Microwave easy-to-remove modified hot-melt marked line for cement pavement and preparation method

A cement pavement and modification technology, applied in road signs, roads, roads, etc., can solve the problems of long removal time, increase the thickness of the marking line, and difficult to control the color of the coating material, so as to improve the mechanical strength and high temperature resistance. Improve the workability of high temperature construction and ensure the effect of normal road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

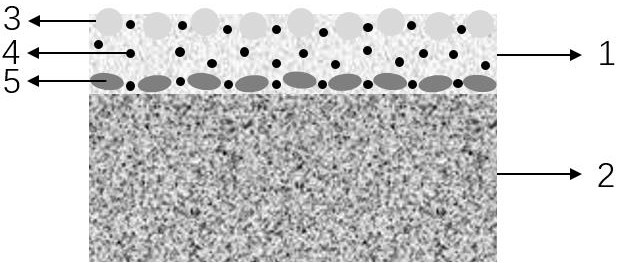

Image

Examples

preparation example Construction

[0059] A preparation method for microwave easy-to-clear modified hot-melt markings for cement pavement, comprising the following steps.

[0060] Step 1. Preparation of resin base mixture: adjust the temperature of the hot-melt kettle to 180°C to 220°C, and add modified C5 petroleum resin, EVA resin, terpene resin, titanium dioxide and silicon low-dielectric to the hot-melt kettle in sequence Constant filler, and mix to obtain a resin base mixture.

[0061] The present invention uses modified C5 petroleum resin, EVA resin and terpene resin for blending and modification, and reduces the high-temperature viscosity of the resin by adding plasticizer and leveling agent to improve its high-temperature construction workability. The flowing resin at high temperature effectively fills the surface pores of the cement pavement, and the existence of the terpene resin makes the resin cool and solidify with strong adhesion to the alkaline cement pavement, ensuring the normal path of the hot...

