Patents

Literature

466results about How to "Improve bending effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

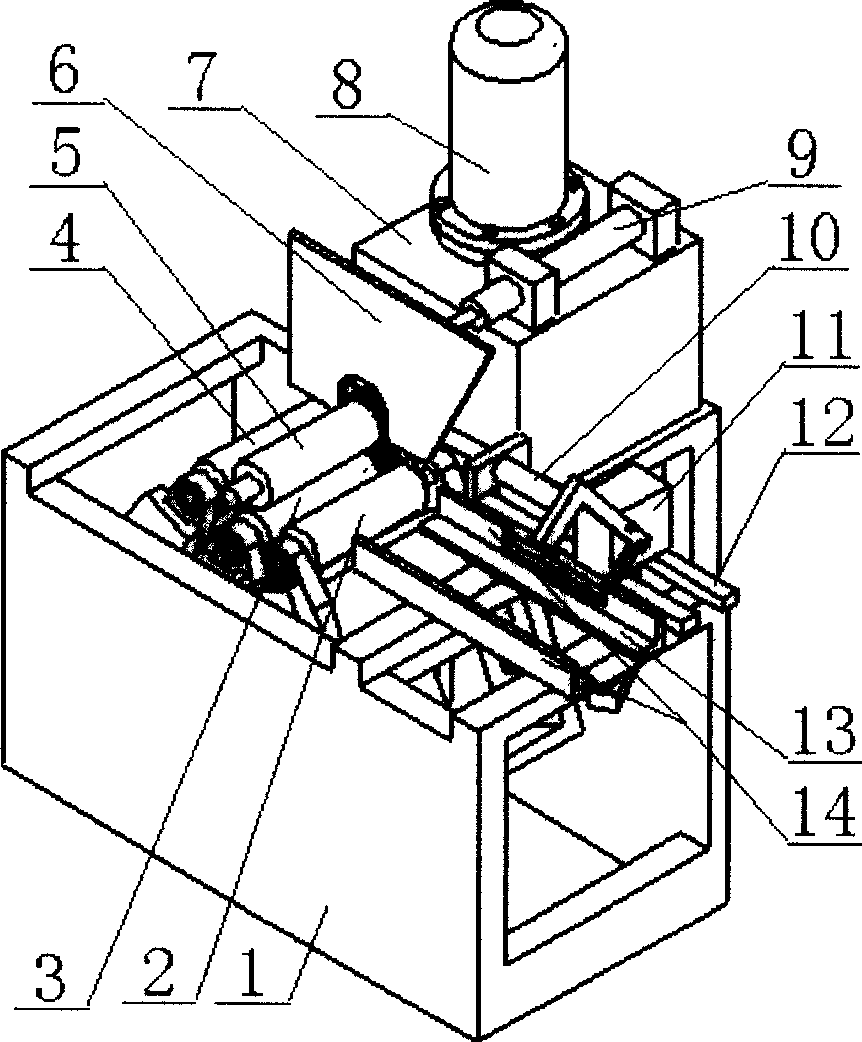

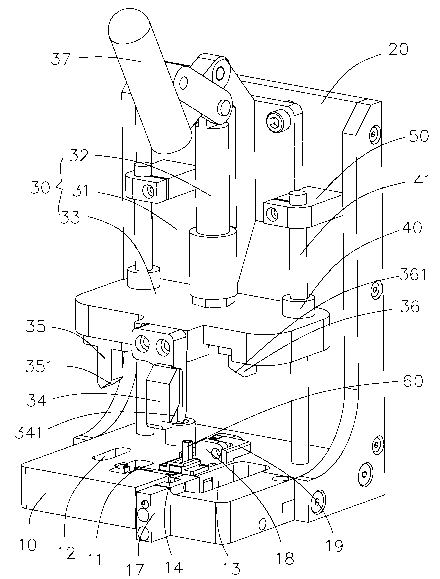

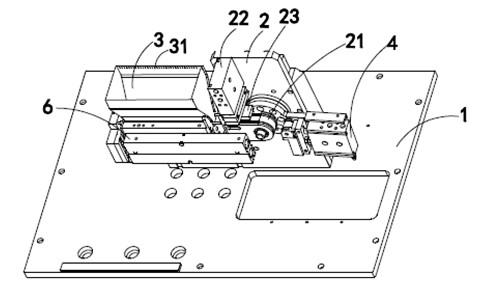

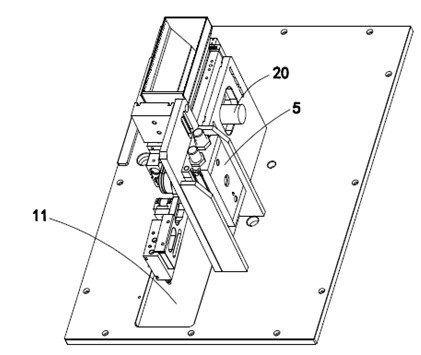

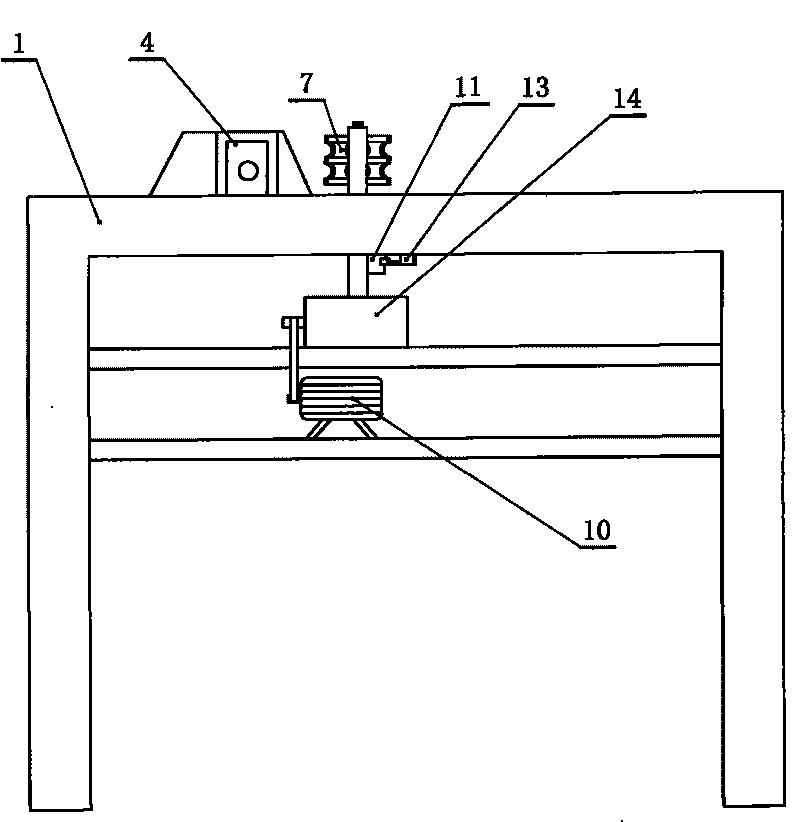

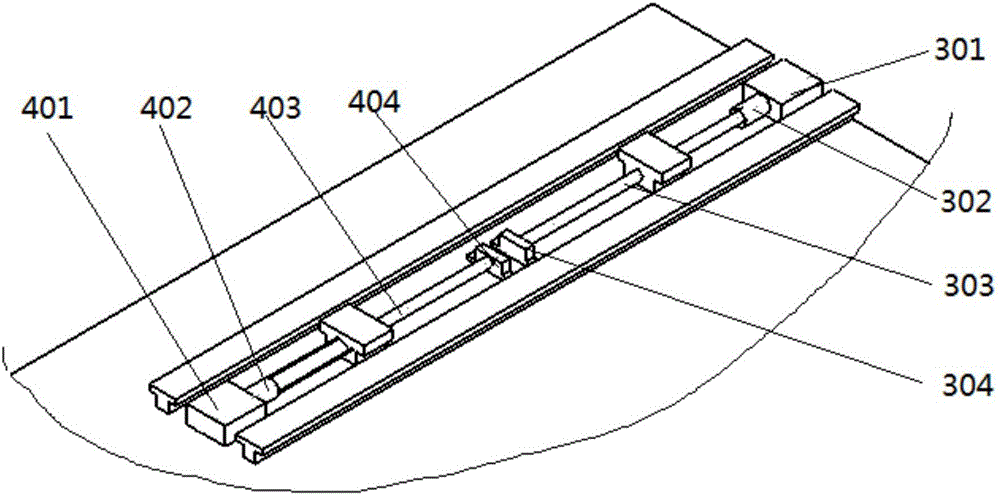

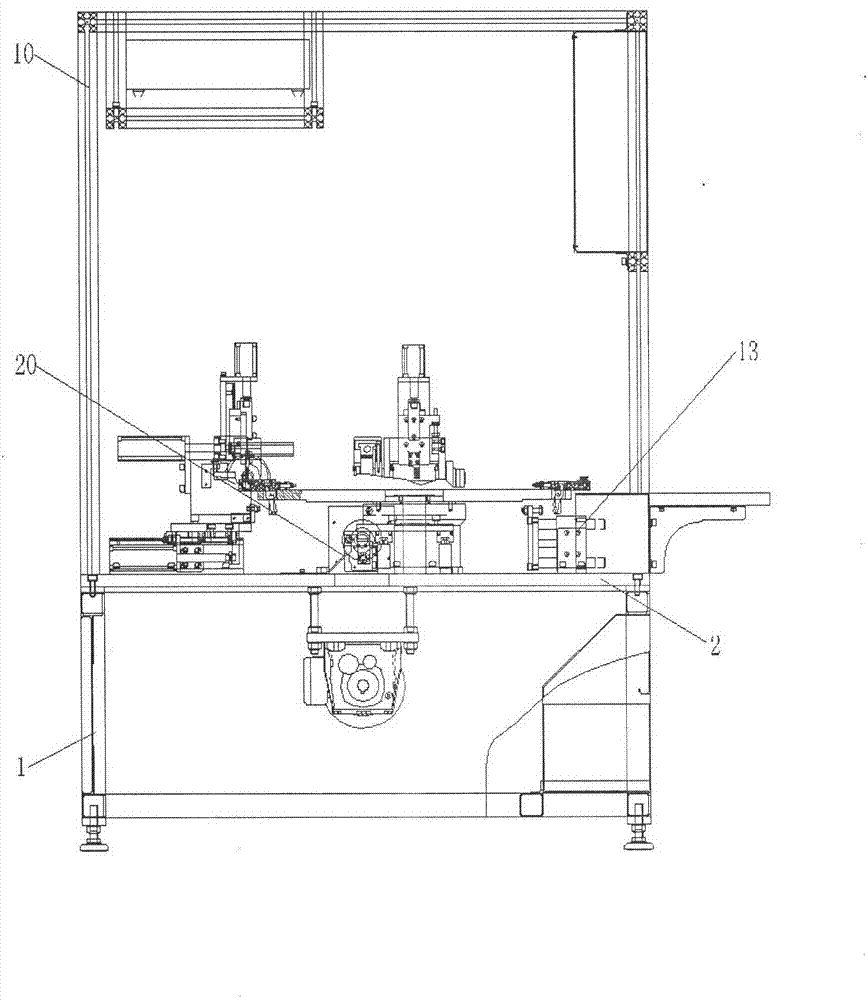

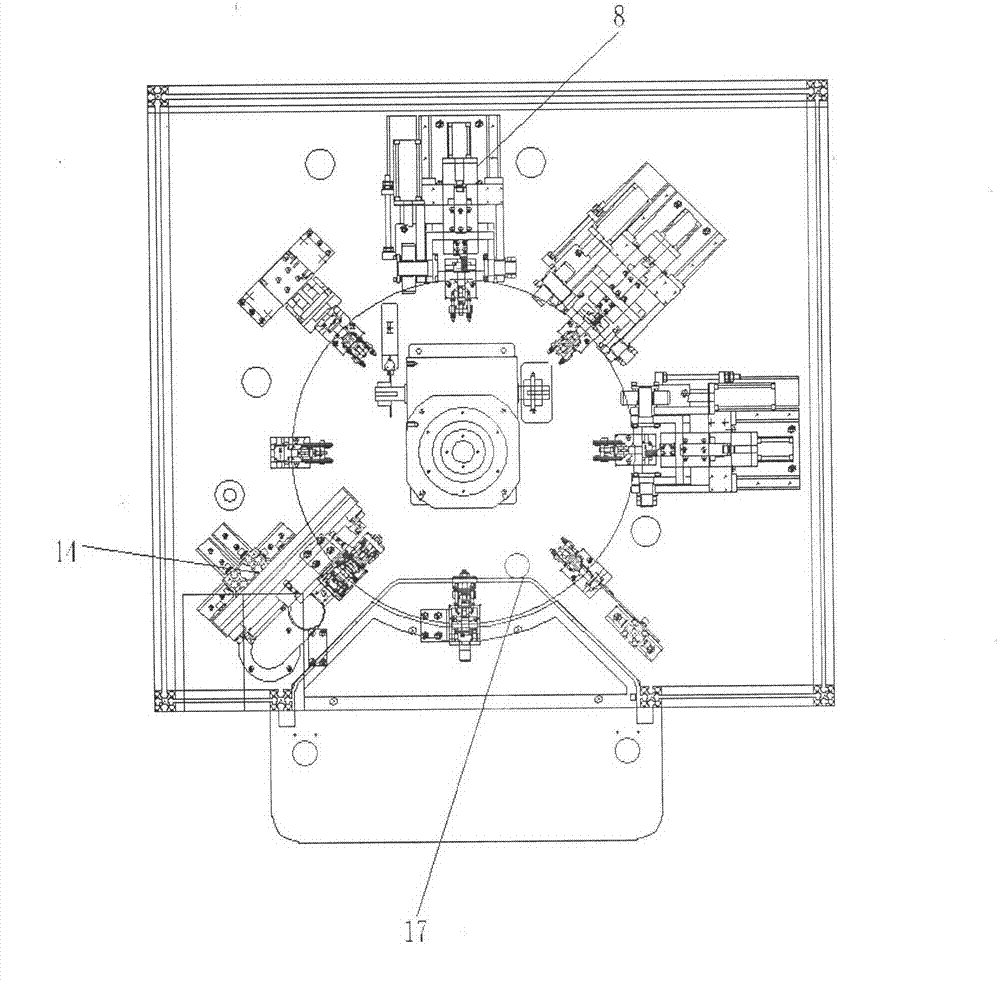

Four rollers automatic reeling mechanism in product line of manufacturing ternary cleaner for tail gas of cars

InactiveCN1759949AMeet the needs of automated productionAdjustable radiusMetal-working feeding devicesPositioning devicesProduction lineBarrel Shaped

An automatic 4-roller barrel shaping unit for the production line of three-element cleaner used to treat the tail gas of car is composed of machine frame, feeding track with both side barrier plates, feeding manipulator with its guide track and cylinder, blanking cylinder with push plate, the upper, lower, front and back rollers, AC motor and speed reducer. Its advantages are high automation level and productivity, and simple structure.

