All-organic engine coolant

An engine coolant, an organic technology, applied in the field of engine coolant, can solve the problems of cast aluminum heat transfer corrosion, the inorganic type coolant can not meet the demand, easy to form precipitation and other problems, to improve the reserve and use stability Performance, improved storage and use stability, excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Get 1000Kg of ethylene glycol, 20 parts by mass of dodecanedioic acid, 5 parts by mass of undecanedioic acid, 5 parts by mass of benzotriazole, 3 parts by mass of 2-ethylhexanoic acid, 0.5 parts by mass of hydroxybenzoic acid, 0.05 parts by mass of hydrolyzed polymaleic anhydride and 0.1 parts by mass of defoamer are prepared by mixing and stirring.

Embodiment 2

[0026] Get 1000Kg of ethylene glycol, 18 parts by mass of dodecanedioic acid, 7 parts by mass of undecanedioic acid, 3 parts by mass of benzotriazole, 5 parts by mass of 2-ethylhexanoic acid, and 2 parts by mass of hydroxybenzoic acid 0.08 parts by mass of hydrolyzed polymaleic anhydride and 0.2 parts by mass of an antifoaming agent are prepared by mixing and stirring.

Embodiment 3

[0028] Get 1000Kg of ethylene glycol, 16 parts by mass of dodecanedioic acid, 9 parts by mass of undecanedioic acid, 1 part by mass of benzotriazole, 6 parts by mass of 2-ethylhexanoic acid, and 3 parts by mass of hydroxybenzoic acid , 0.1 parts by mass of hydrolyzed polymaleic anhydride, and 0.3 parts by mass of an antifoaming agent are prepared by mixing and stirring.

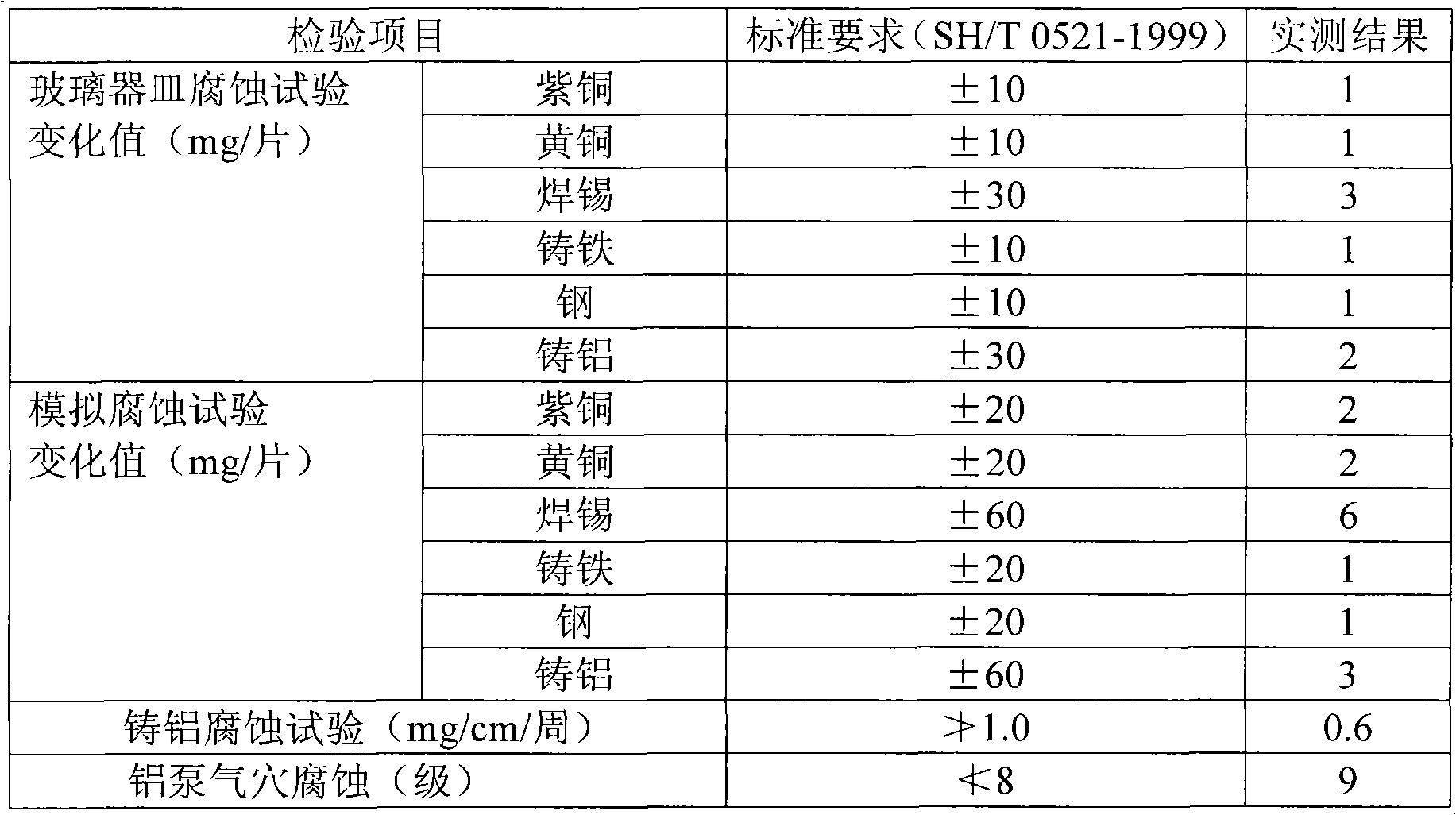

[0029] The all-organic type engine coolant that above-mentioned embodiment obtains is through testing, and performance index is as follows:

[0030]

[0031] The results show that the results of the all-organic engine coolant in the glassware and simulated corrosion test and the cavitation corrosion test of the aluminum pump are better than the values specified in the SH / T 0521-1999 standard, and it is anti-corrosion to various metals, especially cast aluminum Better performance.

[0032] The scale inhibition performance evaluation method of antifreeze of the present invention:

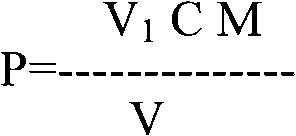

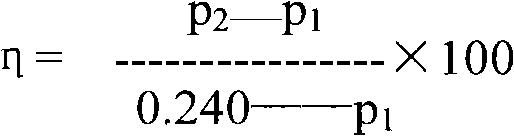

[0033] Add a certain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com