Patents

Literature

393results about How to "Release stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

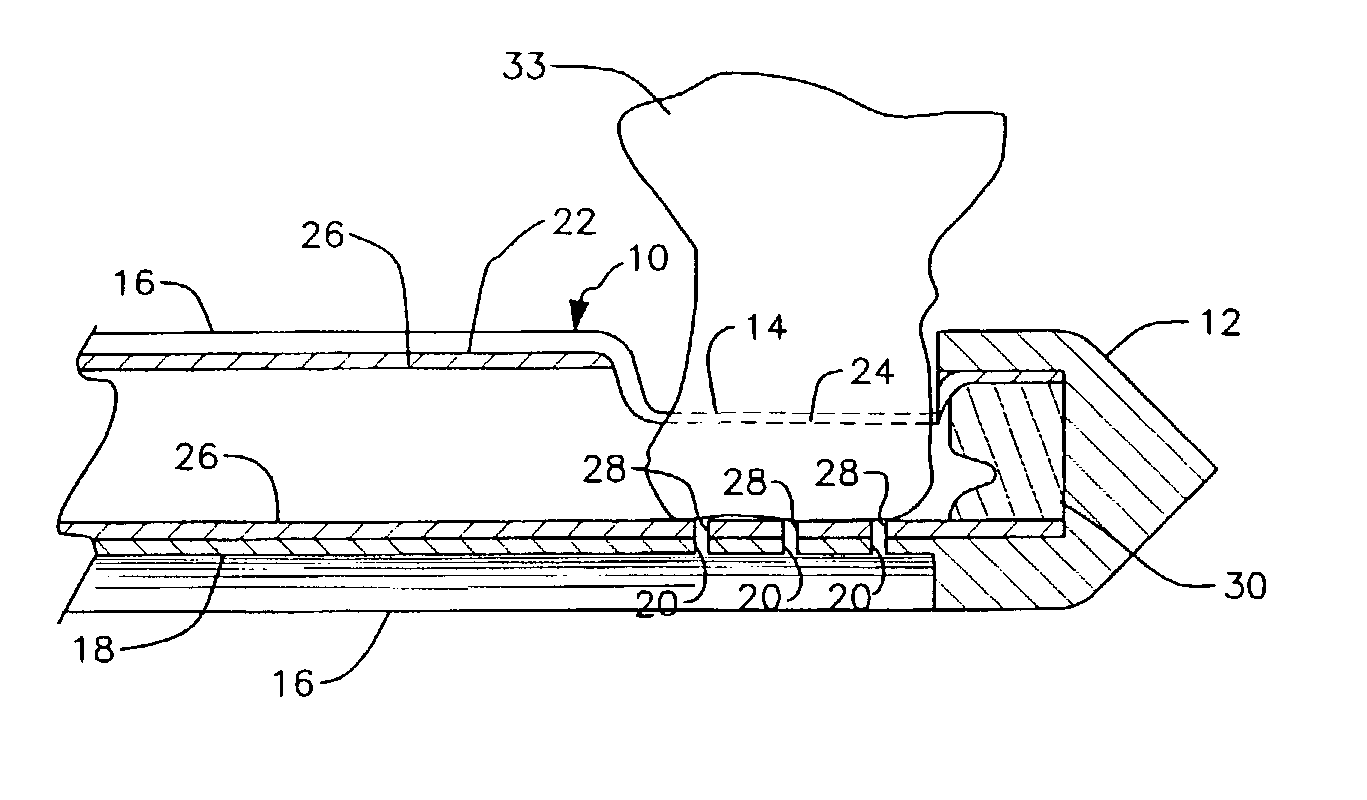

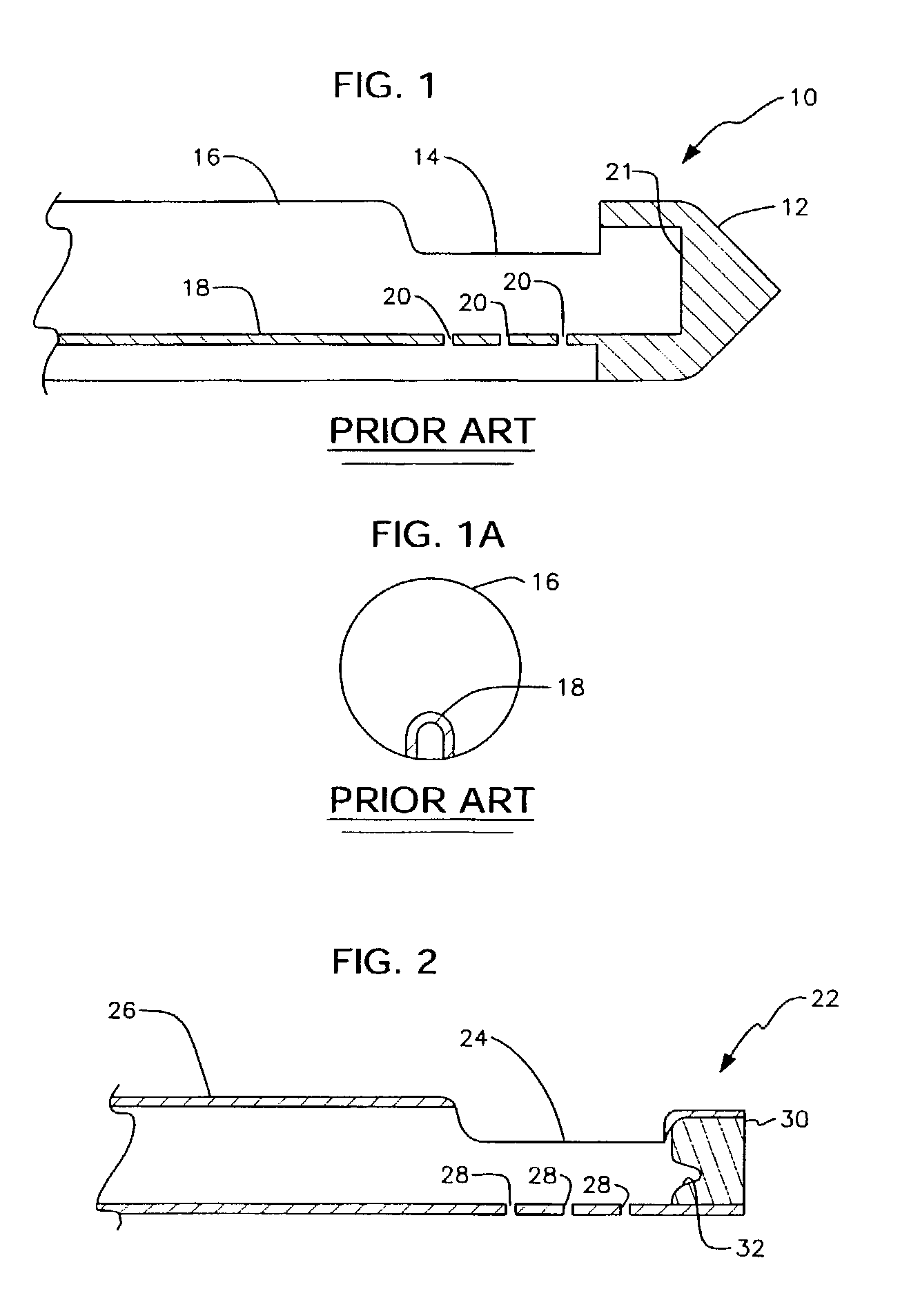

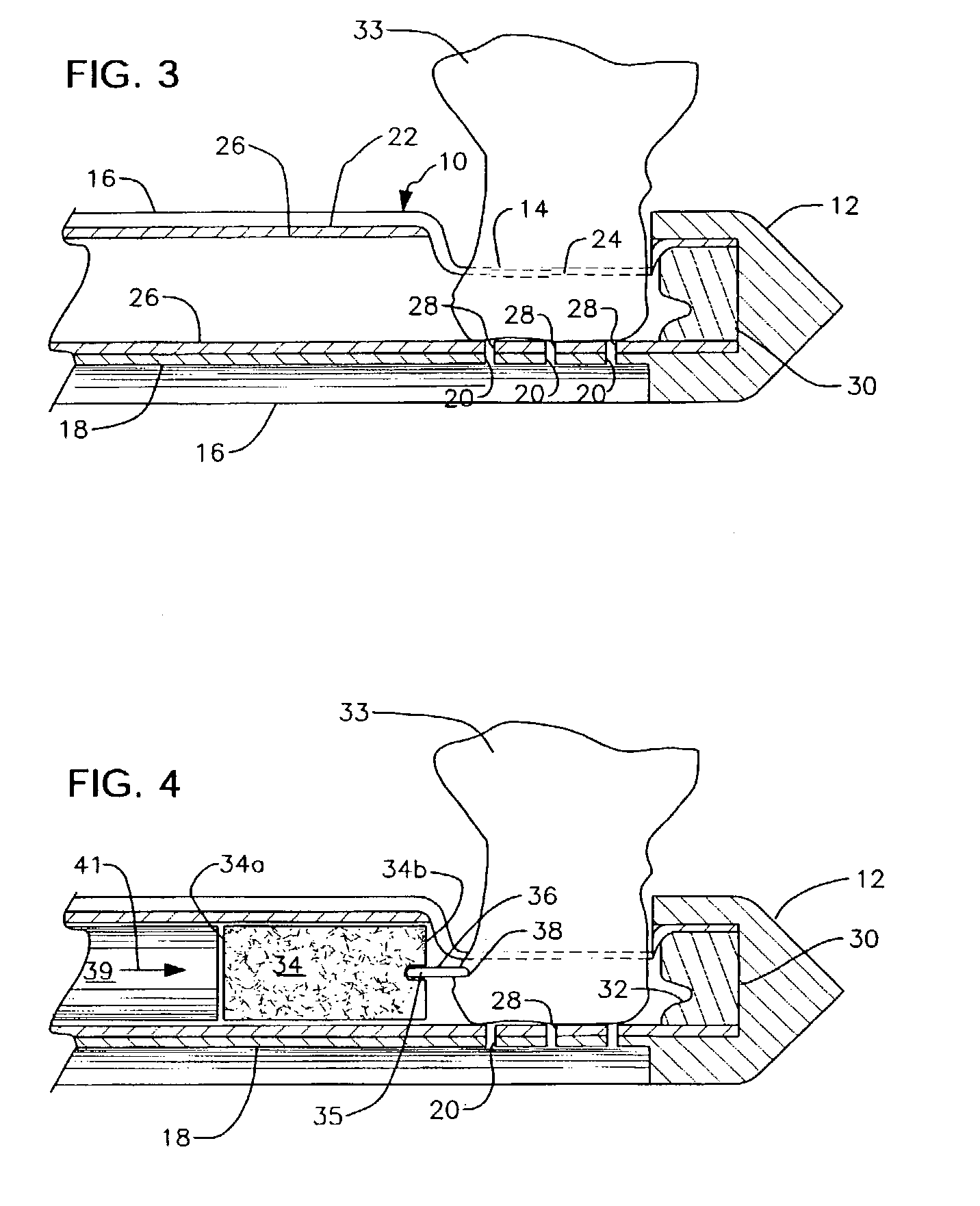

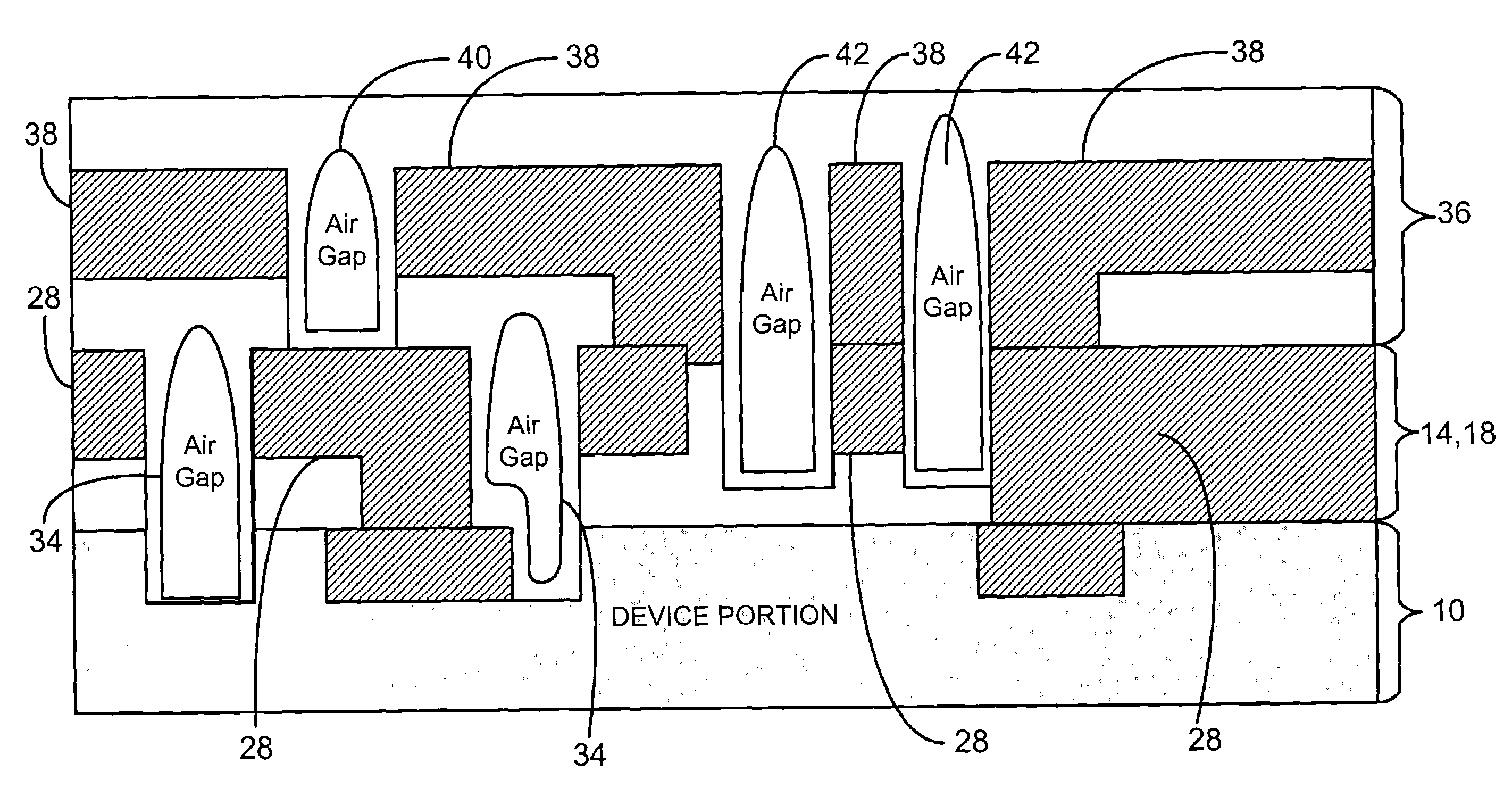

Bioabsorbable marker having external anchoring means

ActiveUS6994712B1Release stressInhibit migrationInfusion syringesSurgeryPermanent markerBiopsy needles

A clip and a bioabsorbable marker are employed to mark a biopsy site. The former provides a permanent marker that is clamped onto tissue and that cannot migrate from the site over time. The latter is gradually bioabsorbed over time but the time may vary widely from weeks to months. In most embodiments, the clip and marker are integrally formed with one another at the time of manufacture. In one embodiment, the clip and marker are independently made but are joined to one another during the site-marking process. The markers are deployed by core biopsy needles of the type employing a vacuum, of the type that does not employ a vacuum, and by coaxial biopsy needles.

Owner:MEDICAL DEVICE TECH

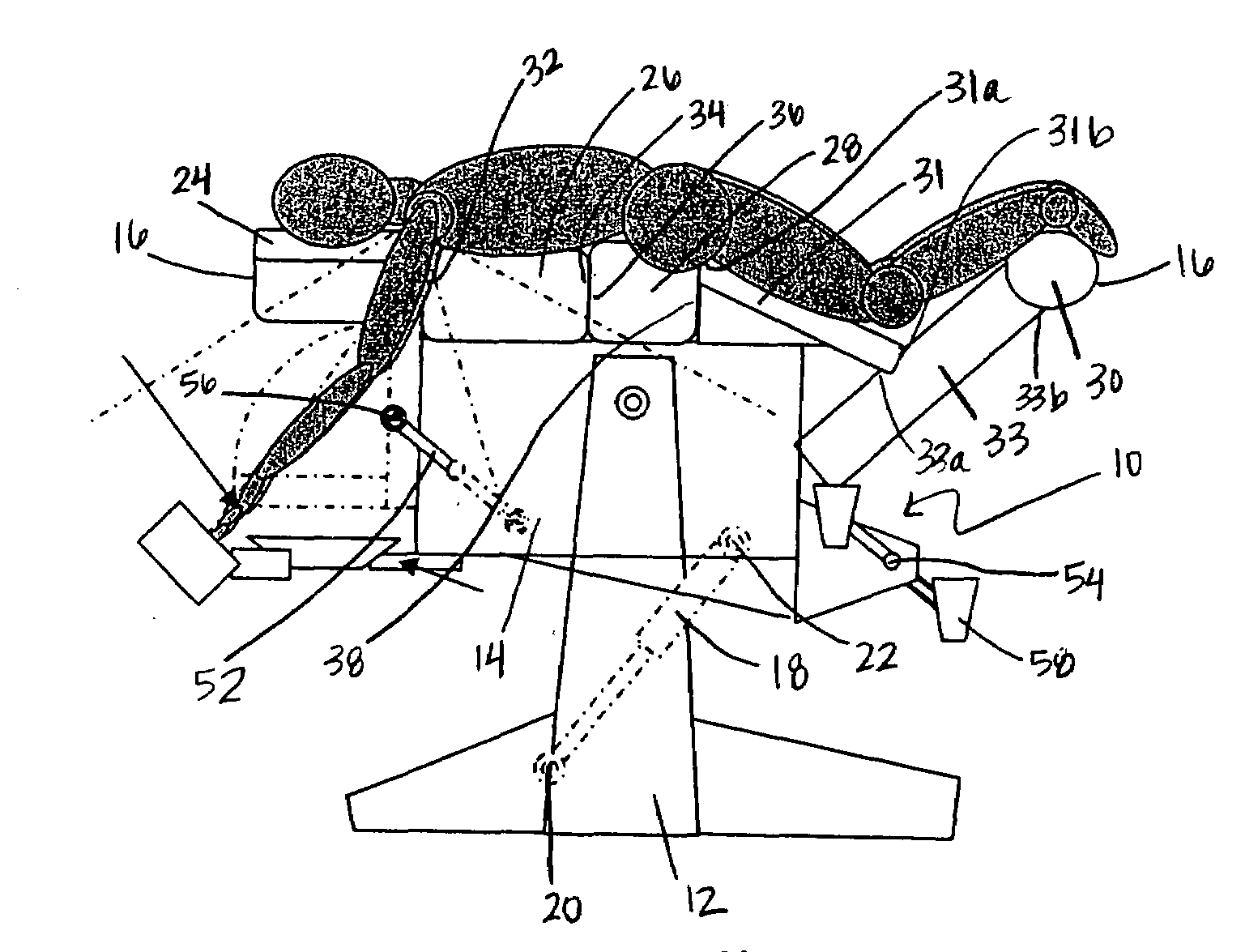

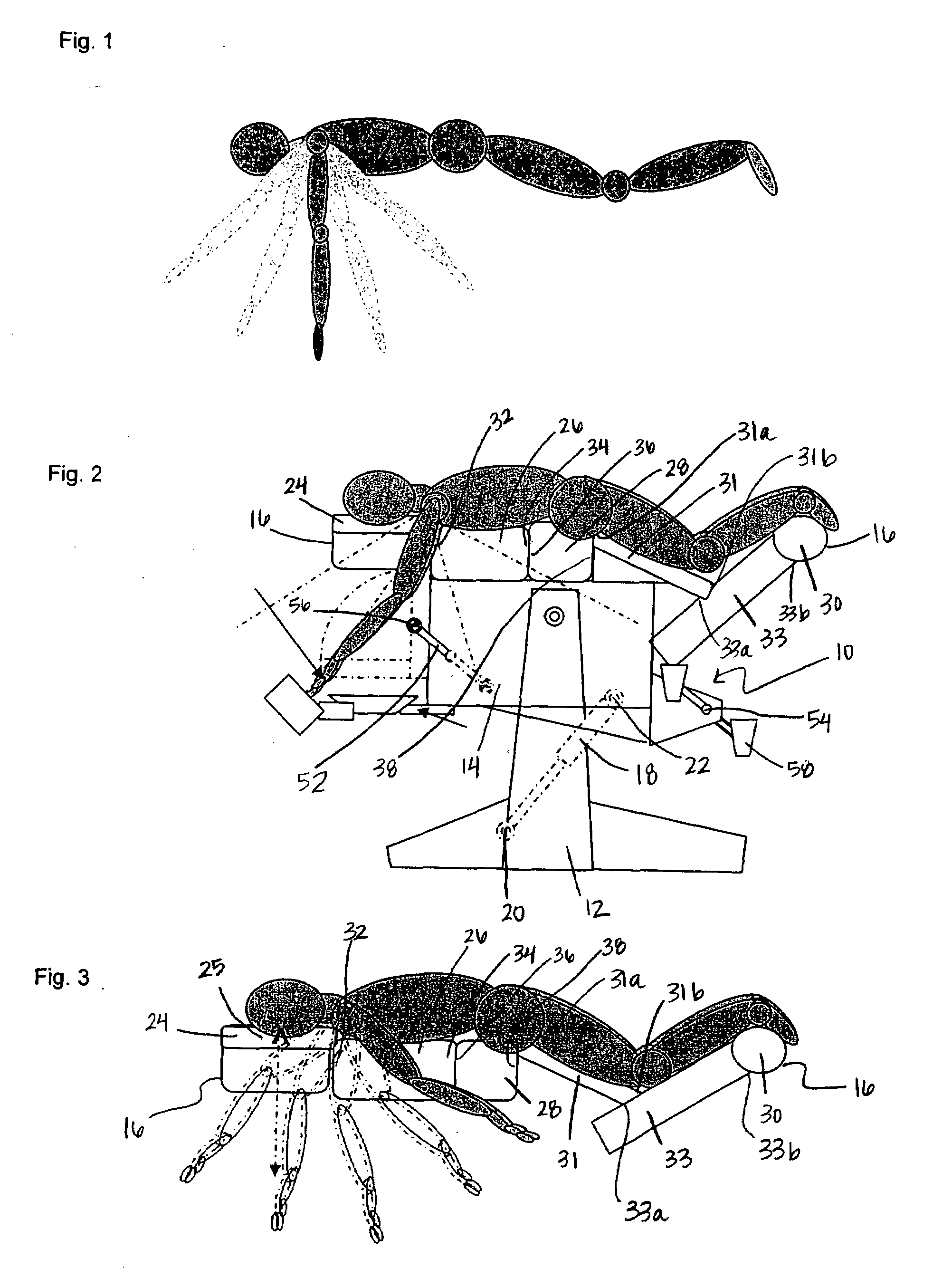

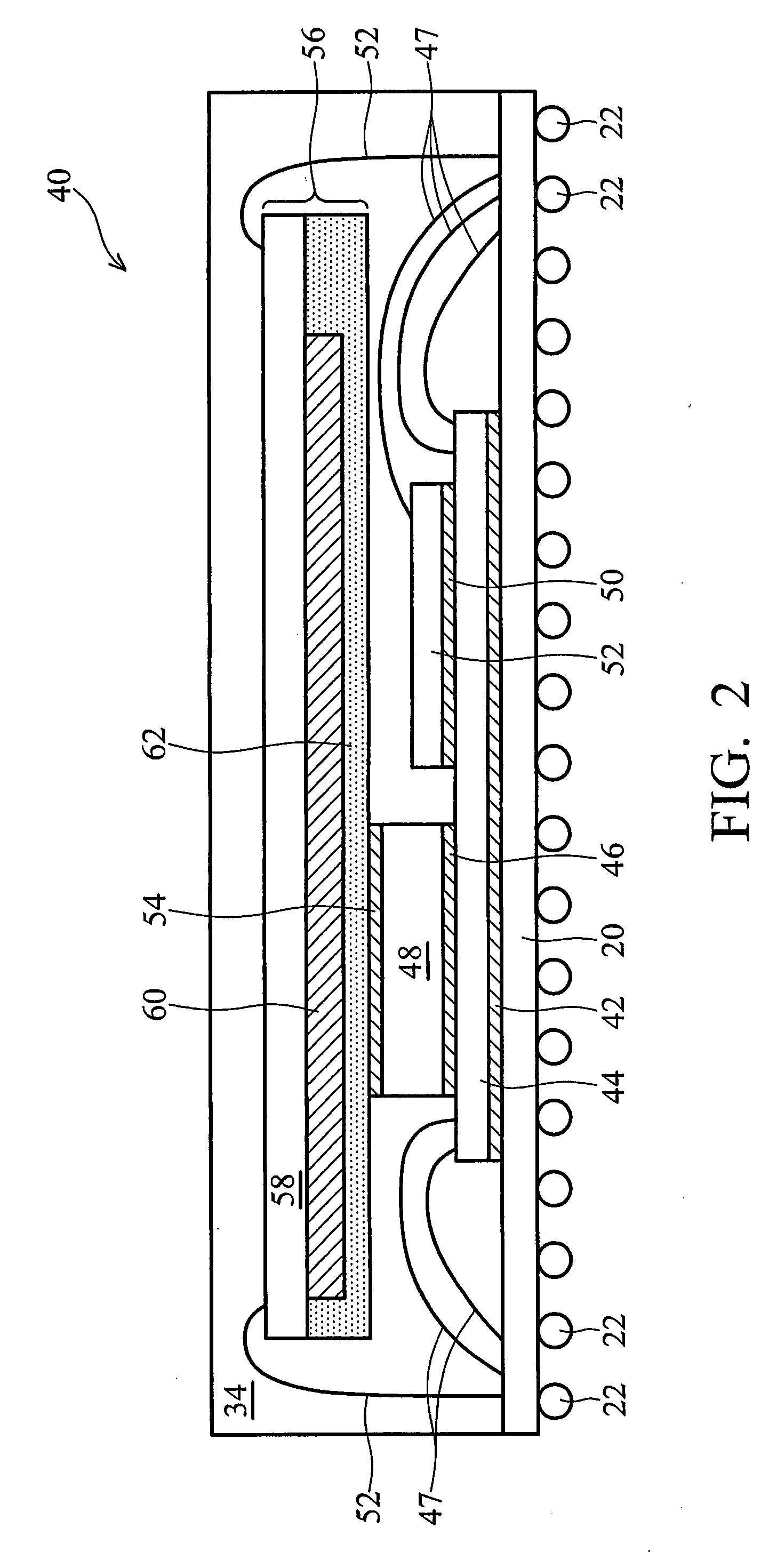

Holistic face-down recovery apparatus and method therefor

InactiveUS20080134434A1Optimizes a patient's recovery regimenMaximize comfortChiropractic devicesNursing bedsEngineeringActuator

A face-down recovery apparatus for use in rehabilitation of patients, particularly vitreoretinal surgical patients. The apparatus has a base and a housing that is pivotally connected to the base by an actuator. A support is positioned contiguously on the housing for received a user in a face-down position. The apparatus is moveable between a substantially vertical, upright orientation to a substantially horizontal orientation. The apparatus is in a substantially upright vertical orientation when the support receives a user in a standing position. The face of a user is secured in a face-down position in a face support, and the rest of the user is secured to the support in a standing position in an unrestricted manner permitting mobility. As the housing is tilted into a horizontal position, the user is positioned in a substantially horizontal orientation. As the user is tilted between the substantially vertical upright orientation and the substantially horizontal orientation, the user's face is continuously maintained in a face-down position in the face support.

