Double reflection crack prevention structure for preventing reflection cracks of composite pavement and implementation method thereof

A technology of compound pavement and reflective cracks, which is applied to roads, roads, on-site coagulation pavements, etc. It can solve the problems of reducing bearing capacity and anti-deformation capacity, weakening the structural integrity of the surface layer, and not setting drainage facilities, etc. , to achieve the effects of resolving stress concentration, solving the problem of reflective cracks, and good adaptability to deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

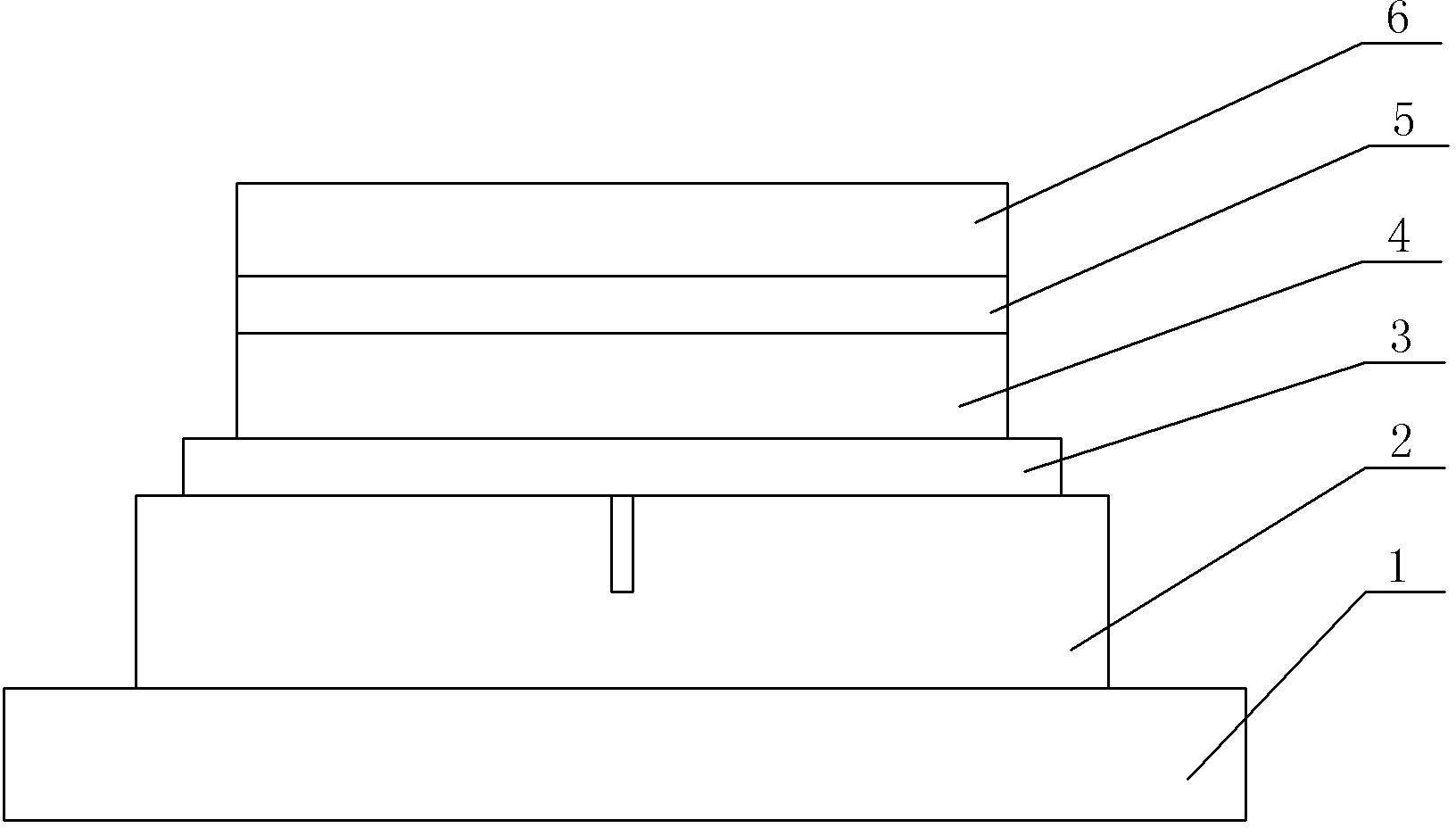

[0023] like figure 1 As shown, the double anti-reflection structure for the prevention and treatment of composite pavement reflective cracks includes, from top to bottom, asphalt upper layer 6, upper anti-reflection layer 5, asphalt lower layer 4, lower anti-reflection layer 3, cement concrete panel 2 and subgrade 1, The upper anti-reflection layer 5 is made of high-viscosity modified asphalt mortar and the lower anti-reflection layer 3 is made of polyester fiberglass cloth, which is especially suitable for joint laying; the thickness of the upper asphalt layer 6 is 4cm, and the mixture type is modified AC13; the thickness of the lower asphalt layer 4 5cm, the mixture type is modified AC16; cement concrete panel 2 C40 cement concrete panel with a thickness of 28cm.

[0024] The concept of "double anti-reverse layer" was proposed for the first time, and it was proposed that in the composite pavement structure, double-layer asphalt mixture pavement should be used, with a total t...

Embodiment 2

[0031] like figure 1 As shown, the double anti-reflection structure for the prevention and treatment of composite pavement reflective cracks includes, from top to bottom, asphalt upper layer 6, upper anti-reflection layer 5, asphalt lower layer 4, lower anti-reflection layer 3, cement concrete panel 2 and subgrade 1, The upper anti-reflection layer 5 adopts polyester fiberglass cloth, and the lower anti-reflection layer 3 adopts rubber asphalt stress absorption layer; the thickness of the upper asphalt layer 6 is 4cm, and the mixture type is modified SMA13; the thickness of the asphalt lower layer 4 is 5cm, and the mixture type is Modified AC16; cement concrete panel 2 C40 cement concrete panel with a thickness of 28cm.

Embodiment approach

[0032] A method for implementing a double anti-reflective structure for preventing and treating reflective cracks on a compound pavement, comprising the following steps:

[0033] (1) Lay cement concrete panel 2 on subgrade 1, and subgrade 1 and cement concrete panel 2 adopt the general cement concrete pavement structure and standard in "Code for Design of Highway Cement Concrete Pavement JTG D40-2011";

[0034] (2) Lay the lower anti-reflection layer 3, the lower asphalt layer 4, the upper anti-reflection layer 5, and the asphalt upper layer 6 on the cement concrete panel 2 in sequence.

[0035] The concept of "double anti-reverse layer" was proposed for the first time, and it was proposed that in the composite pavement structure, double-layer asphalt mixture pavement should be used, with a total thickness of 10~12cm, and fiber sealant or polyester fiberglass cloth should be used between the asphalt layers And other anti-reflection materials are used as the upper anti-reflection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com