Owner:SHANGHAI JIAO TONG UNIV

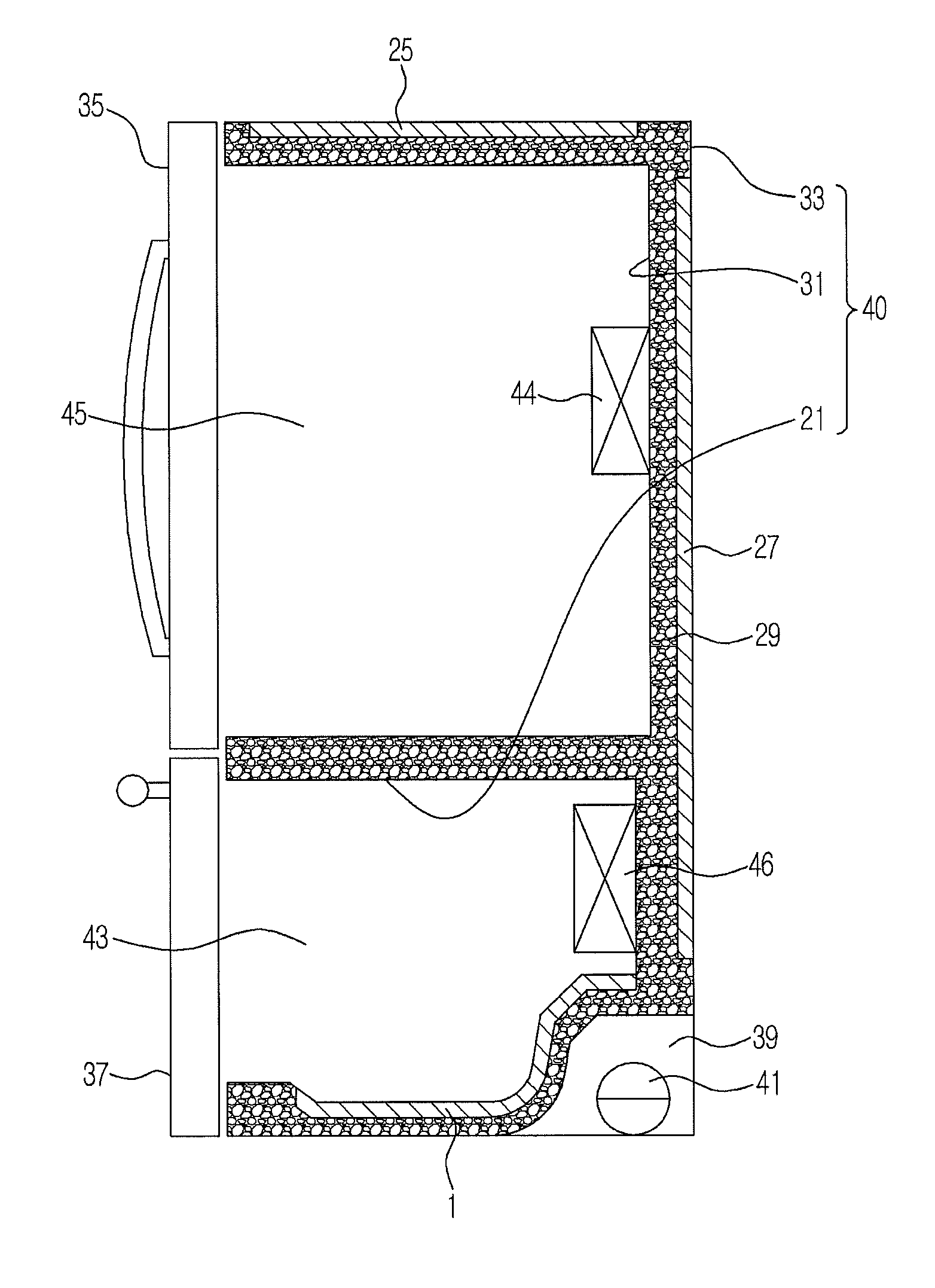

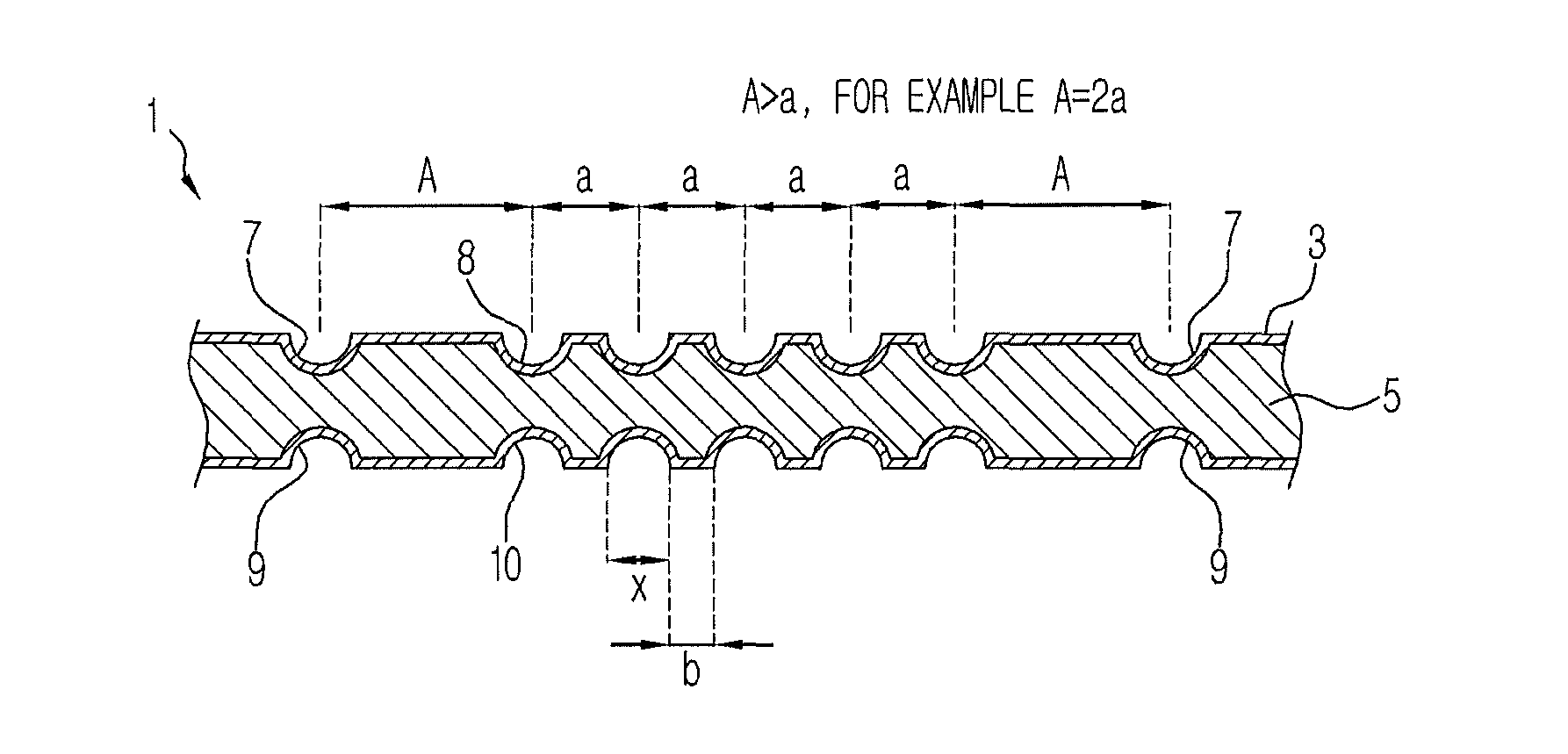

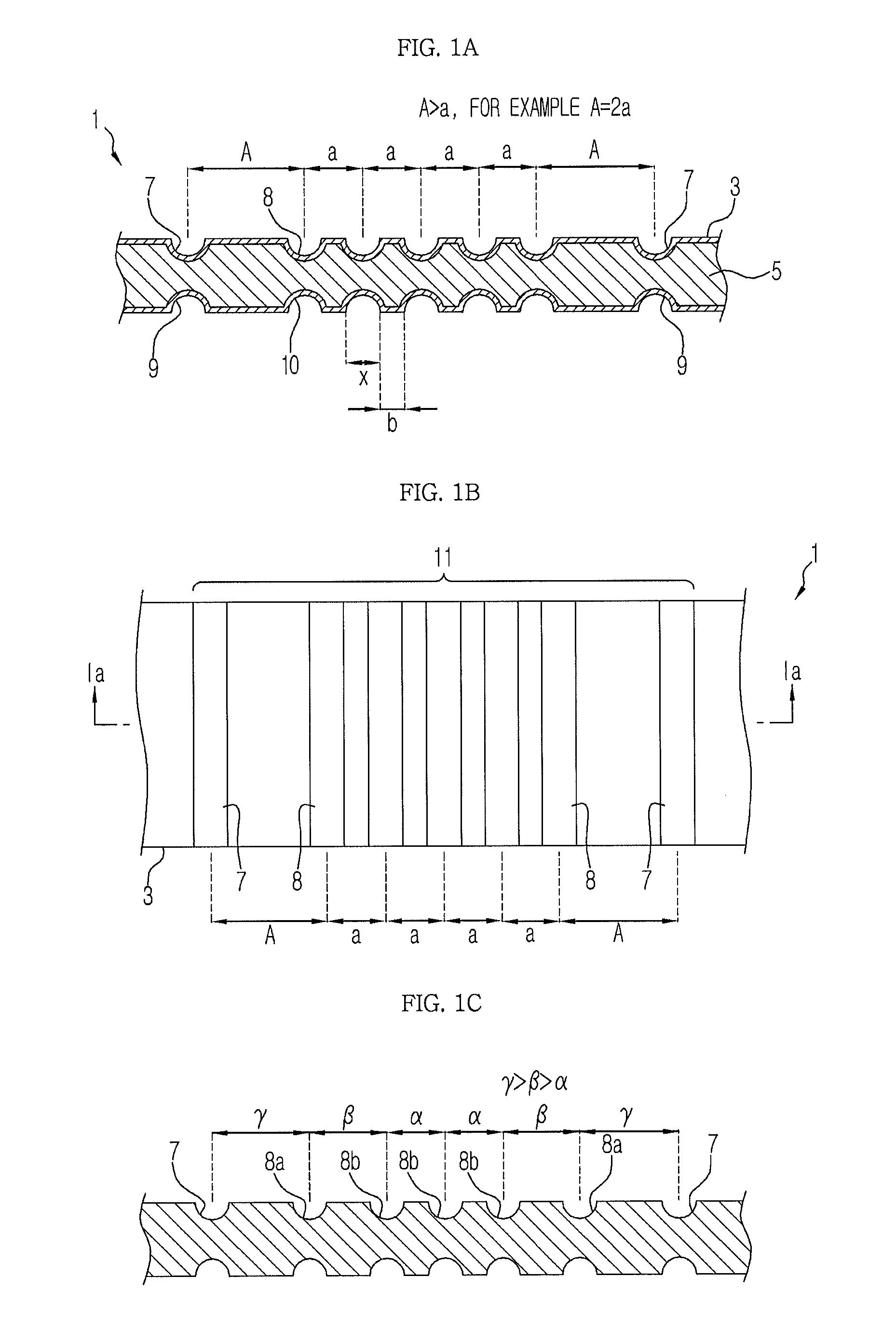

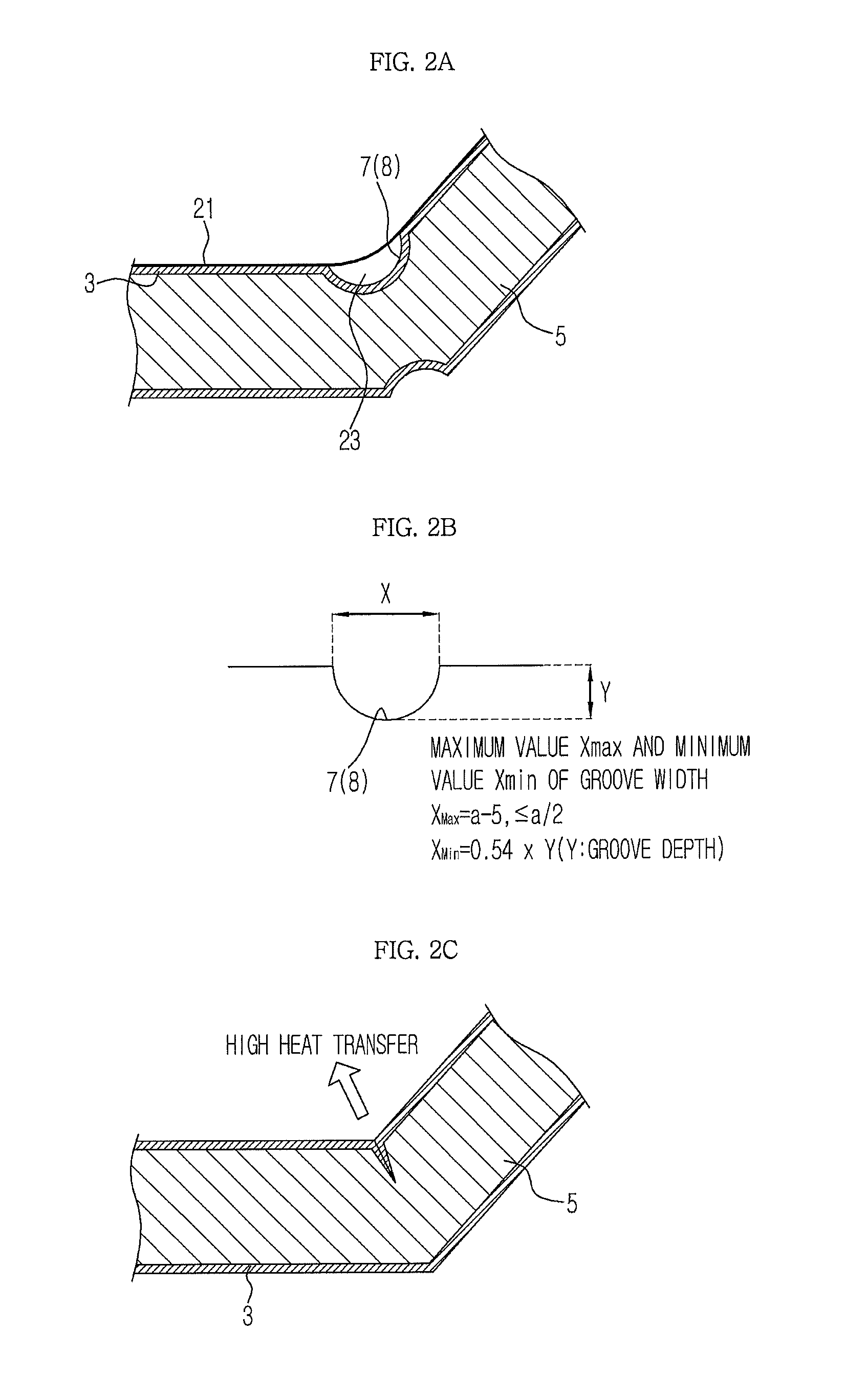

Vacuum insulation material, insulation case unit, and refrigerator

InactiveUS20140216100A1Improve bending effectImprove suppression propertiesThermal insulationLayered productsEngineeringRefrigerated temperature

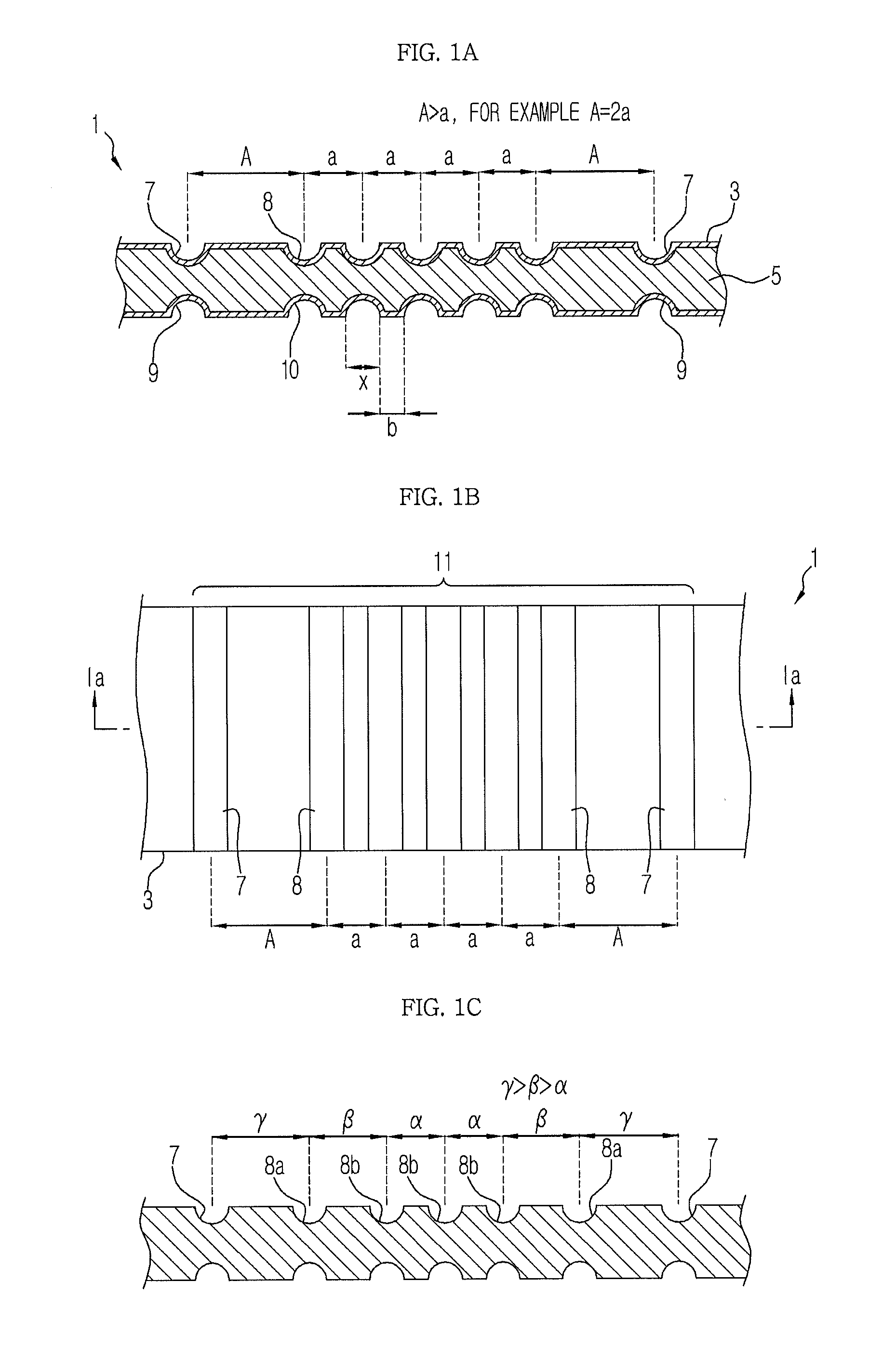

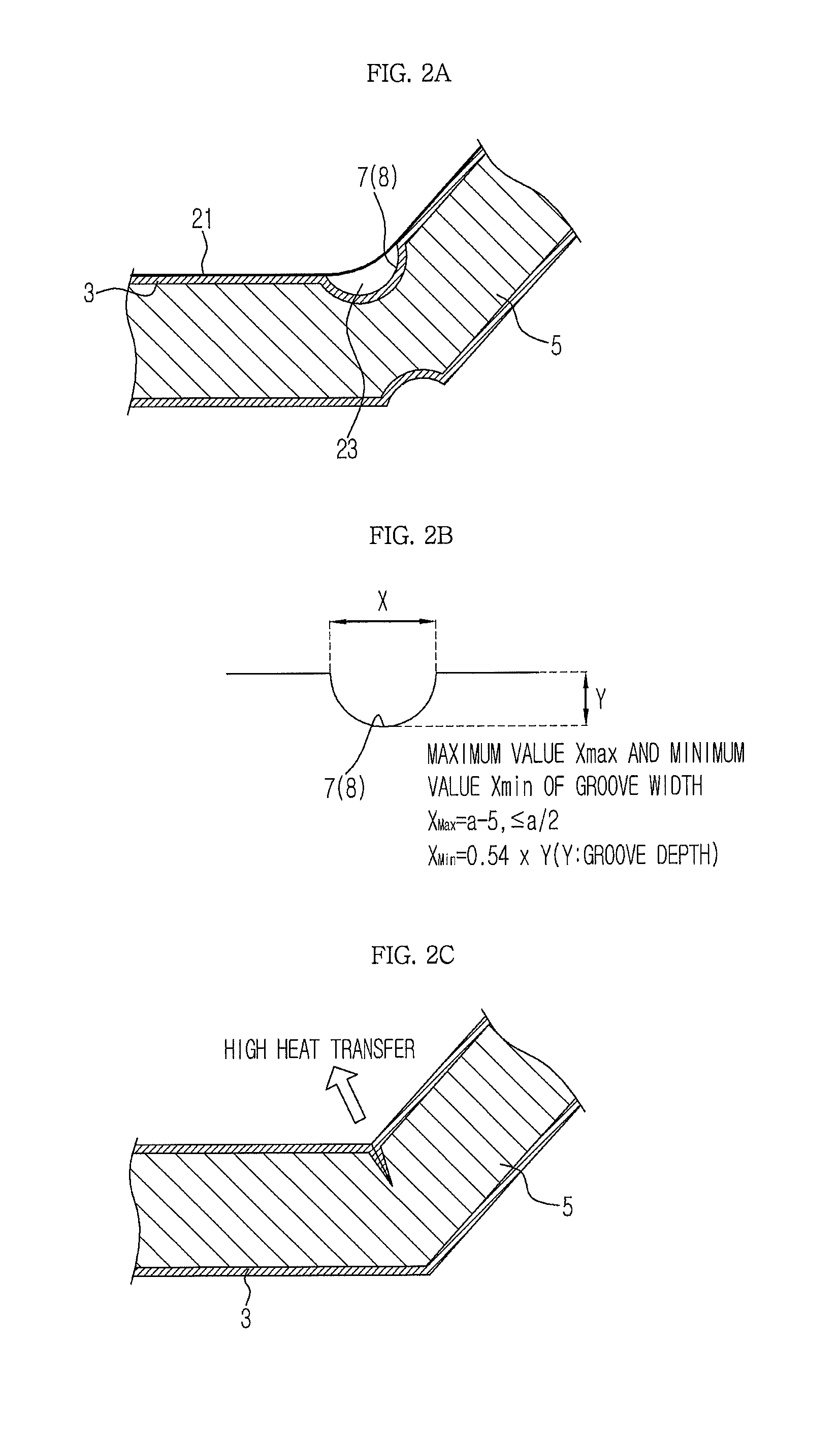

A vacuum insulation material having bending formability while restraining reduction in a gas barrier property of a sheathing material. The vacuum insulation material includes a pouch-shaped sheathing material having a gas barrier property and a core received in the sheathing material as a spacer, the vacuum insulation material having a bendable region, a first surface, and a second surface opposite to the first surface, wherein at least one of the first and second surfaces in the bendable region is provided with a plurality of grooves extending at intervals, the grooves include a pair of outer grooves formed in the bendable region and a plurality of inner grooves formed inside the outer grooves, and an interval between each outer groove and a corresponding one of the inner grooves adjacent to each outer groove is greater than an interval between the inner grooves.

Owner:SAMSUNG ELECTRONICS CO LTD

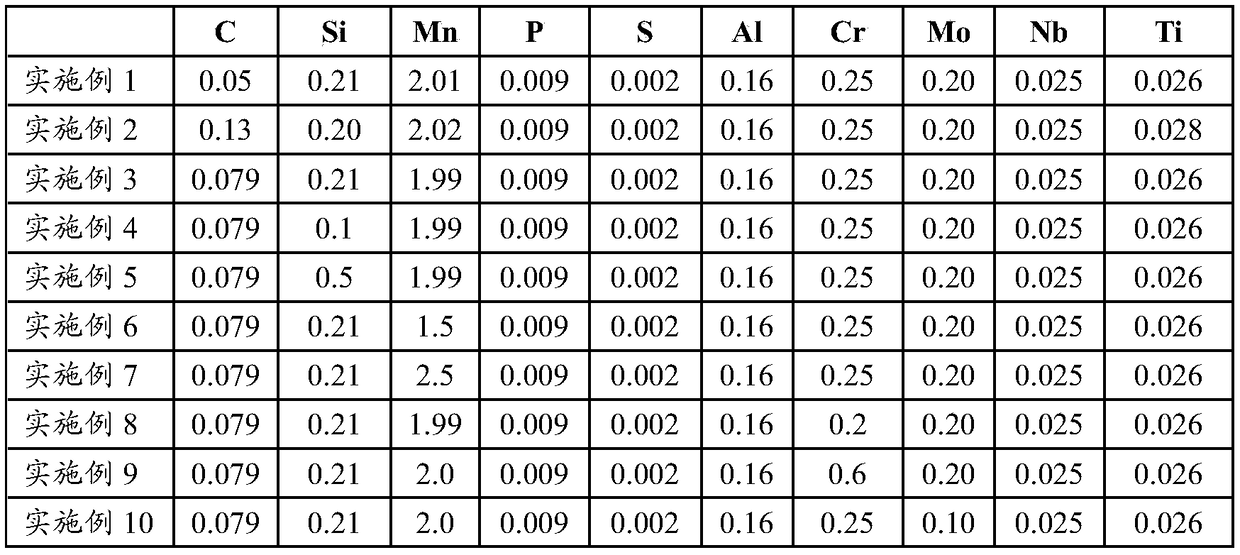

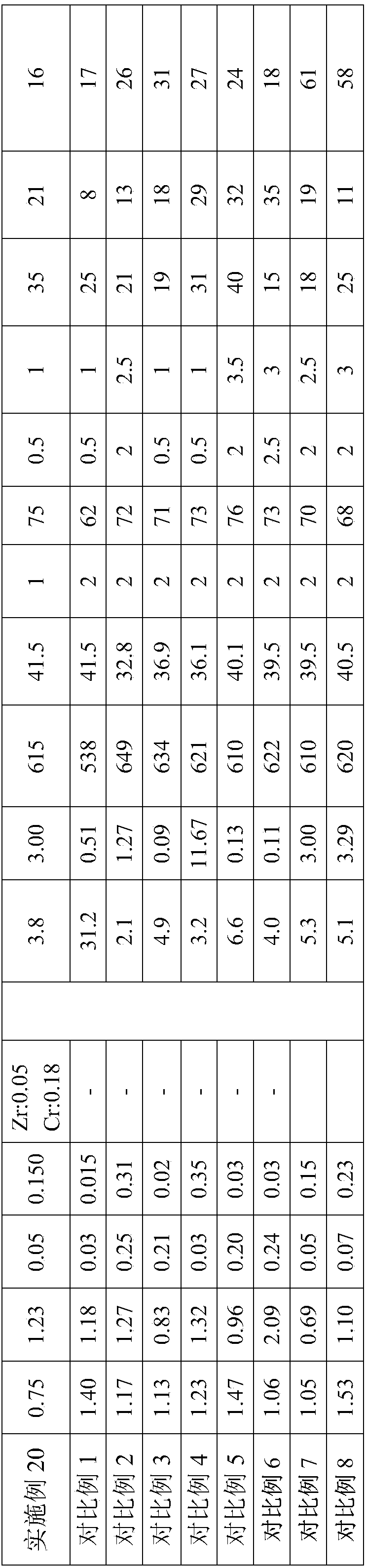

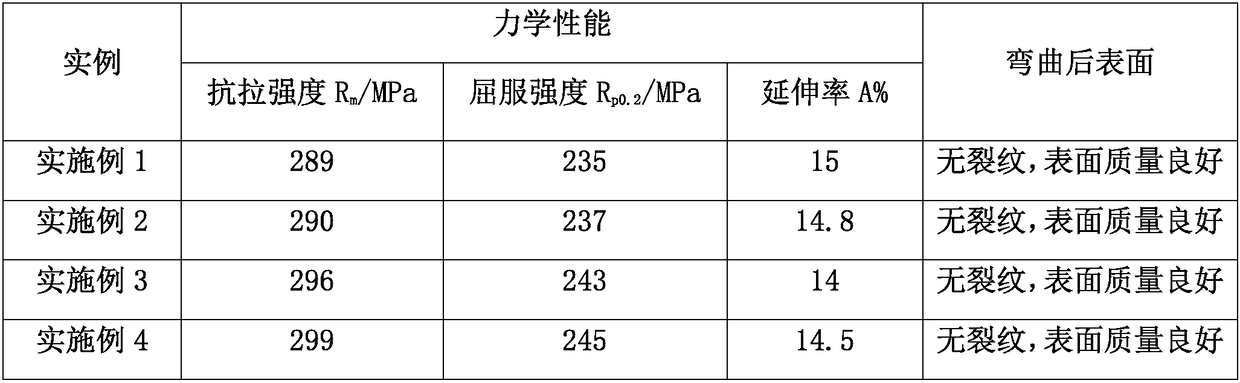

Cold-rolled hot-galvanized complex phase steel and preparation method thereof

The invention relates to a kind of cold-rolled hot-galvanized complex phase steel. Chemical components of the cold-rolled hot-galvanized complex phase steel comprise, by weight, 0.05-0.13% of C, 0.1-0.5% of Si, 1.5-2.5% of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 0.1-0.6% of Al, 0.2-0.6% of Cr, 0.1-0.5% of Mo, 0.01-0.06% of Nb, 0.01-0.06% of Ti, and the balance Feand inevitable impurities. The invention further relates to a preparation method of the cold-rolled hot-galvanized complex phase steel. The preparation method comprises the following steps of castingmolten steel into a steel billet; conducting hot rolling on the steel billet to obtain a hot-rolled plate and conducting cold rolling on the hot-rolled plate to obtain a cold-hardened steel strip; conducting continuous galvanizing and annealing process treatment on the cold-hardened steel strip to obtain a finished cold-rolled hot-galvanized complex phase steel product. The bending performance ofthe cold-rolled hot-galvanized complex phase steel is improved on the basis of meeting the requirement for strength.

Owner:SHOUGANG CORPORATION

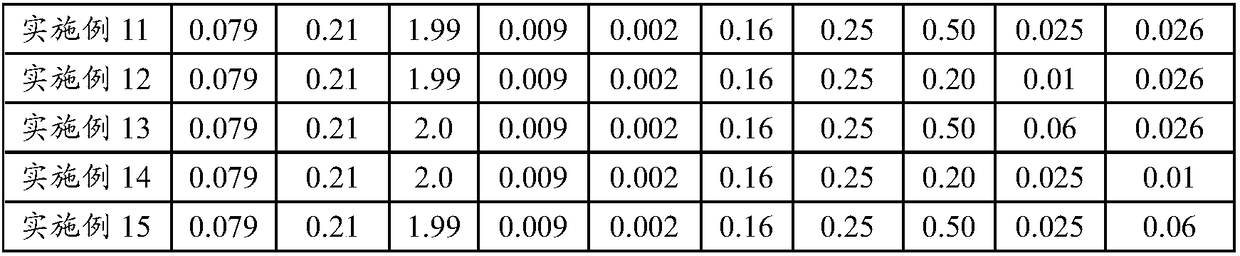

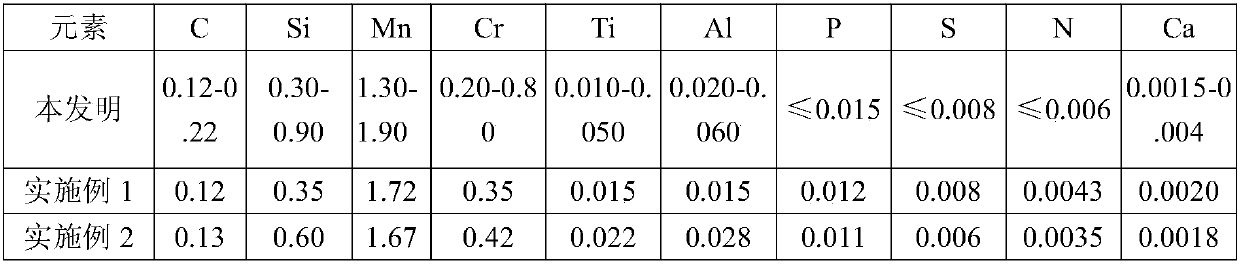

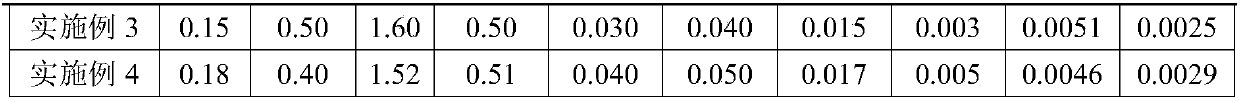

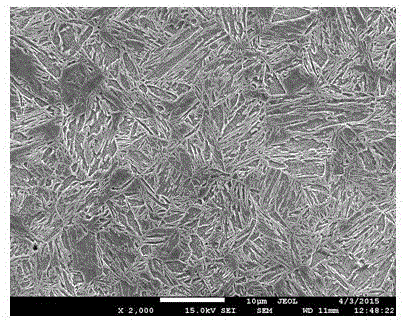

Cold-rolled martensite steel plate with yield strength of 750 MPa grade and manufacturing method thereof

ActiveCN107619993ALightweight effect is goodImproved Chemical Composition DesignUltimate tensile strengthMartensite

The invention relates to a cold-rolled martensite steel plate with yield strength of 750 MPa grade and a manufacturing method thereof, and mainly aims to solve the technical problem that the existingcold-rolled martensite steel plate with yield strength of 750 MPa grade is high in manufacturing cost. The cold-rolled martensite steel plate provided by the invention consists of the following chemical components in percentage by weight: 0.12-0.22% of C, 0.30-0.90% of Si, 1.30-1.90% of Mn, 0.20-0.80% of Cr, 0.010-0.050% of Ti, 0.020-0.060% of Al, less than or equal to 0.015% of P, less than or equal to 0.008% of S, less than or equal to 0.006% of N, 0.0015-0.004% of Ca and the balance of iron and inevitable impurities. The steel plate has yield strength of 790-830 MPa, tensile strength greater than 980 MPa, and percentage elongation after fracture A80 greater than or equal to 6%. The cold-rolled martensite steel plate is mainly used for manufacturing a truck boundary beam, a square tube stand column and the like.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Excellent-cold-bending-performance steel plate with yield strength larger than 1100 MPa and manufacturing method thereof

The invention relates to a quenched type ultra-high-strength steel plate with yield strength larger than 1100 MPa. The production technology of the quenched type ultra-high-strength steel plate with the yield strength larger than 1100 MPa comprises the steps of smelting, external refining, vacuum degassing, Ca treatment, continuous casting, dehydrogenation treatment on a casting blank, heating, rolling, cooling, warm straightening, quenching and powerful straightening. According to the quenched type ultra-high-strength steel plate with the yield strength larger than 1100 MPa, the ingredients are economical, the technology is simple, the comprehensive mechanical performance of the steel plate is excellent, the yield strength is over 1100 MPa, the tensile strength is over 1200 MPa, and the Charpy impact energy at the minus 40 DEG C is larger than or equal to 30 J; meanwhile, the performances of the steel plate are uniform, the steel plate is flat, and the waviness of the steel plate is smaller than or equal to 5 mm / m; the cold bending forming performance of the whole steel plate is good, d is equal to 3a, and the result of the 180-degree laboratory GB / T232 cold bending test of the steel plate is qualified; b is larger than or equal to 500 mm, r is equal to 3a, and no crack is generated during 90-degree industrial cold bending forming; and therefore, the machining and use requirements on the ultra-high-strength steel plate of the domestic and overseas large machinery industry are met.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Bending device of flexible circuit board

ActiveCN102938979ASimple structural designReasonable structural designPrinted circuit manufactureFlexible circuitsEngineering

Owner:DONGGUAN NVT TECH

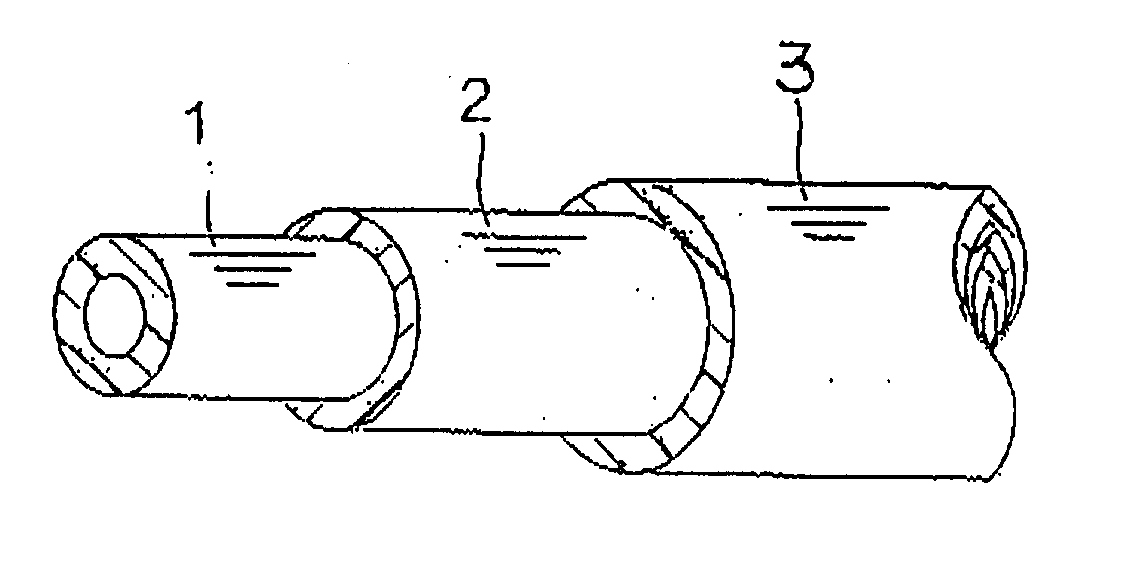

Mold core and preparation method thereof and method for producing casting inner cavity by using mold core

InactiveCN102059321AImprove structural strengthStress reliefFoundry mouldsFoundry coresUltimate tensile strengthLow melting point

The invention provides a mold, a preparation method thereof and a method for producing a casting inner cavity by using the mold core. The mold core is made of hollow material; and an alloy is arranged in the hollow structure of the mold core. The mold core made of brass replaces the traditional sand core, has higher structural strength and is suitable for complex fine hole inner cavities of an aluminum alloy casing to form. In the method for producing the mold core, the characteristic of low melting point aluminum alloy is used and the mold core is filled into a hollow brass tube to relieve the stress generated by bending the brass tube with favorable bending effect; in addition, the hollow brass section is prevented from being deformed due to external action in the bending process.