Owner:CELAURO PAUL J

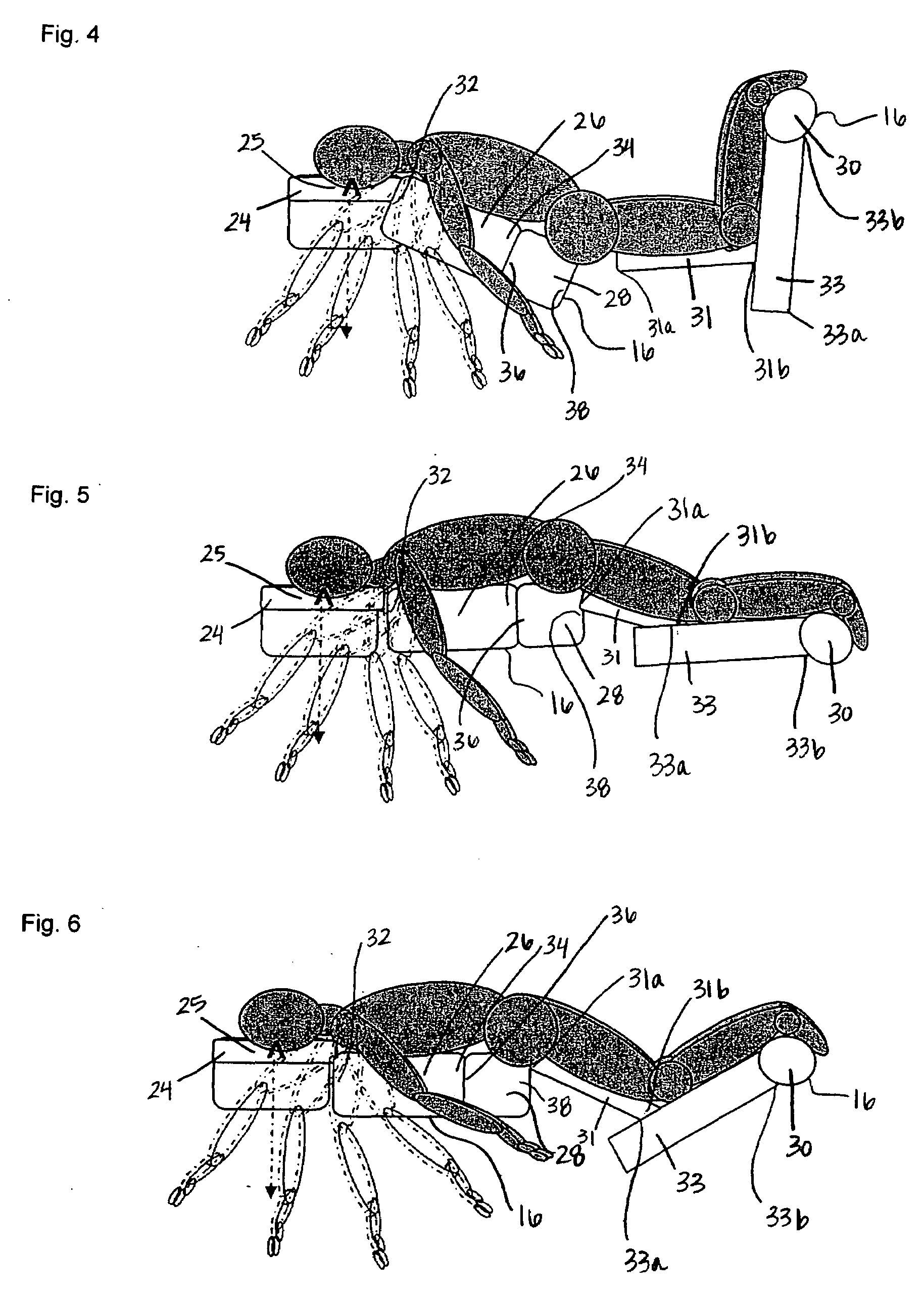

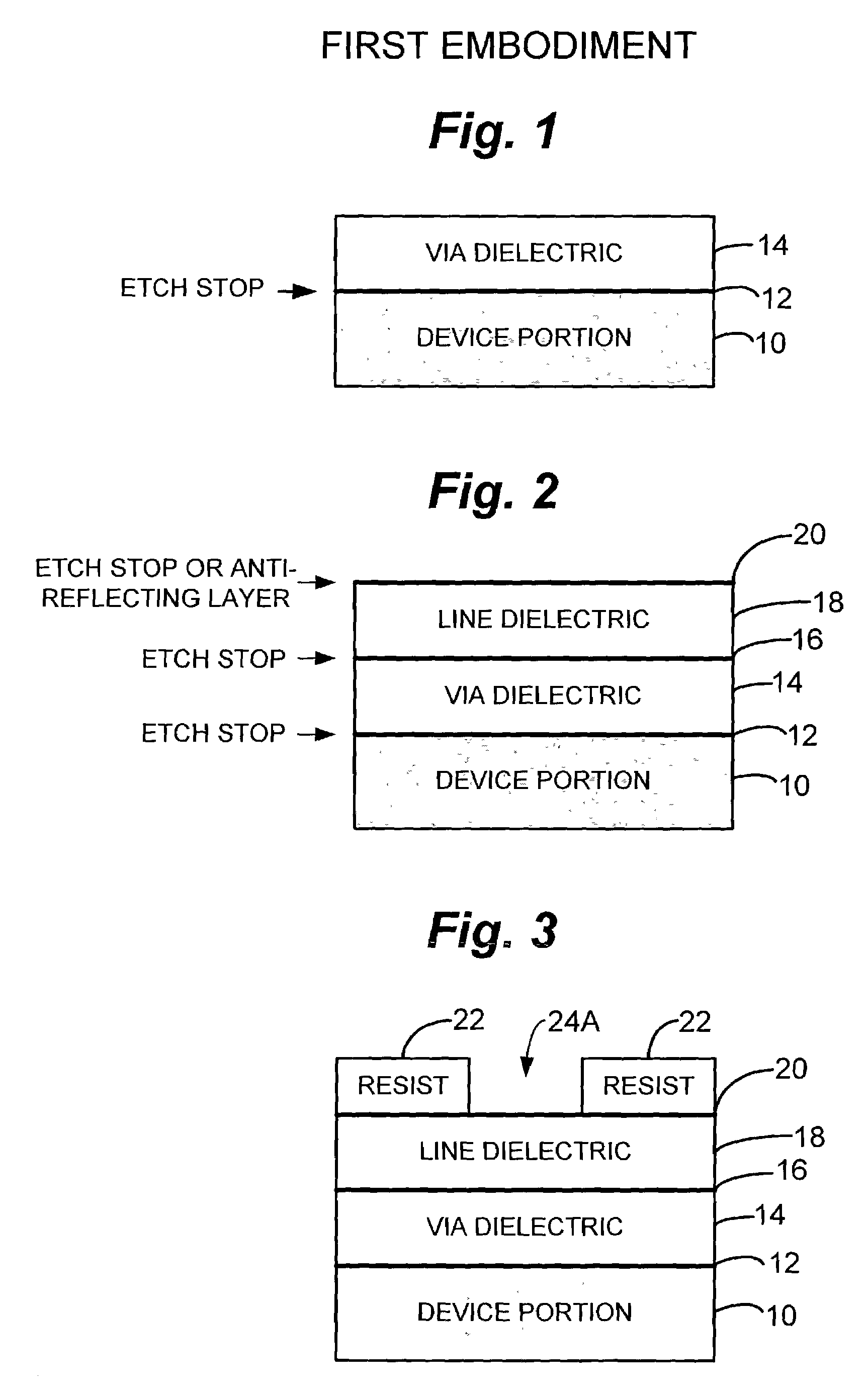

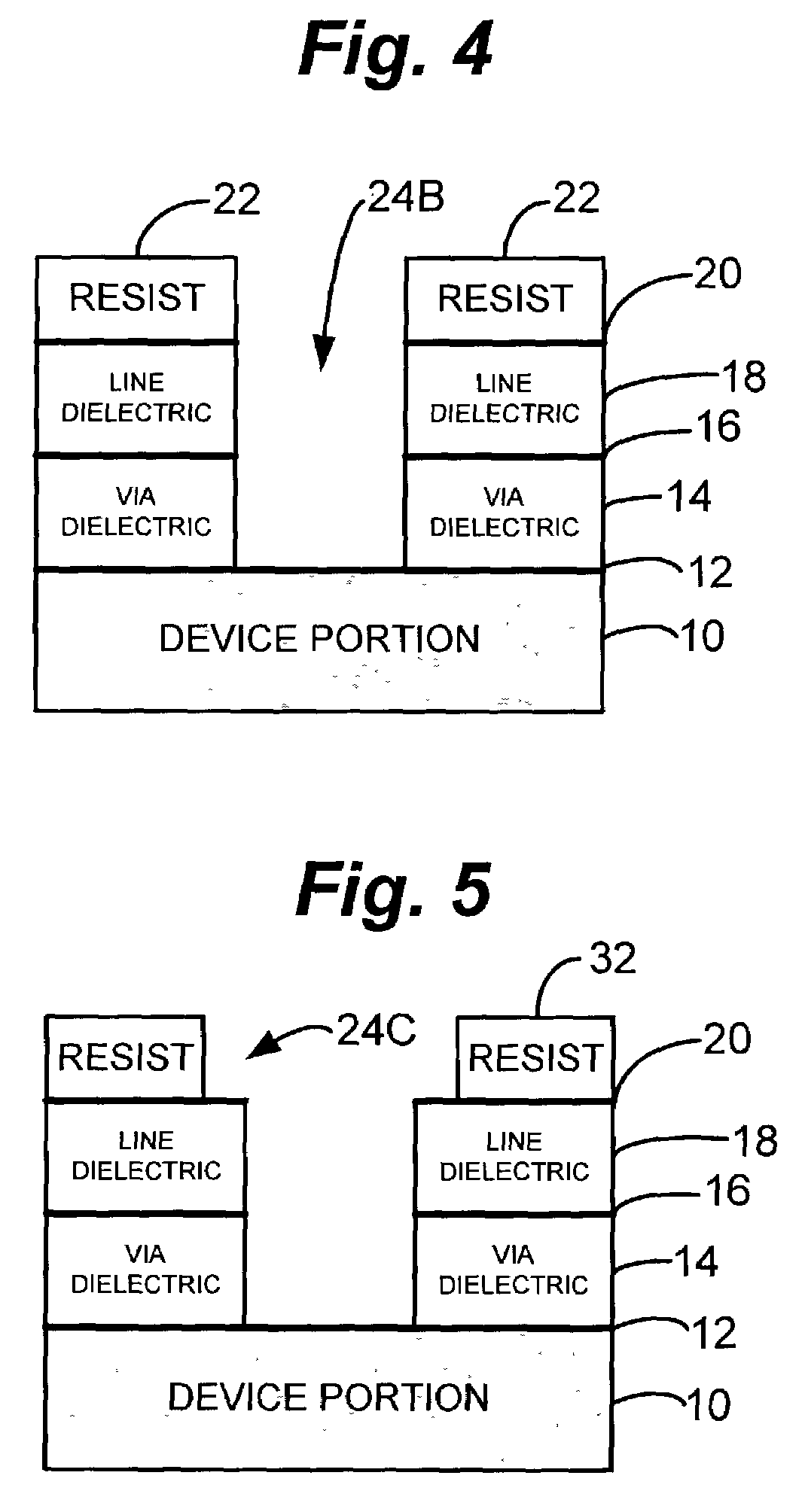

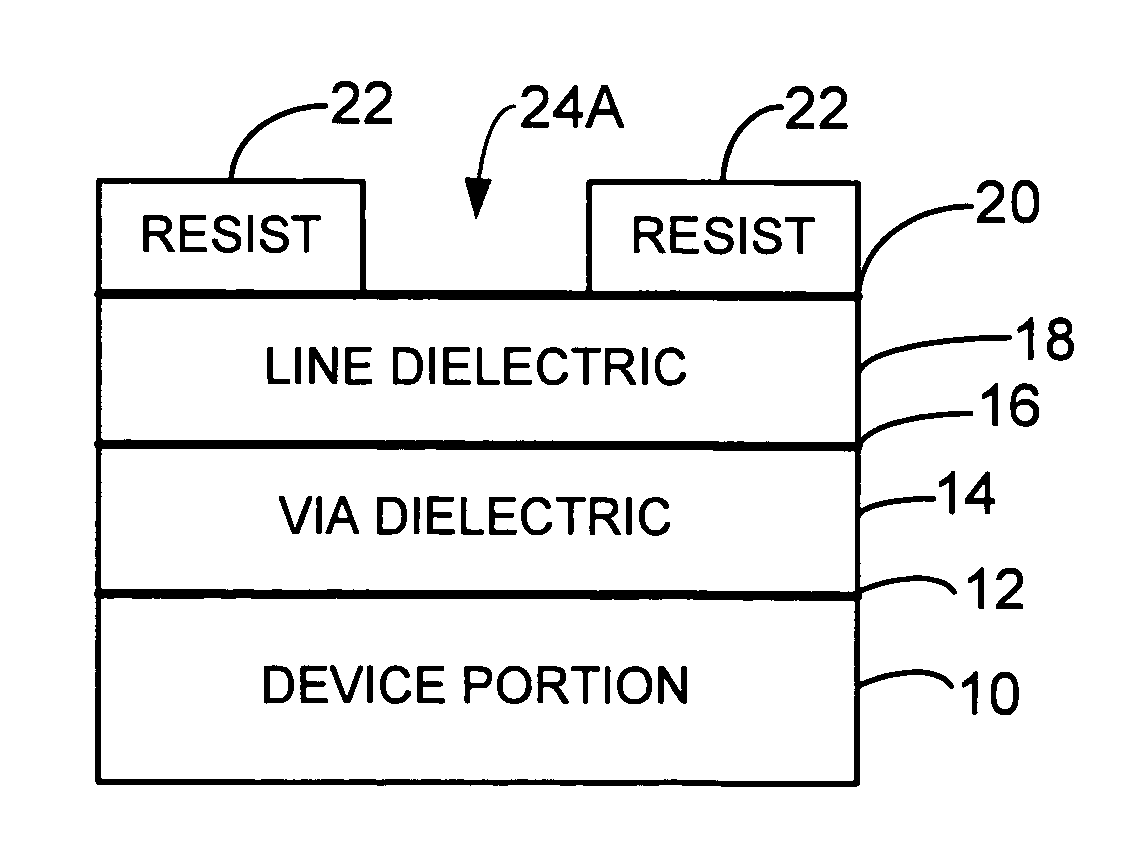

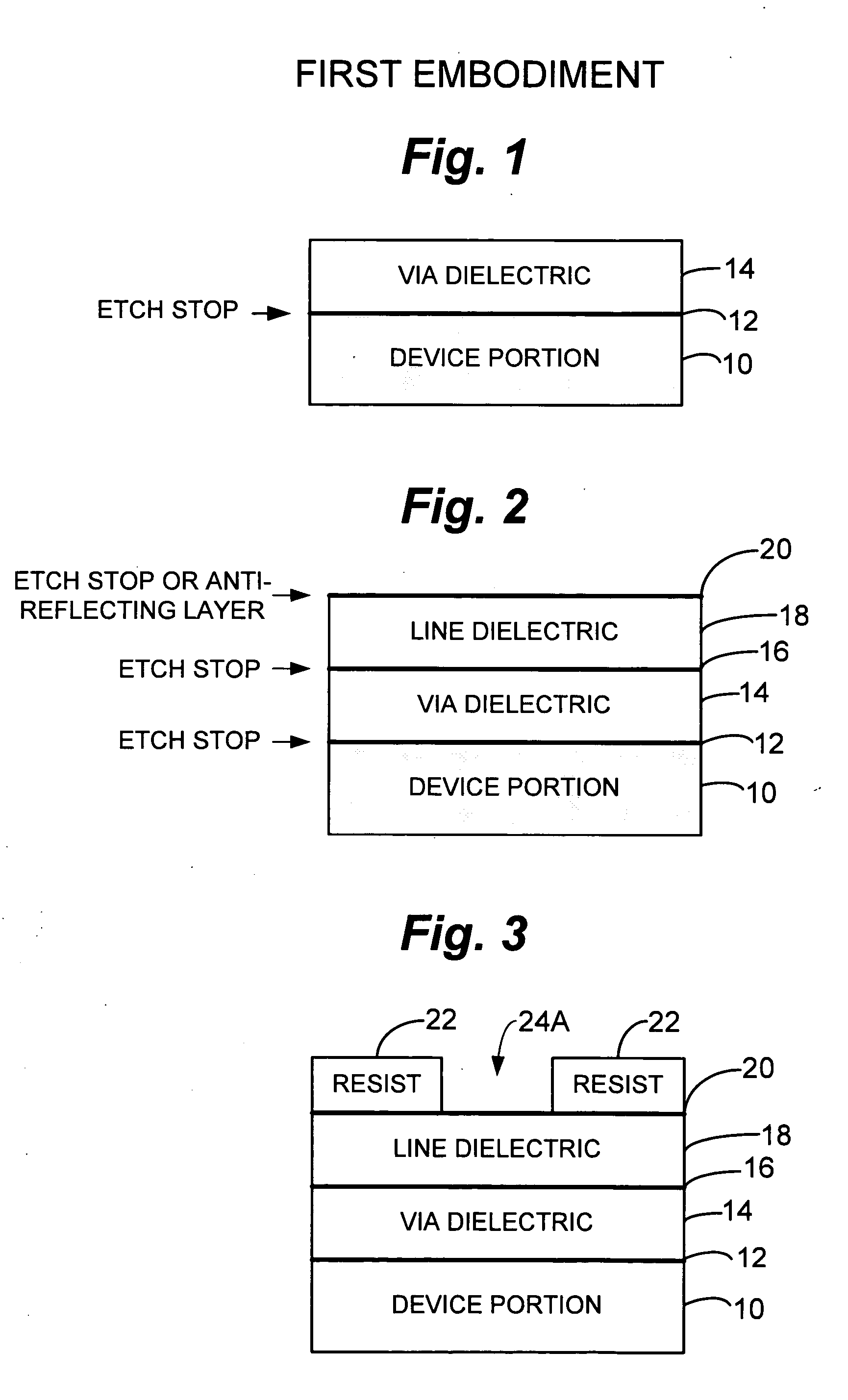

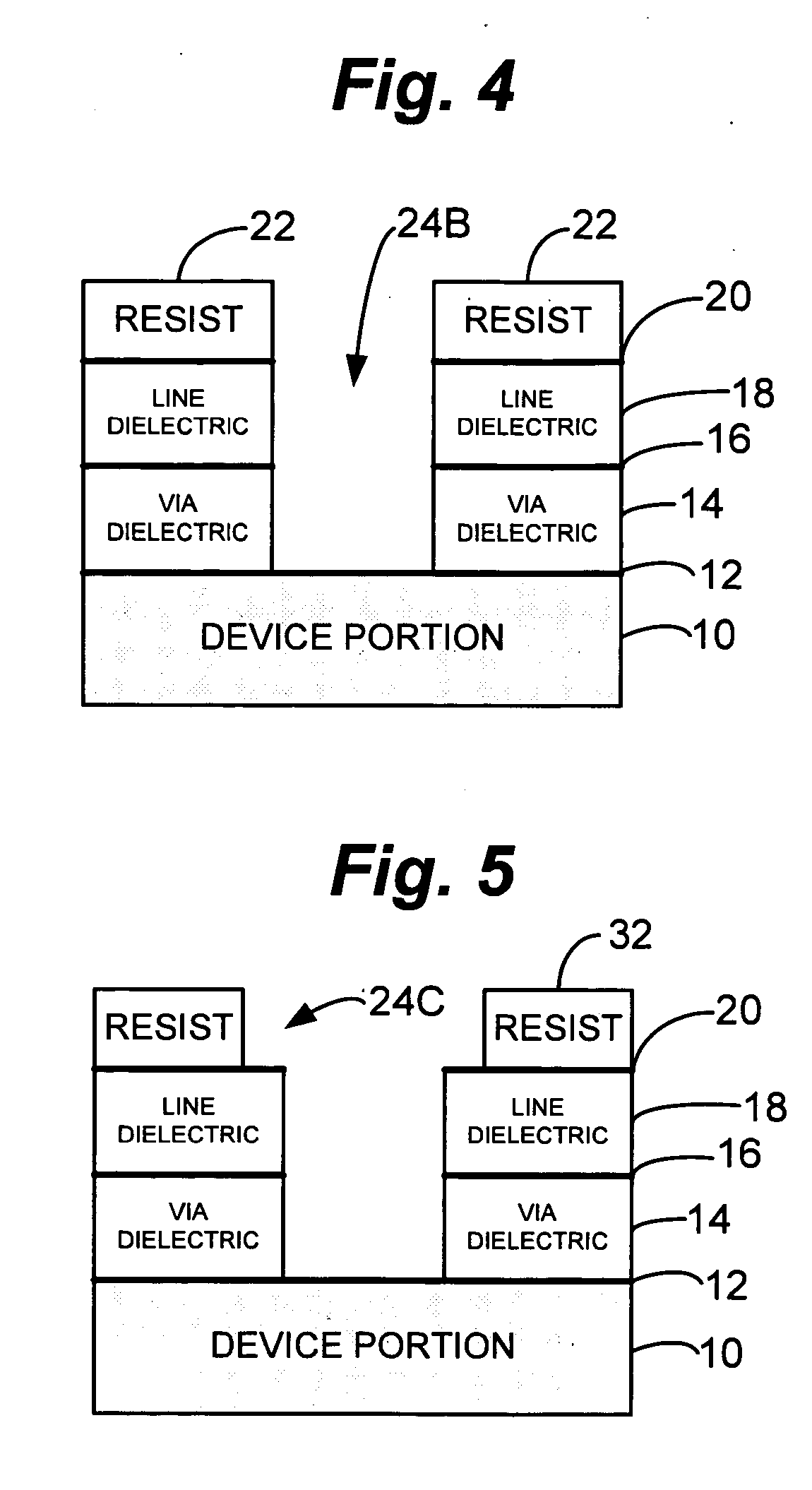

Air gap for dual damascene applications

InactiveUS7449407B2Easily compatibleReadily manufacturableSemiconductor/solid-state device detailsSolid-state devicesCapacitanceEngineering

An air gap structure and formation method for substantially reducing capacitance in a dual damascene based interconnect structure is disclosed. The air gap extends above, and may also additionally extend below, the damascene interconnects desired to be isolated thus minimizing fringing fields between the lines. Multiple levels of the integrated air gap structure can be fabricated to accommodate multiple metal levels.

