Patents

Literature

44results about How to "Guaranteed road performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

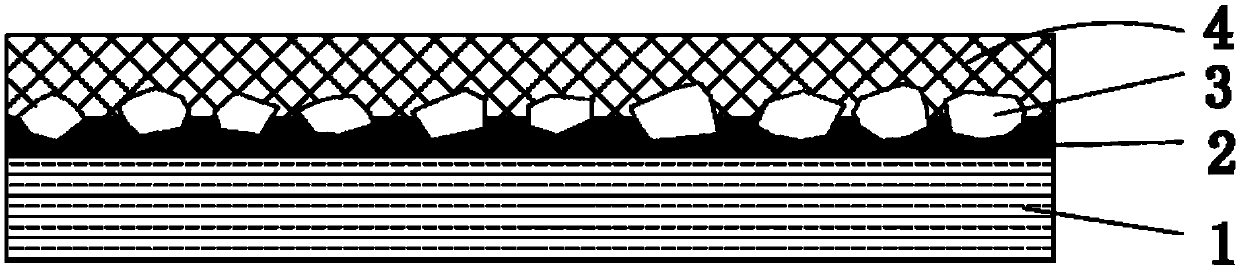

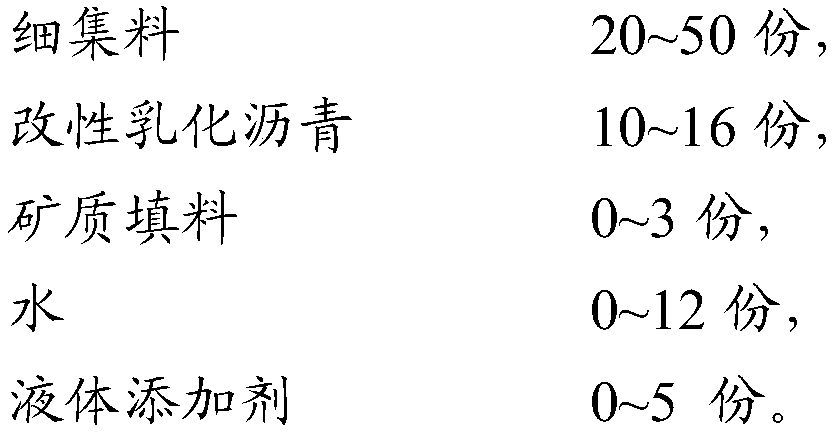

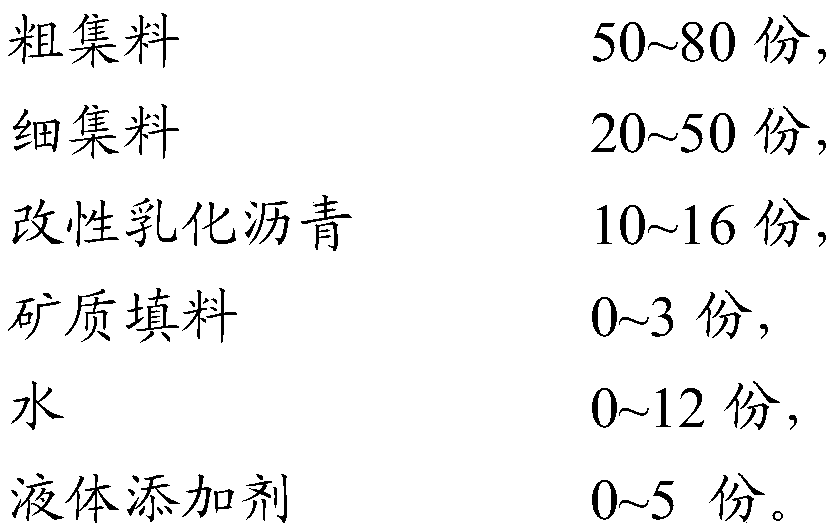

Cold-mixed and cold-laid asphalt mixture, and cold-mixed and cold-laid asphalt mixture wearing layer

ActiveCN108129073AImprove bonding effectReduce driving noiseIn situ pavingsPitch blendeHigh resistance

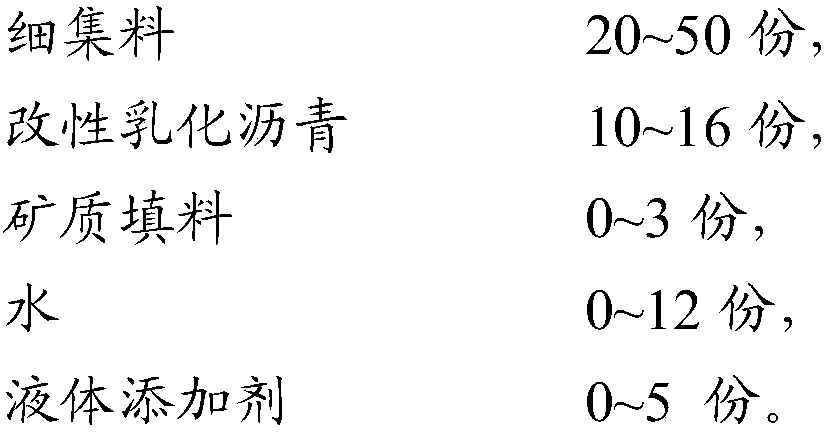

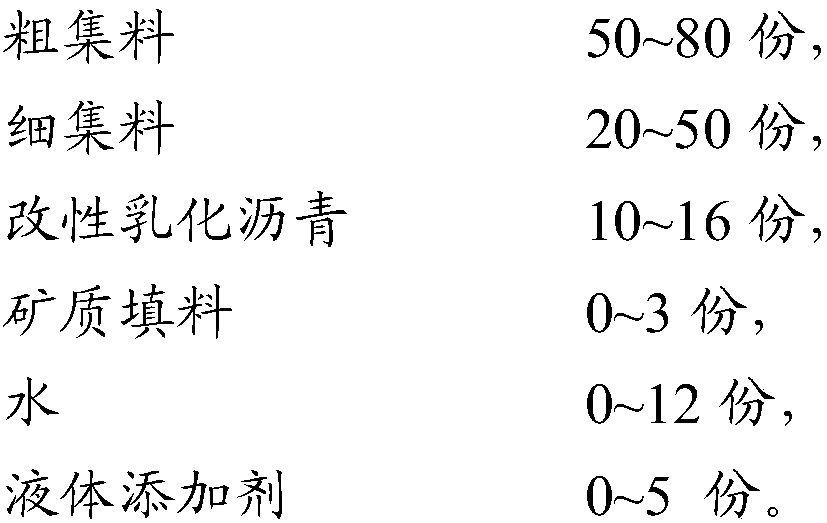

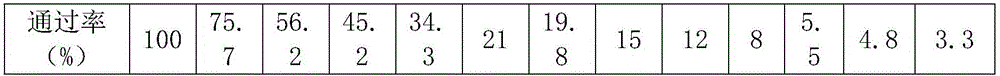

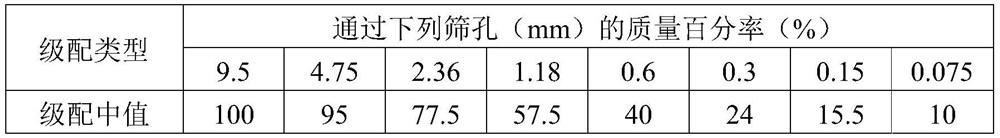

The invention provides a cold-mixed and cold-laid asphalt mixture, and a cold-mixed and cold-laid asphalt mixture wearing layer, and belongs to the technical field of road engineering. The cold-mixedand cold-laid asphalt mixture comprises coarse aggregates, fine aggregates, high-performance modified emulsified asphalt, a mineral filler, water and a liquid additive. The asphalt mixture prepared from above cold-mixed and cold-laid material components according to a special mineral grading range can be closely bonded to an old asphalt pavement and a cement pavement; and compared with traditionalmicro-surfacing and super-sticky wearing layer materials, the mixture has higher resistance to crack, water and skid and lower driving noises.

Owner:SOUTH CHINA UNIV OF TECH +1

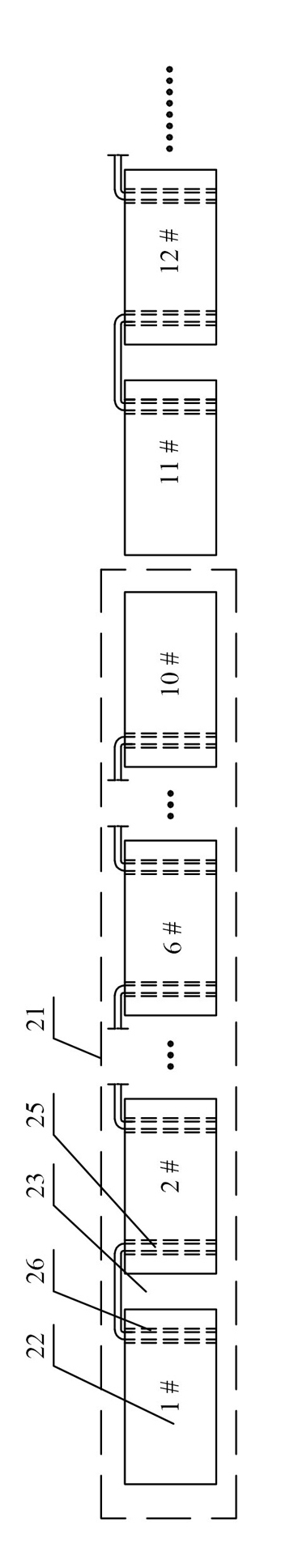

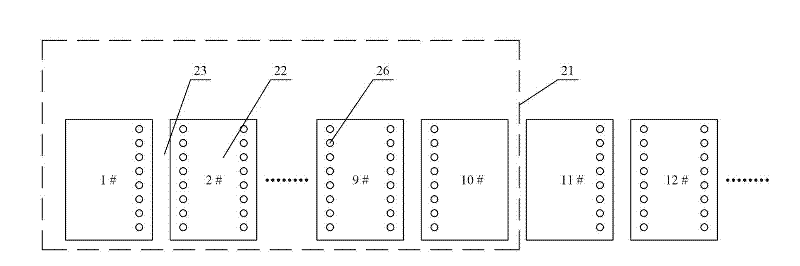

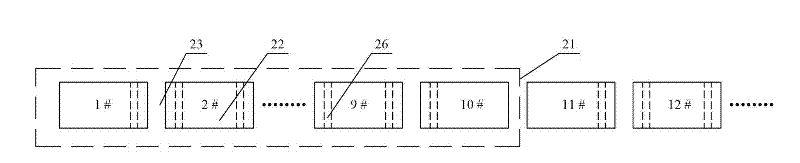

Hot recycling method of asphalt mixing materials and hot recycling device of asphalt mixing materials

InactiveCN102677570AShorten mixing timeGuaranteed adhesionRoads maintainenceAsphaltConstruction aggregate

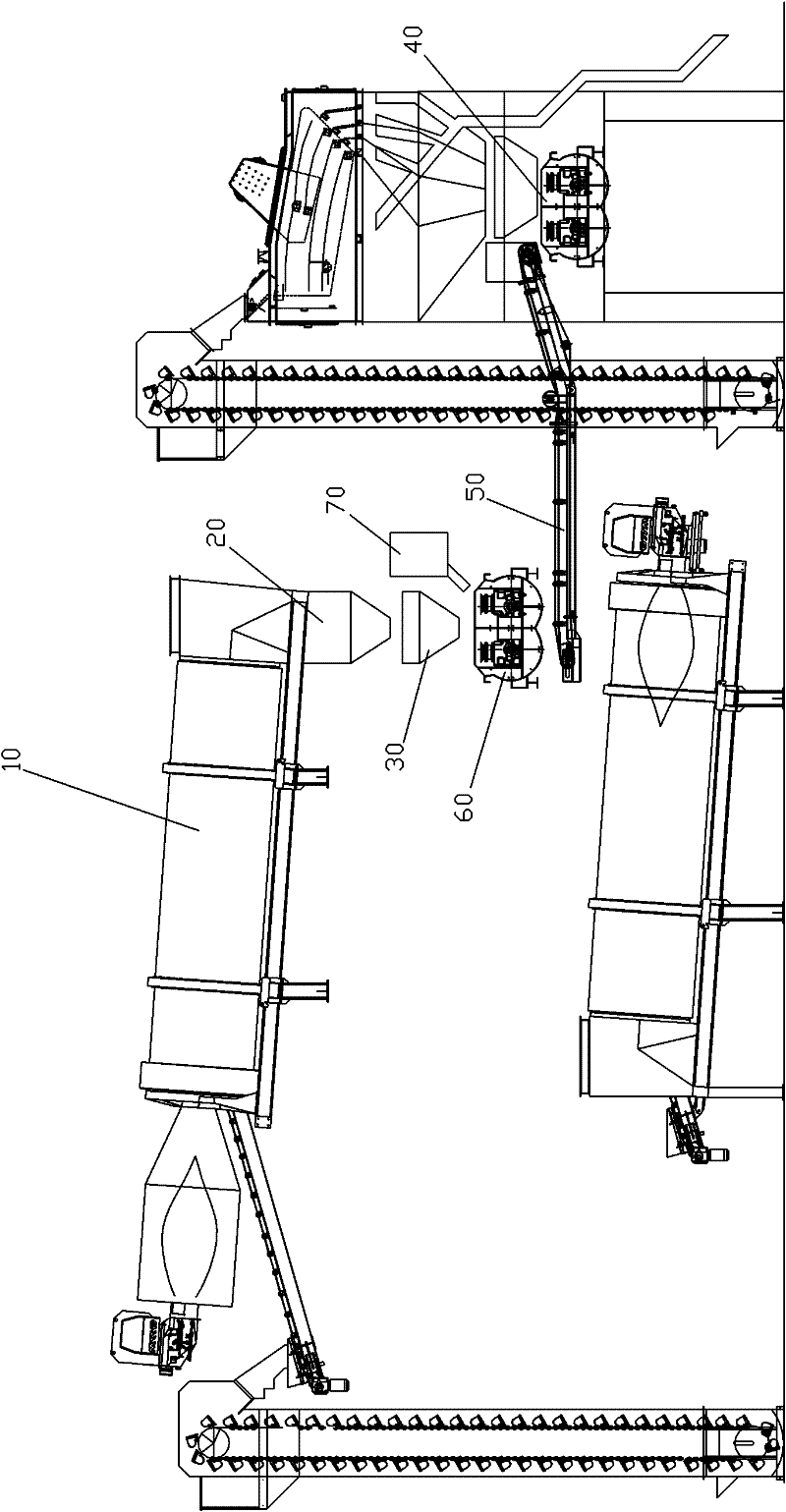

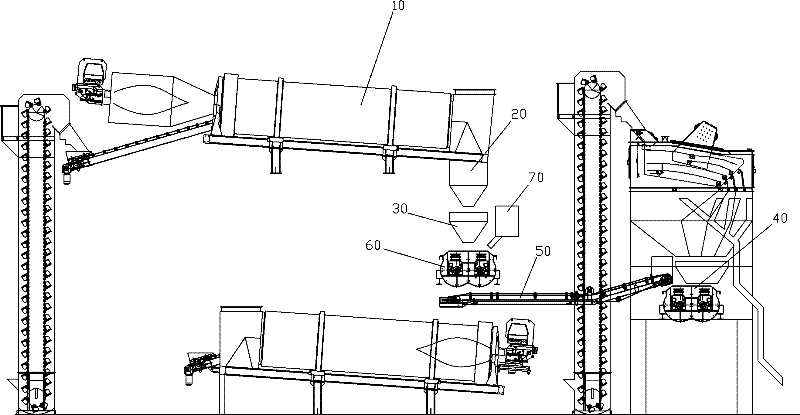

Provided are a hot recycling method of asphalt mixing materials and a hot recycling device of asphalt mixing materials. The hot recycling method comprises the following steps: pretreating and calculating new stone powder; pretreating and calculating new asphalt; pretreating and calculating new construction aggregates, pretreating and calculating waste asphalt, placing the calculated waste asphalt into a secondary stirring cylinder, placing reclaiming agents into the secondary stirring cylinder, and evenly stirring the waste asphalt and the reclaiming agents; and placing the waste asphalt evenly mixed with the reclaiming agents and the calculated new stone powder, new asphalt and construction aggregates into a primary stirring cylinder and evenly stirring the mixture. Compared with the prior art, the waste asphalt is firstly placed in the secondary stirring cylinder to be evenly mixed with the reclaiming agents before the waste asphalt is placed in the main stirring cylinder, accordingly, the reclaiming agents and the waste asphalt are evenly mixed in advance, the stirring time of the main stirring cylinder is shortened, and production capacity of the whole device is improved.

