Patents

Literature

299 results about "Dodecanedioic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dodecanedioic acid (DDDA) is a dicarboxylic acid mainly used in antiseptics, top-grade coatings, painting materials, corrosion inhibitors, surfactants, and engineering plastics such as nylon 612 . Experimental work with dodecanedioic acid in type 2 diabetic patients has demonstrated that IV infusion helps to maintain normal blood sugar and energy levels without increasing the blood glucose load in the process.

Human sweat malodor counteractant composition and process for using same

InactiveUS6379658B1Increase in level of perceived pleasantnessMalodor-reducing concentrationBiocideCosmetic preparationsFuranPropionate

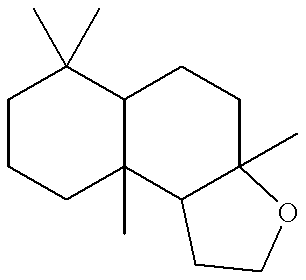

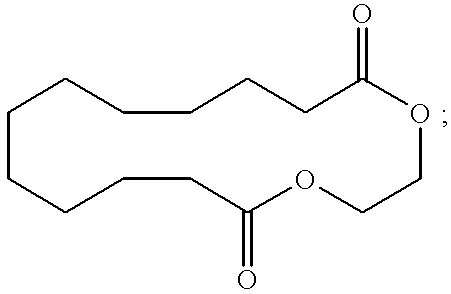

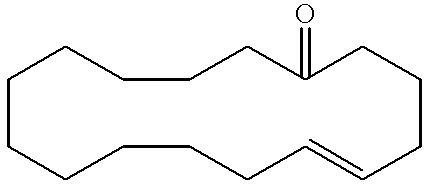

Described is a process and compositions for counteracting human sweat malodor. The compositions containing at least 10 weight percent of either 3,7-dimethyl-2,6-nonadienenitrile or 3,7-dimethyl-2,6-octadienenitrile. Additional ingredients may be added including napthyl methyl ether, methyl beta-naphthyl ketone, benzyl acetone, methanoinden propionates, methyl ionone, tetramethylnaphtho furan, ethylene glycol cyclic ester of dodecanedioic acid, 1-cyclohexadecen-6-one, 1-cycliheptadecen- 10-one, and corn mint oil. These compositions are applied to either fabric or a defined surface area of the human epidermis.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

Copolyamide powder and its preparation, use of copolyamide powder in a shaping process and mouldings produced from this copolyamide powder

ActiveUS20090236775A1Low viscosityHigh dimensional accuracyAdditive manufacturing apparatusElectric discharge heatingLaurolactamPolyamide

A task often encountered in very recent times is the rapid provision of prototypes. Particularly suitable processes are those based on pulverulent materials and in which the desired structures are produced layer-by-layer through selective melting and solidification. The invention provides the constitution, production and use of a copolyamide powder which was produced using the following monomer units: a) laurolactam or ω-aminoundecanoic acid, and also b) dodecanedioic acid, and either c) decanediamine or dodecanediamine, in shaping processes, and also to mouldings produced through a layer-by-layer process which selectively melts regions of a powder layer, using this specific powder. Once the regions previously melted layer-by-layer have been cooled and solidified, the moulding can be removed from the powder bed. The mouldless layer-by-layer processes for the production of components using the copolyamide powder result in simplified and more reliable conduct of the process and better recyclability.

Owner:EVONIK OPERATIONS GMBH

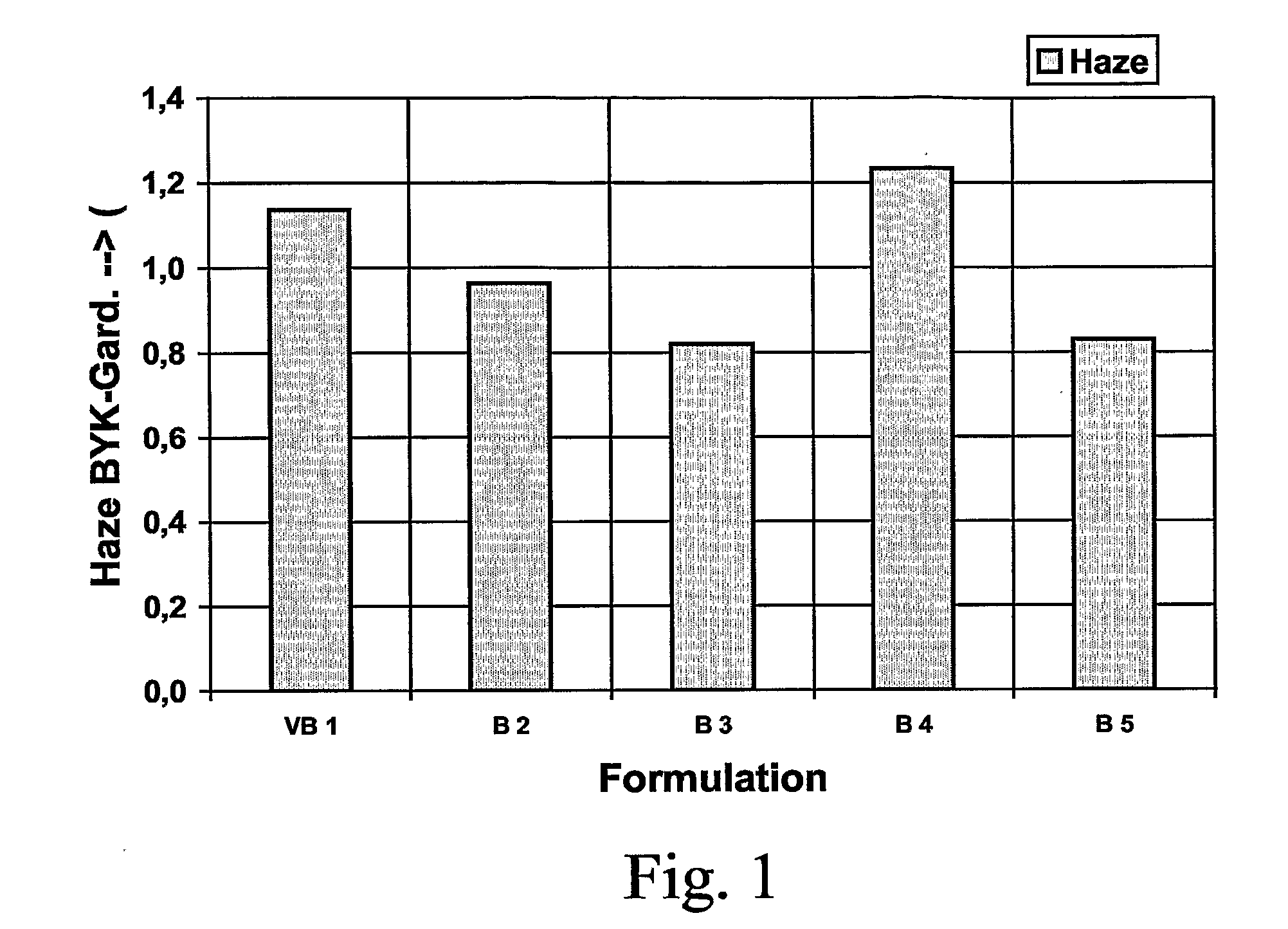

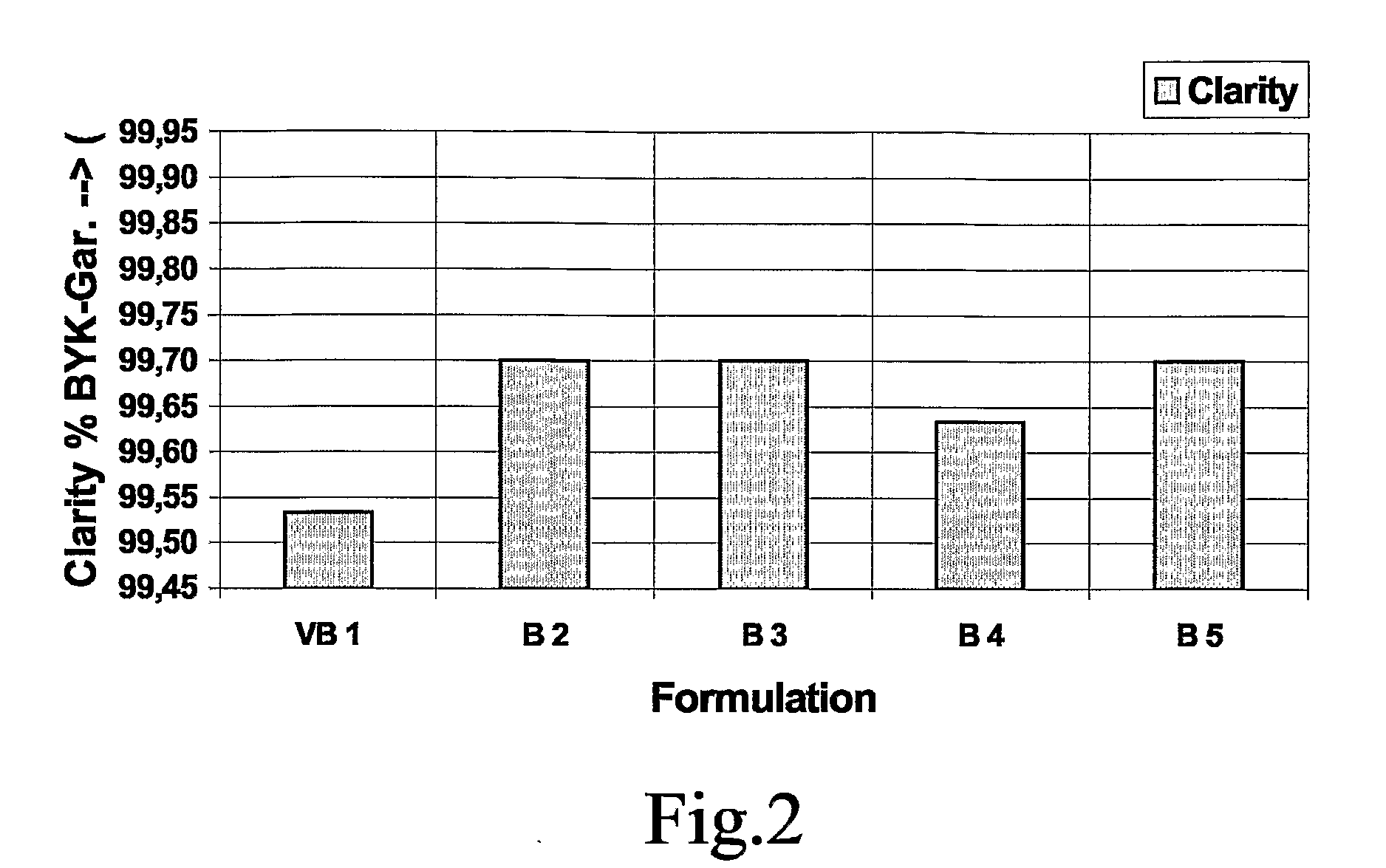

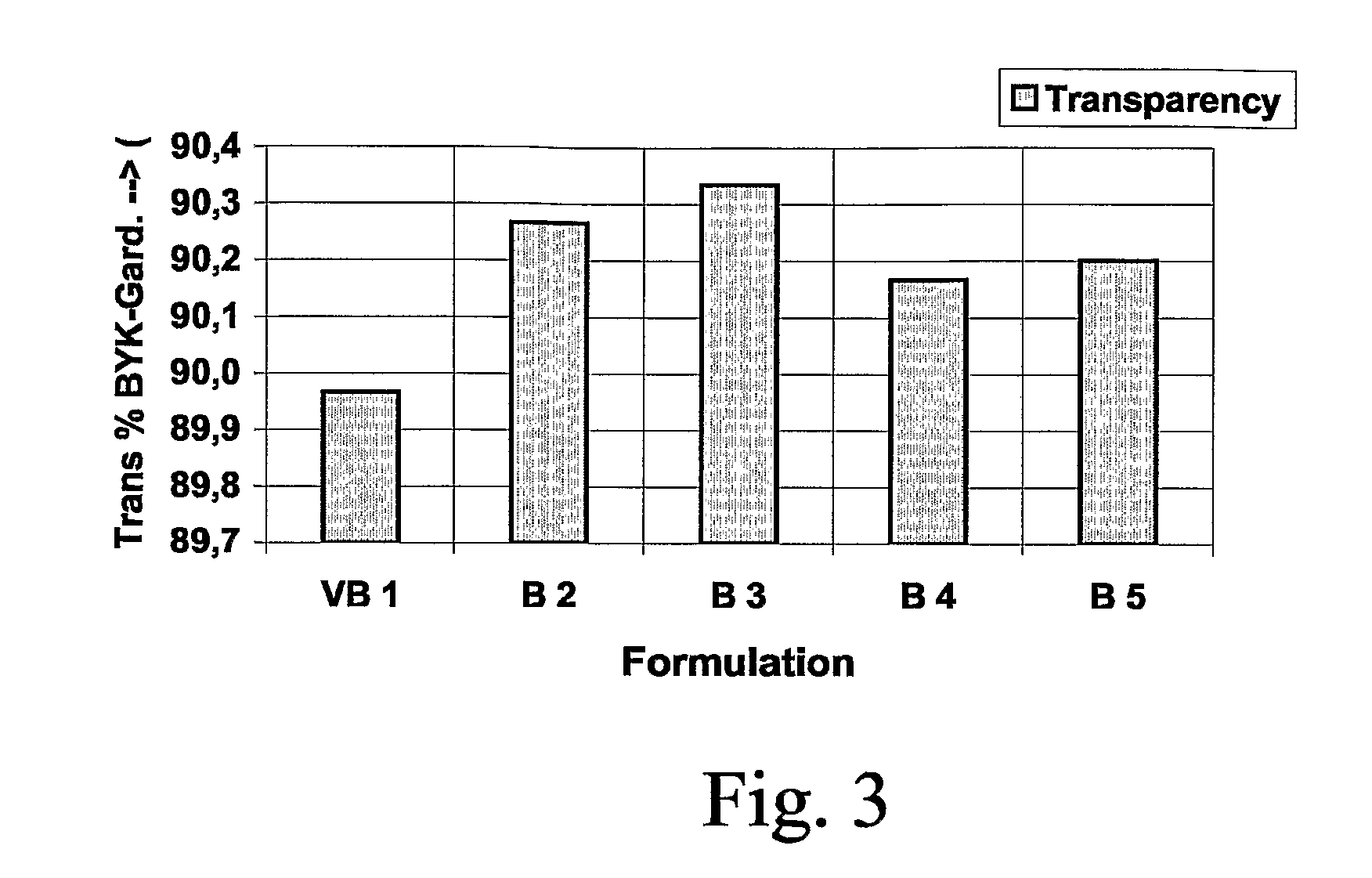

Materials composites of a moulded article of transparent or translucent dyeable plastics moulding compounds