Owner:UNITED MICROELECTRONICS CORP

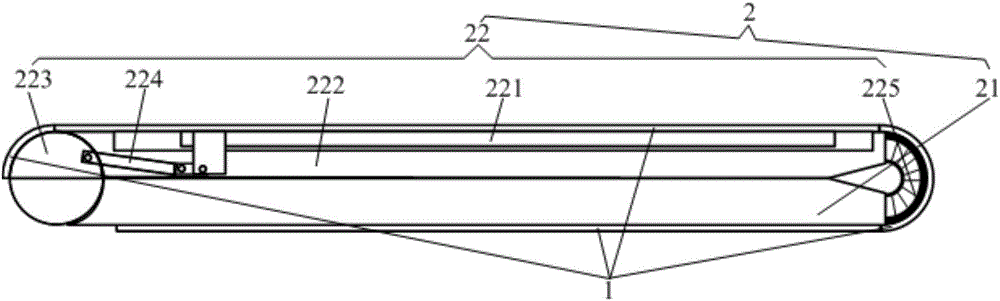

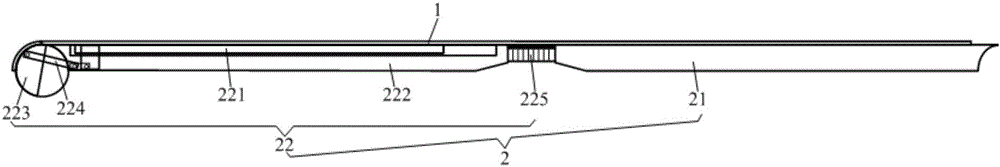

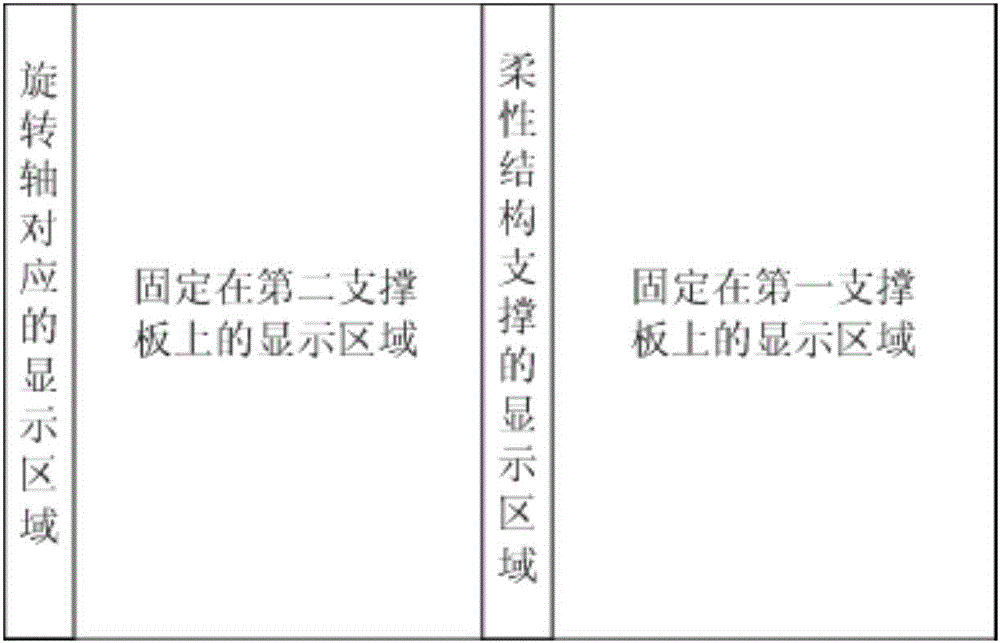

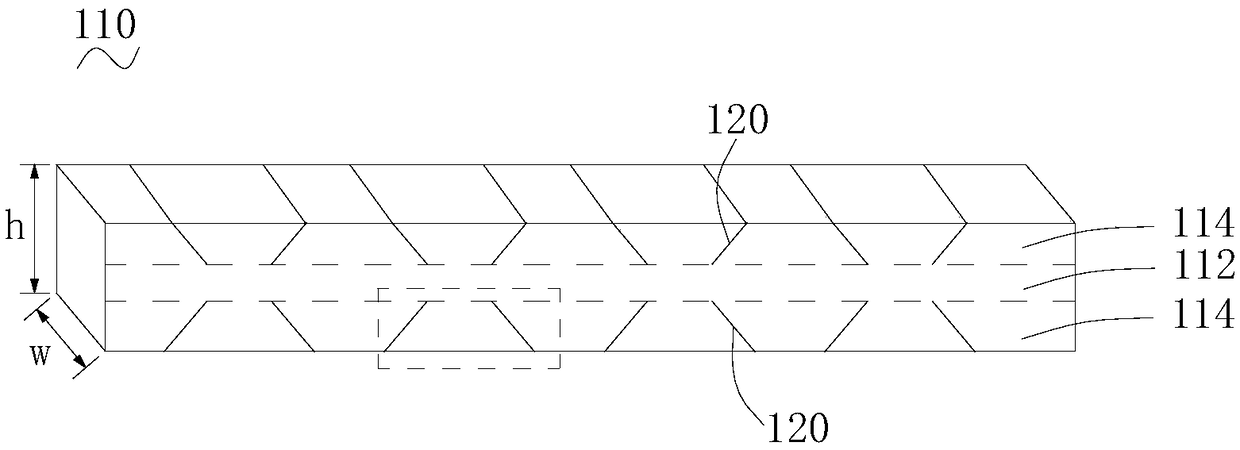

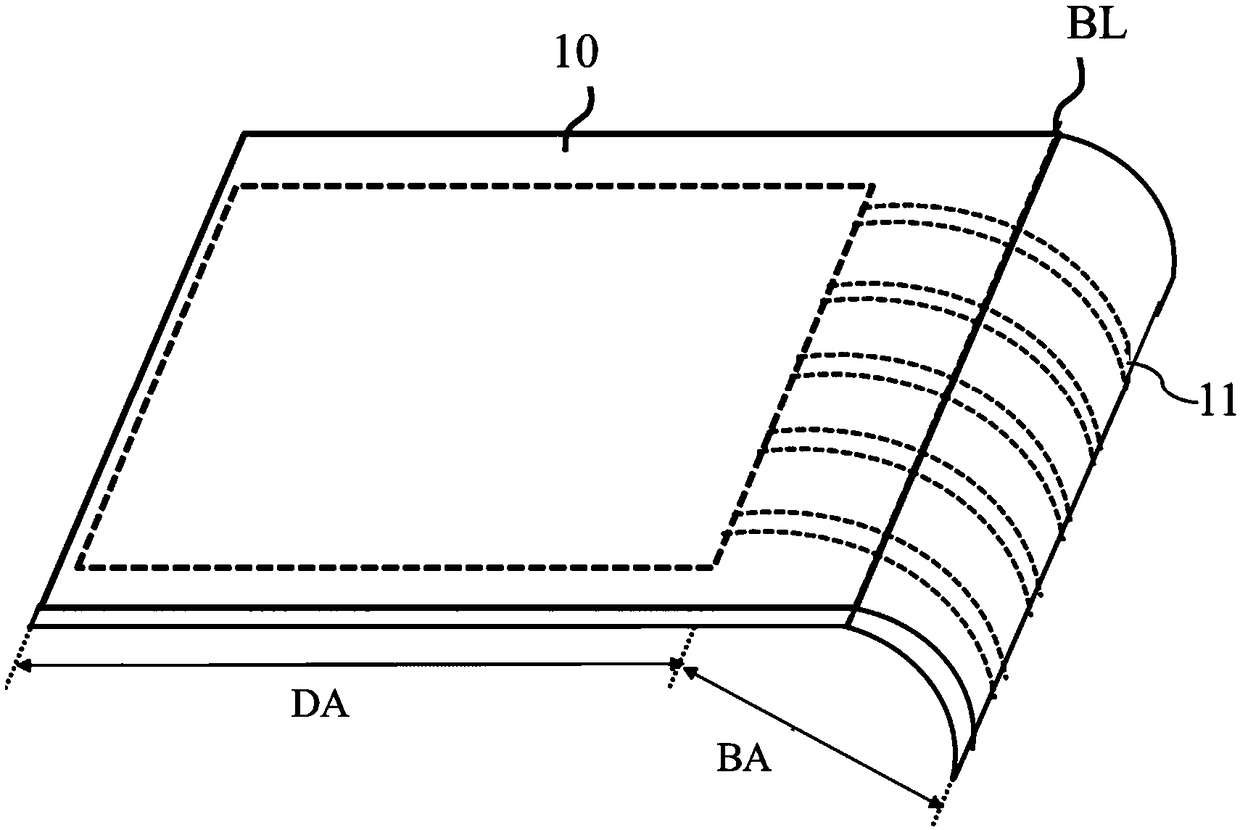

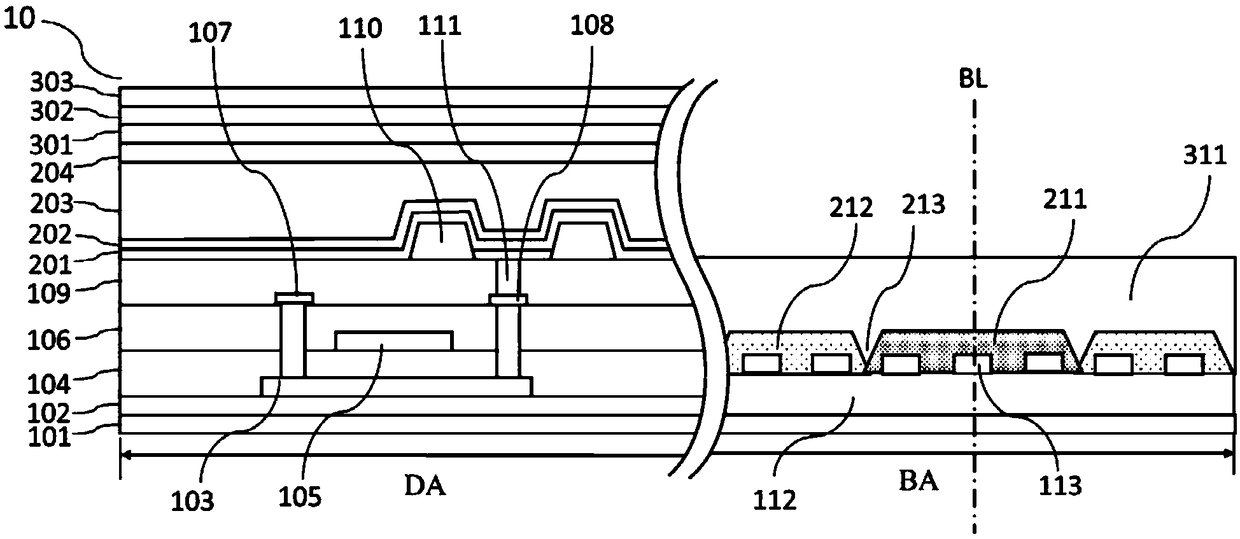

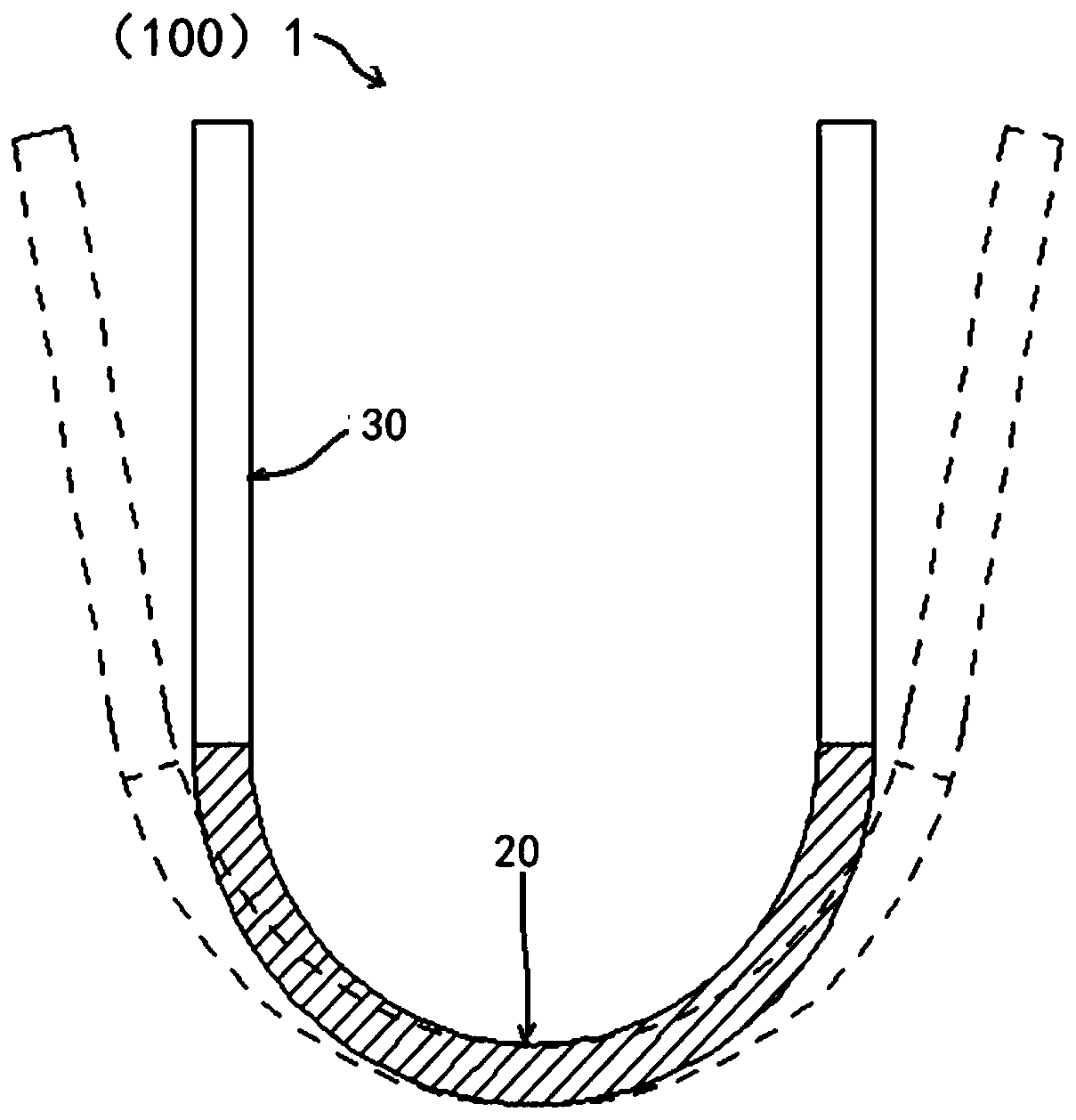

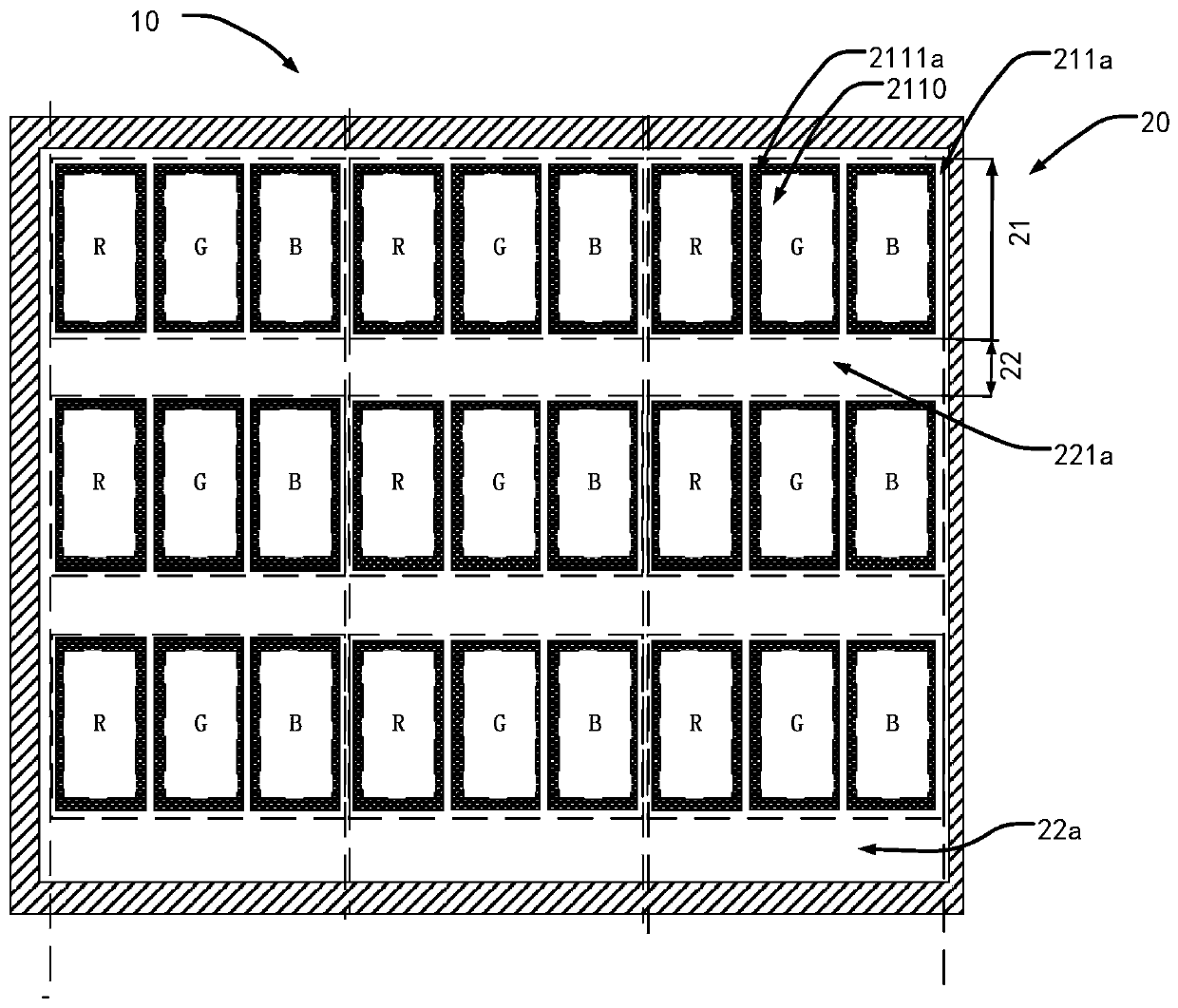

Display device

InactiveCN106157819ARelease stressNot easy to damageCircuit bendability/stretchabilityDetails for portable computersDisplay deviceEngineering

The invention provides a display device which comprises a flexible display screen and an auxiliary folding mechanism. The flexible display screen is arranged on the auxiliary folding mechanism which is used for assisting the flexible display screen in folding and unfolding. By arranging the auxiliary folding mechanism, the auxiliary folding mechanism can assist the flexible display screen in folding and unfolding and adjust inner-outer radius difference of the flexible display screen in the process of folding and unfolding to enable the flexible display screen to effectively release stress in the process of folding and unfolding, so that the flexible display screen is less prone to being damaged in the process of folding and unfolding.

Owner:BOE TECH GRP CO LTD

Air gap formation method for reducing undesired capacitive coupling between interconnects in an integrated circuit device

InactiveUS20050263896A1Easy to manufactureRelease stressSemiconductor/solid-state device detailsSolid-state devicesCapacitanceCapacitive coupling

Owner:UNITED MICROELECTRONICS CORP

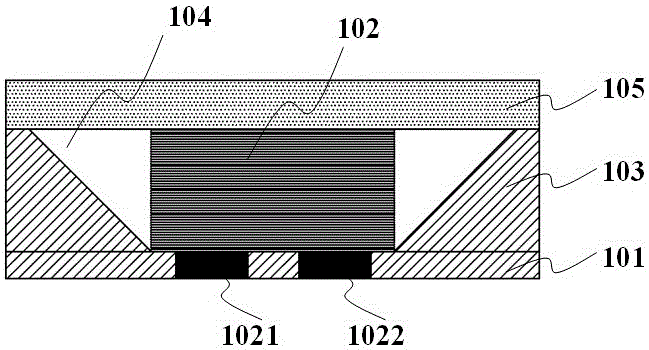

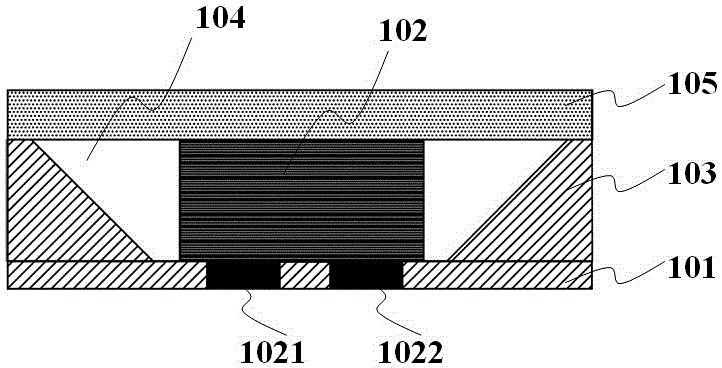

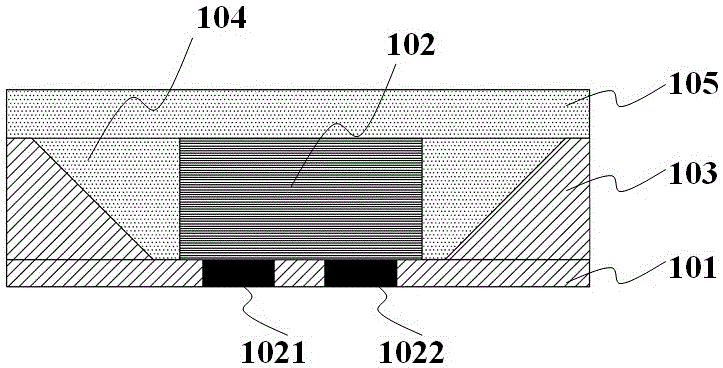

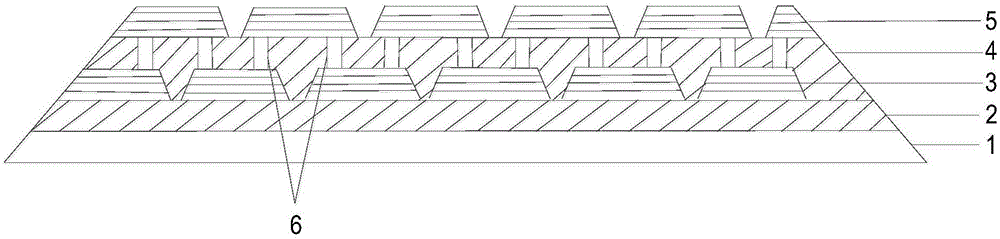

Display device and manufacturing method thereof

ActiveCN103927941ARelease stressImprove the display effectLamination ancillary operationsLayered product treatmentAdhesiveDisplay device

The invention relates to the technical field of display, in particular to a display device and a manufacturing method thereof. The display device comprises at least one curing adhesive layer which is provided with a hollowed-out structure. Internal stress of the display device can be decreased since the curing adhesive layer is provided with the hollowed-out structure. The manufacturing method of the display device includes: preparing a flexible display panel used for displaying images; coating curing adhesives on the flexible display panel to form a first curing adhesive layer with the hollowed-out structure; providing a first flexible panel, placing the first flexile panel on the first curing adhesive layer, and curing the first curing adhesive layer. Using the method can decrease the internal stress of the display device to improve display effects.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

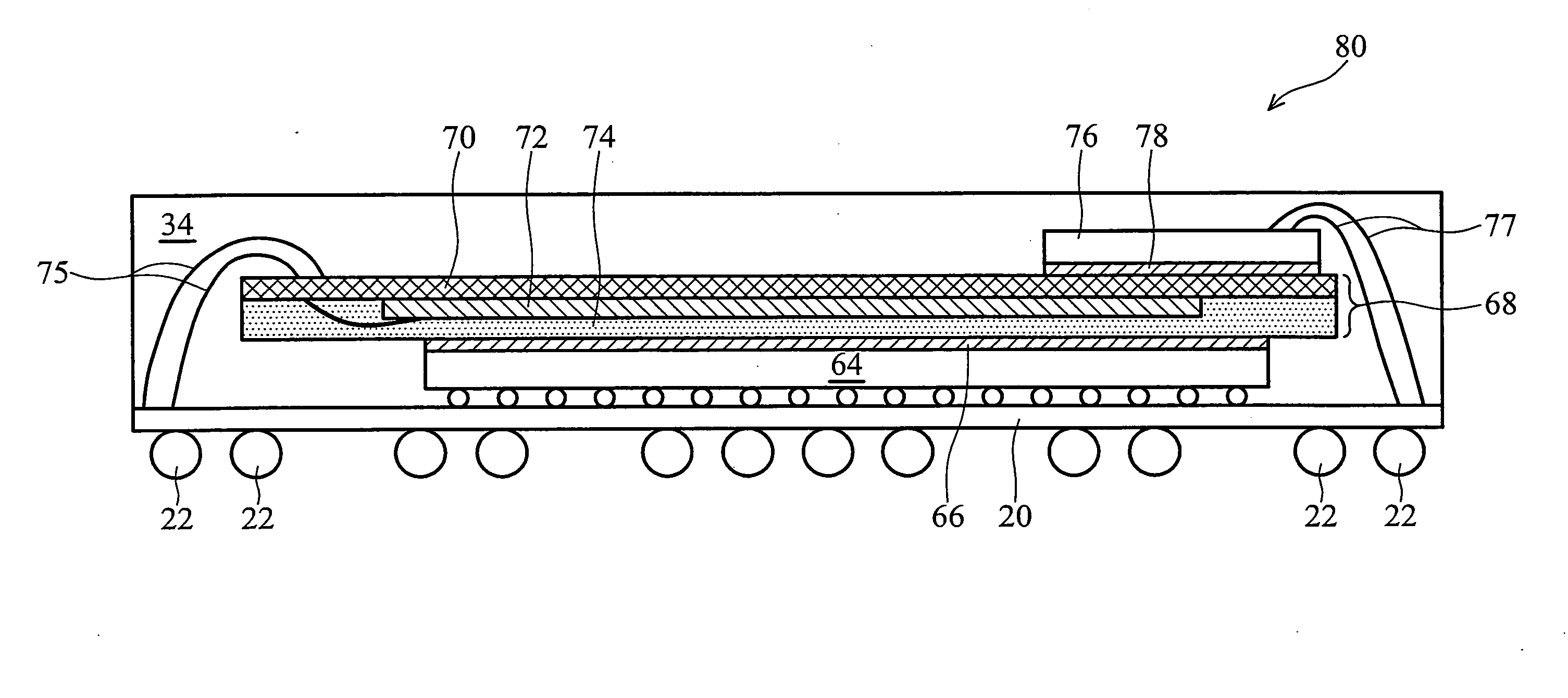

Stress buffer layer for packaging process

InactiveUS20080203566A1Release stressReliable bondingSemiconductor/solid-state device detailsSolid-state devicesHardnessSemiconductor package

A semiconductor package structure is provided. The semiconductor package structure includes a first module; a second module, wherein the first and the second modules each are selected from the group consisting essentially of a package substrate, a die and a package module; and an elastic die-attaching film having a hardness of less than about 150 MPa interposed between the first and the second modules.

Owner:TAIWAN SEMICON MFG CO LTD

Light emitting diode packaging structure

ActiveCN105006508ALow production costConcentration of color point outputSemiconductor devicesLight reflectionMaterials science

The invention discloses a light emitting diode packaging structure. The light emitting diode packaging structure is characterized in that the packaging structure comprises a first light reflection material layer with through holes, an inverted chip located on the first light reflection material layer, a first transparent material layer surrounding the side surface, except the electrodes, of the inverted chip and a second light reflection material layer surrounding the first transparent material layer. Electrodes of the inverted chip are inlaid in the through holes of the first light reflection material layer. The interface surface of the first transparent material layer and the light reflection material layer is an inclined plane or a cambered surface or an irregular shape, which facilitates light of the inverted chip to reflect upwards. A wavelength conversion material layer covers the above structure.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

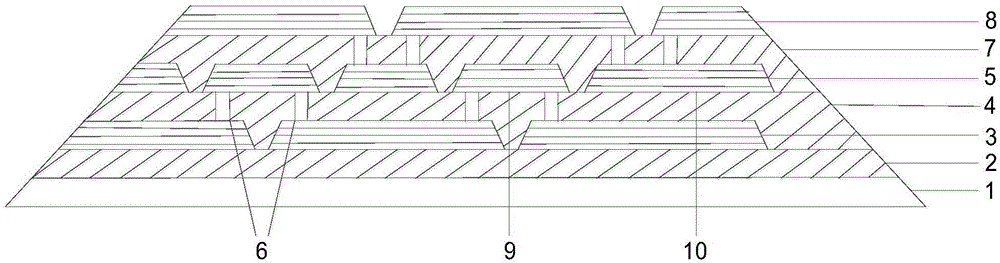

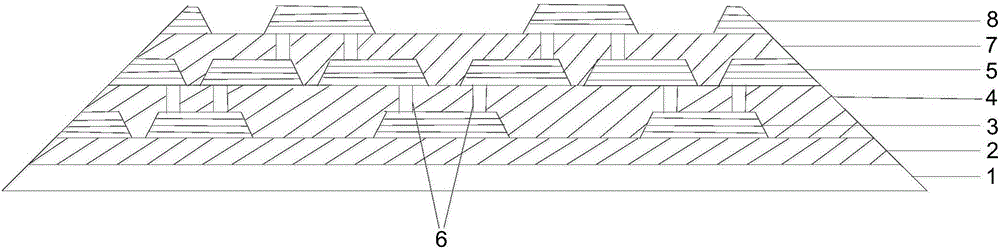

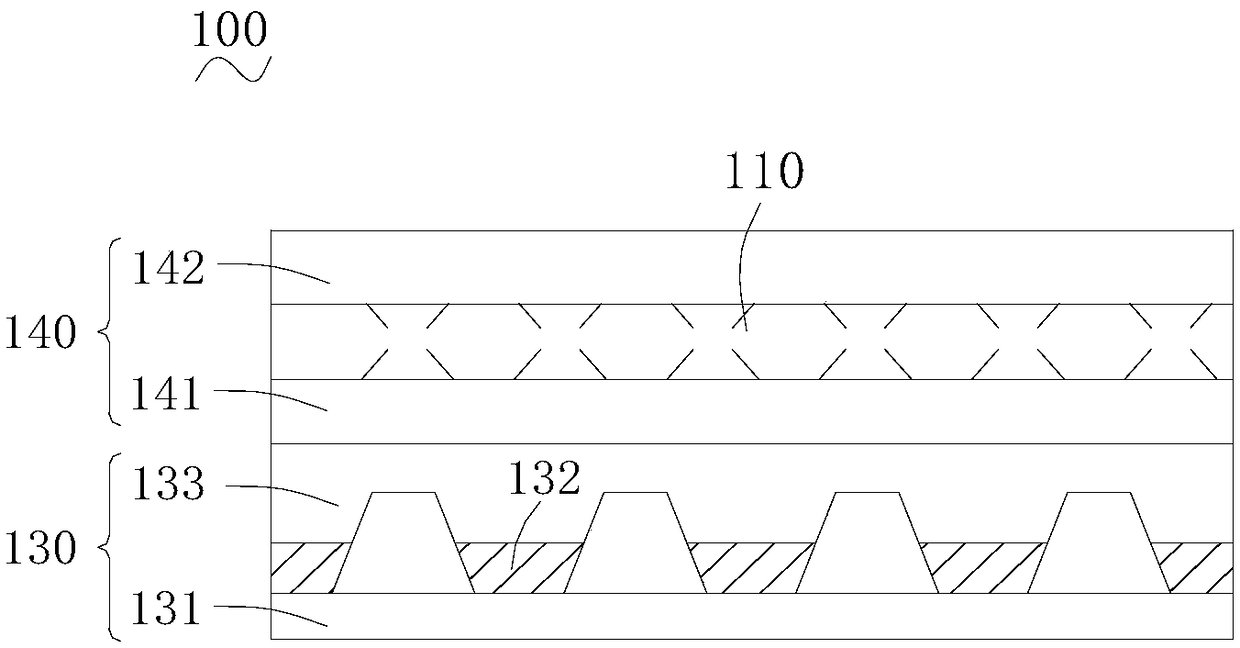

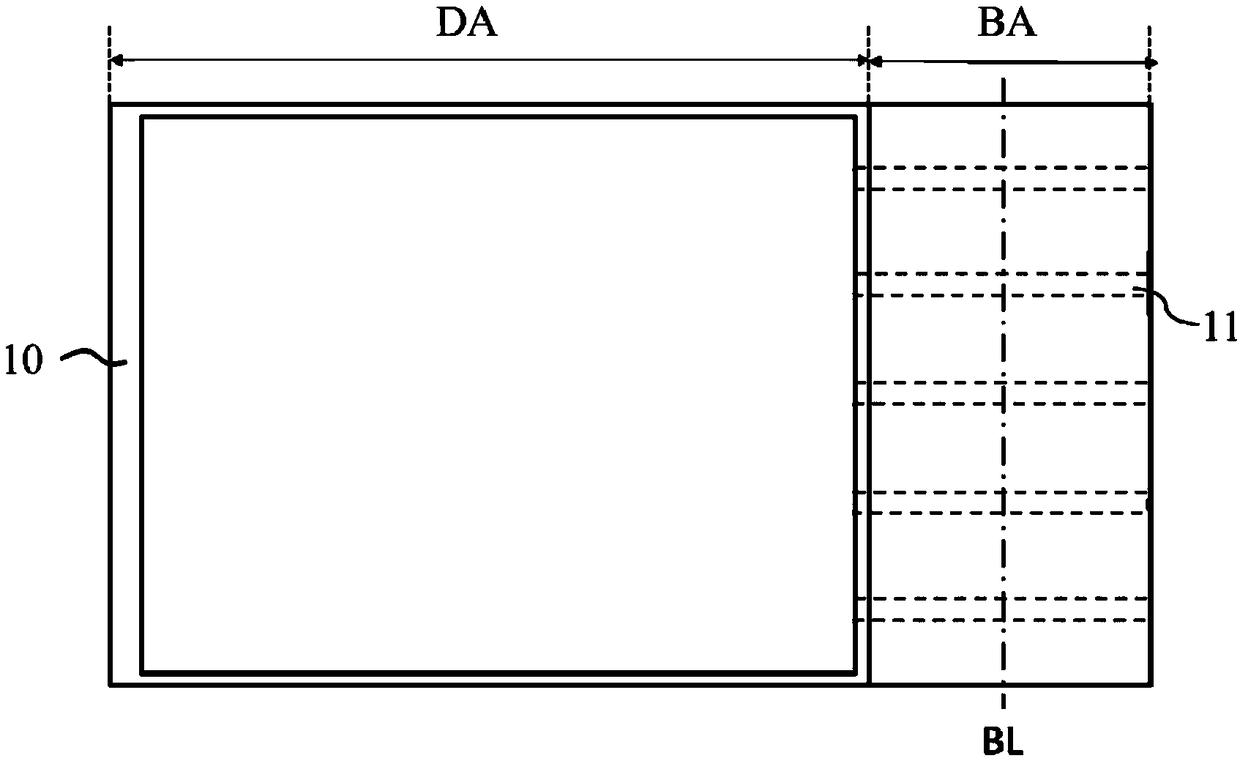

Array substrate and manufacturing method thereof, and display screen

ActiveCN107910336AExtended service lifeAvoid breakingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMetal

The invention relates to an array substrate. The array substrate comprises a display region and a non-display region positioned on the outer side of the display region; and the non-display region comprises a flexible substrate with multiple grooves in the surface, and peripheral metal lines positioned in the grooves. According to the array substrate, the grooves are formed in the surface of the substrate, and the peripheral metal lines are positioned in the grooves, so that the thickness, in the peripheral metal lines, of the flexible substrate is reduced, and extrusion of the flexible substrate on the peripheral metal lines is reduced in a bending process; and in addition, by virtue of setting of the grooves, the stress of the flexible substrate can be effectively released in bending, thereby effectively preventing cracking of the peripheral metal lines and improving reliability of the array substrate. The invention also provides a display screen and a manufacturing method of the array substrate.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Flexible display substrate and preparing method thereof

ActiveCN106206613AReduce the chance of breakagePrevent agingSemiconductor/solid-state device detailsSolid-state devicesInsulation layerEngineering

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

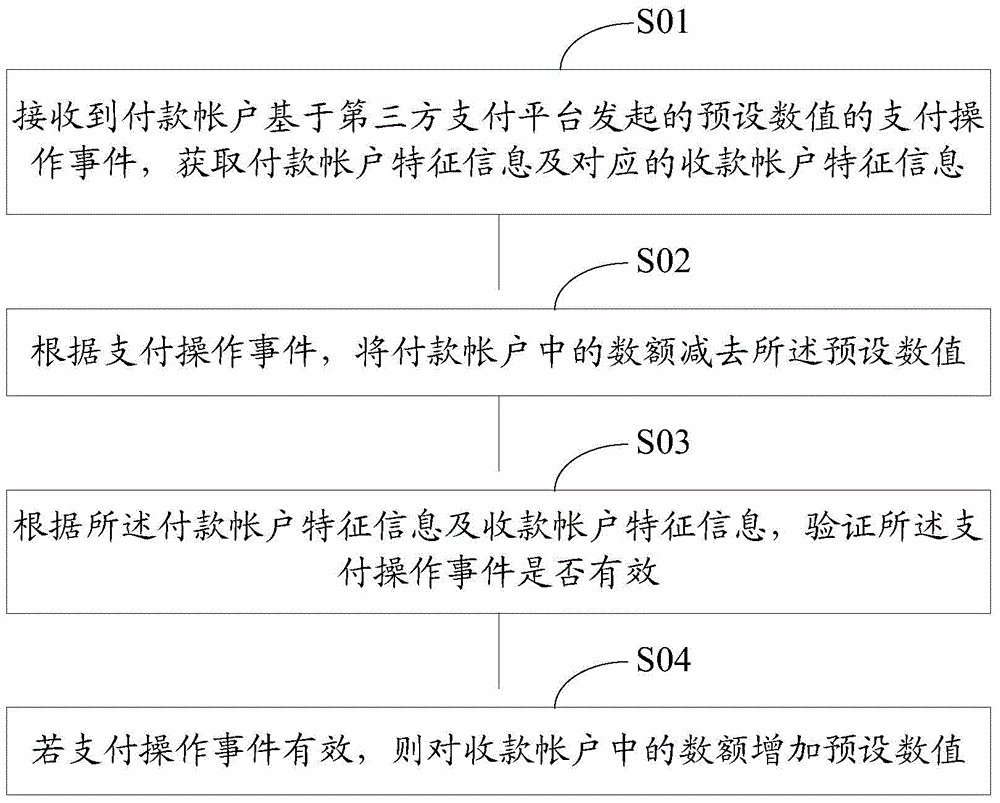

Security payment method, server and system

InactiveCN104616137ARelease stressImprove securityPayments involving neutral partyProtocol authorisationPaymentMan machine

The invention discloses a security payment method, a server and a system. The server disclosed by the embodiment of the invention executes a security verification operation of on-line payment in a stage that the server adds a preset numerical value into an amount in a collection account. Compared with the prior art that the server executes the security verification operation in the stage that the server deducts preset data from a payment account, the embodiment of the invention has the beneficial effect that payment operation duration for the server to process the payment operation of the payment account is shortened, the man-machine interactivity is improved, and the pressure of the server is released; and furthermore, on-line payment security is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

