Ready-to-use high-dispersion high-viscosity modifier and preparation method thereof

A modifier, high dispersion technology, applied in building components, building insulation materials, construction and other directions, can solve the problems affecting the promotion and use of high viscosity modifiers, high price of high viscosity modifiers, poor high temperature stability, etc. , to achieve the effect of significant social and economic benefits, superior performance and excellent high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] 1. Preparation of high-dispersion and high-viscosity modifier:

[0037] First, heat the polymer modifier and swelling agent at 100°C for 30 minutes to 60 minutes to swell to a fluid state, then pour it into the dispersant that has been heated to a fluid state, and add plasticizer and crosslinking agent, and then Cut through a high-speed shear for 5 to 15 minutes, the speed of the high-speed shear is 1000 to 3000r / min, and the temperature is 140 to 180°C; after completion, pour it into an evaporating dish and put it in a vacuum oven at 120°C for 1 hour. Then it is extruded and pelletized in a single-screw extruder.

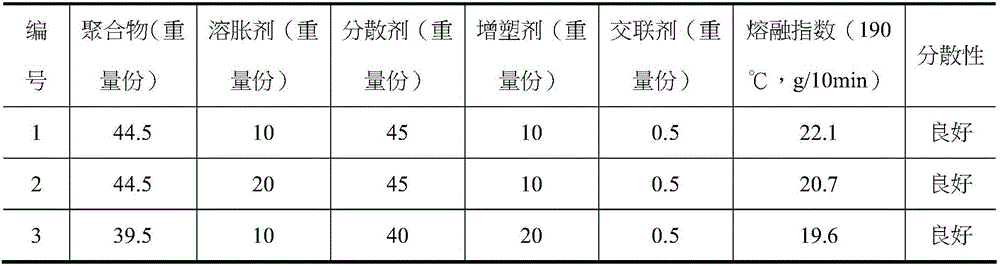

[0038] Three groups of different raw material components and the melt indices of the highly dispersed high viscosity modifiers prepared therefrom are shown in Table 1 below:

[0039] Table 1 prepares high-dispersion high-viscosity modifiers in different proportions

[0040]

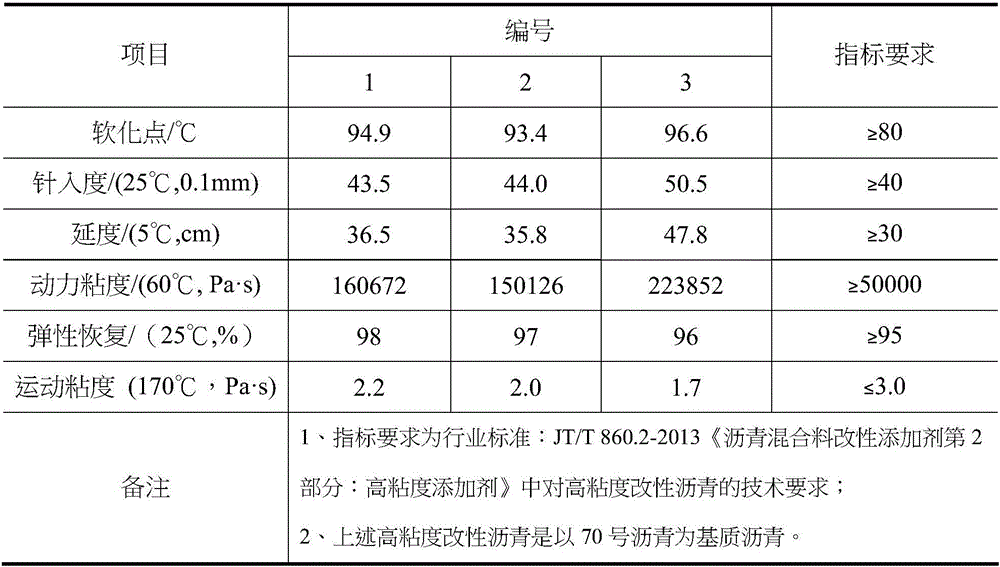

[0041] 2. Application examples: Prepare corresponding modified asphalt with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com