Owner:XIAN AERO ENGINE CONTROLS

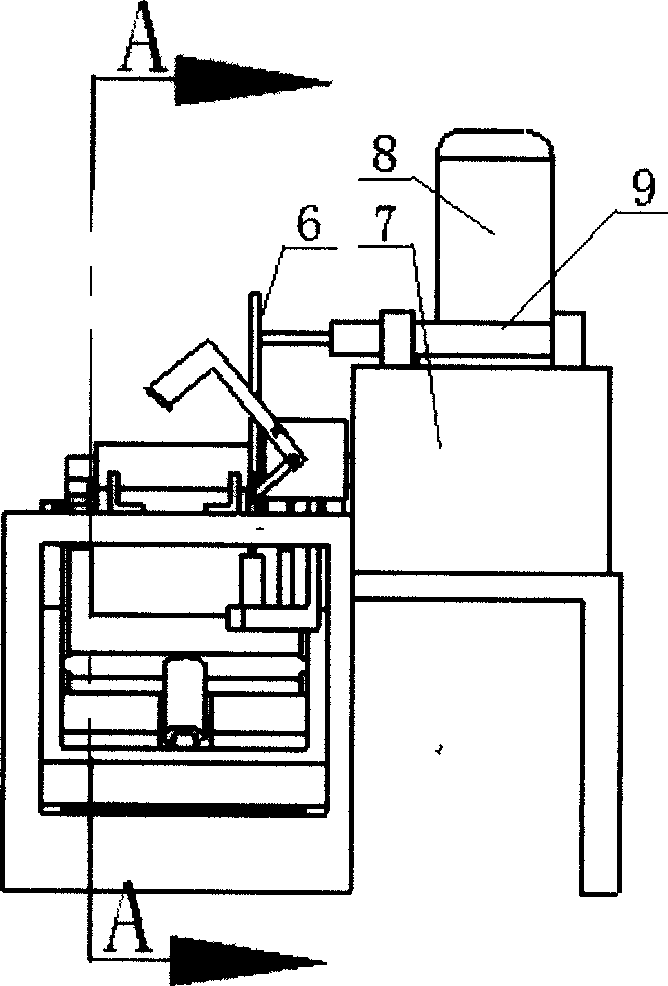

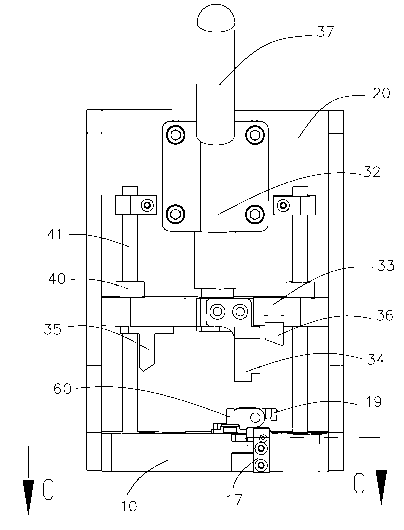

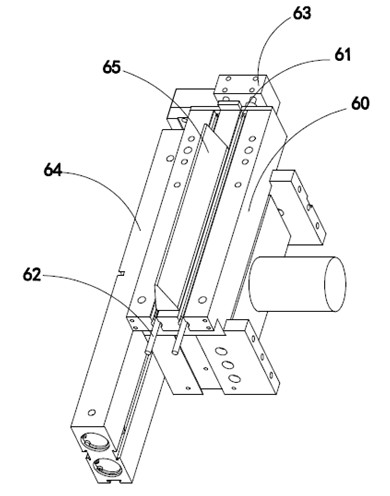

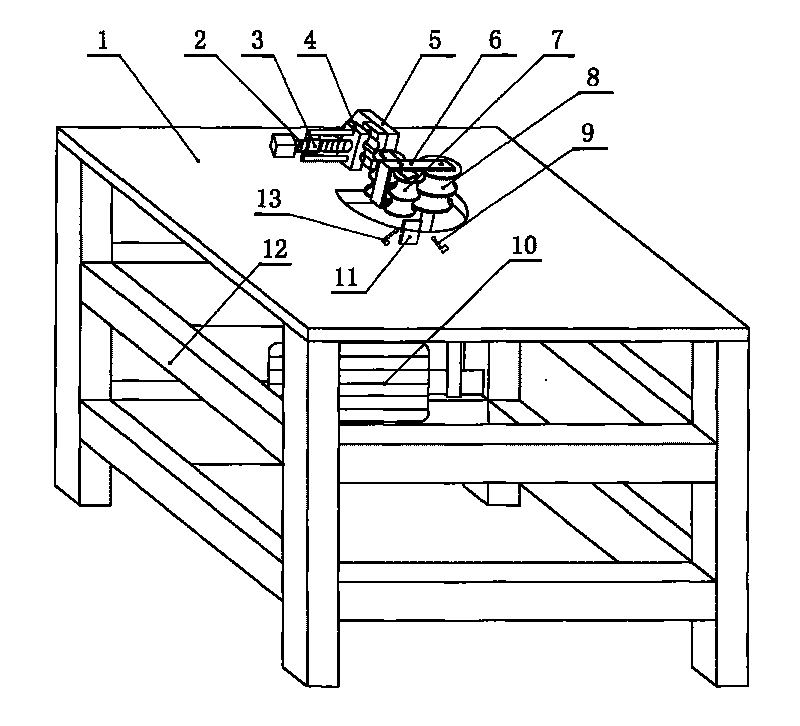

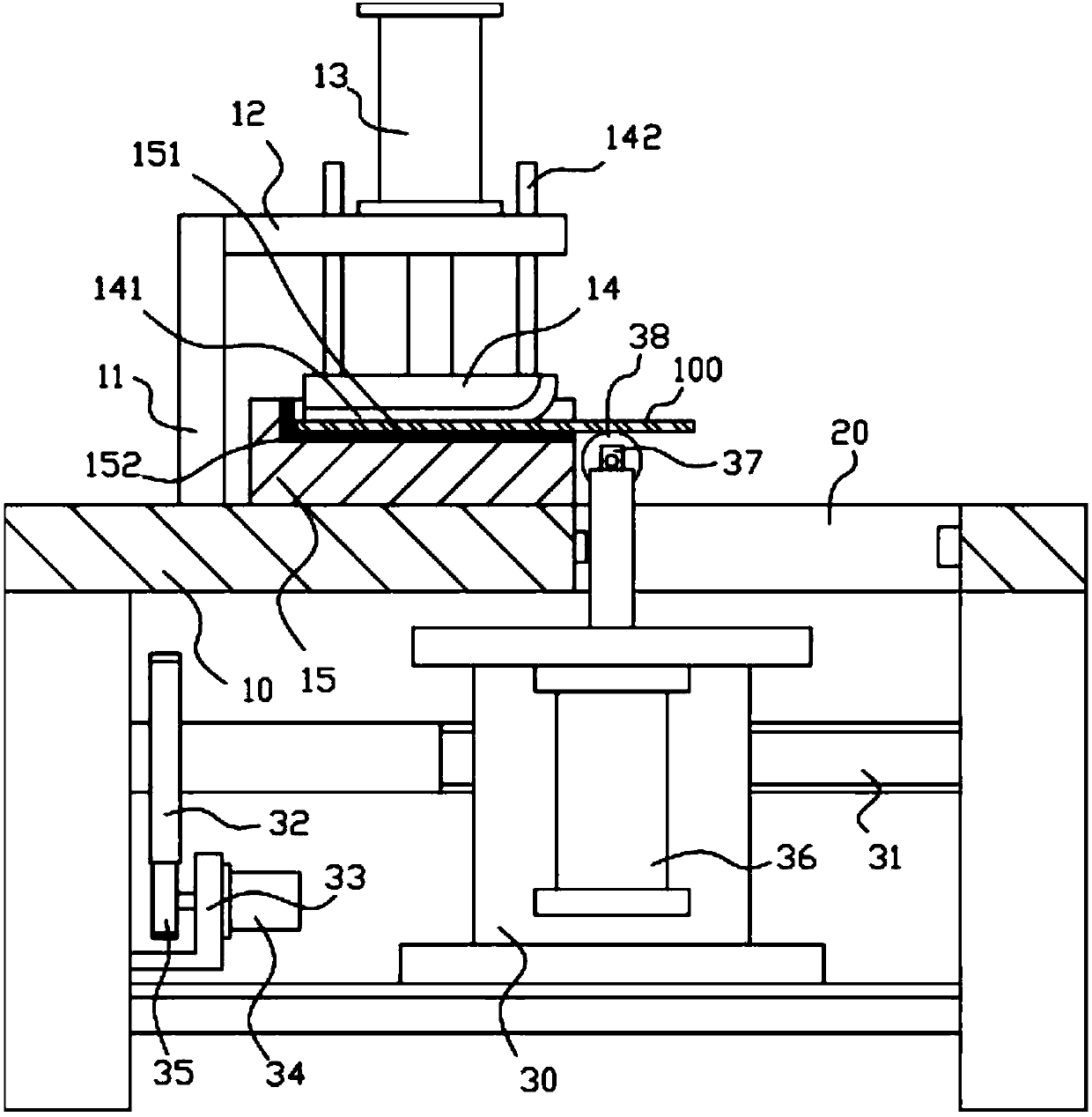

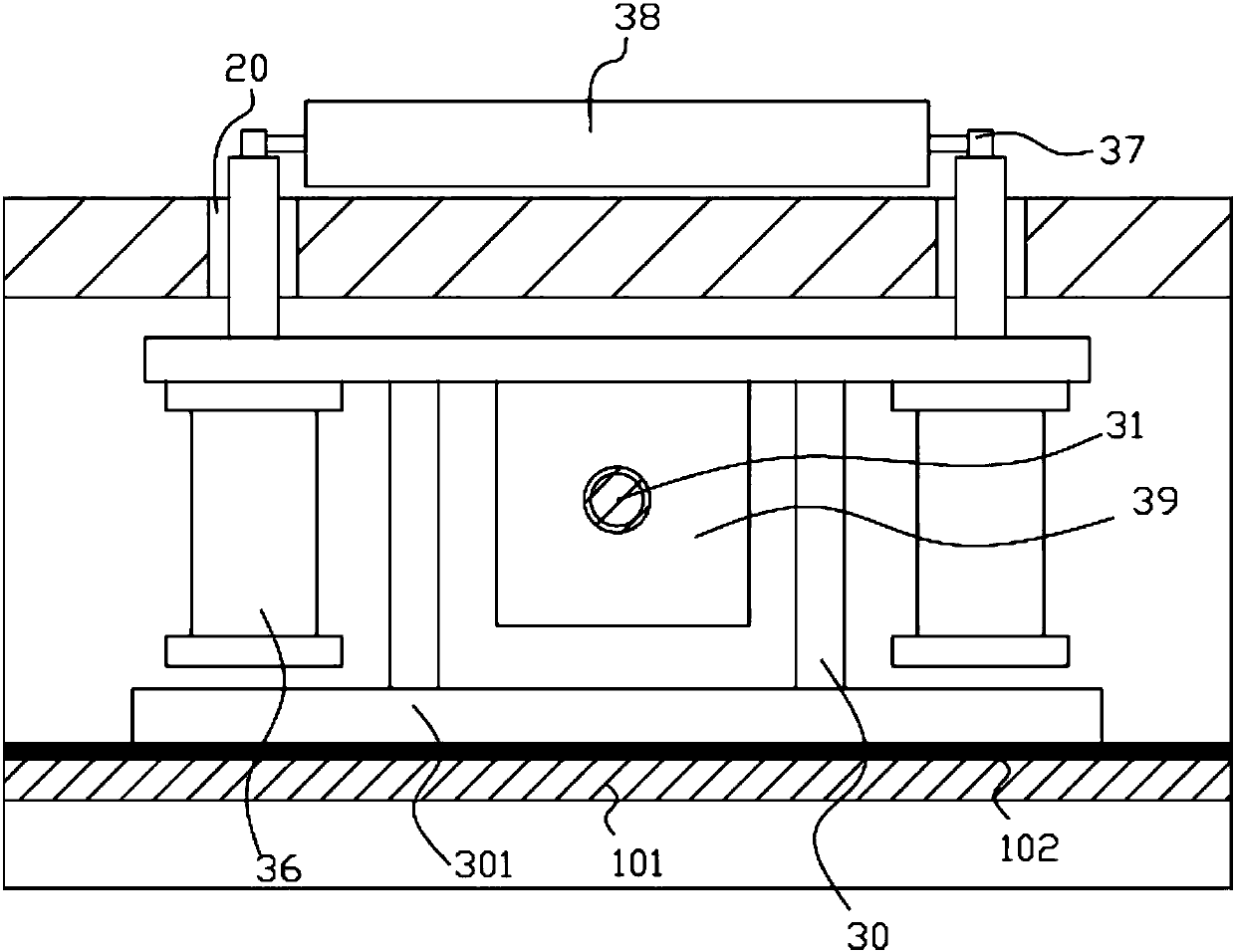

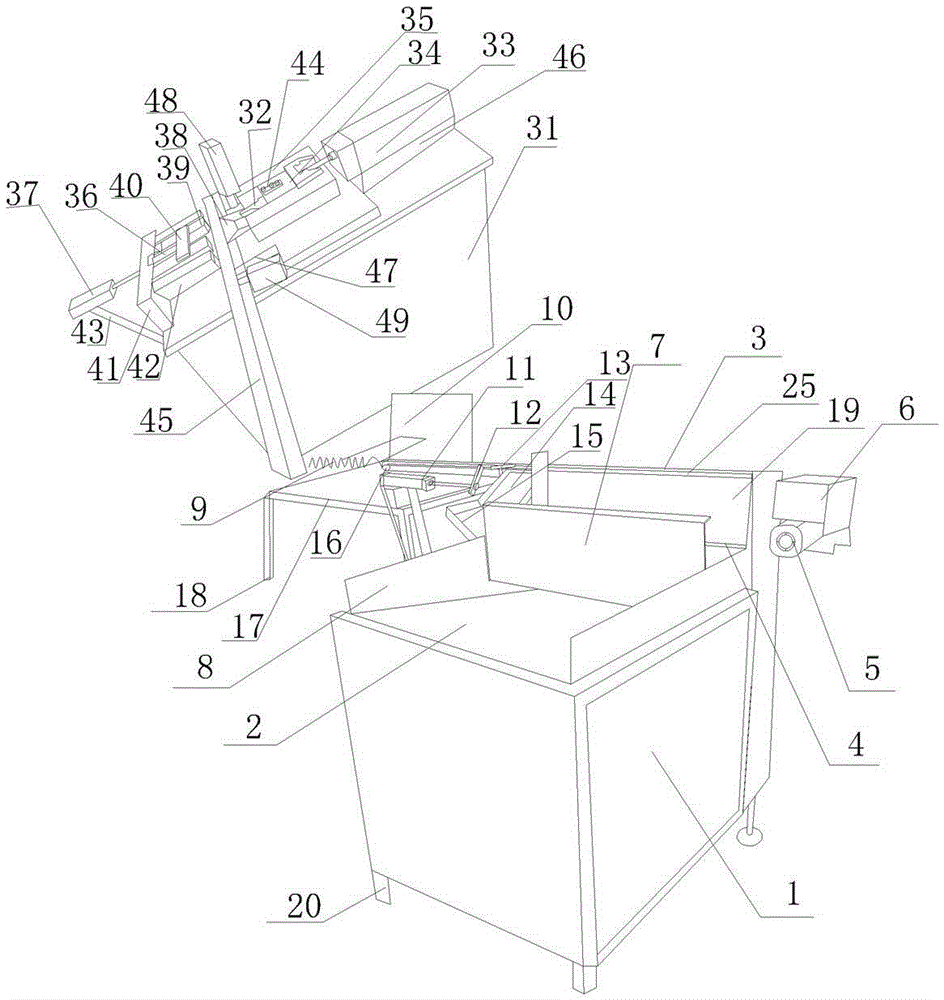

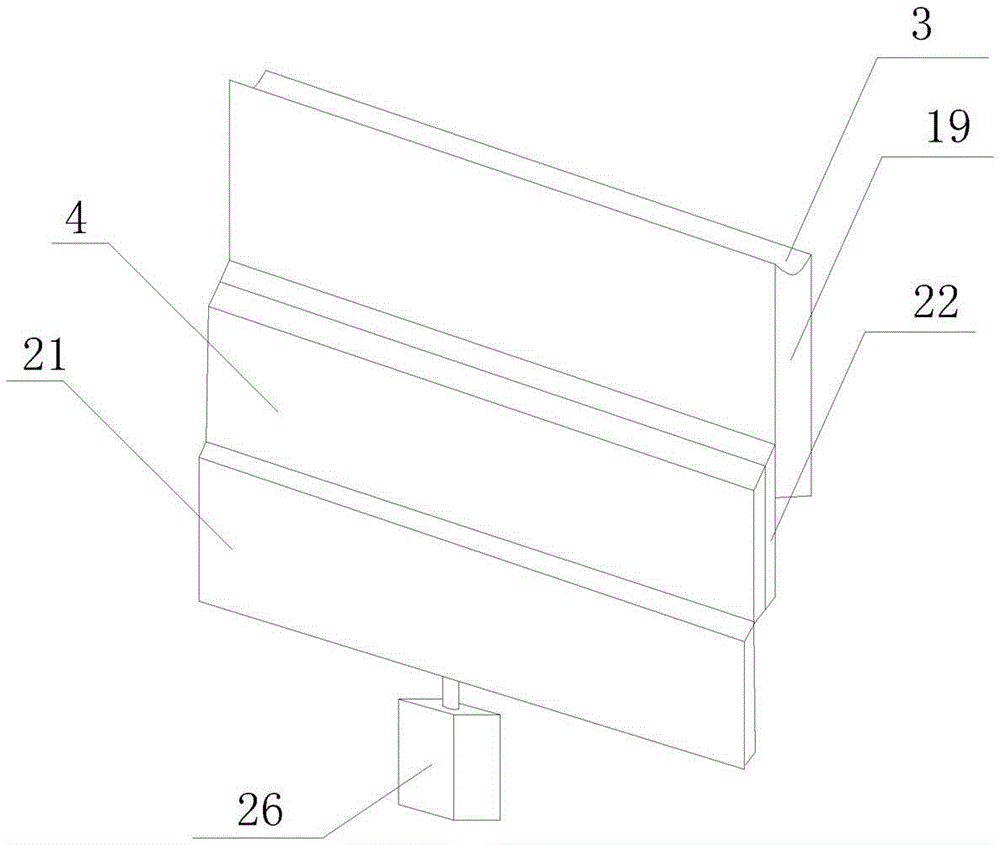

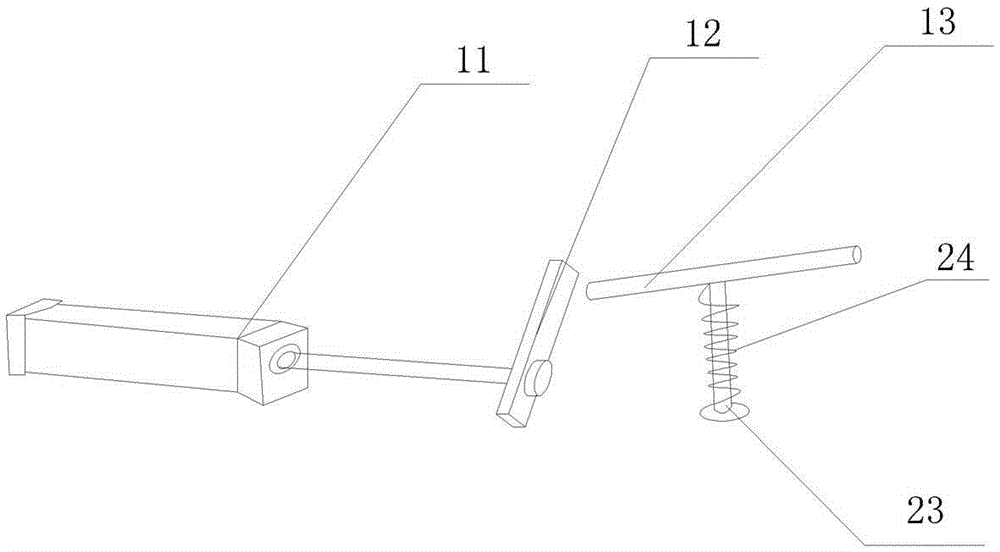

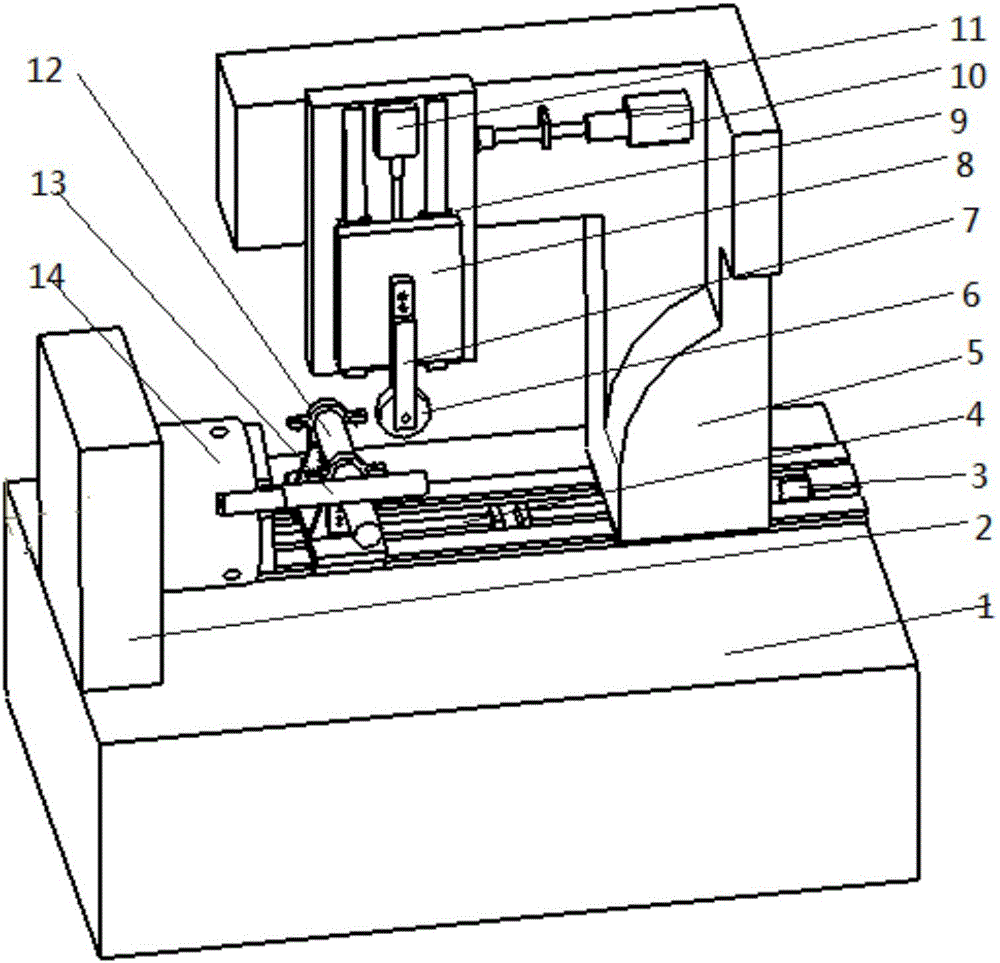

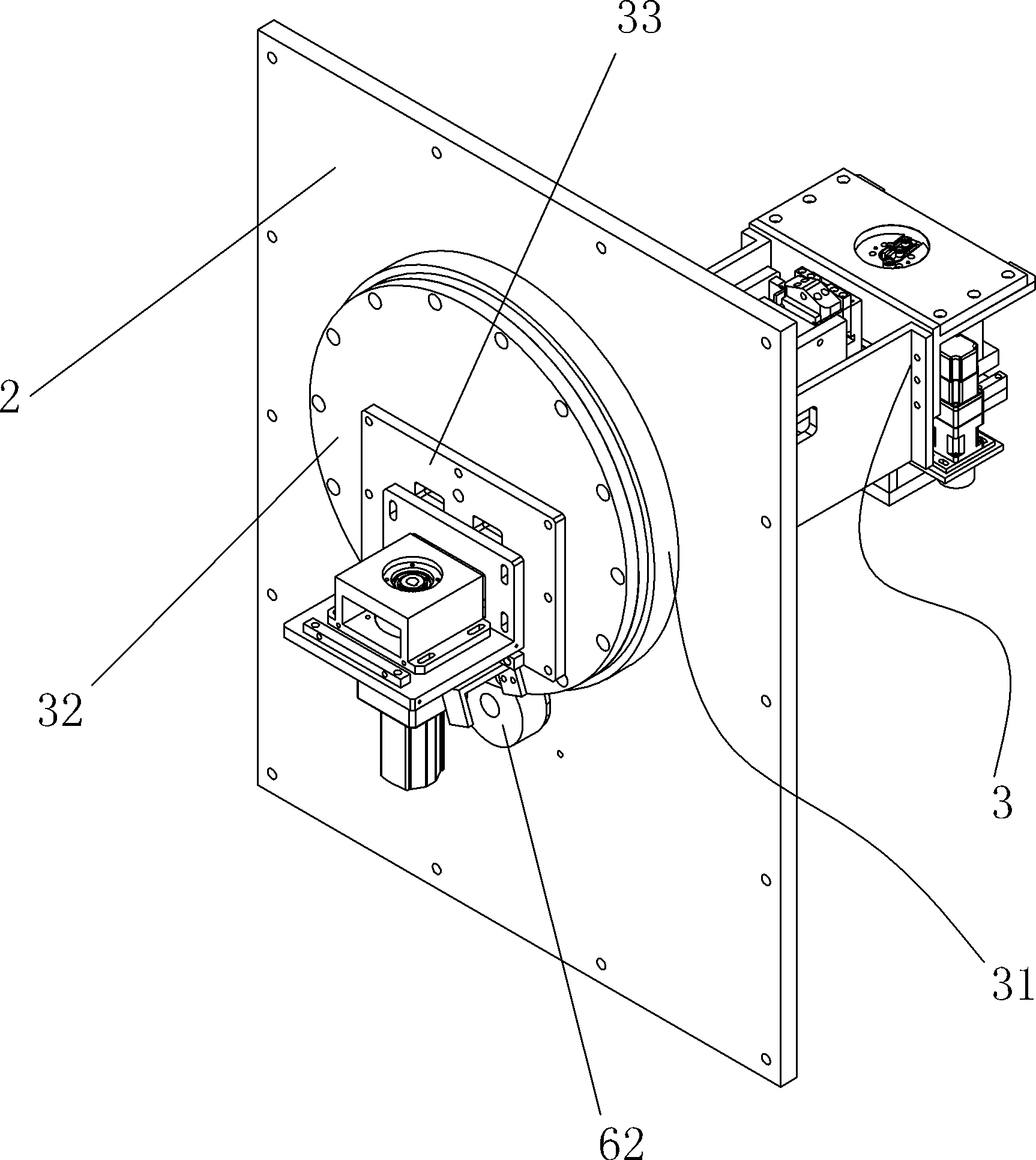

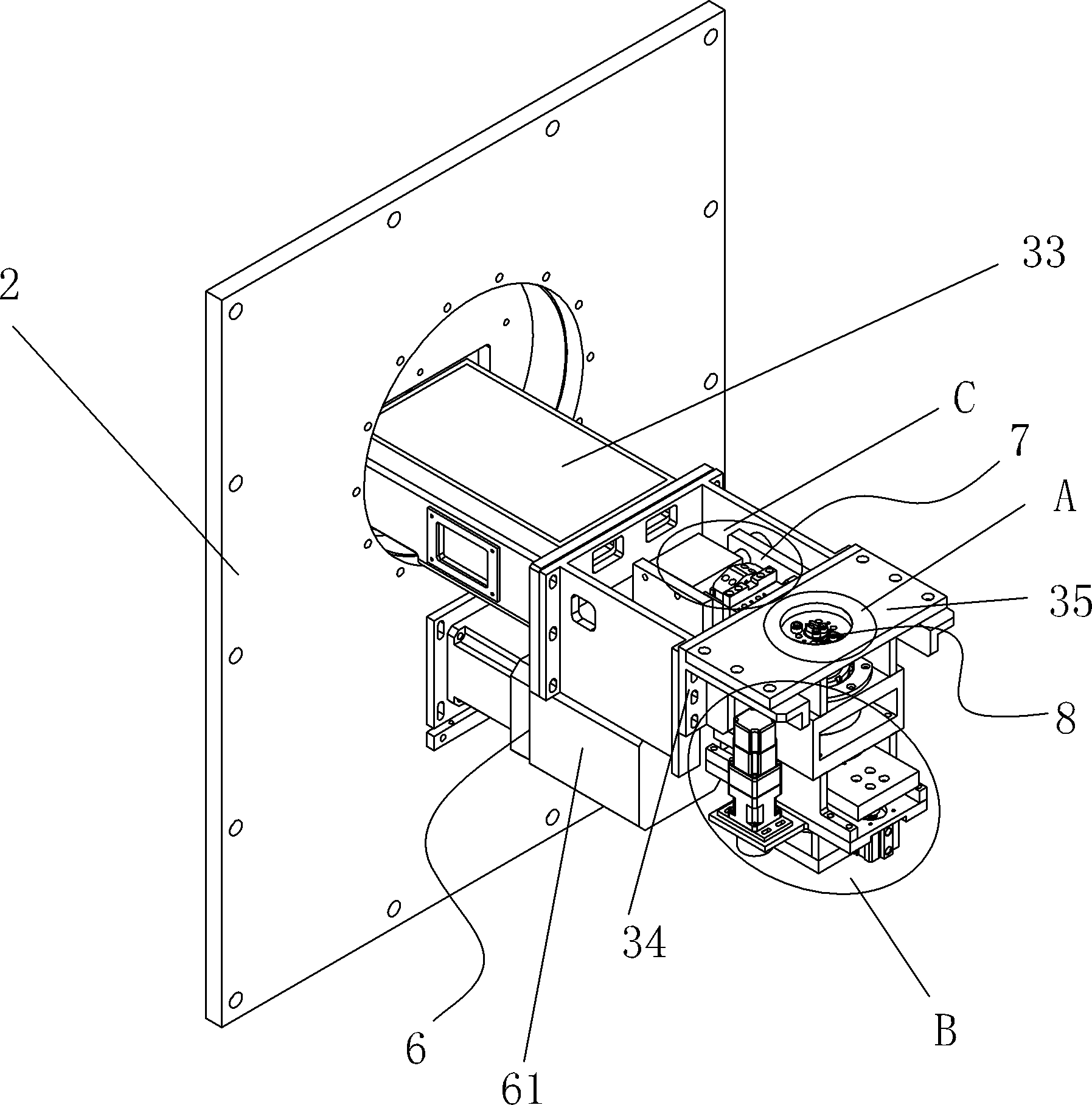

Automatic bending device for heat pipe

InactiveCN102632118AAvoid bend quality varianceGood bending effectMetal-working feeding devicesPositioning devicesContinuous operationEngineering

The invention provides an automatic bending device for a heat pipe. The automatic bending device comprises a frame, wherein a bedplate is vertically fixed on the frame; a shaking machine is arranged at one side of the bedplate; the shaking machine is connected with a charging barrel for arranging the heat pipe through the bedplate; a feeding mechanism for conveying the heat pipe is arranged under the charging barrel; the feeding mechanism is fixed on a table board; the bending device also comprises a fixed block and a rotating mechanism for driving the fixed block to rotate; a rotating shaft of the rotating mechanism is connected with the fixed block; the rotating mechanism and the shaking machine are arranged at the same side of the bedplate; a fixed block pressing mechanism is arranged on the fixed block; a movable block pressing mechanism is arranged in front of the fixed block; a gap is arranged between the movable block pressing mechanism and the fixed block; the movable block pressing mechanism presses an end to be bent of the heat pipe downwards; a blanking opening is arranged on the frame, and the blanking opening is arranged under the gap. According to the invention, the heat pipe can be automatically bent, the difference of bending quality completely caused by manual work is avoided and the bending effect is good. Two heat pipes are bent once, and continuous operation can be carried out, time and labor are saved, and the efficiency is greatly improved.