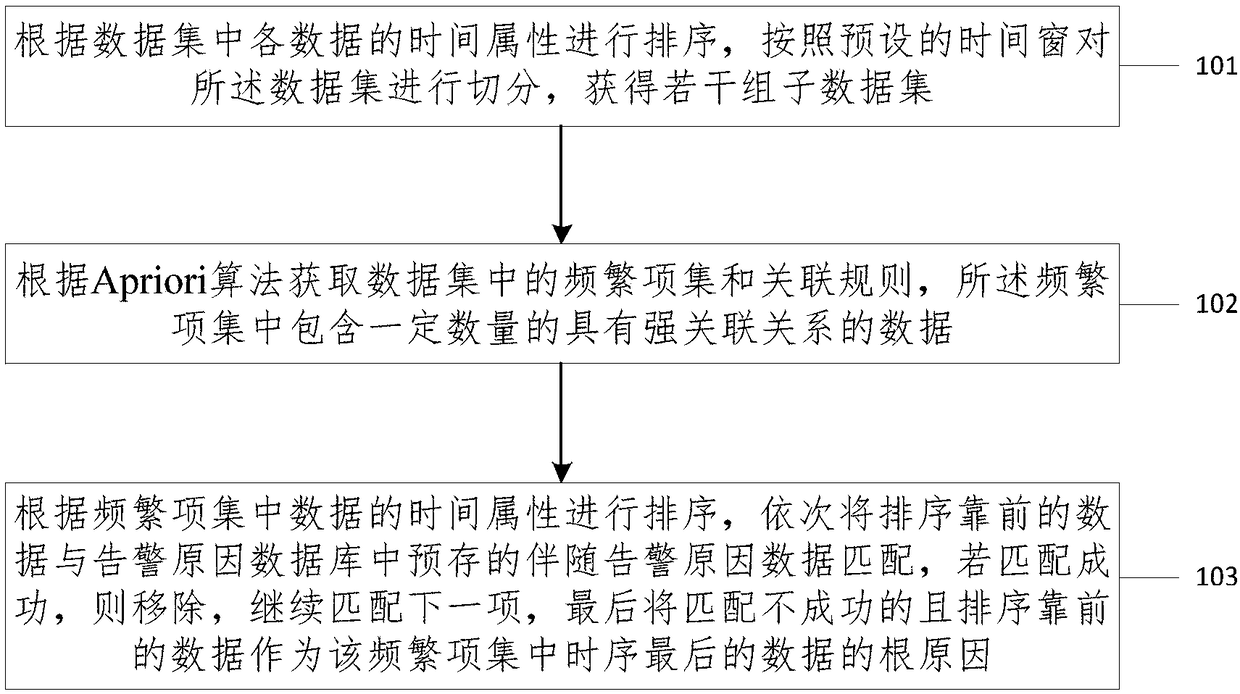

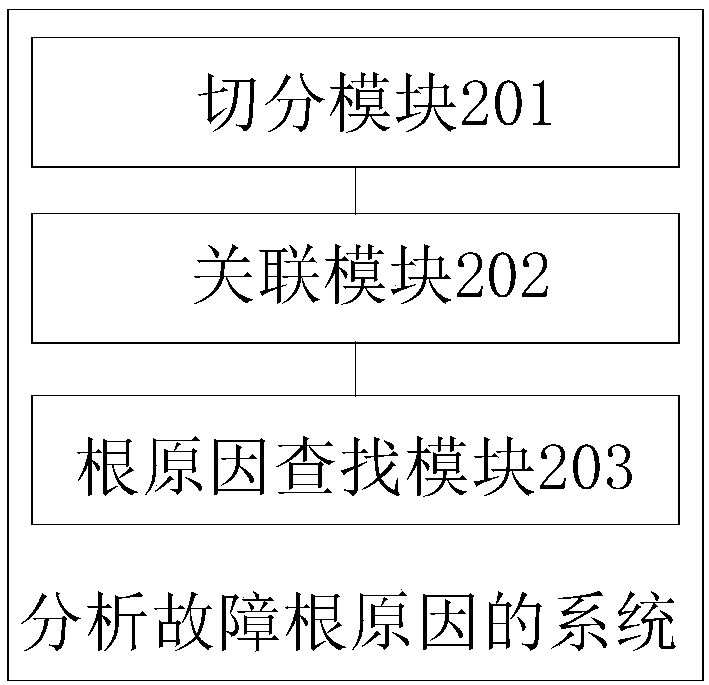

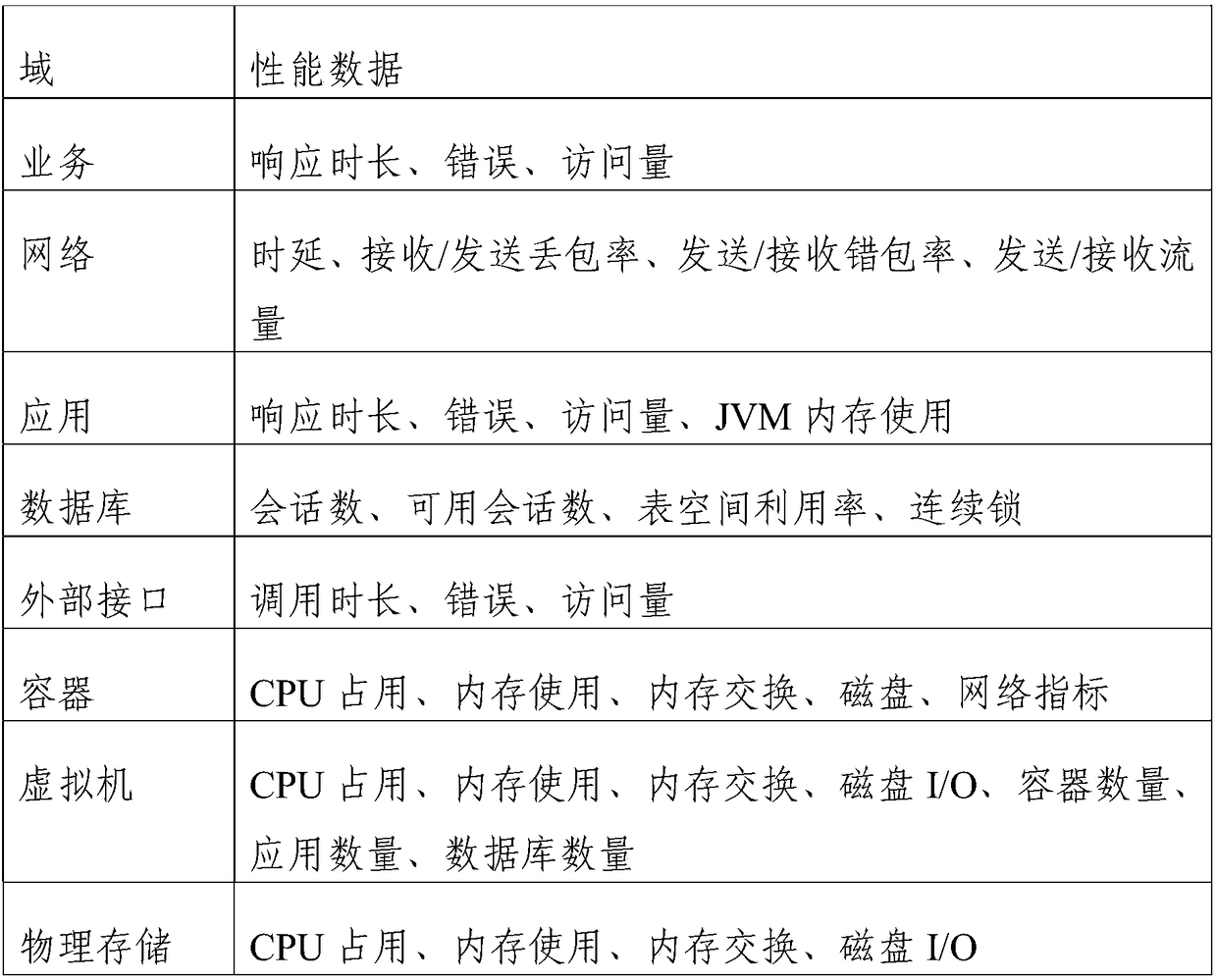

Method and system for analyzing fault root cause

ActiveCN108446184ARelease stressLower quality requirementsFault responseHardware monitoringData setRoot cause

The invention provides a method and a system for analyzing a fault root cause. The method comprises the following steps that: according to the time attribute of each piece of data in a dataset, carrying out sorting, and segmenting the dataset according to a preset time window to obtain multiple groups of sub-datasets; according to an Apriori algorithm, obtaining a frequent item set and an association rule in the dataset, wherein the frequent item set contains a certain quantity of data with a strong association relationship; and according to the time attributes of the data in the frequent itemset, carrying out sorting, matching the data which ranks higher with adjoint warning cause data pre-stored in a warning cause database in sequence, if the data which ranks higher is successfully matched with the adjoint warning cause data pre-stored in the warning cause database, removing the data which ranks higher from the dataset, and continuously carrying out comparison from a next data itemuntil the data which fails to be matched and ranks higher is taken as the root cause of the data of which the time sequence ranks at the bottom in the frequent item set. The method is suitable for thefull-dimension monitoring scene of an IT (Information Technology) system, the pressure of operation and maintenance personnel is released, and the quality requirements of the operation and maintenance personnel are lowered.

Owner:BEIJING TIANYUAN INNOVATION TECH CO LTD

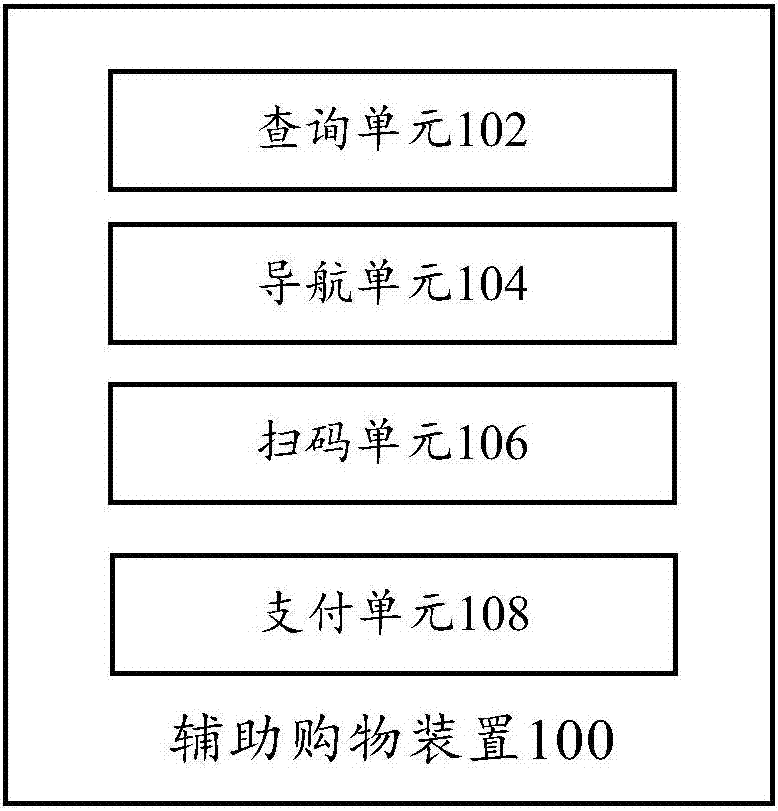

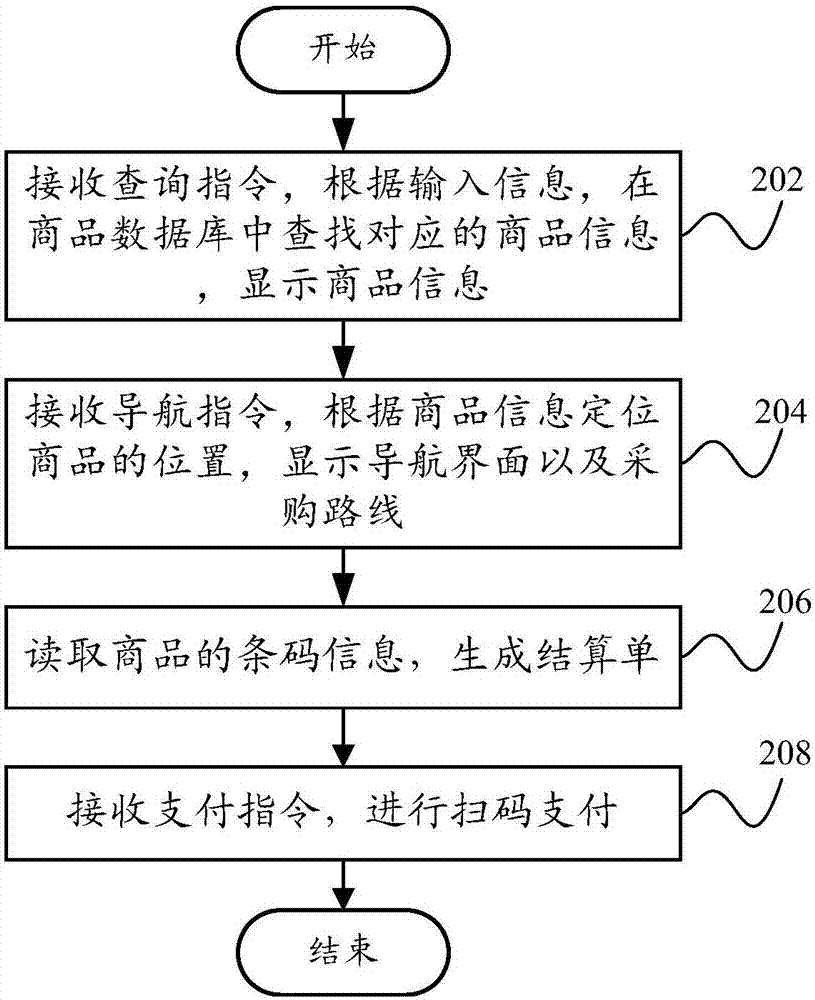

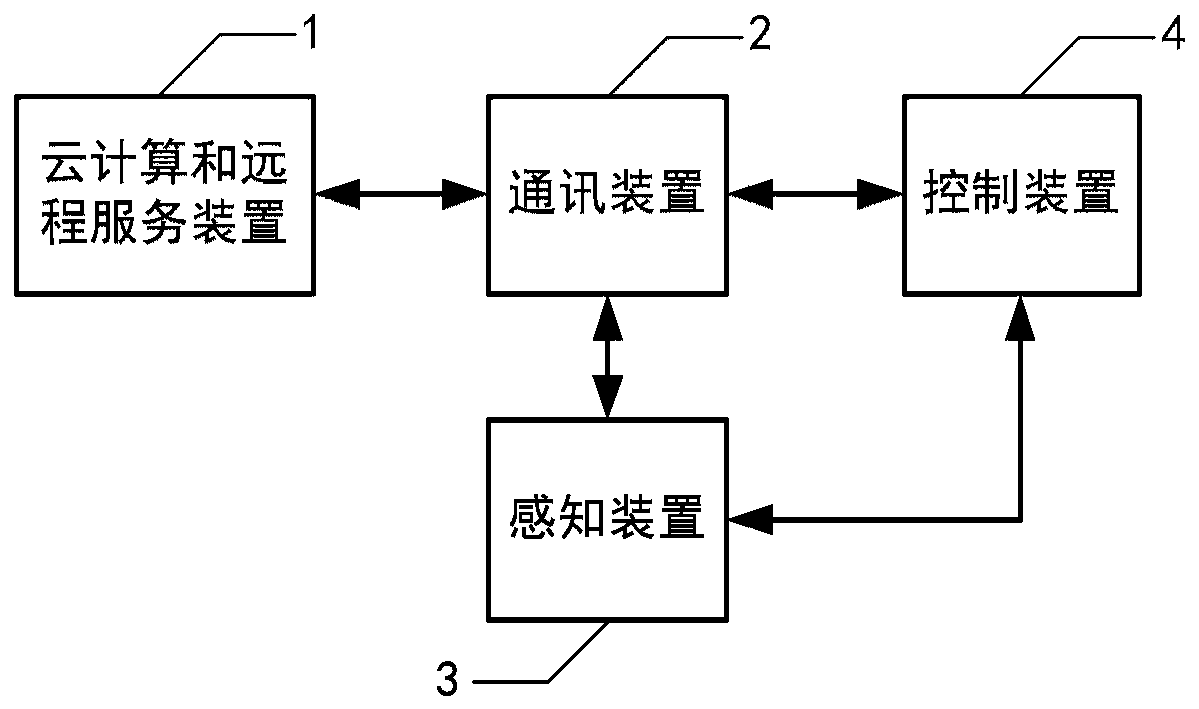

Auxiliary shopping method and apparatus, and an intelligent shopping cart

InactiveCN107221098ASave time looking for productsReduce labor costsCash registersPayment architectureCartPurchasing

The invention, which relates to the technical field of a shopping cart, provides an auxiliary shopping method and apparatus, and an intelligent shopping cart. The auxiliary shopping apparatus comprises a query unit, a navigation unit, a code scanning unit, and a payment unit. The query unit is used for receiving a query instruction, searching corresponding commodity information in a commodity database based on input information, and displaying the commodity information. The navigation unit is used for receiving a navigation instruction, localizing a commodity based on the commodity information, and displaying a navigation interface and a purchasing route. The code scanning unit is used for reading bar code information of a commodity and generating a final statement. The payment unit is used for receiving a payment instruction and carrying out code scanning payment. Therefore, the shopping efficiency of the consumer can be improved and self-service during the whole course from shopping list generation, commodity obtaining, to payment is realized.

Owner:ZICT TECH CO LTD

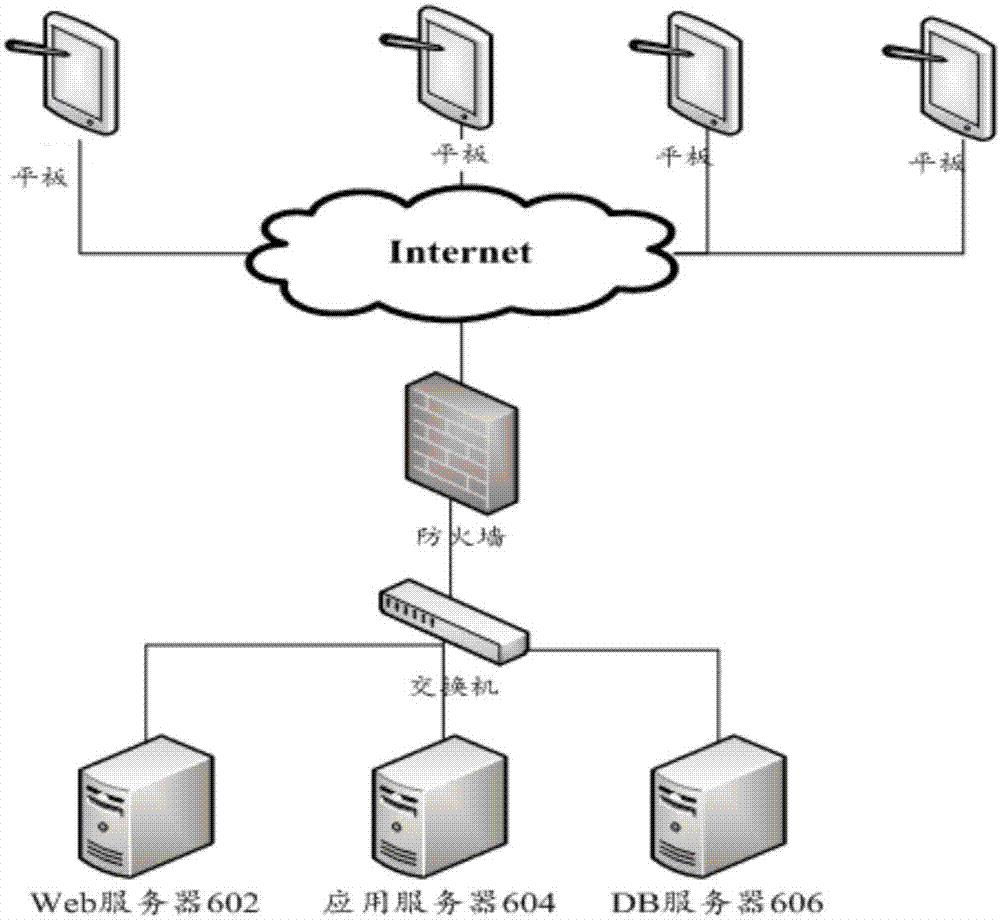

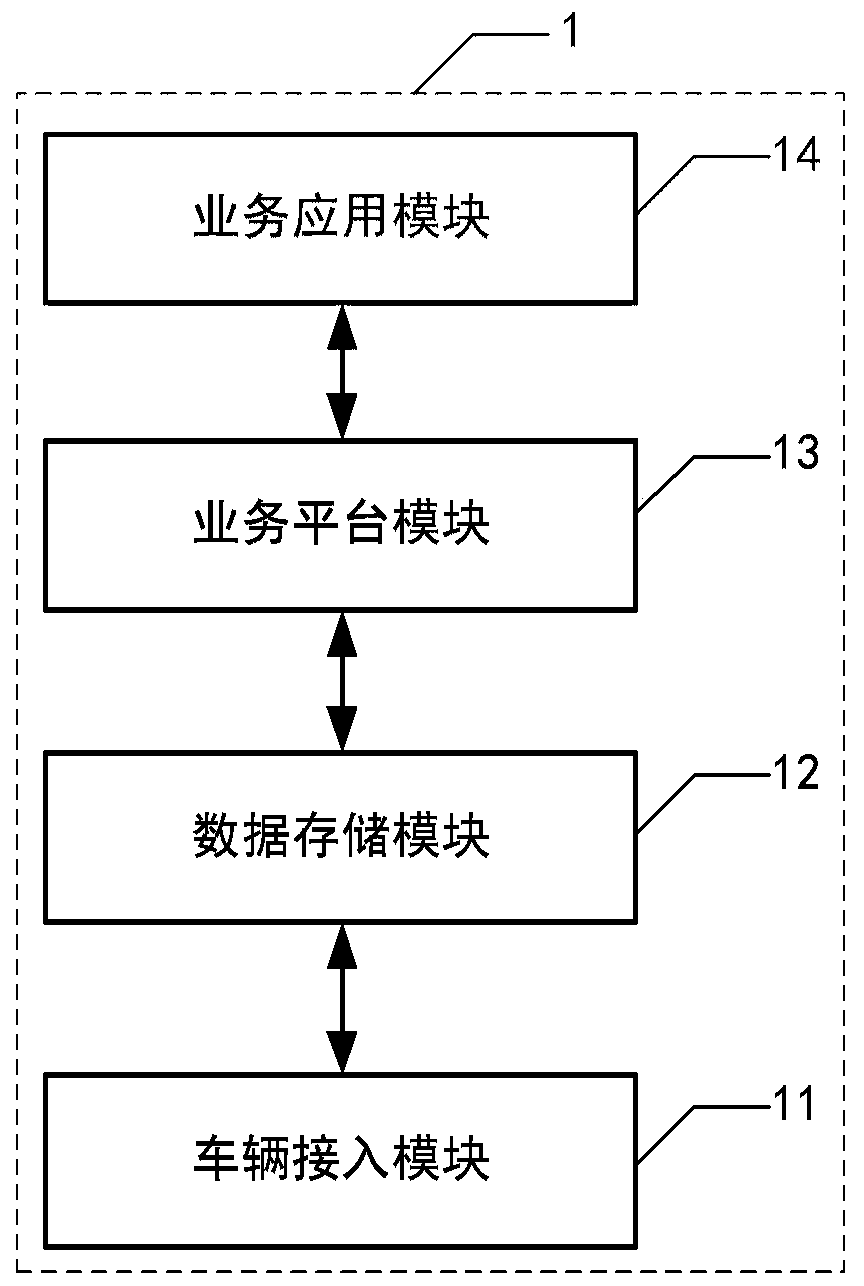

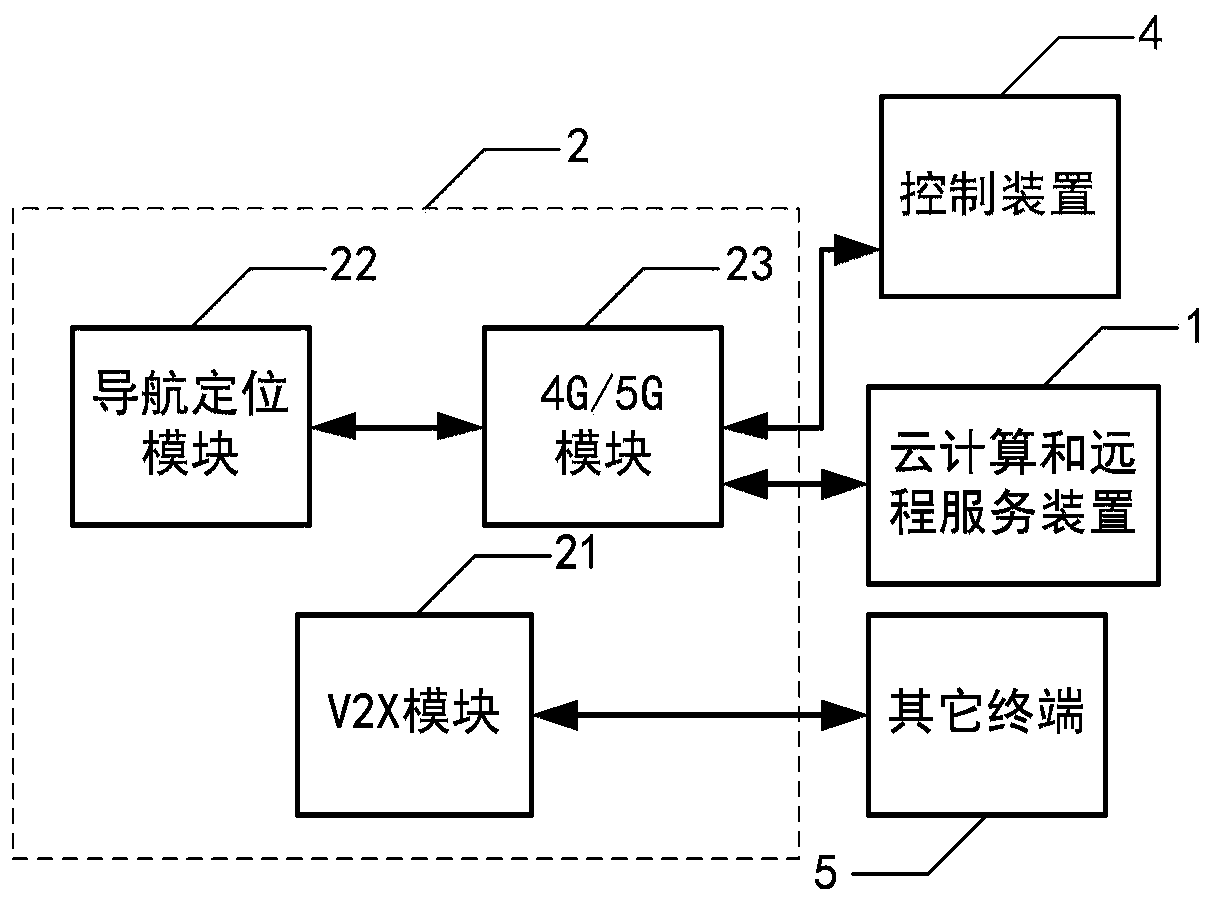

Mine car unmanned system

InactiveCN110519703AReduce the need for real-time communicationSolve positioningRoad vehicles traffic controlParticular environment based servicesWork taskComputer science

A mine car unmanned driving system comprises a cloud computing and remote service device (1), a communication device (2), a sensing device (3) and a control device (4), the cloud computing and remoteservice device (1) is used for generating a global path and a work task, and the global path and the work task are sent to the control device (4) through the communication device (2); the sensing device (3) is used for sensing the surrounding environment of the vehicle and sending the surrounding environment of the vehicle to the control device (4), and the sensing device (3) is composed of more than one sensing sensor; and the control device (4) is used for controlling the vehicle to run according to the global path, the work task and the vehicle surrounding environment.