Owner:FUJIAN TIETUO MACHINERY

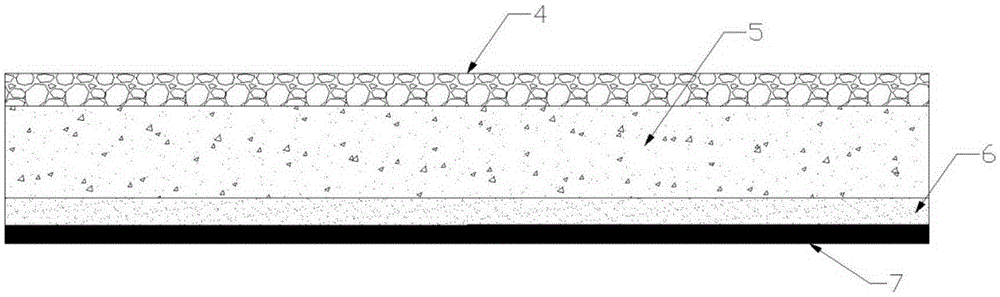

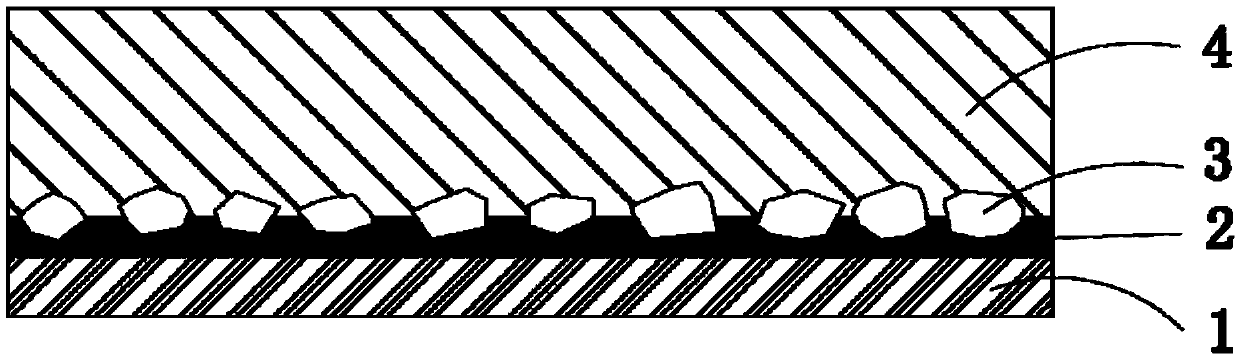

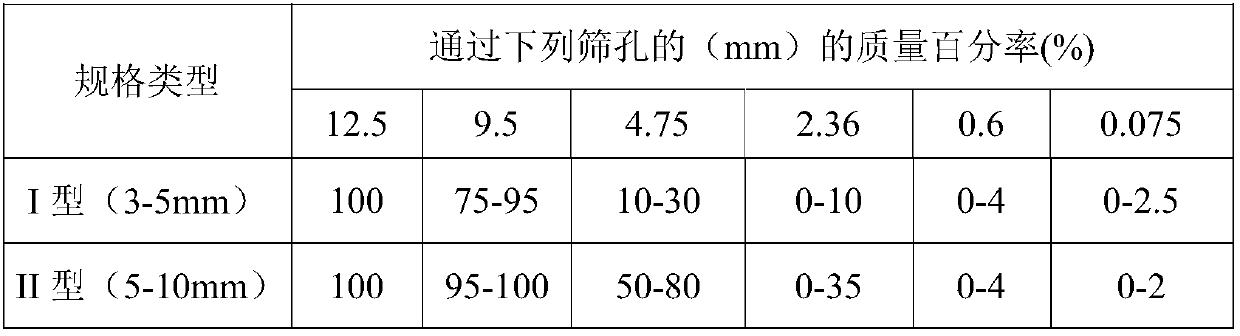

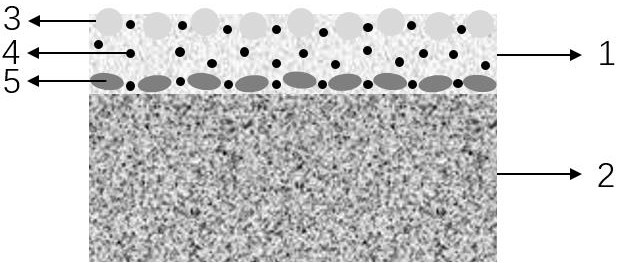

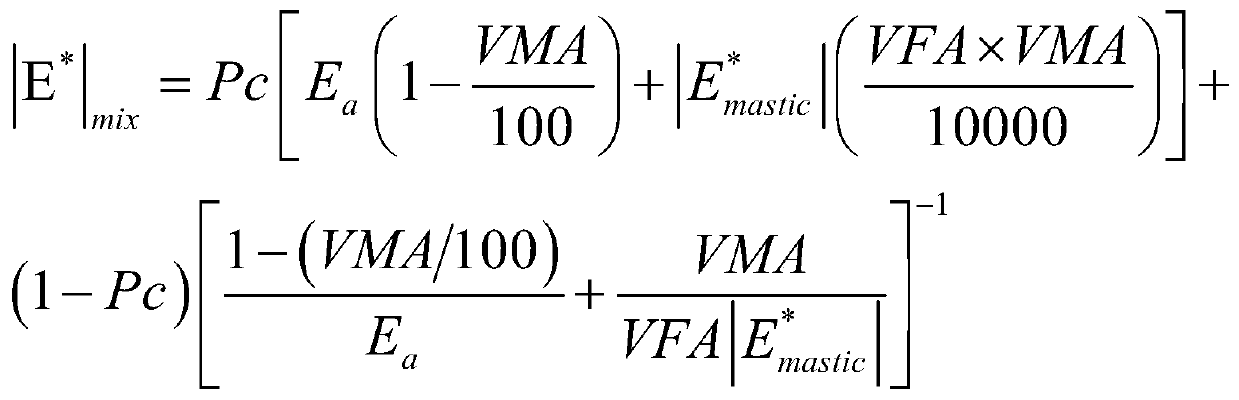

Electric-conduction anti-skid wearing layer for pavement and preparation method thereof

ActiveCN105256694AReduce deliveryLow priceNon-macromolecular adhesive additivesPaving detailsFiberCarbon fibers

The invention discloses an electric-conduction anti-skid wearing layer for a pavement and a preparation method thereof. An electric-conduction carbon fiber cloth layer (6) is arranged on a heat-insulation bonding layer (7) and is provided with a broken basalt protection layer (5); and the broken basalt protection layer (5) is provided with a black corundum metalling layer (4), and is integrally 7mm-9mm in thickness. The electric-conduction anti-skid wearing layer has high heating efficiency, and is suitable for deicing and snow melting on the pavements in winter. The electric-conduction carbon fiber cloth layer is thin integrally, and is constructed at normal temperature, thus having the advantages of flexible construction; and the electric-conduction anti-skid wearing layer is suitable for deicing and snow melting on the pavements in winter, so that the driving safety on the pavements is improved.

Owner:HUNAN ZHITONG ENG TECH CO LTD +1

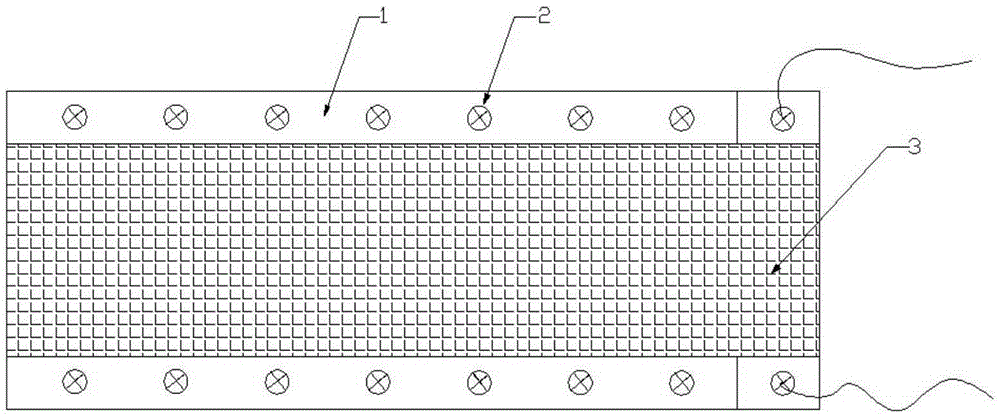

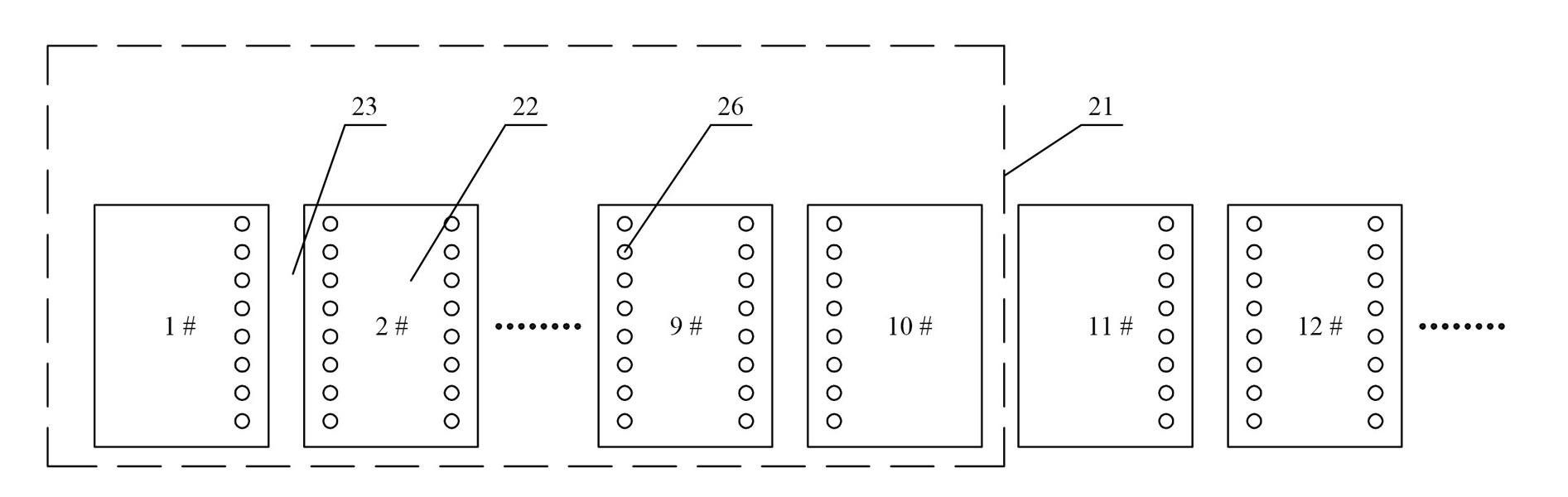

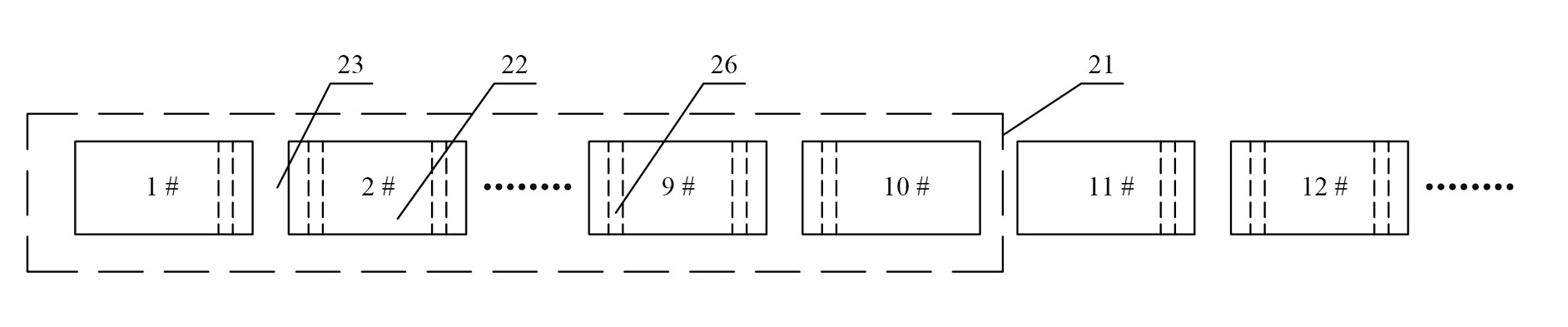

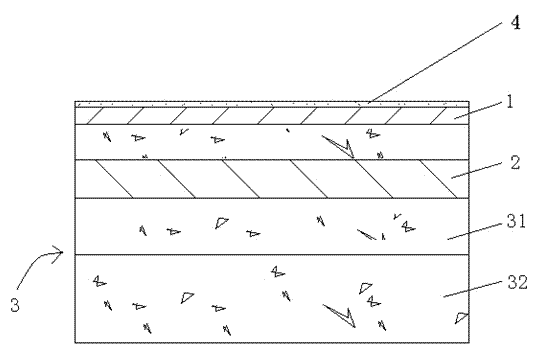

Composite pavement structure and construction method thereof

InactiveCN102031744AReduce reflection cracksGuaranteed road performance and service lifeIn situ pavingsSingle unit pavingsReflective crackCement mortar

The invention discloses a composite pavement structure and a construction method thereof. The composite pavement structure comprises an upper asphalt concrete finishing coat and a lower old cement concrete slab layer, wherein the slab layer comprises a plurality of old cement concrete slab connection groups; and each connection group is formed by connecting a plurality of old cement concrete slabs by means of connecting parts arranged at the joints of the old cement concrete slabs. The construction method of the composite pavement structure comprises the following steps: firstly determining the connection type in the road section to be reconstructed based on the plan; secondly determining the arrangement type of rake nails at the joints; thirdly drilling rake nail holes corresponding to the rake nails in terms of quantity and space on the edges of the old cement concrete slabs at the two sides of the joints; fourthly implanting the rake nails and pouring epoxy cement mortars into the rake nail holes to fix the rake nails; fifthly sprinkling water to cover the old cement concrete slabs to cure and form the old cement concrete slab layer; and finally paving the asphalt concrete finishing coat on the old cement concrete slab layer, thus obtaining the composite pavement structure. The composite pavement structure has the advantages of good economical efficiency, obvious reflection crack resistance effect, good road property, long service life and the like, and is convenient for construction.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