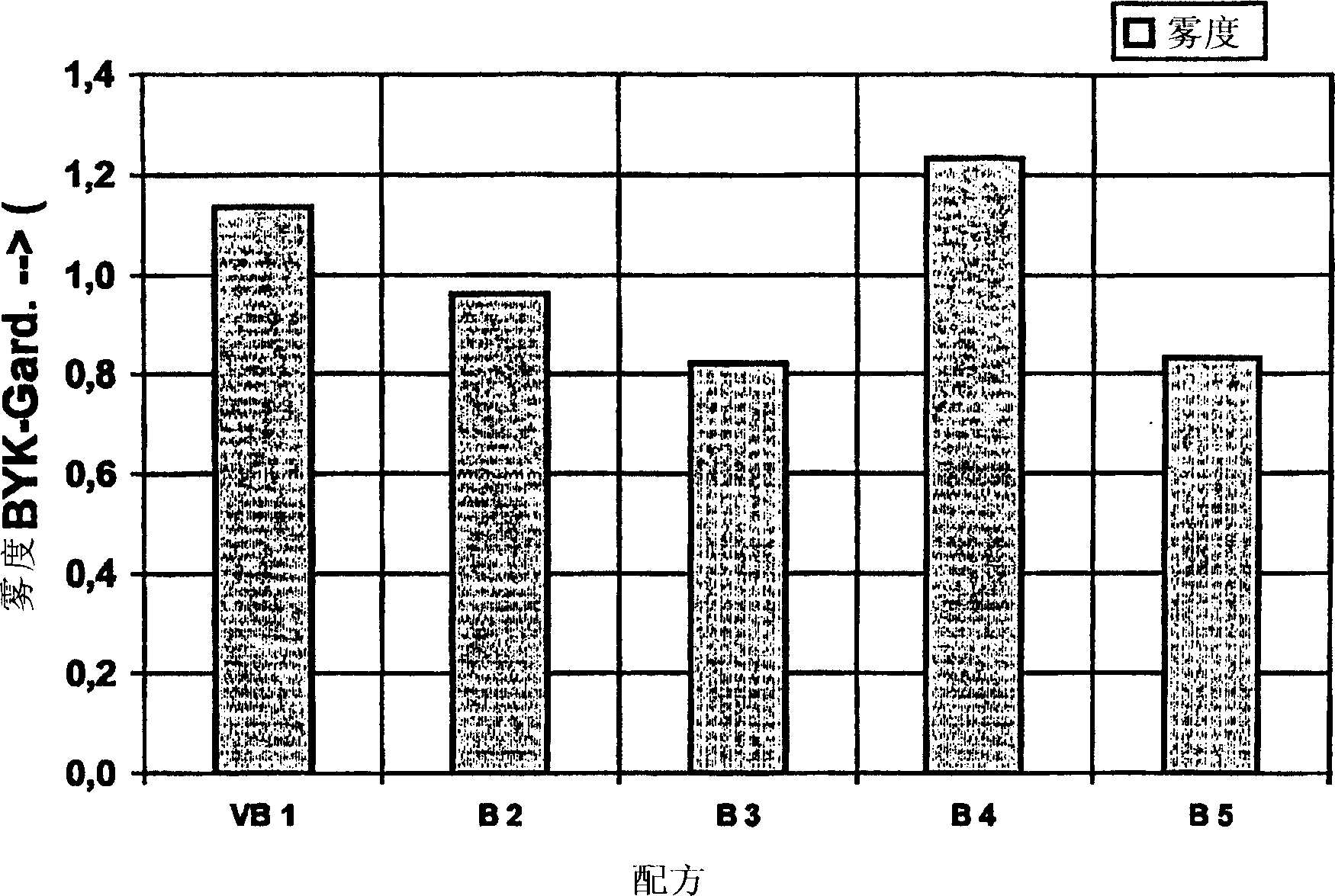

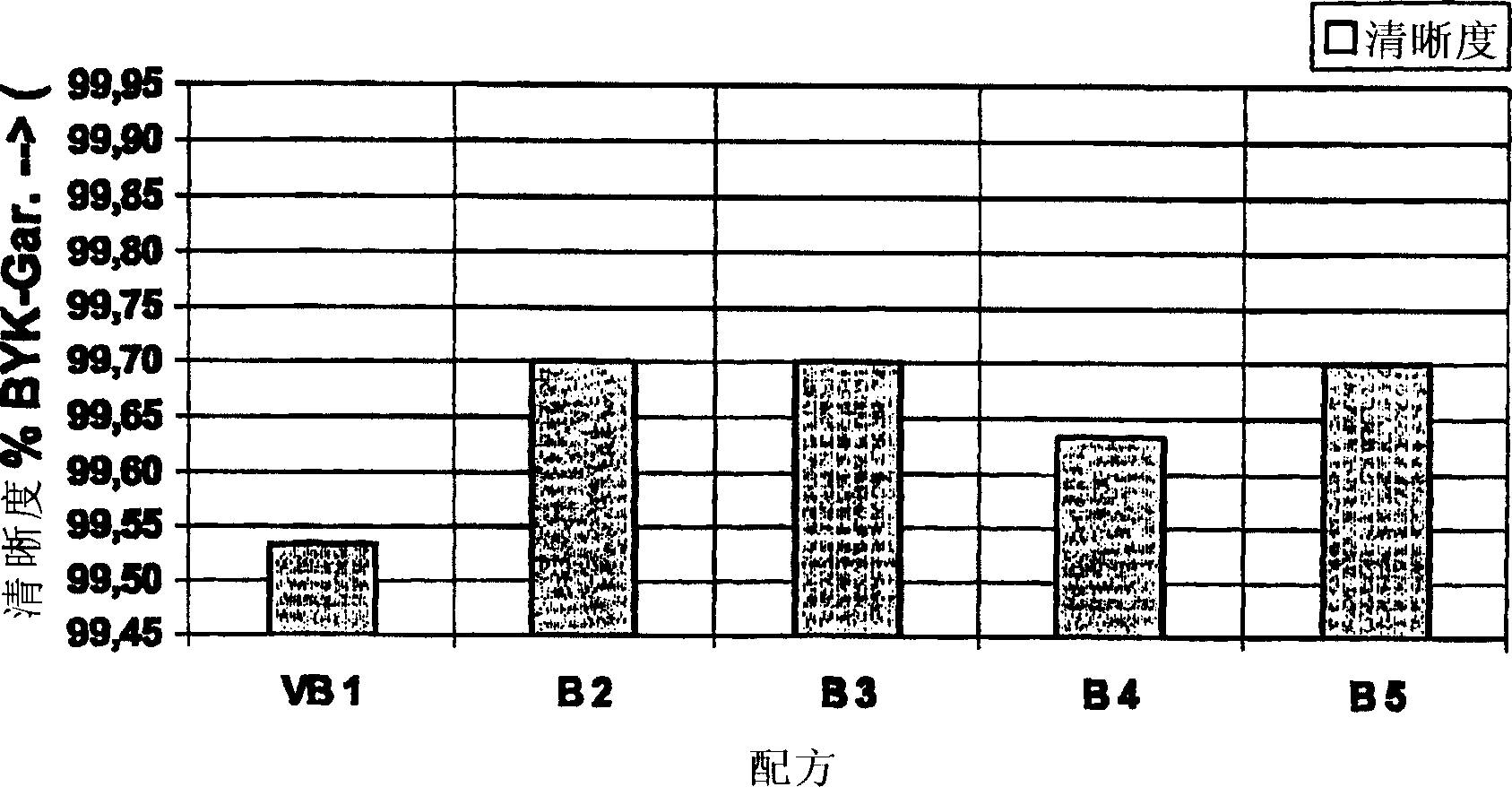

InactiveUS20070128442A1Large flow lengthPerfect purityLayered productsThin material handlingPolymer scienceStearic acid

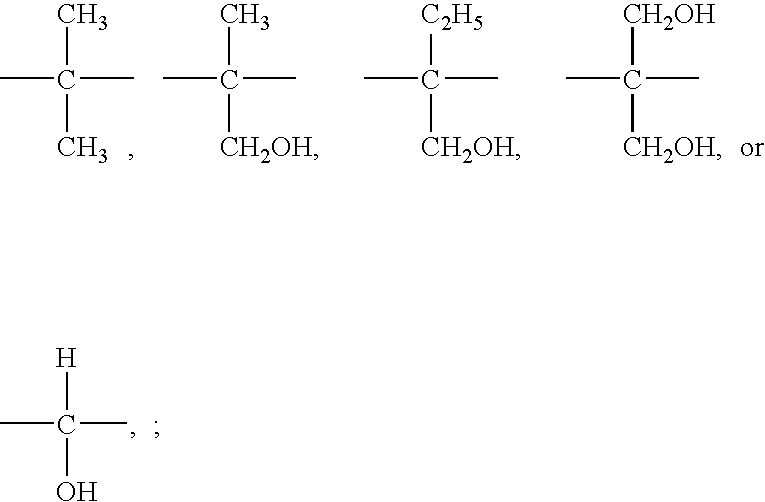

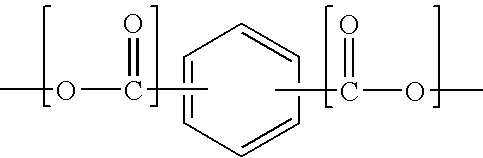

The present invention relates to materials composites of a moulded article of at least one transparent or translucent dyeable plastics moulding compound which moulded article is bonded to at least one transparent or translucent surface layer and / or to decorative films, functional films or coats or rubbers or other plastics, wherein the plastics moulding compound used for the manufacture of the moulded article, the surface layer or the other plastics contains in an amount of 0.01 to 5.0% by weight, preferably 0.01 to 2.0% by weight, each related to the total weight of the moulding compound, at least one lubricant selected from the group consisting of sorbitan esters, sebacic acid esters, dodecanedioic acid esters, docosanoic acid esters, glycerine, glycol, diethylene glycol, stearoyl amide, stearyl stearate, ethylene bissteroyl amide, octane pyrrolidone, and from the group consisting of non-polar paraffin oils and of tetracosanes, and wherein a permanent adhesion to the other plastics layers and / or sheets or coats or rubbers or other plastics is achieved.