Owner:FURUKAWA AVC ELECTRONICS (SUZHOU) CO LTD

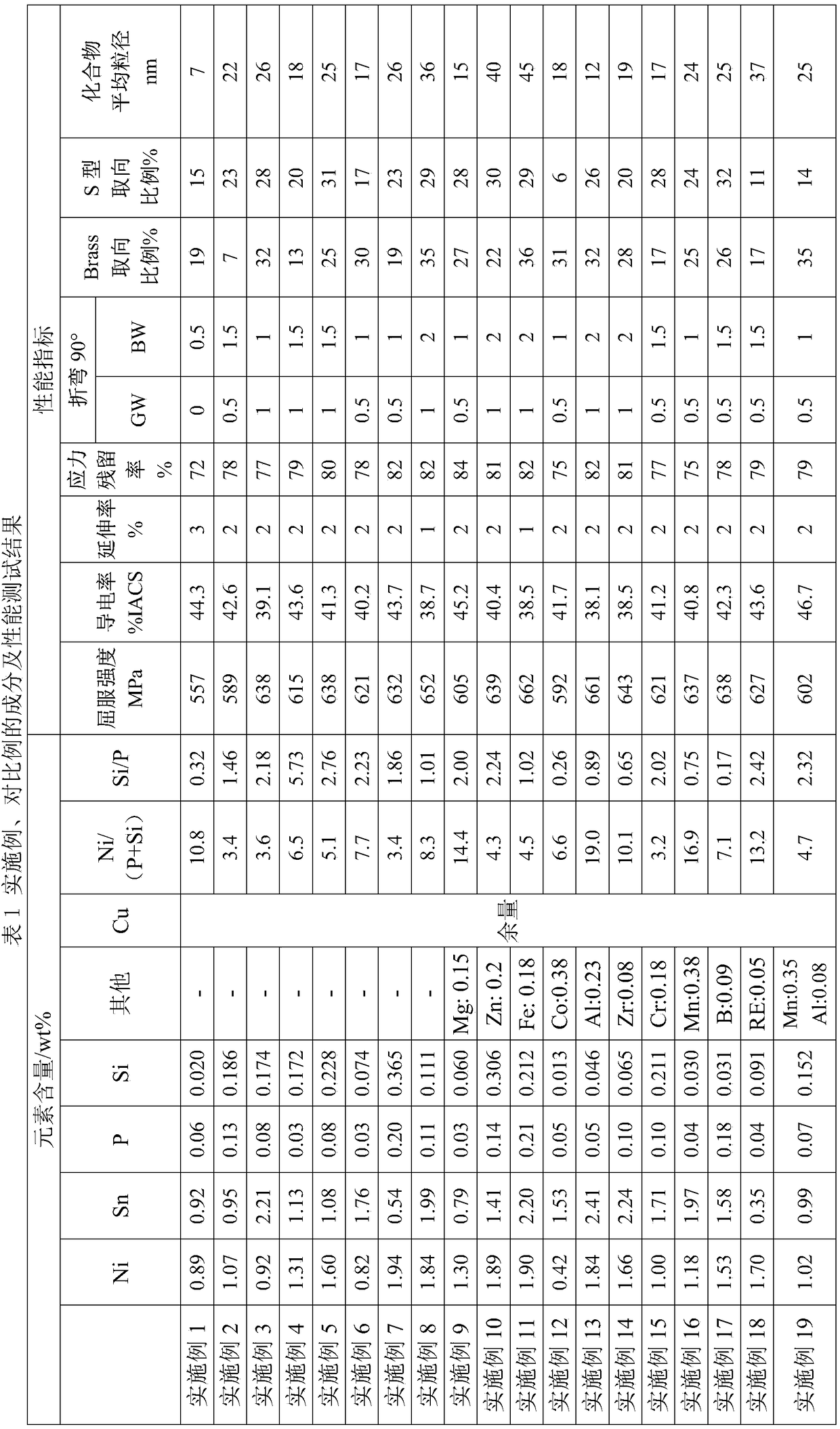

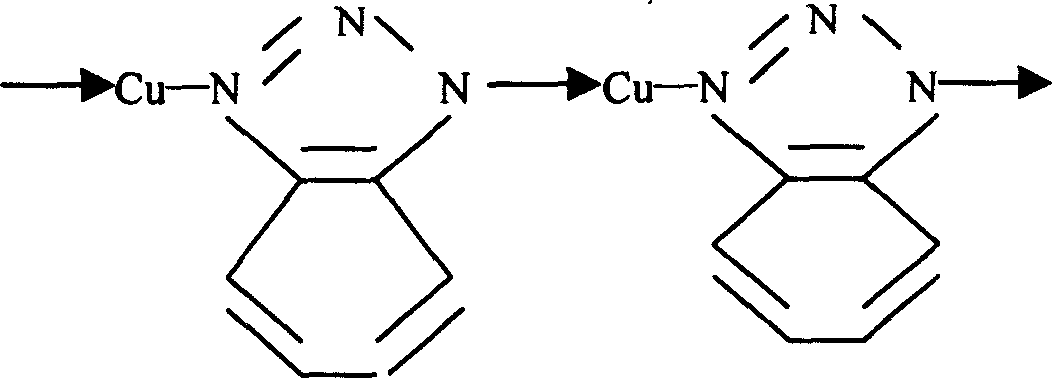

Copper alloy with outstanding comprehensive performance and application thereof

ActiveCN109022900AGuaranteed electrical conductivityHigh strengthConductive materialMetal/alloy conductorsWire rodUltimate tensile strength

Owner:NINGBO POWERWAY ALLOY MATERIAL

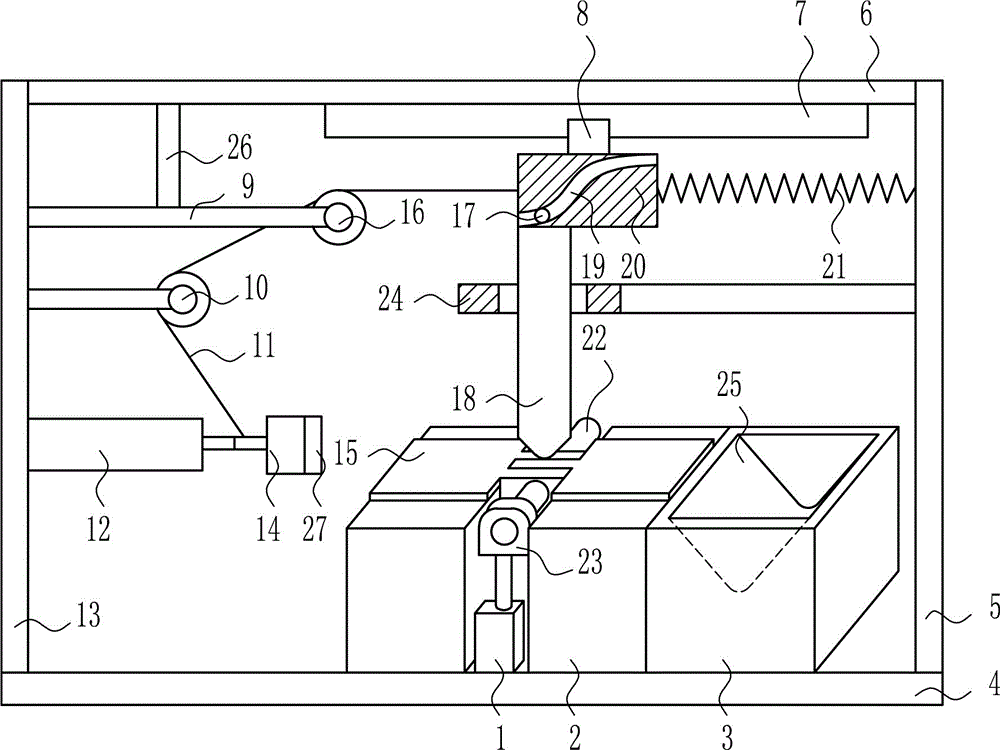

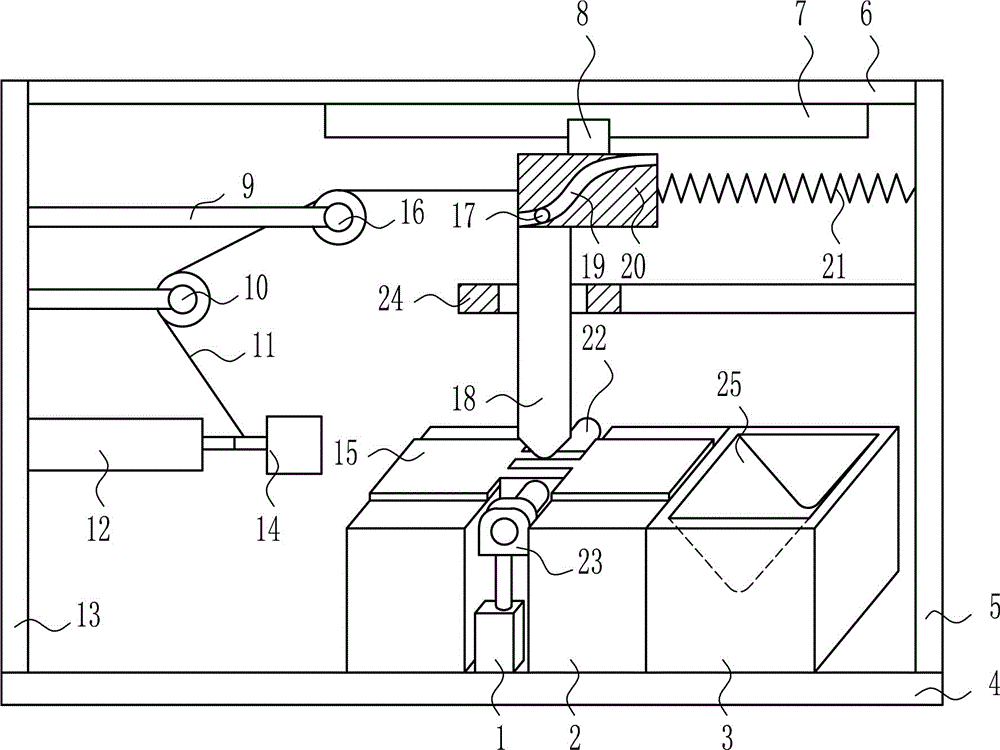

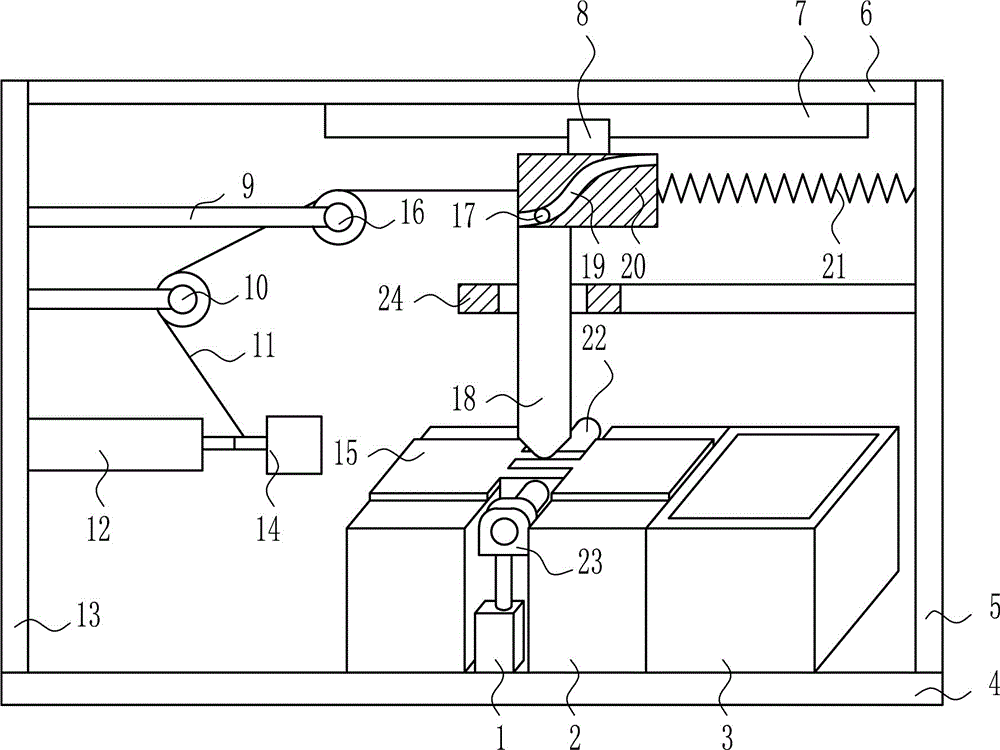

Metal plate bending device

The invention relates to a bending device, in particular to a metal plate bending device, and provides the metal plate bending device which is good in bending effect, convenient to operate and few in reject products to solve the technical problems. In order to solve the technical problems, the metal plate bending device comprises a cylinder, a placement block, a collecting frame, a bottom plate, a right support, a top support, a slide rail, a slider, a supporting rod, a first guide wheel, a pull rope, an electric push rod, a left support, a push block, a pressing plate, a second guide wheel, a slide shaft, a lifting rod, a telescopic block, a spring, a transverse bar, a fixed block and a slide sleeve. The cylinder is arranged in the middle of the bottom plate, the fixed block is connected to the upper end of the cylinder, the transverse bar is arranged on the fixed block, and the pressing plate is rotationally connected with the transverse bar. The metal plate bending device has the effects of being good in bending effect, convenient to operate and few in reject products; by means of the metal plate bending device, metal plates can be rapidly bent to 90 degrees, and high-quality products can be rapidly produced.

