Warm mix asphalt viscosity breaking agent

A technology of warm mix asphalt and viscosity reducer, which is used in the field of bridge, road and tunnel paving materials, can solve the problems of lowering mixing temperature, lowering high-temperature viscosity of asphalt, and lowering other properties of asphalt, so as to reduce high-temperature viscosity and reduce aging. , the effect of increasing the softening point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

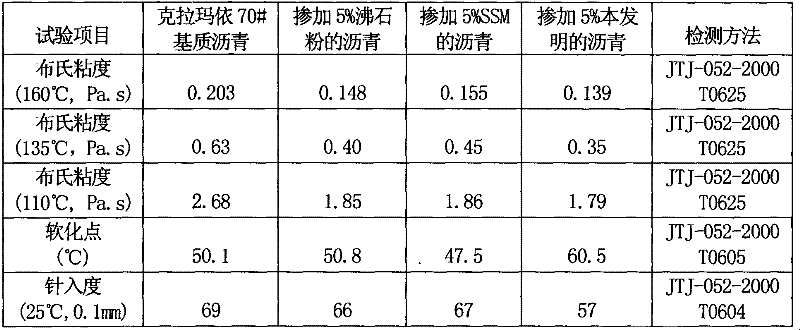

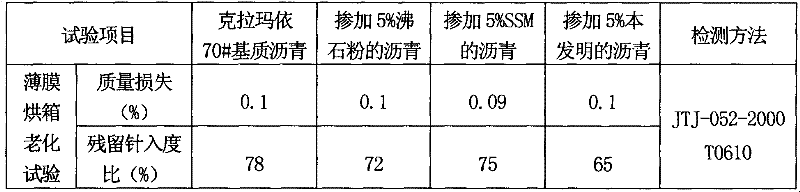

Examples

Embodiment 1

[0014] Taking the preparation of 100g of warm-mix asphalt viscosity reducer of the present invention as an example, it is made from the raw materials of the following mass proportions:

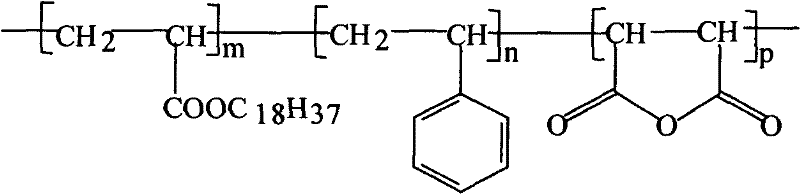

[0015] Octadecyl Acrylate-Styrene-Maleic Anhydride Copolymer 50g

[0017] The above-mentioned zeolite powder has a fineness of 40-80 mesh and a calcium ion exchange capacity of ≥20 mg / g, and is provided by Xinyang Zhongyuan Perlite Thermal Insulation Material Factory.

[0018] The preparation method of above-mentioned warm-mix asphalt viscosity reducer is: 100g stearyl acrylate, 60g styrene, 60g maleic anhydride are added in the there-necked flask, mix well, add 2.2g benzoyl peroxide, pass into nitrogen 30 minutes, Stir, heat in a water bath to 80°C, react at a constant temperature for 6 hours, blow nitrogen until the product is cooled, precipitate with methanol, and dry under vacuum at 60°C for 6 hours to obtain a yellow solid octadecyl acrylate-styrene-maleic anh...

Embodiment 2

[0020] Taking the preparation of 100g of warm-mix asphalt viscosity reducer of the present invention as an example, it is made from the raw materials of the following mass proportions:

[0021] Octadecyl acrylate-styrene-maleic anhydride copolymer 66.67g

[0022] Zeolite powder 33.33g

[0023] Its preparation method is identical with embodiment 1.

Embodiment 3

[0025] Taking the preparation of 100g of warm-mix asphalt viscosity reducer of the present invention as an example, it is made from the raw materials of the following mass proportions:

[0026] Octadecyl Acrylate-Styrene-Maleic Anhydride Copolymer 25g

[0027] Zeolite powder 75g

[0028] Its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com