Owner:EMS CHEM AG

Polyester polyols for polyurethane adhesives

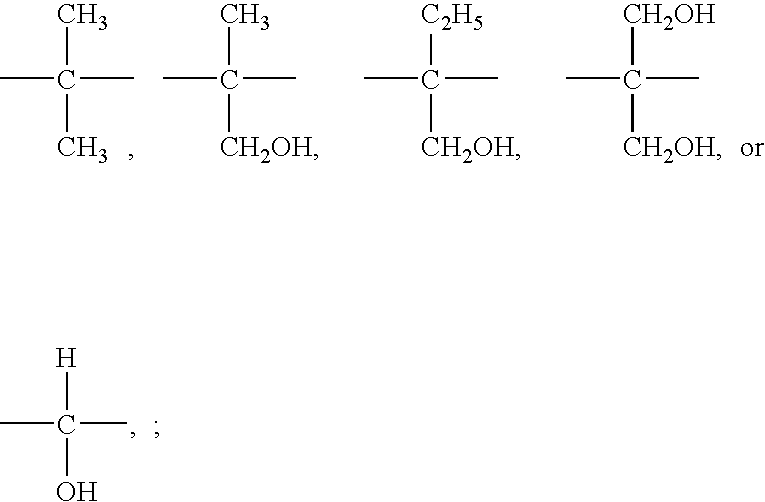

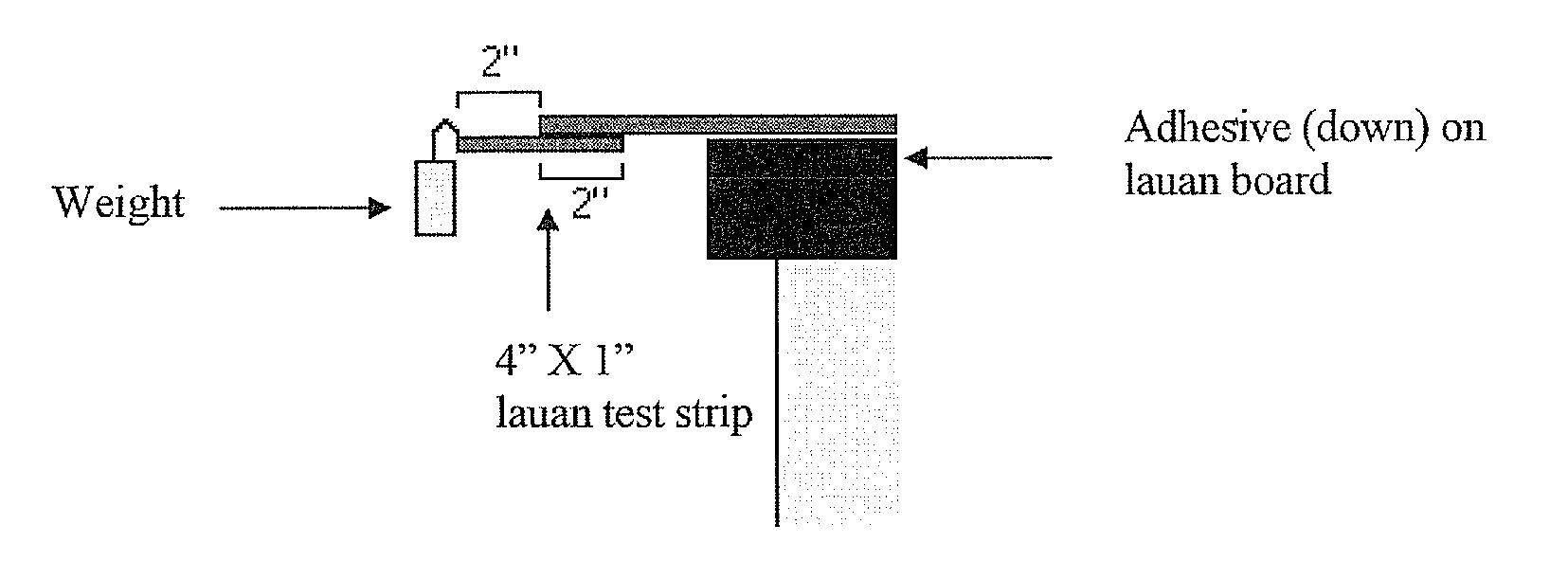

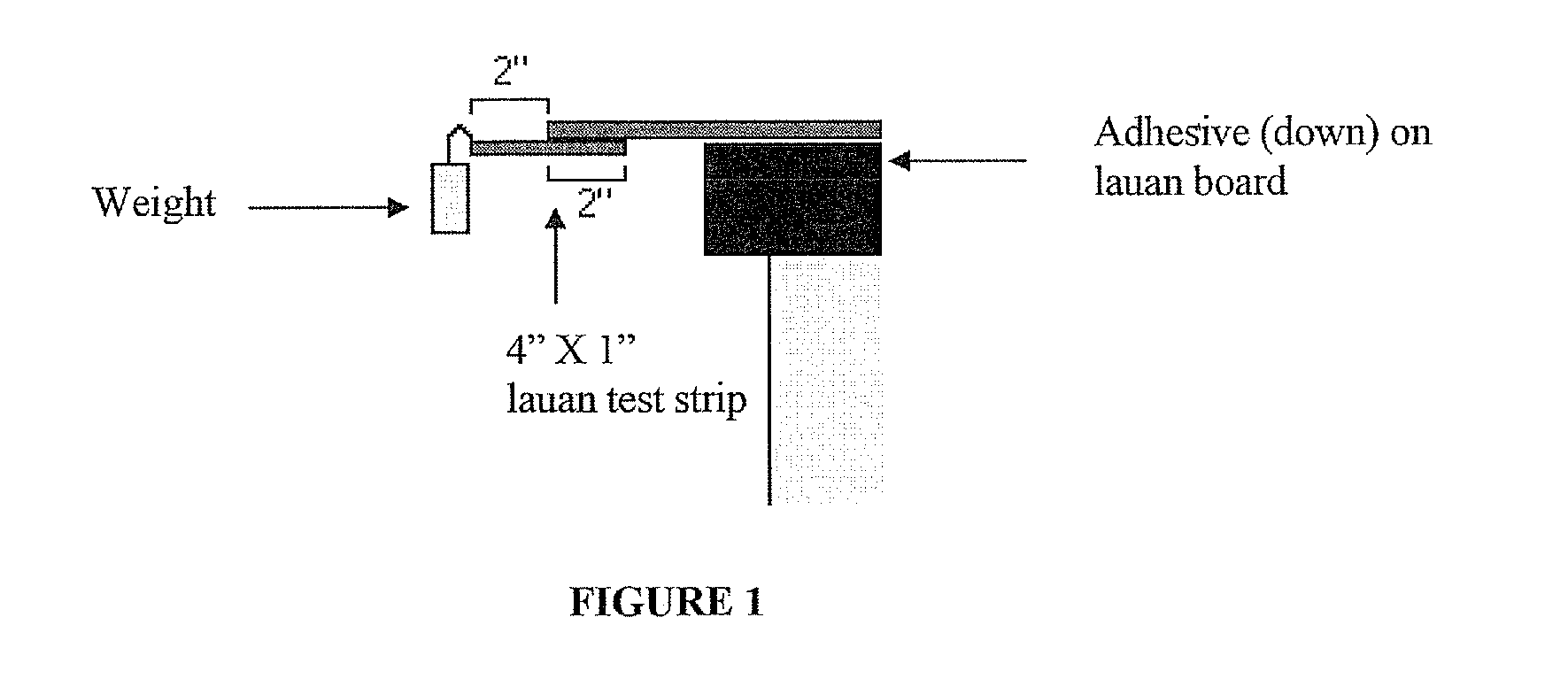

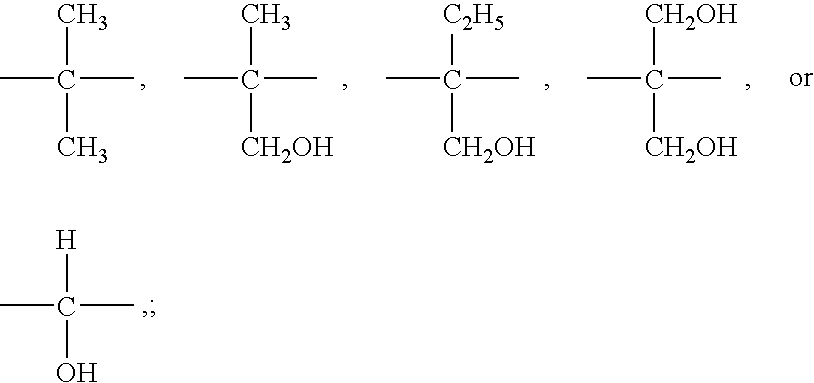

A polyester polyol prepared from a composition including a phthalic acid based material containing more than 10% by weight of ortho-phahalic or derivatives thereof, an aliphatic dicarboxylic acid (e.g., dodecanedioic acid), and a polyol (e.g., a glycol). A polyurethane adhesive, such as a polyurethane reactive hot-melt adhesive, is made using the polyester polyol, which exhibits improved initial bonding strength, shortened setting time, and ability to bond to low surface energy substrates such as ABS. The methods to prepare the polyester polyol and the polyurethane adhesive, and the method to use them are also disclosed.

Owner:OBRIEN MICHAEL E

Polyester Polyols for Polyurethane Adhesives

InactiveUS20100126664A1Improve adhesionHigh bonding strengthPolyureas/polyurethane adhesivesLaminationPolyesterPolymer science

A polyester polyol prepared from a composition including a phthalic acid based material containing more than 10% by weight of ortho-phthalic or derivatives thereof, an aliphatic dicarboxylic acid (e.g., dodecanedioic acid), and a polyol (e.g., a glycol). A polyurethane adhesive, such as a polyurethane reactive hot-melt adhesive, is made using the polyester polyol, which exhibits improved initial bonding strength, shortened setting time, and ability to bond to low surface energy substrates such as ABS. The methods to prepare the polyester polyol and the polyurethane adhesive, and the method to use them are also disclosed.

Owner:STEPAN COMPANY

Polyamide resin, composition containing polyamide resin, and molded articles of polyamide resin and composition

InactiveCN102131845AImprove heat resistanceExcellent melt retention stabilityLaurolactamPolymer science

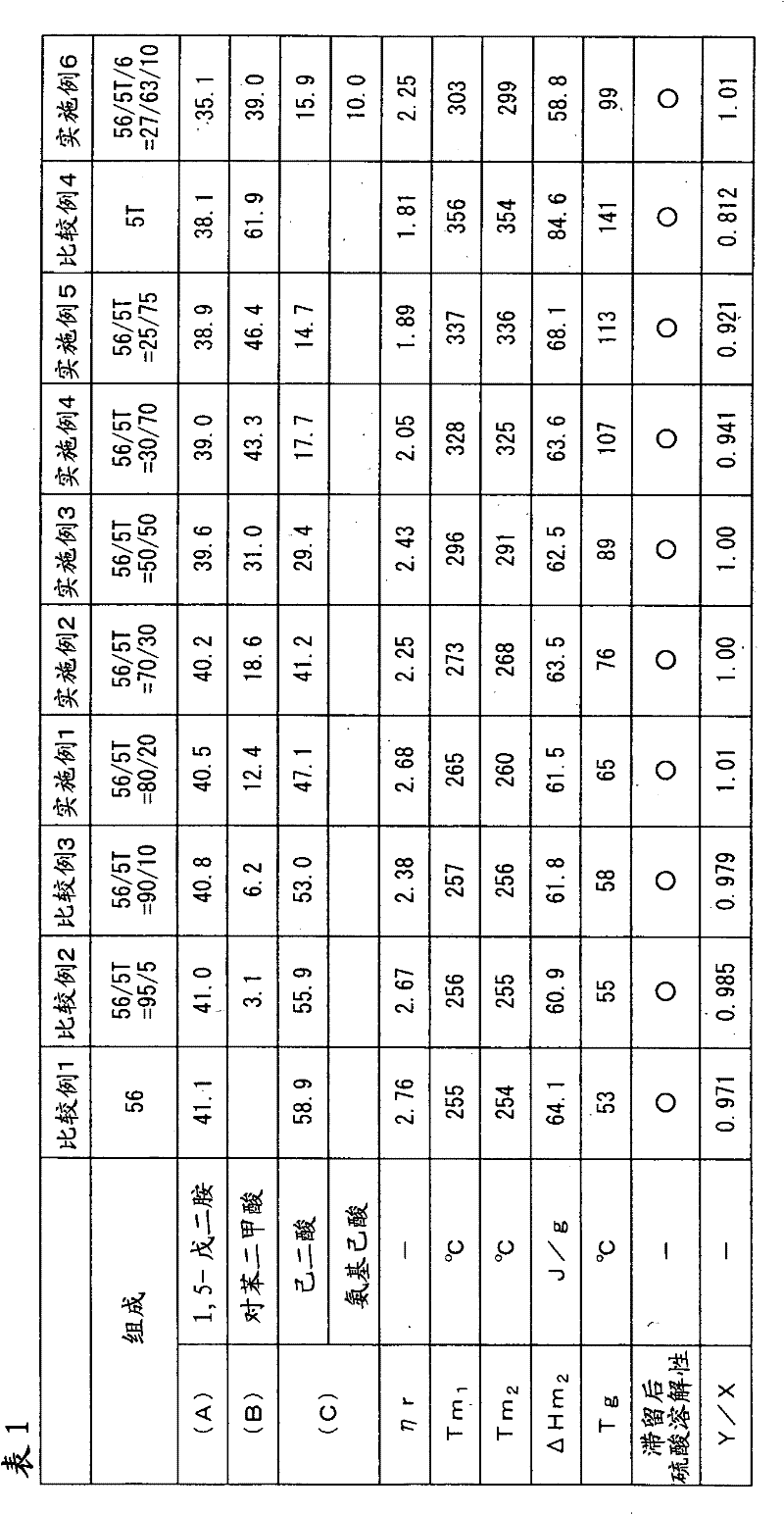

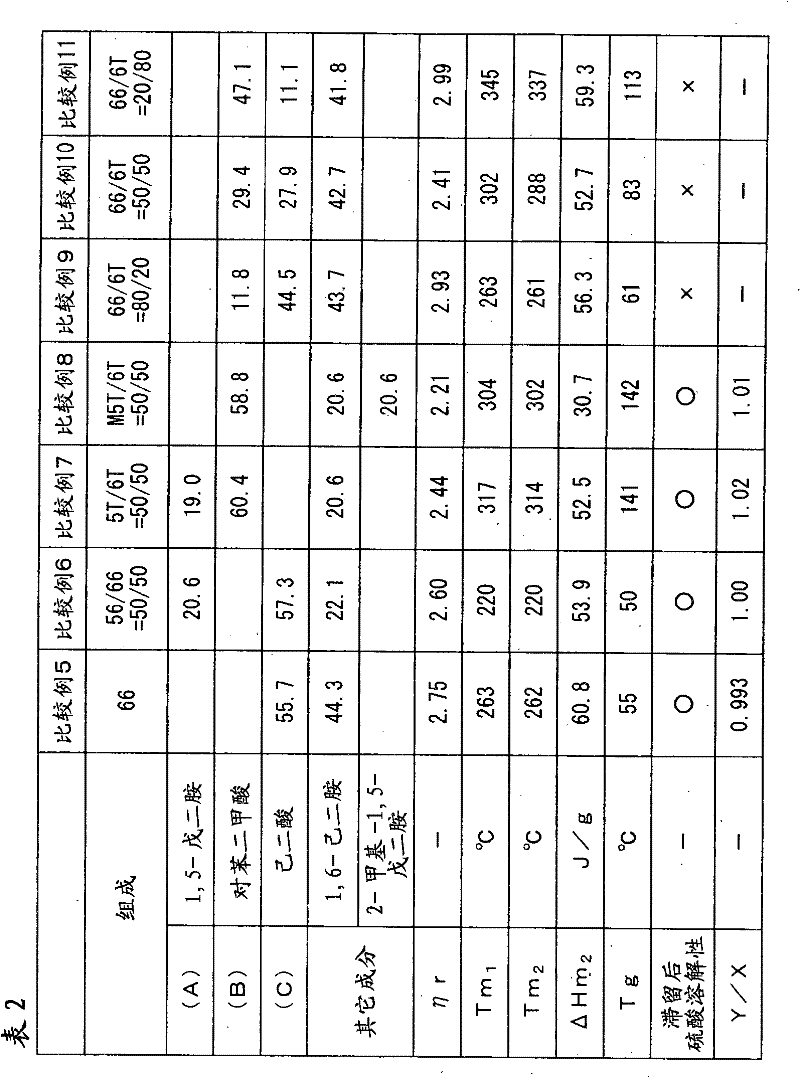

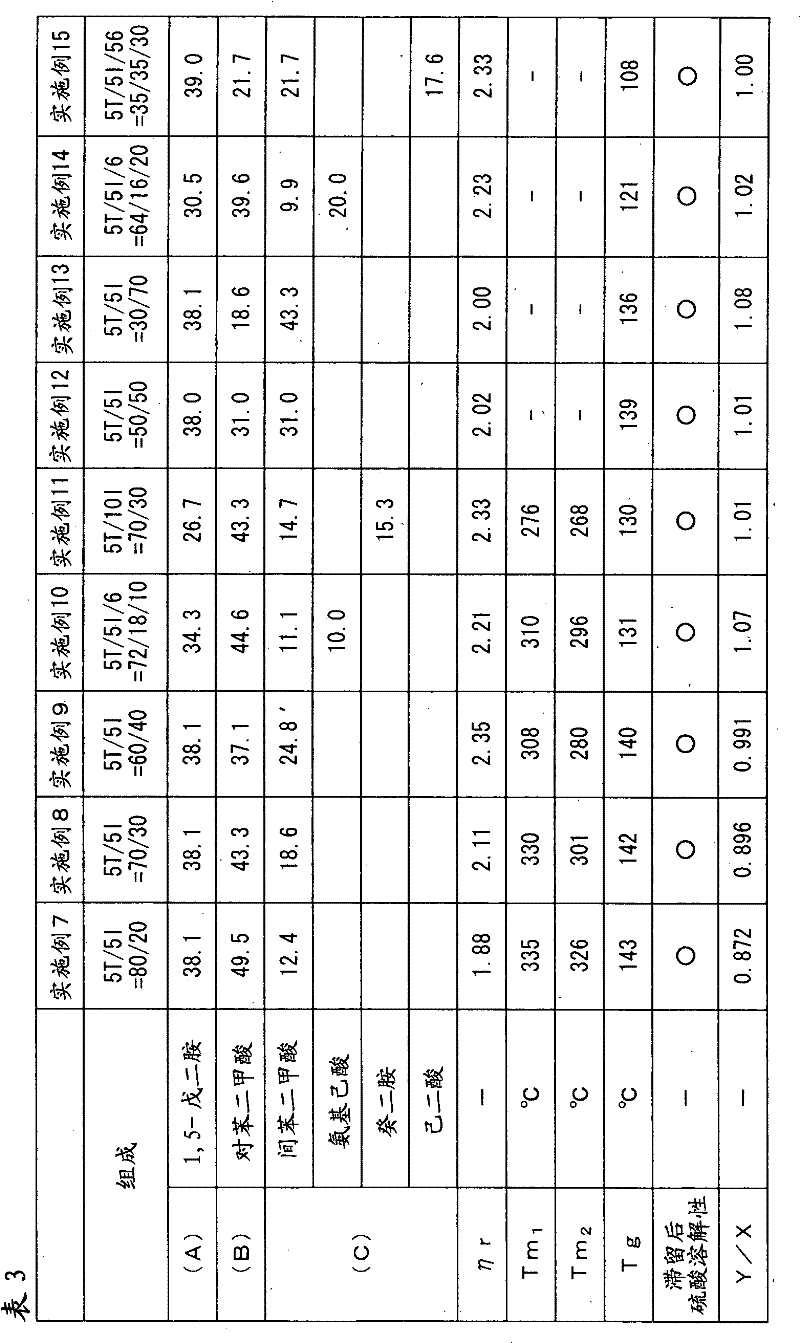

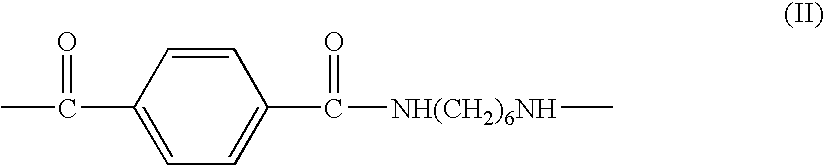

Disclosed is a polyamide resin which is produced by the polycondensation of (A) pentamethylenediamine, (B) terephthalic acid and / or a derivative thereof, and (C) at least one compound selected from adipic acid, azelaic acid, sebacic acid, undecanedioic acid, dodecanedioic acid, isophthalic acid, 1,9-diaminononane, 1,10-diaminodecane, 1,11-diaminoundecane, 1,12-diaminododecane, caprolactam, undecalactam, laurolactam, aminocaproic acid, 11-aminoundecanoic acid, 12-aminododecanoic acid, and derivatives of these compounds. In the polyamide resin, the ratio of a repeating unit derived from the component (C) is 10 to 50 wt% (inclusive) relative to the total weight of the polymer. A solution of the polyamide resin in 98% sulfuric acid, which contains the polyamide resin at a concentration of 0.01 g / ml, has a relative viscosity of 1.5 to 4.5 at 25 DEG C.

Owner:TORAY IND INC

Salt resistant polyamide compositions

Polyamides made from 1,6-hexanediamine, and the dicarboxylic acids 1,10-decandioic acid and / or 1,12-dodecanedioic acid, and terephthalic acid in specified proportions are particularly resistant to salt stressed (induced) corrosion cracking. This makes them particularly useful as vehicular parts which may be exposed to salts. Particularly when these polyamides contain tougheners and / or plasticizers they are especially useful for hoses and tubes.