Owner:广州帝森建材有限公司

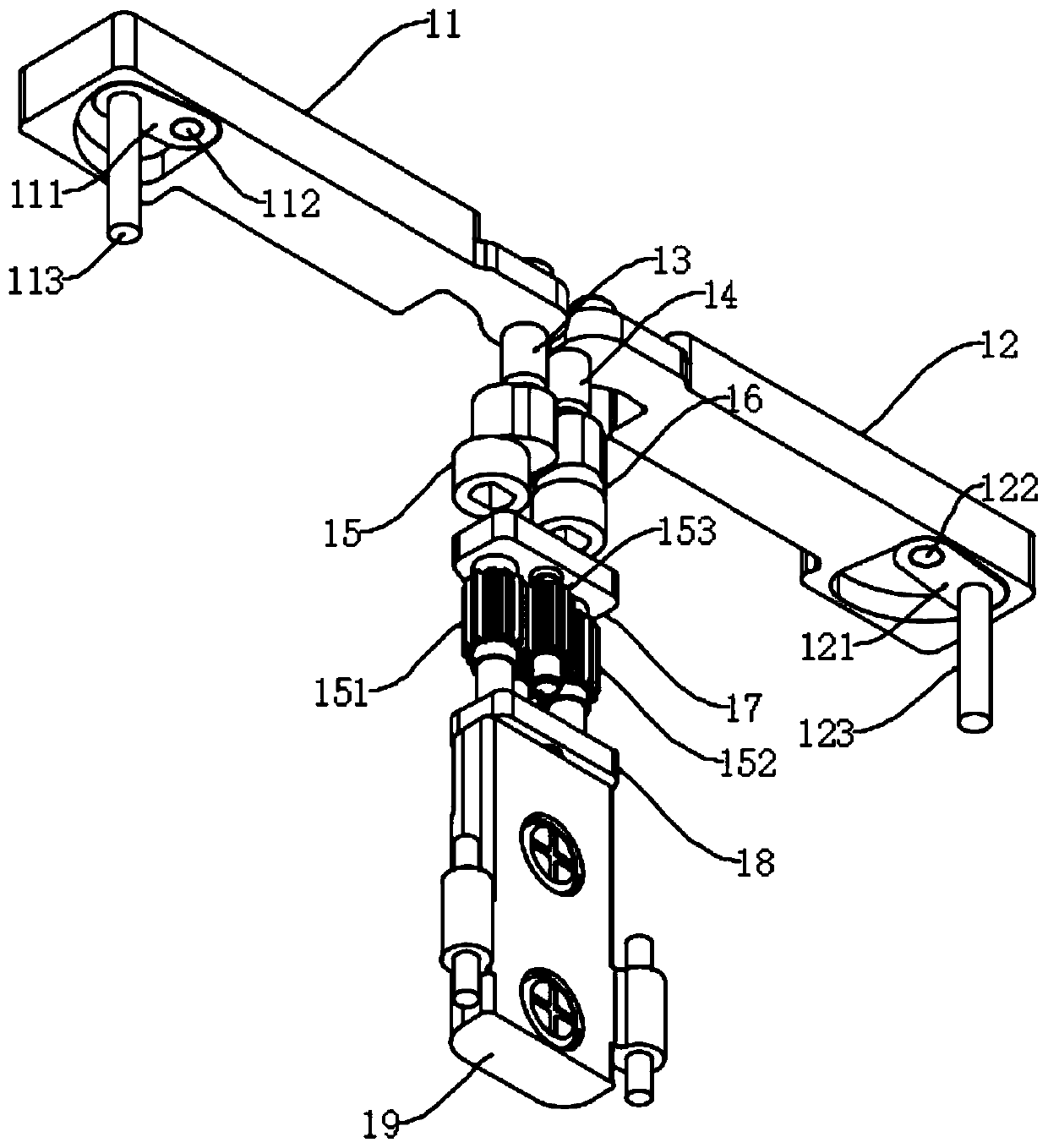

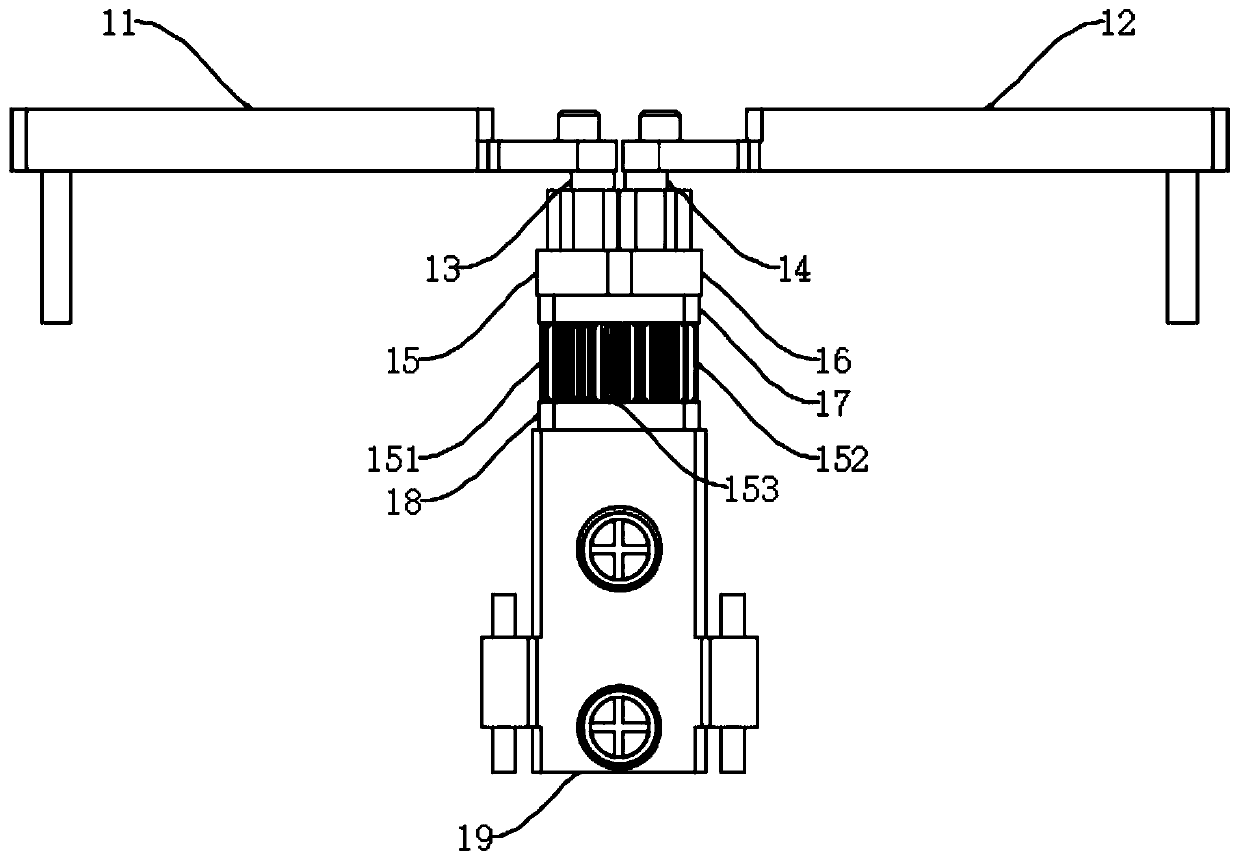

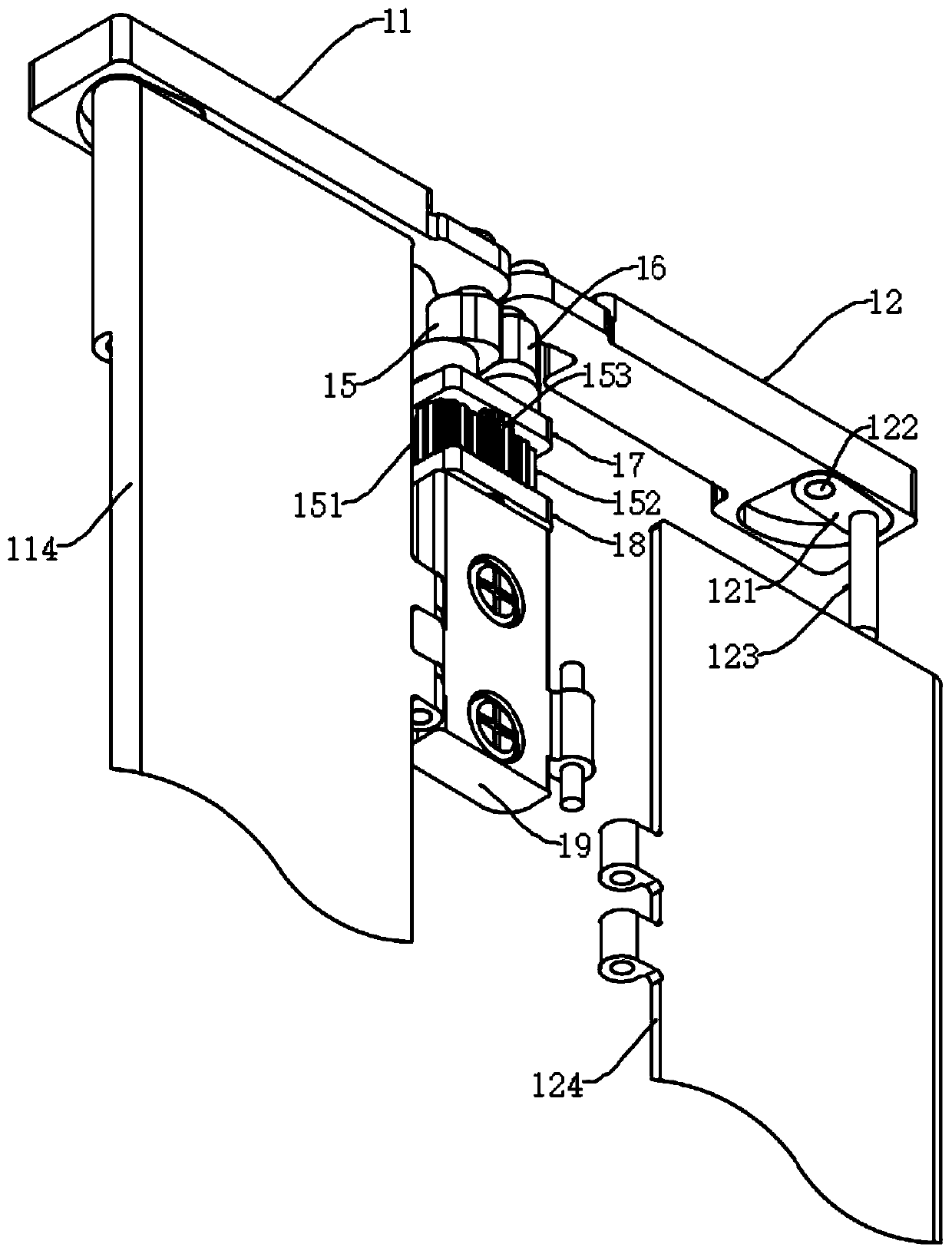

Rotating shaft mechanism for folding screen, folding screen assembly and foldable mobile terminal

ActiveCN110958337AImprove bending effectReduce frictionDigital data processing detailsTelephone set constructionsStructural engineeringMechanical engineering

The invention discloses a rotating shaft mechanism for a folding screen, a folding screen assembly and a foldable mobile terminal. The rotating shaft mechanism comprises a left supporting arm and a right supporting arm which are symmetrically arranged, and the left supporting arm and the right supporting arm are fixed to a support. A left rotating shaft on the left support arm is connected with the left cam, a right rotating shaft on the right support arm is connected with the right cam, the left gear is in transmission connection with the left cam, the right gear is in transmission connectionwith the right cam, and at least one transmission gear is in transmission connection between the left gear and the right gear. The folding screen assembly comprises the rotating shaft mechanism, andthe foldable mobile terminal comprises the folding screen assembly or the rotating shaft mechanism. The folding screen of the foldable terminal can work more reliably and more smoothly, has the outstanding advantages of being simple in structure, easy to implement, low in cost, high in reliability, long in service life, wide in application range and the like, and can be widely applied to foldablemobile terminals.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

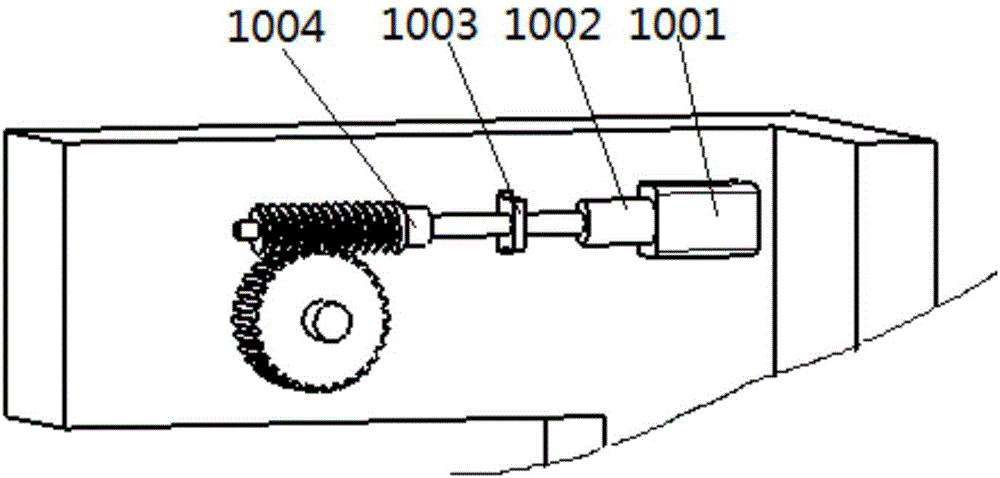

Electric pipe bending machine

The invention relates to an electric pipe bending machine which comprises a frame. An operation platform is arranged on the frame, and a bending pipe fixing frame is fixedly installed on the operation platform. The bending pipe fixing frame comprises a fixed press block, wherein the fixed press block is fixedly installed on the operation platform, and the inner side of the fixed press block is provided with a groove; a screw rod frame is fixedly installed on the operation platform, and a screw rod is installed on the screw rod frame; one end of the screw rod is connected with a moving press block, and the inner side of the moving press block is provided with a groove; the operation platform is provided with an opening, and a motor is arranged under the operation platform; the motor is connected with a reduction box, and an output shaft of the reduction box passes upwards through the opening on the operation platform vertically to be connected with a main wheel of a bending pipe; a bending pipe U-shaped bracket is fixedly connected to the main wheel of the bending pipe, and two bending pipe secondary wheels are connected between the inner side of the bending pipe U-shaped bracket and the main wheel of the bending pipe by pins; a travel switch baffle plate is fixedly connected to the output shaft of the reduction box, and an arriving sensor and a return sensor are installed under the operation platform. The invention has the characteristics of low rotating speed, small inertia, low power requirement of the motor and low cost.

Owner:王克启

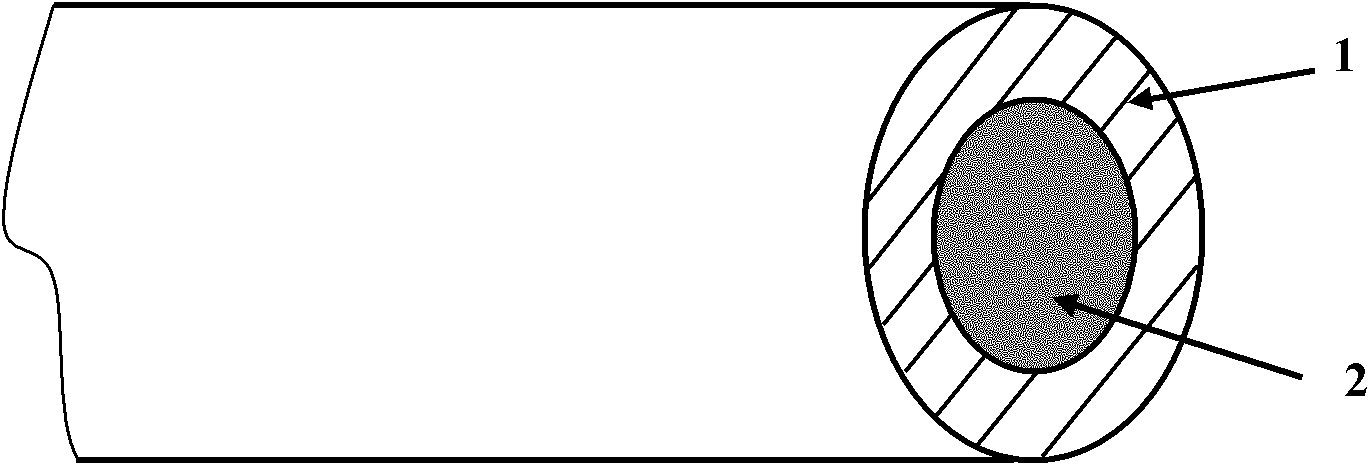

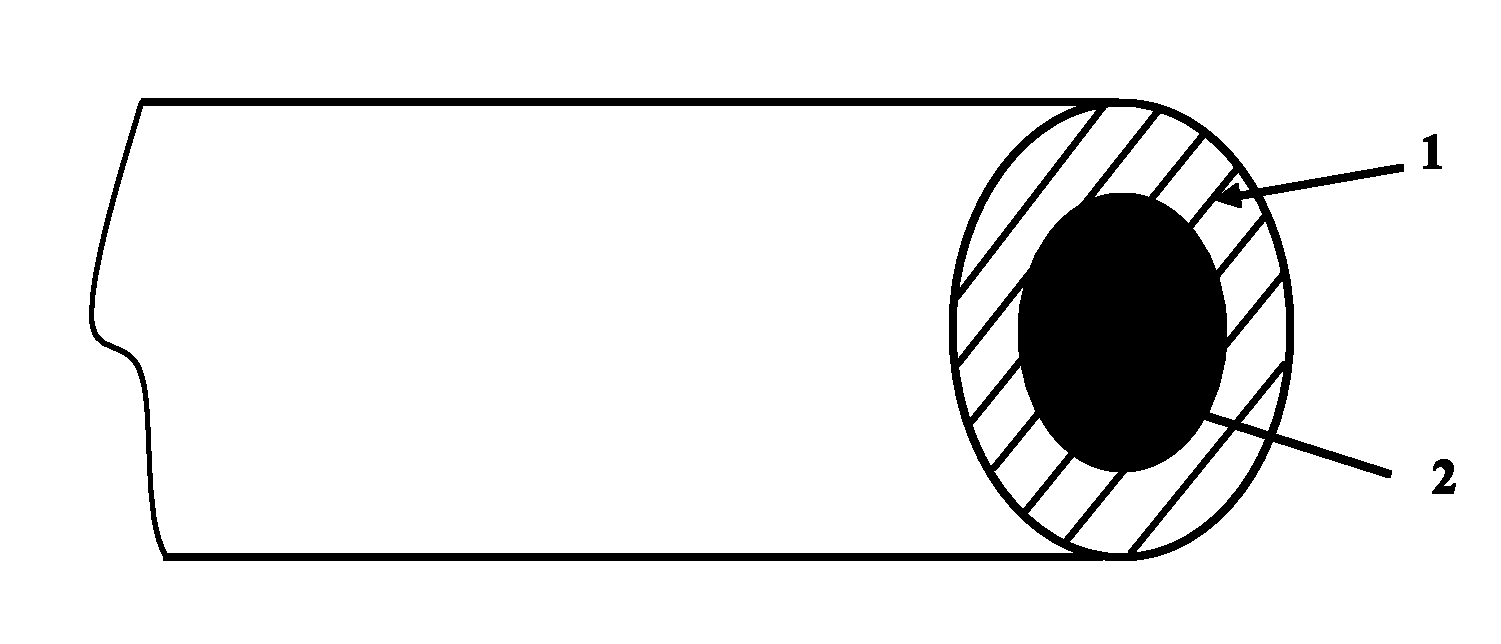

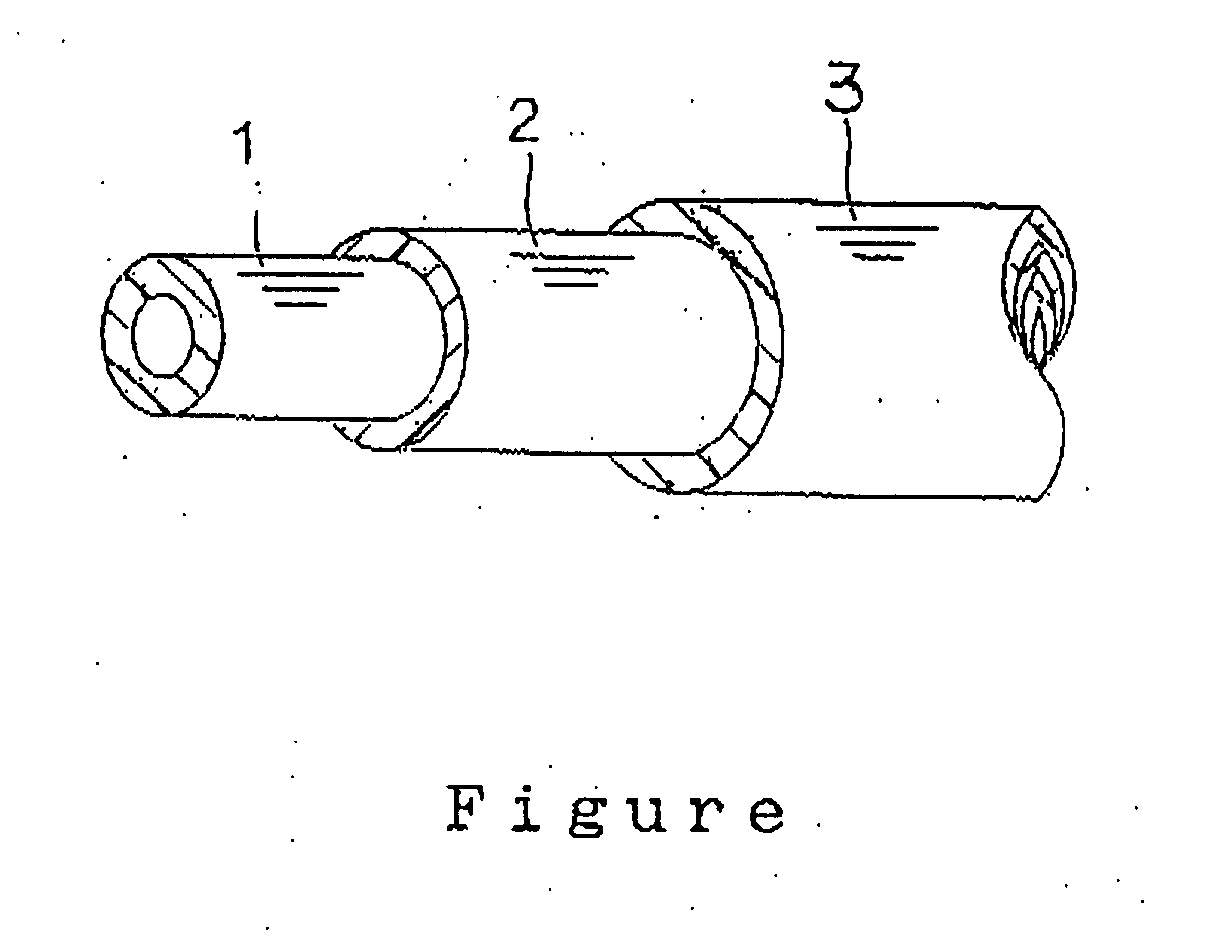

Automotive fuel hose

ActiveUS20050067035A1Reduce crystallinityInferior in sour gasoline resistanceSynthetic resin layered productsMachines/enginesPolyolefinGasoline

An automotive fuel hose having a three-layer structure excellent in sour-gasoline resistance and impact resistance. The automotive fuel hose includes a tubular inner layer in which fuel is adapted to flow; a low fuel permeability layer provided on an outer peripheral surface of the inner layer; and an outer layer provided on an outer peripheral surface of the low fuel permeability layer. The inner layer and the outer layer each including at least one of a polyolefin resin having a functional group and a polyamide resin and the low fuel permeability layer including a polyphenylene sulfide resin.