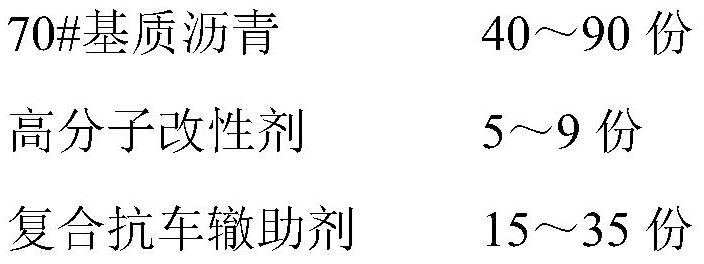

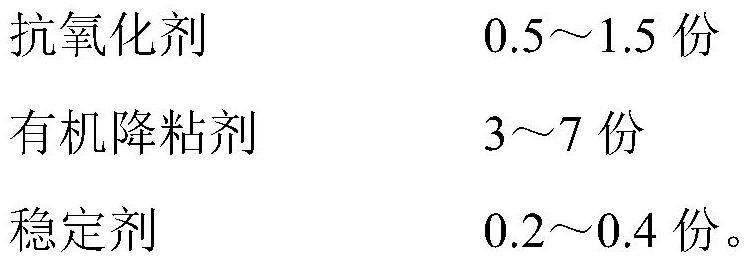

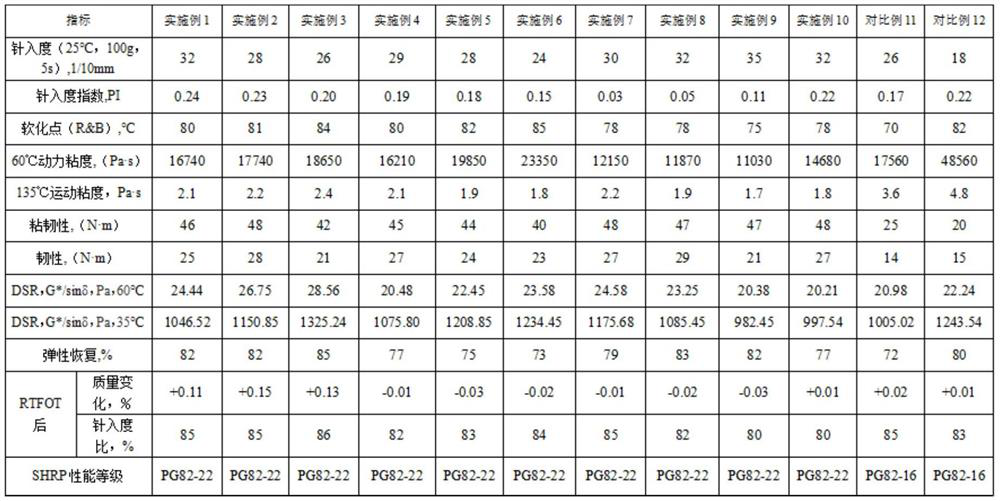

High-strength modified asphalt and preparation method thereof

ActiveCN112608607AImprove high temperature performanceLow viscosityBuilding insulationsPetroleum resinAsphalt

The invention relates to high-strength modified asphalt and a preparation method thereof. The high-strength modified asphalt comprises the following components in parts by weight: 40-90 parts of 70# matrix asphalt, 5-9 parts of a polymer modifier, 15-35 parts of a composite anti-rut aid, 0.5-1.5 parts of an antioxidant, 3-7 parts of an organic viscosity reducer and 0.2-0.4 part of a stabilizer. Different from existing single rock asphalt modification with a large mixing amount, composite modification has the characteristics that on the premise of reducing the mixing amount of rock asphalt, other materials such as petroleum resin are used for compounding or replacing rock asphalt to improve the high-temperature performance of asphalt, and on the premise of guaranteeing the high-temperature performance of asphalt, the modified asphalt is stable in storage and not prone to depositing at the bottom of a tank or polluting a production pipeline, and the asphalt production quality is guaranteed.

Owner:JIANGSU SINOROAD TRANSPORTATION SCI & TECH CO LTD +1

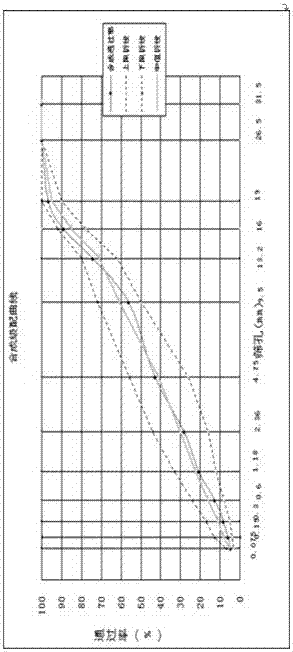

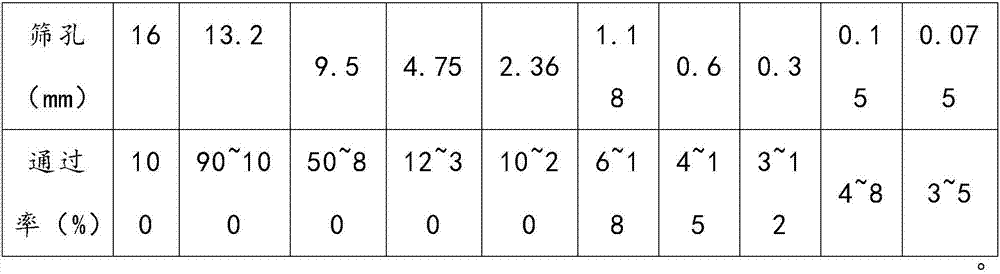

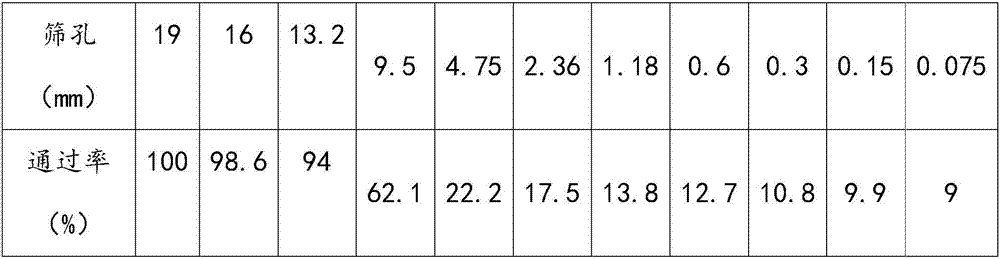

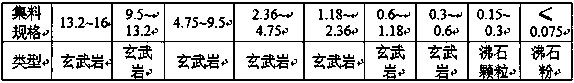

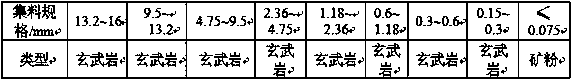

Drainage regenerated asphalt mixture and match ratio design method thereof

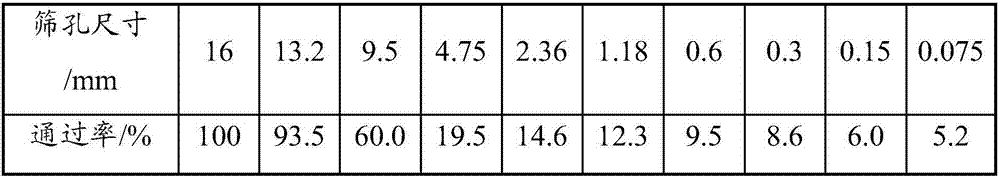

InactiveCN106904871ABlending ratio optimizationGuaranteed road performanceSolid waste managementFiberPolymer modified

The invention discloses a drainage regenerated asphalt mixture. The mixture comprises a recycled material, aggregate, padding, a fiber stabilizer and cutback asphalt, wherein the recycled material is formed by digging and milling a used drainage asphalt mixture on a pavement for more than ten years; the aggregate comprises coarse aggregate and fine aggregate; the coarse aggregate adopts basalt; the fine aggregate adopts limestone; the nominal maximum aggregate size of the aggregate is 13.2mm; the padding adopts lime stone dust; the fiber stabilizer adopts lignin fiber, basalt mineral fiber or mixed fiber of the lignin fiber and the basalt mineral fiber; the mixing amount of the fiber stabilizer is 0.1 to 0.6 percent of the mass of the drainage regenerated asphalt mixture; the cutback asphalt adopts cutback polymer modified asphalt, and the mixing amount of the cutback asphalt is 4.8 to 7.6 percent of the mass of the drainage regenerated asphalt mixture. The invention further discloses a match ratio design method of the drainage regenerated asphalt mixture. The match ratio design method ensures that the blending ratio of the recycled material is optimized while guaranteeing the pavement performance of the drainage asphalt mixture.

Owner:SHANGHAI PUDONG ROAD & BRIDGE CONSTR +1

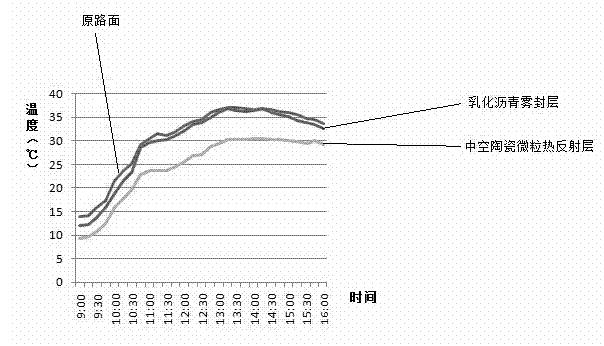

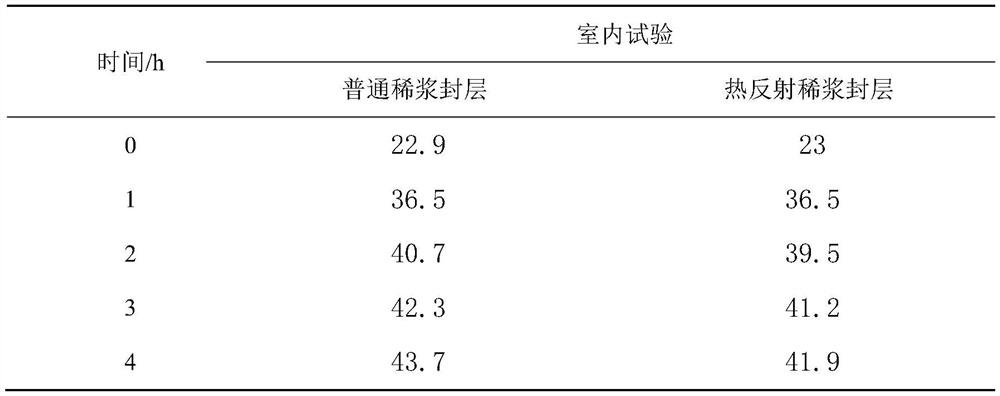

Heat reflection fog sealing layer material, and anti-rut pavement structure for high temperature heavy duty conditions

ActiveCN104846714AReduce road surface temperatureSimple recipeIn situ pavingsCeramic particlePitch blende

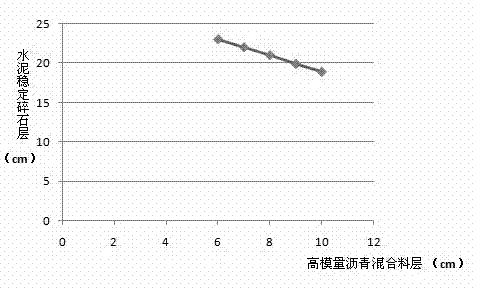

The invention discloses an anti-rut pavement structure of a heat reflection fog sealing layer material for high temperature heavy duty conditions. The structure is made by mixing 0.5-3 parts by mass of hollow ceramic particles with 7-9.5 parts by mass of emulsified bitumen. The anti-rut pavement structure of the heat reflection fog sealing layer material for high temperature heavy duty conditions sequentially comprises an upper surface layer, a medium lower surface layer and a base layer; and the upper surface layer is an SMA-13 bitumen mixture layer, the medium lower surface layer is an HMAC-20 high modulus bitumen mixture layer, the base layer is an LSAM large particle size bitumen mixture layer and a cement stable crushed rock layer, and the surface of the upper surface layer is coated with the heat reflection fog sealing layer material.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

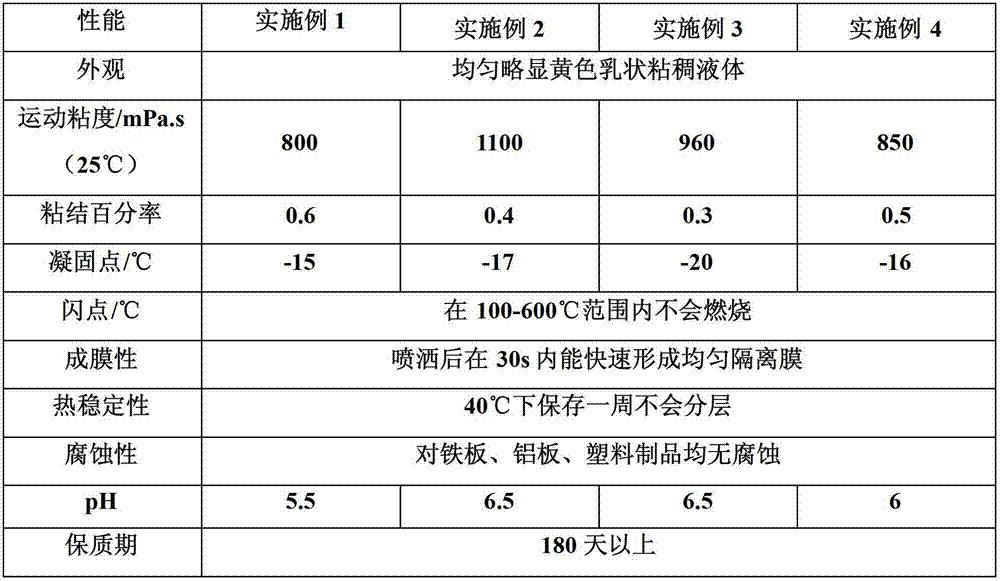

Asphalt concrete isolating agent for adhesion prevention of paver and transportation car hopper and preparation method thereof

ActiveCN102807818ANo damageGuaranteed road performanceAnti-corrosive paintsPolyvinyl alcoholMaterial resources

The invention discloses asphalt concrete isolating agent for adhesion prevention of a paver and a transportation car hopper and a preparation method thereof, and belongs to the field of preparation of asphalt concrete isolating agents. The asphalt concrete isolating agent is prepared by mixing long-chained alkyl modified silicone fluid, monoethanolamine, triethanolamine, oleic acid, polyethylene alcohol solution, water and other additives. The isolating agent has performance such as high temperature and low temperature resistance, weather resistance, flame resistance, corrosion resistance, physiological inertia, good biological compatibility and the like. Due to the adoption of the isolating agent, the asphalt concrete can be prevented from adhering to a transportation vehicle hopper and a paver, so that the waste of the asphalt concrete can be greatly reduced, the cost of the labor and the material resource in the mixing, transportation and paving process can be saved, and the economical benefit is remarkable. The asphalt concrete isolating agent is a kind of novel energy-saving and environment-friendly asphalt concrete isolating agent.

