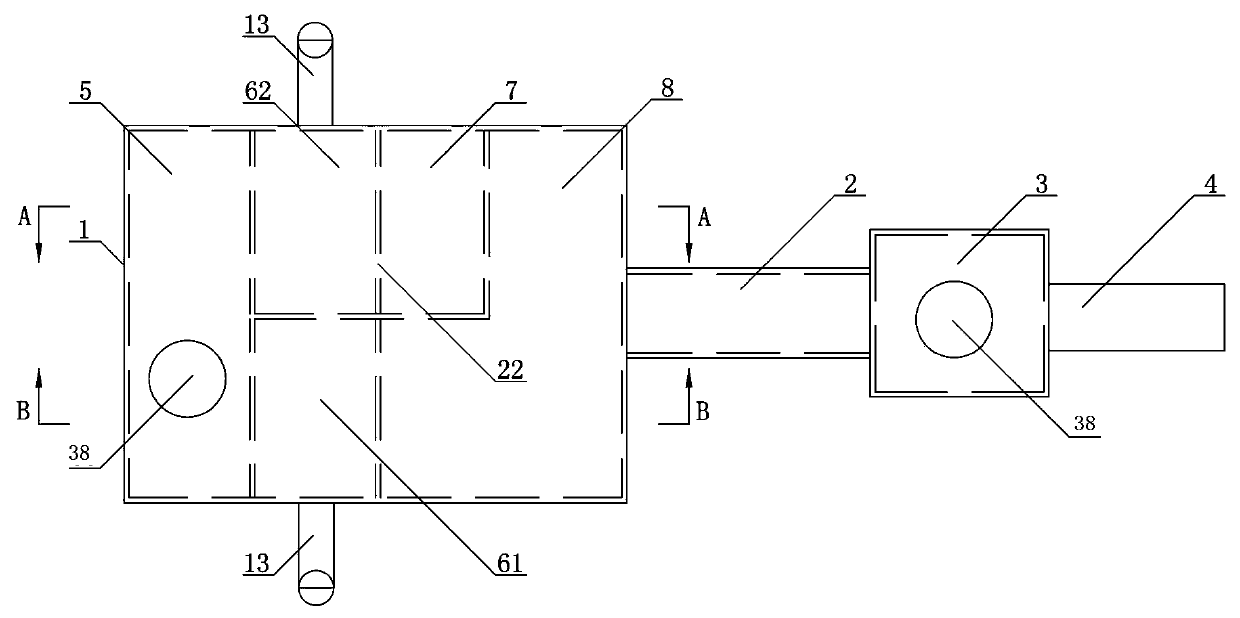

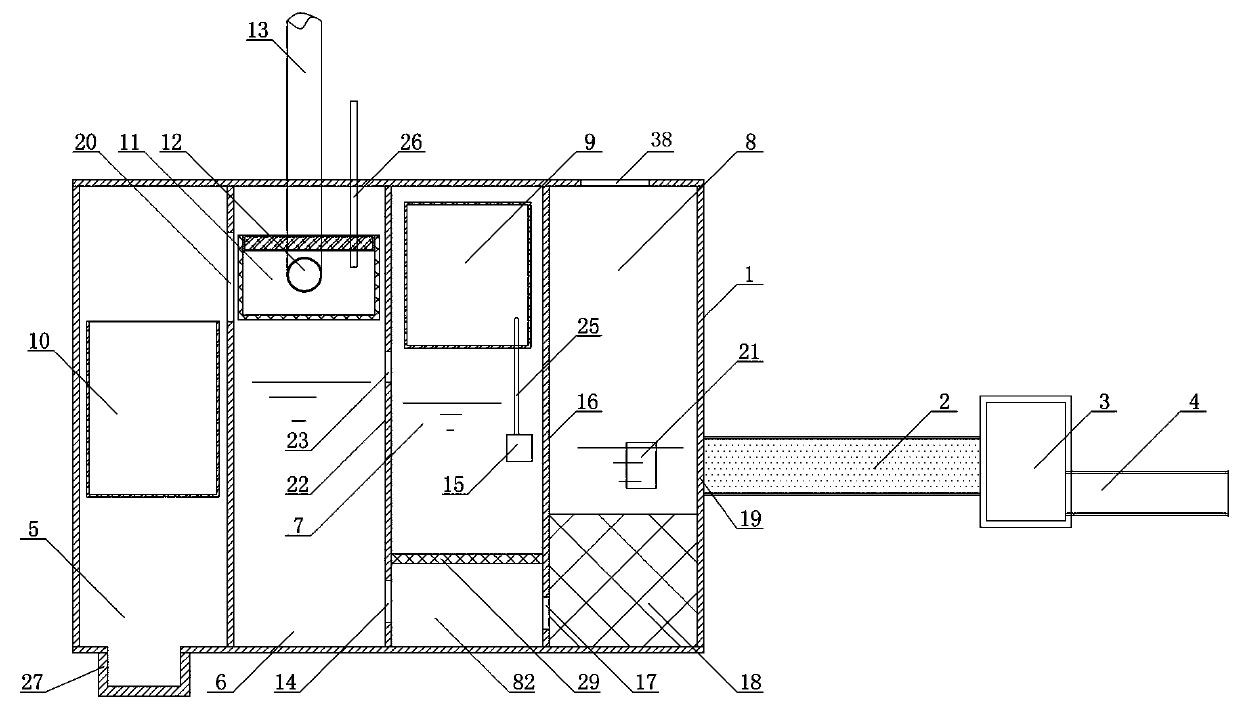

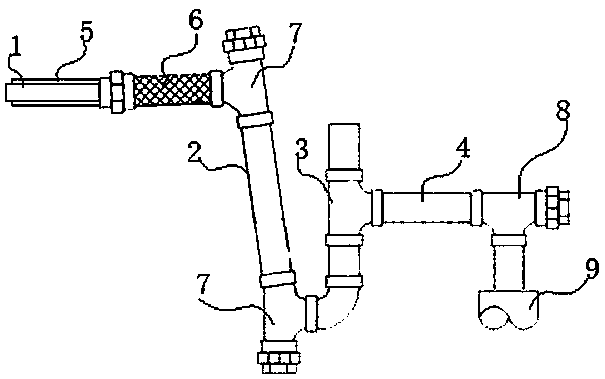

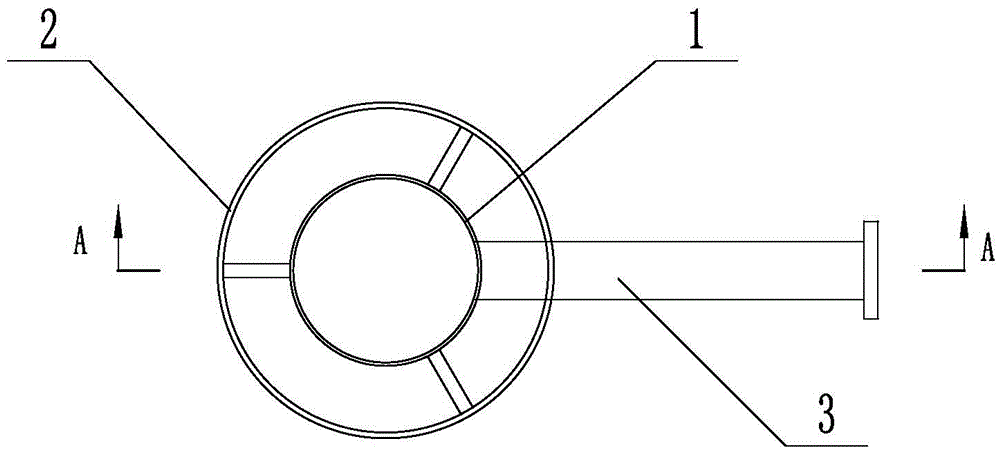

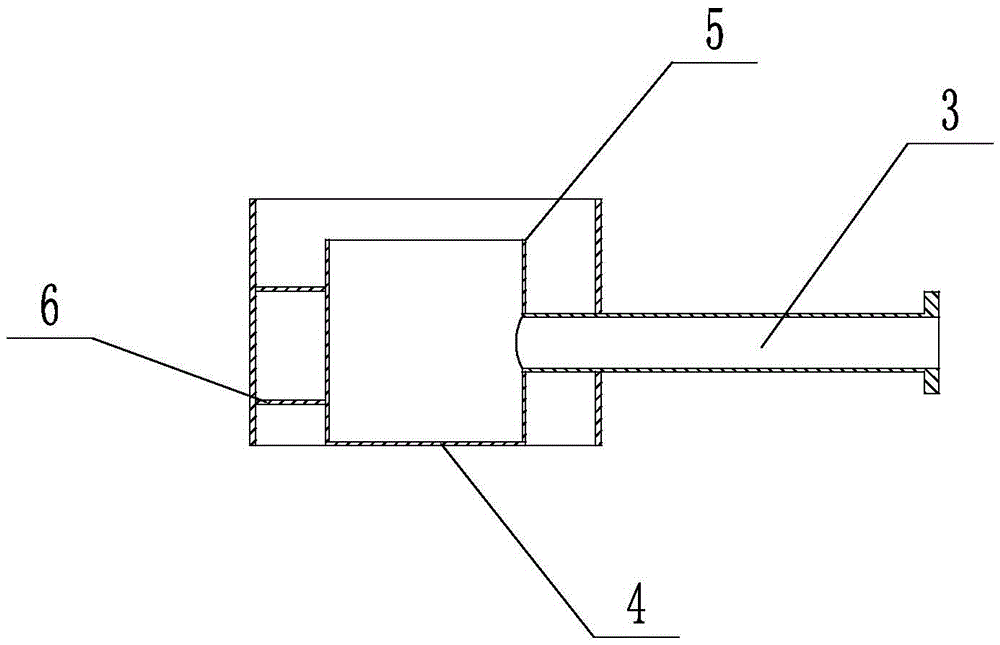

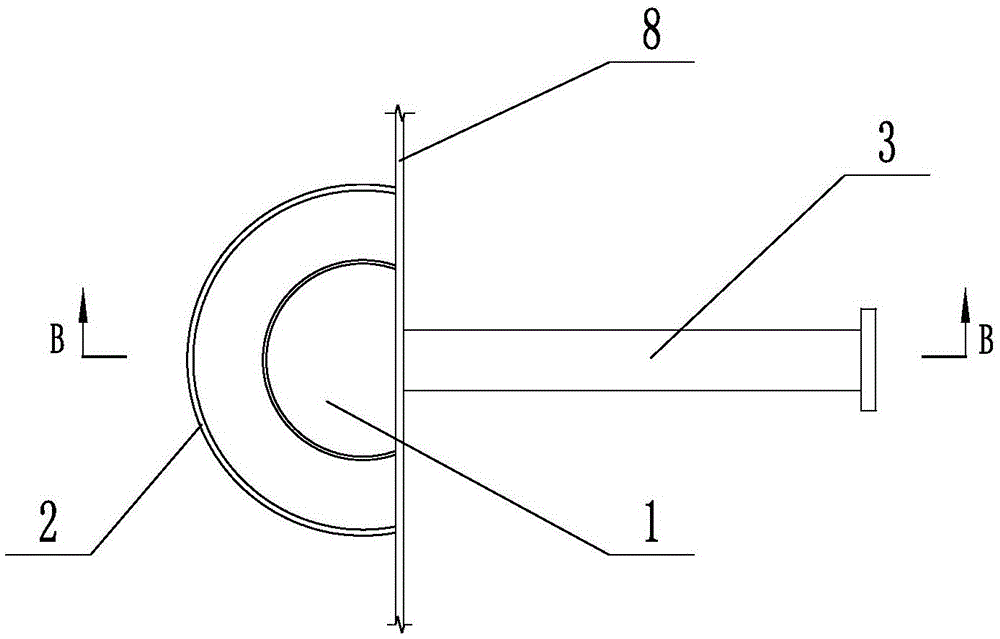

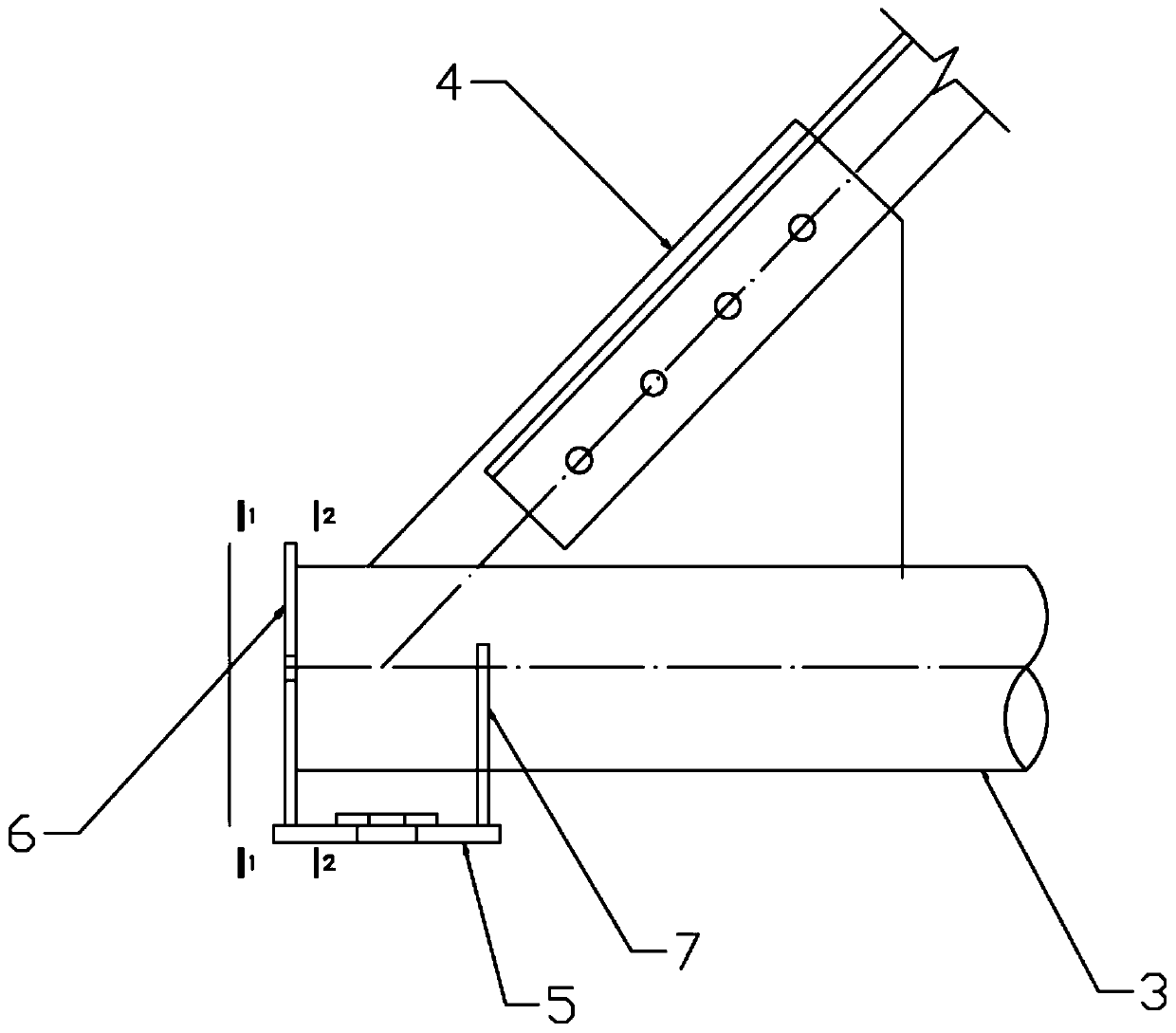

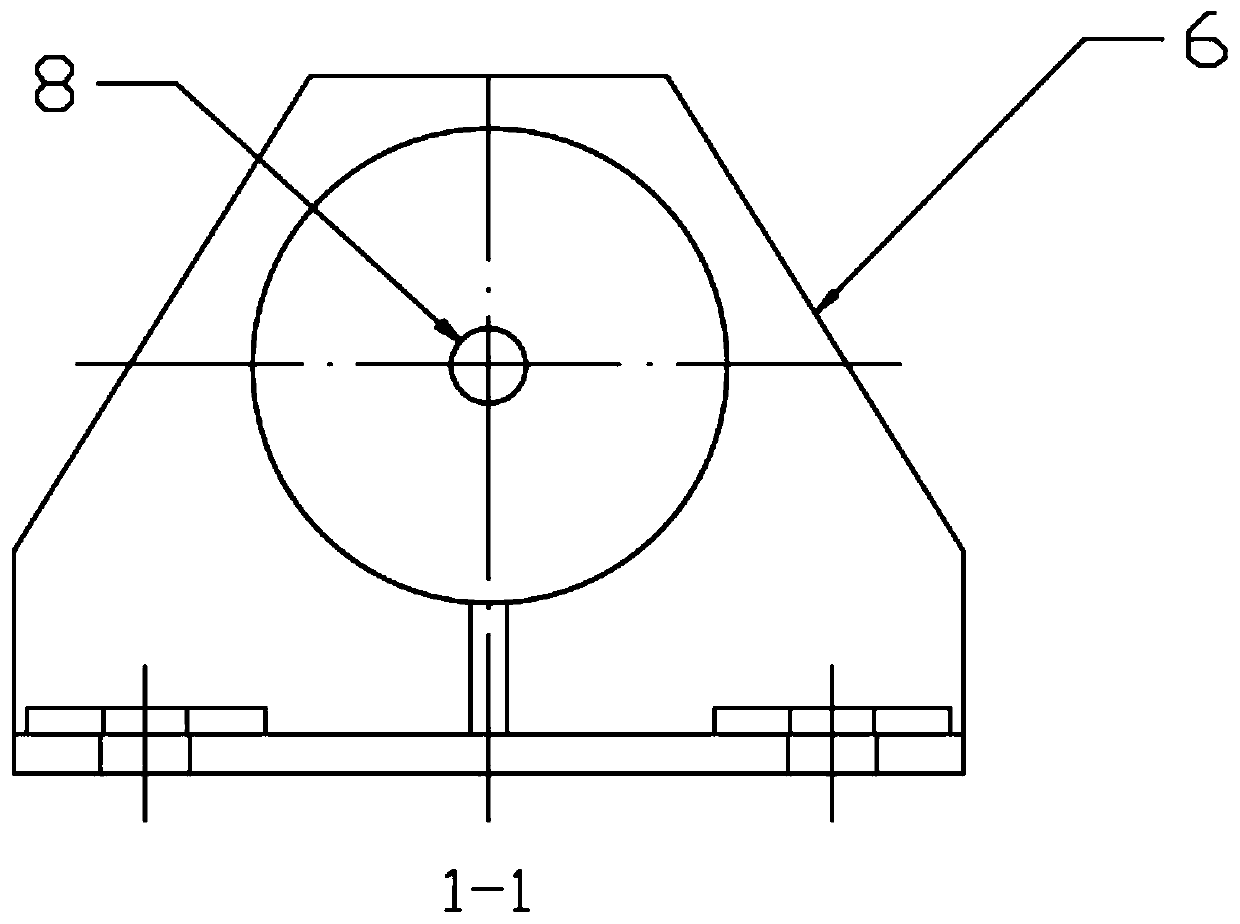

Drainage system of air conditioner

InactiveCN107781969AMeet drainage requirementsCondensate preventionLighting and heating apparatusEngineeringOuter core

The invention discloses an air conditioner drainage system, comprising a water collecting pipe (1), a connecting hose connected to the water collecting pipe (1), an anti-backflow pipe (2) communicating with the connecting hose, and an anti-backflow pipe (2) communicating with The drain pipe (3) is connected to the outlet pipe (4) of the drain pipe (3); the water collecting pipe (1) is covered with a heat insulating pipe (5); the thickness of the heat insulating pipe (5) is 1-5mm; the connecting soft The pipe includes a PVC core pipe and an anti-friction aluminum pipe (6) sleeved outside the PVC core pipe; the thickness of the PVC core pipe is 3-4mm; the two sections of the anti-backflow pipe (2) are provided with a first drain plug ( 7); the drain pipe (3) and the first drain plug (7) form a U-shaped anti-backflow structure; the end of the outlet pipe (4) is provided with a second drain plug (8); the outlet pipe (4) and The floor drain (9) or the water collector is connected, and the included angle between the anti-backflow pipe (2) and the horizontal plane is 55‑75. The invention adopts the air-conditioning drainage system, and the structure design is reasonable.

