Yb2O3-doped fluorine-free low-dielectric constant glass fiber and preparation method thereof

A low dielectric and glass fiber technology, applied in the field of glass fiber, can solve the problems of unfavorable industrial production of glass fiber, lower glass forming temperature, and lower dielectric loss

Inactive Publication Date: 2019-11-15

UNIV OF JINAN

View PDF9 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] A low-dielectric glass fiber disclosed in Chinese patent 96194439.0 reduces the content of CaO, which means that the possibility of glass crystallization is reduced, and its dielectric constant reaches about 4.2~4.5. However, in order to improve the melting performance, the glass The fiber introduces 1~4% TiO 2 , while TiO 2 The introduction of glass will tint, limiting its application

The domestic patent CN102503153A of Chongqing International Composite Materials Co., Ltd. introduces a glass fiber with a low dielectric constant, and its dielectric constant can reach about 4.1, but the molding temperature of the glass fiber is about 1300 ° C, which is not conducive to the industrial production of glass fiber

The patent CN102531401A of PPG Industry Ohio Company of the United States introduces the reduction of the forming temperature of the glass under the condition of ensuring the dielectric properties of the glass fiber, and the lowest temperature can reach 1244°C. Elements, the introduction of F elements will cause serious harm to the environment in production

French patent 02810477.3 discloses a low dielectric glass fiber, P 2 o 5 It is one of the components, so that the dielectric loss of glass fiber at high frequencies is significantly reduced at lower frequencies, but its dielectric constant is around 5 during the frequency change process, and there is no significant improvement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0031] The present invention will be illustrated by the following series of specific example schemes, however, those skilled in the art will appreciate that many other embodiments are contemplated in accordance with the principles of the invention. The specific embodiments described herein should not be considered as limiting the scope of the present invention, which is defined by the claims.

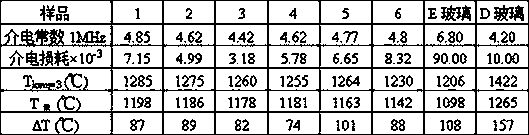

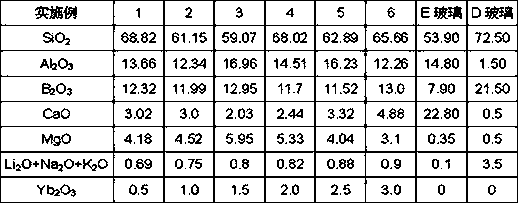

[0032] Embodiment 1~6 and comparative example.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides Yb2O3-doped fluorine-free low-dielectric constant glass fiber and a preparation method thereof. The dielectric constant and dielectric loss of glass fiber are reduced through addition of rare earth oxide Yb2O3. The glass fiber composition does not contain the fluorine element at all, so that the environment is protected to a large extent. The glass fiber comprises the components: in percent by mole, 55-75% of SiO2, 5-20% of Al2O3, 7-15% of B2O3, 0-8% of CaO + MgO, 0.1-1% of Li2O + Na2O + K2O and 0.1-7% of Yb2O3. The dielectric constant and dielectric loss of the preparedglass fiber can reach a good level, the dielectric constant and dielectric loss at room temperature and 1 MHz are 4.4-4.97 and 3.1x10<-3)-8.45x10<-3> separately, and the glass fiber has excellent lowdielectric properties, good thermal stability and a wide molding temperature range at the same time, and is suitable for a reinforcing material for substrates for printed circuit boards.

Description

technical field [0001] The invention belongs to the technical field of glass fiber and relates to a rare earth oxide doped Yb 2 o 3 (ytterbium oxide) fluorine-free low-dielectric glass fiber, which is conducive to large-scale production and can be applied to the field of copper clad laminate production. Background technique [0002] Low-dielectric glass fiber has a low dielectric constant and dielectric loss, and can be woven into electronic-grade glass fiber cloth, and used as a supporting skeleton material for copper-clad laminates and composited with resin to enhance the strength of copper-clad laminates. Copper clad laminates are used as electrical components for circuit etching and finally made into printed circuit boards, making the equipment light, flexible and highly integrated. Copper clad laminates can be widely used in aerospace, communications, military weapons, household appliances and all aspects of life. Since excessive dielectric constant and dielectric lo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03C13/00C03B5/16C03B37/08C03C25/12

CPCC03B5/16C03B37/08C03C13/00C03C25/12

Inventor 岳云龙杨胜赟康俊峰张路路屈雅

Owner UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com