Owner:SHANXI PROVINCIAL RES INST OF COMM

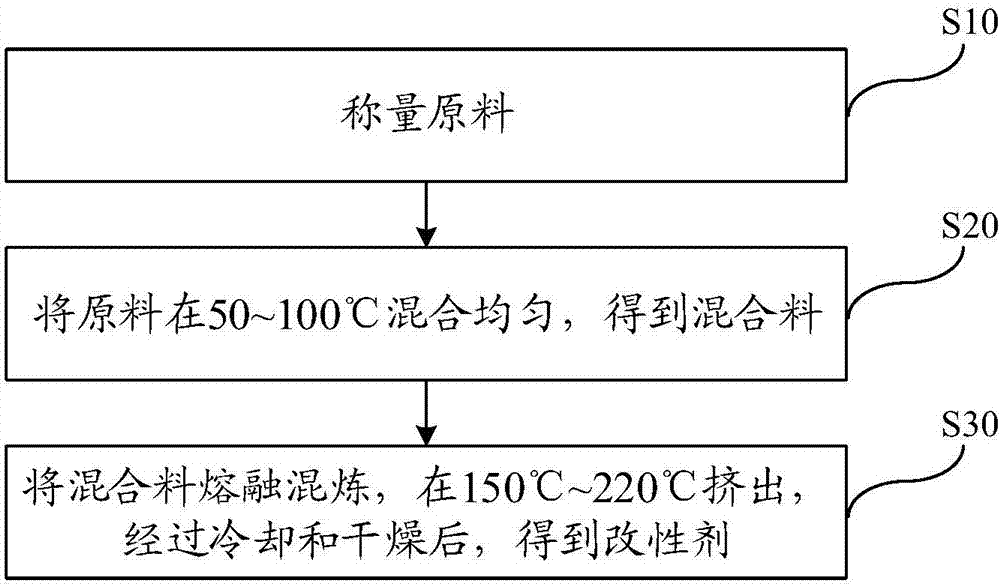

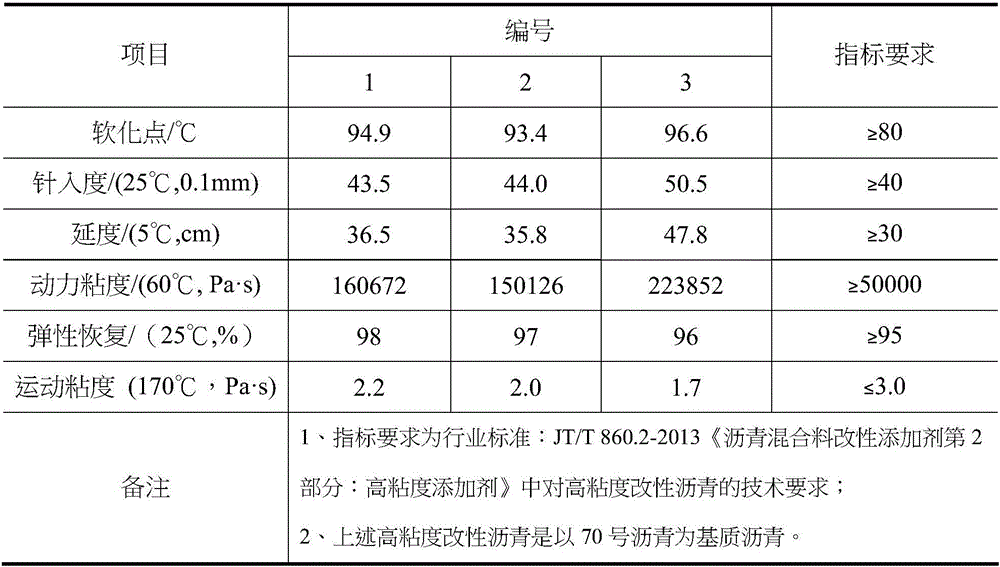

Modifier as well as preparation method and application thereof

InactiveCN107880576AGuaranteed high and low temperature performanceImproved melt dispersion propertiesBuilding insulationsPlasticizerAntioxidant

The embodiment of the invention discloses a modifier as well as a preparation method and application thereof. The modifier is prepared from the following raw materials in parts by weight: 40-80 partsof thermoplastic elastomer polymer, 10-30 parts of modified petroleum resin, 5-20 parts of thermally sensitive resin, 1-5 parts of a stabilizer, 5-20 parts of a plasticizer and 1-3 parts of an antioxidant. The thermoplastic elastomer polymer in the embodiment of the invention has an effect of enhancing and toughening the modifier, so that the high / low-temperature service performance of the modifier can be ensured; the modified petroleum resin has strongly polar groups and is matched with the thermoplastic elastomer polymer, so that the viscosity of asphalt at a service temperature can be obviously improved, and the pavement performance of the mixture is ensured; the thermally sensitive resin has the characteristic of excellent temperature sensitivity and is matched with the plasticizer andthe stabilizer, so that the applicable viscosity of the asphalt at a high temperature can be effectively reduced, and the construction workability of the mixture is improved; and moreover, since thehigh temperature viscosity is reduced, the melting dispersion characteristic of the modifier can be improved.

Owner:ROADMAINT CO LTD

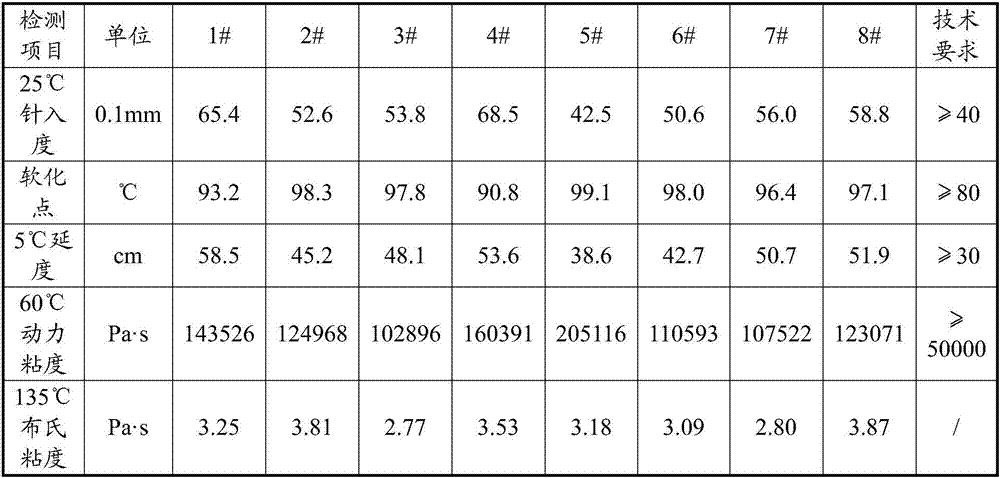

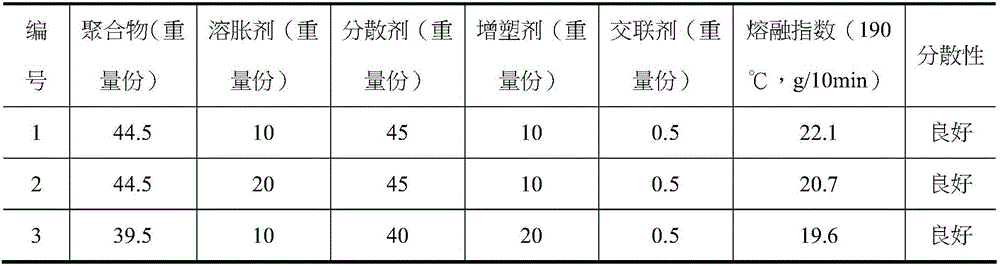

Ready-to-use high-dispersion high-viscosity modifier and preparation method thereof

InactiveCN106398248AGood dispersionGood high temperature stabilityBuilding insulationsPlasticizerReady to use

The invention provides a ready-to-use high-dispersion high-viscosity modifier and a preparation method thereof. The modifier comprises, by weight, 20-60 parts of polymer modifier, 5-10 parts of swelling agent, 20-45 parts of dispersing agent, 4-10 parts of plasticizer and 0.2-0.5 part of crosslinking agent. The method includes the following steps that first, the polymer modifier and the swelling agent are heated for 30-60 minutes at the temperature of 100 DEG C to be swelled to be in a flowing state, then the mixture is poured into the dispersing agent which is already heated to be in a flowing state, the plasticizer and the crosslinking agent are added, and then the mixture is sheared for 5-15 minutes through a high-speed shearing machine, wherein the rotating speed of the high-speed shearing machine is 1000-3000 r / min, and the temperature ranges from 140 DEG C to 180 DEG C; after completion, the mixture is poured into an evaporating vessel, then the evaporating vessel is put into a vacuum drying box of 120 DEG C to be kept warm for 1 h, and then the mixture is pulled into strips, extruded out and granulated through a single-screw extruder. The production cost is low, dispersion and evenness are excellent, the high-temperature stability of high-viscosity modified asphalt can be further improved, and social and economic benefits are remarkable.

Owner:福建省建筑科学研究院有限责任公司

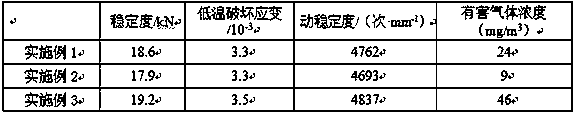

Low-odor rubber asphalt mixture used for road engineering

The invention discloses a low-odor rubber asphalt mixture used for road engineering. The mixture is prepared from the following components: 85-92 parts of aggregate, 1-3 parts of zeolite particles, 8-12 parts of zeolite powder, 4-8 parts of rubber asphalt, and 0.2-0.4 part of a warm-mixed additive. The mixture is prepared by the following steps: firstly preheating the aggregate, the zeolite particles and the zeolite powder to 160-170 DEG C, and performing heat preservation for 2-4 h; preheating the rubber asphalt to 145-155 DEG C; adding the aggregate and the zeolite particles sequentially into a mixing pot, performing mixing for 90 s at 150-155 DEG C, adding the warm-mixed additive and the rubber asphalt, performing mixing for 90 s, finally adding the zeolite powder, and continuing mixing for 90 s to obtain the finished product of the target mixture. According to the mixture provided by the invention, the zeolite is innovatively applied to the rubber asphalt mixture, the zeolite powder is used to replace mineral powder in an original mixture, the zeolite particles with a same particle size are used to replace aggregate with a corresponding specification in the original mixture, so that the content of the zeolite in the mixture is improved under the premise that road performance of the mixture is ensured, harmful gas is absorbed more effectively, and emission of the harmful gases during mixing and transportation of the rubber asphalt mixture is greatly reduced.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD +2

High-solid-content emulsified asphalt for stress absorbing layer, preparation method and construction method thereof

InactiveCN109535751AFix reflection cracksReduce construction proceduresIn situ pavingsRoads maintainenceChipsealColloid

The invention discloses a high-solid-content emulsified asphalt for a stress absorbing layer, a preparation method and a construction method thereof. The high-solid-content emulsified asphalt is prepared from ordinary asphalt, asphalt additive, emulgator, modifier, water and pH regulator; the solid content is 67-75%; the raw materials by weight percent are as follows: 50-70% of ordinary asphalt, 1-12% of asphalt additive, 0.2-3.0% of emulgator, 2.0-10.0% of modifier and the balance of water and pH regulator. The preparation method comprises the following steps: heating ordinary asphalt; addingasphalt additive into ordinary asphalt at a ratio and uniformly stirring, thereby acquiring a mixture of ordinary asphalt and asphalt additive; preparing emulgator into an aqueous solution, and thenadding modifier, thereby acquiring an emulgator liquid soup; using pH regulator for regulating pH value of the emulgator liquid soup, and then heating; successively putting the emulgator liquid soup and the mixture of ordinary asphalt and asphalt additive into a colloid mill, and then milling, thereby acquiring an end product of emulsified asphalt. According to the invention, a synchronous macadamseal coat vehicle is adopted for spraying / spreading emulsified asphalt and macadam; a 'prime coat and stress absorbing layer' effect can be achieved through once construction; construction process isreduced; construction cost is lowered.