Owner:朱小平

Method for treating quicksand stratum drainage ditch slope collapse and purifying and recycling ditch water

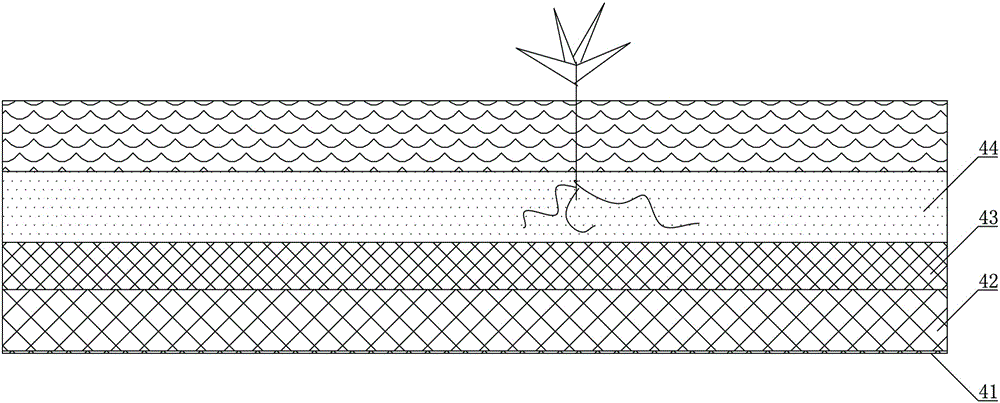

PendingCN113863335AImprove channel slope stabilityMeet drainage requirementsExcavationsBulkheads/pilesSoil scienceEngineering

The invention belongs to the technical field of drainage ditch slope treatment, and discloses a method for treating quicksand stratum drainage ditch slope collapse and purifying and recycling ditch water. Geotextile is sewn into geotechnical bags, the geotechnical bags are filled with corresponding fillers to form geotechnical filling bags, and the drainage ditch slope is built and protected. The method specifically comprises the following steps that filling preparation of the geotechnical filling bags is conducted, specifically, white artificial leather base cloth is selected as the geotextile to be sewn into the geotechnical bags, and the geotechnical bags are filled with the corresponding fillers to form the geotechnical filling bags which are used for building and protecting the drainage ditch slope; and a foundation is paved. According to the method, a new geosynthetic material, a new plastic steel composite sheet pile material, miniature concrete piles, timber piles and farmland drainage ditch slope treatment are successfully combined, the problems of collapse, slippage and the like of the ditch in an irrigation area are effectively solved, field infiltration water drained into the ditch can be filtered and purified, and ditch water recycling is achieved.

Owner:NINGXIA UNIVERSITY

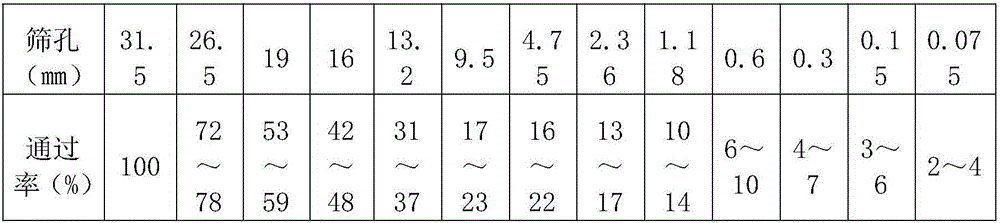

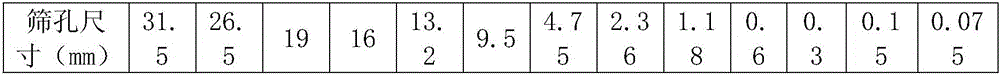

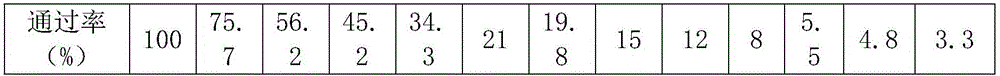

Drainage type modified asphalt coarse aggregate discontinuous semi-open graded bituminous stabilized macadam

InactiveCN105821734AMeet drainage requirementsGuaranteed road performanceIn situ pavingsPaving gutters/kerbsFiberSemi open

The present invention belongs to the field of transportation engineering, and discloses drainage type modified asphalt coarse aggregate discontinuous semi-open graded bituminous stabilized macadam. A mixture is composed of SBS modified asphalt, coarse aggregate, fine aggregate and mineral powder (or a certain amount of fiber can be added), the void ratio is 10%-13%, and the asphalt-aggregate ratio is 3.5%-4.5%. The mixture has certain drainage ability, and the anti-reflection crack performance, the anti-fatigue performance and the anti-rutting resistance are obviously improved compared with matrix asphalt AC-25 and matrix asphalt ATB-25. An important role is played in guaranteeing the pavement performance and the service life of an asphalt pavement when the drainage type modified asphalt coarse aggregate discontinuous semi-open graded bituminous stabilized macadam is applied to the structure of the asphalt pavement.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Underground pipe gallery structure

InactiveCN106284405AReduce in quantityEasy accessArtificial islandsUnderwater structuresEngineeringUtility tunnel

The invention discloses an underground pipe gallery structure, which comprises a pipeline compartment and a cable compartment that are disposed in the pipe gallery, respectively. A grating cover plate is disposed at the bottom of the pipeline compartment, and a sump is disposed under the pipeline compartment. A grating cover plate is disposed at the bottom of the cable compartment, and an open drain is disposed under the cable compartment and has a depth less than the depth of the sump. The open drain communicates with the sump, and a one-way blocking piece is disposed at the communication position of the open drain and the sump. The one-way blocking piece allows one-way communication in a direction from the open drain to the sump. The underground pipe gallery structure meets the requirements of the various functional compartments without increasing the sump; leakage water in the cable compartment and the like can be discharged in time through the one-way blocking piece; and water in the sump for the pipeline compartment cannot enter the cable compartment.