Owner:北京易控智驾科技有限公司

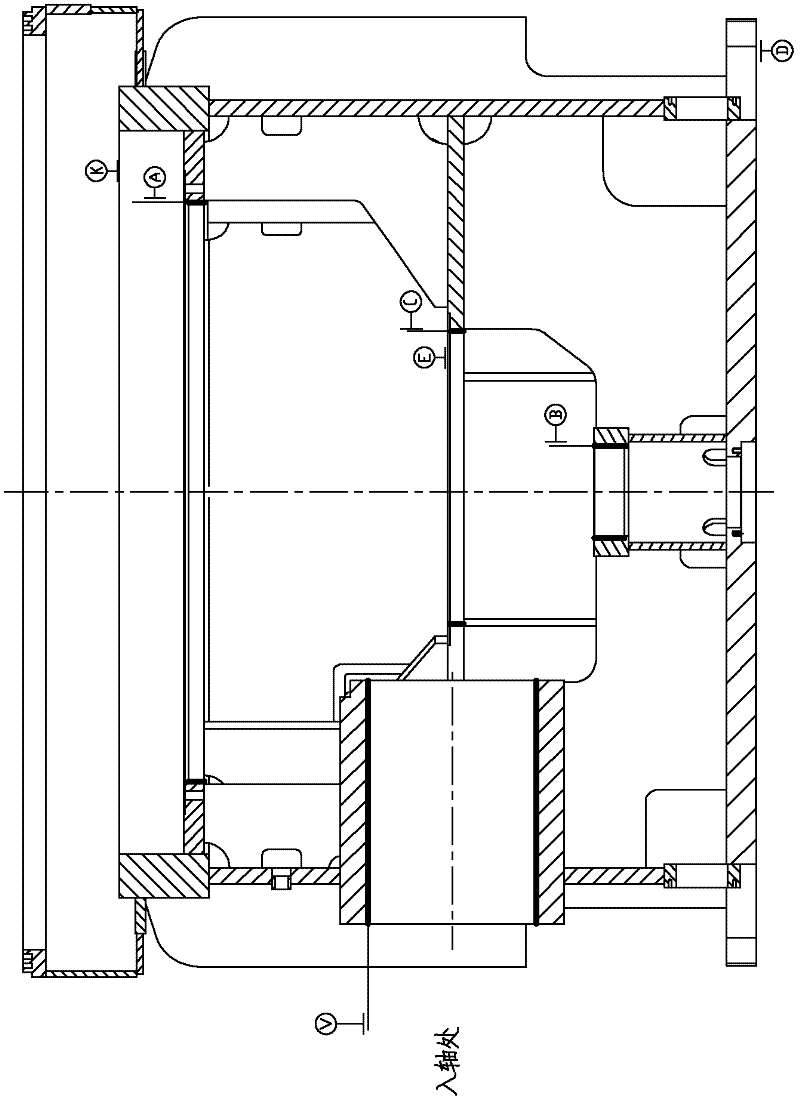

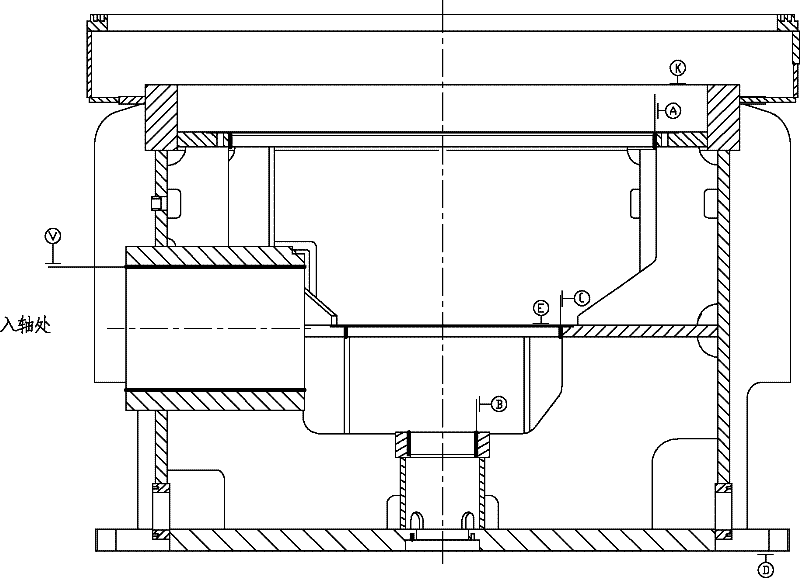

Machining method of perpendicularly intersected hole system of speed reducer body

InactiveCN102642114AReduce surface roughness requirementsGuaranteed shape and position accuracyMeasurement/indication equipmentsMetal working apparatusNumerical controlSurface finish

The invention discloses a machining method of a perpendicularly intersected hole system of a speed reducer body. Holes A-B on the vertical axis are machined by a vertical numerical control machining center so as to meet the concentric requirement of the holes on the axis, and simultaneously, a section of horizontal hole is bored based on the vertical axis; the horizontal hole is long in length, only a section of horizontal hole is bored to be used as an aligning basis in order to ensure the machining precision so as to avoid a mark error, so that the section of horizontal hole is used as an aligning basis for machining a horizontal hole V. In the same way, a hole V on the horizontal axis is machined by a high-precision numerical control boring and milling machine by not using a mark as an aligning basis but on the aligning basis on which the vertical holes are machined, and the aligning precision is high; and meanwhile, the space laser detection technology and the numerical control machining technology are matched to ensure the form-position precision of the perpendicularly intersected hole system of the body. The fine surface finishing technology and the numerical control simulation technology of a high-precision numerical control machine are applied to select reasonable cutting amount to meet the low roughness requirement of the surface of the perpendicularly intersected hole system of the body. Through the machining method, the amount of adjustment of assembly is greatly reduced, and the assembly precision is improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

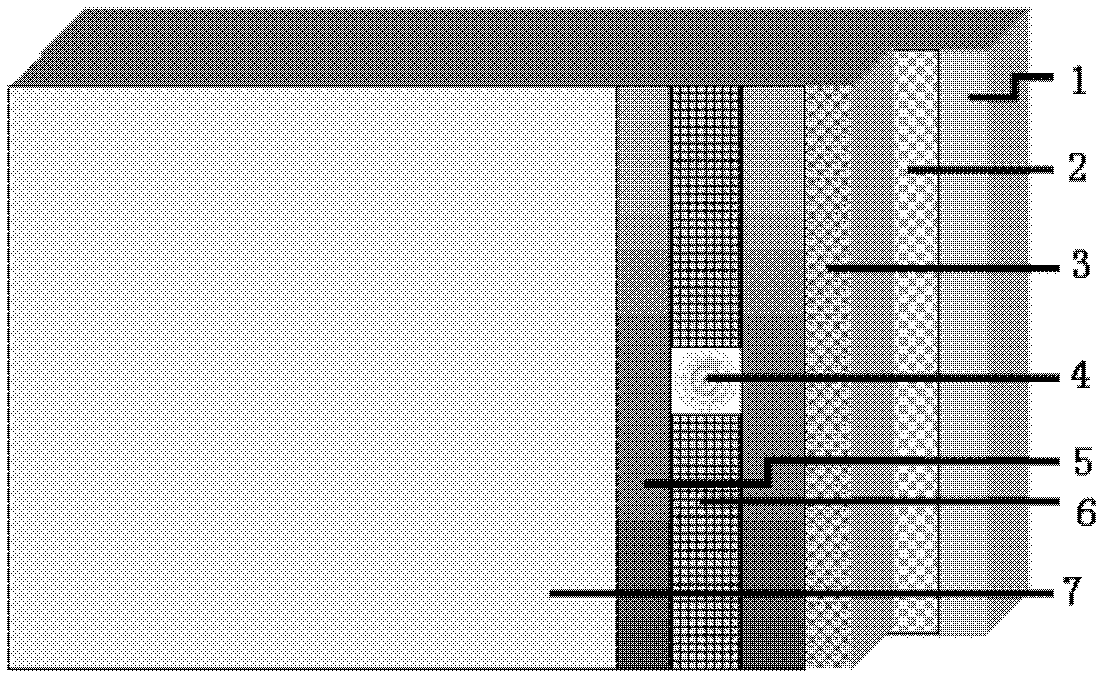

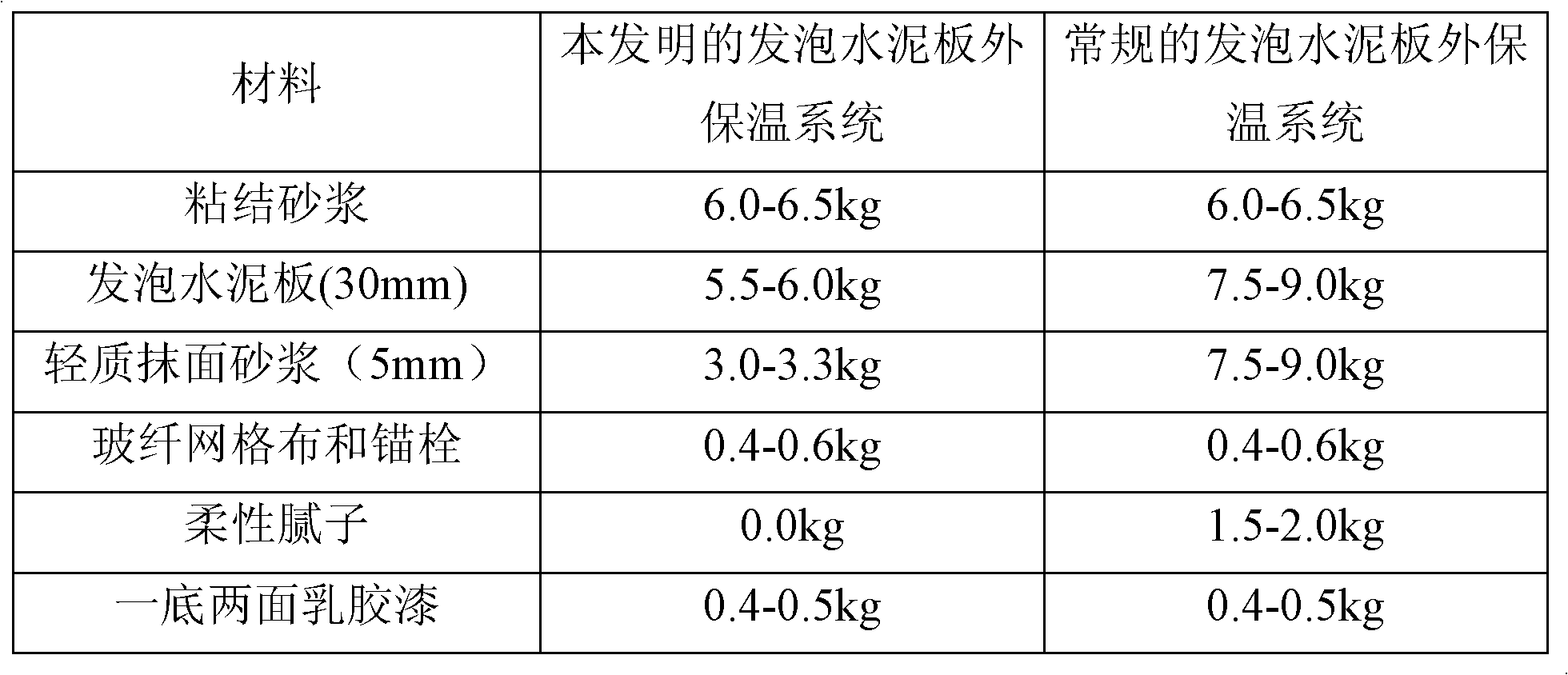

External wall insulation structure through foaming cement board and construction method thereof

ActiveCN102605867ALess affected by heat shrinkageReduce temperature differenceClimate change adaptationHeat proofingCelluloseCement board

The invention relates to an external wall insulation structure through a foaming cement board and a construction method of the external wall insulation structure through the foaming cement board. Polymer bonding mortar, a foaming cement board, an anti-cracking layer and a decorating layer are arranged in sequence from the surface of a base wall body, the anti-cracking layer is formed by light plastering mortar and glass fiber gridding cloth, and the external wall insulation structure is characterized in that the light plastering mortar consists of the following components by weight percent: 12-25% of polyacrylic emulsion, 0.15-0.24% of cellulose ether, 0.1-0.5% of polypropylene fiber, 0.1-0.2% of dispersing agent, 0.1-0.2% of mildew preventive, 15-25% of ordinary portland cement, 15-30% of glazed hollow bead, 5-20% of quartz sand, 0-30% of coal ash and 0.5-1% of water reducing agent.

Owner:上海天补科技有限公司

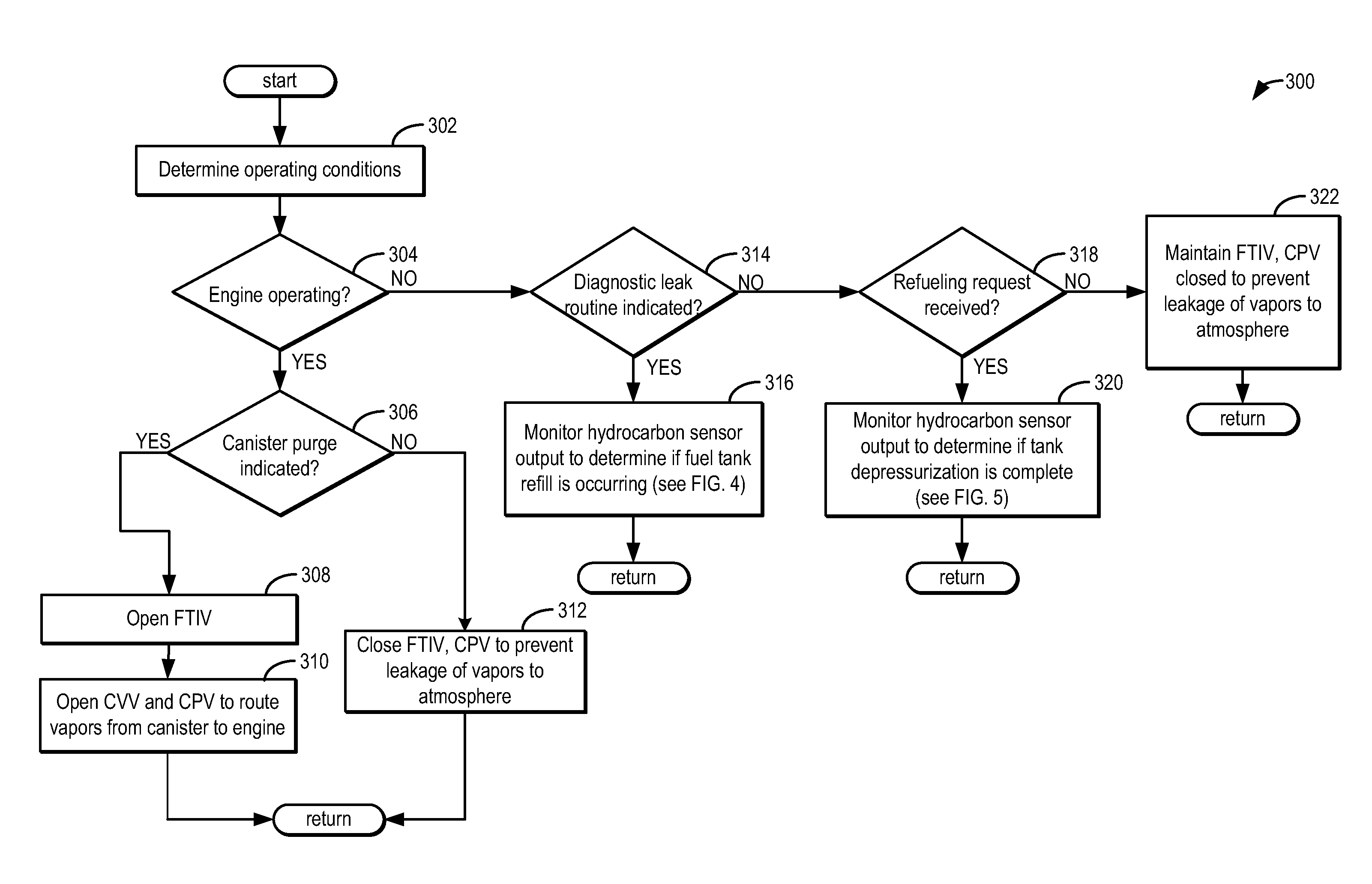

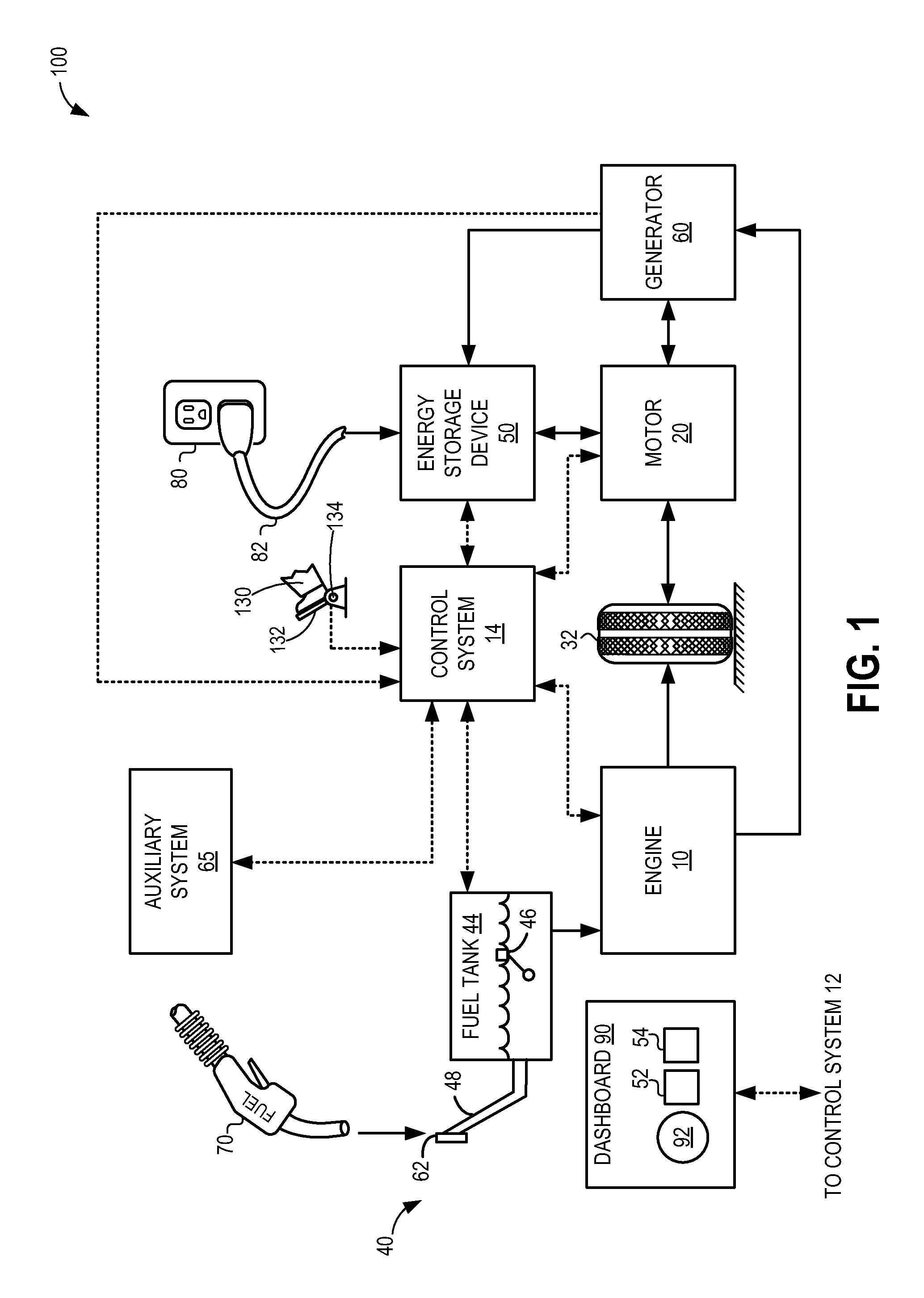

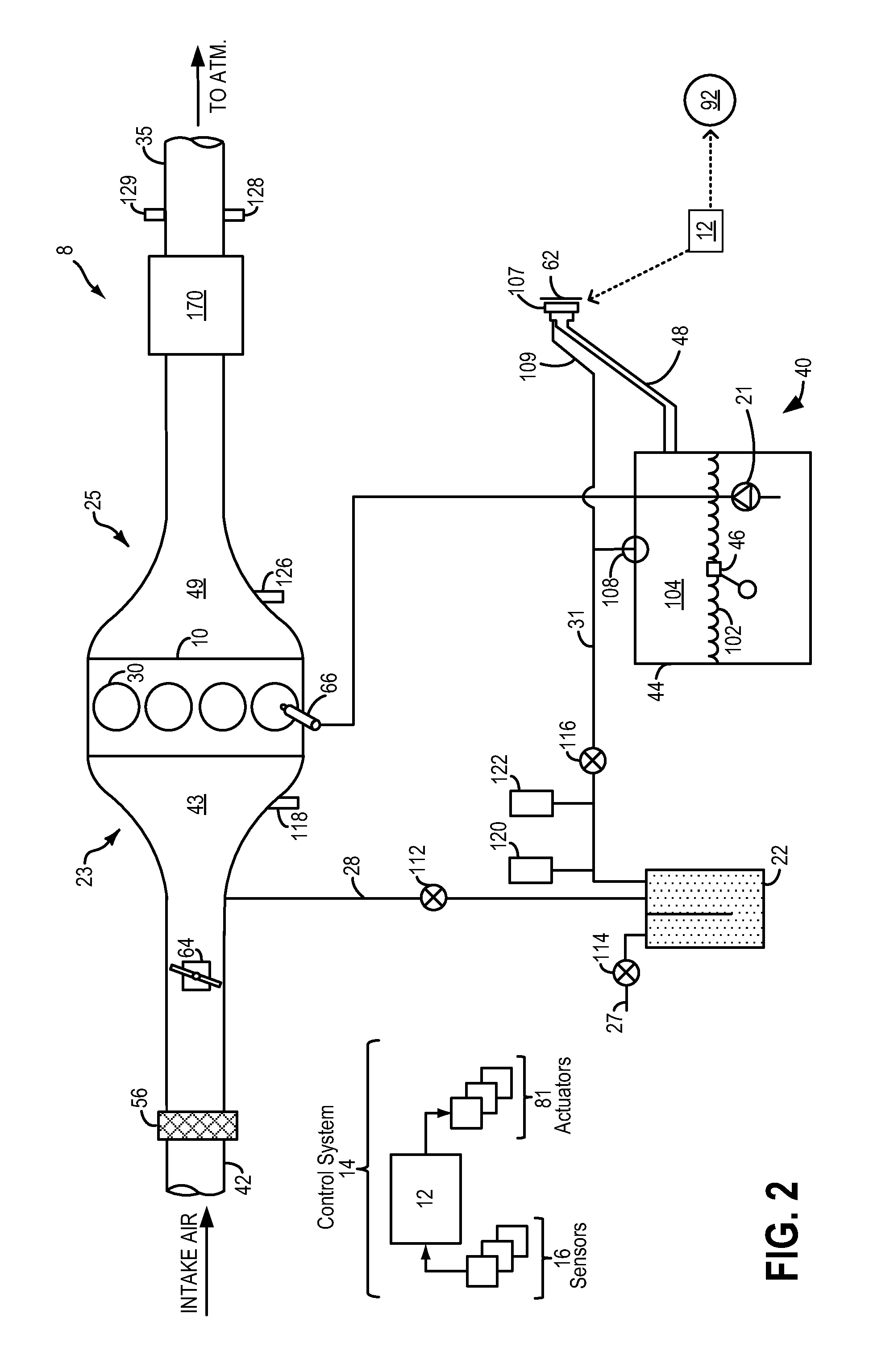

Refueling detection method

ActiveUS20150121999A1Release stressPrevent leakageHybrid vehiclesElectrical controlHydrocotyle bowlesioidesFuel vapor

Embodiments for detecting fuel events are presented. In an embodiment, a method comprises performing an action responsive to a fuel event indicated based on output from a hydrocarbon sensor positioned between a fuel tank and a fuel vapor canister. In this way, the hydrocarbon sensor may be used to detect fuel events and engine operation may be adjusted accordingly.

Owner:FORD GLOBAL TECH LLC

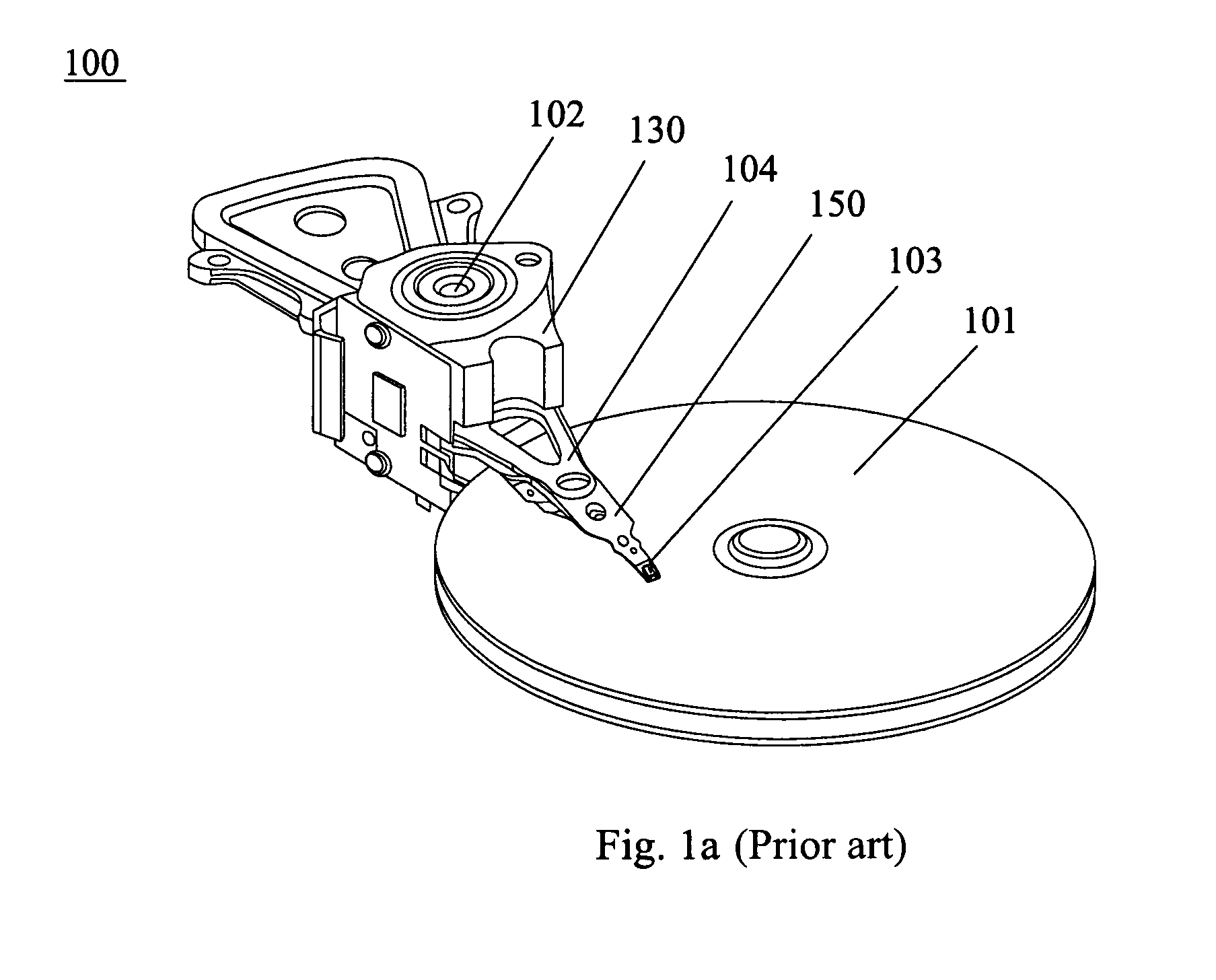

Display screen and display device

ActiveCN109166472ARelease stressImprove the display effectIdentification meansAdhesiveDisplay device

The invention relates to a display screen and a display device. The display screen comprises a laminated film sheet, and an optical adhesive disposed between adjacent films. In the thickness directionof the optical adhesive sheet, the optical adhesive sheet comprises a core layer and two layers on both sides of the core layer, and stress buffer openings are provided in either or both of the two layers. As that surface lay of the optical glue is provided with a stress buff opening, when the display screen is bent toward one side of the stress buffer opening, the stress buff opening can form astress buffer area, thereby effectively releasing the stress of the display screen, avoiding poor display and facilitating application. In addition, the present invention also provides a display device including the above-mentioned display screen.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

