Electric-conduction anti-skid wearing layer for pavement and preparation method thereof

A sliding grinding and conductive carbon fiber technology, applied in roads, roads, pavement details, etc., can solve the problems of low heating efficiency, difficult construction, high thermal load, etc., and achieve the effect of improving safety performance, flexible construction, and small generating resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

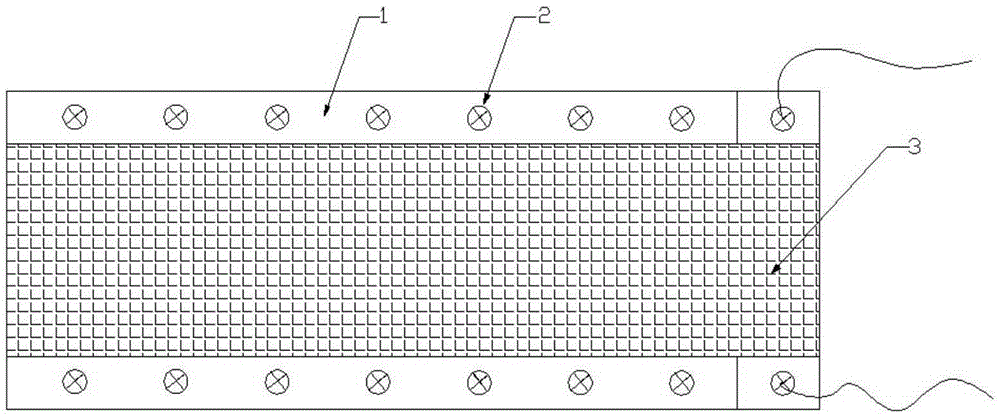

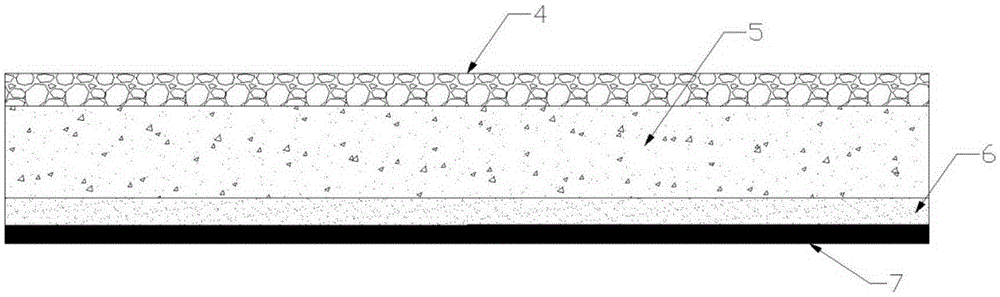

[0042] see figure 1 with figure 2 , a pavement conductive anti-slip wear layer, a layer of conductive carbon fiber cloth layer 6 is provided on the heat-insulating bonding layer 7, and a layer of basalt gravel protective layer 5 is provided on the conductive carbon fiber cloth layer 6. The basalt crushed stone A layer of black corundum crushed stone layer 4 is arranged on the stone protection layer 5, and the overall layer thickness is 7 mm to 9 mm.

[0043] Specifically, the structure of the conductive carbon fiber cloth layer 6 is as follows: the cutting width of the conductive carbon fiber cloth 3 is 0.8m to 1.2m, and the length is cut according to the width of the road surface. The copper electrode sheet 1 is installed through the riveting buckle 3, the width of the copper electrode sheet 1 is 4cm-6cm, the thickness is 0.03mm-0.08mm, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com