Owner:许陈菲

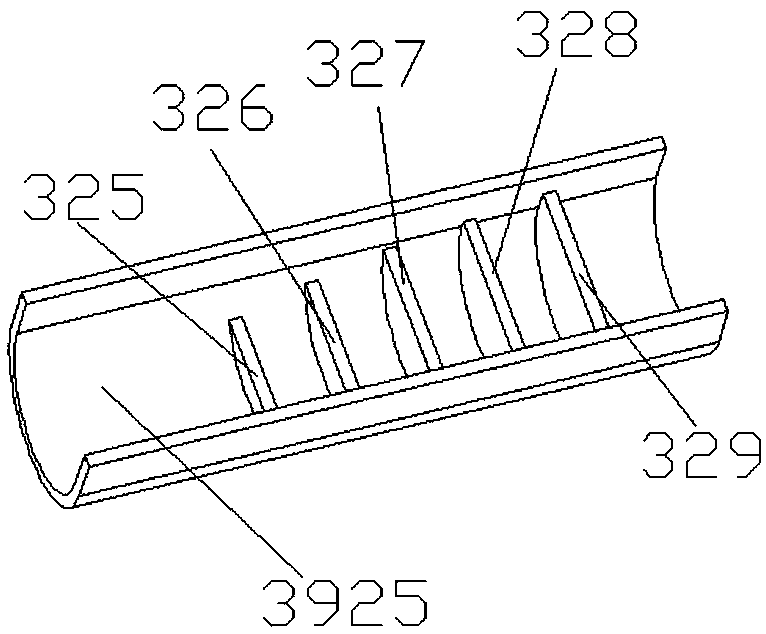

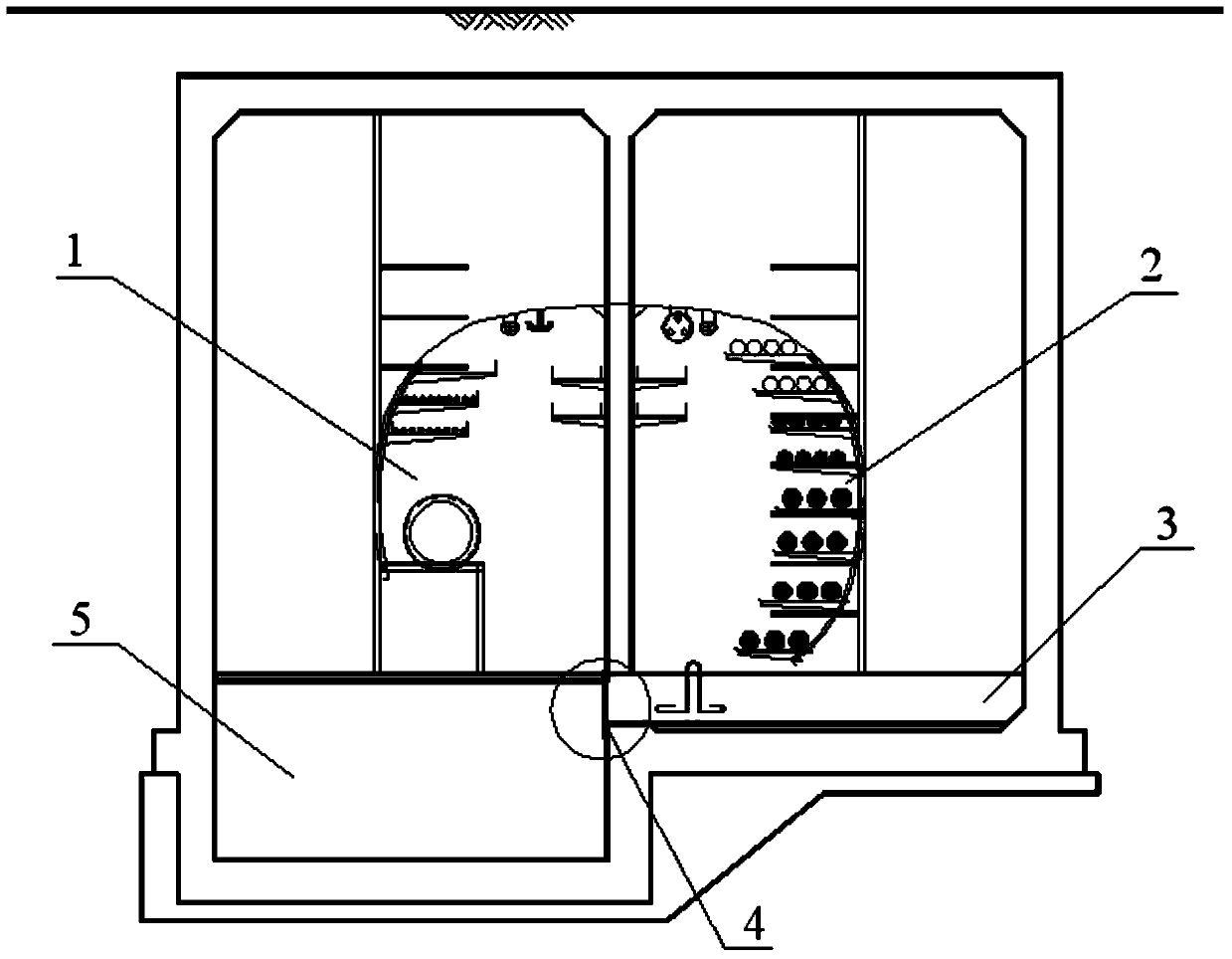

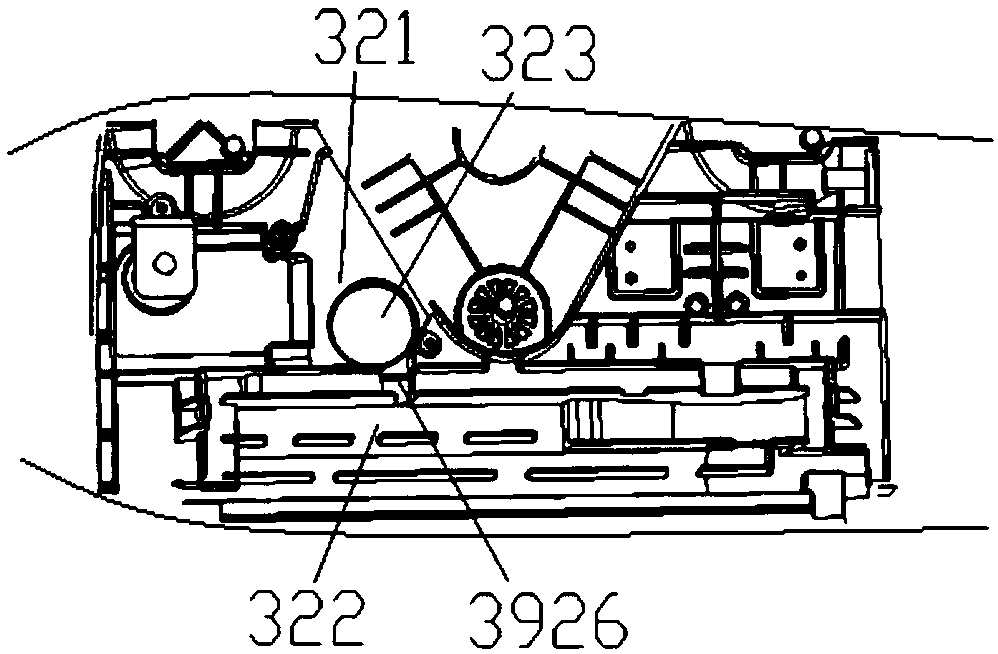

Middle-layer water receiving disc and mobile air conditioner with water receiving disc

PendingCN108507143AImprove drainageEasy dischargeCondensate preventionLighting and heating apparatusCofferdamEngineering

The invention provides a middle-layer water receiving disc and a mobile air conditioner with the water receiving disc. The middle-layer water receiving disc comprises a middle partition plate, the middle partition plate is obliquely arranged and provided with supporting ribs, water falling holes and a water drainage nozzle, the supporting ribs are provided with at least one flow guiding hole, theflow guiding holes are used for guiding condensate water to the water drainage nozzle, the water drainage nozzle is used for draining condensate water guided from the flow guiding holes, and the waterfalling holes are provided with cofferdams. According to the middle-layer water receiving disc, the middle partition plate is provided with the water falling holes and the water drainage nozzle simultaneously, the water falling holes have multiple modes, therefore, the water drainage function of the middle-layer water receiving disc is greatly improved, the probability that the condensate water is accumulated on the middle-layer water receiving disc is reduced, and the mobile air conditioner with the middle-layer water receiving disc has the good working performance.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

A kitchen and bathroom garbage and sewage treatment method and its integrated treatment device

ActiveCN103693817BAvoid new pollution problemsReduce dosageMultistage water/sewage treatmentWastewaterEngineering

The invention relates to a treatment method and device for kitchen wastes and wastewater. The treatment method comprises the following steps: (1) instantly filtering the kitchen wastewater and the smashed kitchen wastes to achieve solid-liquid separation; performing oil-water separation on the wastewater; instantly disinfecting toilet wastewater and filtering to achieve solid-liquid separation; (2) disinfecting the wastewater obtained after the oil-water separation of the kitchen wastewater, and further filtering the wastewater together with the wastewater obtained after the solid-liquid separation of the toilet wastewater. According to the integrated treatment device, a kitchen wastewater solid-liquid separation chamber and a toilet wastewater solid-liquid separation chamber are formed in a wastewater box, the kitchen wastewater solid-liquid separation chamber is connected with an oil storage chamber, and a solid-liquid separation filter box in the kitchen wastewater solid-liquid separation chamber is provided with a kitchen waste inlet. According to the treatment method and device, the discharge problem of household wastes and wastewater is solved from the source.

Owner:王凤蕊

Mobile air conditioner

ActiveCN109237630APlay a guiding rolePrevent backflowMechanical apparatusCondensate preventionEngineeringControl zone

The invention provides a mobile air conditioner, comprising a middle water pan and a chassis structure. The chassis structure comprises a water absorption zone, a water tank zone, a water fetching zone, a water level control zone, and also comprises a water retaining rib for isolating the water absorption zone from the water tank zone, and a convergence portion, arranged between the water fetchingzone and the water tank zone and being close to a convergence port of the water fetching zone. A water fetching wheel is disposed on the convergence portion. Cooperation of the middle water pan and the chassis can improve the water fetching efficiency of the water fetching wheel, and a water guiding path of the water fetching zone is reasonably planned.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