Owner:山东高速建材集团有限公司

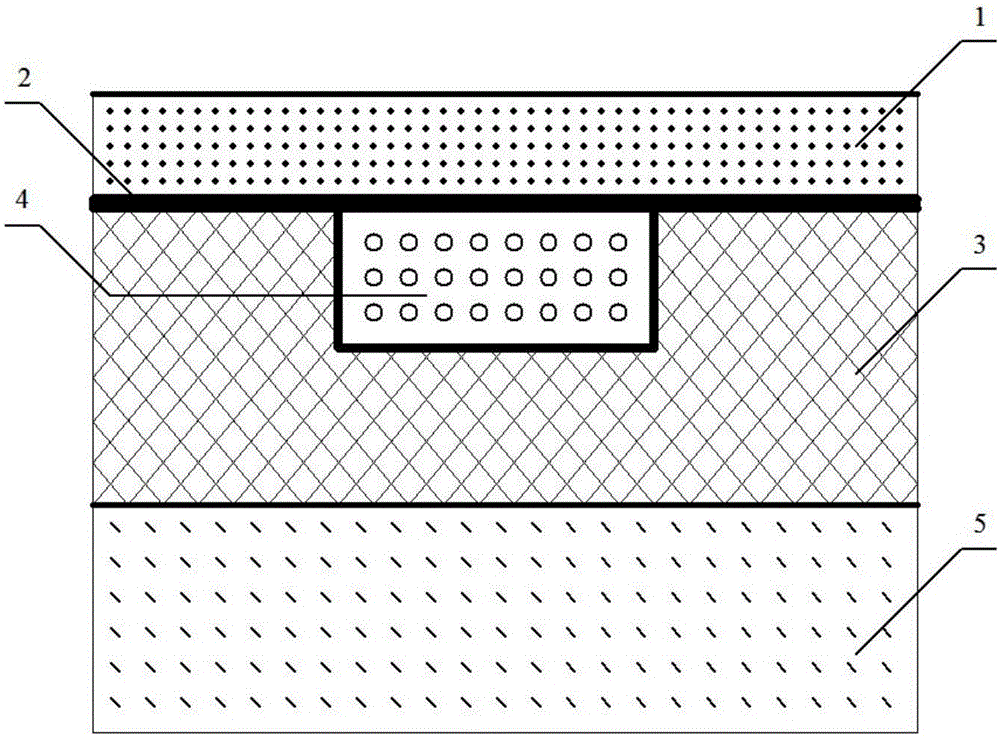

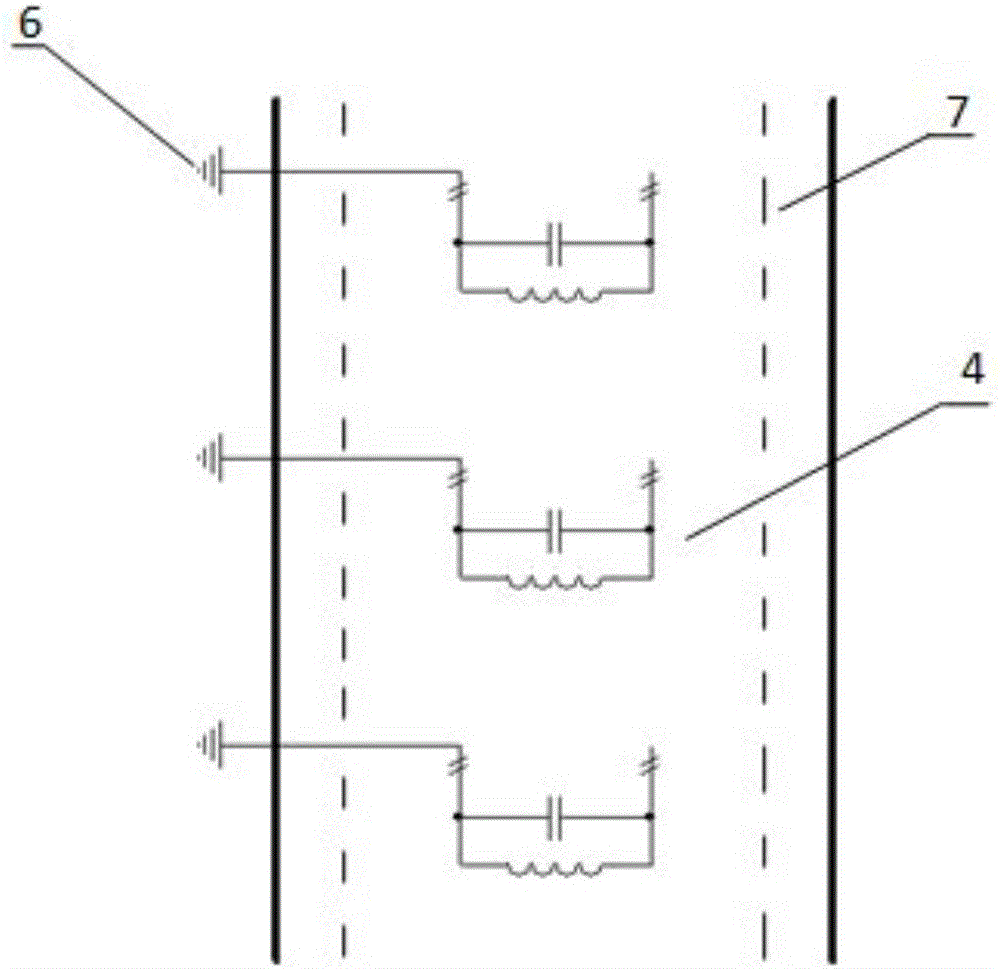

Asphalt pavement capable of providing charging function for vehicles in driving process

InactiveCN106592371ASolve the lack of battery lifeExtended driving distanceBatteries circuit arrangementsIn situ pavingsEngineeringRoad surface

The invention discloses an asphalt pavement capable of providing a charging function for vehicles in a driving process. The asphalt pavement sequentially comprises an asphalt concrete sealing layer, a grille, a polymer cement concrete structure layer and a base layer from top to bottom, wherein the polymer cement concrete structure layer comprises an emitting circuit; an external alternating current power supply generates an alternating current electromagnetic field to realize the mutual induction with a secondary coil arranged in an underpan of a driving vehicle; an electromagnetic induction charging system is formed. The problem of insufficient cruising power of an electric automobile is solved. On the premise of not influencing the automobile driving, the driving distance of the electric automobile is prolonged; meanwhile, the possibly generated potential safety hazard of electricity leakage of the conventional manual direct charging type parking charging is also solved. The asphalt concrete sealing layer uses aggregates with low iron bearing rate; on the basis of ensuring road-use performance and structural intensity, the pavement structure thickness on an emitting circuit primary coil is controlled.

Owner:WUHAN UNIV OF TECH

Preparation method of environment-friendly asphalt mixture additive

ActiveCN106147252AImprove the ability to resist rutting deformationReduce pollutionSludge treatment by de-watering/drying/thickeningClimate change adaptationSludgeGlycoside formation

The invention discloses an environment-friendly asphalt mixture additive and a preparation method thereof. The environment-friendly asphalt mixture additive is prepared from, by weight, 55%-90% of powdery solids, 7%-20% of polyethylene, 1%-5% of a fluorocarbon surfactant, 1%-10% of Kaloamine and 1%-10% of alkyl glycoside. The preparation method comprises the following steps that the powdery materials, polyethylene, the fluorocarbon surfactant, Kaloamine and alkyl glycoside are put into a screw extruder in proportion, mixed to be uniform and extruded to obtain a finished product, and then the asphalt mixture additive is obtained. According to the asphalt mixture additive, the powdery solids generated after thermal extraction treatment of oily sludge can be fully reused and can be put into asphalt mixture production by replacing ore powder, environmental pollution is reduced, the cost is reduced, the rutting deformation resistance of the asphalt mixture is improved, and the service life of a pavement can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid waste asphalt mixture for concrete pavement and preparation method thereof

InactiveCN112142371AGood resistance to rutting deformationImprove temperature stabilitySolid waste managementProcess engineeringRoad surface

The invention relates to a solid waste asphalt mixture for a concrete pavement and a preparation method of the solid waste asphalt mixture. The solid waste asphalt mixture comprises the following rawmaterials in parts by weight: 4-9 parts of natural sand, 4-9 parts of machine-made sand, 12-27 parts of iron tailings, 38.5-52.5 parts of asbestos tailings, 16.5-22.5 parts of basalt aggregate, 4-6 parts of asphalt, 0.2-0.4 part of asphalt modifier, 3-5 parts of modified desulfurized ash and 2-3 parts of iron tailing sand. According to the invention, the industrial solid waste iron tailings, asbestos tailings and steel slag are used as raw materials, the prepared asphalt mixture has good rut deformation resistance and good temperature stability, and the addition of the modified desulfurized fly ash can improve the adhesion between the asphalt and the aggregate, so the asphalt mixture has good enterprise benefits. Not only is the pavement performance of the asphalt mixture ensured to meet various index requirements, but also the solid waste is fully utilized, and the influence of tailing stacking on the environment is reduced.

Owner:张延年

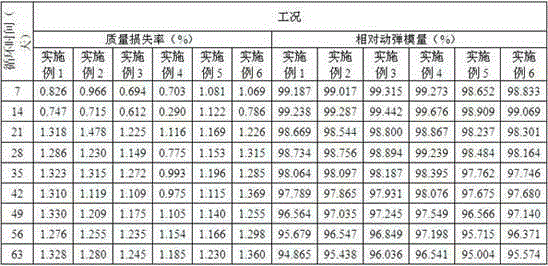

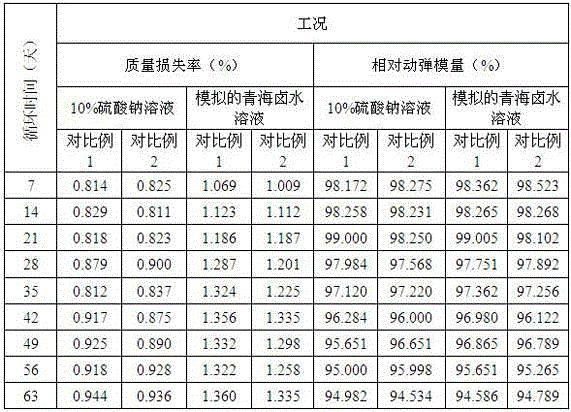

Semi-buried concrete for salinized soil area and preparation method thereof

InactiveCN104692733AIncreased durabilityIncrease the crystal-to-gel ratioAqueous corrosionSoil science

The invention discloses a semi-buried concrete for a salinized soil area and a preparation method thereof. The semi-buried concrete is composed of 10-24% of cement, 55-80% of aggregate, 1-2% of nano mineral admixtures, 2-5% of polymer additive, 0.1-0.5% of adjuvant, 0.2-0.5% of nano-modifier, 2-5% of barium hydroxide microcapsule powder and 7-8% of water, wherein the aggregate consists of fine aggregate of which the particular size is 200 meshes and coarse aggregate of which the particular size is 5-20mm, the weight of the coarse aggregate of which the particular size is 5-20mm is greater than 43% of the total weight of the aggregate. When the concrete is prepared, the above raw materials are placed in a forced mixer in batches to uniformly stir and mix, therefore the uniformity of concrete can be ensured; furthermore, a polymer and a light nano-material are adopted, the good pavement performance can be realized, the sulfate corrosion resistance and the bittern corrosion resistance can be improved, and the frost-resistance of the concrete can be improved, therefore the semi-buried concrete has an important meaning on the development of the salinized soil regional economy and road transportation.

Owner:LUOYANG INST OF SCI & TECH

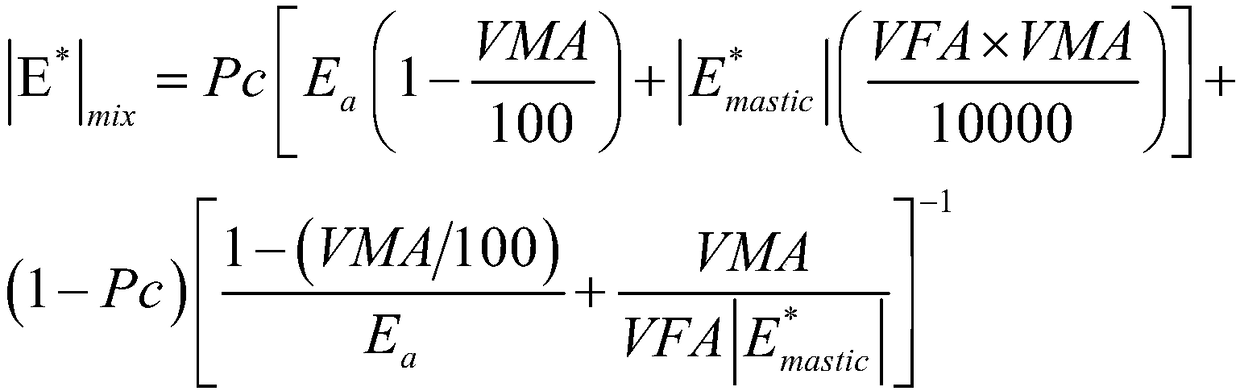

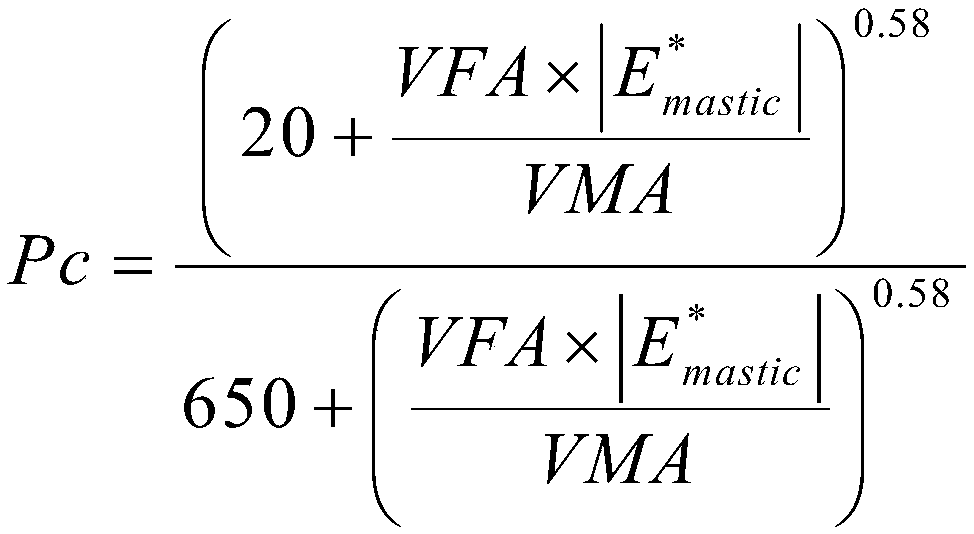

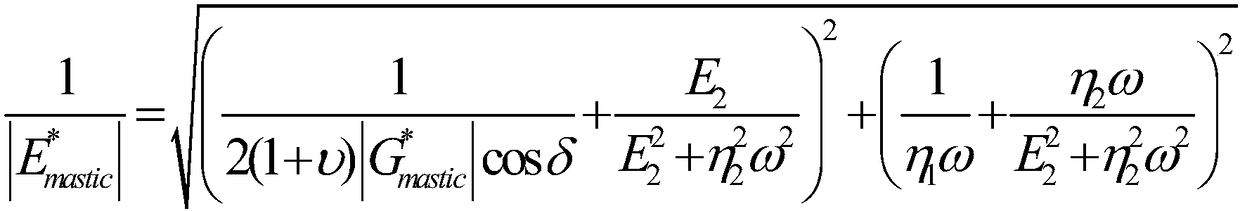

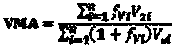

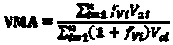

Designing and evaluating method for modulus-based bituminous mixture

The invention discloses a designing and evaluating method for a modulus-based bituminous mixture. The designing and evaluating method for the modulus-based bituminous mixture comprises the following steps: surveying or detecting performance of local aggregates and asphalt; primarily selecting grading according to local aggregate grading and standard suggested grading; predicting a VMA value of themixture by a bituminous mixture mineral aggregate clearance rate VMA predicting formula, and preliminarily adjusting grading to enable the VMA value to meet the standard requirement; primarily selecting the use amount of asphalt and calculating the effective asphalt use amount VFA of the mixture; calculating the dynamic modulus of the bituminous mixture; comparing whether a dynamic modulus predicted value is in a bituminous mixture dynamic modulus range in which the performance of the mixture is acceptable; and manufacturing a test piece according to the matching ratio of the bituminous mixture of which the dynamic modulus meets requirements, and verifying whether the pavement performance of the mixture meets the requirements or not.

