Processing method for high-quality bamboo flattened floor

A high-quality flooring technology, applied in wood processing equipment, sugarcane machining, and joining of wooden veneers, etc., can solve problems such as increased difference in equilibrium moisture content, release of harmful substances such as formaldehyde, and difficult control of dimensional stability , to achieve the effect of good natural wear resistance, excellent physical and mechanical properties, and simple and quick billet assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

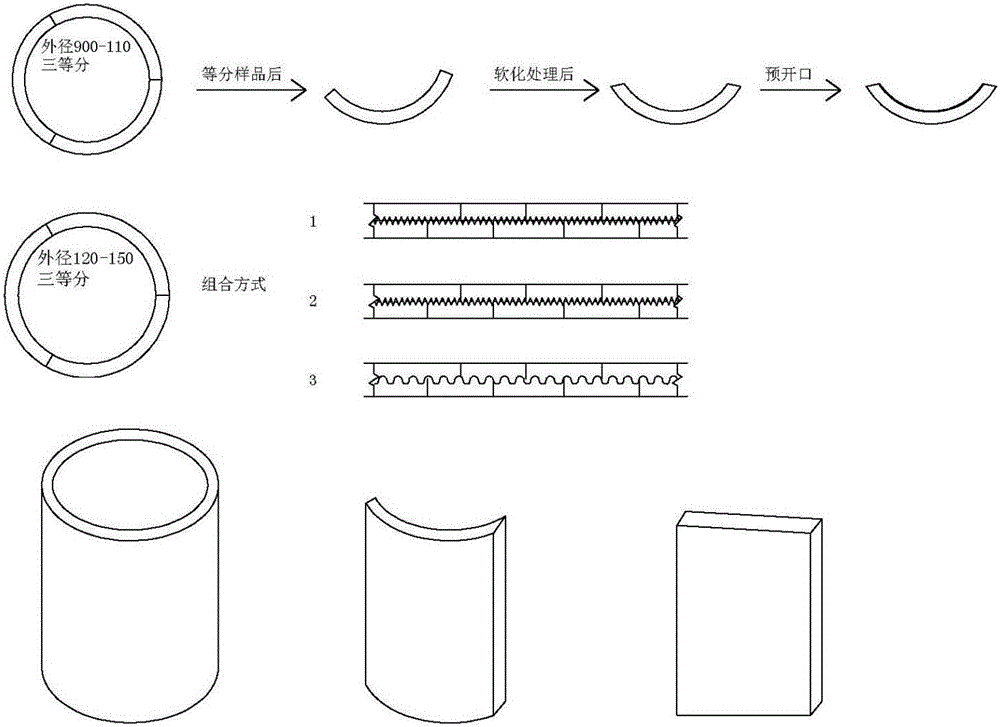

[0039] (1) Material selection and division: Select high-quality moso bamboo tubes with a length of about 2.0 meters, an outer diameter of more than 11 cm, and a wall thickness of more than 1.1 cm as raw materials. First, process the bamboo tubes into 0.5-meter-long bamboo segments, and then divide the bamboo segments into three grades Divided or quartered bamboo strips, with an outer diameter of 11 to 12 cm, divided into three equal parts, and an outer diameter of 12 to 15 cm, divided into four equal parts, and the inner and outer bamboo joints are smoothed;

[0040](2) Cooking and softening: After the bamboo yellow surface of the bamboo strip is divided longitudinally and pre-opened, the softening solution is used to cook and soften, the cooking temperature is about 130 ° C, and the cooking time is 1.0 hour; the quality of the softening solution is composed as follows: NaOH 36g / L , 0.8g / L sodium dodecylbenzenesulfonate, 0.2g / L bis(2-ethylhexyl) phthalate (DEHP); NaOH quality i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com