Additive for warm-mixing rubber-asphalt mixture and mixing method of mixture

A technology of rubber asphalt and additives, which is applied in building insulation materials, building components, climate change adaptation, etc. It can solve the problems of threatening the personal safety of operators and harmfulness to human body, and achieve the effects of improving the working environment, reducing emissions, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

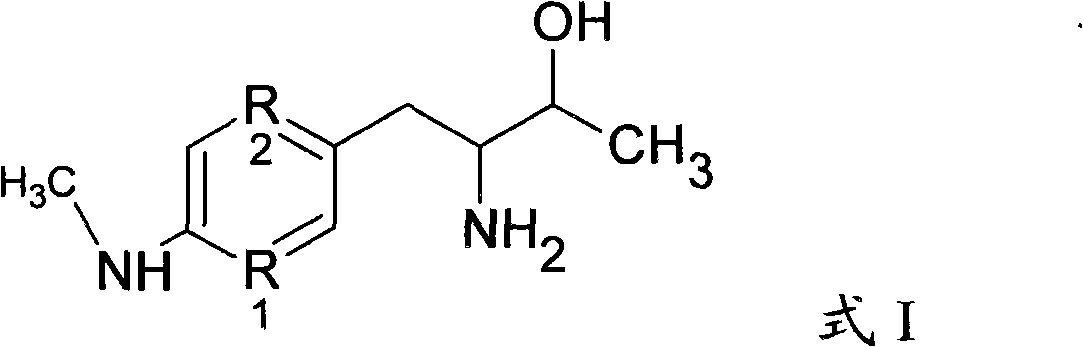

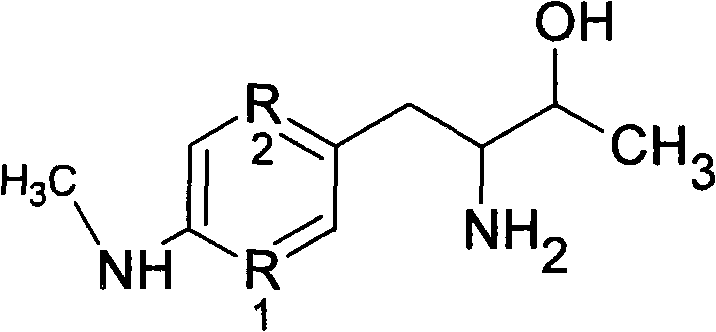

[0031] Example 1: Synthesis of 2-methylamino-5-(2'-amino-3'-hydroxybutyl)pyrazine

[0032] 9g (0.1mol) triethylamine and 146g (1mol) 1,4-diamino-4 hydroxy-pentan-2-ketone are installed in a four-neck flask equipped with a dropping funnel of a thermometer, a stirring rod, and a condenser tube, to 400ml of dichloromethane was dissolved, and 96.7g (1.1mol) of 1-aminoacetylmethylamine was added dropwise to the bottle through the dropping funnel, and reacted at 60-70°C for 10 hours. The reaction solution was cooled to room temperature, and concentrated to remove the solvent. Recrystallize twice with a 30:70 toluene and ethanol solution to obtain 2-methylamino-5-(2'-amino-3'-hydroxybutyl)pyrazine as a light yellow solid, melting point, 78-79°C, liquid -The molecular weight measured by mass spectrometry is 197.

Embodiment 2

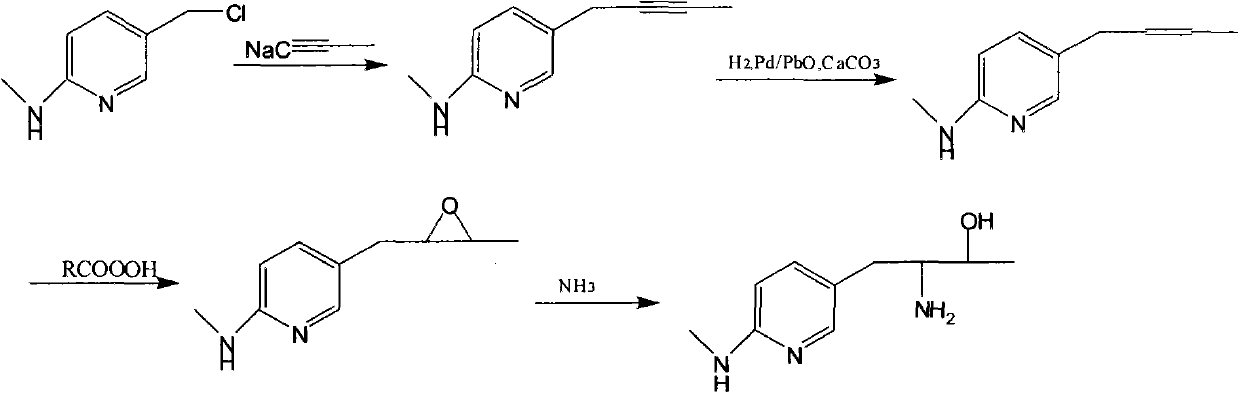

[0033] Example 2: Synthesis of 2-methylamino-5-(2'-amino-3'-hydroxybutyl)pyridine

[0034]Put 68.2g (1.1mol) of propargyl sodium and 200ml of pyridine in a 1L four-necked flask equipped with a thermometer, a stirring rod, a condenser tube and a dropping funnel. Add 157g (1mol) 1-methylamino-5-chloromethylpyridine dropwise, stir the reaction at 50°C after the dropwise addition, and concentrate to remove Solvent, the residue was dissolved in 500ml of ethyl acetate, washed three times with 50ml of water, dried over sodium sulfate, put into the solution 5g of sodium silk, and placed in a desiccator for 24 hours. The mixture was transferred to a 2L autoclave equipped with 50g of Lindlar catalyst, and the air in the autoclave was purged with hydrogen to keep the temperature of the autoclave at about 40°C and the pressure of hydrogen at 1.8 atmospheres. The reaction was carried out for 24 hours. Open the autoclave, add 80g of peracetic acid thereinto, and continue to react at 40°C ...

Embodiment 3

[0036] The stone gradation used is shown in Table 1.

[0037] Table 1 Grading of warm mix rubber asphalt mixture

[0038] square hole sieve

(mm)

Synthesis pass rate (%)

16

100

13.2

95.43

9.5

65.69

4.75

30.00

2.36

23.60

1.18

18.38

0.6

14.45

0.3

11.42

0.15

8.44

0.075

7.05

[0039] The rubber asphalt used was purchased from Shandong Dashan Road and Bridge Engineering Co., Ltd., and its performance indicators are listed in Table 2, which meets the requirements of the "Technical Guidelines for Design and Construction of Beijing Waste Tire Rubber Powder Asphalt and Mixture".

[0040] Table 2 Test results of rubber asphalt performance indicators

[0041]

[0042] Asphalt Rotating Thin Film Oven Test TFOT

[0043]

[0044] The mixing operation of the mixture is as follows:

[0045] (1) Pre-heat the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com