Owner:嘉兴市嘉海建设有限公司 +1

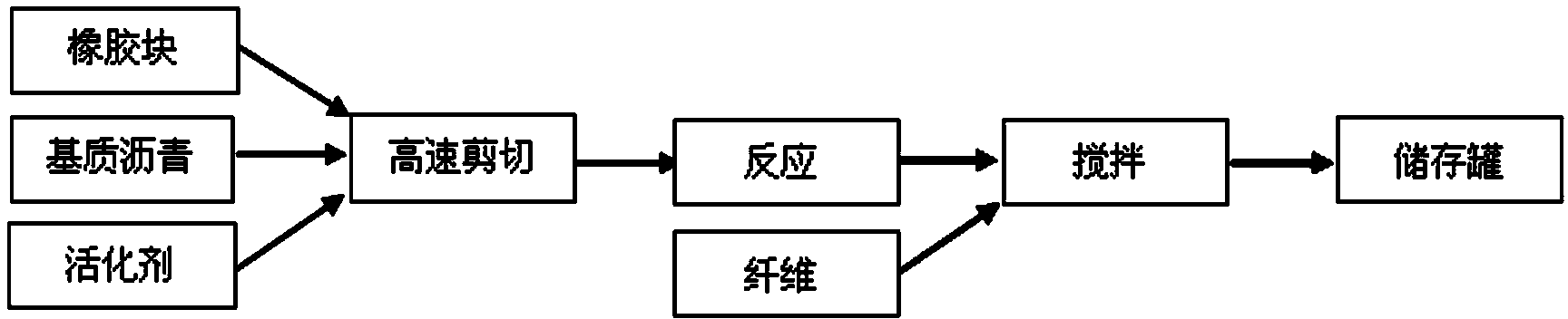

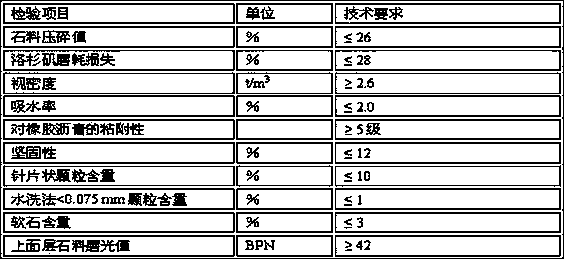

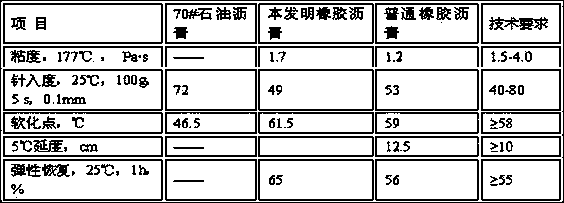

Large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer and preparation method thereof

The invention discloses a large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer and a preparation method thereof, and relates to a pavement structure layer consisting of large-grain-diameter rubber block-modified asphalt and fiber together with single-grain-diameter gravels, and a preparation method thereof. The large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer consists of aggregate, fiber and rubber block-modified asphalt. The preparation method comprises the following steps: 1) sweeping, blowing dust and cleaning an underlayer; 2) preparing the rubber block-modified asphalt; 3) preparing the rubber block-modified asphalt mastic; 4) before sprinkling the rubber asphalt mastic, inspecting various indexes; 5) sprinkling the rubber block-modified asphalt mastic; 6) scattering and paving the gravels; 7) performing rolling compaction; 8) sweeping the large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer. The large-grain-diameter rubber block-modified asphalt mastic and gravel sealing layer is low in production cost, low in energy consumption, free of pollution and high in storage stability. The preparation method is convenient in construction, simple and feasible, and can be easily applied to industrial production.

Owner:NANJING TONGAN ROAD ENG +2

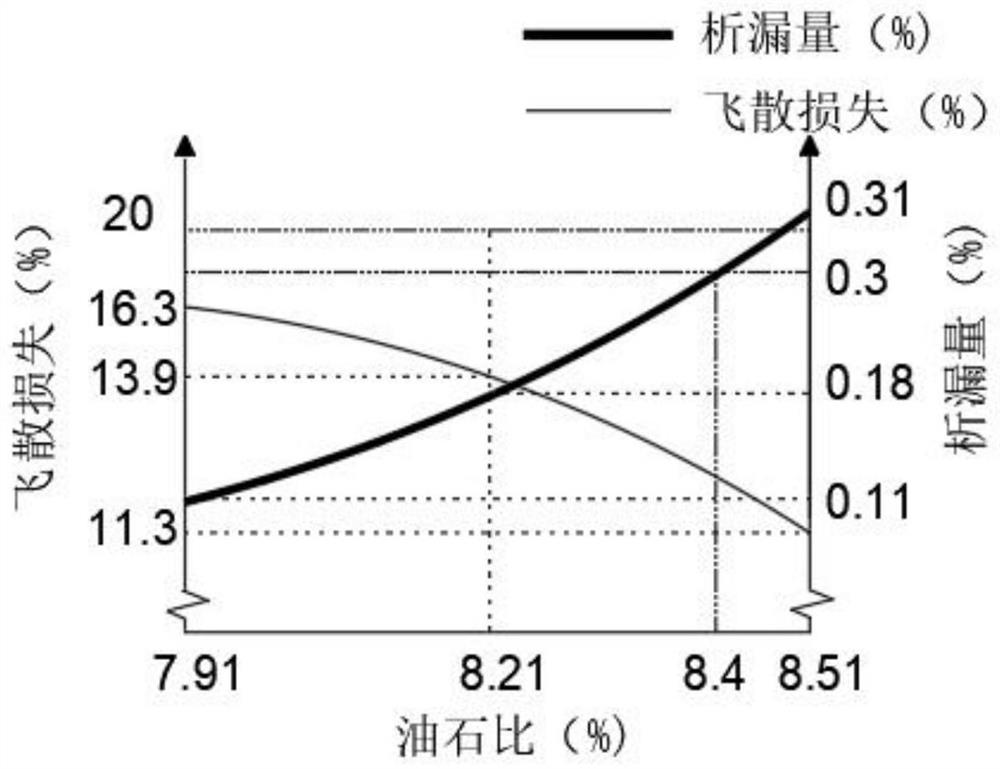

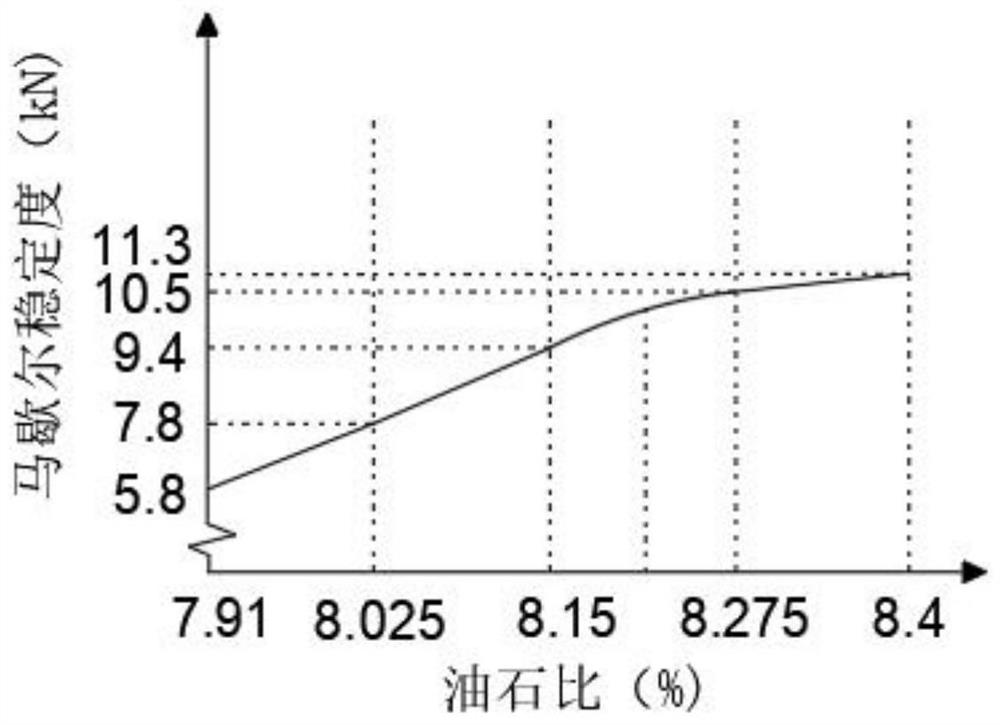

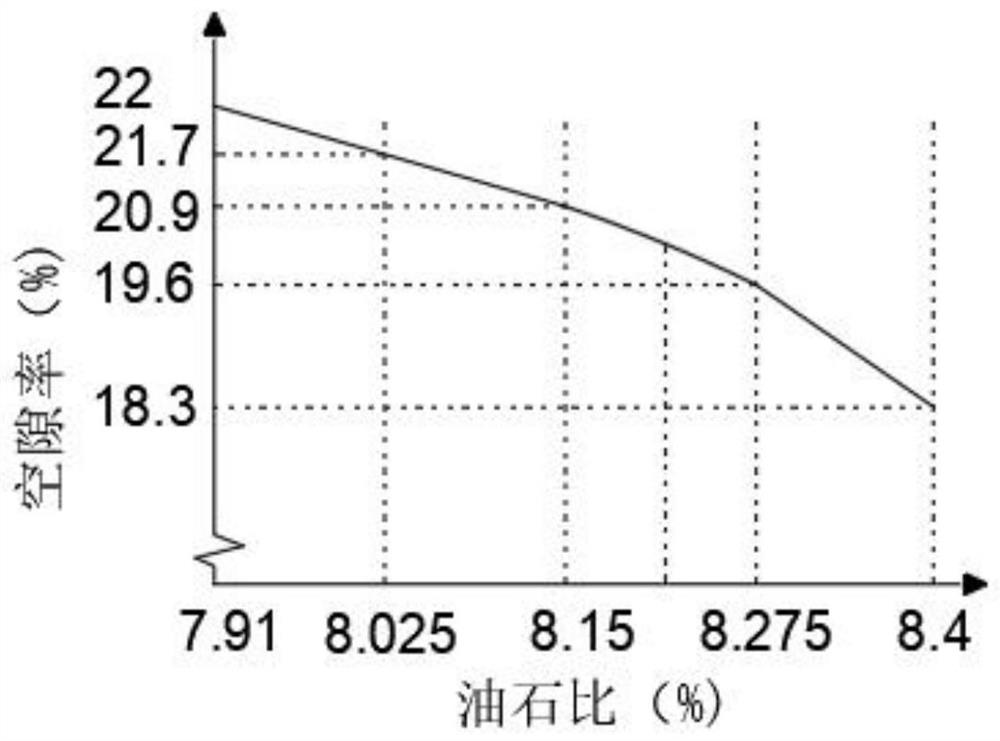

Method for correcting production mix proportion of high-viscosity rubber skeleton void type asphalt mixture

InactiveCN112777964AGuaranteed stone-stone structureImprove structural stabilityRatio controlComputational materials scienceProcess engineeringRoad surface

The invention discloses a method for correcting the production mix proportion of a high-viscosity rubber skeleton void type asphalt mixture. The method comprises the following steps: S1, calculating a designed mix proportion; S2, adjusting the high-temperature volume ; S3, initially adjusting the asphalt-aggregate ratio; S4, determining the mixing amount of rubber; S5, determining the asphalt-aggregate ratio; S6, inspecting the asphalt-aggregate ratio; and S7, performing performance inspection. According to the method disclosed by the invention, influence of high temperature of a production environment on swelling and dissolution of rubber is considered when the production mix proportion of the asphalt mixture is corrected, and when rubber particles are used for replacing aggregate, the swelled and dissolved rubber is used for replacing the isopyknic aggregate, influence on the structure of the mixture due to the change of the volume of the rubber is reduced, new indexes are adopted, the optimal asphalt-aggregate ratio is determined, the asphalt-aggregate ratio is detected by considering the influence on the structure under the dual action of water and changing temperature aiming at the structural characteristics of the high-viscosity rubber particle skeleton void type asphalt mixture, the use performance of a pavement is improved, and the service life of the pavement is prolonged.

Owner:江苏建通绿色工程有限公司

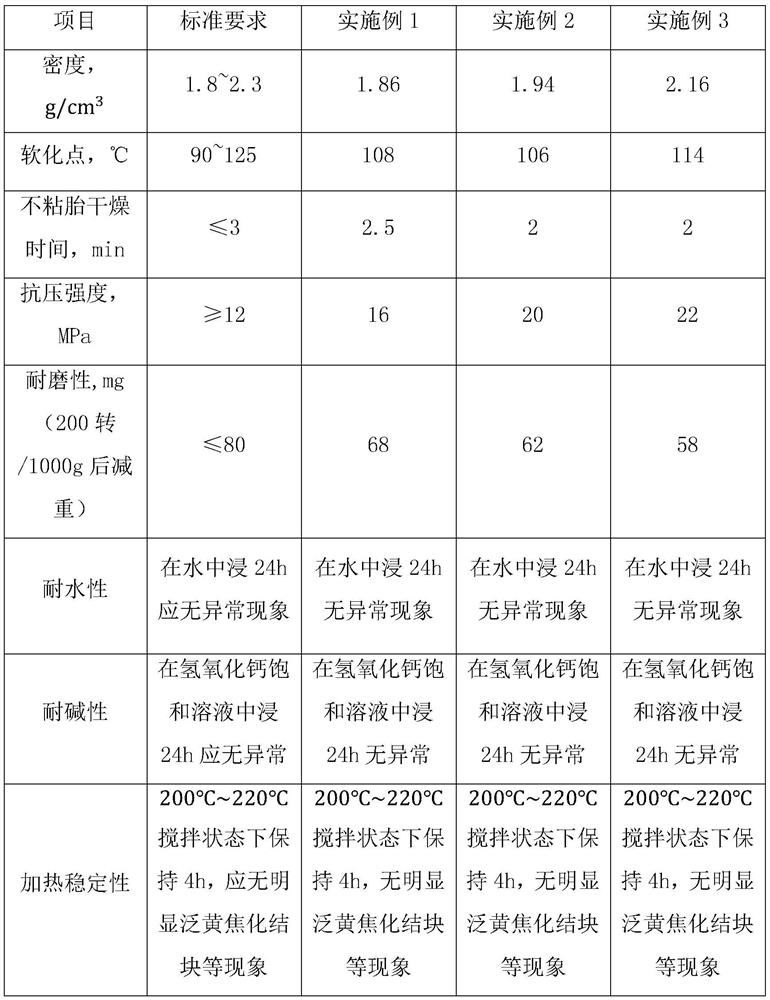

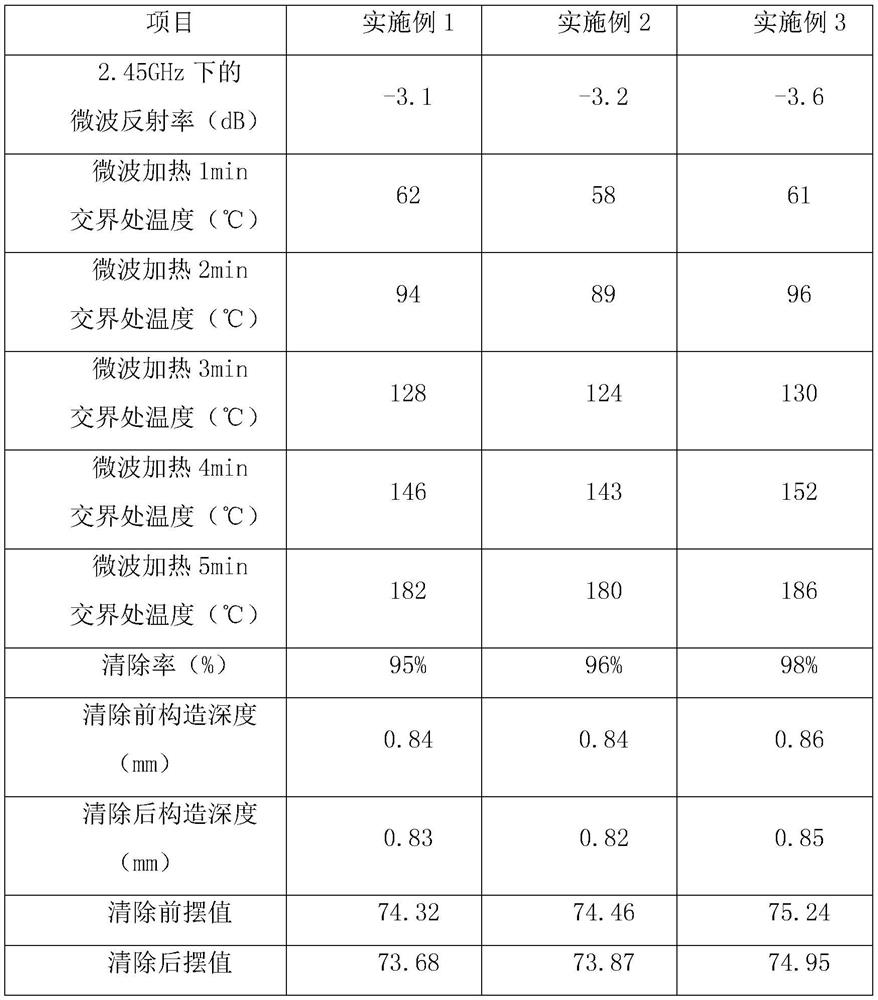

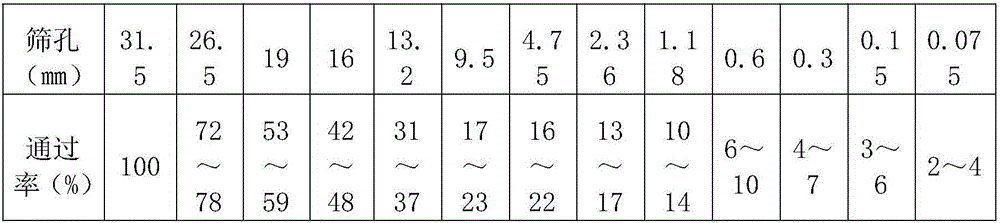

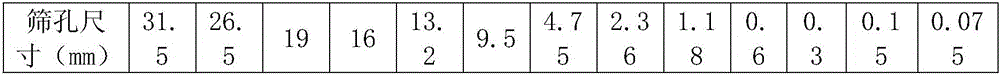

Microwave easy-to-remove modified hot-melt marked line for cement pavement and preparation method