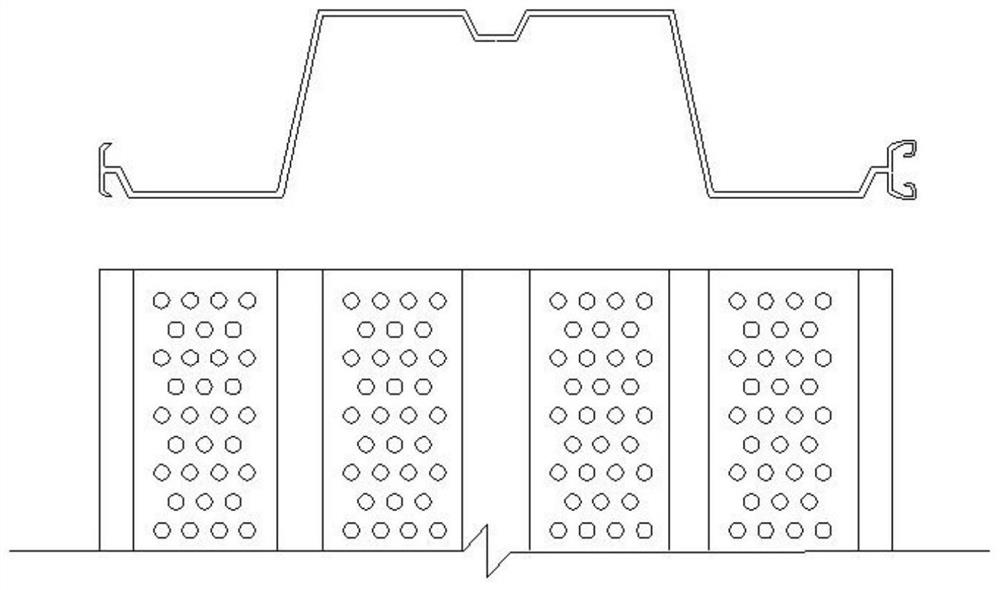

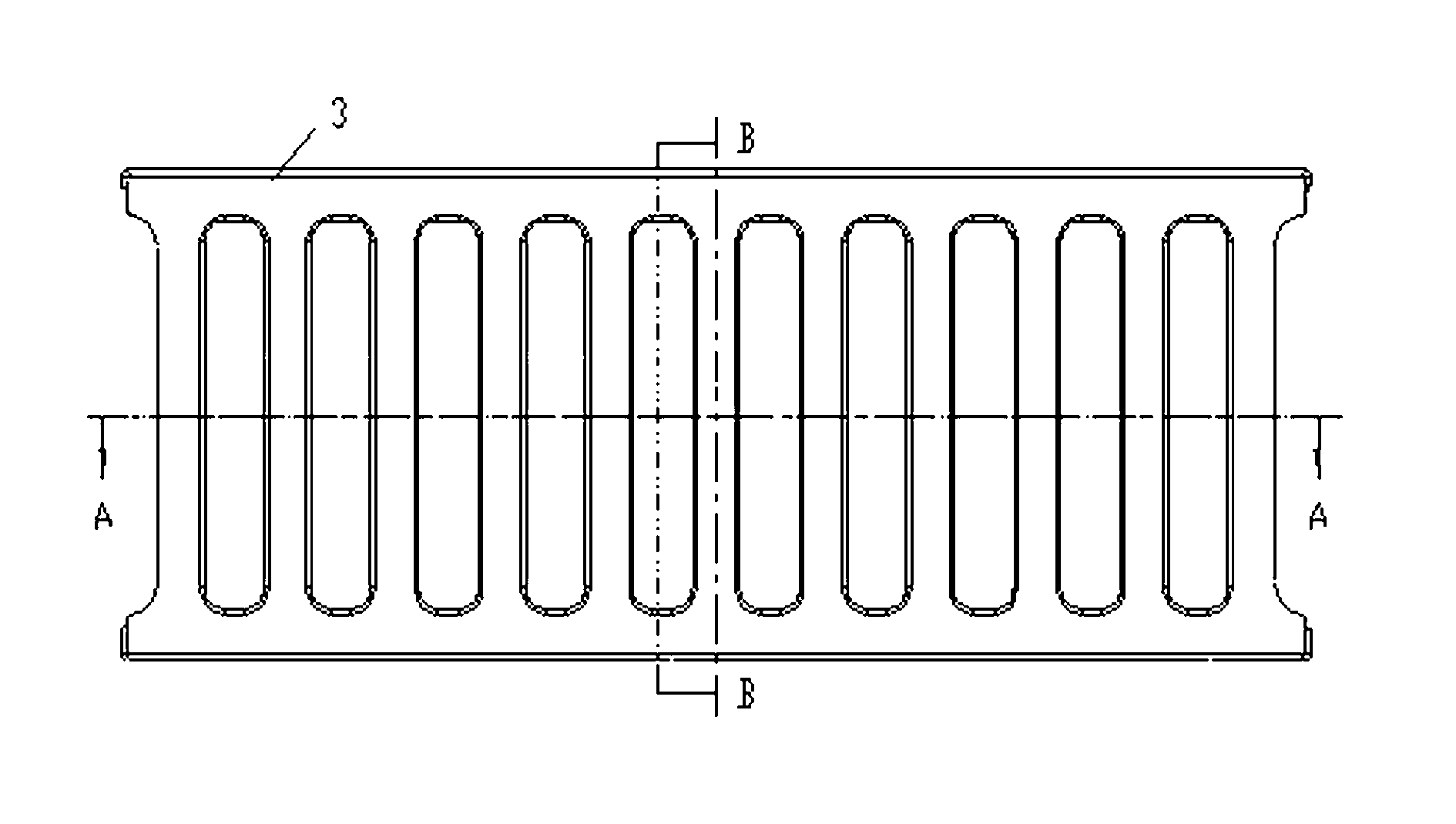

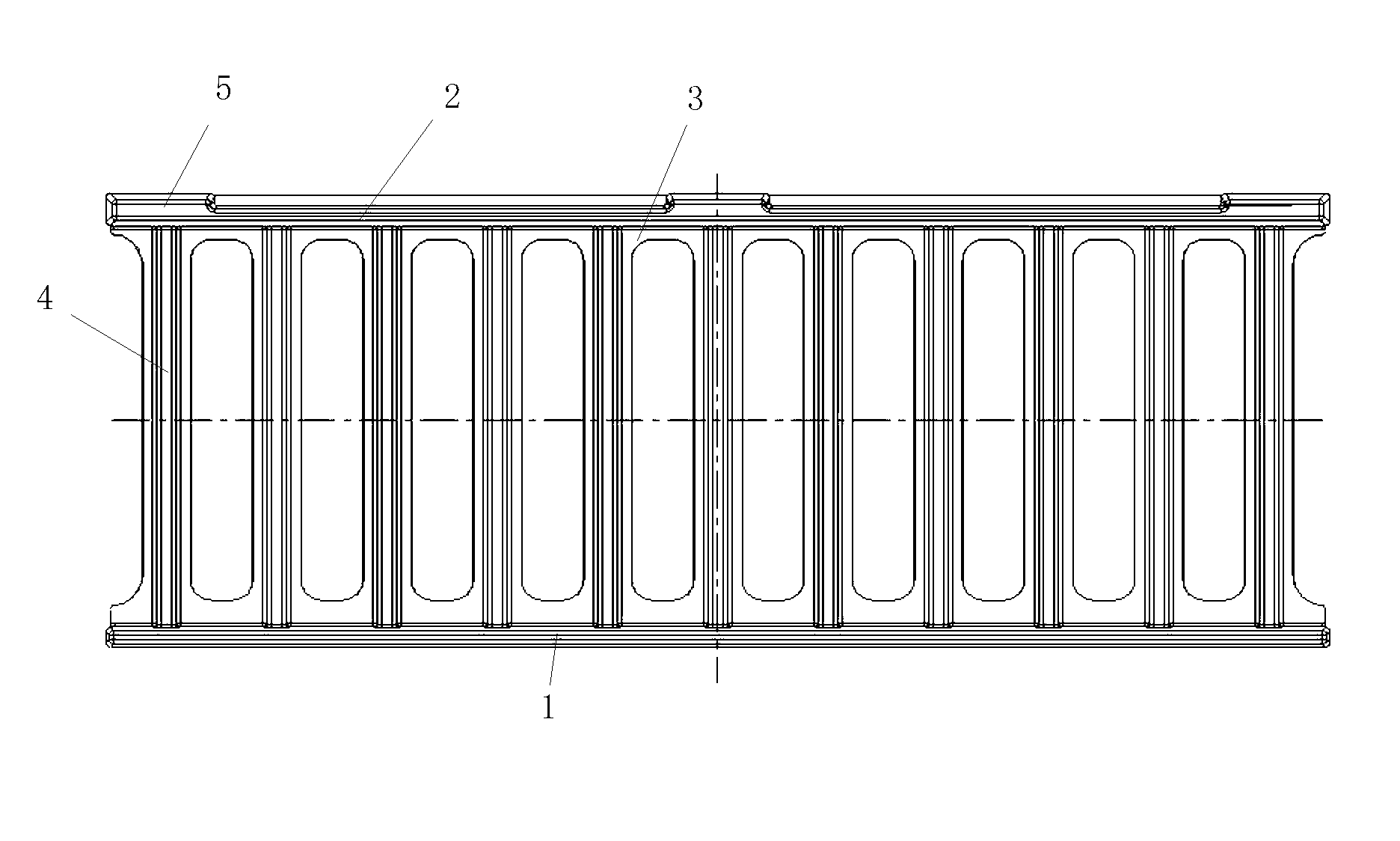

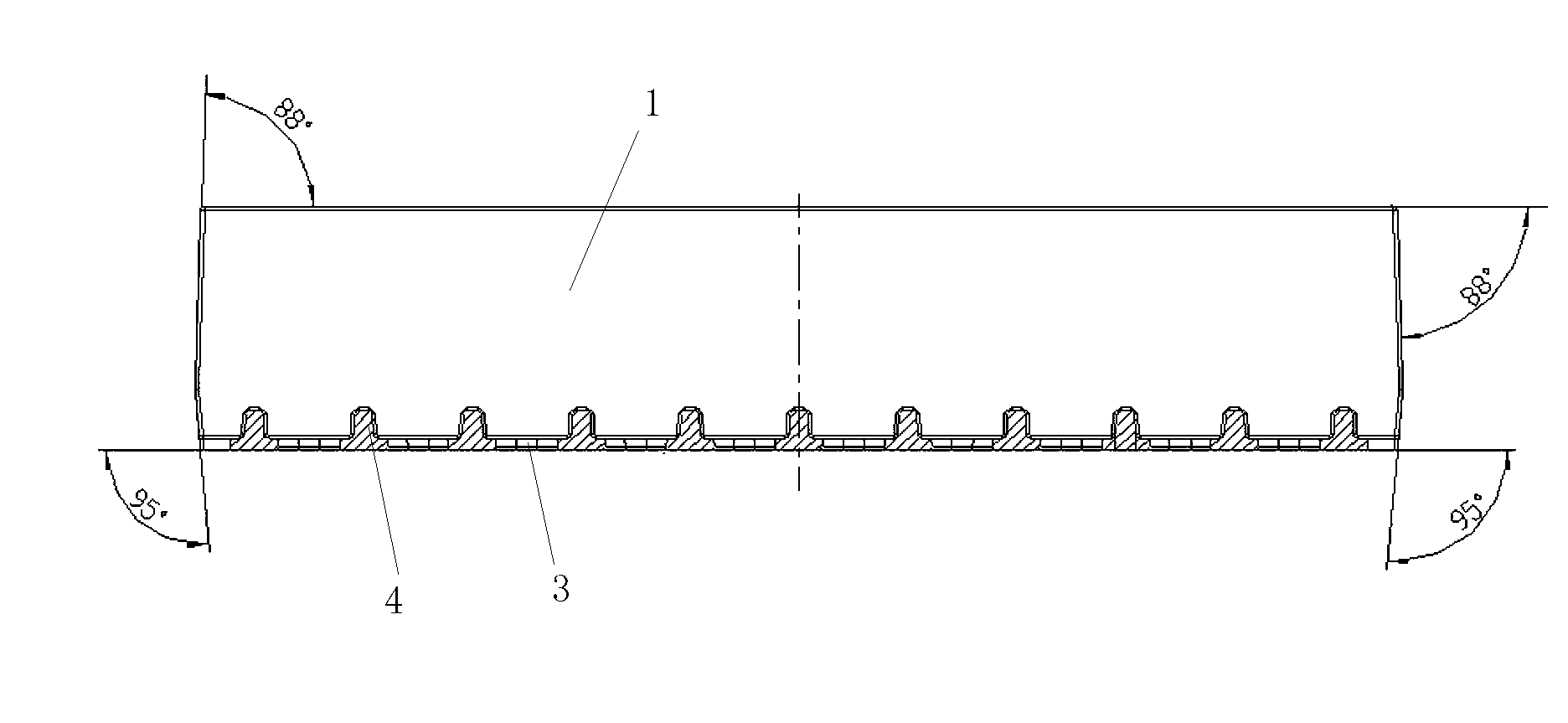

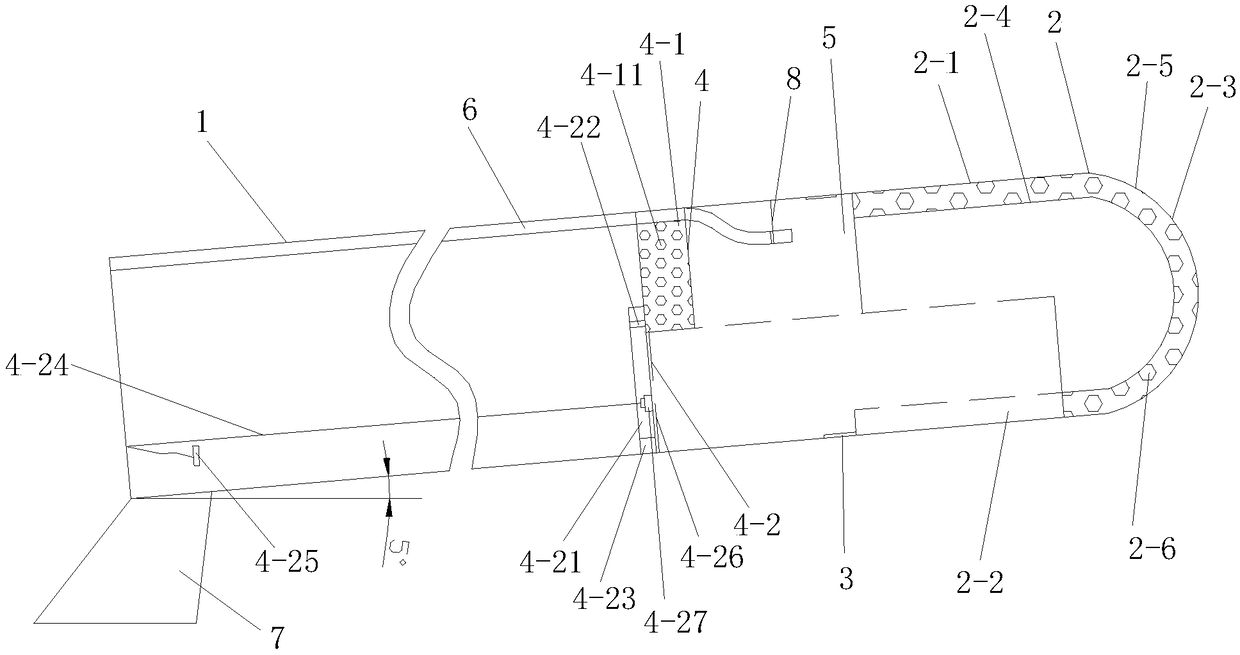

Tunnel ditch cover plate

ActiveCN103046640AIncrease water collection capacitySolve drainage problemsSewerage structuresLayer thicknessDitch

The invention discloses a tunnel ditch cover plate which is characterized in that a first tooth root is arranged at the bottom of one side of the cover plate, and a second tooth root is arranged at the bottom of the other side of the cover plate. The tunnel ditch cover plate has the advantages of greatly improving water capacity of a pitch, effectively resolving the problem of tunnel water discharge without arranging an embedding part and a building block and facilitating construction. Simultaneously, the novel cover plate utilizes the pavement layer thickness part in a tunnel and does not affect a main body structure. System members are suitable for various tunnel structures. An opening cover plate and a fixed cover plate can be arranged at intervals for further maintenance, or only the opening cover plate is arranged to facilitate maintenance and dredging. The novel cover plate is stable and excellent in performance and capable of resolving the problem of sudden cover skipping.