Owner:EI DU PONT DE NEMOURS & CO

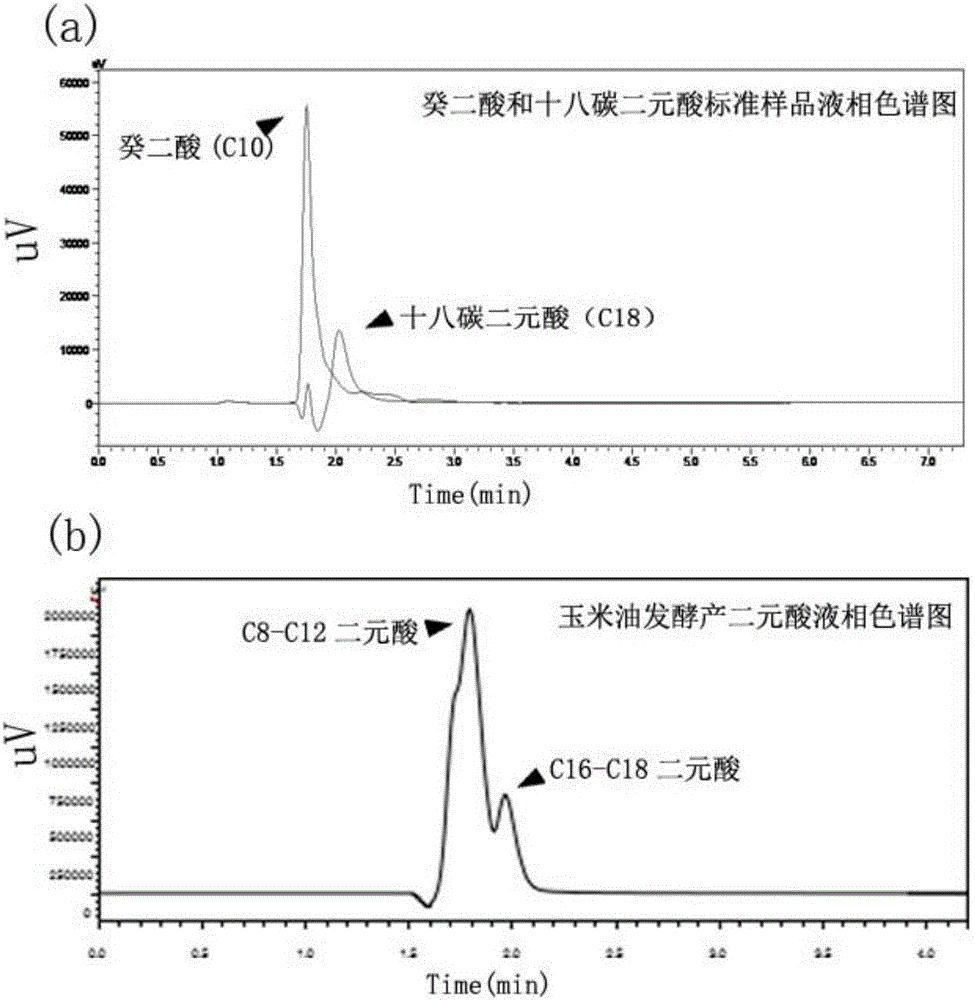

Method for fermentation-membrane separation combined production of long-chain dicarboxylic acid

ActiveCN104862348AHigh substrate conversion rateReduce inhibitionMicroorganism based processesFermentationAlkaneCandida viswanathii

The invention discloses a method for fermentation-membrane separation combined production of long-chain dicarboxylic acid and especially relates to a method for high yield production of dodecanedioic acid (DC12). The method comprises introducing a Candida viswanathii culture seed liquid into a liquid fermentation medium mixed solution which contains 5-40% (v / v) of C10-C18 n-alkane and 95-60% (v / v) of saccharic multielement substrate as a growth carbon source and has pH of 5.0-8.5, carrying out culture on the mixed solution under conditions of a temperature of 24-40 DEG C and ventilatory capacity of 0.1-3.0vvm for 42-194h, starting a fermentation-membrane separation combined device, returning the cells separated by the combined device into a fermentation cylinder, feeding the permeate liquid separated by the combined device into an extraction unit, preparing long-chain dicarboxylic acid, simultaneously, supplying a medium into the fermentation cylinder and carrying out fermentation. In n-dodecane transformation production of DC12, the method has an acid yield of 250g / L and an acid production rate of more than 1.6g / h.L, improves microbial density in fermentation, shortens a fermentation period, improves dicarboxylic acid production intensity and returns the unused n-dodecane into the fermentation unit.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Composite having two or more layers, including an EVOH layer

InactiveUS20060141188A1Solve the lack of resistanceSynthetic resin layered productsFlexible pipesLaurolactamHexamethylenediamine

The present invention provides a layered composite, which includes the following layers: (I) a layer I composition including: (a) from 0 to 80 part by weight of at least one polyamide selected from the group including PA6, PA66, PA6 / 66 and mixtures thereof; (b) from 0 to 100 parts by weight of at least one polyamine-polyamide copolymer that includes the following monomer units: (α) from 0.5 to 25% by weight, based on the weight of the polyamine-polyamide copolymer, of at least one polyamine having at least 4 nitrogen atoms and having a number-average molar mass Mn of at least 146 g / mol, and (β) at least one polyamide-forming monomer selected from the group including lactam, ω-aminocarboxylic acid, equimolar combination of diamine and dicarboxylic acid, and mixtures thereof; and (c) from 0 to 80 parts by weight of at least one polyamide selected from the group including PA11, PA12, PA612, PA1012, PA1212 and wherein, in the layer I, a total of the parts by weight of (a), (b) and (c) is 100; wherein within an entirety of (a) and (b), at least 20 parts by weight of the entirety include monomer units selected from the group including caprolactam, combination of hexamethylenediamine / adipic acid, and mixtures thereof; and wherein within an entirety of (b) and (c), at least 20 parts by weight of the entirety include monomer units selected from the group including ω-aminoundecanoic acid, laurolactam, combination of hexamethylenediamine / 1,12-dodecanedioic acid, combination of 1,10-decanediamine / 1,12-dodecanedioic acid, combination of 1,12-dodecanediamine / 1,12-dodecanedioic acid, and mixtures thereof; and (II) a layer II composition which includes at least one ethylene-vinyl alcohol copolymer.

Owner:EVONIK OPERATIONS GMBH

Salt resistant polyamide compositions

Polyamides made from 1,6-hexanediamine, and the dicarboxylic acids 1,10-decandioic acid, 1,12-dodecanedioic acid, or 1,14-tetradecanedioic acid and terephthalic acid in specified proportions are particularly resistant to salt stressed (induced) corrosion cracking. This makes them particularly useful as vehicular parts which may be exposed to salts. Particularly when these polyamides contain tougheners and / or plasticizers they are especially useful for hoses and tubes.