ActiveCN112480775AReduce high temperature viscosityImprove workabilityFireproof paintsTraffic signalsPlasticizerPetroleum resin

The invention discloses a microwave easy-to-remove modified hot-melt marked line for a cement pavement and a preparation method. The microwave easy-to-remove modified hot-melt marked line is preparedfrom the following components in parts by weight: 20-40 parts of modified C5 petroleum resin, 10-20 parts of EVA resin, 5-20 parts of terpene resin, 5-10 parts of a plasticizer, 2-5 parts of a leveling agent, 10-30 parts of titanium dioxide, 10-20 parts of siliceous low-dielectric-constant filler, 10-30 parts of wave-transmitting glass beads and 5-40 parts of a modified composite microwave absorber. According to the invention, an impedance matching structure is formed by adjusting the structure and material composition of the hot-melt marked line, and the propagation loss of microwaves in thehot-melt marked line is reduced. The obtained modified hot-melt marked line can meet the pavement performance of a conventional hot-melt marked line, can be quickly softened and efficiently separatedfrom the cement pavement after absorbing microwaves, basically has no residue on the cement pavement after being heated and removed by the microwaves, and does not damage the original surface textureof the cement pavement; and the preparation method and the clearing method are simple and efficient.

Owner:SOUTHEAST UNIV

Drainage type modified asphalt coarse aggregate discontinuous semi-open graded bituminous stabilized macadam

InactiveCN105821734AMeet drainage requirementsGuaranteed road performanceIn situ pavingsPaving gutters/kerbsFiberSemi open

The present invention belongs to the field of transportation engineering, and discloses drainage type modified asphalt coarse aggregate discontinuous semi-open graded bituminous stabilized macadam. A mixture is composed of SBS modified asphalt, coarse aggregate, fine aggregate and mineral powder (or a certain amount of fiber can be added), the void ratio is 10%-13%, and the asphalt-aggregate ratio is 3.5%-4.5%. The mixture has certain drainage ability, and the anti-reflection crack performance, the anti-fatigue performance and the anti-rutting resistance are obviously improved compared with matrix asphalt AC-25 and matrix asphalt ATB-25. An important role is played in guaranteeing the pavement performance and the service life of an asphalt pavement when the drainage type modified asphalt coarse aggregate discontinuous semi-open graded bituminous stabilized macadam is applied to the structure of the asphalt pavement.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

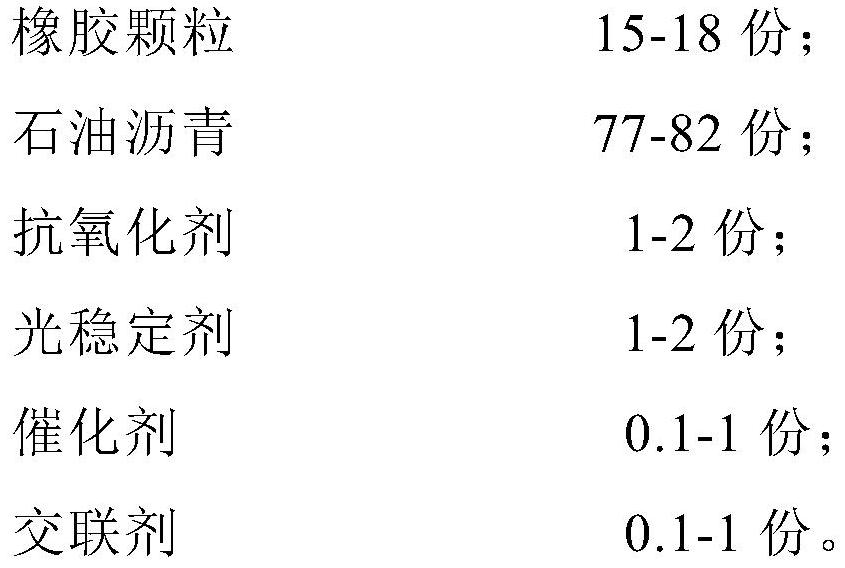

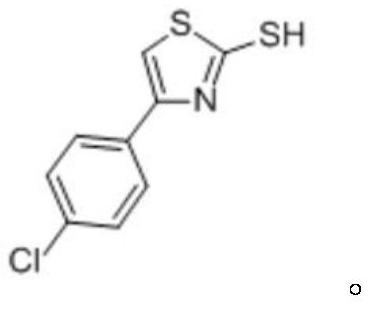

Anti-aging soluble rubber powder modified asphalt and preparation method thereof

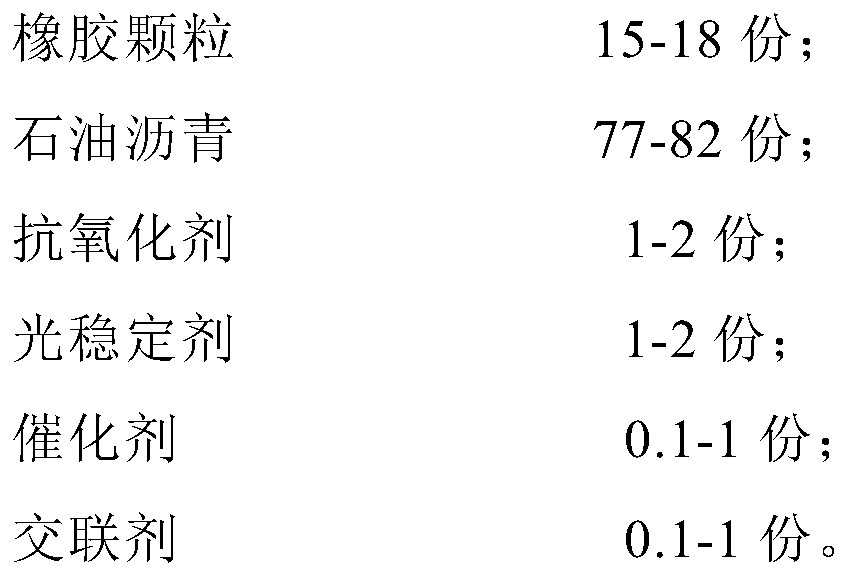

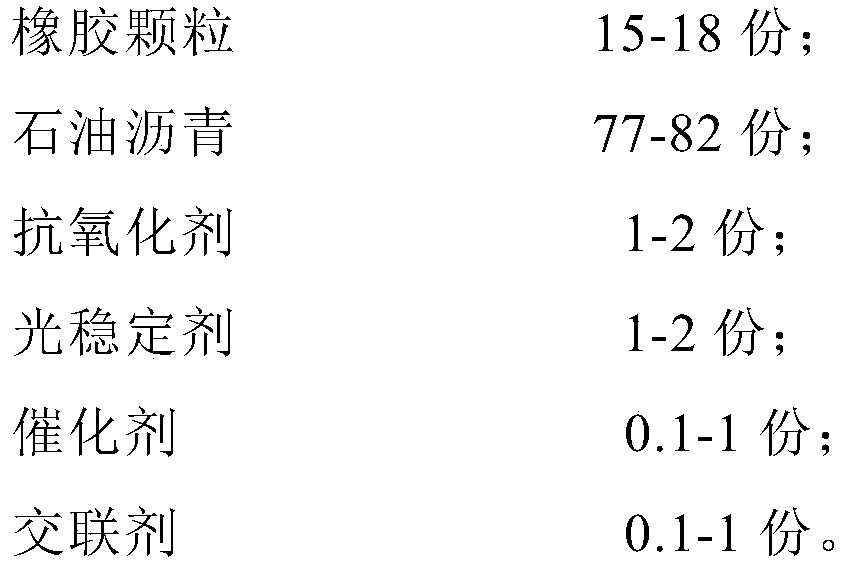

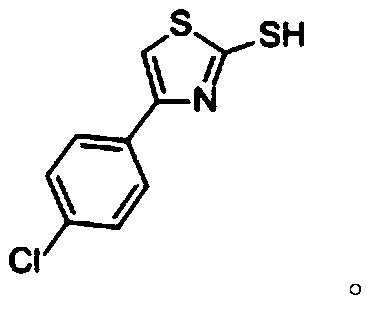

ActiveCN110903659AEvenly dispersedReduce contact areaBuilding insulationsPhosphorous acidChlorobenzene

The invention relates to anti-aging soluble rubber powder modified asphalt which comprises the following components in parts by weight: 15-18 parts of rubber particles, 77-82 parts of petroleum asphalt, 1-2 parts of antioxidant tri (2, 4-di-tert-butylphenyl) phosphite, 1-2 parts of light stabilizer 2-hydroxy-4-methoxybenzophenone, 0.1-1 part of catalyst 4-(4-chlorphenyl)-4-thiazoline-2-thioketoneand 0.1-1 part of cross-linking agent 3-phenyl-2-thioketone-1, 3-thiazoline-4-ketone. Compared with the prior art, under the condition of ensuring that other main pavement performance technical indexes of the asphalt are not reduced or not remarkably reduced, the aging of the soluble rubber powder in the preparation process can be remarkably reduced, and the thermo-oxidative aging resistance and the ultraviolet aging resistance of the asphalt for pavements are remarkably improved.

Owner:TONGJI UNIV

A cold-mixed cold-paved asphalt mixture and a cold-mixed cold-paved asphalt mixture abrasive layer

ActiveCN108129073BImprove crack resistanceGood water sealing effectIn situ pavingsRoad engineeringMining engineering

The invention provides a cold-mixed and cold-laid asphalt mixture, and a cold-mixed and cold-laid asphalt mixture wearing layer, and belongs to the technical field of road engineering. The cold-mixedand cold-laid asphalt mixture comprises coarse aggregates, fine aggregates, high-performance modified emulsified asphalt, a mineral filler, water and a liquid additive. The asphalt mixture prepared from above cold-mixed and cold-laid material components according to a special mineral grading range can be closely bonded to an old asphalt pavement and a cement pavement; and compared with traditionalmicro-surfacing and super-sticky wearing layer materials, the mixture has higher resistance to crack, water and skid and lower driving noises.

Owner:SOUTH CHINA UNIV OF TECH +1

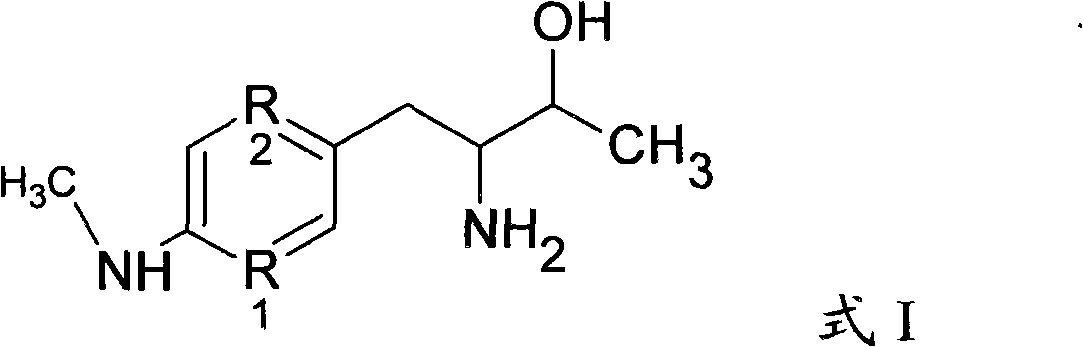

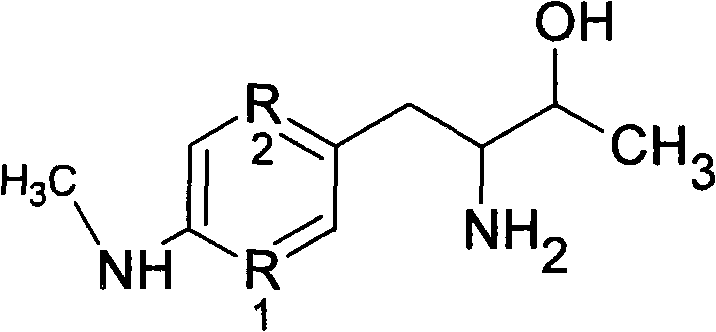

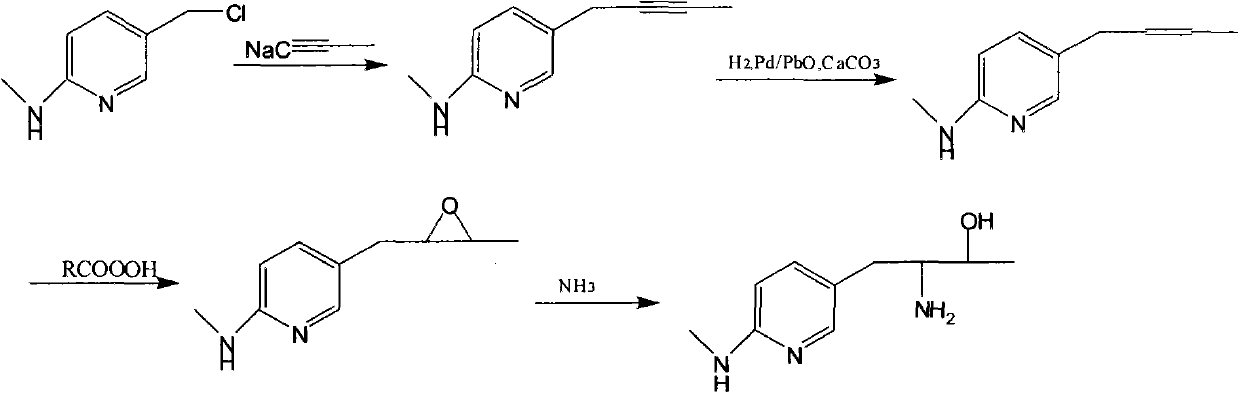

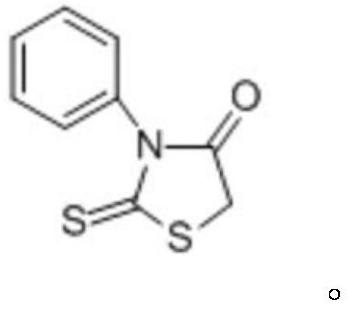

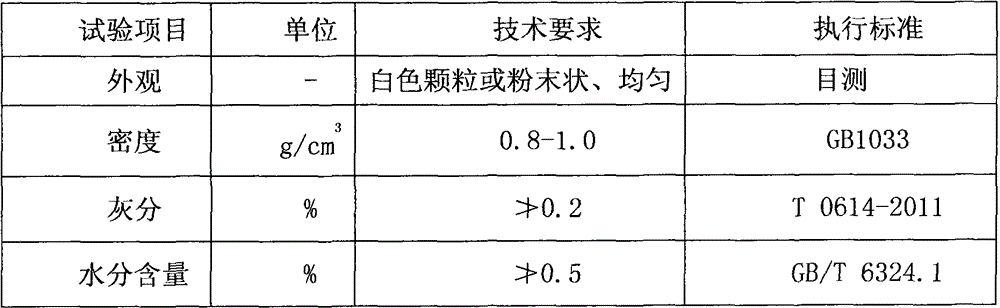

Additive for warm-mixing rubber-asphalt mixture and mixing method of mixture

InactiveCN101830661BReduce the temperatureGuaranteed road performanceClimate change adaptationBuilding insulationsRoad surfaceMaterials science