Owner:上海城市交通设计院有限公司

Anti-blocking drainage pipe for muck side slope

ActiveCN108797611AAvoid cloggingSimple structureExcavationsSoil preservationEngineeringDrainage amount

The invention relates to the technical field of muck side slope drainage systems, in particular to an anti-blocking drainage pipe for a muck side slope. The anti-blocking drainage pipe for the muck side slope comprises a drainage pipe body which is obliquely arranged. The drainage pipe body is formed by connecting a plurality of drainage pipe sections end to end. A large-aperture filtering troughis arranged at the end of the drainage pipe body, a small-aperture filtering trough is arranged on the drainage pipe body, the small-aperture filtering trough is connected with the drainage pipe bodythrough connecting threads, the small-aperture filtering trough and the large-aperture filtering trough are arranged in a spaced mode, a hollow portion is formed between the small-aperture filtering trough and the large-aperture filtering trough, a water inlet pipe is arranged at the top of the inner wall of the drainage pipe body, and the water inlet pipe is fixed along the top of the inner wallof the drainage pipe body. The anti-blocking drainage pipe for the muck side slope is simple in structure, convenient to install and capable of meeting drainage requirements under the situation that the drainage amount is large or small, the drainage pipe can be effectively prevented from being blocked, the drainage pipe can be cleaned even under a blocking situation, and drainage efficiency is guaranteed.

Owner:SHENZHEN GEOTECHN INVESTIGATION & SURVEYING INST

Overhaul trench drainage ditch system with one well and two ditches and used for railway in city area

PendingCN110424512ASolve the problem of uneven laying and affecting personnel inspection operationsReduce the excavation depthSewerage structuresClimate change adaptationEngineeringWater well

The invention discloses an overhaul trench drainage ditch system with one well and two ditches and used for a railway in a city area. The overhaul trench drainage ditch system with one well and two ditches and used for the railway in the city area is characterized by comprising lateral drainage ditches (2), a pre-drainage transversal drainage pipe (3) and a water collection well (4), wherein the water collection well (4) is arranged between overhaul trenches (1) at the two transversal sides; the lateral drainage ditches (2) are arranged at one transversal side close to the water collection well (4), of the overhaul trenches (1) separately; and the lateral drainage ditches (2) communicate with the water collection well (4) through the pre-drainage transversal drainage pipe (3) separately, so that drainage for accumulated water in the overhaul trenches (1) is realized. The lateral drainage ditches (2) are full-length longitudinal slopes, and the longitudinal sections are W-shaped. According to the overhaul trench drainage ditch system, the problem of influence on the polling working of personnel due to uneven laying for cover plates of the drainage ditches in the actual engineering is solved by reducing the section dimensions of the lateral drainage ditches, cancelling the cover plates of the drainage ditches, and omitting the later-period maintenance expense for the cover platesof the drainage ditches.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

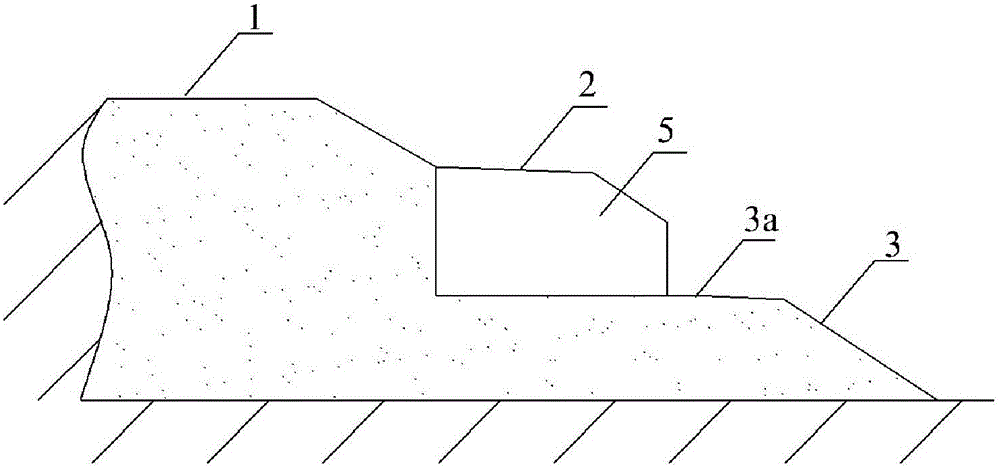

A shoulder widening method for existing railway embankment

A shoulder widening method of an existing railway embankment, the steps of which are: A. On the shoulder of the railway embankment and on the embankment slope outside the road shoulder, excavate at equal intervals along the longitudinal direction of the line for placing the transverse direction of the unit "┥" shaped component The transverse groove of the rib plate; the inner end of the transverse groove is located at the junction of the road shoulder and the ballast bed; the length of the transverse rib plate is equal to the width of the widened new road shoulder; The slope platform for placing the longitudinal panels of the unit "┥"-shaped components; C. Place the transverse ribs of the unit "┥"-shaped components in the transverse grooves, and place the longitudinal panels on the slope platform; D. On the inner side of the longitudinal panel and on both sides of the transverse rib, backfill the soil layer by layer and tamp it until the soil is flush with the road shoulder to form a widened new road shoulder. By using this method to widen the road shoulder, the stability of the subgrade soil is high, the disturbance to the soil is small, the amount of masonry is small, the construction period is short, and the cost is low.

