Whole wheat fritters and preparation method thereof

A production method and technology of deep-fried dough sticks, applied in pre-baked dough processing, baking, baked food, etc., can solve problems such as no effective solutions have been found, and achieve the effects of large specific volume, small specific volume loss, and increased oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

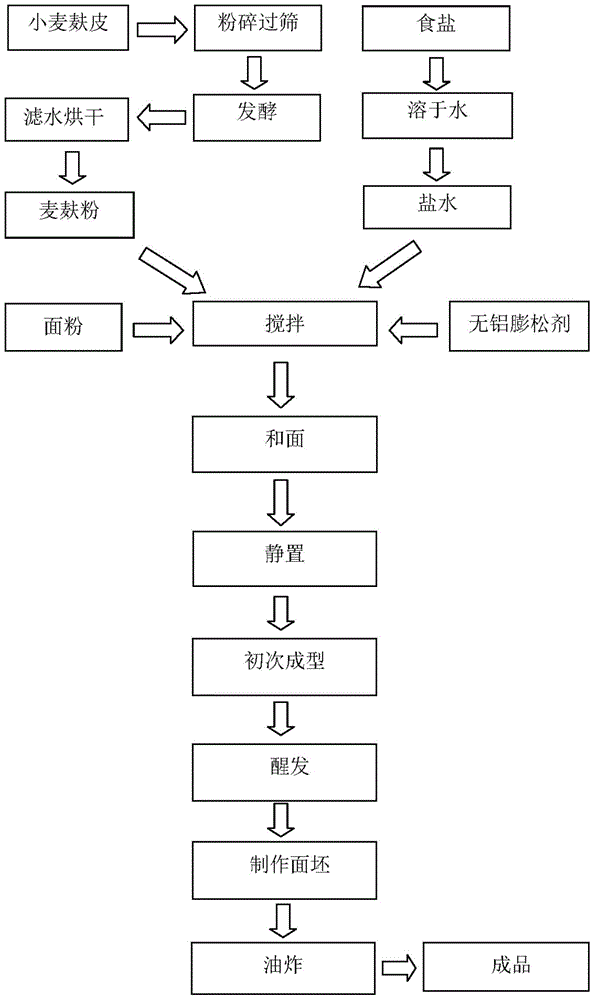

Image

Examples

Embodiment 1

[0041] A whole wheat deep-fried dough stick, the formula of which is 285 g of flour and 15 g of wheat bran powder. The contents of other additives are: 9 g of leavening agent for Anqi aluminum-free fried dough sticks, and 3.6 g of table salt.

[0042] The production process of the whole wheat fried dough sticks is as follows:

[0043] Crush the wheat bran first, pass through a 40-mesh sieve, and then pass through a 20-mesh sieve to obtain wheat bran with a particle size between 380-830 μm; mix 100 g of wheat bran with 1.5 g of yeast, add 350 g of water, and store at 25°C Fermentation at low temperature for 20 hours; after the fermentation, the excess water was filtered off, and dry heat treatment was carried out in an oven at 55°C for 6 hours to become spare wheat bran powder, which was sealed and stored in a dry place. Dissolve 3.6 g of table salt in 180 mL of water to become brine and set aside. Stir 15 g of pretreated wheat bran powder, 285 g of flour and 9 g of Angel’s a...

Embodiment 2

[0045] A whole wheat fritters, the formula of which is 276 g of flour and 24 g of wheat bran powder. The contents of other additives are: 12 g of leavening agent for Anqi aluminum-free fried dough sticks, and 3.6 g of table salt.

[0046] The production process of the whole wheat fried dough sticks is as follows:

[0047] Crush the wheat bran first, pass through a 40-mesh sieve, and then pass through a 20-mesh sieve to obtain wheat bran with a particle size between 380-830 μm; mix 100 g of wheat bran with 2 g of yeast, add 380 g of water, and heat at 30°C Fermentation at low temperature for 15 hours; after the fermentation, the excess water was filtered off, and dry heat treatment was carried out in an oven at 60°C for 5 hours to become spare wheat bran powder, which was sealed and stored in a dry place. Dissolve 3.6 g of table salt in 190 mL of water to become brine and set aside. Stir 24 g of wheat bran powder, 276 g of flour and 12 g of Angel’s aluminum-free leavening age...

Embodiment 3

[0049] A whole wheat deep-fried dough stick, the formula of which is 285 g of flour and 15 g of wheat bran powder. The contents of other additives are: 12 g of leavening agent for Anqi aluminum-free fried dough sticks, and 3.6 g of table salt.

[0050] The production process of the whole wheat fried dough sticks is as follows:

[0051] Crush the wheat bran first, pass through a 60-mesh sieve, and then pass through a 40-mesh sieve to obtain wheat bran with a particle size between 250-380 μm; mix 100 g of wheat bran with 1 g of yeast, add 300 g of water, and store at 25°C Fermentation at low temperature for 20 hours; after the fermentation, the excess water was filtered off, and dry heat treatment was carried out in an oven at 55°C for 6 hours to become spare wheat bran powder, which was sealed and stored in a dry place. Dissolve 3.6 g of table salt in 190 mL of water to become brine and set aside. Stir 15 g of wheat bran powder, 285 g of flour and 12 g of Angel’s aluminum-fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com