Owner:EI DU PONT DE NEMOURS & CO

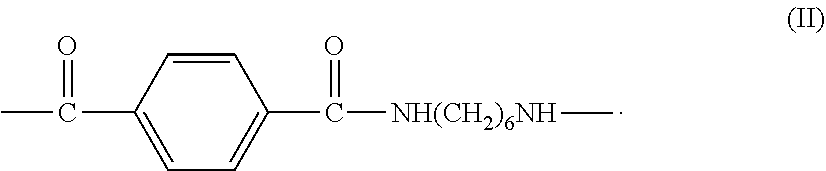

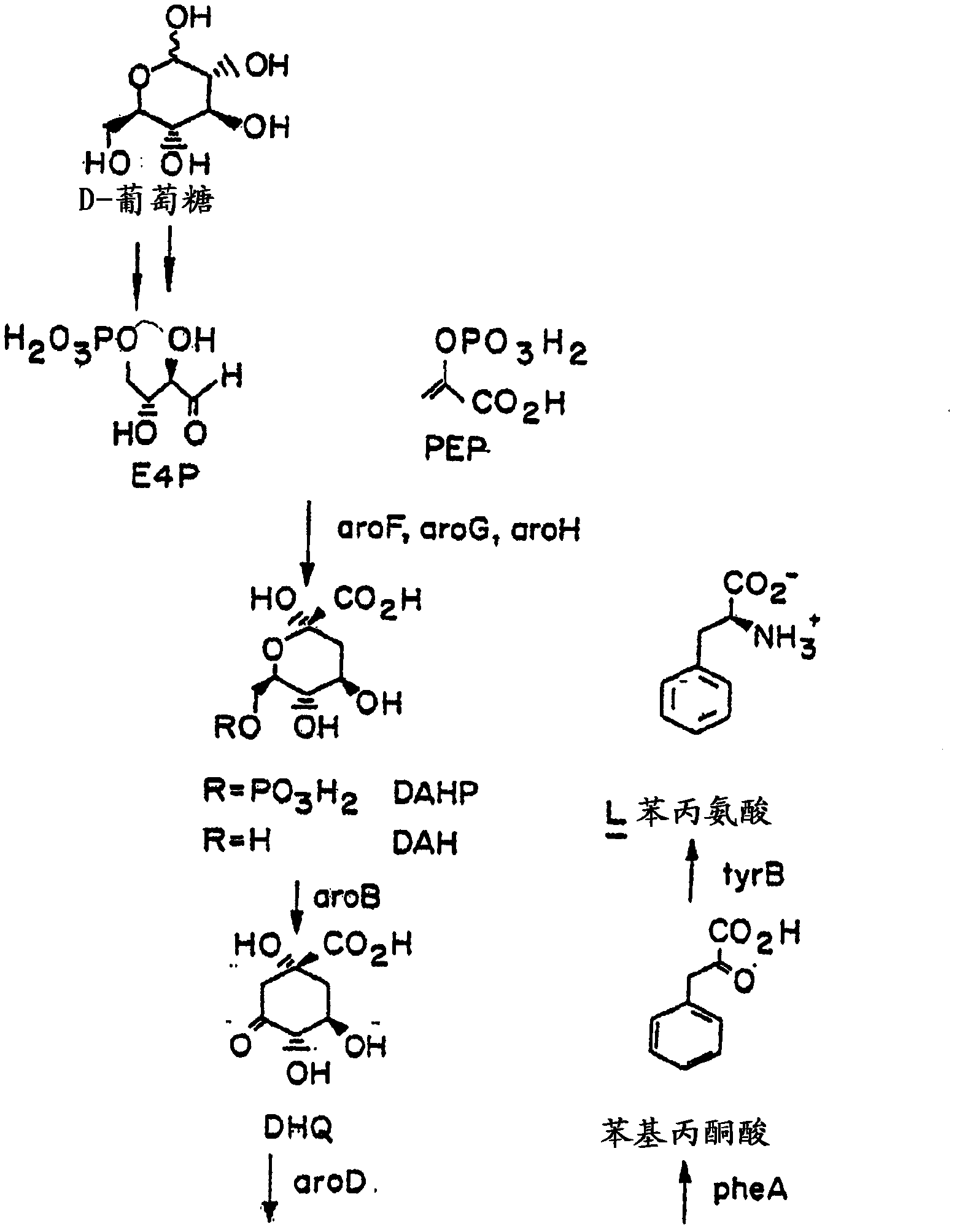

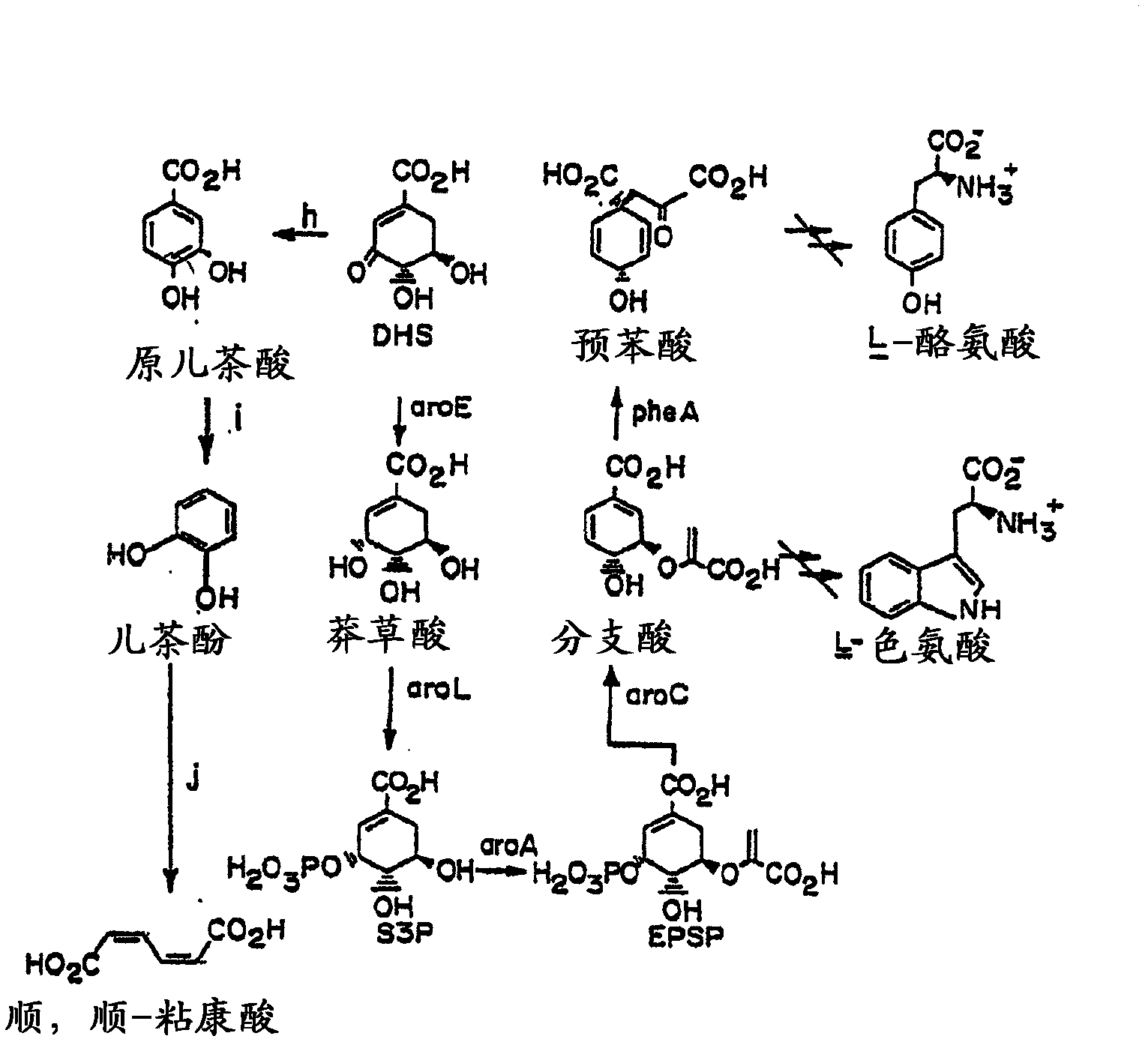

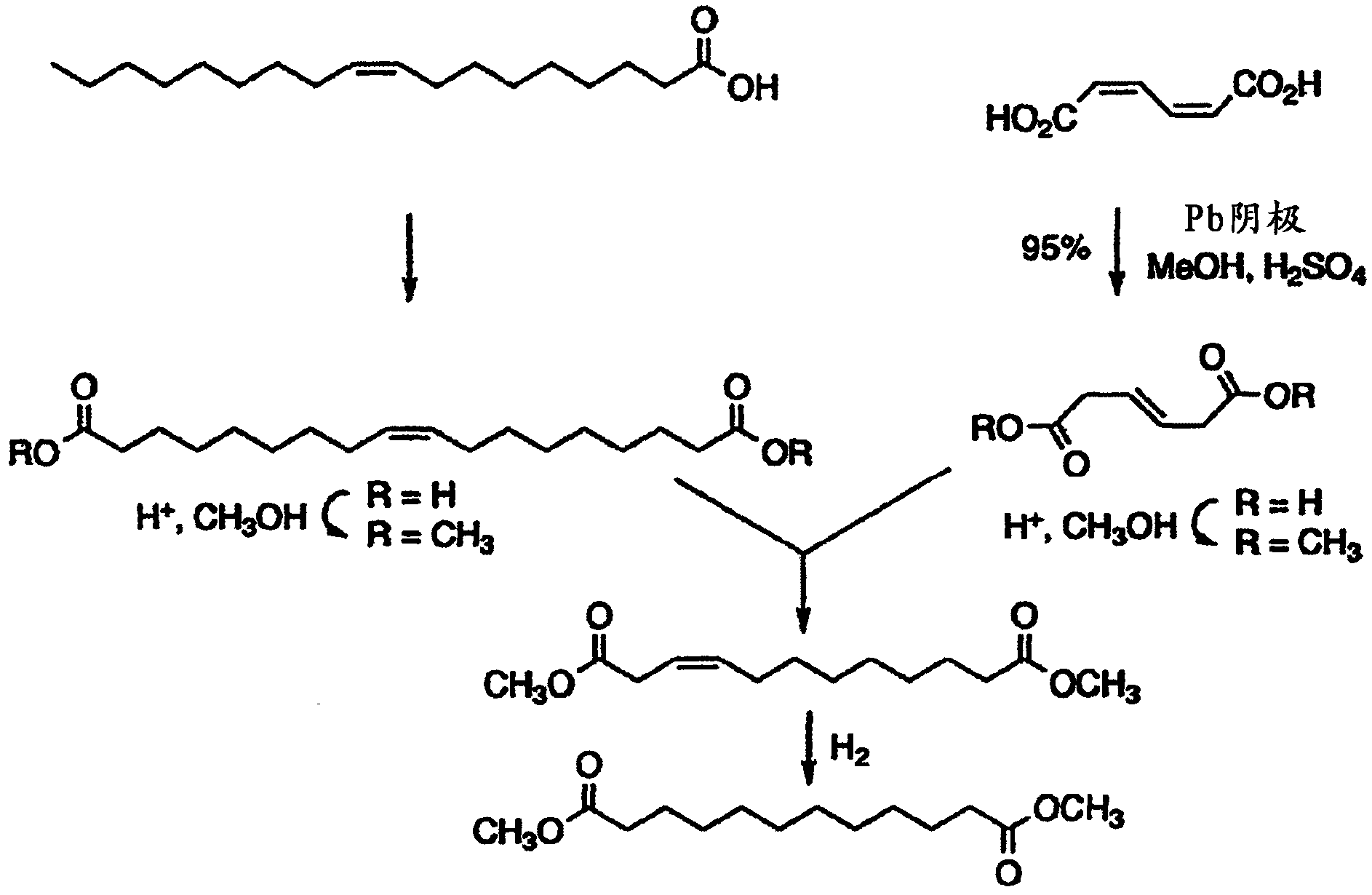

Methods for producing dodecanedioic acid and derivatives thereof

InactiveCN102498086AOrganic compound preparationCarboxylic acid esters preparationHexamethyldiamineMuconic acid

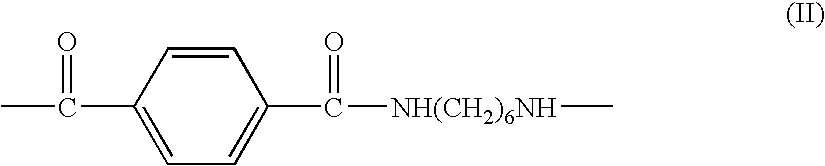

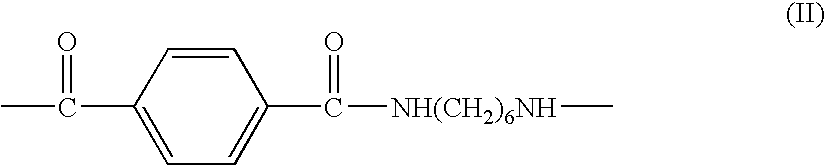

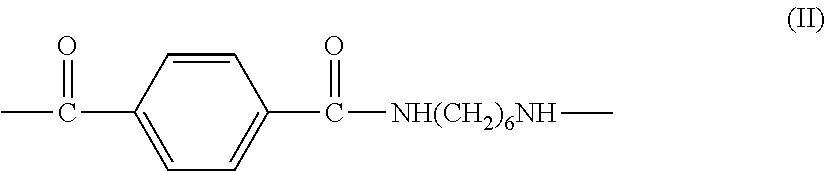

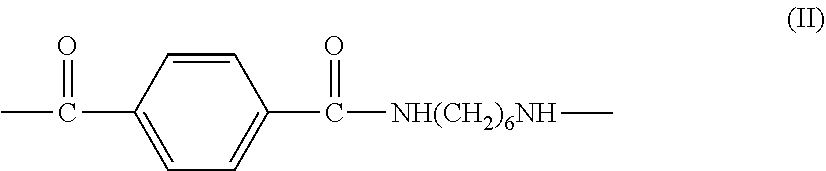

Methods for producing biosourced dodecanedioic acid and compositions comprising biosourced dodecanedioic acid are provided. In some embodiments, the method comprises first forming muconic acid biologically from a renewable carbon source, reducing the muconic acid to hexenedioic acid, and then reacting the hexenedioic acid with an unsaturated fatty acid, typically a Delta9 unsaturated fatty acid, in a metathesis reaction to produce dodecenedioic acid. Dodecenedioic acid is then reduced to dodecanedioic acid. Dodecanedioic acid is can be used to form polymers, such as polyamides. Examples of polyamides include nylon, such as nylon 6,12. Nylon 6,12 can be formed by reacting dodecanedioic acid with 1,6-hexamethylene diamine.

Owner:AMYRIS INC

Composition and method for diversion agents for acid stimulation of subterranean formations

InactiveUS6994166B2Effectively and temporarily divertLess permeableFluid removalFlushingCarboxylic acidSolid particle

It has been discovered that solid, particulate dicarboxylic acids are useful as diverting agents in methods for acidizing subterranean formations to improve the uniformity of the acid treatments (acid displacement) by diverting acid to intervals of relatively less permeability. Particularly suitable solid, particulate dicarboxylic acids include, but are not necessarily limited to, those insoluble in both aqueous and hydrocarbon liquids, but which are soluble in mutual solvents or alcohol blends. These acids may have melting points of from about 180 to about 300° F. (about 82 to about 149° C.), formula molecular weights of from 146 to 400, and mesh sizes of from about 20 mesh to about 400 mesh (about 841 to about 38 microns). Particular dicarboxylic acids that fit this description include, but are not necessarily limited to, dodecanedioic acid, undecanedioic acid, decanedioic acid, azelaic acid, suberic acid, and mixtures thereof.

Owner:SUPERIOR ENERGY SERVICES LLC

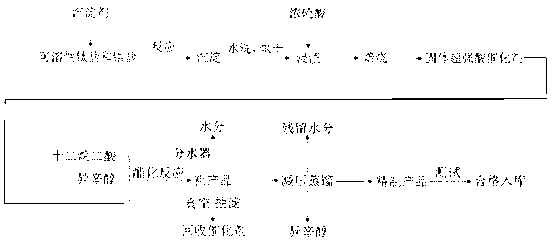

Method for purifying dodecanedioic acid

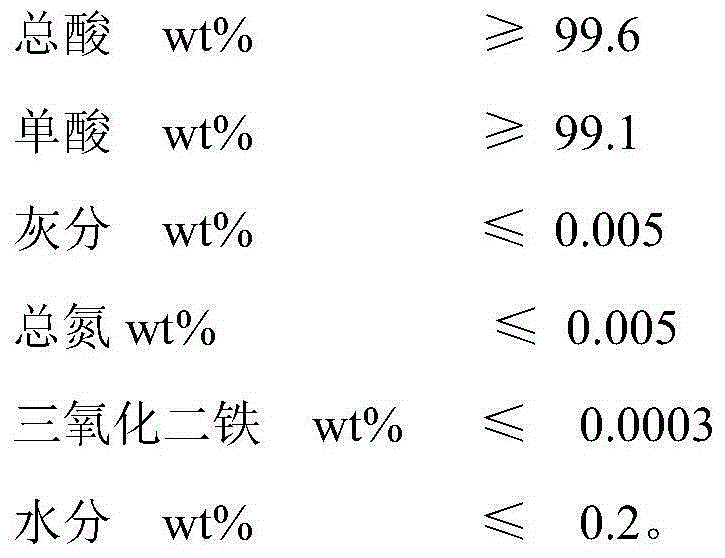

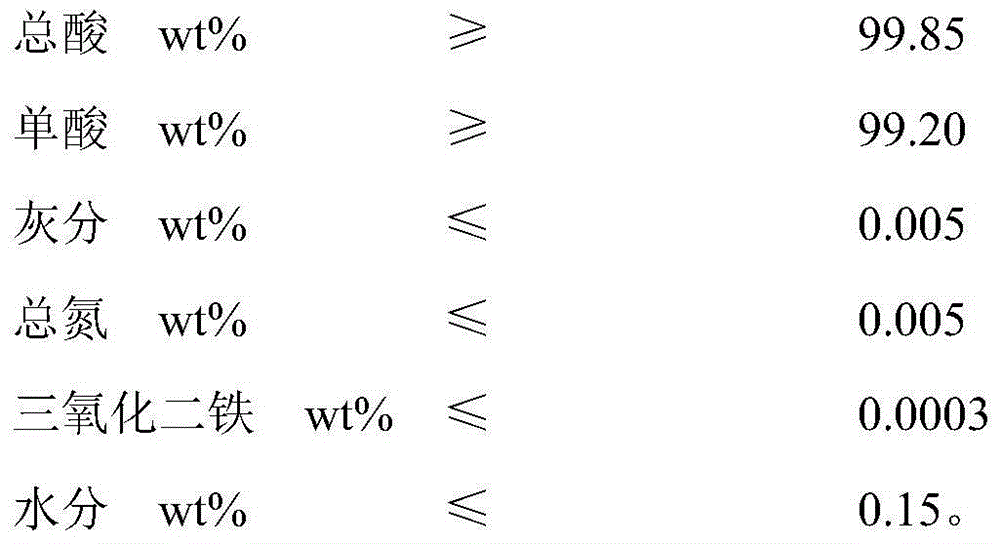

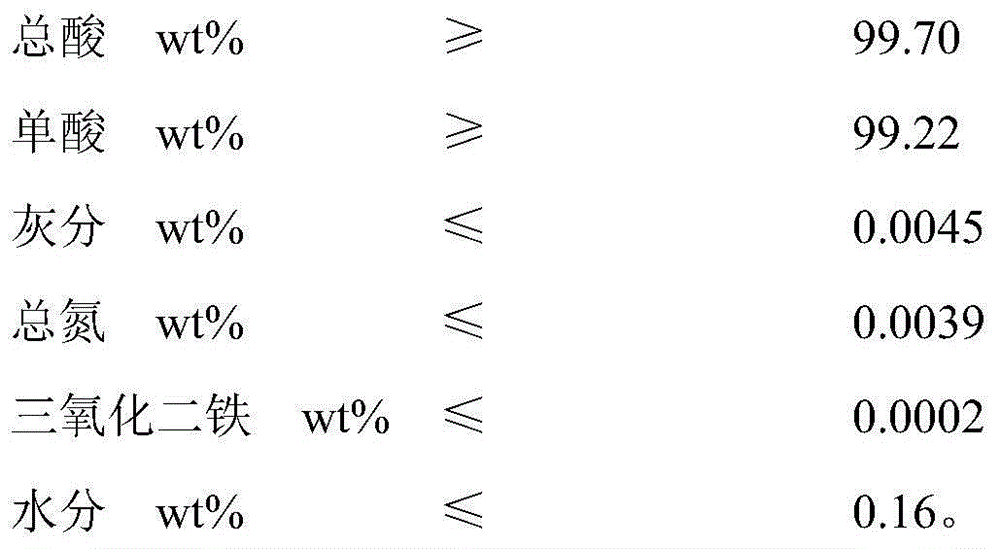

ActiveCN102329224ALow local supersaturationReduced nucleation rateCarboxylic compound separation/purificationCrystal growth rateMoisture

The invention discloses a method for purifying dodecanedioic acid, which comprises the following steps of: carrying out demulsification, filtration and decoloration on stop fermentation liquor of dibasic acid and adding pure water to dilute; adding purified water into a crystallization kettle, pumping diluted fermented clear liquid into a crystallizer, simultaneously filling dilute sulphuric acid with the mass concentration of 30 percent into a discharge hole of an external circulating pump and adding the dilute sulphuric acid into the crystallizer, and controlling the PH of reaction materials; ensuring crystal mush to flow to the lower part of a crystallization chamber through a central downcomer and then flow upwards, so that crystals with large granularities are enriched on the bottom layer of the crystallization chamber; and cooling the crystals outflowing from a discharge hole of the crystallizer by a cooler and carrying out filter pressing, washing and drying to obtain the dodecanedioic acid. Due to the adoption of the purifying method, the micro mixing effect is achieved by diluting local concentration of the reaction mass through the material circulating pump, the solution nucleation rate, the crystal growth rate and the aggregation rate are reduced, the moisture percentage and the impurity content of a filter cake are obviously reduced, the dried dibasic acid product has large and uniform particles, good glossy and high purify, and the continuity of the crystallizing process is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing long-chain binary acid through fermentation separation coupling

ActiveCN104862347AHigh substrate conversion rateReduce inhibitionMicroorganism based processesFermentationTO-18Alkane

The invention discloses a method for producing long-chain binary acid through fermentation separation coupling, in particular to a method of high-yield dodecanedioic acid (DC12). According to the technical scheme, the method includes the steps that candida viswanathii is cultivated into a seed solution which is led into 5-40% (v / v) n-alkane and 60-95% (v / v) liquid fermentation medium mixture, wherein the pH of the n-alkane ranges from 5.0 to 8.5, and 10 to 18 carbon atoms are contained in the n-alkane; a saccharic multielement substrate serves as a growth carbon source of the liquid fermentation medium mixture; mixing liquid is cultivated for 42 h to 194 h under the conditions that the temperature ranges from 24 DEG C to 40 DEG C, and the air passing amount ranges from 0.1 vvm to 3.0 vvm, a centrifugal fermentation separation coupling device or a plate frame filtering fermentation separation coupling device is started, cells passing through the separation coupling device are circulated back to a fermentation cylinder, and clear liquid passing through the separation coupling device enters an extraction link to prepare long-chain binary acid; and meanwhile the fermentation process is continuously carried out on a cultivation medium in a fermentation tank. The method is used for converting n-dodecane so as to produce the DC12, the produced acid reaches 240 g / L, and the acid production rate is larger than 1.5 g / h.L.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Production method of mixed binary acid with long carbon chain

ActiveCN102795984AReduce pollutionImprove efficiencyPreparation from carboxylic acid saltsHydroxy compound separation/purificationCarbon chainTower

The invention belongs to the technical field of solid waste recovery and regeneration, and in particular relates to a production method of mixed binary acid with a long carbon chain. The method comprises the following steps of: with heavy constituents remained after ethanol obtained in the dodecanedioic acid refining process is recovered as raw materials, enabling the heavy constituents to react with and a superfluous alkali solution at the temperature of 95-100 DEG C to generate sodium binary acid with a long carbon chain and ethanol; recovering the ethanol in the reaction process by using an alcohol fog recovery tower; and after the reaction is ended, carrying out aftertreatment on the obtained sodium salt to obtain the mixed binary acid with the long carbon chain. According to the invention, the heavy constituents remained after the ethanol obtained in the dodecanedioic acid refining process is recovered as raw materials and reacts with the superfluous alkali solution to generate the binary acid with the long carbon chain, and thus not only are wastes utilized, but also the environment pollution is reduced, and the benefit is increased.