Owner:SOUTHWEST JIAOTONG UNIV

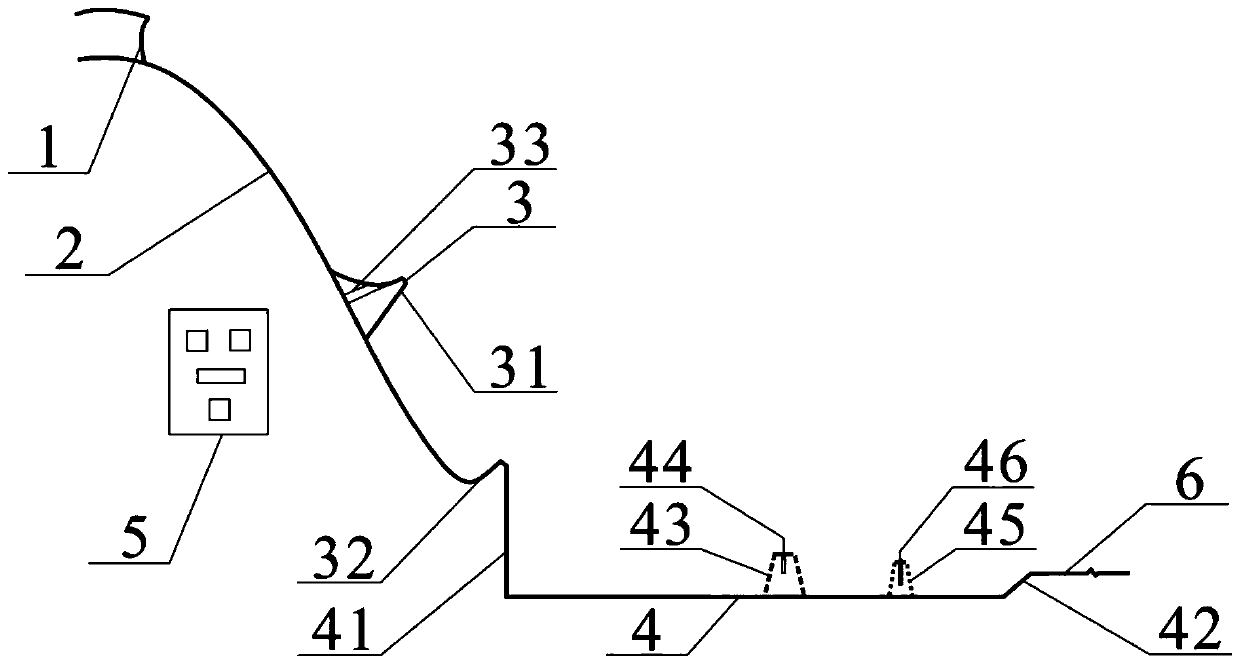

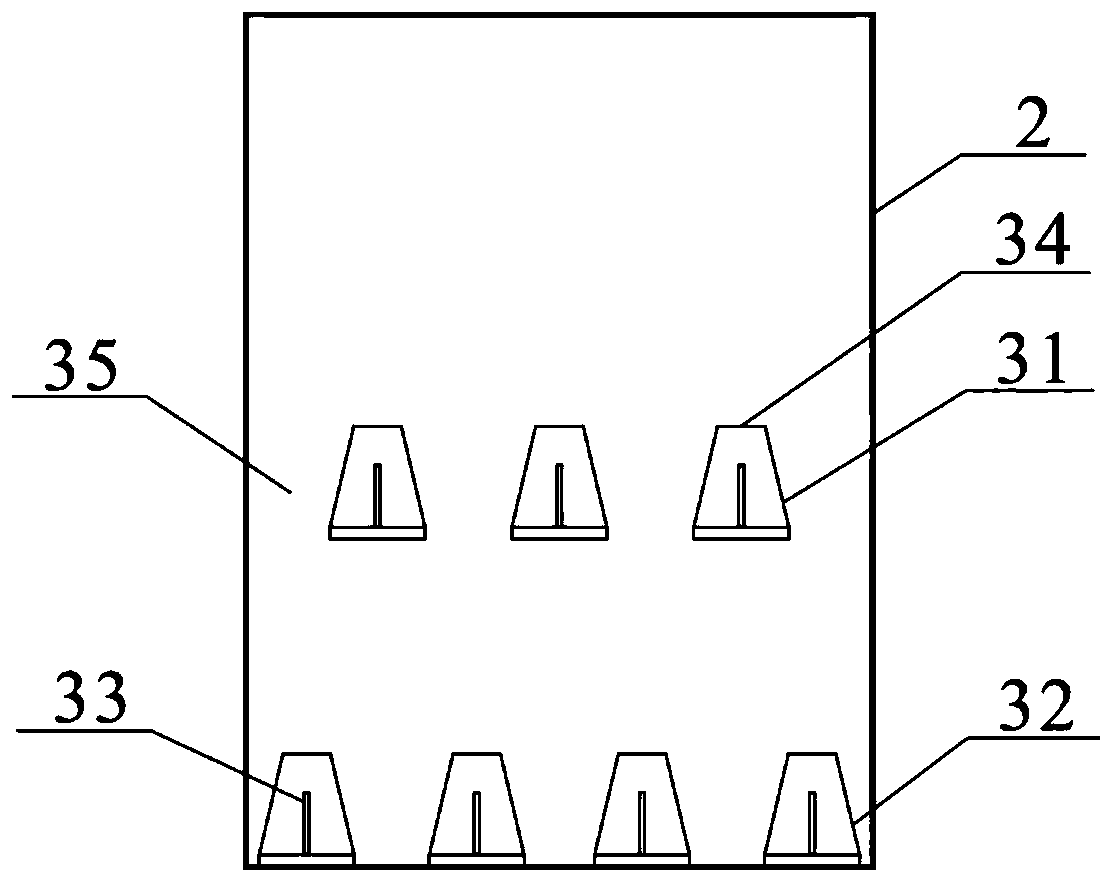

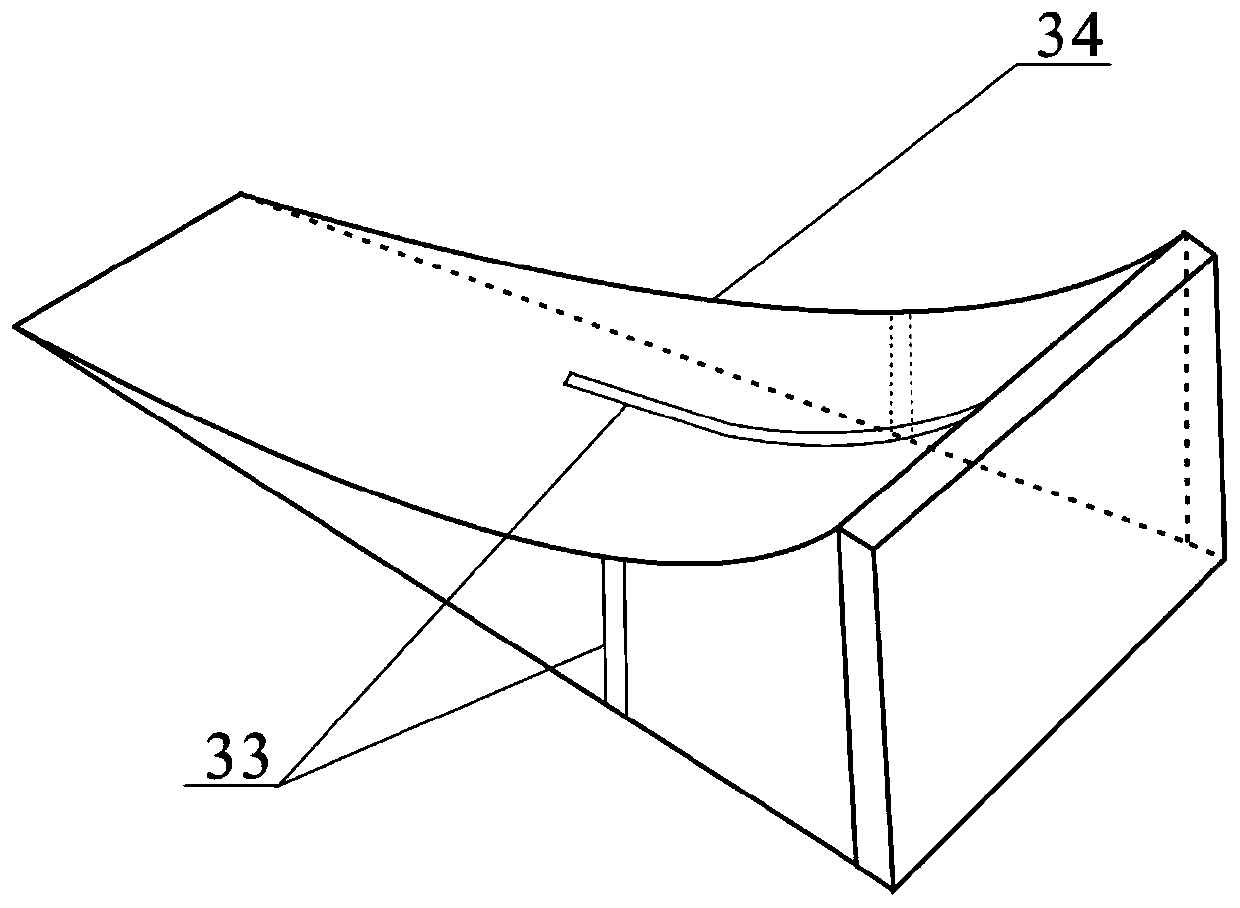

Differential type high and low sill deflecting energy dissipator-high sill type stilling pool system and energy dissipation method

The invention discloses a differential type high-low threshold trajectory bucket energy dissipater-high-drop-threshold type stilling pool system and an energy dissipation method, and relates to the technical field of high-dam flood discharge energy dissipation. The system comprises a differential type high-low threshold trajectory bucket energy dissipater, a high-drop-threshold type stilling pooland an intelligent control unit. According to the differential type high-low threshold trajectory bucket energy dissipater, the longitudinal separation, the transverse expansion and the air collisionenergy dissipation of discharged water flow are realized; the high-drop-threshold type stilling pool is used for carrying a water tongue which enters in the form of an oblique impact jet flow, the jetflow generates the mixed flow state which submerges the jet flow and a hydraulic pump transition in the high-drop-threshold type stilling pool, and the energy is greatly dissipated; and the intelligent control unit is used for controlling the working state of the high-drop-threshold type stilling pool by analyzing the signals of a water level sensor. The collision energy dissipation is carried out through trajectory bucket collision, turbulence shearing, turbulence diffusion and submerging of the hydraulic jump, so that the energy dissipation effect is remarkably improved, and the scouring ofhigh-speed discharge water flow to a downstream riverbed is reduced; and meanwhile, the length of the stilling pool is shortened, an apron is not needed to be arranged at the bottom of the stilling pool, and the construction cost is reduced.