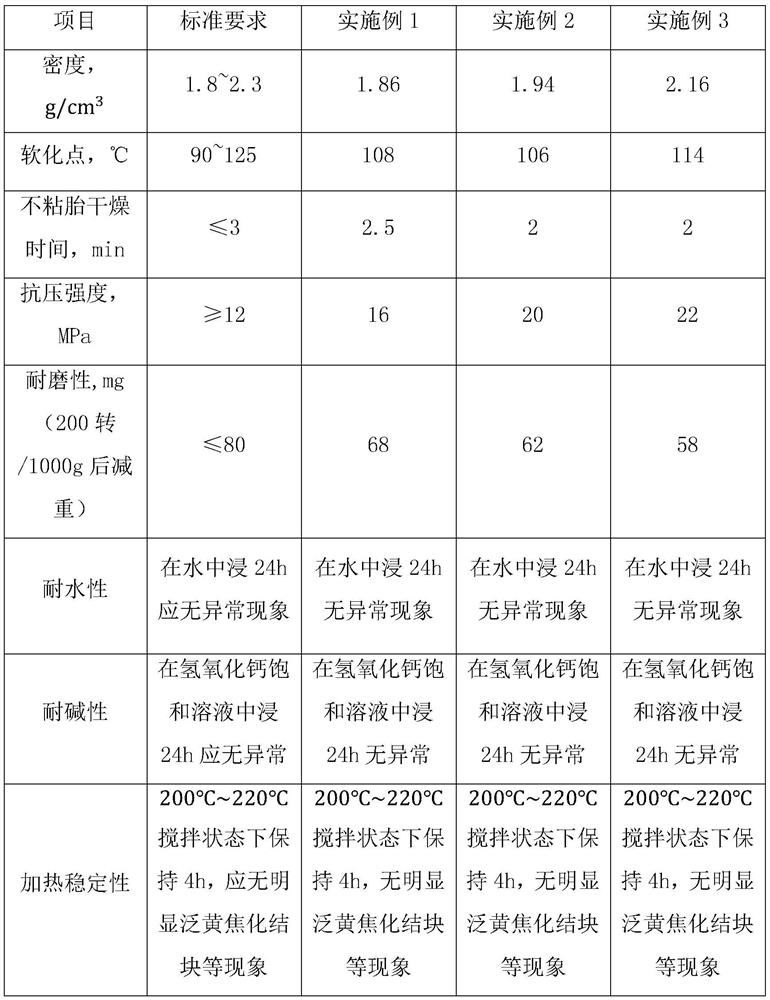

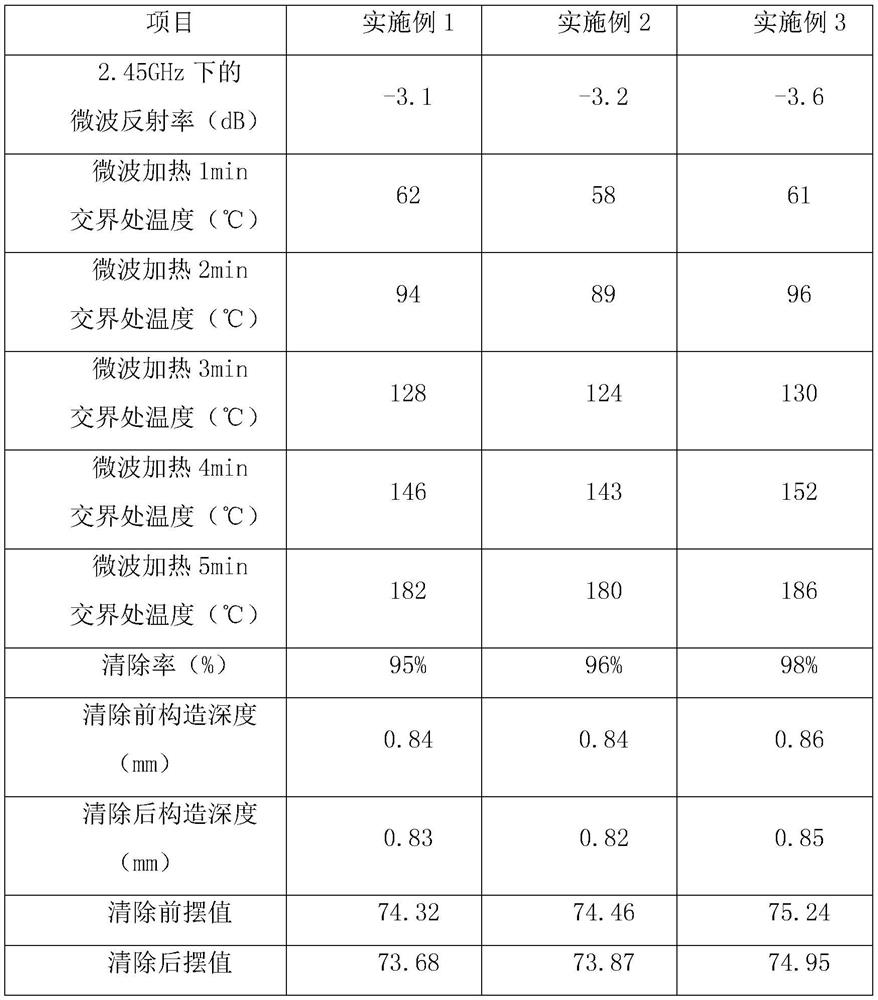

Embodiment 1

[0068] A preparation method for microwave easy-to-clear modified hot-melt markings for cement pavement, comprising the following steps.

[0069] Step 1. Prepare the resin base mixture: adjust the temperature of the hot-melt kettle to 180°C, and add 20 parts of modified C5 petroleum resin, 10 parts of EVA resin, 10 parts of terpene resin, 10 parts of titanium dioxide and 10 parts of siliceous low dielectric constant fillers were stirred at a constant speed for 5 minutes to make them evenly mixed to obtain a resin base mixture.

[0070] Step 2. Prepare the coating mixture: adjust the temperature of the hot-melt kettle to 200°C, and add 5 parts of plasticizer, 2 parts of leveling agent and 20 parts of modified composite microwave absorber to the hot-melt kettle in turn, and stir at a constant speed for 5 minutes Make it mix evenly, let it stand for 5 minutes and wait for it to cool down to room temperature naturally to prepare the mixture.

[0071] The above-mentioned modified c...

Embodiment 2

[0075] A microwave easy-to-clear modified hot-melt marking for cement pavement and a preparation method thereof comprise the following steps.

[0076] Step 1. Prepare the resin base mixture: adjust the temperature of the hot-melt kettle to 180°C, and add 30 parts of modified C5 petroleum resin, 10 parts of EVA resin, 15 parts of terpene resin, 15 parts of titanium dioxide and 15 parts of siliceous low dielectric constant fillers were stirred at a constant speed for 10 minutes to make them evenly mixed to obtain a resin base mixture.

[0077] Step 2. Prepare the coating mixture: adjust the temperature of the hot-melt kettle to 200°C, and add 8 parts of plasticizer, 2 parts of leveling agent and 30 parts of modified composite microwave absorber to the hot-melt kettle in turn, and stir at a constant speed for 10 minutes Make it mix evenly, let it stand for 10 minutes until it cools down to room temperature naturally, and prepare the coating mixture.

[0078] The above-mentioned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com