High-solid-content emulsified asphalt for stress absorbing layer, preparation method and construction method thereof

A stress-absorbing layer and emulsified asphalt technology, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of complex construction procedures and high construction costs, achieve excellent fatigue resistance, reduce construction costs, and ensure adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

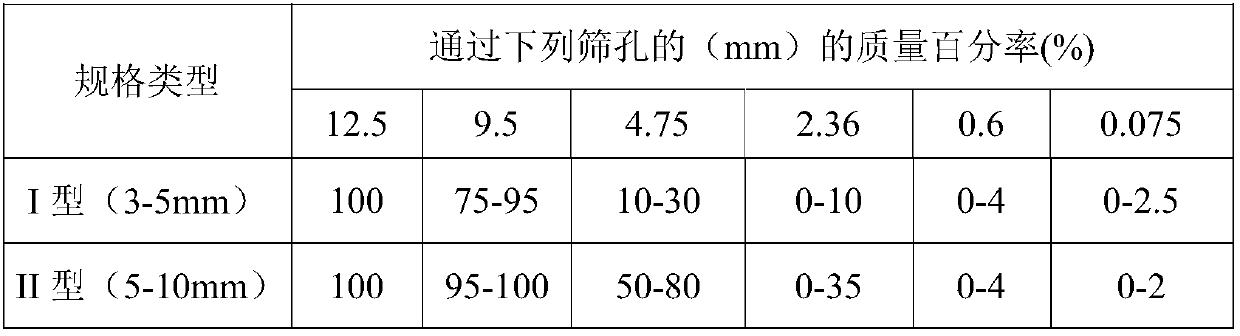

Method used

Image

Examples

Embodiment 1

[0068] 1. Preparation of emulsified asphalt

[0069] a. Preparation of raw materials: AH-50 ordinary asphalt accounts for 50wt%, oxygen amine emulsifier accounts for 0.7wt%, styrene-butadiene latex modifier accounts for 10.0wt%, furfural extract oil asphalt additive accounts for 12wt%, and the remaining components are water And pH regulator, wherein water adopts tap water, and pH regulator is hydrochloric acid, by mass percentage;

[0070] b. Add the asphalt modifier described in a to ordinary asphalt, mix well, and heat to 135°C;

[0071] c. Weigh the emulsifier, modifier and water in proportion to prepare the soap solution, adjust the pH value of the soap solution to 2.0 with acid, and then heat to 50°C;

[0072] d. Pass the above-mentioned emulsifier soap solution and the mixture of asphalt and asphalt additives through a colloid mill in sequence to obtain emulsified asphalt finished product after grinding.

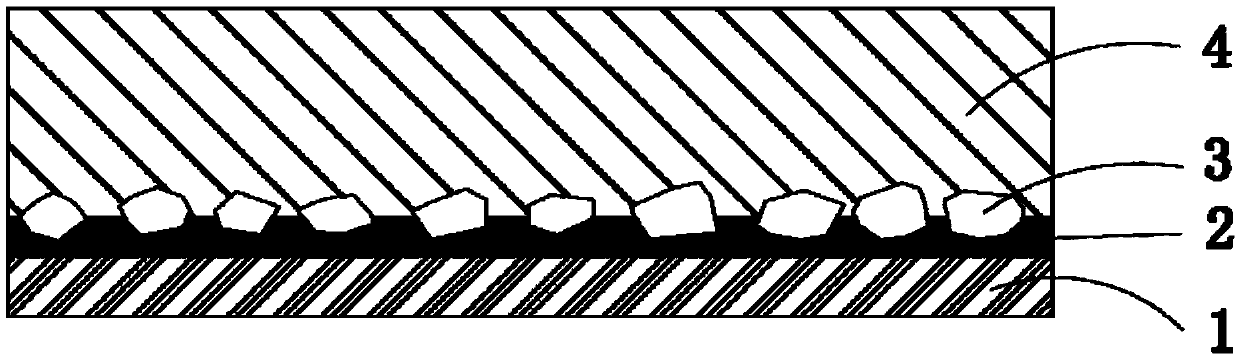

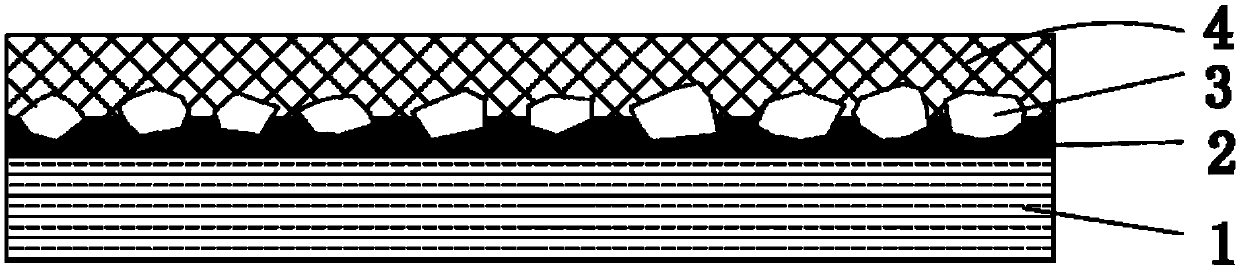

[0073] 2. Construction of emulsified asphalt

[0074] combine ...

Embodiment 2

[0080] 1. Preparation of emulsified asphalt

[0081] a. Preparation of raw materials: AH-70 ordinary asphalt accounts for 61wt%, alkyl polyamine or quaternary ammonium salt emulsifier accounts for 0.2wt%, nitrile latex modifier accounts for 5.0wt%, aromatic hydrocarbon extraction oil asphalt additive accounts for 7wt% %, the remaining components are water and a pH regulator, wherein the water adopts industrial water, and the pH regulator is formic acid, in mass percent;

[0082] b. Add the asphalt additive described in a to ordinary asphalt, mix well, and heat to 135°C;

[0083] c. Weigh the emulsifier, modifier and water in proportion to prepare the soap solution, adjust the pH value of the soap solution to 2.0 with acid, and then heat to 50°C;

[0084] d. Pass the above-mentioned emulsifier soap solution and the mixture of asphalt and asphalt additives through a colloid mill in sequence to obtain emulsified asphalt finished product after grinding.

[0085] 2. Construction ...

Embodiment 3

[0092] 1. Preparation of emulsified asphalt

[0093] a. Preparation of raw materials: AH-130 ordinary asphalt accounts for 70wt%, imidazoline or amide emulsifier accounts for 2.0wt%, butylpyridine latex modifier accounts for 2.0wt%, residual oil asphalt additive accounts for 1wt%, and the remaining components Be water and pH adjusting agent, wherein water adopts distilled water, and pH adjusting agent is hydrochloric acid, by mass percentage;

[0094] b. Add the asphalt additive described in a to ordinary asphalt, mix well, and heat to 135°C;

[0095] c. Weigh the emulsifier, modifier and water in proportion to prepare the soap solution, adjust the pH value of the soap solution to 2.0 with acid, and then heat to 50°C;

[0096] d. Pass the above-mentioned emulsifier soap solution and the mixture of asphalt and asphalt additives through a colloid mill in sequence to obtain emulsified asphalt finished product after grinding.

[0097] 2. Construction of emulsified asphalt

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com