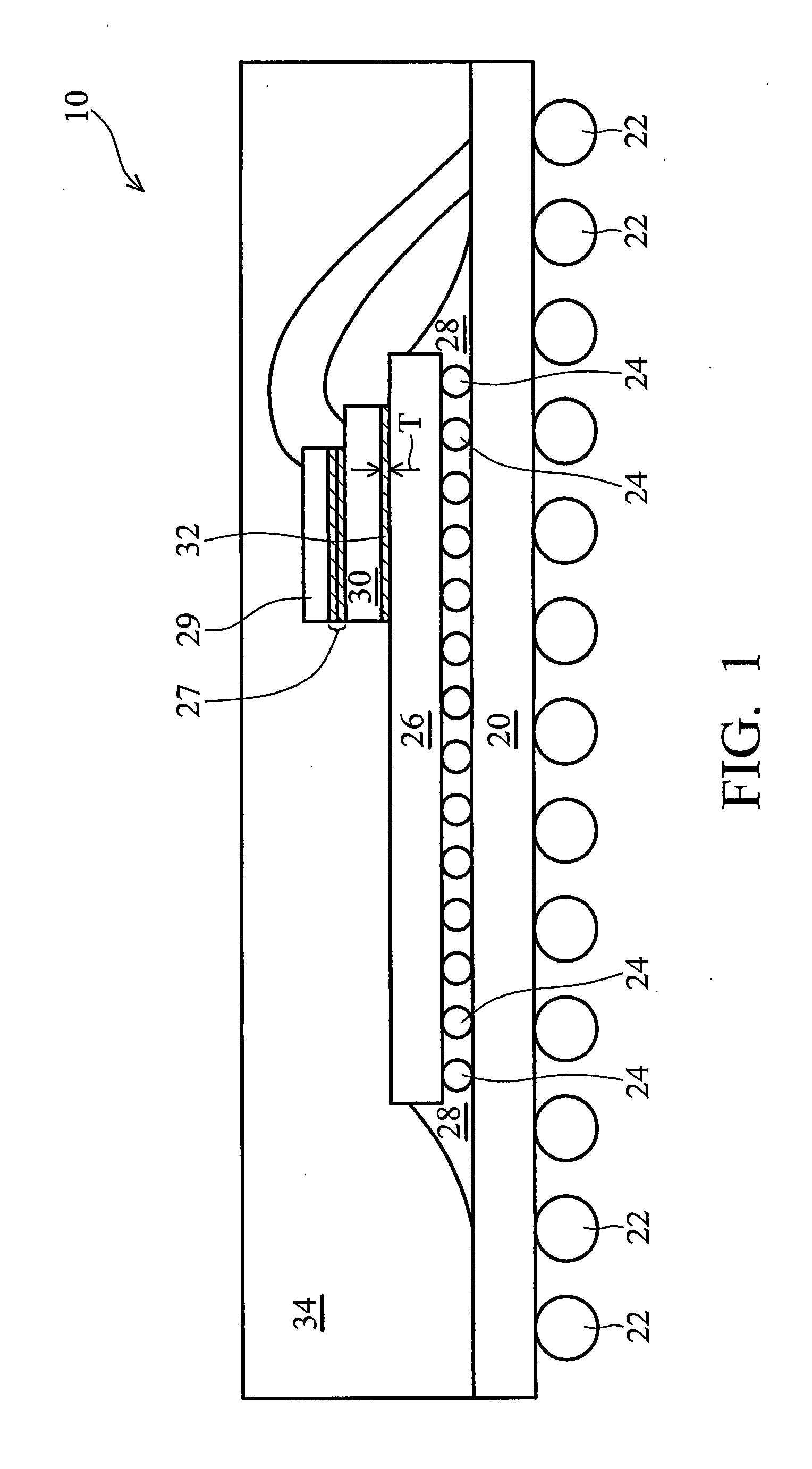

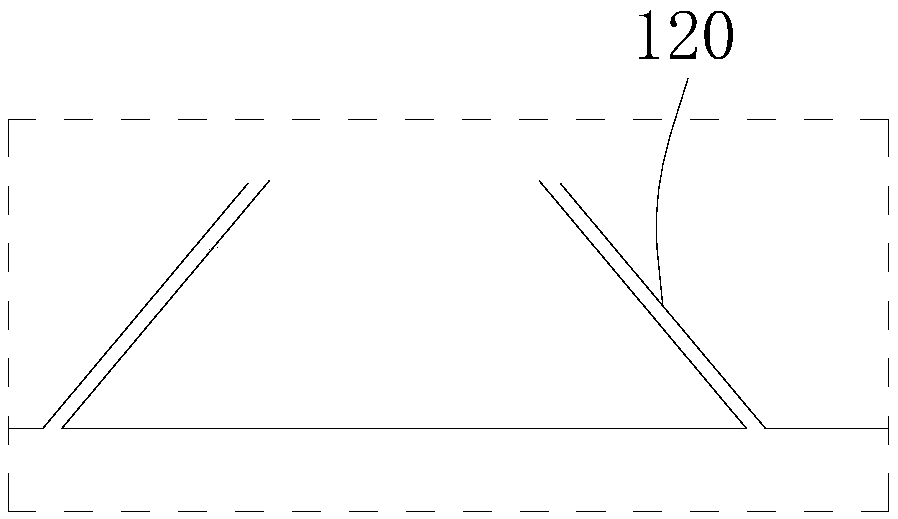

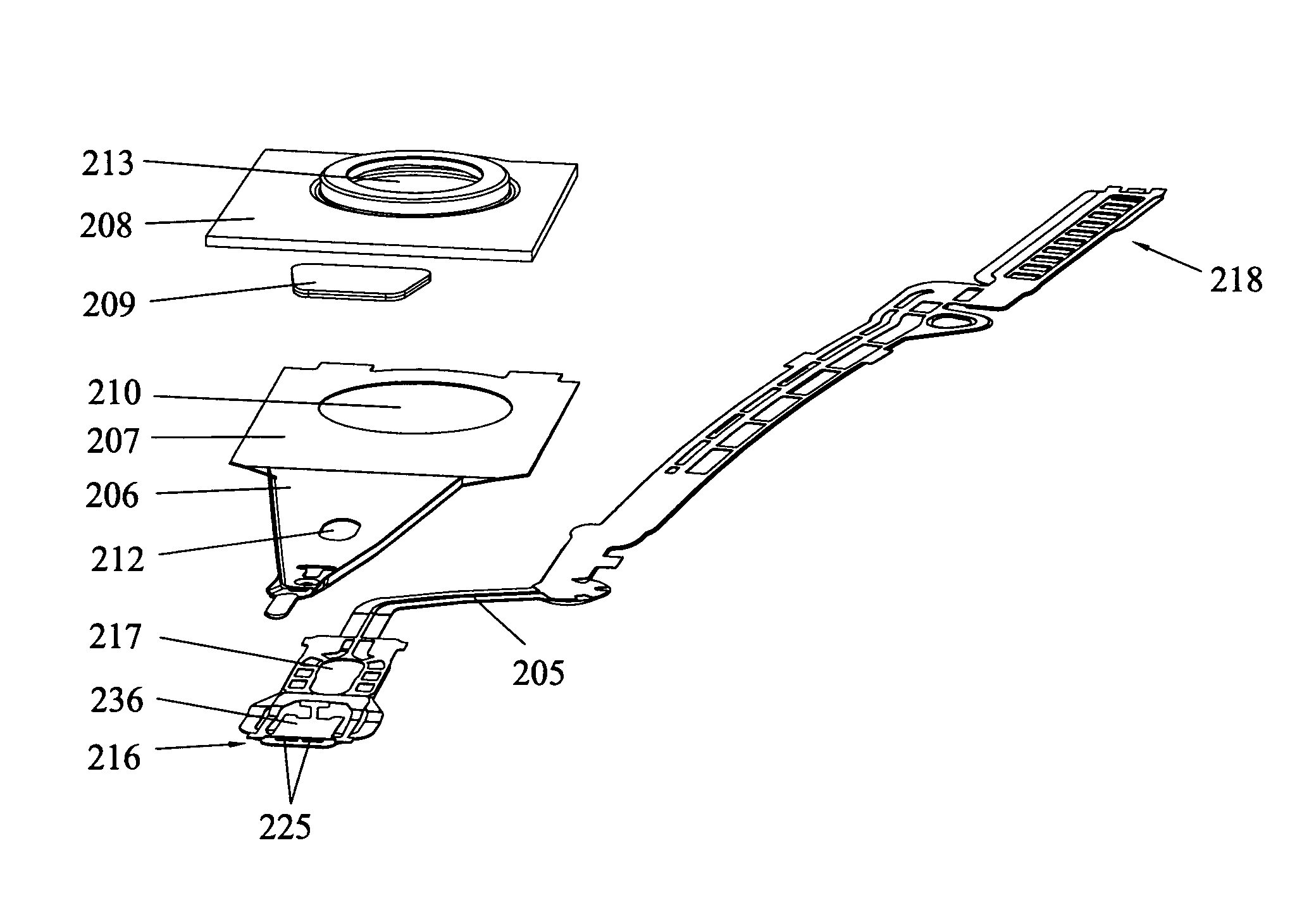

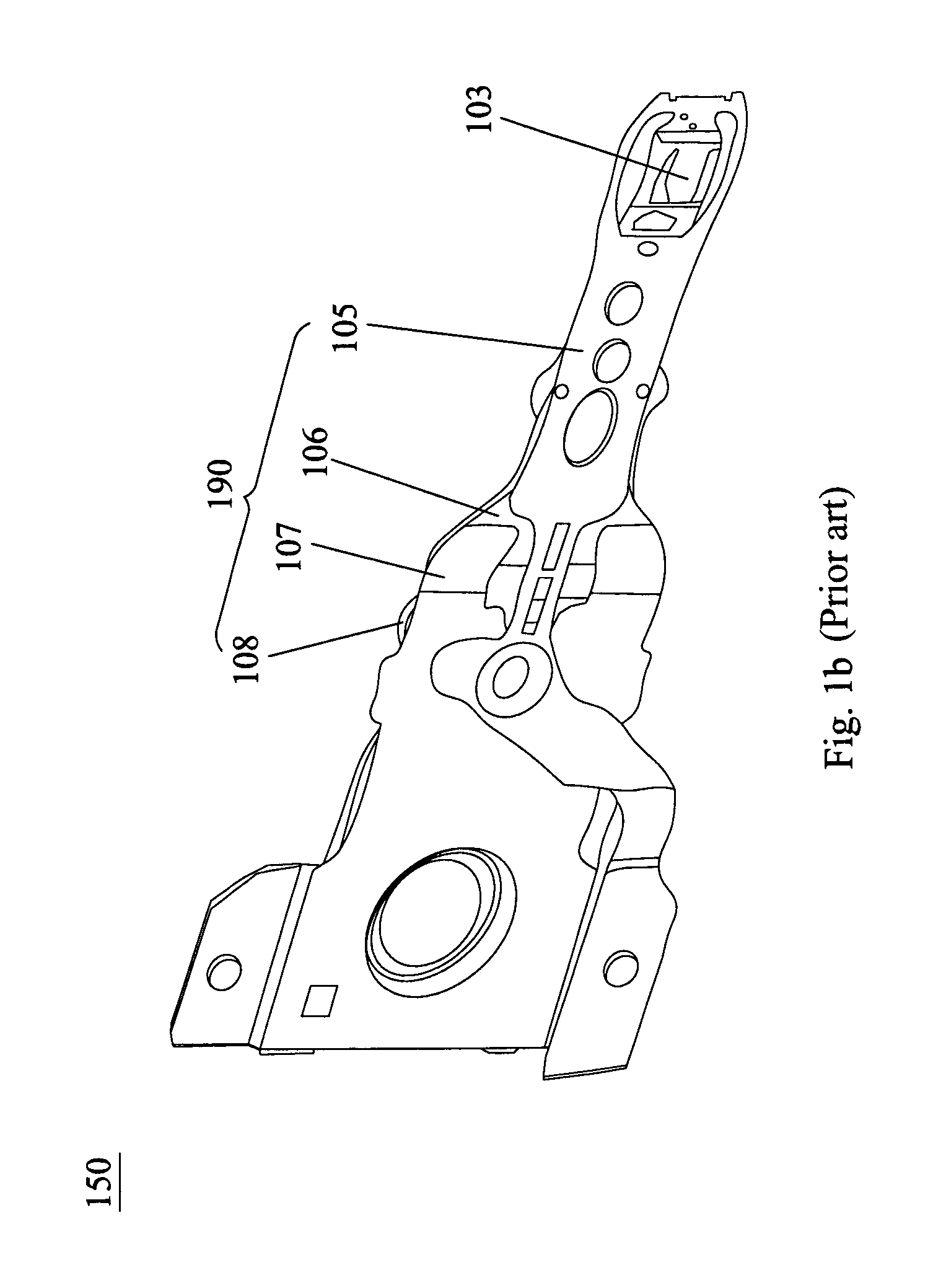

Suspension with supporting pieces, head gimbal assembly and disk drive unit with the same

ActiveUS8582243B2Reduce the temperatureReduce changesElectrical connection between head and armRecord information storageEngineeringDielectric layer

Owner:SAE MAGNETICS (HK) LTD

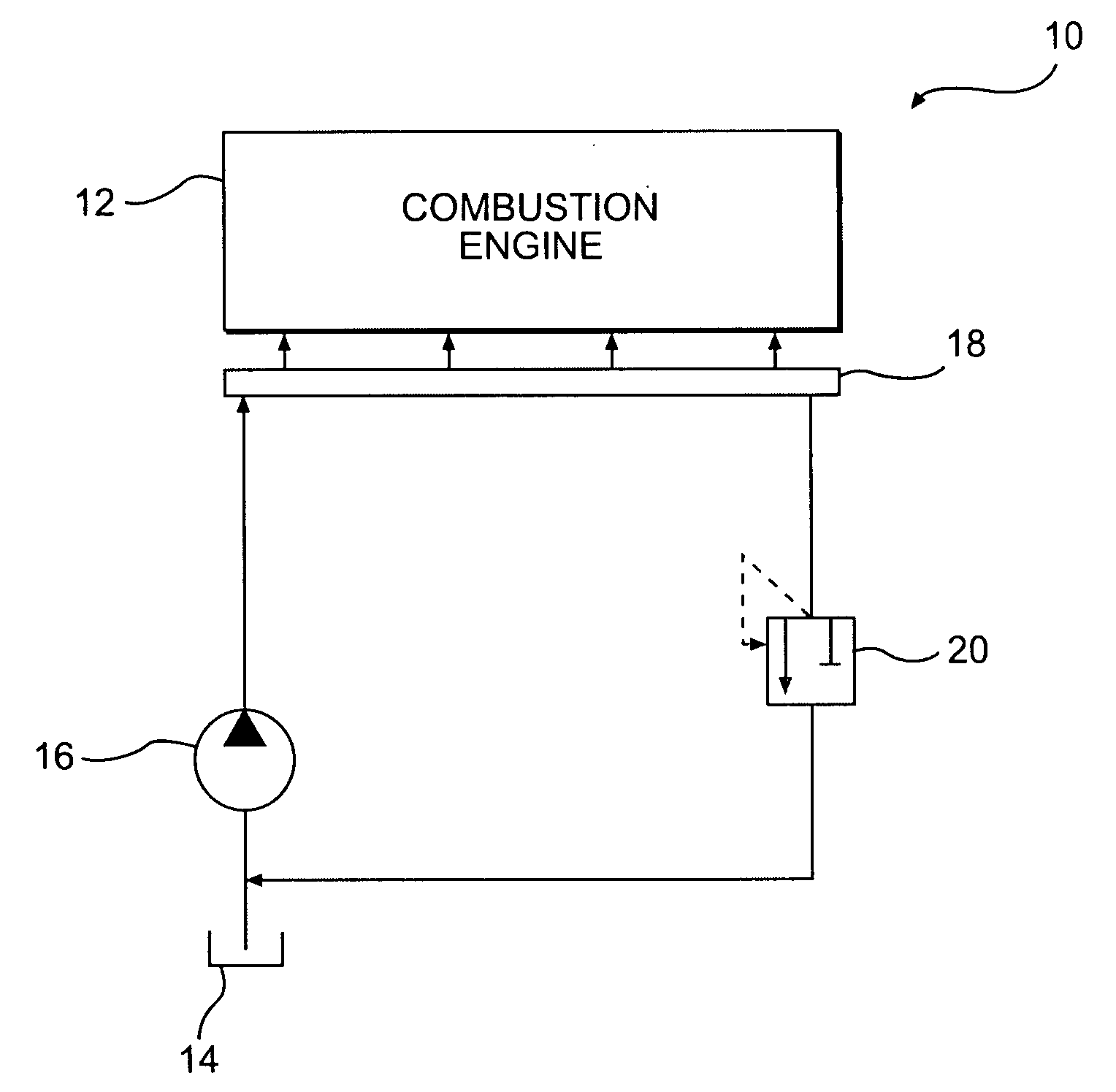

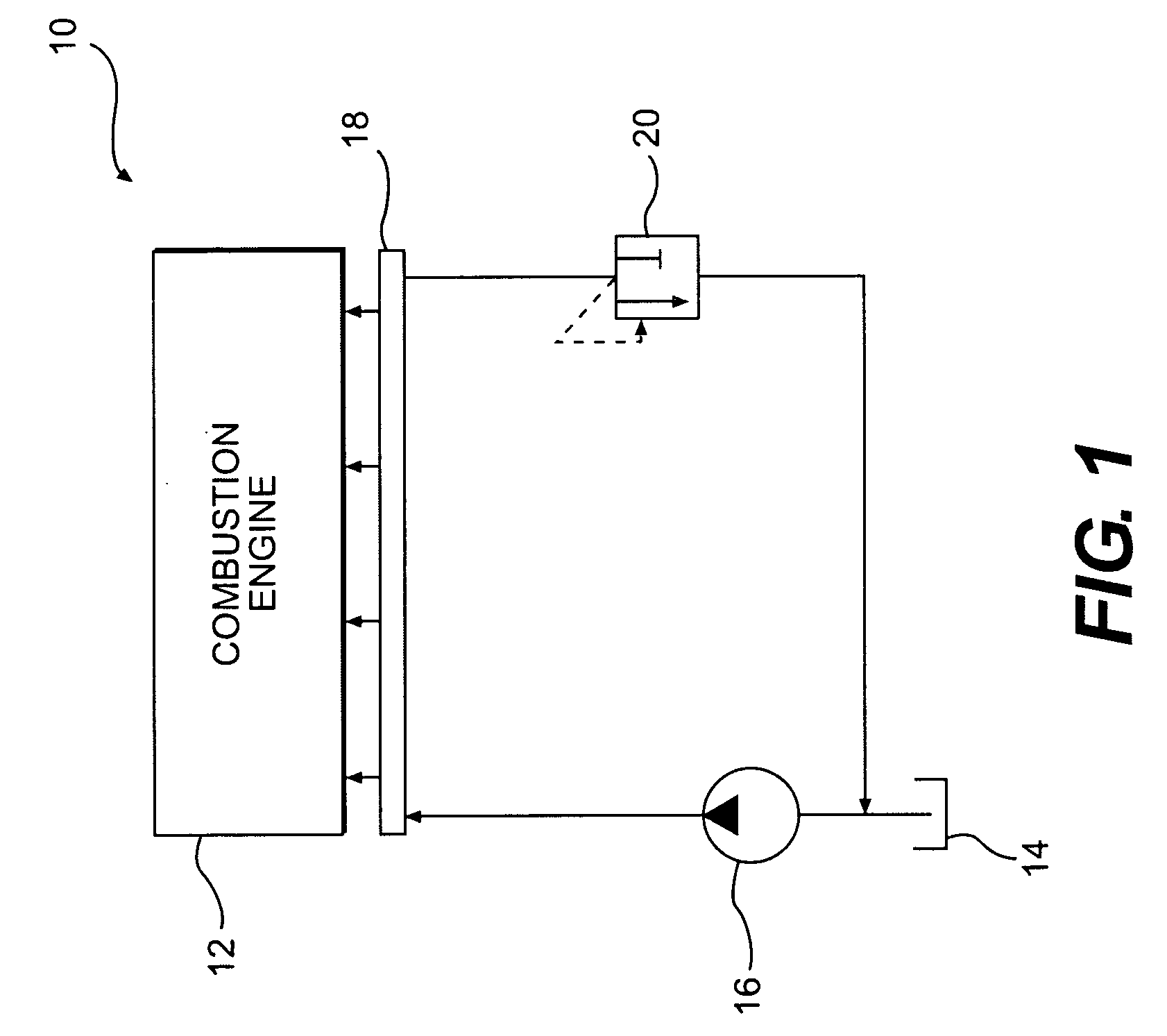

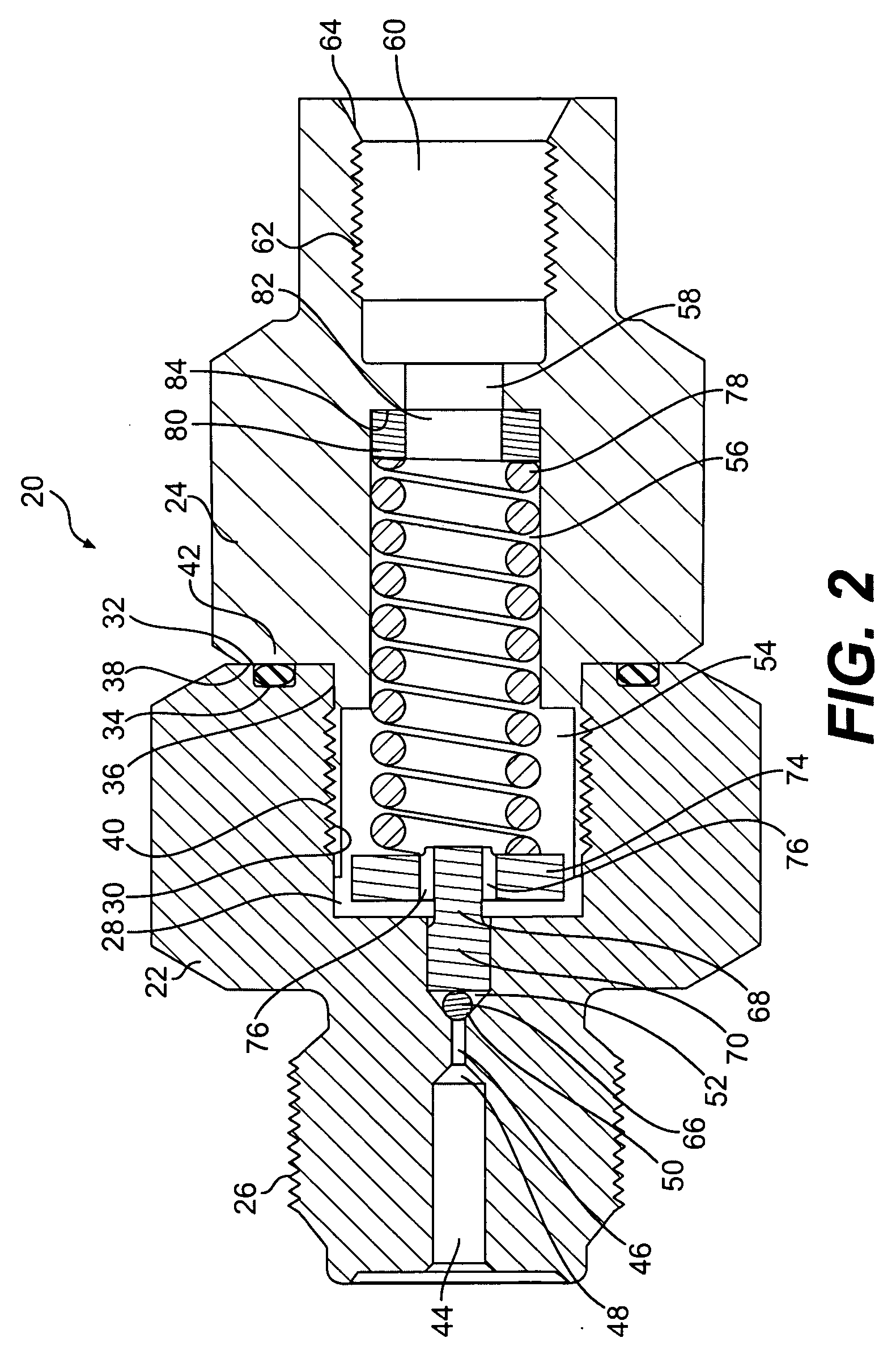

Pressure relief valve

A pressure relief valve includes a valve body defining an inlet configured to receive fluid from a fluid system, a pressure control orifice ending in a valve seat, and a guideway extending from the valve seat. The pressure relief valve further includes a valve closing member configured to abut the valve seat in a closed position and to be displaced from the valve seat in an open position, thereby releasing pressure from the fluid system. The pressure relief valve also includes a flow member including a stem and a flow plate. The stem is operably associated with the valve closing member and is configured to reciprocate within the guideway. The pressure relief valve further includes a valve spring operably associated with the valve body.

Owner:CATERPILLAR INC

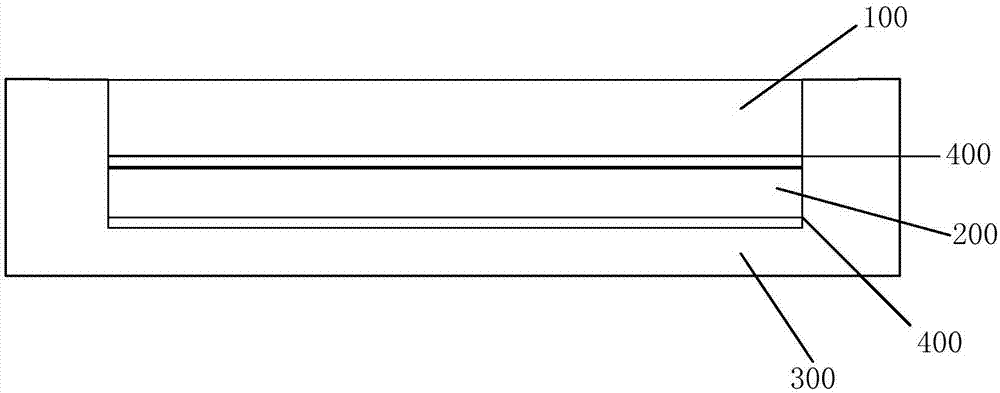

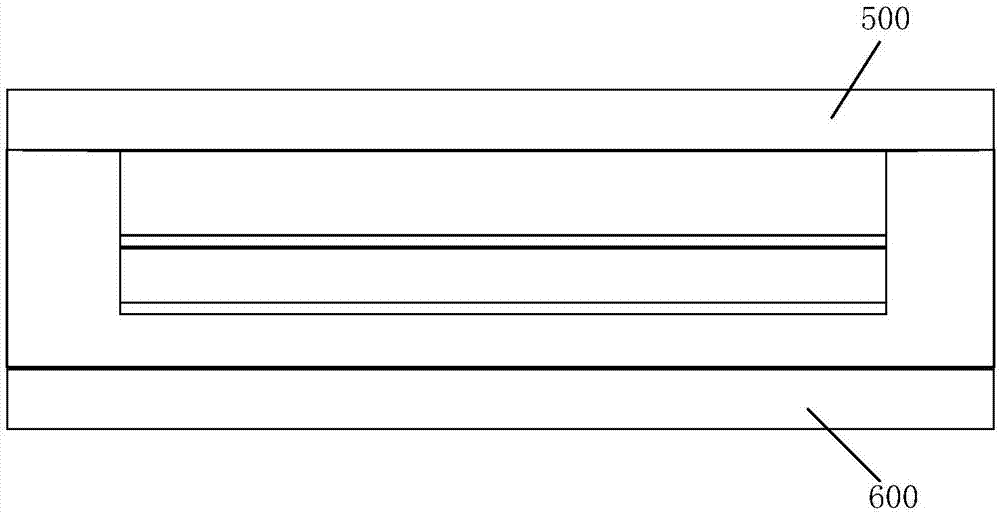

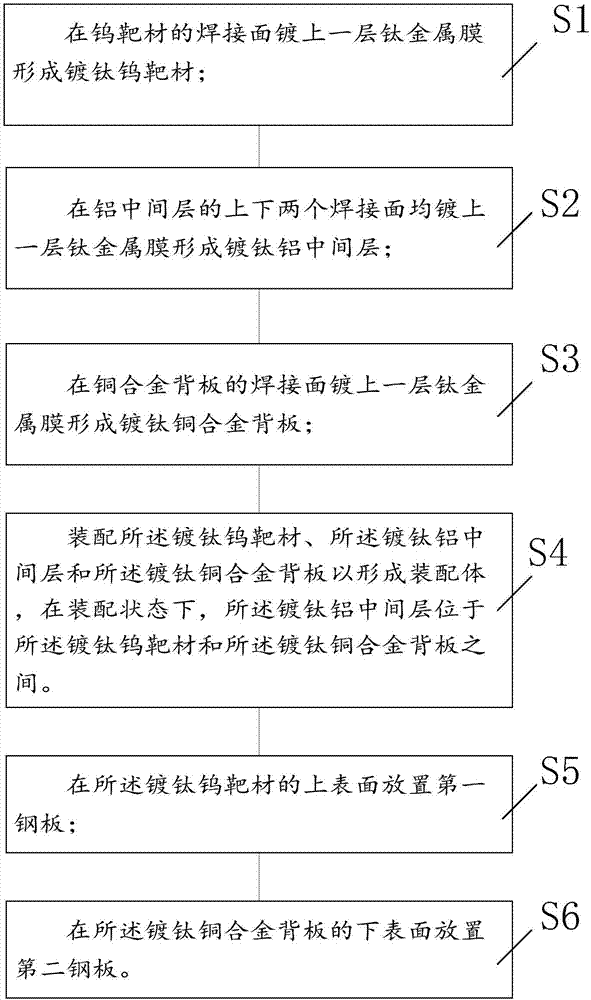

Tungsten target diffusion welding method and target assembly

InactiveCN107971620AAvoid crackingRelease stressVacuum evaporation coatingSputtering coatingTitanium metalAluminium

The invention relates to the technical field of semiconductor targets, in particular to a tungsten target diffusion welding method and a target assembly. The technical problems that a crack is prone to occurring when a tungsten target is directly welded to a copper alloy backing plate, and diffusion welding is not prone to being conducted between the tungsten target and an aluminum intermediate layer as well as between the aluminum intermediate layer and the copper alloy existing in the prior art are solved. The tungsten target diffusion welding method comprises the steps that firstly a weld face of the tungsten target is plated with a layer of titanium metal film to form a titanium-plated tungsten target, each of an upper weld face and a lower weld face of the aluminum intermediate layeris plated with a layer of titanium metal film to form a titanium-plated aluminum intermediate layer, and a weld face of the copper alloy backing plate is plated with a layer of titanium metal film toform a titanium-plated copper alloy backing plate; and then the titanium-plated tungsten target, the titanium-plated aluminum intermediate layer and the titanium-plated copper alloy backing plate areassembled to form an assembly body, wherein the titanium-plated aluminum intermediate layer is located between the titanium-plated tungsten target and the titanium-plated copper alloy backing plate. According to the technical scheme provided by the tungsten target diffusion welding method, occurring of the crack can be avoided, and diffusion welding is easy.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

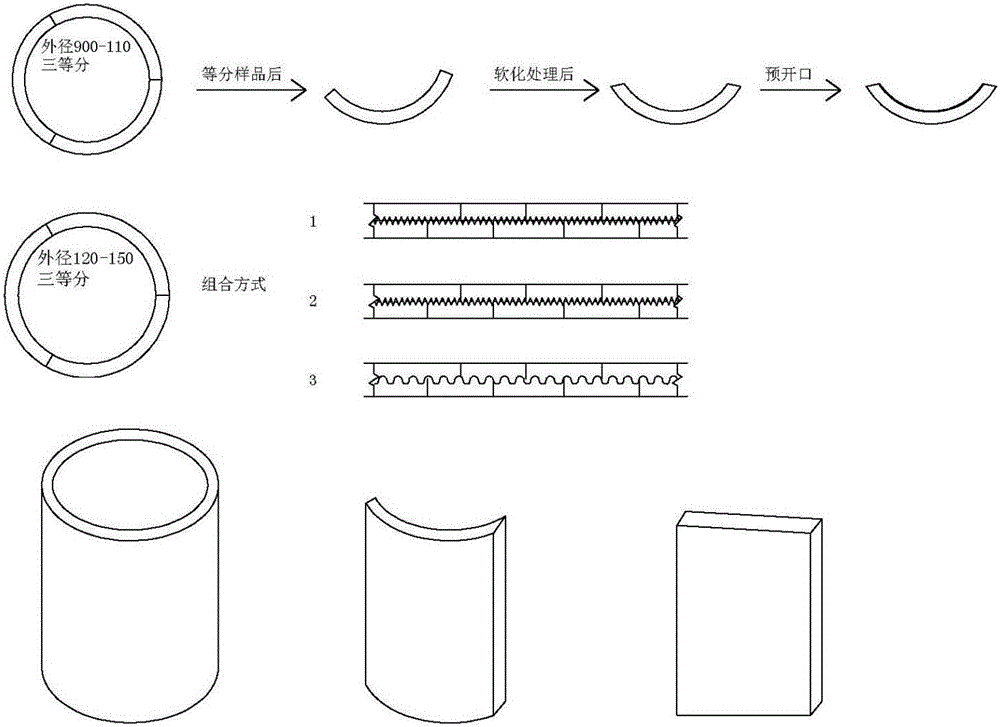

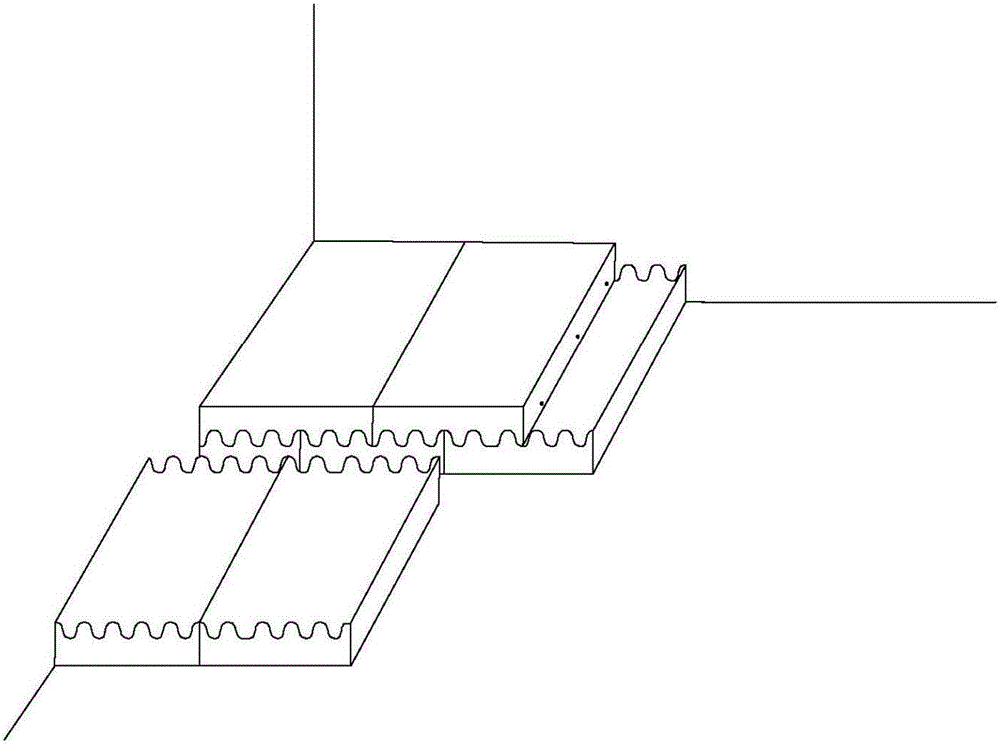

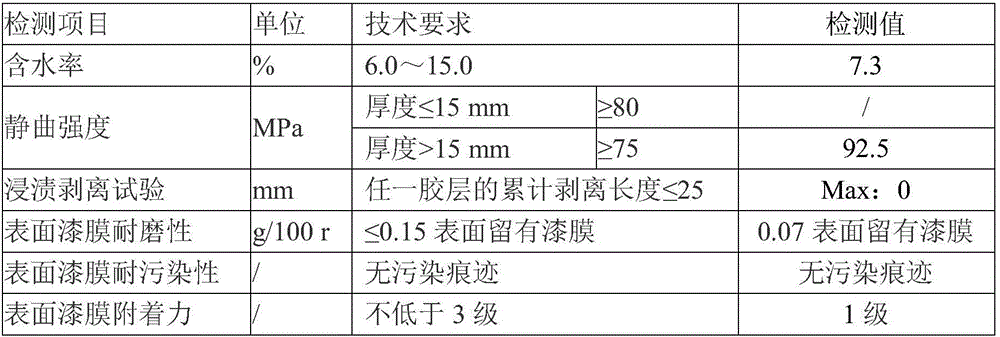

Processing method for high-quality bamboo flattened floor

ActiveCN106426487ASmall volume lossRelease stressWood treatment detailsCane mechanical workingEngineeringHardness

The invention relates to a processing method for high-quality bamboo flattened floor. The processing method comprises the steps of selecting materials and splitting, pre-forming concave slots, cooking and softening, flattening at a high temperature, drying, processing comb teeth, preparing substrate, gluing, transversely reinforcing and the like. The bamboo floor has density which is only 0.6g / cm<3> (optimum density of produced floor), has surface-layer density and core-layer density which are in step distribution, has relatively good elasticity and keeps natural textures of a high-hardness bamboo green surface. Besides, the high-quality bamboo flattened floor can be mounted in a staggered mode on the scene, and floor units are mutually clamped, so that the floor has higher integral stability. The high-quality bamboo flattened floor has the advantages of being not liable to crack, high in surface hardness and good in wear resistance, simple in process, and the like, and is novel high=quality floor with excellent physical property and excellent mechanical property.

