Light emitting diode packaging structure

A technology of light-emitting diodes and packaging structures, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of unfavorable light emitting upward, affecting light extraction efficiency, unfavorable integration, etc., to achieve concentrated color point output, high light efficiency, Production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

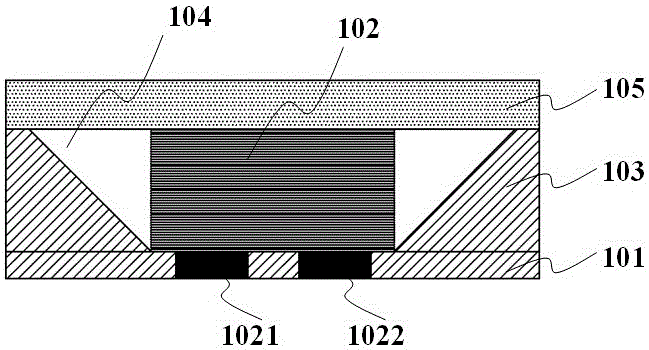

[0055] like figure 1As shown, this embodiment discloses a light emitting diode packaging structure, which is composed of a flip chip 102 , a first reflective material layer 101 , a second reflective material layer 103 , a first transparent material layer 104 and a wavelength conversion material layer 105 .

[0056] Wherein the flip chip 102 is located on the first reflective material layer 101 having a through hole, and the electrode 1021 and the electrode 1022 of the flip chip 102 are embedded in the through hole of the first reflective material layer 101, that is, the side surface of the electrode or Part of the side surface is surrounded by the first reflective material layer 101 . The positive and negative electrodes ( 1021 and 1022 ) of the flip chip 102 contain one of metal copper or gold, and the thickness thereof is between 10 μm and 100 μm. The first light-reflecting material layer 101 and the thicker electrodes can relieve the stress of the PCB on the flip-chip when...

Embodiment 2

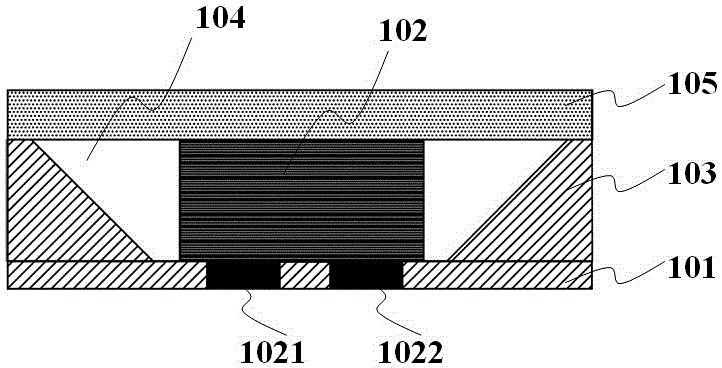

[0060] Such as figure 2 As shown, compared with Embodiment 1, there is a certain distance between the inner edge of the bottom of the second light-reflecting material layer 103 of this embodiment and the side surface of the flip chip 102, so that the size of the flip chip can be kept constant. Increase the light-emitting area, and improve the light efficiency to a certain extent.

Embodiment 3

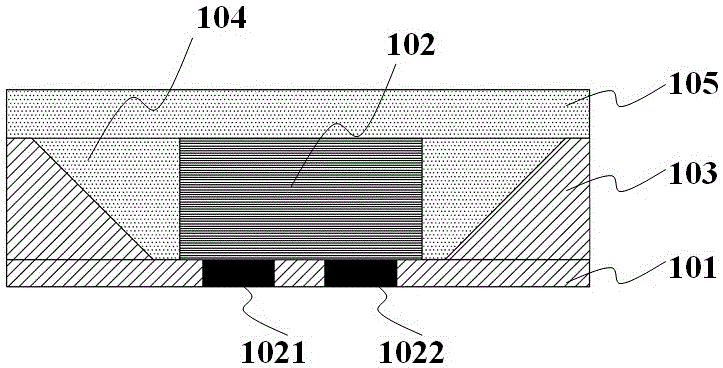

[0062] Such as image 3 As shown, compared with Embodiment 1, the first transparent material layer 104 of this embodiment contains a wavelength conversion material. For example, a red light conversion material is added to the first transparent material layer, and only yellow light or green light conversion material is contained in the wavelength conversion material layer 105, so as to avoid the secondary absorption of yellow light or green light by the red light conversion material, which can effectively Improve light efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com