Asphalt pavement heat reflection slurry seal material and preparation method thereof

A slurry seal, asphalt pavement technology, applied in the direction of roads, roads, coagulation pavement paved on site, etc. layer peeling and other problems, to achieve the effect of alleviating road rutting and other diseases, light weight and reducing road temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

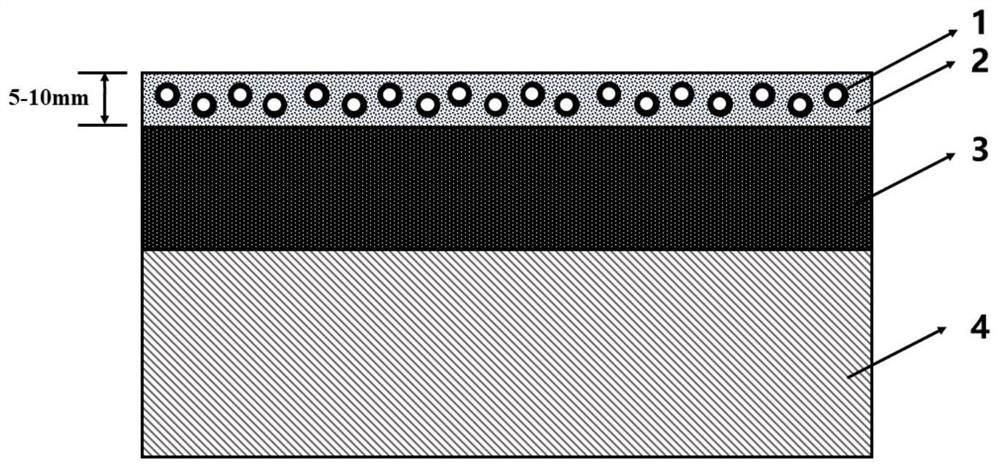

Embodiment approach 1

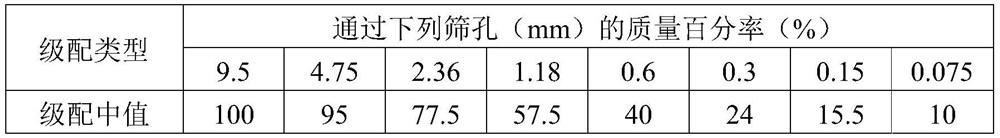

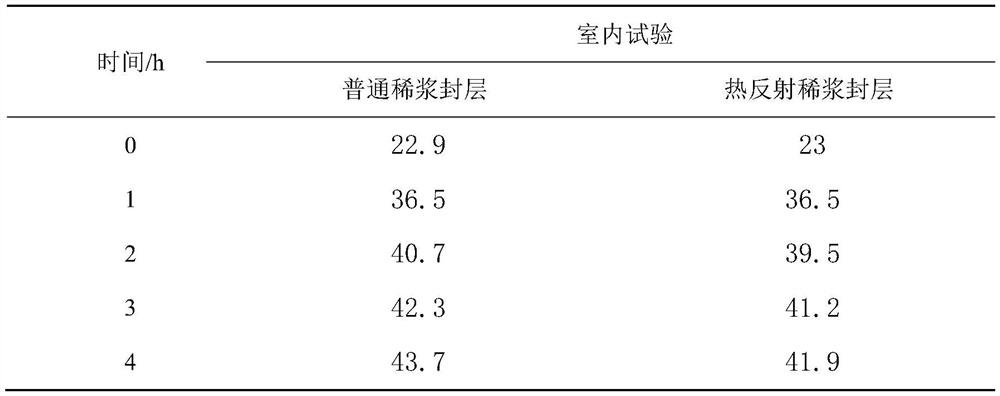

[0034] Implementation plan (indoor implementation effect test)

[0035] Test Methods

[0036] Refer to the Japanese indoor temperature test method, support high-power lamps with tripod to simulate sunlight, test fittings are placed under the source, and the surrounding and bottom heat insulating materials are separated by the air test to conduct heat to the outside. .

[0037] In order to ensure the thickness of the slurry sealing layer of 5 mm, a frame of 300 mm × 300 mm is made by a long wooden strip having a cross section of 5 mm × 5 mm, and the slurry seal is placed on the rut pad.

[0038] The temperature value is read and recorded and recorded with a non-contact infrared temperature gun.

[0039] As shown in Table 2, the 6 groups were measured once every half hour in 4 hours, and temperature data was obtained.

[0040] Table 2

[0041]

[0042] The indoor cooling layer of the thermal reflective material in the present invention is remarkable, and the ordinary slurry sealin...

Embodiment example 2

[0044] Implementation case two (outdoor asphalt pavement implementation effect test)

[0045] Test Methods:

[0046] In order to obtain more accurate and effective experimental data, you need to select a day with a higher temperature and less temperature to observe and record data.

[0047] The mating ratio used in this experiment is used in the actual road, and a slurry sealing layer sample having a thickness of 5 mm is equally paveled.

[0048] The test time is 10:00 to 14:00, and the data is collected every 1 hour.

[0049] The outdoor cooling effect of the thermal reflective material of the present invention is remarkable. The temperature change of the test piece on the 4-hour pavement, as shown in Table 3, can be found that the temperature of the ordinary slurry sealing layer is up to 56.8 ° C, which is approximately 2 ° C higher than the original asphalt pavement. At a temperature of 35 ° C, the temperature reduction effect of the tester containing the hollow glass beads is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com