Owner:SUMITOMO RIKO CO LTD

6060 aluminum alloy board for curtain wall and preparation method thereof

The invention belongs to the technical field of aluminum alloys, and relates to a 6060 aluminum alloy board for a curtain wall and a preparation method thereof. The alloy elements such as magnesium, iron and chromium are optimally adjusted, the product is enabled to have the relatively high elongation while having the high strength, the compound is enabled to be uniformly distributed in the thickness direction of the board through the optimized technologies of casting, hot rolling, cold rolling and solid solution and ageing, the size of the compound is thin and small, the aluminum alloy boardwith the high surface and bending performance and flat board shape can be obtained, meanwhile, by combining the specific rolling technology rule and solid solution ageing rule, the technological procedure is simple, and the aluminum alloy board is suitable for factory large-scale production, and has the high yield.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

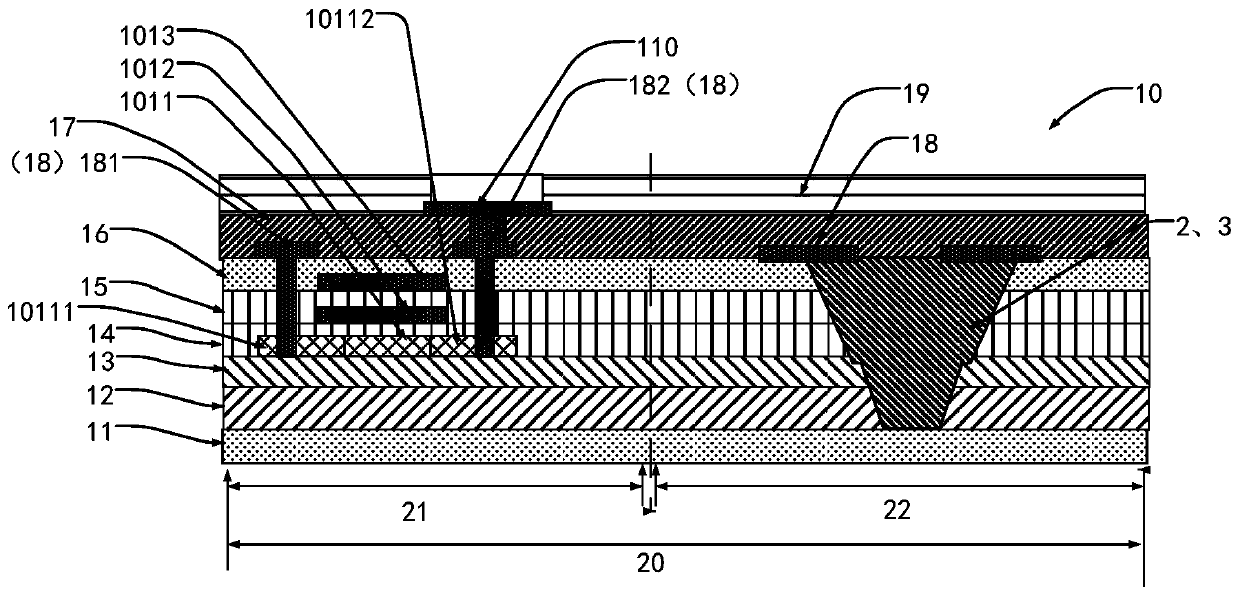

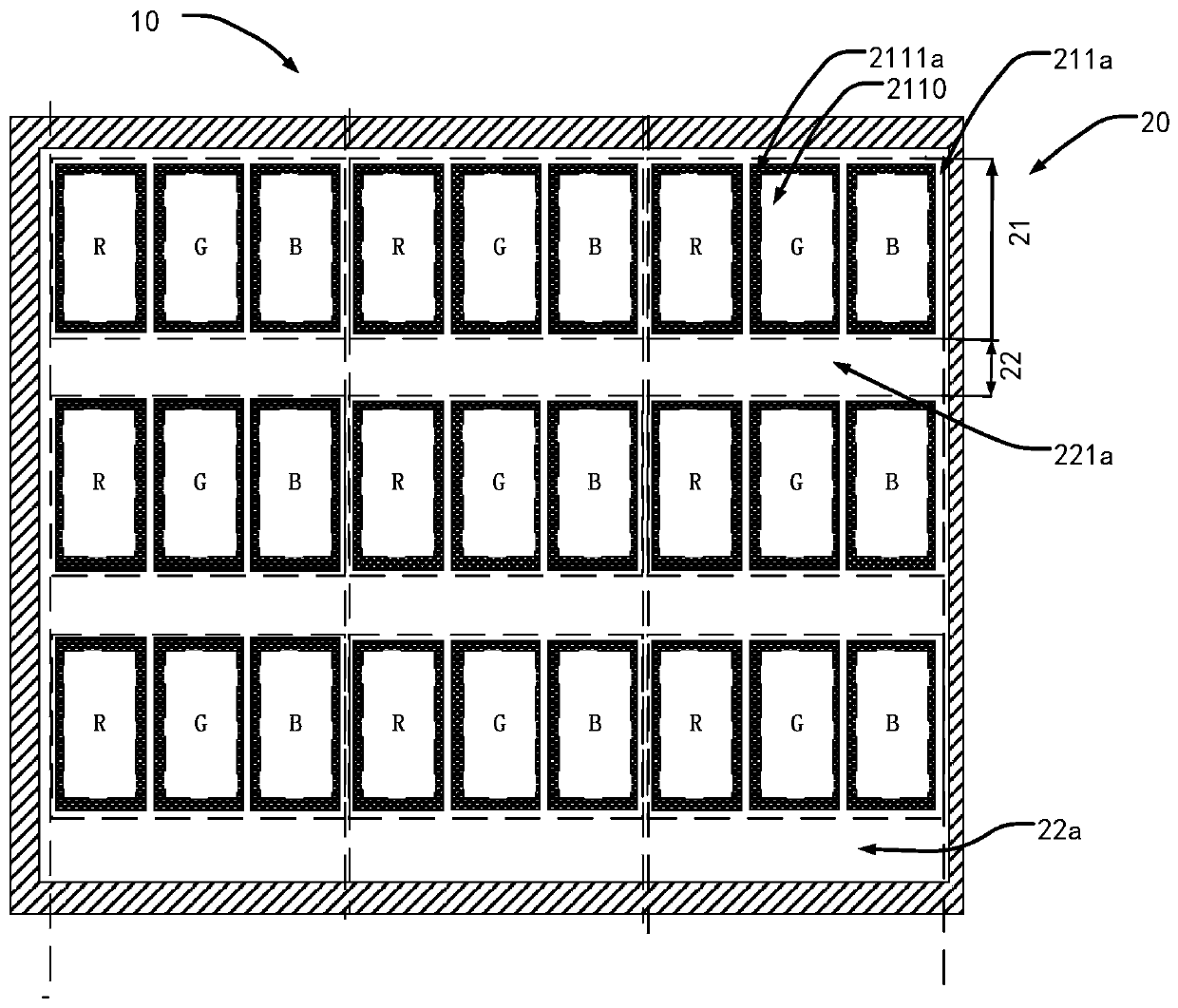

Display panel and display device

ActiveCN109860252AImprove bending effectRelease stressSolid-state devicesIdentification meansPhotoresistSurface plate

The present invention discloses a display panel. The display panel comprises a bending region and a non-bending region connected with the bending region, and the display panel further comprises an array substrate. The array substrate comprises: a plurality of first pixel regions which are mutually arranged in parallel in multiple lines and arranged in the bending region; a plurality of second pixel regions which are mutually arranged in parallel in multiple lines and arranged in the non-bending region; and a plurality of flexible connection regions configured to connect with adjacent first pixel regions and connect with the first pixel regions and the second pixel regions, wherein each flexible connection region is internally provided with a slot, and each slot is filled with an organic photoresist layer. According to the invention, the slots are arranged in the flexible connection regions of the bending region to form an inorganic layer slot between two adjacent lines of pixel regionsin the bending region to separate from each two lines of pixel regions, and the slots are filled with the organic photoresist layers so as to effectively relieve the stress of each inorganic layer ormetal wiring corresponding in the display panel, especially in the array substrate.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

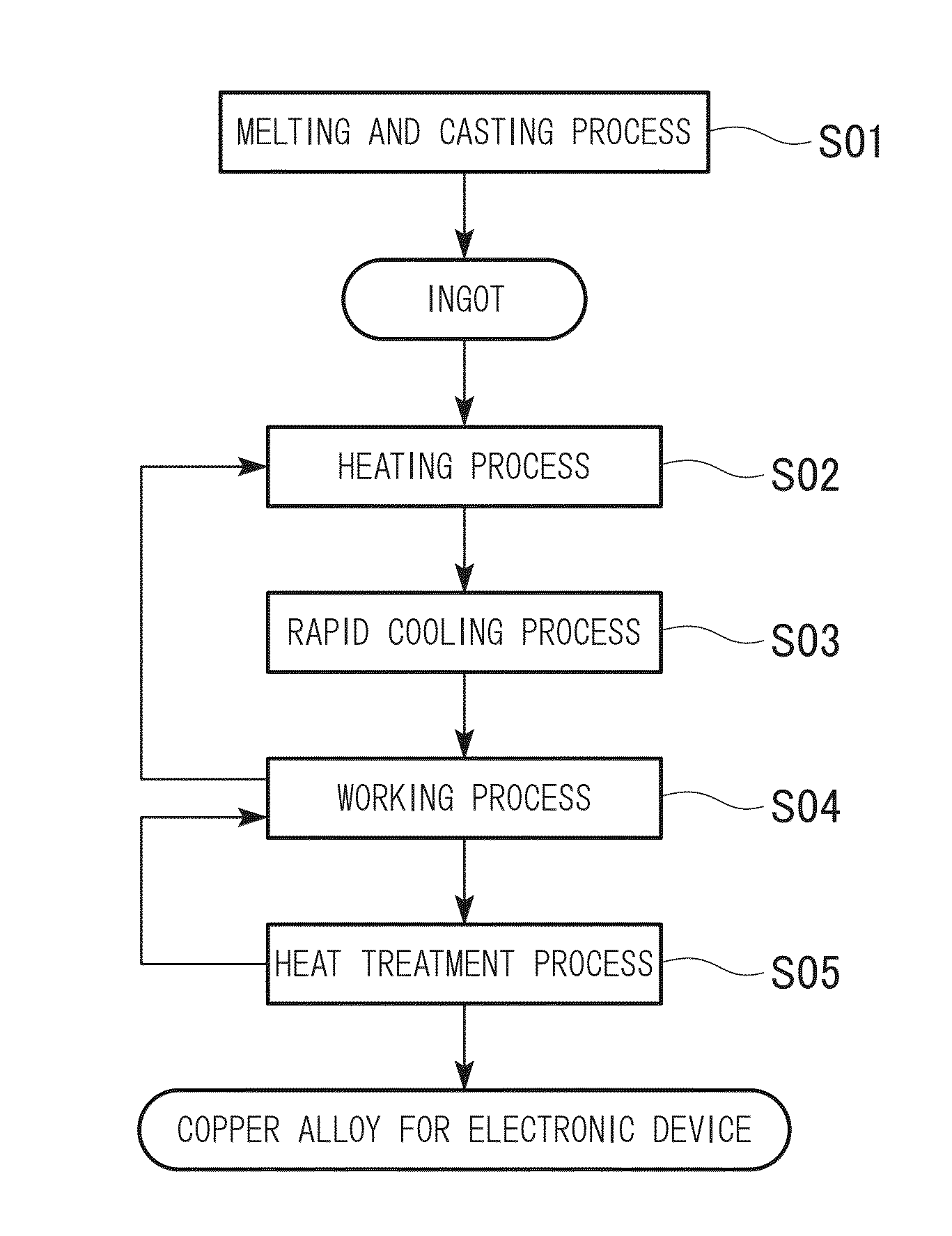

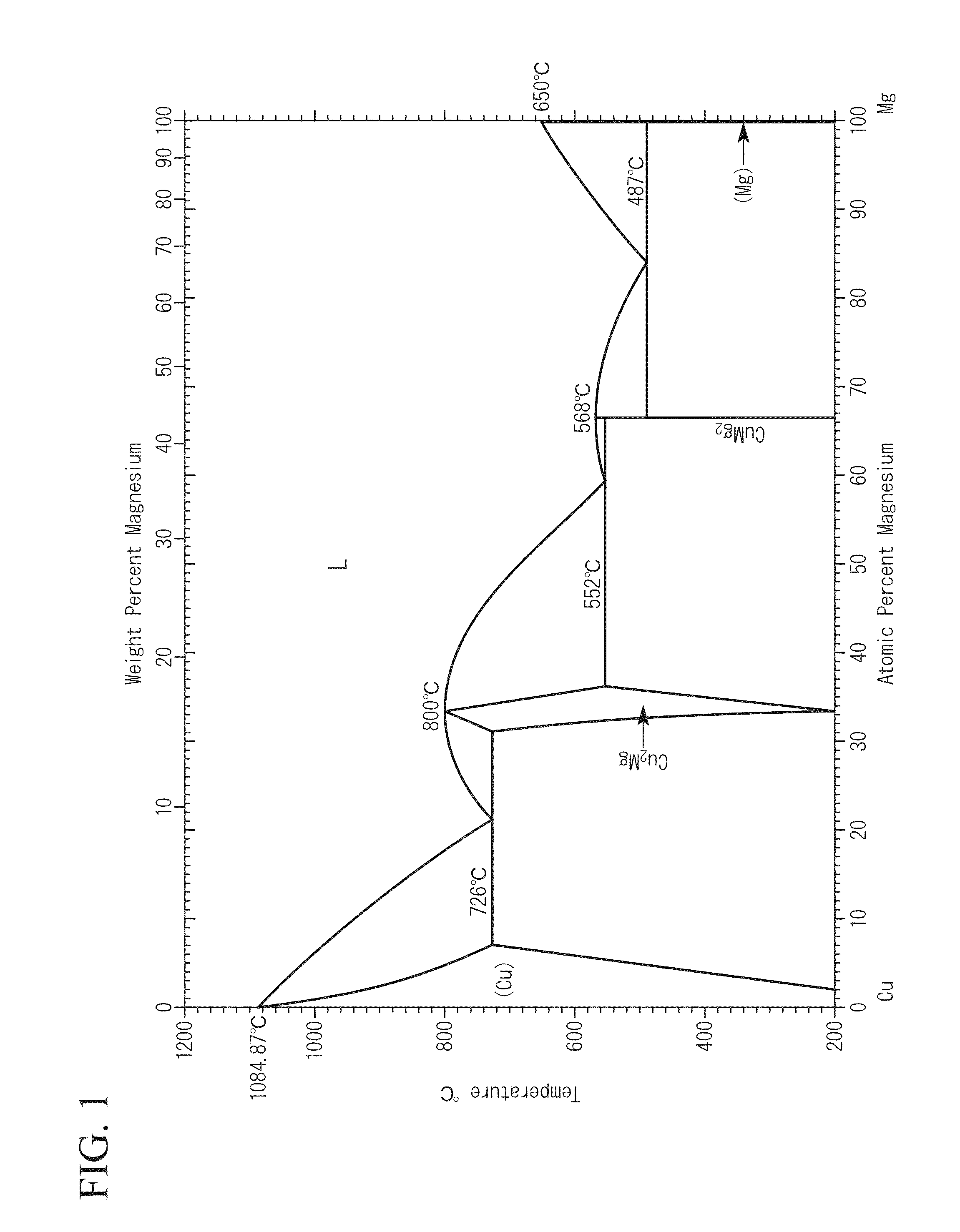

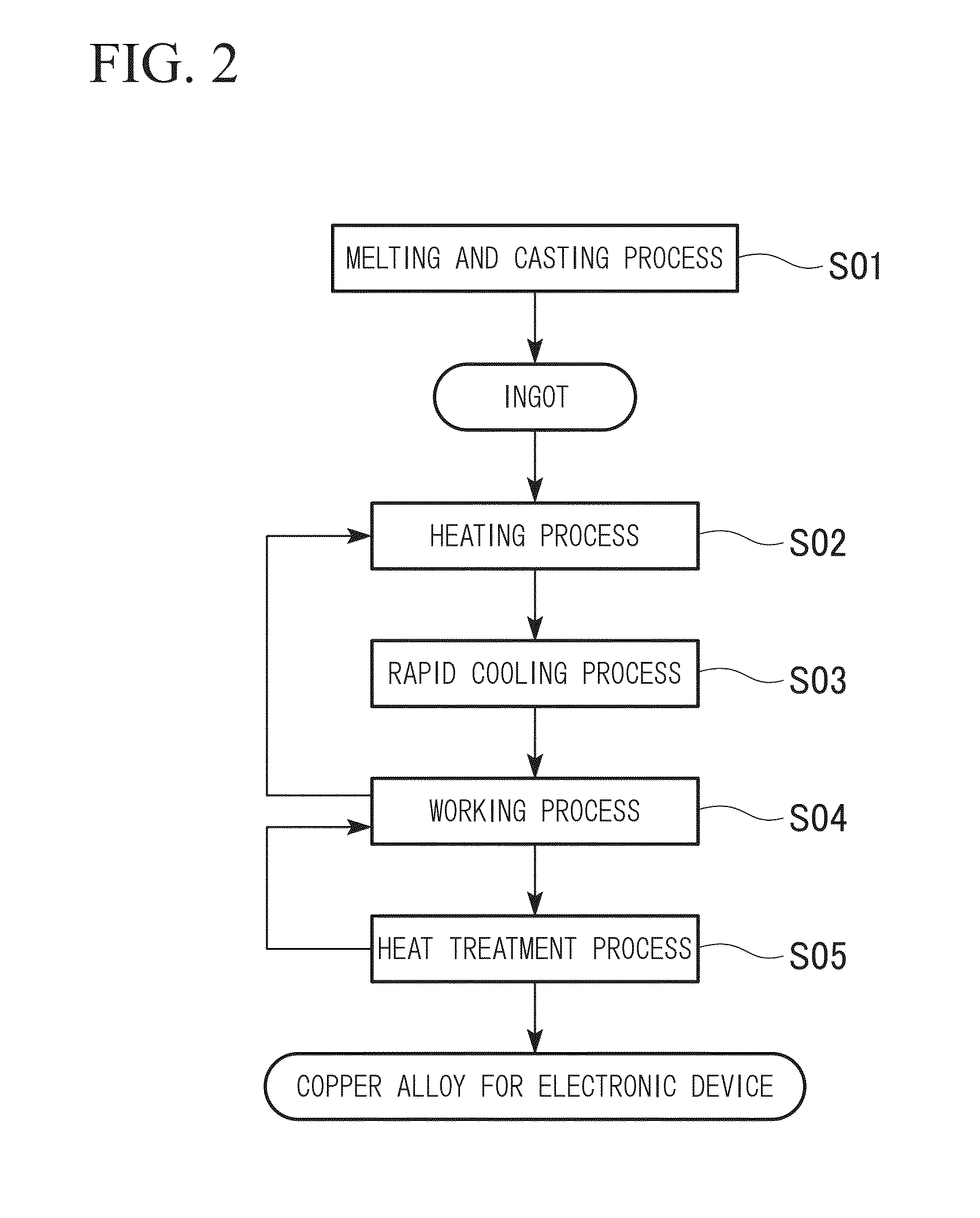

Copper alloy for electronic device, method for producing copper alloy for electronic device, and copper alloy rolled material for electronic device

ActiveUS20130048162A1Low young 's modulusHigh proof stressConductive materialMetal/alloy conductorsTernary alloyBinary alloy

One aspect of this copper alloy for an electronic device is composed of a binary alloy of Cu and Mg which includes Mg at a content of 3.3 to 6.9 atomic %, with a remainder being Cu and inevitable impurities, and a conductivity σ (% IACS) is within the following range when the content of Mg is given as A atomic %,σ≦{1.7241 / (−0.0347×A2+0.6569×A+1.7)}×100.Another aspect of this copper alloy for an electronic device is composed of a ternary alloy of Cu, Mg, and Zn which includes Mg at a content of 3.3 to 6.9 atomic % and Zn at a content of 0.1 to 10 atomic %, with a remainder being Cu and inevitable impurities, and a conductivity σ (% IACS) is within the following range when the content of Mg is given as A atomic % and the content of Zn is given as B atomic %,σ≦{1.7241 / (X+Y+1.7)}×100X=−0.0347×A2+0.6569×A Y=−0.0041×B2+0.2503×B.

Owner:MITSUBISHI MATERIALS CORP

Production method of explosion inhibiting material

InactiveCN1904103ACrystallization changes and uniformImprove bending effectRoll mill control devicesMetal rolling arrangementsChemical compositionSludge

This invention relates to the process of a kind of explode restrain material. chemical composition of it includes Si 0.1-0.6,Fe 0.2-0.7,Cu 0.05-0.1,Mn 0.6-1.2,Zn 0.05- 0.1,Ti 0.03-0.12,Na 0.02-0.07,and Al the rest .the process includes steps as follows: melt, de-sludge and de-airing, make body, milling, first anneal, hot press, cold press, second anneal, stamp to open the sew, tension.

Owner:王季庄 +1

Simple bending mechanism with adjustable compression roller for hardware plates

The invention discloses a simple bending mechanism with an adjustable compression roller for hardware plates. The bending mechanism comprises a machine frame, wherein a main supporting plate is fixedin the middle part of a top plate of the machine frame; an upper supporting plate is fixed on the inner side wall of the top part of the main supporting plate, a pressing oil cylinder is fixed to thetop surface of the upper supporting plate, and a push rod of the pressing oil cylinder penetrates through the upper supporting plate and is fixedly provided with a main pressing block; a lower fixingblock is fixed to the top surface of the part, right below the upper supporting plate, of the top plate of the machine frame, a containing groove is formed in the middle part of the top surface of thelower fixing block, and the right side of the containing groove extends out of the right side wall of the lower fixing block; the bottom face of the main pressing block faces the containing groove; transverse through grooves are formed in the two sides of the middle part of the top plate of the machine frame; and a movable frame is in threaded connection with a transverse screw rod, two ends of the transverse screw rod are hinged to two side supporting plates arranged on the left side and the right side of the machine frame respectively, and a transmission gear is fixed to the left part of the transverse screw rod. The simple bending mechanism has the advantages that structure is simple, bending effect is good, the position of the compression roller can be adjusted according to needs, a bending part is not prone to be damaged, and effect is good.

Owner:FOSHAN BENJIEPU ELECTROMECHANICAL TECH CO LTD

Manufacturing method of high performance antioxidation environmental protection copper raft

InactiveCN1718366AHigh surface finishGuaranteed surface finishOther manufacturing equipments/toolsChemical treatmentElectrolysis

A method for preparing the high-performance antioxidizing copper bus includes such steps as smelting electrolytic copper in LF induction furnace with graphite crystallizer and charcoal covering, casting, water-sealing extruding, acid washing for neutralizing, washing with hot water, rough drawing, removing surfacial skin, brightening annealing in the mixture of N2, and H2, and fine drawing.

Owner:江阴市汇金铜业有限公司

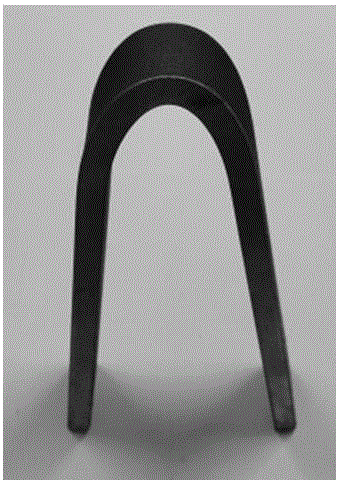

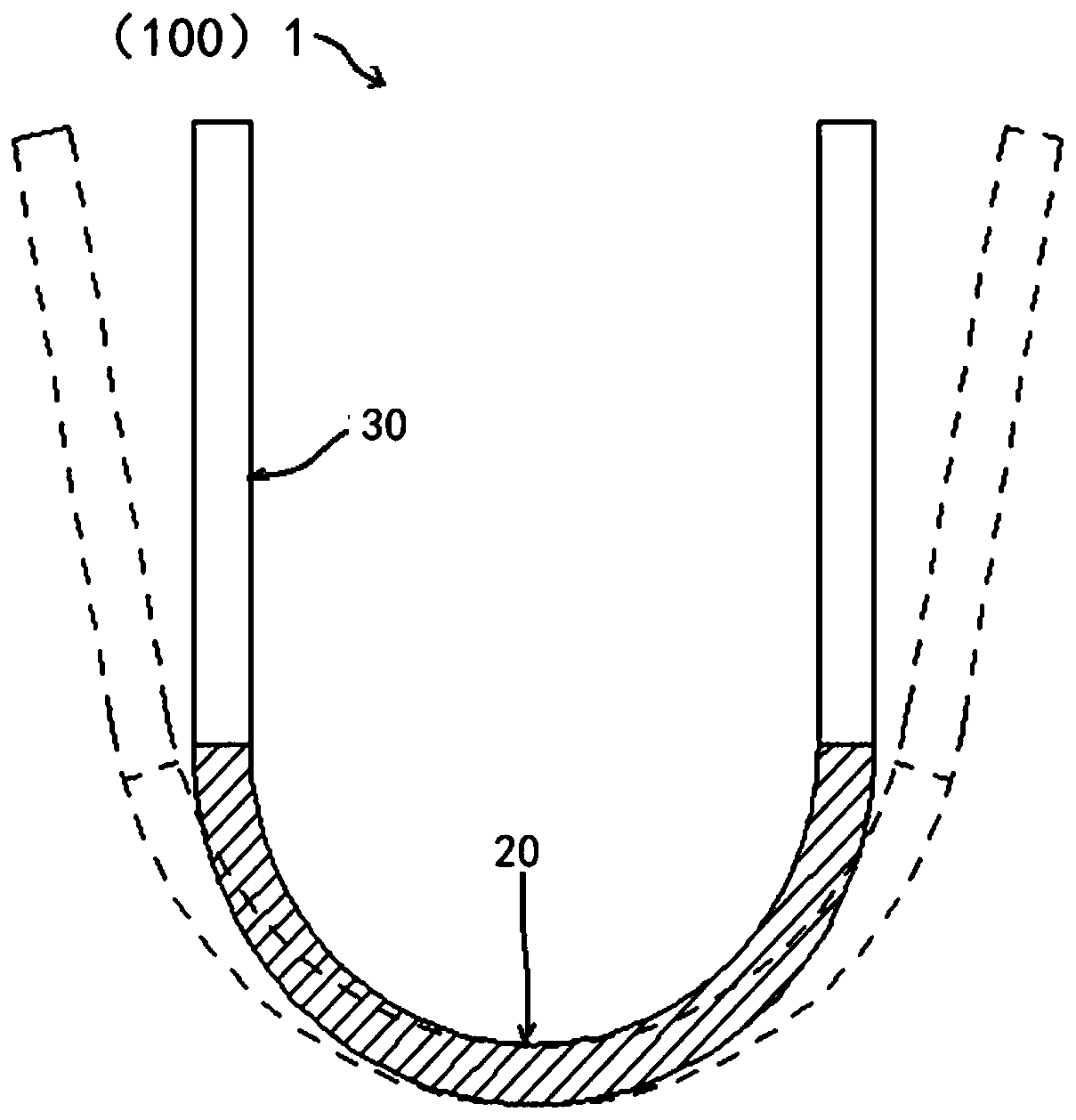

Vacuum insulation material, insulation case unit, and refrigerator

InactiveUS9464751B2Improve bending effectImprove suppression propertiesThermal insulationInsulation for cooling apparatusEngineeringRefrigerated temperature

A vacuum insulation material having bending formability while restraining reduction in a gas barrier property of a sheathing material. The vacuum insulation material includes a pouch-shaped sheathing material having a gas barrier property and a core received in the sheathing material as a spacer, the vacuum insulation material having a bendable region, a first surface, and a second surface opposite to the first surface, wherein at least one of the first and second surfaces in the bendable region is provided with a plurality of grooves extending at intervals, the grooves include a pair of outer grooves formed in the bendable region and a plurality of inner grooves formed inside the outer grooves, and an interval between each outer groove and a corresponding one of the inner grooves adjacent to each outer groove is greater than an interval between the inner grooves.