The invention relates to a compound with a formula I in the specification, which is used for a rubber-asphalt mixture for paving. In the formula, at least one of R1 and R2 is N and the rest is C. The invention also relates to the rubber-asphalt mixture for paving and a mixing method, the mixture comprises the compound shown in the formula I, the rubber-asphalt, building stones and cement and / or mineral power. By utilizing the compound and the method, pavement materials can be mixed under lower temperature, thereby the purposes of emission reduction and energy saving can be realized.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

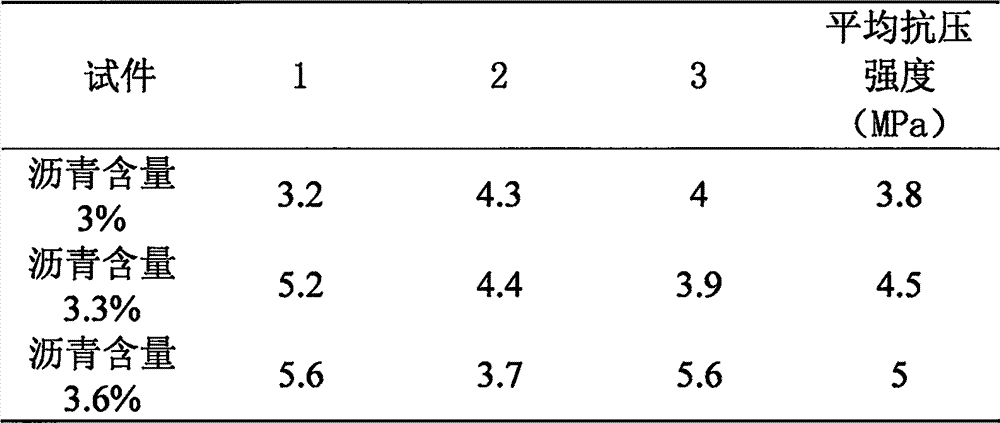

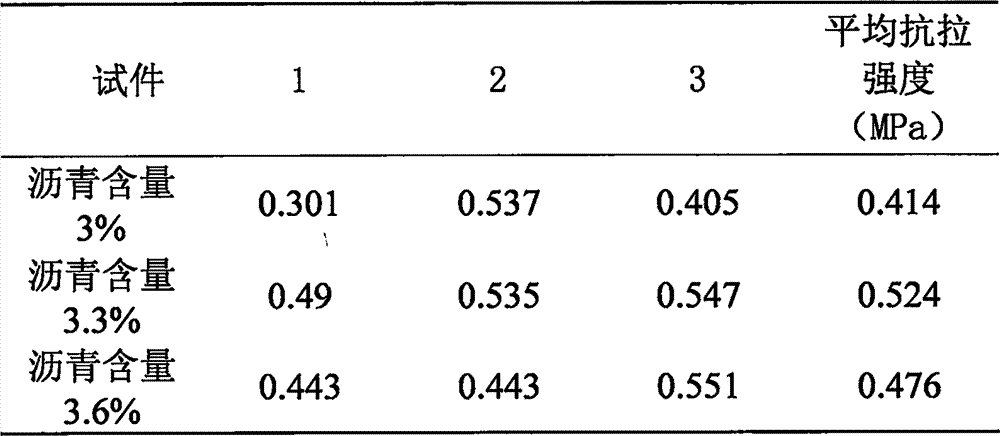

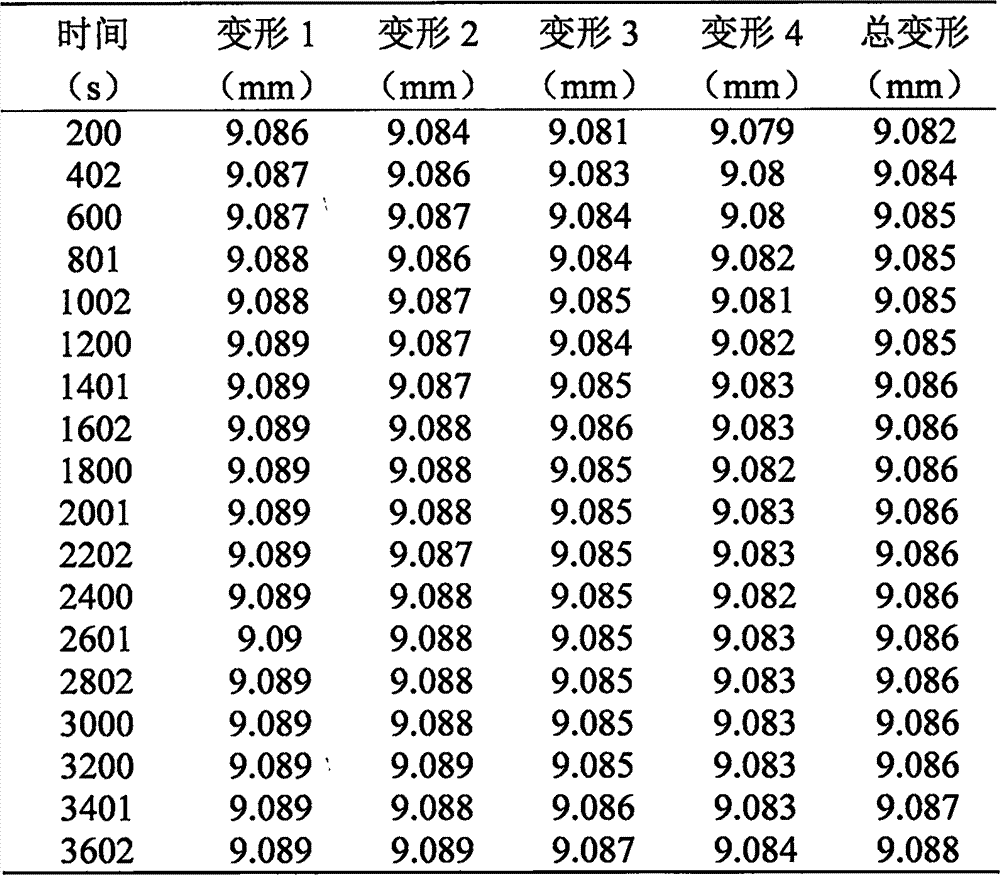

Large grain size asphalt macadam pavement flexible base layer material

The invention discloses a flexible base material for a large-diameter asphalt macadam pavement. An admixture is added to the large-diameter asphalt macadam, wherein the weight percentage of the large-diameter asphalt is 3-3.6%, and the percentage of the admixture is The weight percentage is 0.2-1.1%, and the balance is large-sized gravel. Compared with the prior art, the present invention uses the admixture to replace part of the asphalt, which reduces the construction cost. On the other hand, it can also use industrial waste residues to protect the environment, and at the same time ensure the road performance and mechanical properties of the large-size asphalt macadam flexible base .

Owner:HENAN UNIV OF URBAN CONSTR

Design and Evaluation Method of Asphalt Mixture Based on Modulus

The invention discloses a designing and evaluating method for a modulus-based bituminous mixture. The designing and evaluating method for the modulus-based bituminous mixture comprises the following steps: surveying or detecting performance of local aggregates and asphalt; primarily selecting grading according to local aggregate grading and standard suggested grading; predicting a VMA value of themixture by a bituminous mixture mineral aggregate clearance rate VMA predicting formula, and preliminarily adjusting grading to enable the VMA value to meet the standard requirement; primarily selecting the use amount of asphalt and calculating the effective asphalt use amount VFA of the mixture; calculating the dynamic modulus of the bituminous mixture; comparing whether a dynamic modulus predicted value is in a bituminous mixture dynamic modulus range in which the performance of the mixture is acceptable; and manufacturing a test piece according to the matching ratio of the bituminous mixture of which the dynamic modulus meets requirements, and verifying whether the pavement performance of the mixture meets the requirements or not.

Owner:嘉兴市嘉海建设有限公司 +1

Asphalt pavement heat reflection slurry seal material and preparation method thereof

PendingCN113430892ALow thermal conductivityImprove reflectivityIn situ pavingsManufacturing engineeringMechanical engineering

The invention discloses an asphalt pavement heat reflection slurry seal material and a preparation method thereof. In order to reduce the temperature of the asphalt pavement, hollow glass beads are adopted, and the asphalt pavement heat reflection slurry seal is prepared by combining an asphalt pavement slurry seal technology. According to the slurry seal material, the pavement performance of the material is guaranteed, the pre-curing effect of the slurry seal is exerted, meanwhile, the influence of temperature rise of an asphalt pavement caused by sunlight irradiation is relieved, and the slurry seal material is reasonable in manufacturing cost, convenient to construct, good in using effect and wide in application range.

Owner:BEIJING UNIV OF TECH

A kind of anti-aging soluble rubber powder modified asphalt and preparation method thereof

ActiveCN110903659BPromote rapid formationReduce exposureBuilding insulationsPhosphorous acidPtru catalyst

The invention relates to an anti-aging soluble rubber powder modified asphalt, the raw material of which comprises the following components in parts by weight: 15-18 parts of rubber particles, 77-82 parts of petroleum asphalt, antioxidant tris(2,4 1-2 parts of di-tert-butylphenyl) ester, 1-2 parts of light stabilizer 2-hydroxy-4-methoxybenzophenone, catalyst 4-(4-chlorophenyl)-4-thiazoline- 0.1-1 part of 2-thione, 0.1-1 part of cross-linking agent 3-phenyl-2-thione-1, 3-thiazoline-4-one. Compared with the prior art, the present invention can significantly reduce the aging of the soluble rubber powder during the preparation process and significantly improve the road performance of the asphalt under the condition that other main road performance technical indicators of the asphalt are not reduced or not significantly reduced. With resistance to thermal oxidative aging and UV aging performance.

Owner:TONGJI UNIV

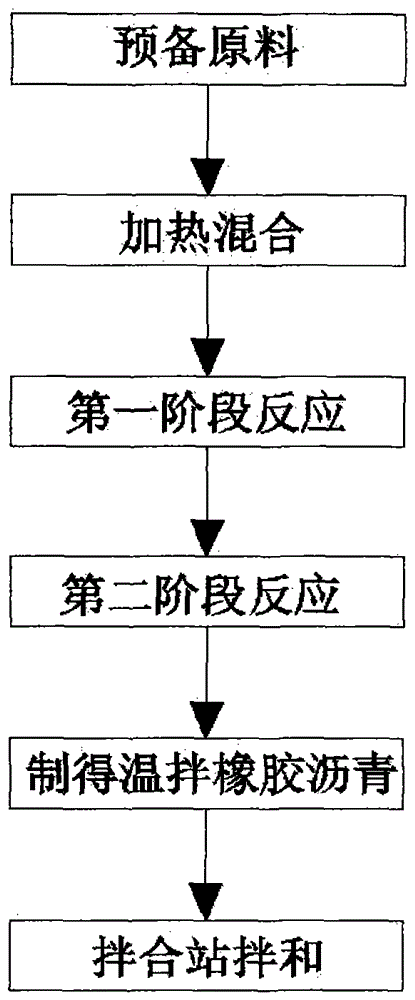

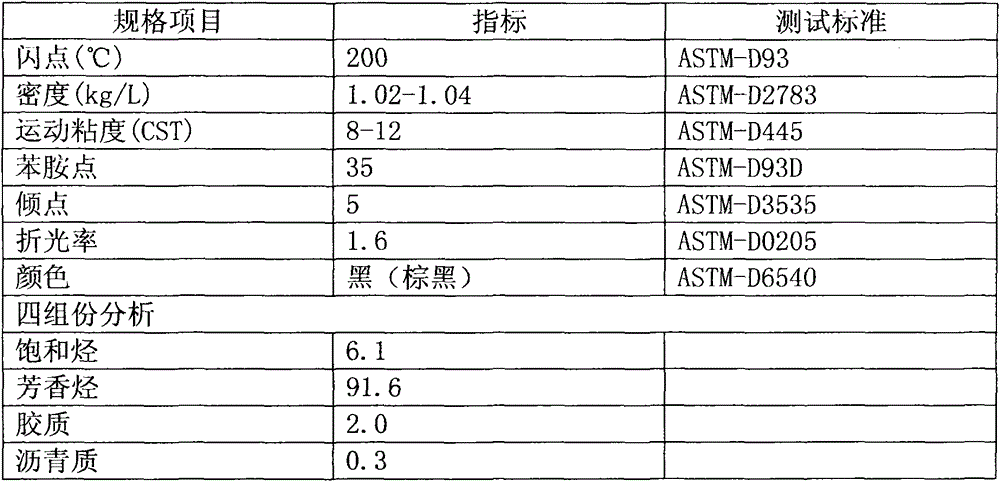

Two-stage warm-mix rubber asphalt method and its products

ActiveCN103923472BLow reaction temperatureReduce consumptionClimate change adaptationBuilding insulationsEngineeringPollution

The present invention discloses a two-stage type rubber asphalt warm mix method, which comprises: 1) preparing raw material; 2) carrying out heating mixing; 3) adding an oil produced from a crude oil vacuum distillation tower, and carrying out a first stage reaction; and 4) adding a RH asphalt warm mix modifier to carry out a second stage reaction, and carrying out a viscosity reduction treatment. The invention further discloses a product prepared by performing the preparation method. According to the present invention, the method has characteristics of simple process, easy achievement and high efficiency; under the premise of assurance of the road performance, the two auxiliary agents are adopted to modify the rubber asphalt at two stages so as to effectively reduce the reaction temperature of the rubber asphalt, reduce the fuel consumption, reduce the emissions of harmful gases and dust, reduce the environmental pollution and improve the construction environment; and the product provided by the present invention has characteristics of low viscosity, low reaction temperature, asphalt pavement construction season prolonging, asphalt mixing material aging reducing, road performance improving, effective reduction of fuel energy consumption required by the mixing material production process, energy source saving and mixing cost reducing.

Owner:北京嘉格伟业筑路科技有限公司 +2

Composite pavement structure and construction method thereof

InactiveCN102031744BReduce thicknessGuaranteed road performanceIn situ pavingsSingle unit pavingsConnection typeRoad surface

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com