Owner:山东广通新材料有限公司

Method for refining dodecanedioic acid

ActiveCN102795989AAvoid product qualityReduce contentCarboxylic compound separation/purificationAlcoholCentrifugation

The invention relates to a method for refining dodecanedioic acid and belongs to the technical field of preparation of chemical products. According to the method, the dodecanedioic acid is refined by using dodecanedioic acid produced by a biological fermentation method or an enzyme method as a raw material and alcohol as a solvent. The method particularly comprises the following steps: mixing the dodecanedioic acid and the alcohol; heating and decoloring, wherein heat is not preserved after heating to a certain temperature in the decoloring process; directly filtering; cooling, crystallizing and centrifuging the filtrate to obtain a centrifugal material; washing the centrifugal material with the alcohol; performing secondary centrifugation; and vacuum drying to obtain the dodecanedioic acid refined product. According to the method, the problem about the product quality of the dodecanedioic acid refined by the alcohol is solved, the single acid content and the total acid content of the dodecanedioic acid product are increased, and the ester content is reduced.

Owner:山东广通新材料有限公司

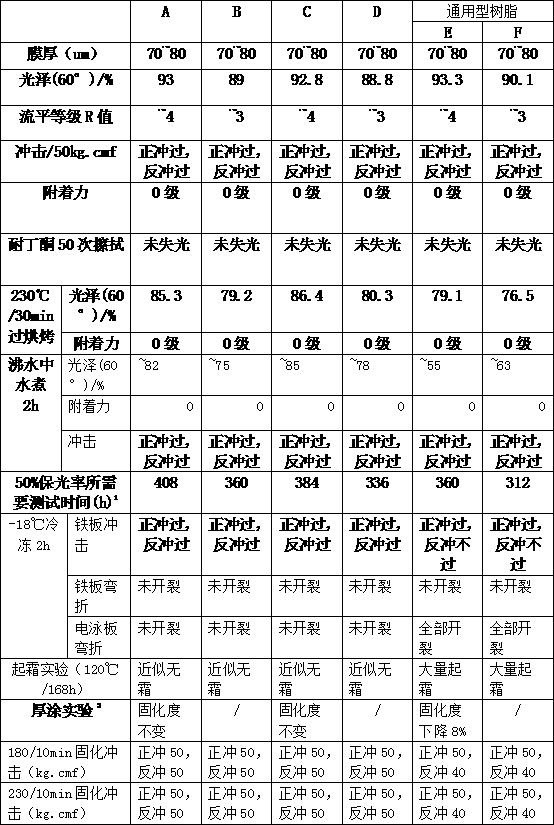

Polyester resin for engineering machinery

InactiveCN110511365AImprove mechanical propertiesGood flexibilityPowdery paintsPolyester coatingsCrack resistanceAntioxidant

The object of the present invention is to provide polyester resin for engineering machinery, the polyester resin comprises polyhydric alcohol, aromatic polybasic acid, a branching agent, an acidolysisagent, an esterification catalyst, an antioxidant and a curing accelerator, the acidolysis agent comprises one or a mixture of at least two of isophthalic acid (IPA), adipic acid (ADA), 1,4-cyclohexanedicarboxylic acid (CHDA), fumaric acid (FCC), trimellitic anhydride (TMA), succinic acid (BA) and dodecanedioic acid (DDDA), more preferably comprises at least the IPA and the ADA; the polyester resin can be combined with curing agents (TGIC, hydroxyalkylamide or blocked isocyanate), curing accelerators, pigments, fillers, leveling agent, degassing agents and the like to prepare powder coatingsfor engineering machinery. Compared with conventional polyester resin, the polyester resin has excellent mechanical properties and flexibility, water boiling resistance, weather resistance, low temperature frost resistance, thick coating resistance and unchanged performance when the curing temperature is changed, and crack resistance under freezing impact and bending of iron plates and electrophoresis plates at-18 DEG C, and the polyester resin is very suitable for coating in the field of engineering machinery.

Owner:ANHUI SHENJIAN NEW MATERIALS

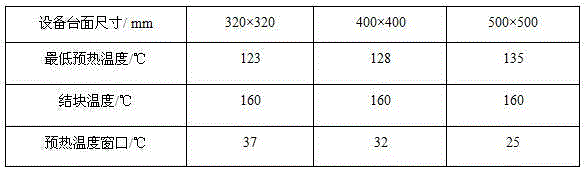

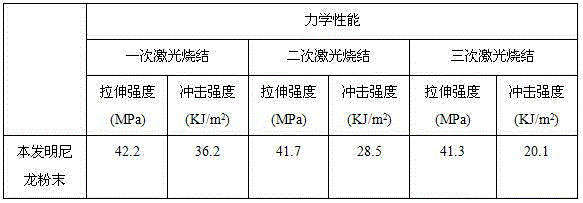

Low-temperature nylon powder material for selective laser sintering and preparation method thereof

ActiveCN104910616AReduced precision requirementsImprove recycling ratesAdditive manufacturing apparatusAdditive manufacturing with solidsSelective laser sinteringPolyethylene glycol

The invention relates to the technical field of polymer composites and particularly relates to a low-temperature nylon powder material for selective laser sintering. The low-temperature nylon powder material mainly comprises nylon 12 particles, dodecanedioic acid, double amino-terminated polyethylene glycol, deuterated trifluoroacetic acid, an antioxidant, a solvent, a nucleating agent, a plasticizer and a silane coupling agent. The low-temperature nylon powder material is prepared by the following steps: uniformly mixing the dodecanedioic acid and nylon 12 particles and putting into a reaction kettle; adding the double amino-terminated polyethylene glycol and deuterated trifluoroacetic acid into the reaction kettle; heating and starting stirring to obtain a product; putting the product together with the antioxidant, solvent, nucleating agent, plasticizer and silane coupling agent into the reaction kettle, and closing the kettle with a cover; vacuumizing the reaction kettle and introducing nitrogen displacement for protection; starting stirring and reducing the temperature of the kettle body to room temperature; taking out the materials, drying and performing ball milling; and drying the powder to obtain powder with good sphericity and fluidity. The low-temperature nylon powder material provided by the invention has the characteristics of low preheating temperature, wide preheating window, good aging resistance and adaptability to table boards of various specifications.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

Polyamide resin, composition containing the polyamide resin, and molded articles of the polyamide resin and the composition

InactiveUS20110105683A1Improve heat resistanceImprove stabilityNon-fibrous pulp additionPaper/cardboardLaurolactam12-aminododecanoic acid

Disclosed is a polyamide resin which is produced by the polycondensation of (A) pentamethylenediamin, (B) terephthalic acid and / or a derivative thereof, and (C) at least one member selected from adipic acid, sebacic acid, undecanedioic acid, dodecanedioic acid, isophthalic acid, 1,9-diaminononane, 1,10-diaminodecane, 1,12-diaminododecane, caprolactam, undecalactam, laurolactam, aminocaproic acid, 11-aminoundecanoic acid, 12-aminododecanoic acid, and derivatives of these compounds. In the polyamide resin, the ratio of a repeating unit derived from the component (C) is 10 to 50 wt % (inclusive) relative to the total weight of the polymer. A solution of the polyamide resin in 98% sulfuric acid, which contains the polyamide resin at a concentration of 0.01 g / ml, has a relative viscosity of 1.5 to 4.5 at 25° C.

Owner:TORAY IND INC

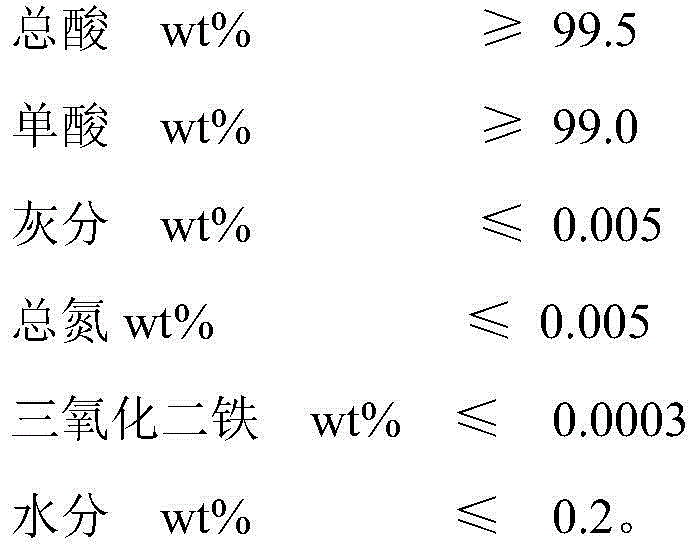

Recycling method of purifying, refining and crystallizing mother liquor of dodecanedioic acid

ActiveCN104447280AInhibition of esterificationSolve complexityOrganic compound preparationHydroxy compound preparationTotal nitrogenSolvent

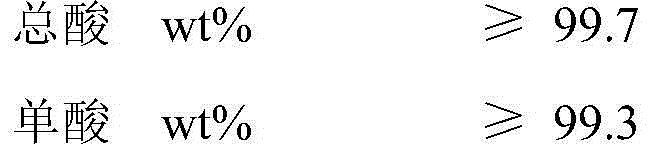

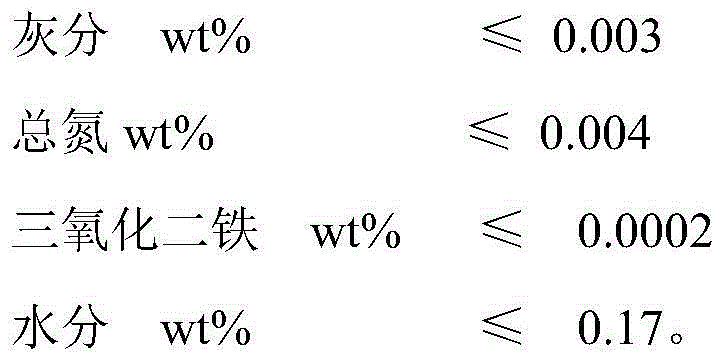

The invention provides a recycling method of mother liquor purifying, refining and crystallizing mother liquor of dodecanedioic acid, and belongs to the separation treatment method of non-acyclic dicarboxylic acid containing 12 carbon atoms. The recycling method comprises the steps of (1) recovering a solvent which is methanol; (2) distilling to dissolve and dilute materials residual at the bottom of a kettle; (3) performing acidification under a high temperature, and crystallizing; (4) drying. The recycling method of mother liquor purifying, refining and crystallizing mother liquor of dodecanedioic acid has the advantages that the recovered dodecanedioic acid product has a good color and luster and is of high purity, and moreover, the recovery yield is raised, the device investment is saved, the operation is simple and convenient, the resource can be saved, and the environment is protected; the recovery yield of the dodecanedioic acid product is not less than 97.0%; the product quality meets the technical indexes that the total acid is not less than 99.7wt% (percentage by weight), single acid is not less than 99.3wt%, ash content is not greater than 0.003wt%, the total nitrogen is not greater than 0.004wt%, ferric oxide is not greater than 0.0002wt%, and water content is not greater than 0.17wt%.

Owner:山东广通新材料有限公司

Material composites made of a moulded part made of transparent or translucent, dyeable plastic thermoplastic moulding compositions

InactiveCN1878665AImprove adhesionImproved rheological propertiesLayered productsThin material handlingThermoplasticPolymer science

The present invention relates to materials composites of a moulded article of at least one transparent or translucent dyeable plastics moulding compound which moulded article is bonded to at least one transparent or translucent surface layer and / or to decorative films, functional films or coats or rubbers or other plastics, wherein the plastics moulding compound used for the manufacture of the moulded article, the surface layer or the other plastics contains in an amount of 0.01 to 5.0 % by weight, preferably 0.01 to 2.0 % by weight, each related to the total weight of the moulding compound, at least one lubricant selected from the group consisting of sorbitan esters, sebacic acid esters, dodecanedioic acid esters, docosanoic acid esters, glycerine, glycol, diethylene glycol, stearoyl amide, stearyl stearate, ethylene bissteroyl amide, octane pyrrolidone, and from the group consisting of non-polar paraffin oils and of tetracosanes, and wherein a permanent adhesion to the other plastics layers and / or sheets or coats or rubbers or other plastics is achieved.

Owner:EMS CHEM AG

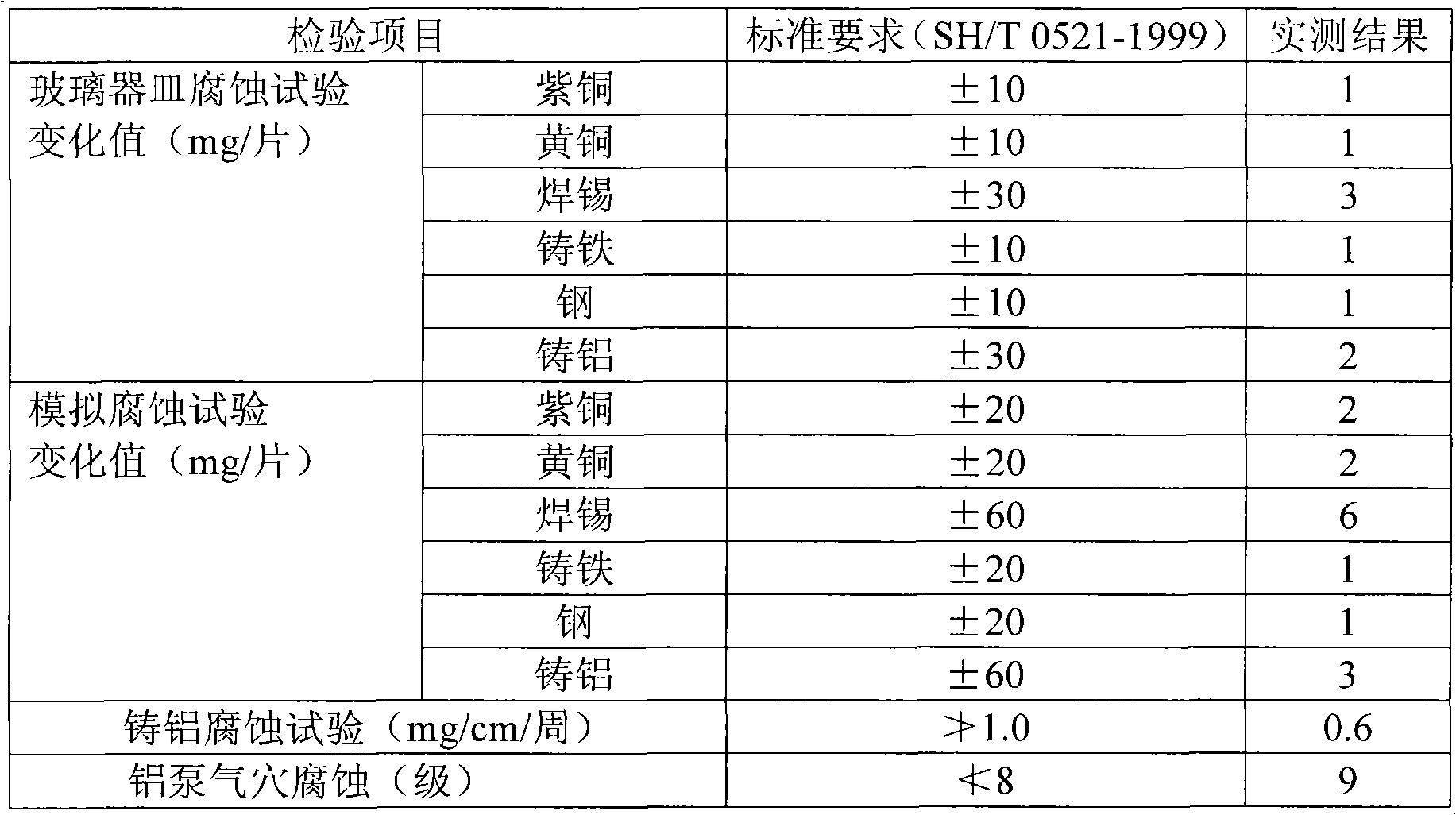

All-organic engine coolant

InactiveCN101955756AIncrease reservesImprove the stability of useHeat-exchange elementsOrganic compoundDefoamer

The invention relates to an all-organic engine coolant, comprising the following components by parts by weight: 1000 parts of glycol, 16-20 parts of dodecanedioic acid, 5-9 parts of undecanedioic acid, 1-5 parts of benzotriazole, 3-6 parts of 2-ethylhexoic acid, 0.5-3 parts of hydroxybenzoic acid, 0.05-0.1 part of hydrolytic polymaleic anhydride and 0.1-0.3 part of antifoaming agent. The engine coolant takes all-organic compounds as raw materials, synergistic effect is good, and anti-corrosion property to multiple metals, especially aluminium, is good; hard water resistance is good; storage and use stability of coolant can be greatly improved; the service life of antifreezing solution can be effectively prolonged; and no influence to the environment is produced as nitrous, amine, phosphorus and chromium components are not contained.