Owner:SAMSUNG ELECTRONICS CO LTD

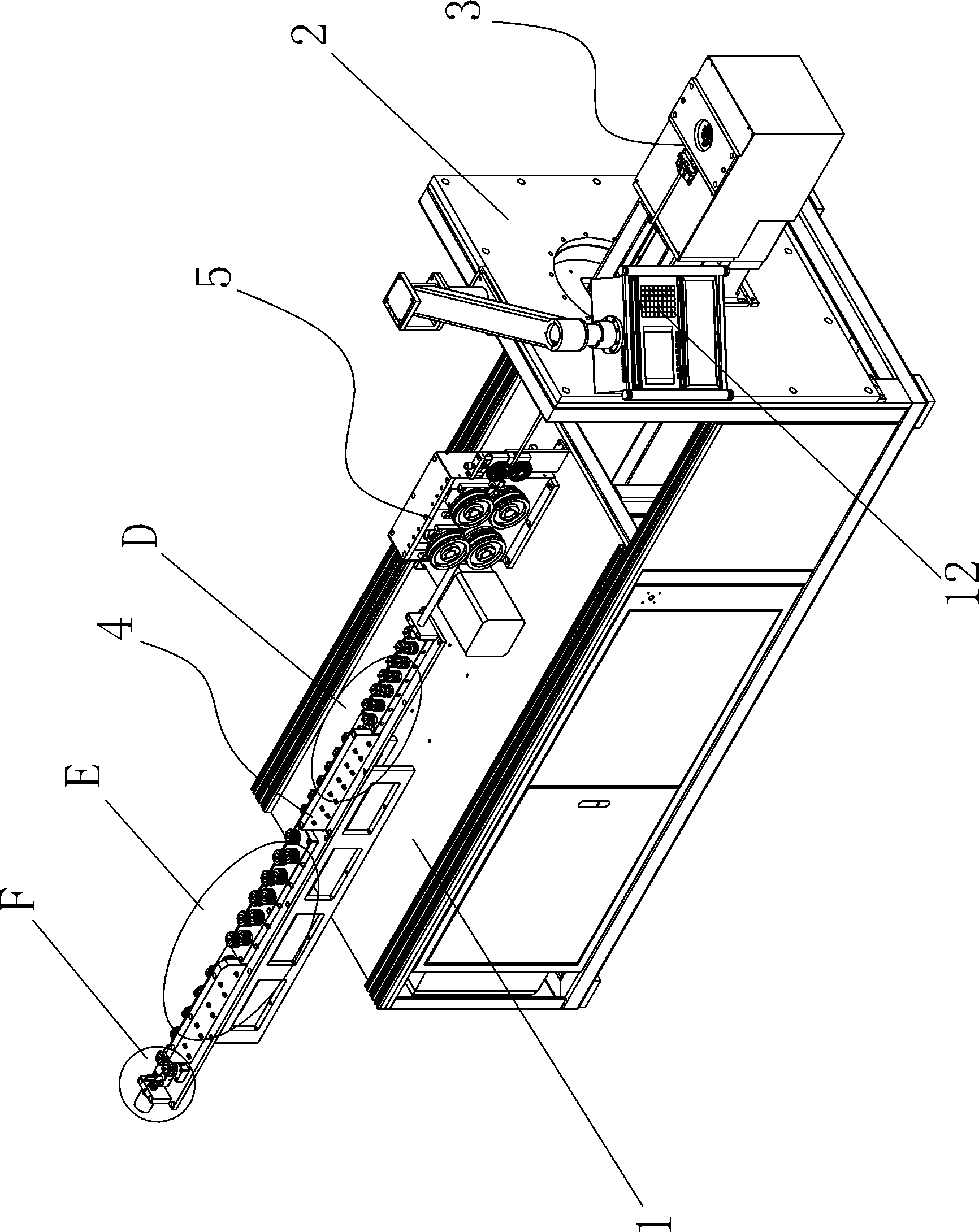

Hook production line

InactiveCN105383896AEnough heating timeTidy upConveyorsConveyor partsProduction lineShortest distance

The invention discloses a hook production line. The hook production line comprises a short rod feeding conveying and heating device and a short rod bending device. The short rod feeding conveying and heating device comprises a feeding mechanism, a conveying mechanism, a material cutting mechanism and a heating mechanism. The feeding mechanism comprises a feeding bin, a feeding slope and a material supporting mechanism. The conveying mechanism comprises a conveying chain wheel, a conveying chain supporting frame, a conveying chain and a conveying motor. The heating mechanism comprises an electrical heating tube and an electric cabinet. The material cutting mechanism comprises a material cutting air cylinder, a material cutting blocking rod and a material falling slop. The electric cabinet is internally provided with a programmable logic controller (PLC) and an electrical heating tube switch controlling the operation of the electrical heating tube. The short rod bending device comprises a material collection box, a conveying track, an ejection bending mechanism and a counter-ejection discharging mechanism. According to the hook production line, the heating effect on short rods is ensured, and the operation is convenient; the efficiency is high; meanwhile, the short rods heated at high temperature automatically fall into the conveying track and can be subjected to ejection bending after a short-distance conveyance, and time and labor are saved. In addition, the discharging is convenient and the ejection bending effect is good.

Owner:建德市马目五金有限公司

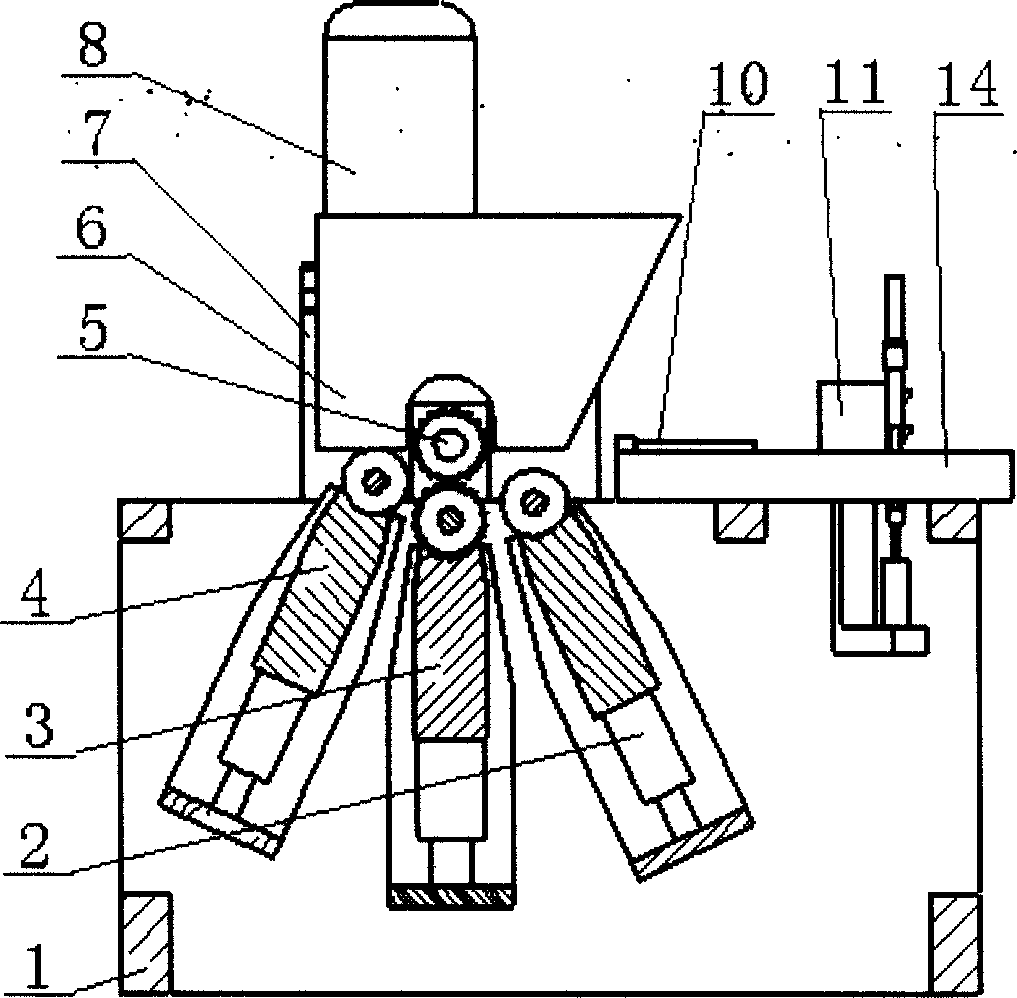

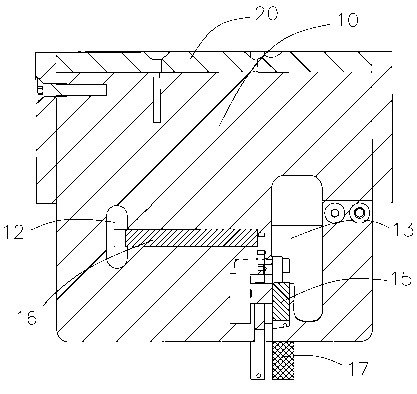

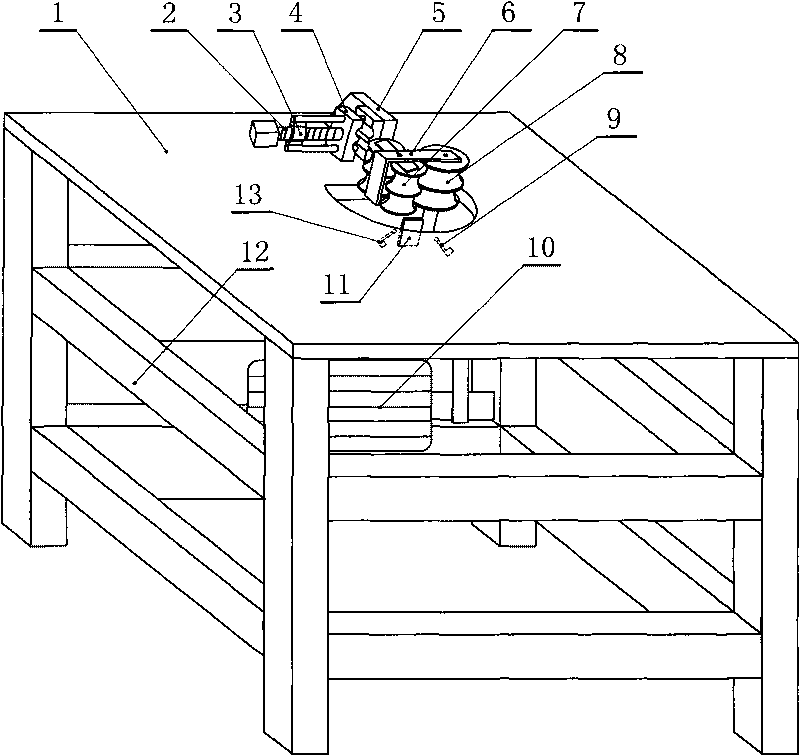

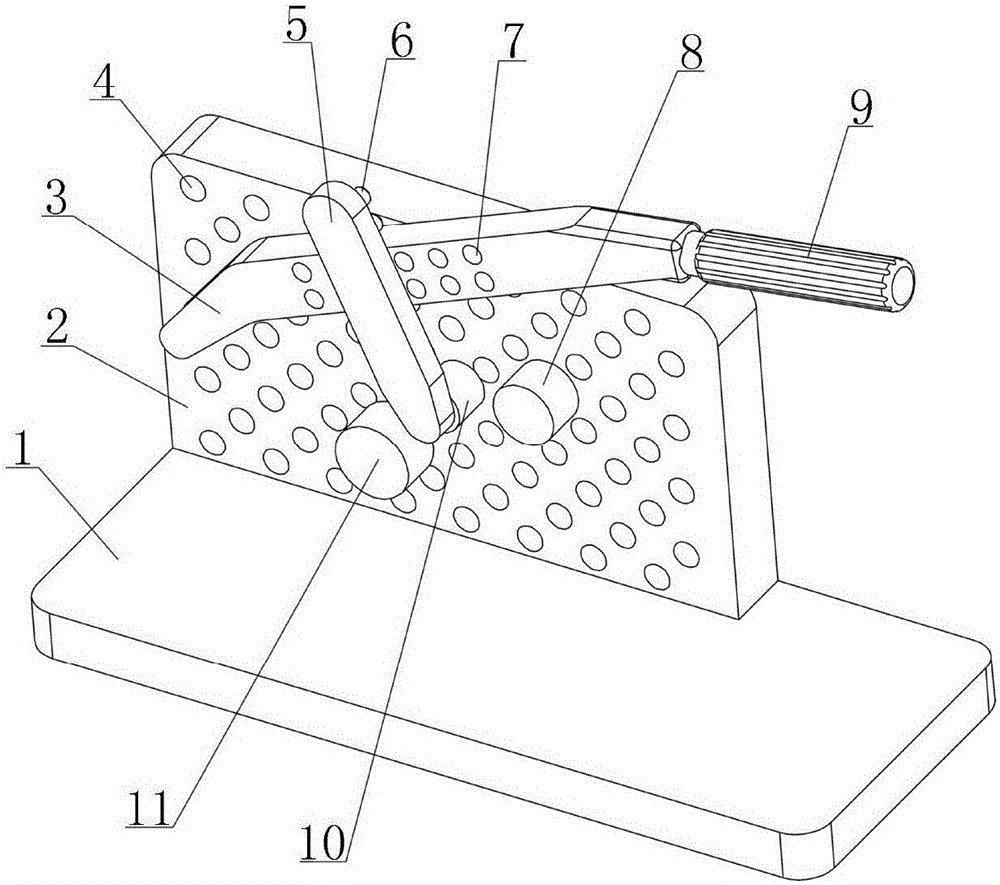

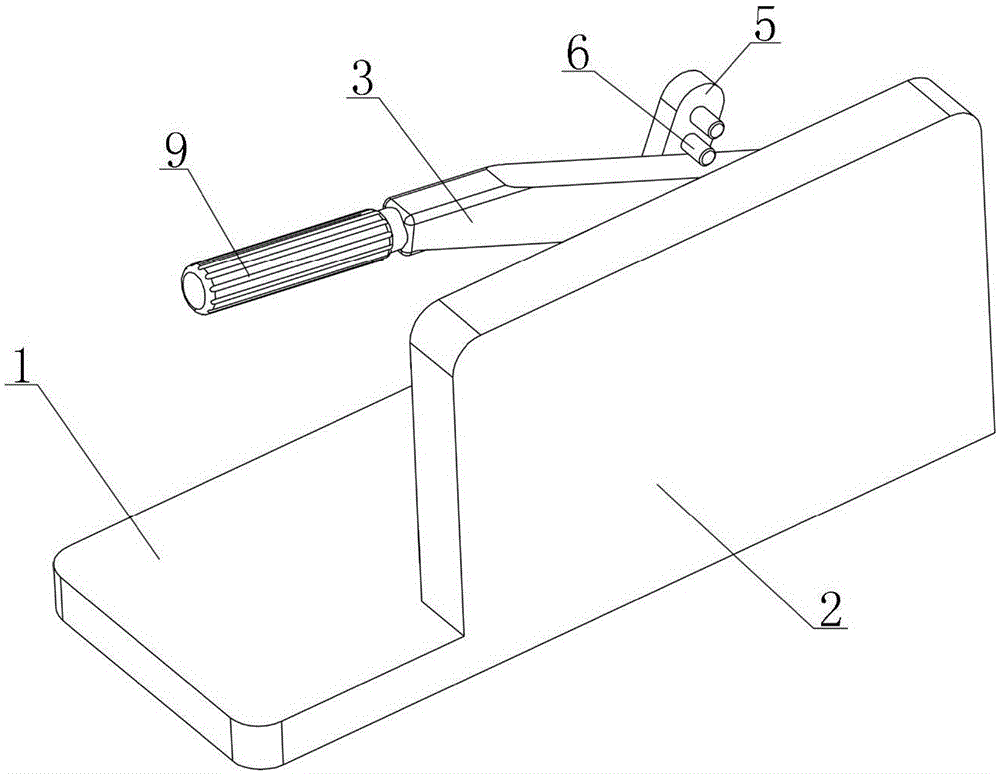

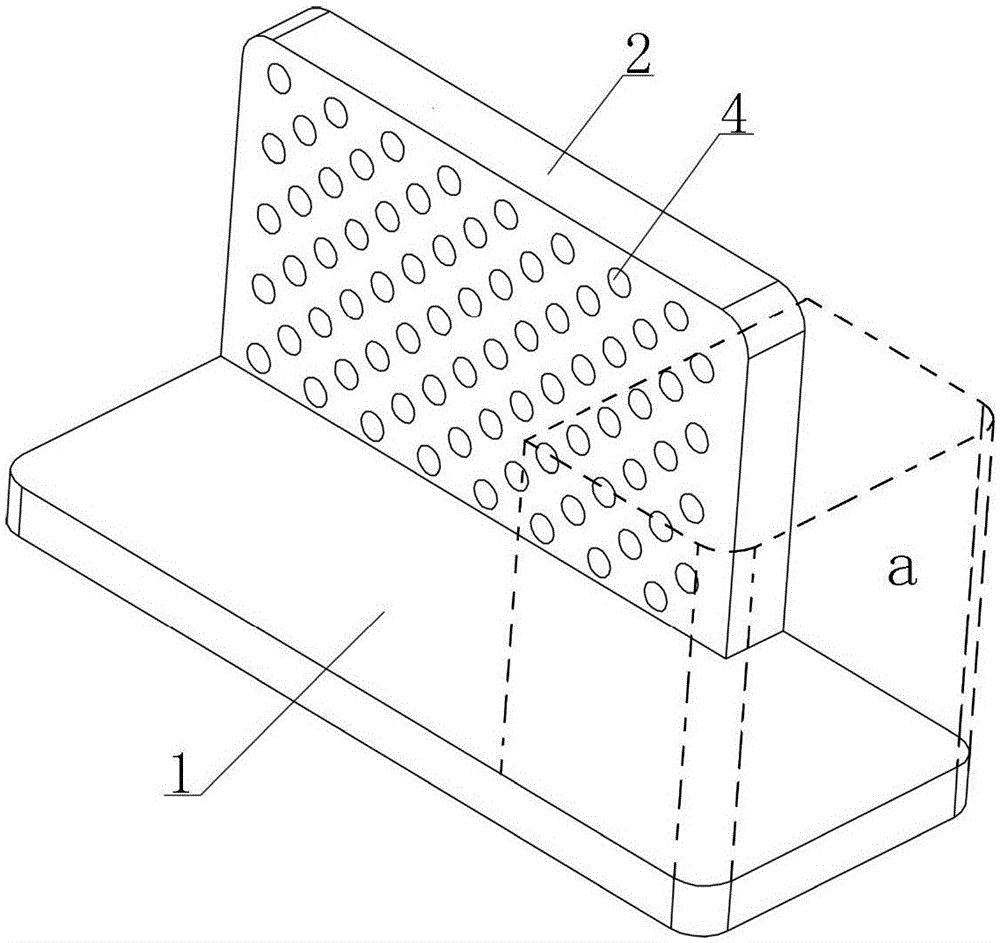

Medical steel plate pre-bending device for orthopedic clinics

InactiveCN105147385AImprove applicabilityReduce or even eliminate scrappingOsteosynthesis devicesPurchasingMechanical engineering

The invention discloses a tool for orthopedic clinics, and in particular discloses a medical steel plate pre-bending device for orthopedic clinics; the pre-bending device is composed of a main body, a rotary arm, a pressing arm and a plurality of bending rollers, wherein the main body is composed of a base plate and a vertical plate; shaft holes A are uniformly distributed in the inner sidewall of the vertical plate; a shaft pin A is arranged at the front end of the rotary arm, and a handle is arranged at the back end; multiple groups of inserting holes are formed in the inner sidewall of the rotary arm; a plurality of bolts are arranged on he inner sidewall of the pressing arm; the pressing arm is combined to the inner side of the rotary arm in a cross mode; a shaft hole B is formed in the outer side of the lower end of the pressing arm; the bending rollers are composed of roller bodies and shaft pins B; the bending rollers can be combined to the inner side of the vertical plate so as to support a medical steel plate; and in additional, the bending rollers can be fixedly arranged at the lower end of the pressing arm so as to provide bending pressure to the medical steel plate. The pre-bending device disclosed by the invention is good in bending effect, high in efficiency, relatively labor-saving in operation and relatively convenient in regulation, and the pre-bending device is good in adaptability to medical steel plates on various parts and of various specifications; and the pre-bending device can reduce, and can even avoid, the circumstance that the medical steel plate is discarded during pre-bending, and the pre-bending device is suitable for clinical purchasing for clinical use.