Owner:ZHEJIANG FORESTRY ACAD

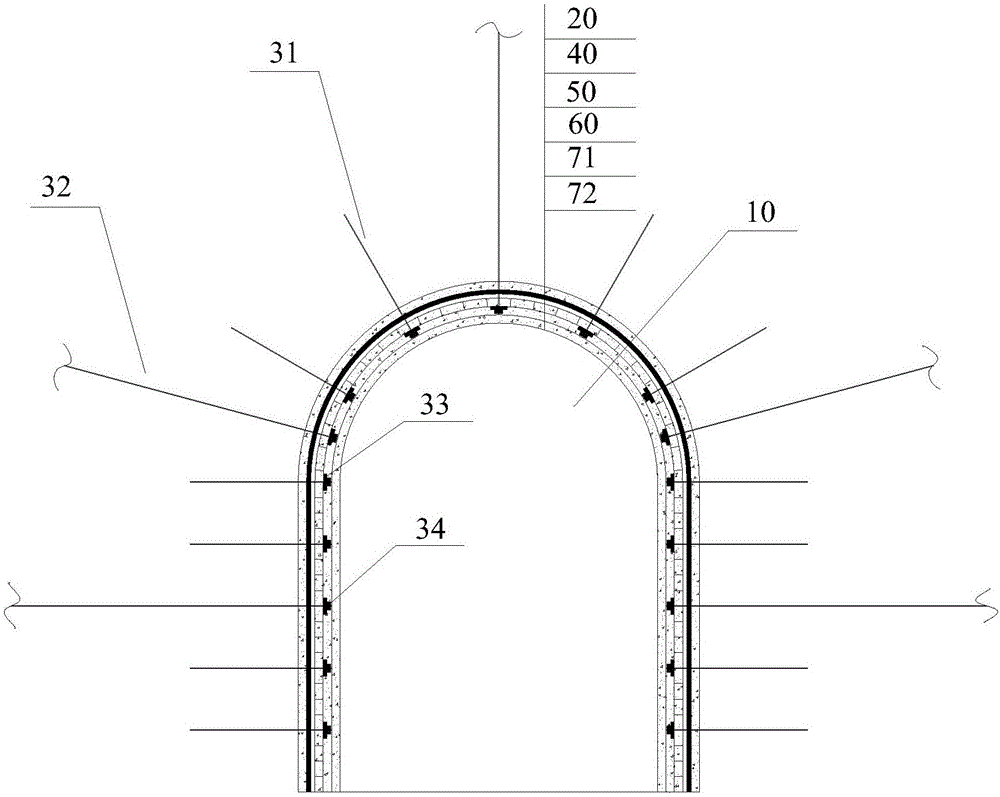

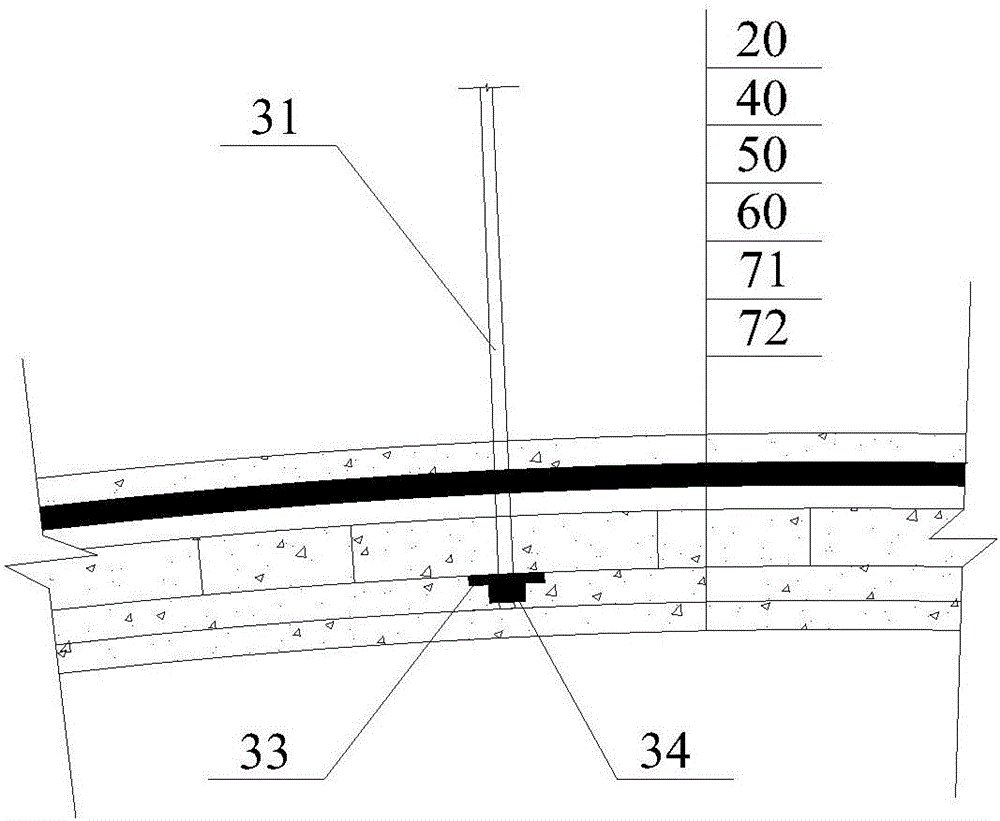

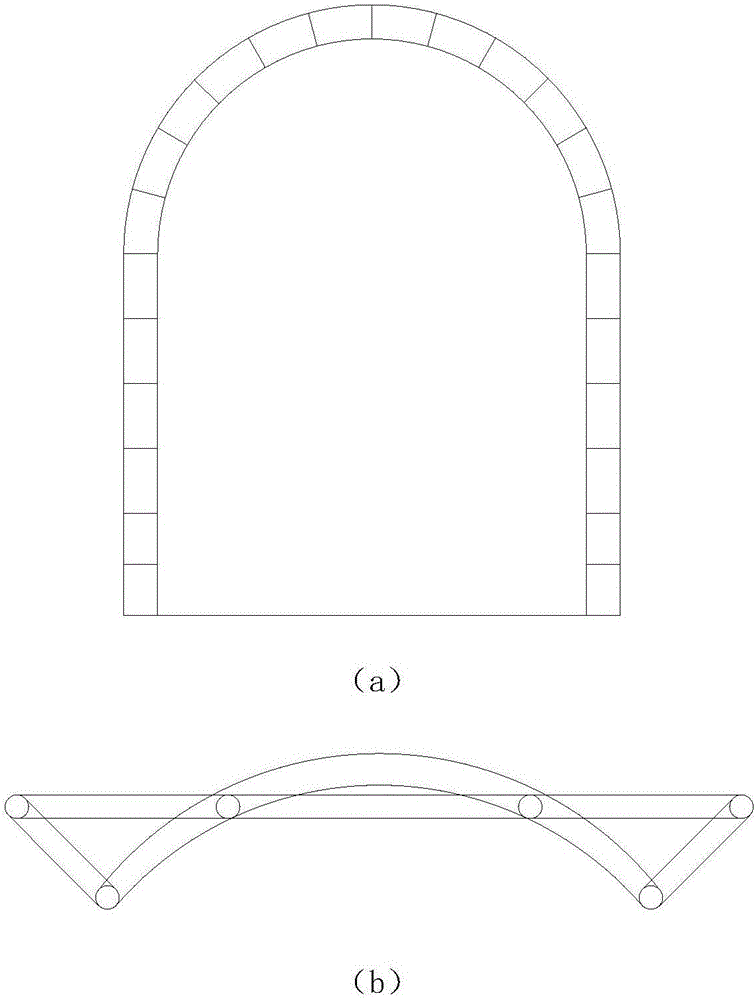

Supporting structure for composite anchor mesh steel bar support of deep well high-stress soft rock roadway and construction method thereof

InactiveCN106761811AImprove stabilityAvoid loose damageUnderground chambersTunnel liningSupporting systemShotcrete

The invention provides a supporting structure for a composite anchor mesh steel bar support of a deep well high-stress soft rock roadway and a construction method thereof. Firstly, anchor rods and anchor ropes are stroke into the interior of surrounding rock, and the set length is exposed; then, steel bar meshes and polyester fiber meshes are laid and hung through the outward-exposing portion of the anchor rods and the anchor ropes, the steel bar meshes are closely attached to the surrounding rock to be laid, and the polyester fiber meshes are closely attached to the steel bar meshes to be laid; a steel bar mesh shell support is erected; the anchor rods and the anchor ropes pass through the steel bar meshes, the polyester fiber meshes and the steel bar mesh shell support in sequence and are fixed on the steel bar mesh shell support through trays and nuts; a first concrete shotcrete layer is poured to close the whole supporting structure, and initial supporting is finished; and finally, a second concrete shotcrete layer is poured, and second supporting is finished. Through initial supporting, the whole structure and the surrounding rock deforms jointly, the yielding effect is given play, and surrounding rock pressure is released, and then second supporting is conducted. Meanwhile, the flexibility and pressure releasing effects of the polyester fiber meshes are utilized, so that the surrounding rock pressure is evenly distributed in the whole supporting system.

Owner:ANHUI UNIV OF SCI & TECH

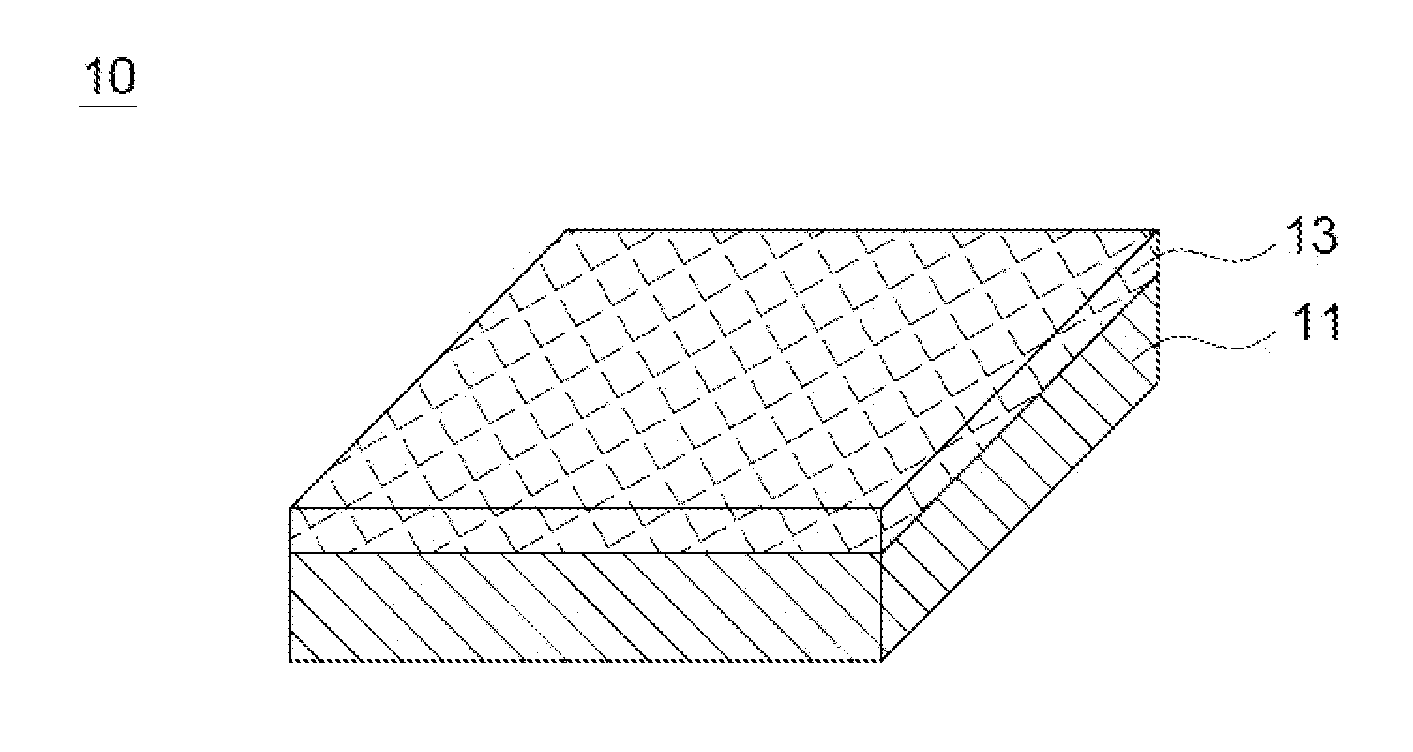

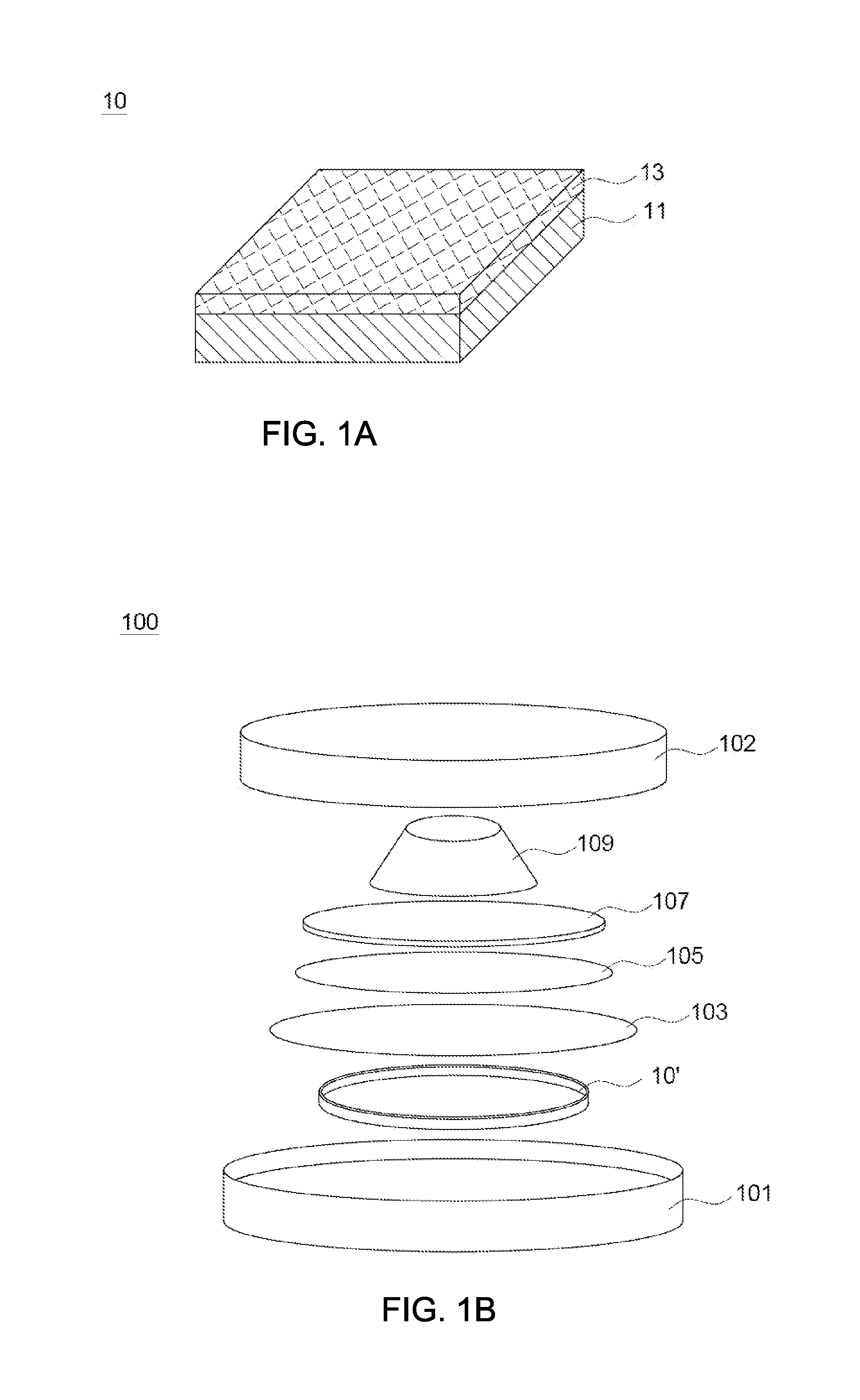

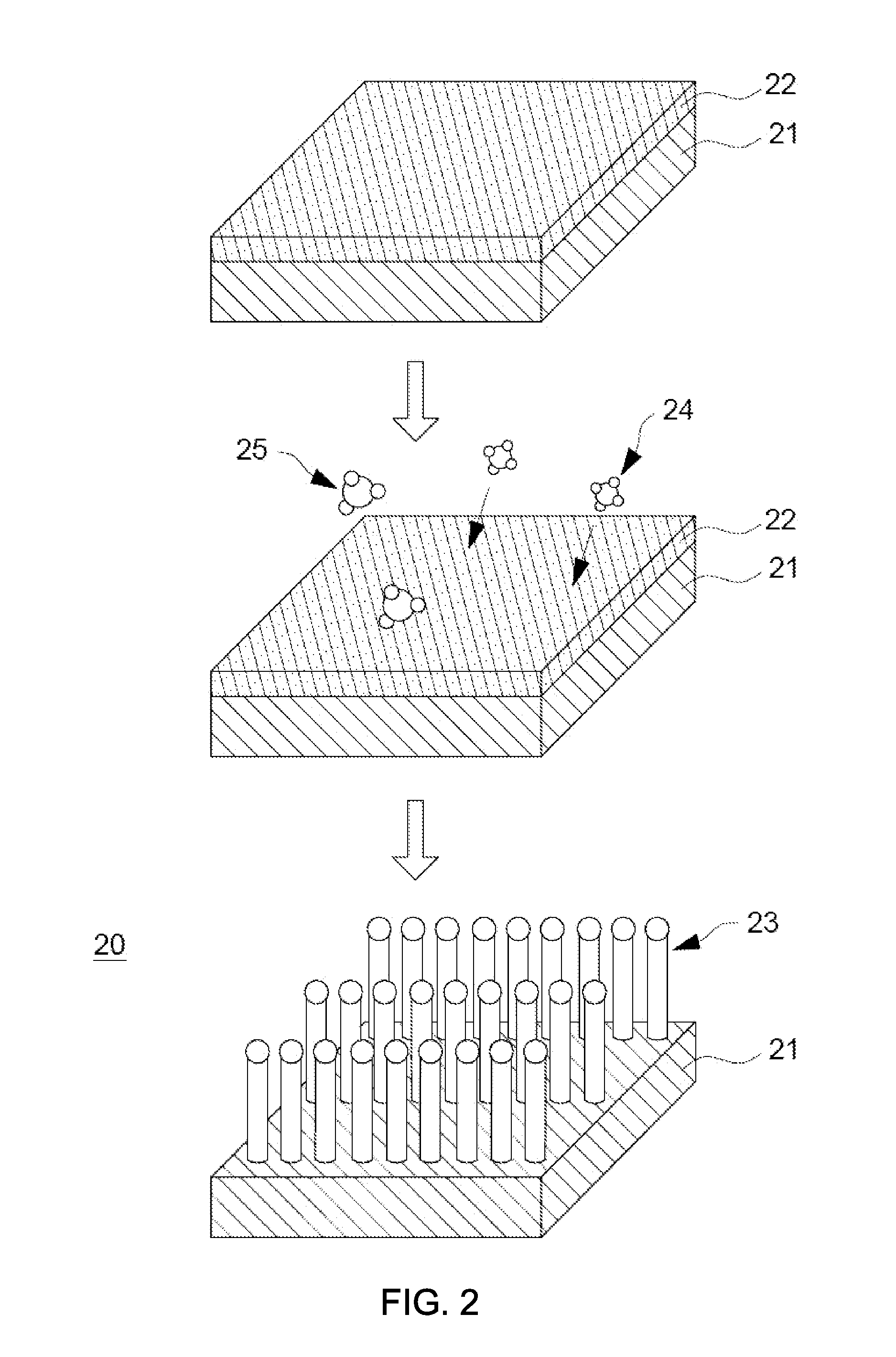

Lithium-ion battery and lithium-ion battery electrode structure with dopants

InactiveUS20140141318A1Increase concentrationImprove conductivityElectrode carriers/collectorsSecondary cellsDopantNanowire

A lithium-ion battery and a lithium-ion battery electrode structure are disclosed. The lithium-ion battery electrode structure comprises a metal foil and a semiconductor nanowire matrix. The semiconductor nanowire matrix is disposed on the metal foil, and is doped with dopants.

Owner:NAT TAIWAN UNIV

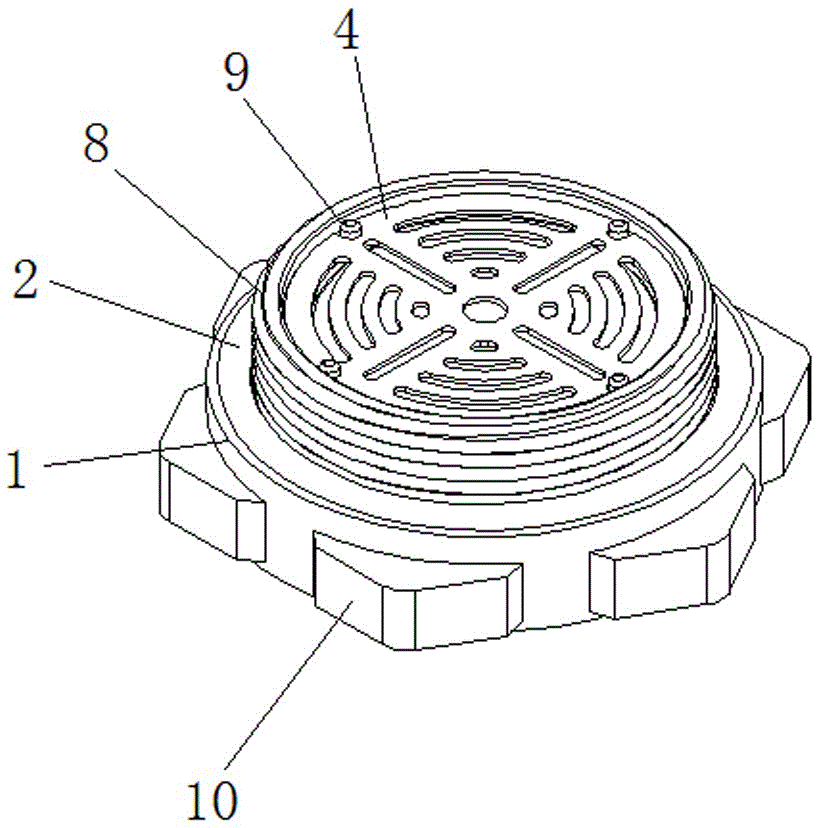

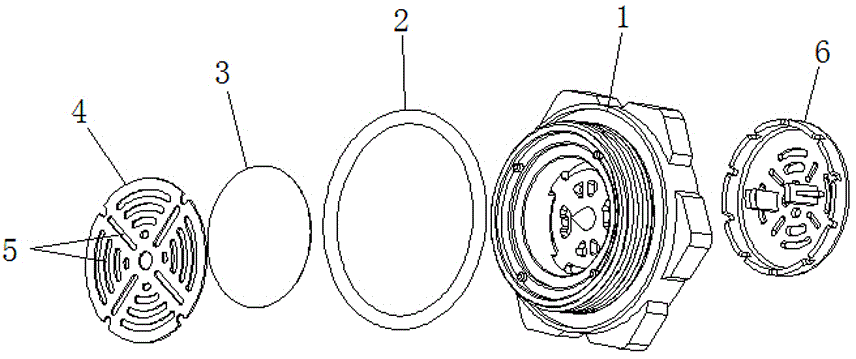

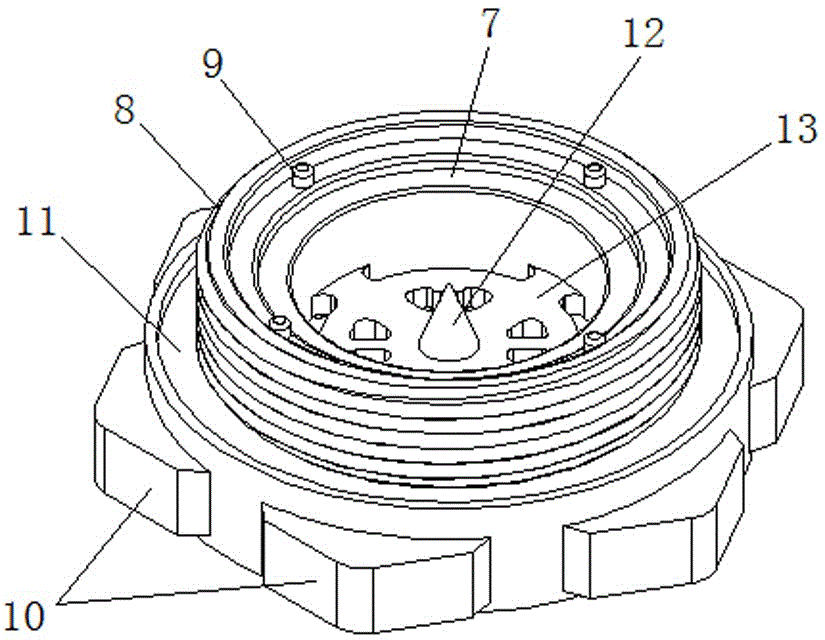

New energy battery explosion-proof valve

The invention discloses a new energy battery explosion-proof valve, which comprises a main valve body, a seal ring, a piece of explosion-proof membrane paper, a membrane paper protection plate and a protective cover, wherein a membrane paper mounting platform is arranged at one side of the main valve body; the explosion-proof membrane paper is welded on the membrane paper mounting platform in a hot melting manner; an annular bump is arranged on the outer circumference of the membrane paper mounting platform; the membrane paper protection plate is arranged in the annular bump; a protective bottom plate is arranged at the lower part of the membrane paper mounting platform; the protective bottom plate is provided with an explosion-proof pointed cone toward the explosion-proof membrane paper; the protective cover is arranged out of the protective bottom plate; the seal ring is arranged between the outer surface of the annular bump and the main valve body; the main valve body is movably connected with a battery shell through the annular bump; and the main valve body and a battery shell are sealed through the seal ring. The new energy battery explosion-proof valve has the advantages of being simple in structure, low in cost, dustproof, waterproof, explosion-proof and breathable, and can balance internal pressure and external pressure of a sealed accommodating cavity of a battery.