Owner:兰州蓝星有限公司

Purification method of dodecanedioic acid

ActiveCN104529747AImprove solubilityReduce dosageCarboxylic compound separation/purificationPurification methodsResource saving

The invention relates to a purification method of dodecanedioic acid, belonging to purification treatment of cycle-free dicarboxylic acid with 12 carbon atoms. The method is characterized by comprising the following steps: by using a dodecanedioic acid crude product produced by microbial fermentation as an initial raw material and water as a dissolving solvent, carrying out alkali fusion at 100-102 DEG C under the condition of pH value of 6.0-6.2 to prepare a dodecanedioic acid crude product water solution; and after carrying out adsorption-oxidation dual decolorization, acidifying at 98-102 DEG C to crystallize, and finally, drying to obtain the scale-like high-purity dodecanedioic acid crystal product. The purification method of dodecanedioic acid has the advantages of favorable product color, high product purity, high refinement yield, equipment investment saving and resource saving, and is simple to operate and beneficial to environmental protection. The purification yield of the dodecanedioic acid is greater than or equal to 98.4%. The dodecanedioic acid is suitable to be used as a polycondensation monomer to perform polycondensation reaction with diamine to synthesize the long-carbon-chain nylon, and is also suitable to be used as a raw material of synthetic perfume and drugs.

Owner:山东广通新材料有限公司

Polyamide composite material with double or multiple layers

InactiveCN1361005ASynthetic resin layered productsThin material handlingLaurolactamHexamethyldiamine

A good layer adhesion can be achieved in a composite having two or more layers wherein a layer I is obtained from a molding composition which has the following components: a) from 0 to 80 parts by weight of a polyamide selected from the group consisting of PA6, PA66, PA6 / 66 and a mixture thereof; b) from 0 to 100 parts by weight of a polyamine-polyamide copolymer; and c) from 0 to 80 parts by weight of a polyamide selected from the group consisting of PA11, PA12, PA612, PA1012, PA1212 and a mixture thereof; wherein a total of the parts by weight of components a), b) and c) is 100; wherein at least 20 parts by weight of components a) and b) is a monomer unit which is obtained from caprolactam and / or from a combination of hexamethylenediamine / adipic acid; and wherein at least 20 parts by weight of components b) and c) is a monomer unit which is obtained from omega-aminoundecanoic acid, laurolactam, a mixture of hexamethylenediamine and 1,12-dodecanedioic acid, a mixture of 1,10-decanediamine and 1,12-dodecanedioic acid, and / or a mixture of 1,12-dodecanediamine and 1,12-dodecanedioic acid.

Owner:EVONIK DEGUSSA GMBH

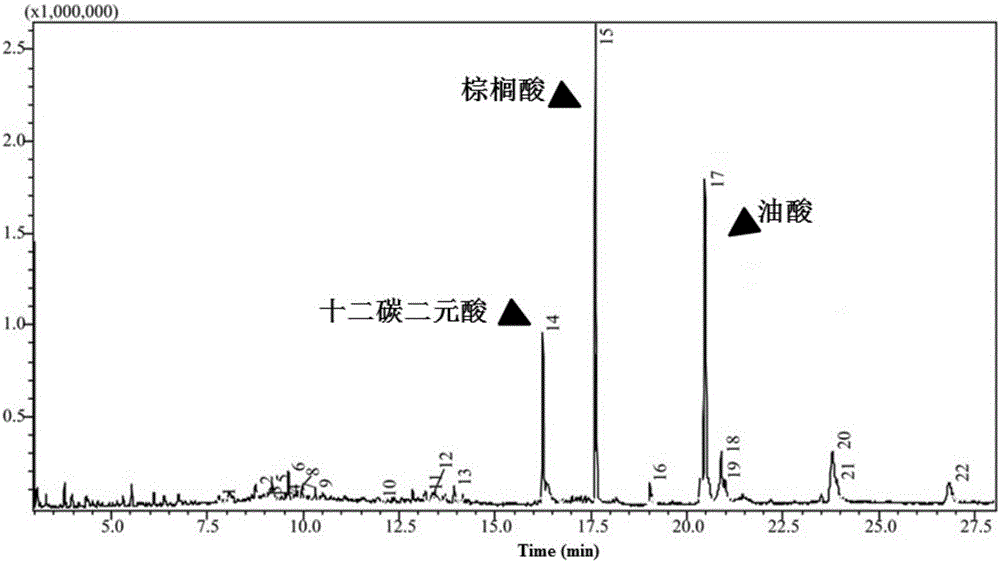

Application of candida tropicalis to preparation of dodecanedioic acid by utilizing unsaturated grease

ActiveCN105154483ABreak through the limitation of producing long-chain dibasic acidReduce manufacturing costMicroorganism based processesFermentationCandida tropicalisPetrochemical

The invention relates to application of candida tropicalis to preparation of dodecanedioic acid by utilizing unsaturated grease. The candida tropicalis is derived from the China's industrial microbial strain preservation management center, and the strain number is CICC 1798. The condition that when the candida tropicalis CICC 1798 is fermented, unsaturated double bonds in long-chain unsaturated fatty acid component (octadeca-carbon unsaturated fatty acid) in grease can be subjected to fragmentation and addition to obtain dodecanedioic acid is discovered for the first time, so that limit of petrochemical products as the raw materials for long-chain binary acid preparation is broken through, and a new path for synthesizing dodecanedioic acid is provided.

Owner:QILU UNIV OF TECH

Corrosion inhibitors

InactiveUS20070152191A1High degreeFast formingOther chemical processesSpecific water treatment objectivesWater basedCarboxylic acid

In general the current invention relates to corrosion inhibitors useful in water-based (aqueous) heat transfer fluids. More particularly, the present invention can be used for protecting ferrous and non-ferrous metal surfaces used in the construction of water-based (aqueous) heat transfer systems such as engine blocks and radiators. The invention particularly applies to a blend of corrosion inhibiting agents that can be added to water or water-glycol or other suitable liquid in a circulating or static heat transfer system to protect metal surfaces from corrosion attack. When used in an aqueous solution the unique blend of corrosion inhibiting agents provides flash corrosion protection of ferrous and non-ferrous surfaces during operation and after the treated aqueous fluid is drained away provides atmospheric corrosion protection of the ferrous and non-ferrous surfaces. The invention further relates to a variety of other practical and industrial applications such as engine coolant corrosion inhibition, dyno fluid corrosion inhibition, and metal working corrosion inhibition applications. The corrosion inhibitor includes several components 1) a dicarboxylic acid component comprising decanedoic and dodecanedoic and one or more C10-C12 dicarboxylic acids or salts of these acids, 2) an oxyalkylated carboxylate imidazoline preferably produced from carboxylate fatty acid and amine, 3) organophosphonic acid or amine salts of the organophosphonic acid and 4) a secondary or tertiary alkanolamine organic acid salting agent. The corrosion inhibitors of the present invention provide improved corrosion protection as compared to conventional inhibitors and provide surprisingly improved corrosion protection as compared to inhibitors containing only a single mono-carboxylic acid or blend of monocarboxylic and dicarboxylic acids or salts of these acids. The corrosion inhibitor of the present invention preferably contains no nitrite, nitrate, or silicate salts.

Owner:TRAHAN DAVID O +1

Thermosetting powder coating composition, film coating manufacturing method and film coating thereof

InactiveCN1456616AFull smoothnessImprove smoothnessLiquid surface applicatorsPowdery paintsDynamic viscoelasticitySolvent

The invention relates to a thermosetting powder coating composition, which is favorable for clear coating of automotive parts and automotive top clear coating, and exhibits, particularly in coating of a thin film of 35 to 50 mu m, excellent appearance (smoothness, gloss, transparency, etc.), physical properties of practical level (hardness, scratch / mar resistance, etc.) and chemical properties (acid resistance, solvent resistance, etc.). The inventive thermosetting powder coating composition comprises a glydicyl group-containing acrylic copolymer component (A) and a curative component (B) composed of dodecanedioic acid linear polyacid anhydride or tetradecanedioic acid linear polyacid anhydride, wherein the time DELTA T required for decrease of the absolute value of a complex elastic modulus ( eta *) of said composition from 100000 Pa.s to 5 Pa.s is not more than 200 seconds, said absolute value of a complex elastic modulus being measured by a dynamic viscoelasticity measuring device under the specific conditions.