Owner:ANHUI UNIV OF SCI & TECH

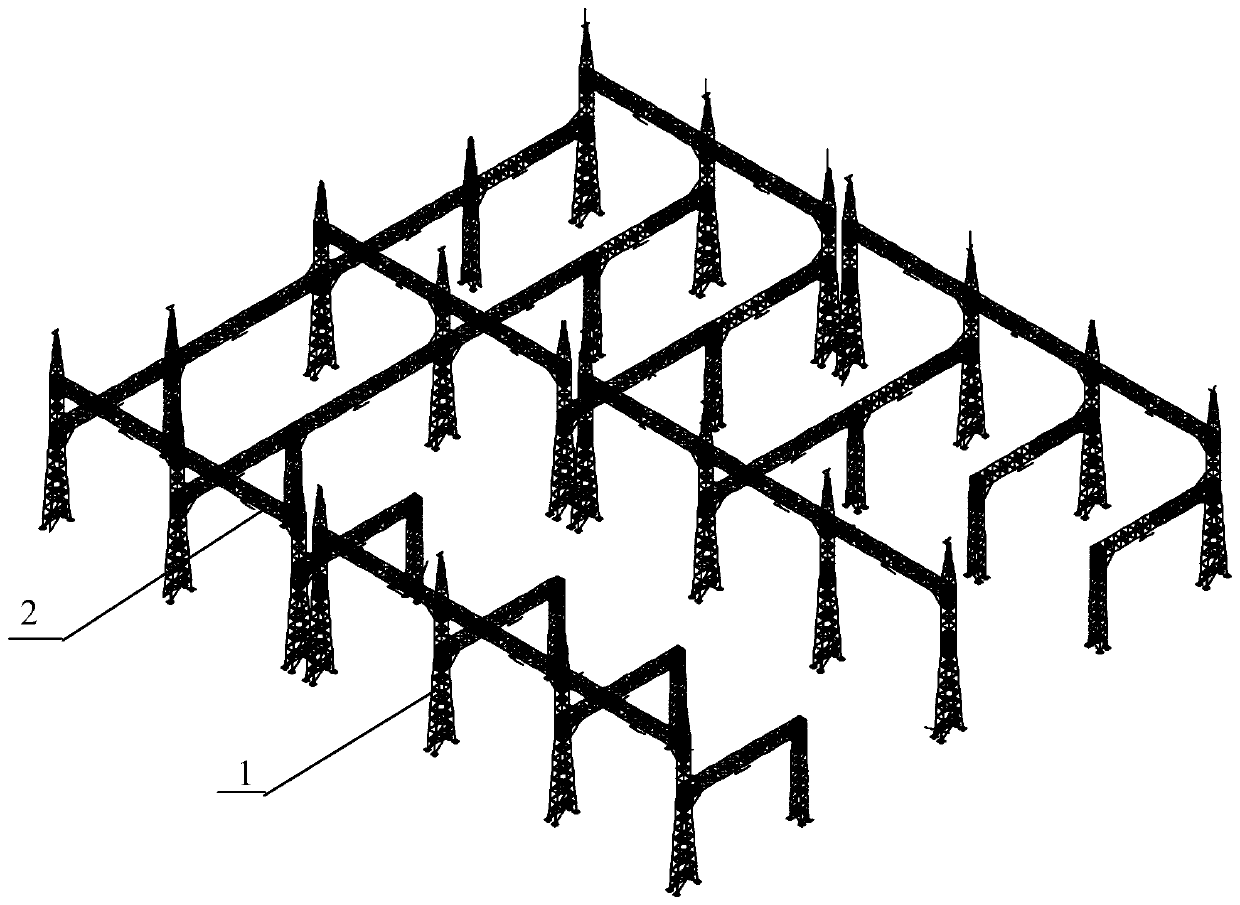

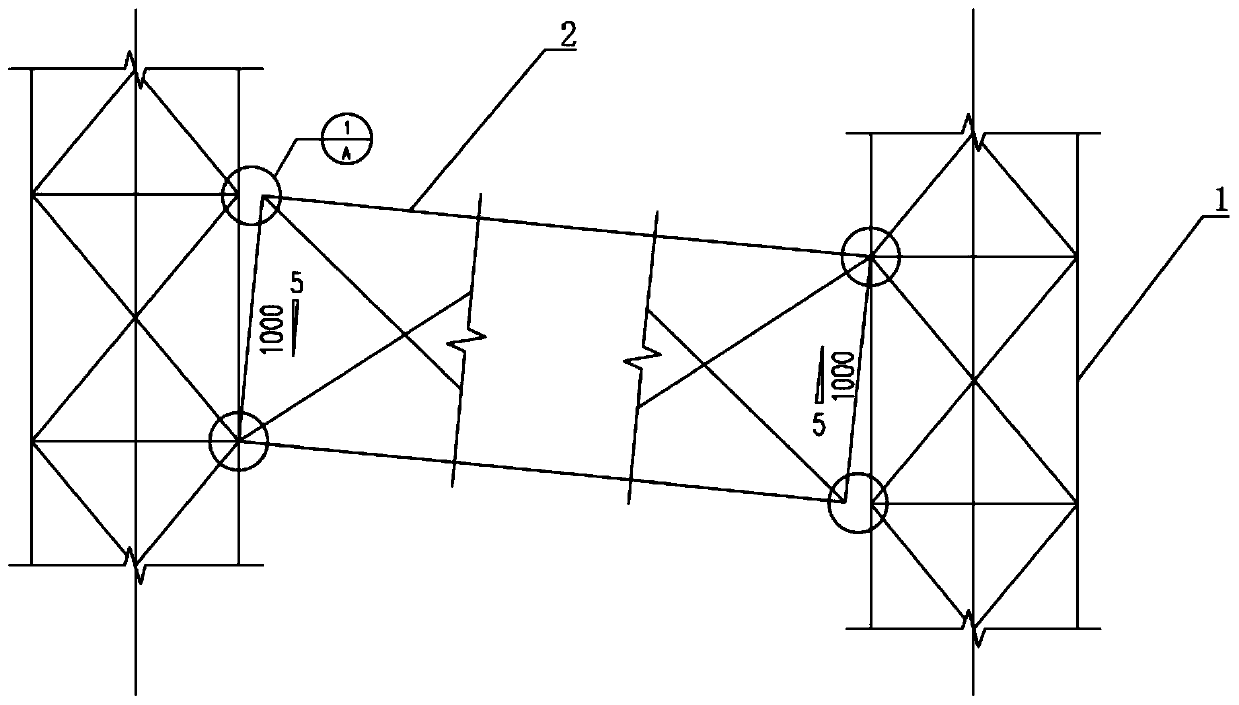

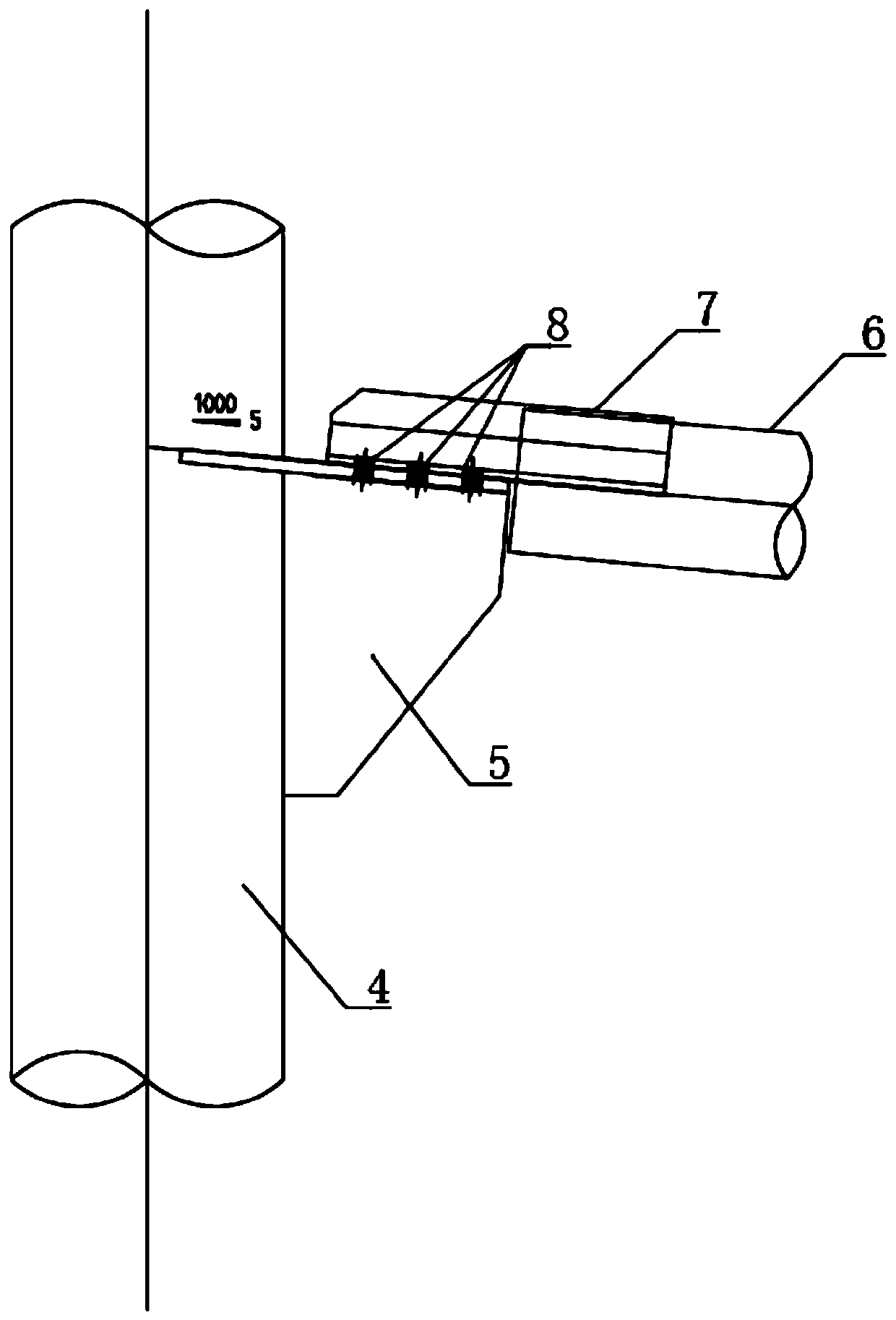

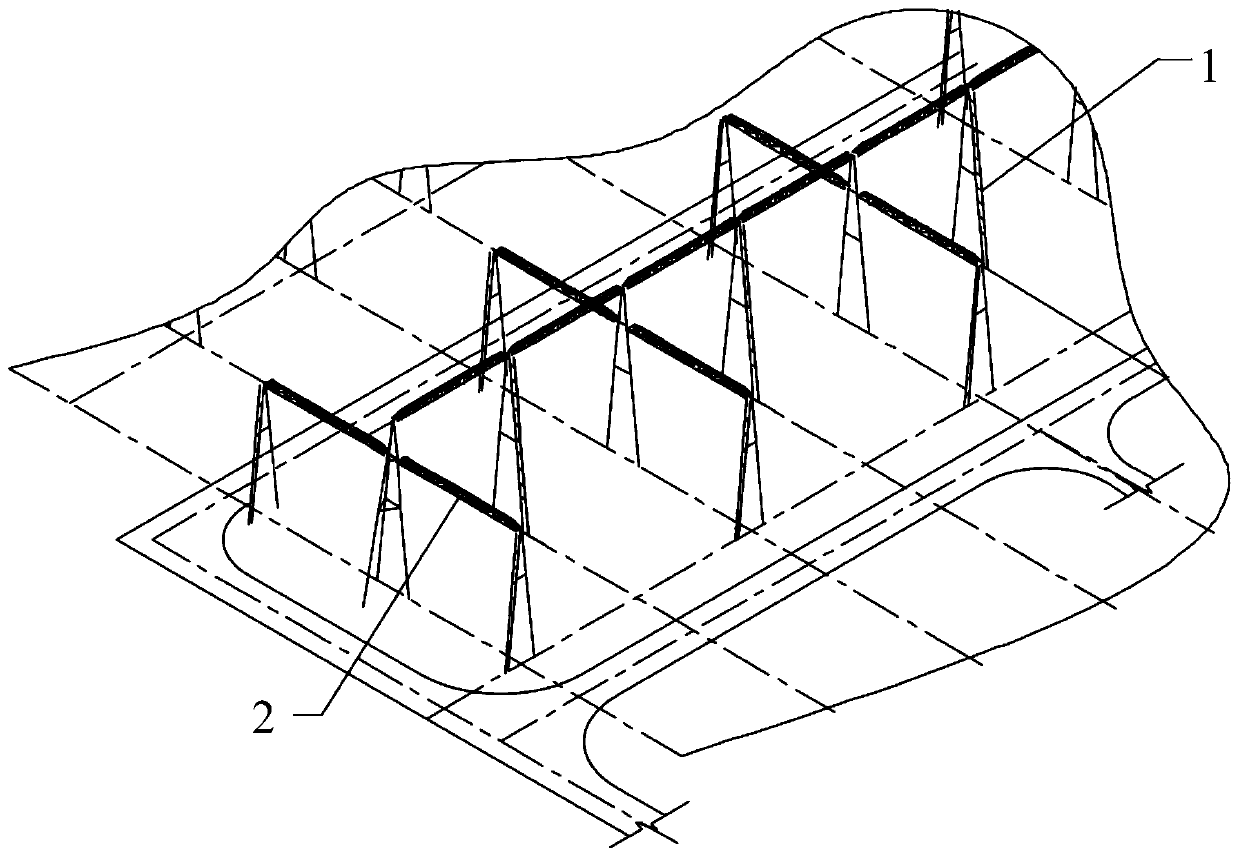

750 kV framework structure suitable for large-gradient site

PendingCN110905266AReduce cut and fillMeet drainage requirementsTowersEconomic benefitsStructural engineering

The invention discloses a 750 kV framework structure suitable for a large-gradient site, and belongs to the technical field of electric power project extra-high-voltage direct-current transmission. The 750 kV framework structure comprises multiple framework columns. The bottom ends of all the framework columns are buried at the same depth relative to the surface of the site, and at least one framework beam is arranged between every two adjacent framework columns. The two ends of all the framework beams are assembled on the every two adjacent framework columns through beam and column joints correspondingly, the straight line direction where all the framework beams are located is parallel to the inclination direction where the gradient of the site is located, and therefore the purposes thatthe requirements of electrical engineering for charged distances are met, the joints are convenient to mount, and good economic benefits are achieved are achieved.

Owner:国网新疆电力有限公司建设分公司 +2

Secondary sedimentation tank dross filtration device

InactiveCN105536305AAvoid running into the sinkEffective blockingSettling tanks feed/dischargeSedimentation settling tanksWater tanksFiltration

The invention discloses a secondary sedimentation tank dross filtration device. The secondary sedimentation tank dross filtration device comprises a water tank, a baffle and a drainage pipe and is characterized in that the water tank is formed by a bottom plate and side plates in a welded mode, the baffle is connected to the outer side of the water tank through cross braces, the water tank is arranged inside the baffle, the upper edges of the side plates are located between the upper edge and the lower edge of the baffle, and the water tank and the drainage pipe are connected and welded together. The secondary sedimentation tank dross filtration device has the advantages that dross is effectively prevented from entering the water tank, and thus the quality of drained water is improved.

Owner:山东金昊三扬环保机械有限公司

220kV framework structure suitable for large slope site

PendingCN110905265AReduce cut and fillMeet drainage requirementsTowersStructural engineeringPower engineering

The invention discloses a 220kV framework structure suitable for a large slope site, and belongs to the technical field of extra-high voltage alternating current transmission of electric power engineering. The 220kV framework structure comprises a plurality of framework columns, wherein the bottom ends of the framework columns are buried at the same depth relative to the surface of the site, at least one framework beam is arranged between every two adjacent framework columns, the two ends of each framework beam are assembled on the two corresponding adjacent framework columns through levelingsupports, the framework beams are in a horizontal state to meet the requirements of electrical wiring and can be adjusted according to different site slopes, and the 220kV framework structure has goodeconomic benefits.

Owner:国网新疆电力有限公司建设分公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com