Owner:惠州市沃瑞科技有限公司

Flexible display device

ActiveCN108962026AAvoid breakingReduces the risk of cracking and spreading to metal layersSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFlexible display

The invention discloses a flexible display device. The device comprises a flexible substrate provided with a non-display area, an organic buffering layer arranged on the non-display area of the flexible substrate, and an organic protective layer arranged on at least one metal wire and provided with a first organic protective layer section and a second organic protective layer section, wherein themetal wires are arranged on the organic buffering layer; the first organic protective layer section is arranged on one folding center line portion of the non-display area, and the first elastic modulus of the first organic protective layer section is greater than the second elastic modulus of the second organic protective layer section. The elasticity of the portion, at the folding center line, ofthe organic buffering layer is greater than that of the materials on the two sides of the folding center line to buffer the stress so as to reduce the risk that the fracturing of a membrane layer iscaused and spreads to a metal conducting layer, so that the short circuit phenomenon is caused.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

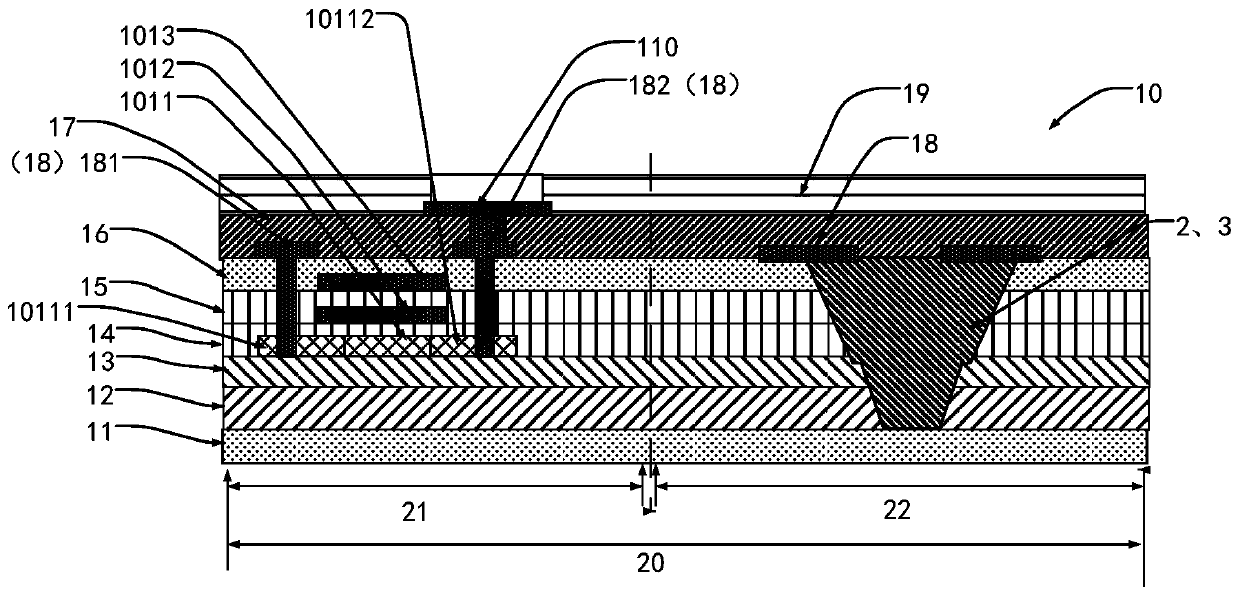

Display panel and display device

ActiveCN109860252AImprove bending effectRelease stressSolid-state devicesIdentification meansPhotoresistSurface plate

The present invention discloses a display panel. The display panel comprises a bending region and a non-bending region connected with the bending region, and the display panel further comprises an array substrate. The array substrate comprises: a plurality of first pixel regions which are mutually arranged in parallel in multiple lines and arranged in the bending region; a plurality of second pixel regions which are mutually arranged in parallel in multiple lines and arranged in the non-bending region; and a plurality of flexible connection regions configured to connect with adjacent first pixel regions and connect with the first pixel regions and the second pixel regions, wherein each flexible connection region is internally provided with a slot, and each slot is filled with an organic photoresist layer. According to the invention, the slots are arranged in the flexible connection regions of the bending region to form an inorganic layer slot between two adjacent lines of pixel regionsin the bending region to separate from each two lines of pixel regions, and the slots are filled with the organic photoresist layers so as to effectively relieve the stress of each inorganic layer ormetal wiring corresponding in the display panel, especially in the array substrate.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

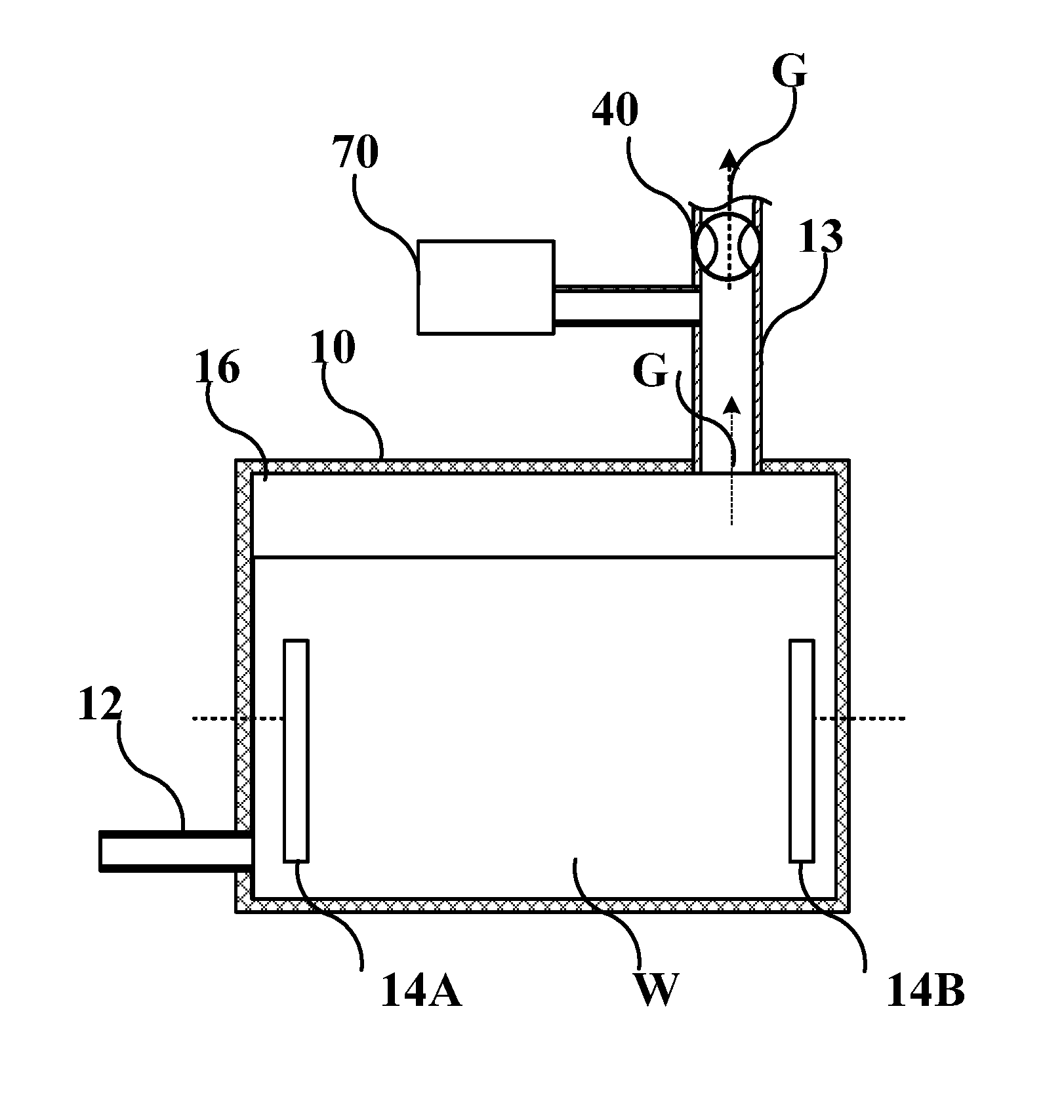

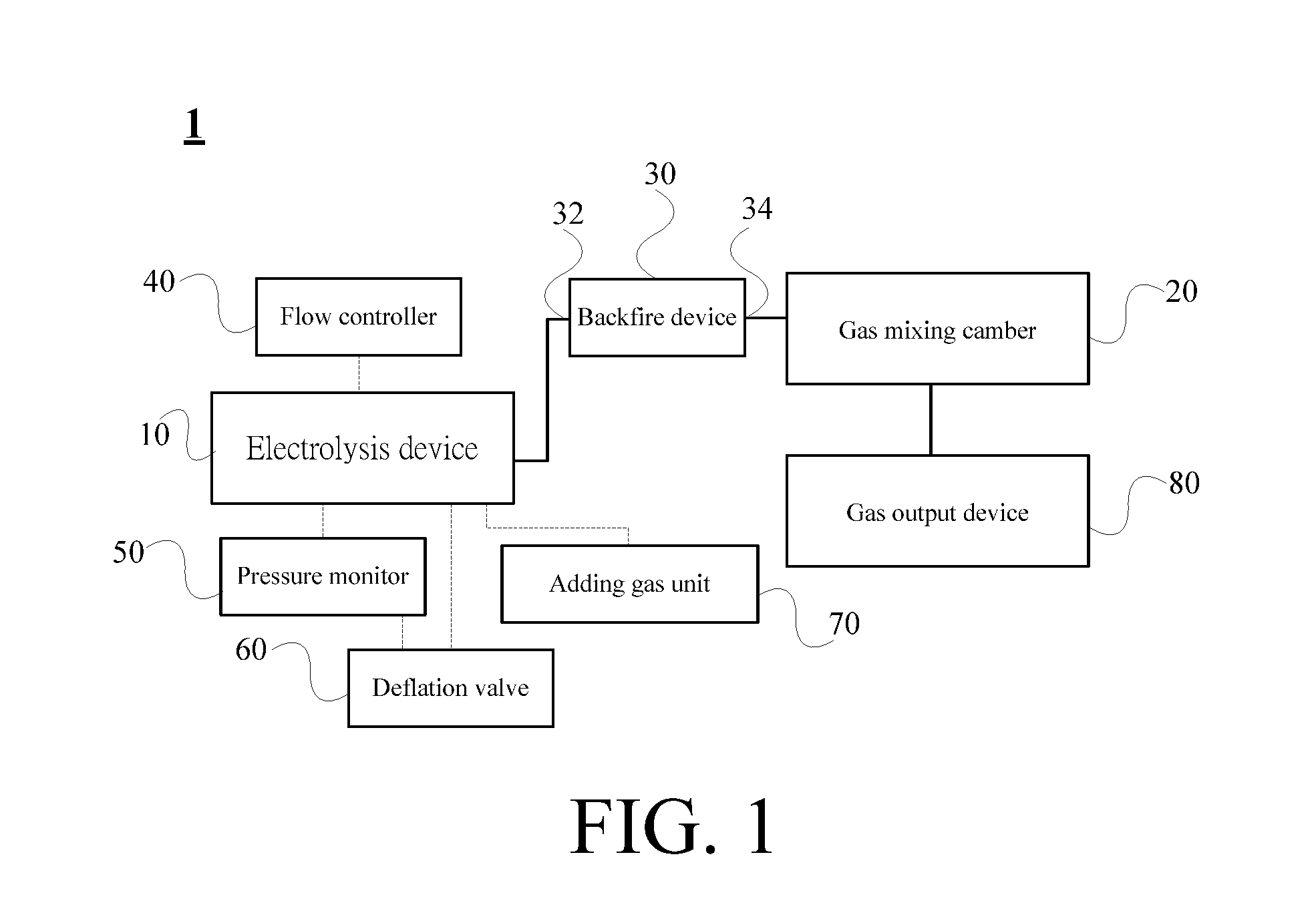

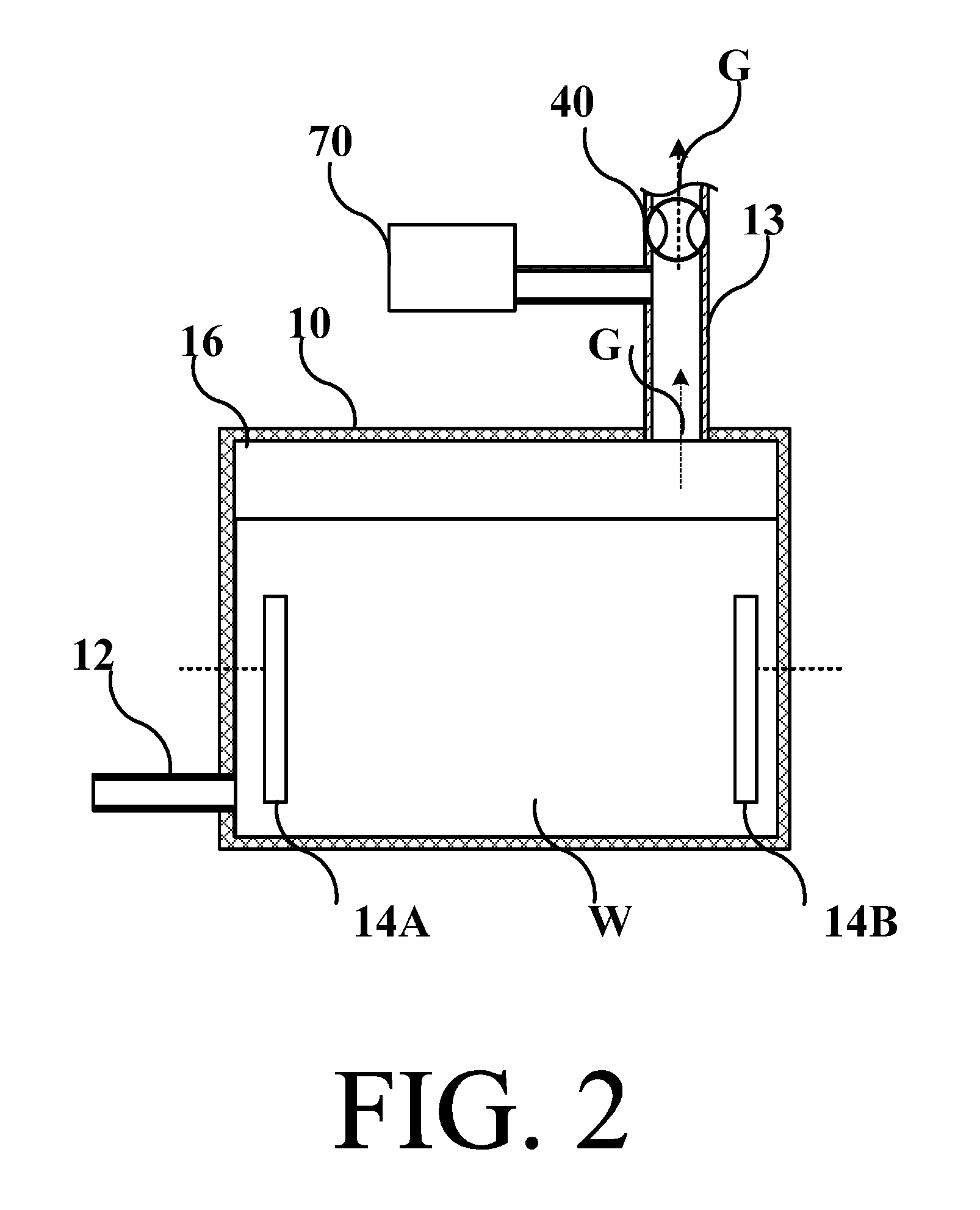

Gas generator

A gas generator for health is provided. The gas generator for health includes an electrolysis device, a gas mixing chamber and a gas output device. The electrolysis device is for electrolyzing water to produce a combination gas including hydrogen and oxygen. The gas mixing chamber includes a shell and a cover. The shell has an anti-explosion hole. The cover is separatably disposed on the anti-explosion hole, and the diameter of the anti-explosion hole is larger than 0.5 cm. The gas mixing chamber is connected to the electrolysis device for receiving the combination gas. A vaporized gas is generated by the gas mixing chamber and mixed with the combination gas to produce a healthy gas. The gas output device is connected to the gas mixing chamber for outputting the healthy gas to a user to breath.

Owner:LIN HSIN YUNG

Lithium-rich cathode material doped with lithium manganate at Mn site, and preparation method of lithium-rich cathode material

InactiveCN107994226AImprove thermal stabilityReduce churnCell electrodesCyclic processOxygen vacancy

The invention provides a lithium-rich cathode material doped with lithium manganate at a Mn site, and a preparation method of the lithium-rich cathode material. The preparation method of the lithium-rich cathode material doped with the lithium manganate at the Mn site comprises the following steps: evenly mixing a lithium source, a manganese source, doped metal salt and a metal complexing agent, carrying out ultrasonic gas atomization on the obtained mixture, and calcining to obtain spherical lithium manganate powder; mixing the obtained spherical lithium manganate powder with a spherical cathode material, coating and calcining. The lithium-rich cathode material provided by the invention is prepared by doping the lithium manganate at the Mn site, thus effectively inhibiting oxygen evolution and solving the problem of voltage drop in a circulating process; the tap density of powder can be improved by mixing, so that the energy density of the material is further improved; due to the stepof coating, the loss of oxygen vacancies and the migration of transition metal ions are reduced; after the lithium-rich cathode material is adopted, the first time efficiency is increased, the safetyperformance of batteries is improved, and the energy density of the material is improved.

Owner:桑顿新能源科技(长沙)有限公司

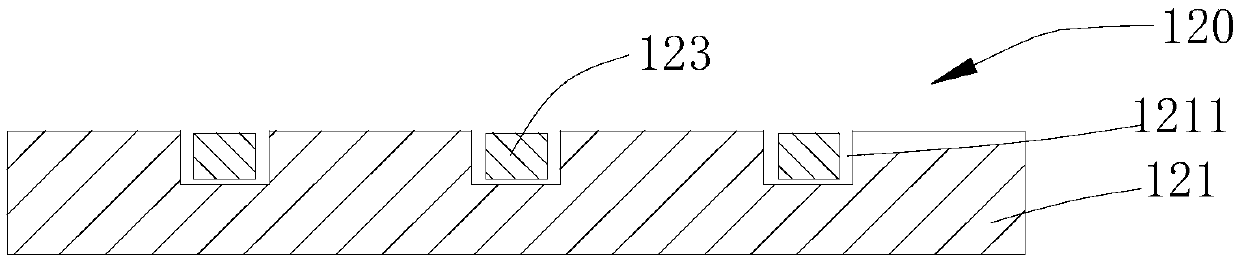

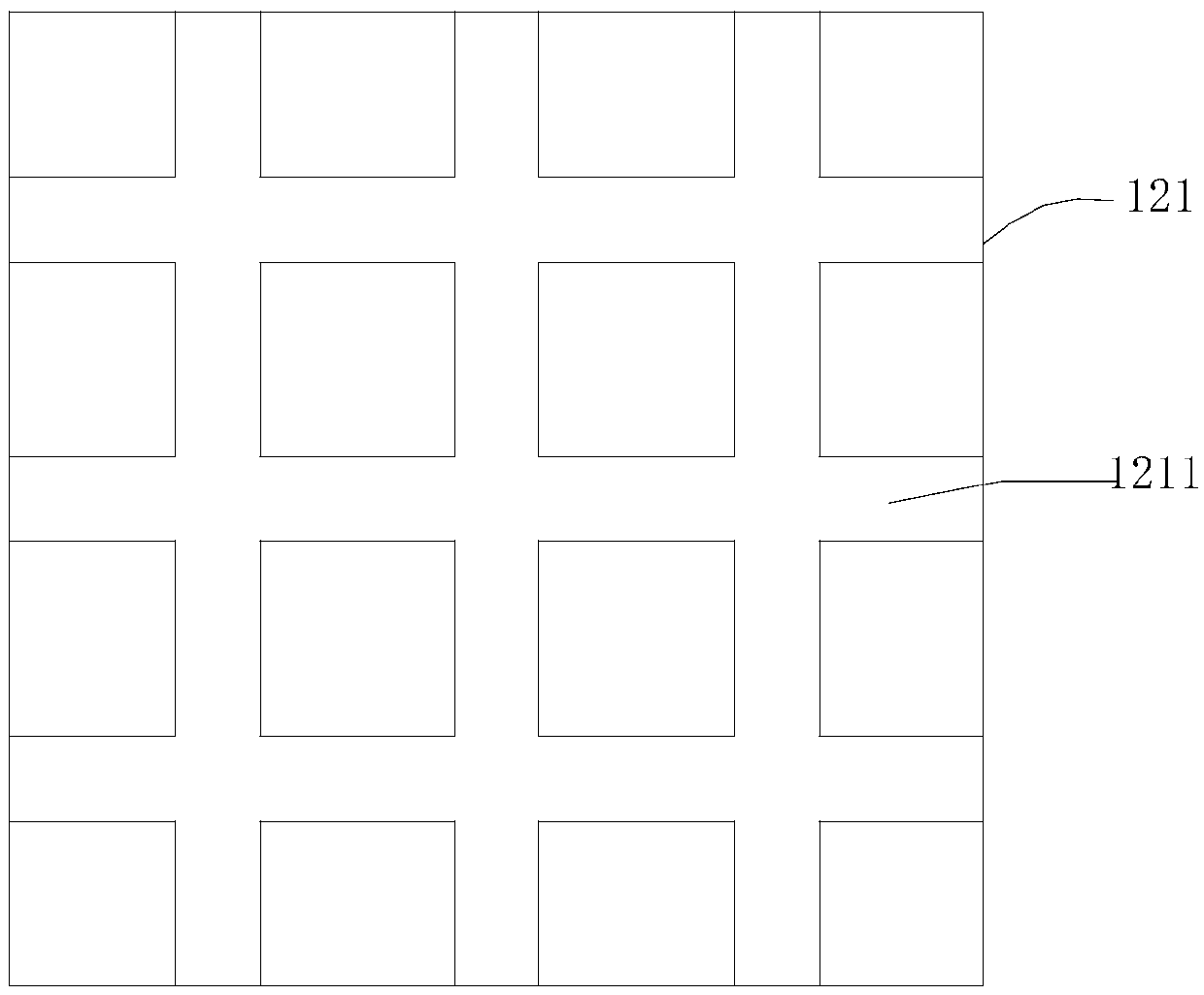

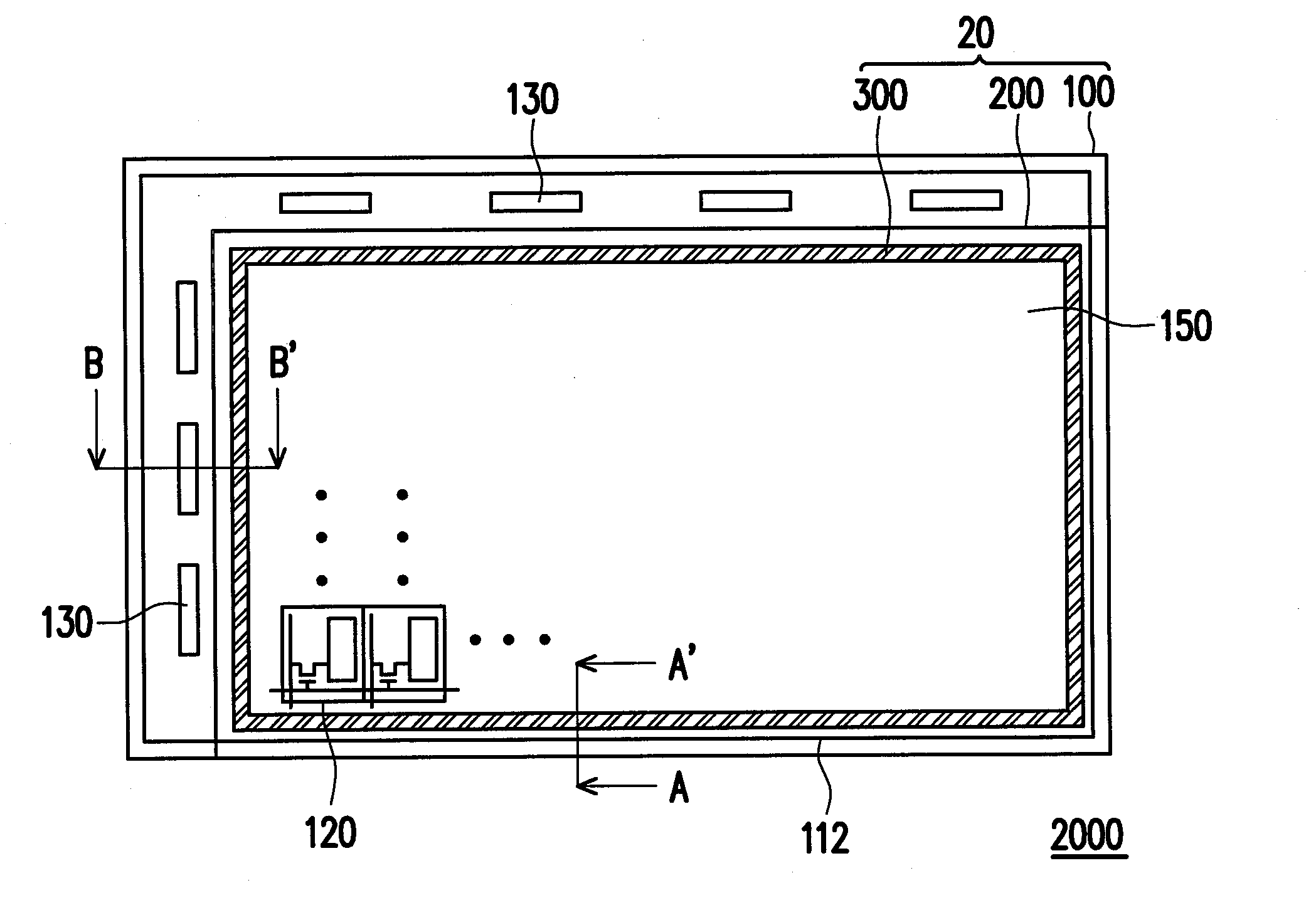

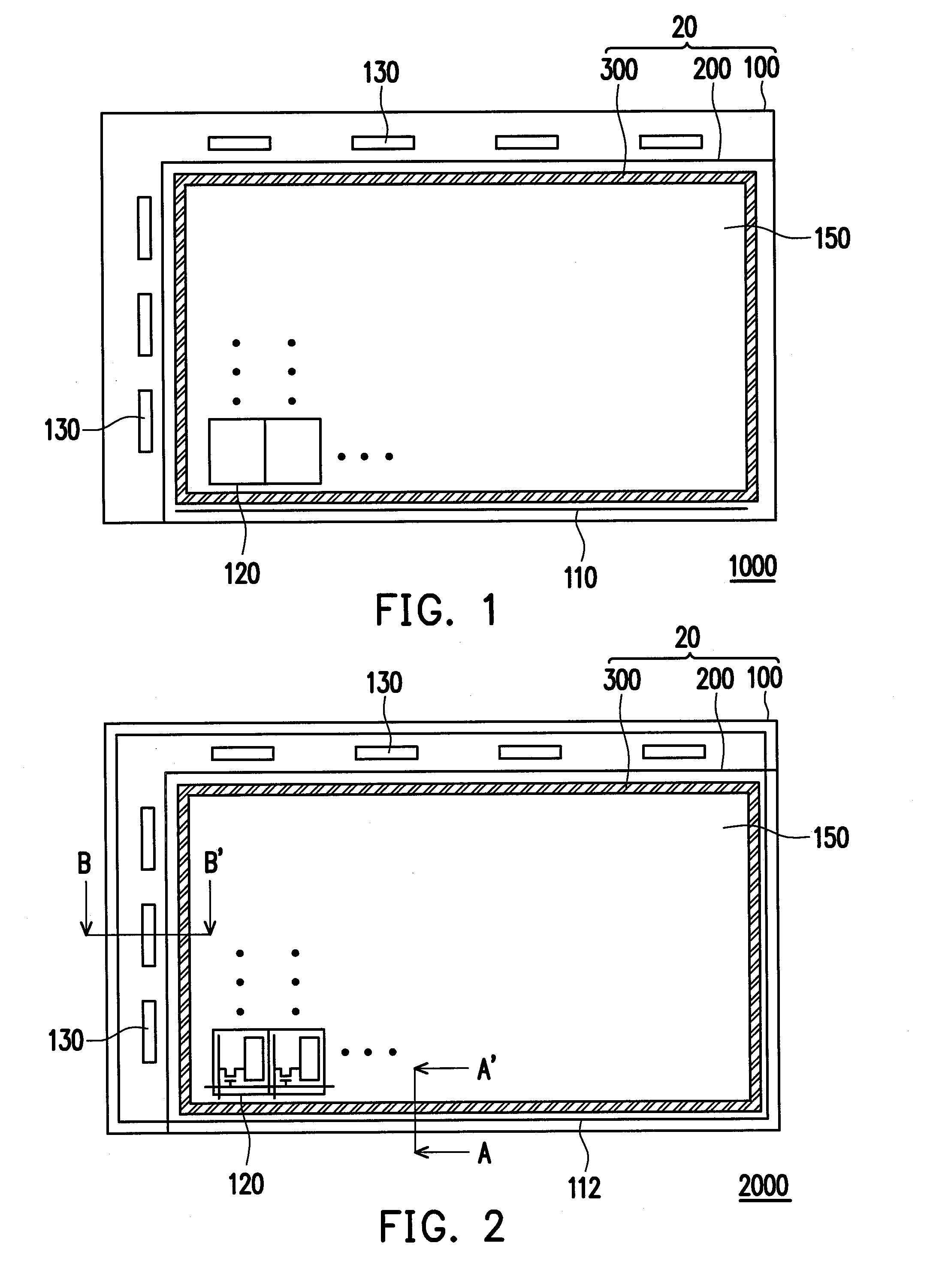

Substrate module

A substrate module suitable for being filled with a display medium to form a display panel is provided. The substrate module includes an active device array substrate, an opposite substrate, and a sealant. The active device array substrate has a groove. The opposite substrate is disposed opposite to the active device array substrate. The active device array substrate and the opposite substrate are assembled through the sealant, wherein the display medium is substantially filled in a region surrounded by the sealant to form the display panel and the groove is located between the sealant and a border of the active device array substrate.

Owner:CHUNGHWA PICTURE TUBES LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com