Owner:MITSUI CHEM INC

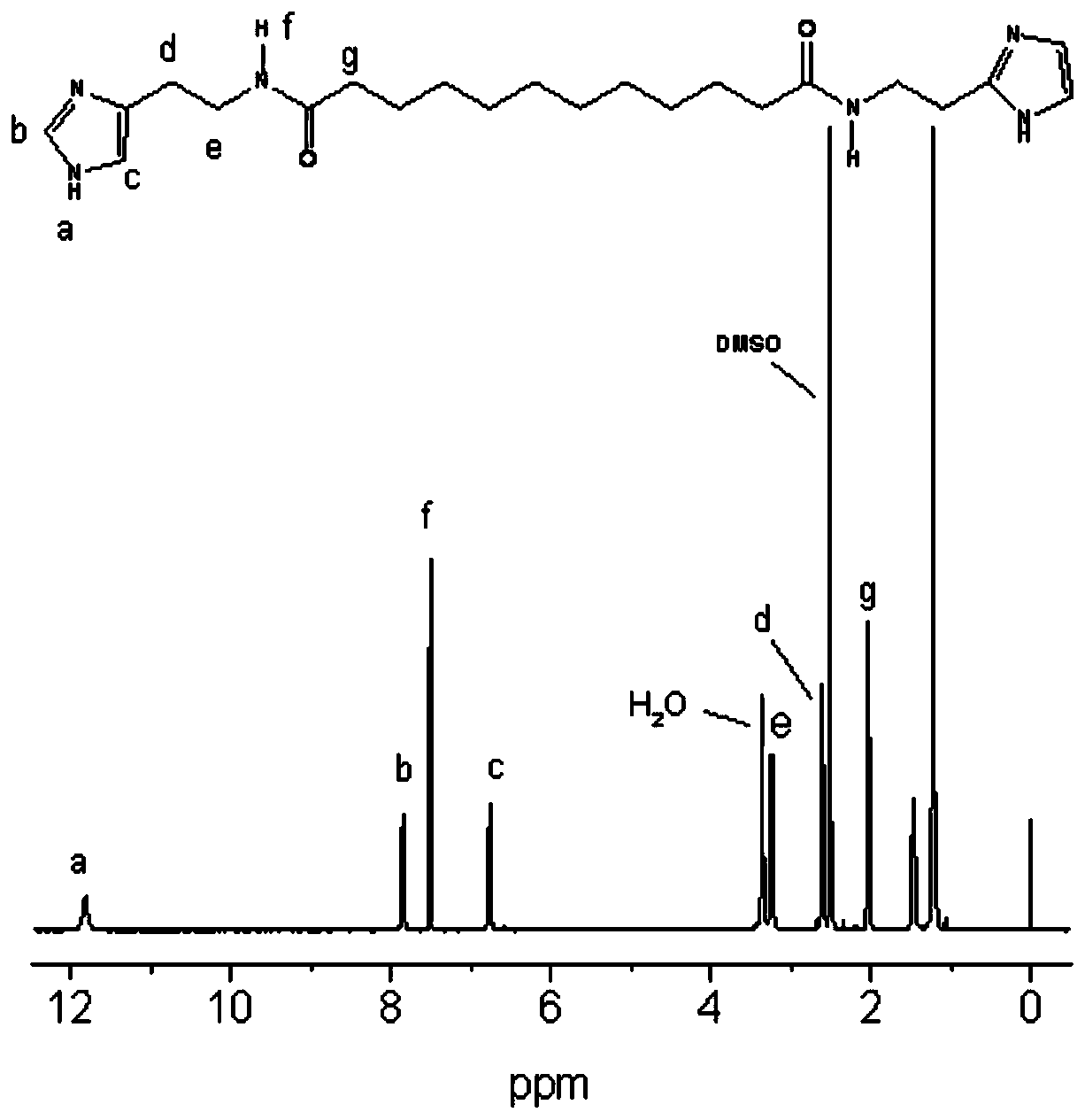

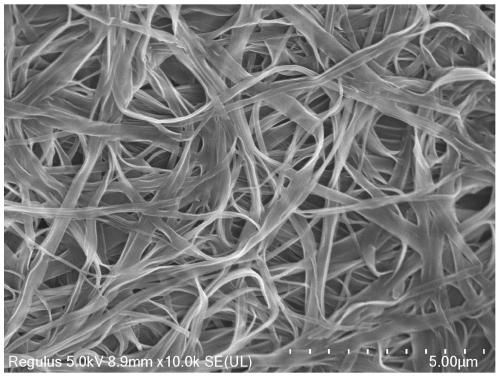

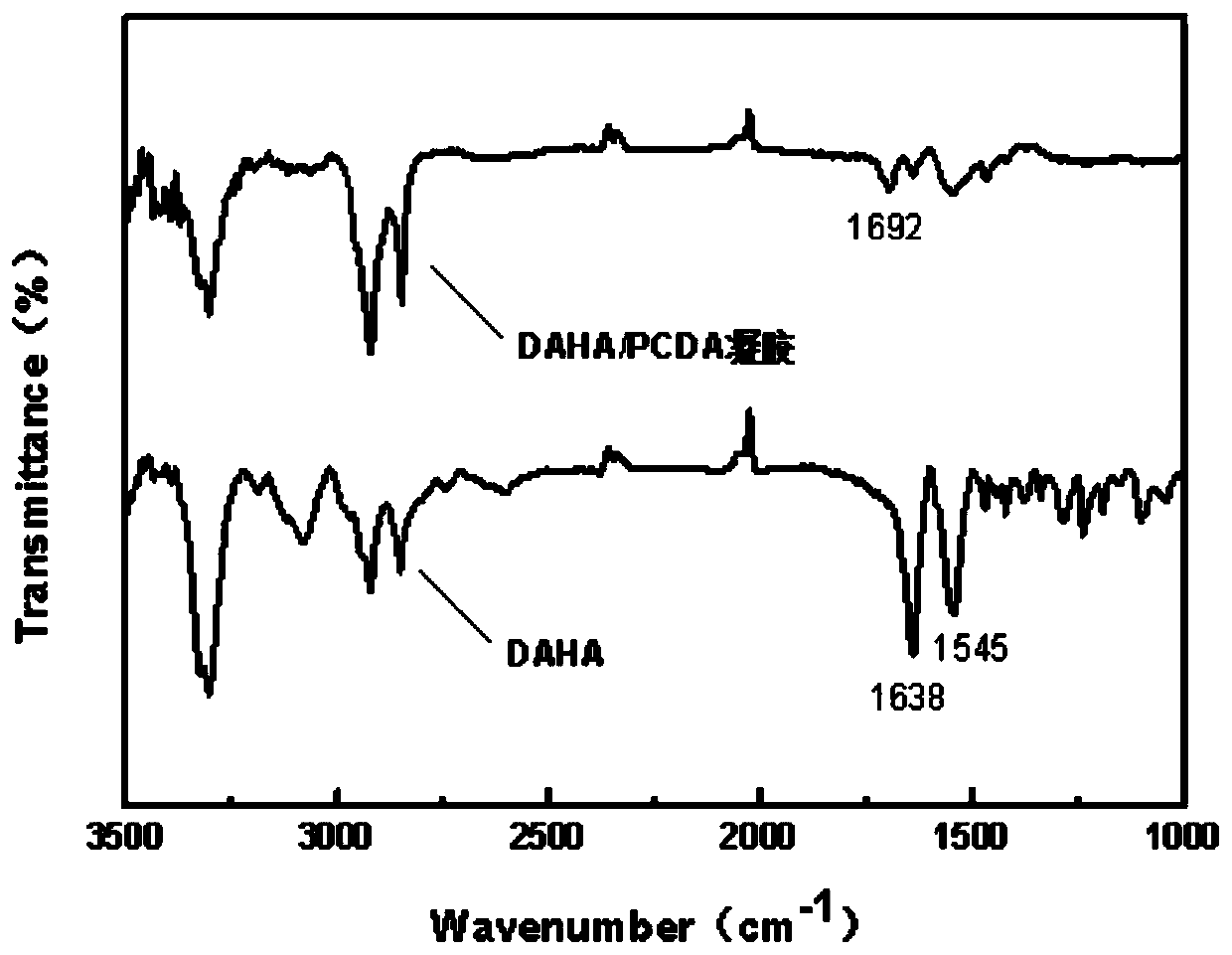

Preparation method of PDA supramolecular gel and application thereof

ActiveCN110078934ASimple pH DetectionInhibit synthesisMaterial analysis by observing effect on chemical indicatorOrganic solventUltraviolet lights

The invention provides a preparation method of a polydiacetylene PDA supramolecular gel, and detects response thereof to temperature, a solvent and pH. The preparation process of the gel is as follows: activating dodecanedioic acid in a system of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride EDC and N-hydroxy succinimide (NHS), then adding triethylamine TEA, together with histamine hydrochloride, into N,N-dimethyl formamide DMF, synthesizing a gelator with an imidazole group through an esterification reaction under an alkaline condition, and assembling with 10,12-pentacosadiynoicacid PCDA through a non-covalent bond in an organic solvent to form the gel. The gel prepared according to the preparation method provided by the invention can stably exist in a variety of organic solvents, is topologically polymerized to form a blue gel when irradiated with 254 nm ultraviolet light, and can respond to the temperature, the solvent and the pH and change the color from blue to red;the gel is prepared into test paper which has simple and clear response to the pH.

Owner:ANHUI NORMAL UNIV

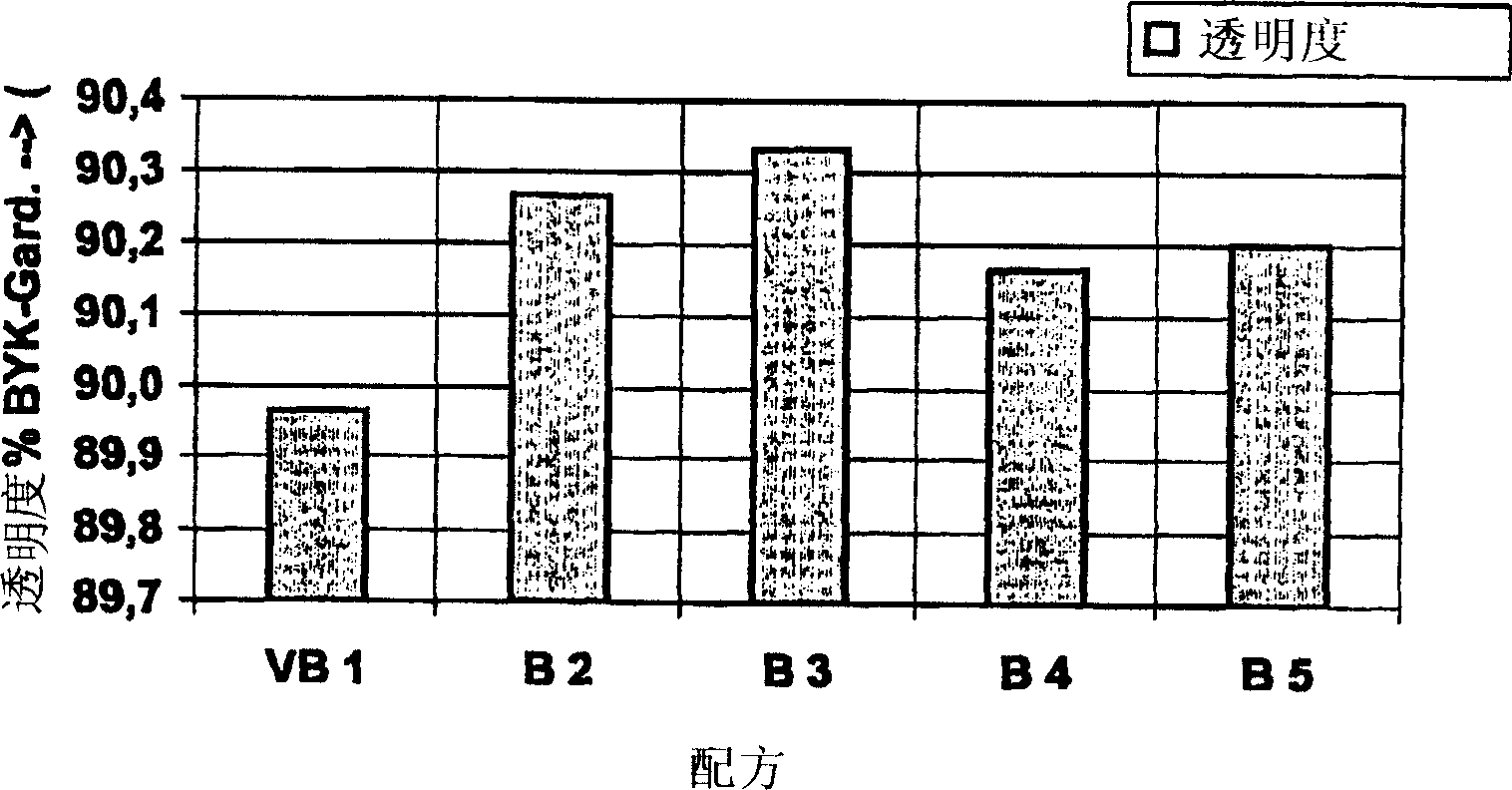

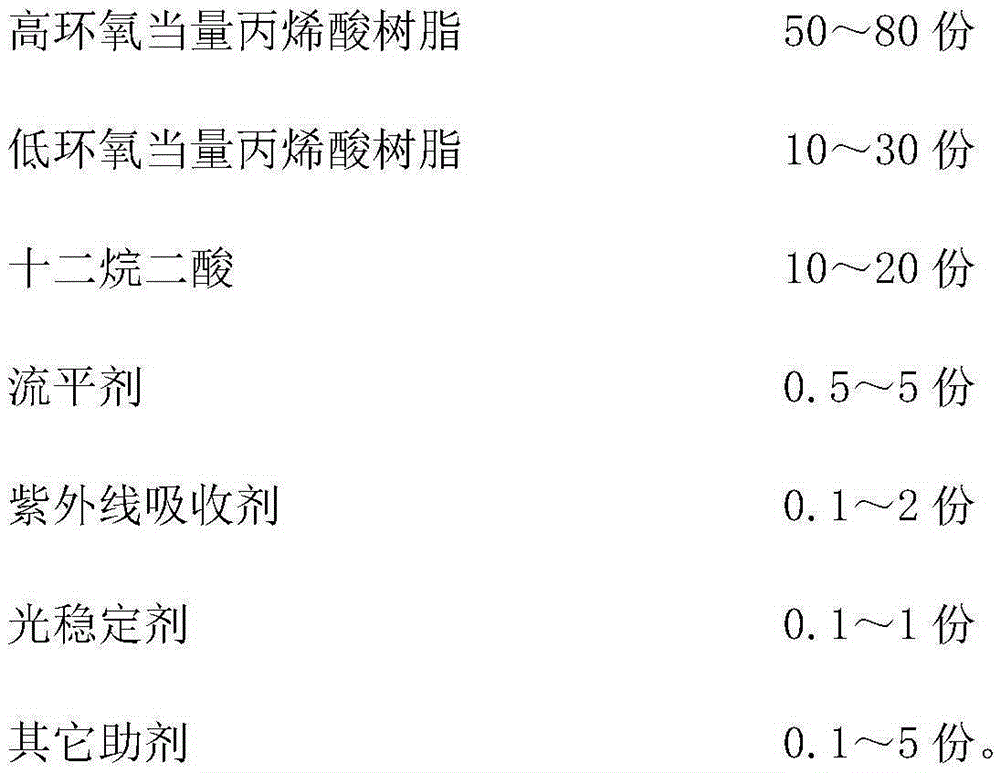

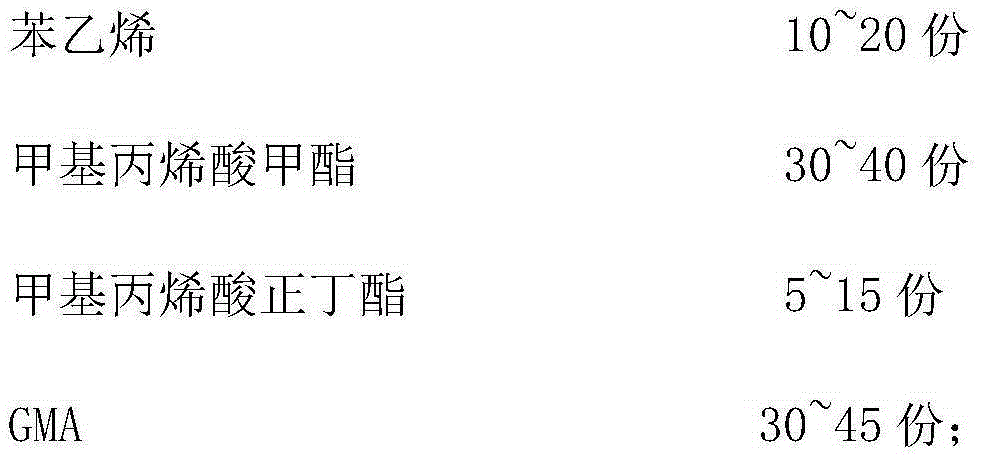

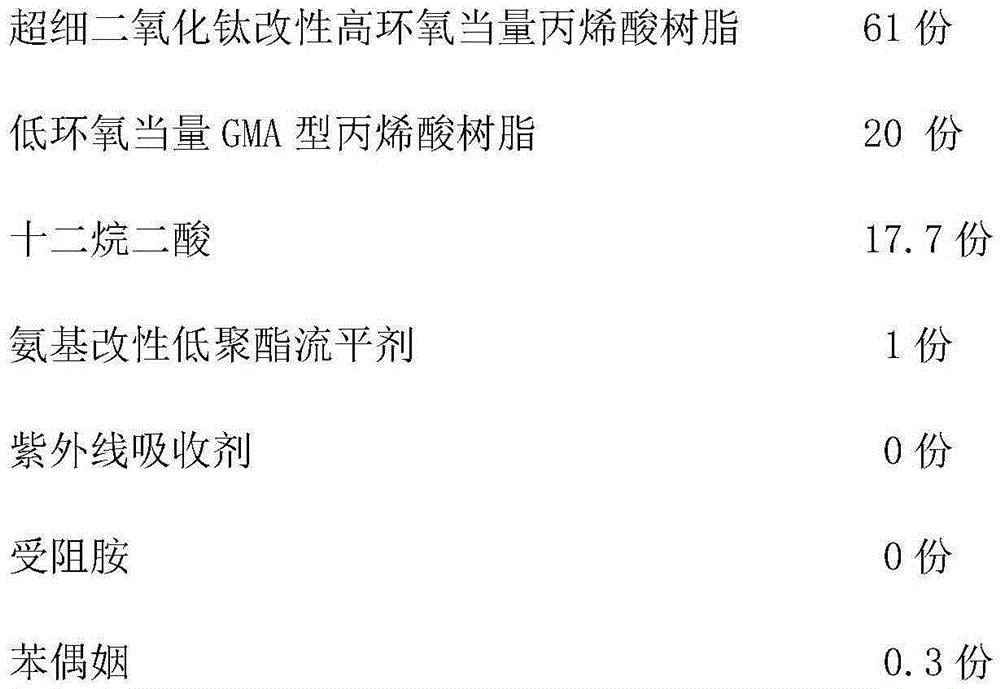

Low-temperature curing type epoxy group acrylic acid transparent powder coating and preparation method thereof

ActiveCN105273558ALower the initial reaction temperatureAchieving Low Temperature CuringPowdery paintsAcrylic resinUltraviolet lights

The invention discloses a low-temperature curing type epoxy group acrylic acid transparent powder coating. The low-temperature curing type epoxy group acrylic acid transparent powder coating is mainly prepared from high-epoxide-equivalent acrylic resin, low-epoxide-equivalent acrylic resin, dodecanedioic acid, an ultraviolet light absorber, a light stabilizer, a flatting agent and other auxiliaries. The high-epoxide-equivalent acrylic resin is modified by ultrafine titanium dioxide, and the low-epoxide-equivalent acrylic resin is in a GMA type. By the adoption of the high-epoxide-equivalent acrylic resin, the low-epoxide-equivalent acrylic resin and the dodecanedioic acid, the initial reaction temperature of the powder coating is decreased, and low-temperature curing is achieved; due to the auxiliary curing of the low-epoxide-equivalent acrylic resin, the enough compactness of the powder coating is improved, and then the corrosion resistance of the coating is improved; by the adoption of the high-epoxide-equivalent acrylic resin modified by the ultrafine titanium dioxide, the best ultraviolet absorption effect is obtained, and the weather resistance of the coating is improved.

Owner:GUANGZHOU KINTE IND

Method for catalytically synthesizing diisooctyl dodecanedioate base oil by solid superacid

InactiveCN103274938AHigh activityEasy to separatePhysical/chemical process catalystsOrganic compound preparationIsooctyl alcoholPtru catalyst

The invention discloses a method for obtaining high-purity diisooctyl dodecanedioate base oil by synthesizing solid superacid SO4<2-> / ZrO2-TiO2 catalyst with a precipitation-impregnation method, catalytically synthesizing diisooctyl dodecanedioate by dodecanedioic acid and isooctanol, and subjecting to separation and purification. The synthesized catalyst has the advantages of high activity, easiness in separation, capacity of recycling, good stability, high product yield and the like. The synthesized ester base oil has the advantages of high viscosity index and open cup flash point, low pour point and toxicity, good low temperature fluidity, wider operating temperature range, and excellent lubrication, environmental protection and biodegradation properties.

Owner:NANTONG ZHONGCHENG BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com