Owner:XIAN HONGHUI HOSPITAL

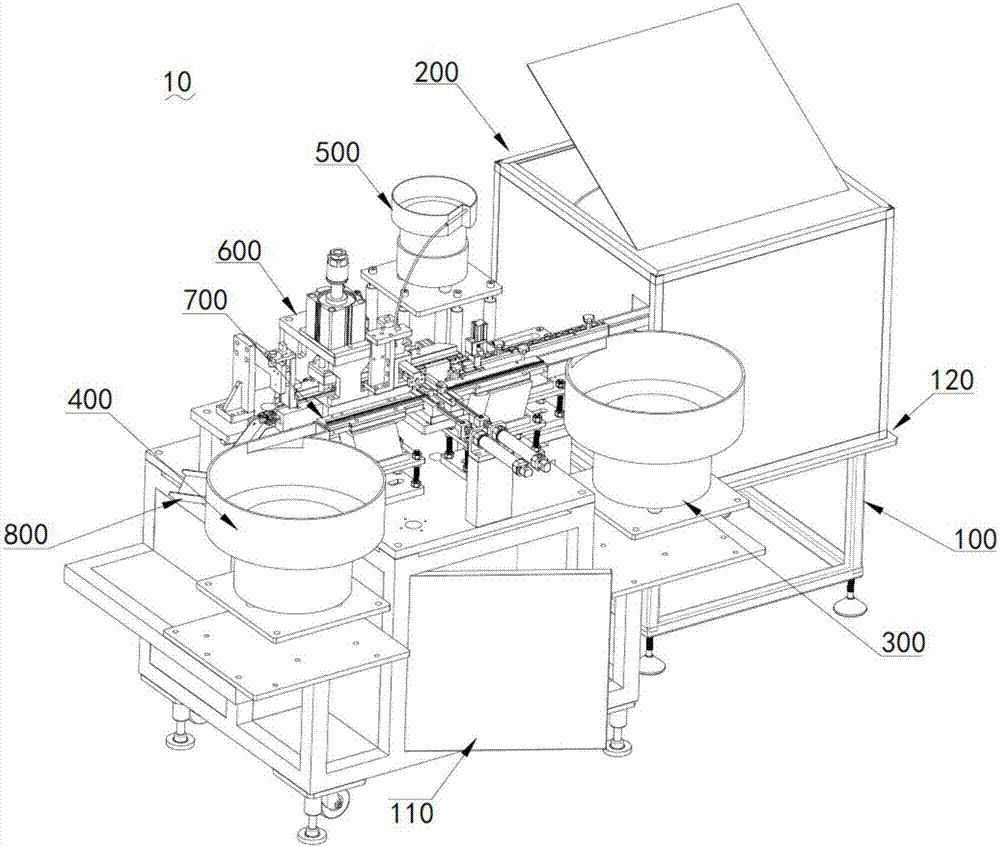

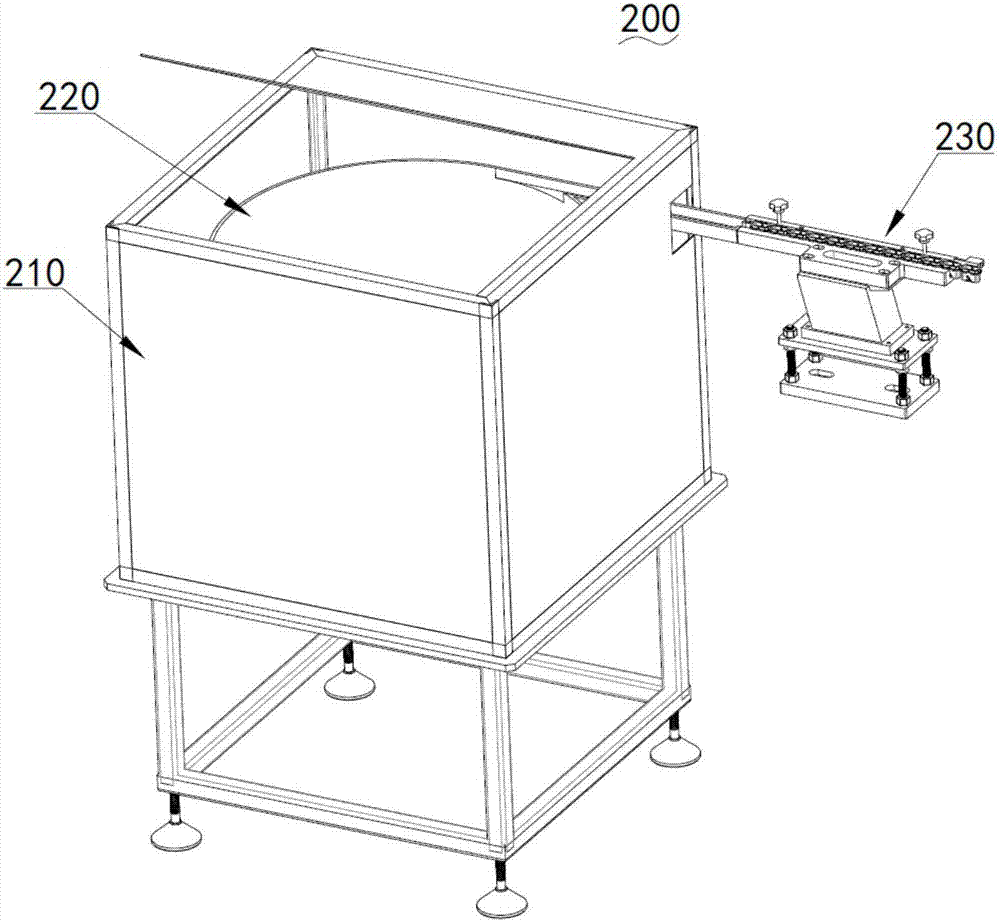

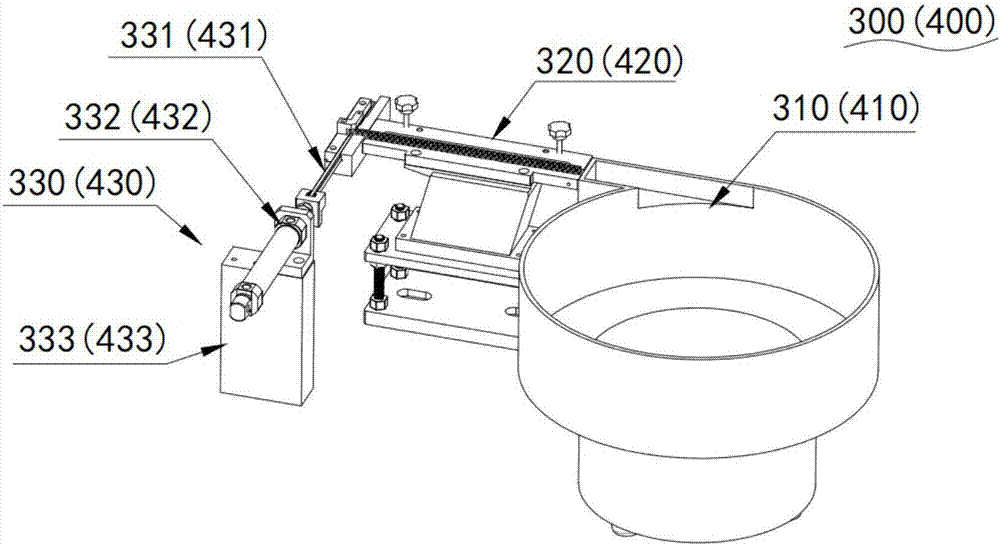

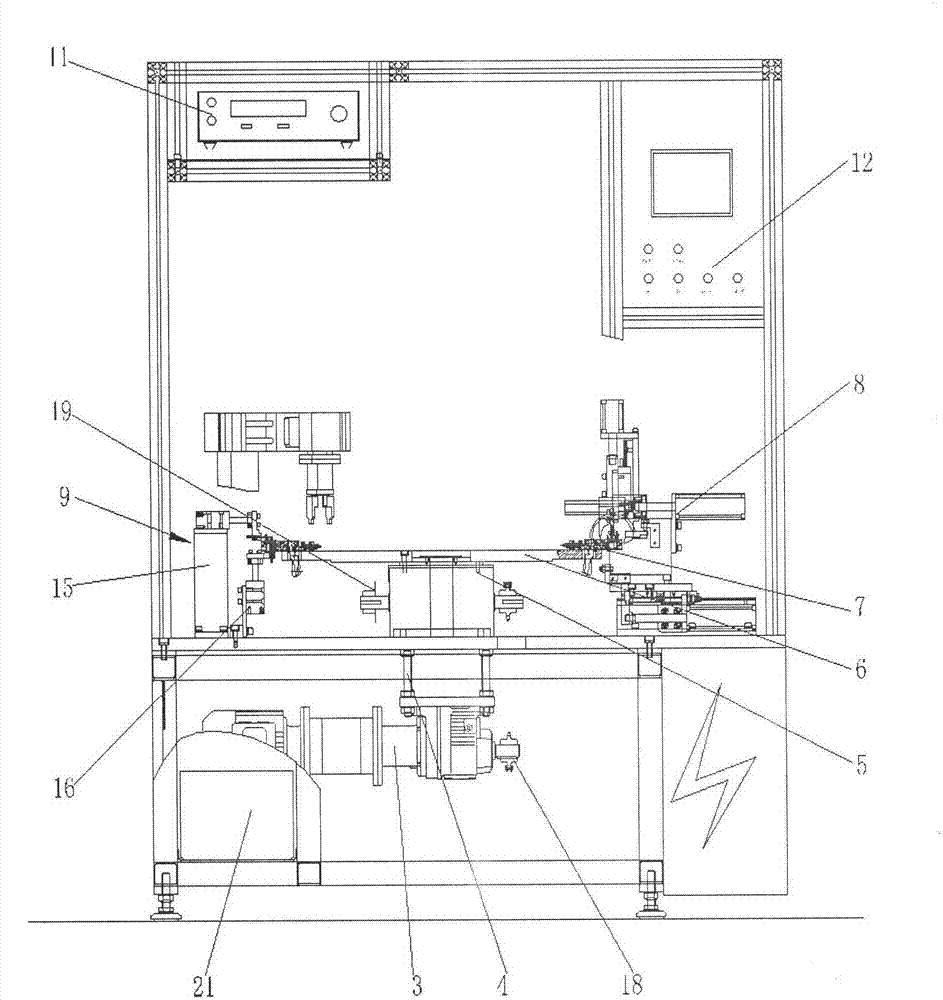

Full-automatic socket switch pedestal assembling equipment

ActiveCN107968007AEasy to assembleHigh degree of automationContact member assembly/disassemblyElectric switchesEngineeringResistor

The invention relates to the technical field of socket switch pedestal assembling, and particularly relates to full-automatic socket switch pedestal assembling equipment comprising a rack and a pedestal loading device, a first pole piece loading device, a second pole piece loading device, a resistor loading device, a bending device and an assembling line which are arranged on the rack. One end ofthe assembling line and the first pole piece loading device pass through the first pole piece loading device, the second pole piece loading device, the resistor loading device and the bending device in turn. One end, which is back to the pedestal loading device, of the assembling line is connected with a material discharge device. The full-automatic socket switch pedestal assembling equipment is high in working efficiency, economical in labor and high in degree of automation.

Owner:DONGGUAN POWER TECHNO ELECTRIC CO LTD

Plastic pipe bending machine

InactiveCN105965864AImprove processing efficiencyReduce processing costsEngineeringElectromagnetic heating

The invention provides a plastic pipe fitting bending machine, which includes a machine body and a three-jaw chuck. A bending die mechanism is slidably connected to the body, and a second X-direction movement mechanism is arranged between the two. The bending die mechanism It includes a bending mold, the body is slidably connected with the body, and a first X-direction movement mechanism is arranged between the two, the side of the body is connected with a first guide plate through a Y-axis rotary movement mechanism, the first guide plate and the second The guide plate is slidingly connected, the second guide plate is fixed with a slide bar, one end of the slide bar is equipped with a bending roller, and the body is also equipped with an electromagnetic heater, the electromagnetic heater includes an electromagnetic heating coil, and the inner ring of the bending roller is close to the bending mold. The inner walls of the pipe parts are all wound with electromagnetic heating coils. The plastic pipe fitting bending machine of the present invention can realize the bending operation of pipe fittings of different specifications on one machine, is suitable for mass production, reduces the scrap rate, saves the operation steps of workers, and reduces the production cost.

Owner:TIANJIN RUILING TECH DEV CO LTD

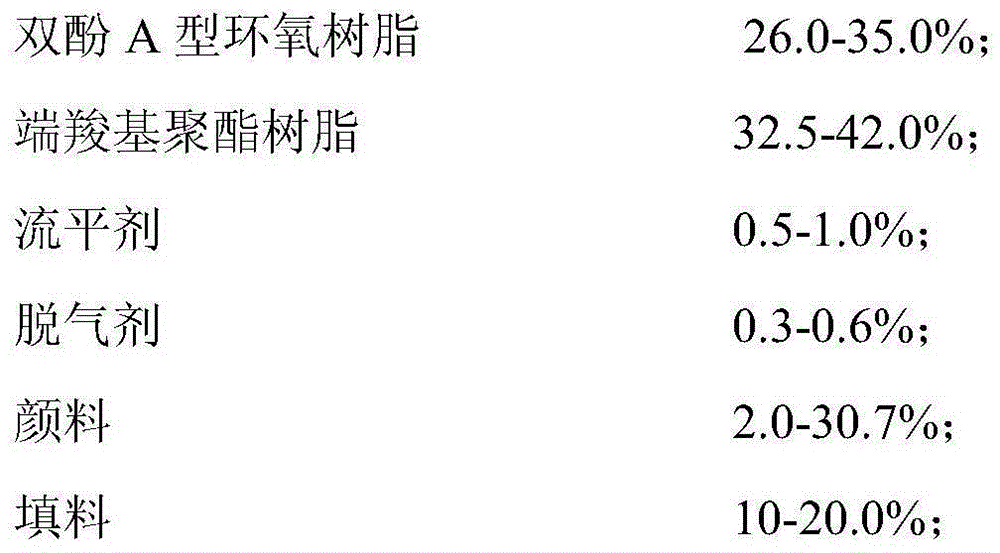

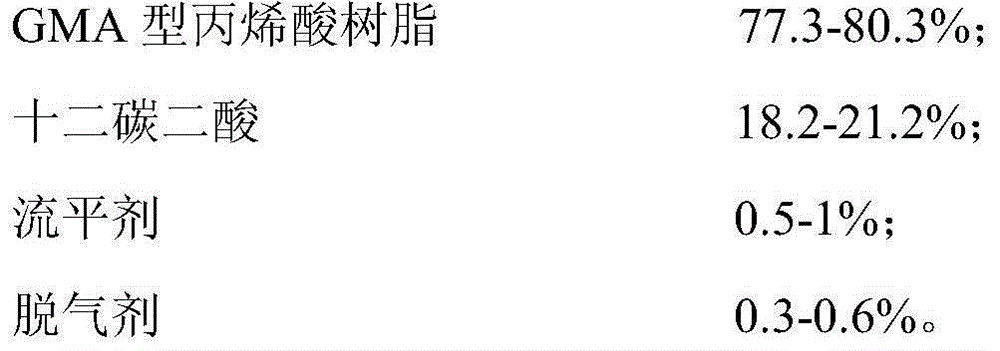

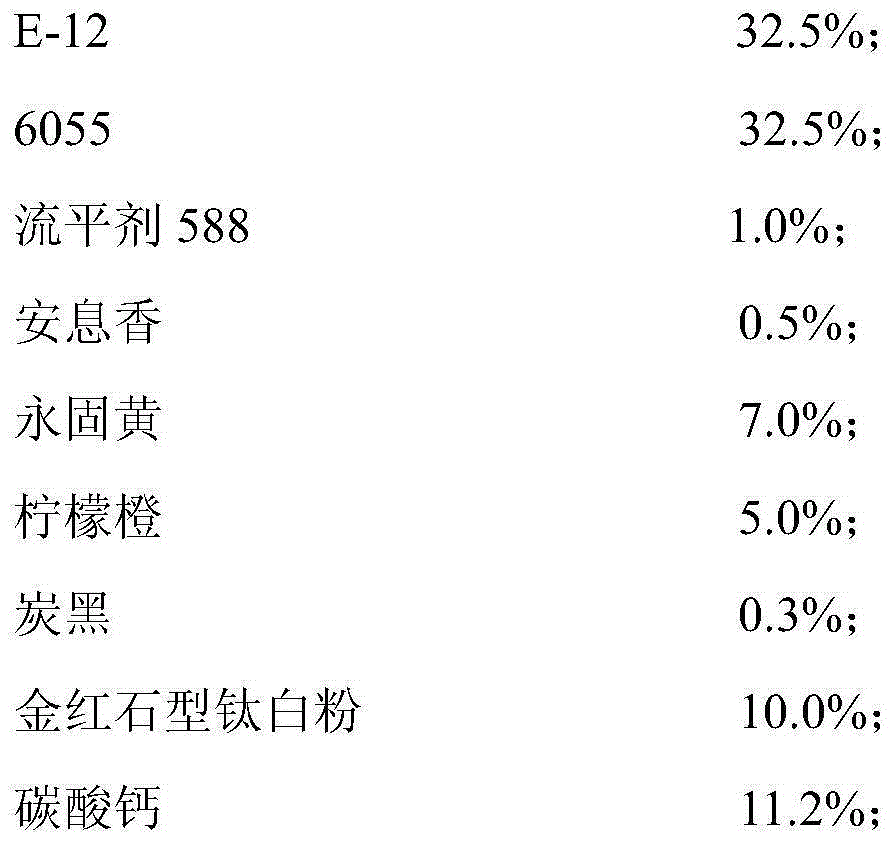

Powder coating with metal flashing effect, as well as preparation method and application method of powder coating

InactiveCN105038447AImprove impact resistanceImprove bending effectPowdery paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention belongs to the field of functional powder coating, and particularly relates to powder coating with a metal flashing effect, as well as a preparation method and an application method of the powder coating. The powder coating is prepared by combining a composition A, a composition B and a composition C, wherein the composition A comprises the following raw materials in percentage by weight: 26.0-35.0% of bisphenol A-type ethoxyline resin, 32.5-42.0% of carboxyl terminated polyester resin, 0.5-1.0% of a leveling agent, 0.3-0.6% of a degassing agent, 2.0-33.5% of one or more pigments and 10-20.0% of a filler; the composition B comprises the following raw materials in percentage by weight: 90-99% of the composition A and 1-10% of one or more metal pigments; the composition C comprises the following raw materials in percentage by weight: 77.3-80.3% of GMA-type acrylic resin, 18.2-21.2% of dodecanedioic acid, 0.5-1% of the leveling agent and 0.3-0.6% of the degassing agent. A double-layer coating film is formed after application of the powder coating, so that the powder coating is high in impact resistance and bending resistance. The invention further provides the preparation method and the application method of the powder coating.

Owner:SAIGAO POWDER TECH YANTAI

High-strength high-conductivity copper alloy material, preparation method thereof and application thereof

ActiveCN111996411AHigh temperature softening resistanceReduce residual stressSemiconductor/solid-state device detailsSolid-state devicesLead frameUltimate tensile strength

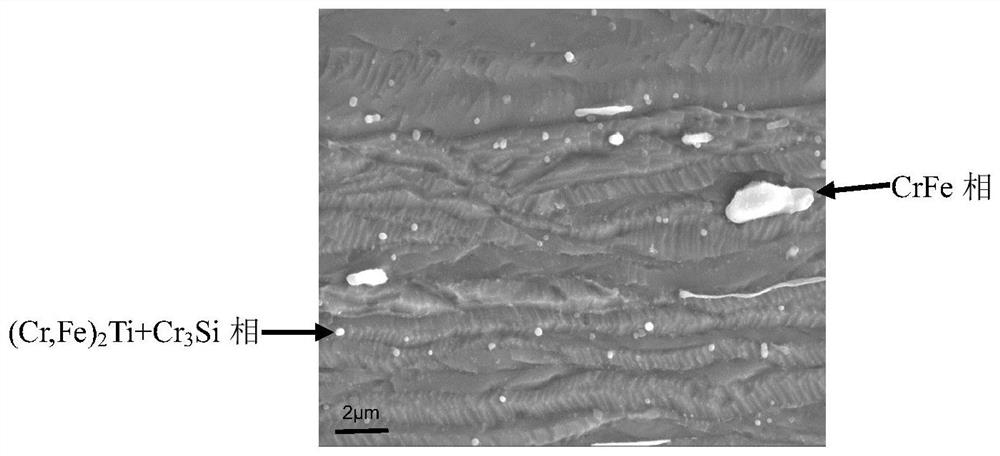

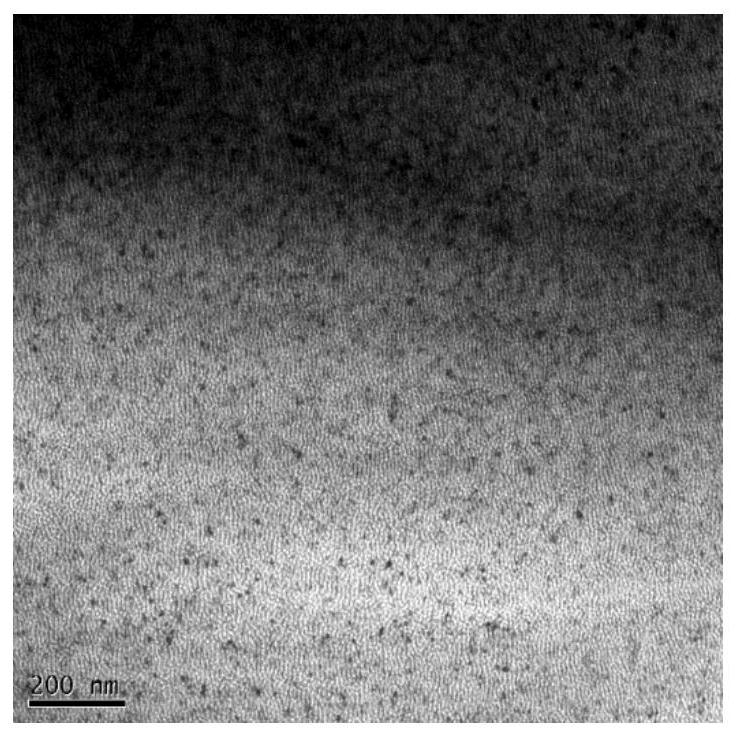

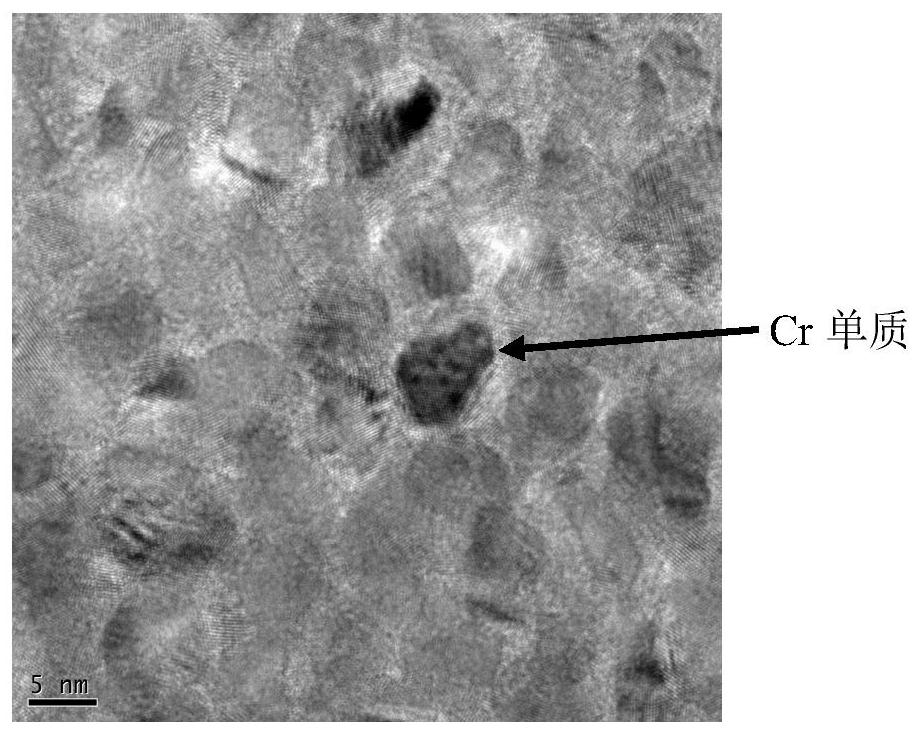

The invention discloses a high-strength high-conductivity copper alloy material. The high-strength high-conductivity copper alloy material comprises, by weight percentage, 0.3wt%-0.8wt% of Cr, 0.05wt%-0.5wt% of Fe, 0.05wt%-0.3wt% of Ti, 0.01wt%-0.1wt% of Si and the balance Cu and inevitable impurities. The high-strength high-conductivity copper alloy is prepared through the alloying design of Cr,Fe, Ti, Si and other elements and a thermo-mechanical treatment technology taking two-stage aging as a main process. By means of the control over the sizes and the densities of a CrFe phase, a (Cr, Fe)2Ti and Cr3Si composite precipitated phase and a Cr elementary substance phase in a microscopic structure of the alloy, the effects of strengthening the alloy and improving the conductivity of the alloy are achieved. The copper alloy material can be applied to large-scale integrated circuit lead frames, folding screens and other products, the yield strength of manufactured strips is 650MPa or above, the electric conductivity is 65%IACS or above, and the good high-temperature softening resistance is achieved.

Owner:NINGBO POWERWAY ALLOY PLATE & STRIP CO LTD +1

Device for bending wire

Owner:OMS MASCH CO LTD

Production method for cast rolling 1100 alloy aluminum foil for mobile-phone battery shell

ActiveCN104624647AImprove performanceGood bending properties and Vickers hardnessMetal rolling arrangementsMetallurgyAluminum foil

Provided is a production method for cast rolling 1100 alloy aluminum foil for a mobile-phone battery shell. The production processes of the production method comprise batching, smelting, cast rolling, cold rolling, recrystallization annealing, cold rolling, trimming, low temperature tempering and foil rolling. In the cold rolling process, blanks obtained by cast rolling are processed to be 3.0-4.0 mm by cold rolling and then recrystallization annealing is performed, one pass of large reduction cold rolling is performed on the blanks which are processed by recrystallization annealing, the pass processing rate is 40%-60%, and finally the blanks which are processed by large reduction cold rolling are rolled to the design thickness of the aluminum foil. According to the production method for cast rolling the 1100 alloy aluminum foil for the mobile-phone battery shell, the blanks are cold rolled to be 3.0-4.0 mm and then recrystallization annealing is performed, the internal grain sizes of the blanks which are processed by recrystallization annealing are increased, and the purpose of improving the performance of cast rolling materials can be achieved by using large reduction cold rolling for smashing the grains; the 1100 alloy aluminum foil obtained by the production method has good buckling performance and Vickers hardness, and can meet the usage requirements of materials for the mobile-phone battery shell.

Owner:中铝西南铝板带有限公司

Leather production technique

InactiveCN105296686AImprove bending resistanceImprove bending effectWax coatingsTanning treatmentEpoxyWax

The invention discloses a leather production technique. The leather production technique comprises the following steps: material selecting, i.e., selecting a leather material; re-tanning, i.e., re-tanning the leather material; base coating, i.e., carrying out prime coating by using a coating obtained by dissolving cationic wax and epoxy resin in water and carrying out drying by baking; tumbling ironing, i.e., performing tumbling ironing by use of a tumbling mill; middle coating, i.e., carrying out middle coating by using a coating obtained by dissolving leather-bonding epoxy resin in water and carrying out drying by baking; top coating, i.e., carrying out top coating by using a coating obtained by dissolving epoxy resin, acrylic resin, leather cracking resin and leather pigment in water and carrying out drying by baking; water washing, i.e., carrying out washing with water; dyeing, i.e., dyeing the surface of the leather material; fat-liquoring, i.e., carrying out fat-liquoring coating on the surface of the leather material; and drum milling, i.e., carrying out drum milling to obtain a finished leather product. The produced leather is good in flex resistance and not prone to crease in wearing and use processes.

Owner:徐秋苹

Bending machine

The invention relates to the technical field of hoisting devices, in particular to a bending machine which comprises a rack, wherein a platen is arranged at the upper end of the rack, a motor reducing gear is arranged in the middle of the platen, the output end of the motor reducing gear is connected with a chain tensioning lead screw, the chain tensioning lead screw is connected with a divider, a turntable is arranged at the upper end of the divider, clamp assemblies are evenly distributed at the upper end of the turntable, a bending assembly and a probe assembly are arranged on the outer periphery of the turntable, and a withstand voltage tester and a control box which pass through an upper enclosure structure are arranged at the outer edge of the platen. When the bending machine is used, the control box controls the clamp assemblies to clamp workpieces, the motor reducing gear drives the turntable, the clamp assemblies rotate to the bending assembly to perform bending processing for the workpieces, after bending processing, the motor reducing gear drives the turntable to rotate to be below a blanking mechanical arm assembly to demount the bent workpieces, and the operation is cycled. Therefore, the bending machine has the advantages of being good in one-time bending effect, high in production efficiency, time-saving, labor-saving and low in cost.

Owner:DELIX SUZHOU AUTOMATION MACHINE & TOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com