Hard carbon negative electrode composite material and preparation method and application thereof

A composite material and hard carbon technology, which is applied in the preparation/purification of carbon, negative electrodes, battery electrodes, etc., can solve the problems of difficulty in controlling the amount of lithium fluoride attached, inconsistent pre-lithiation degree, waste, etc., to simplify production Process flow and chemical formation process, solving SEI instability, and reducing the effect of injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing a hard carbon negative electrode composite material, comprising the steps of:

[0045] Pretreatment of carbon-containing raw materials to prepare hard carbon precursors;

[0046] Mixing the hard carbon precursor with a lithium-containing compound and a binder to prepare a solid pre-lithiated hard carbon precursor;

[0047] Sintering the pre-lithiated hard carbon precursor to prepare pre-lithiated hard carbon;

[0048] Carrying out carbon coating treatment on the pre-lithiated hard carbon to form a carbon coating layer on the surface of the pre-lithiated hard carbon.

[0049] The preparation method of the hard carbon negative electrode composite material provided by one of the embodiments of the present invention comprises the following steps:

[0050] S100: Pretreat carbon-containing raw materials to prepare hard carbon precursors

[0051] In this step, by pretreating the carbon-containing raw material, impurities in the carbon-containing raw m...

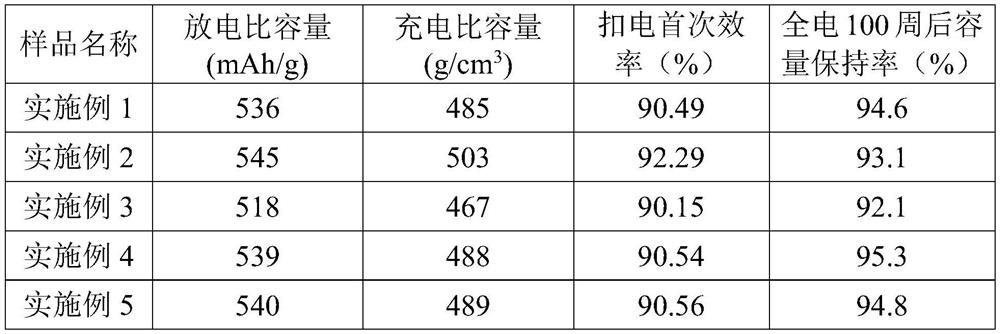

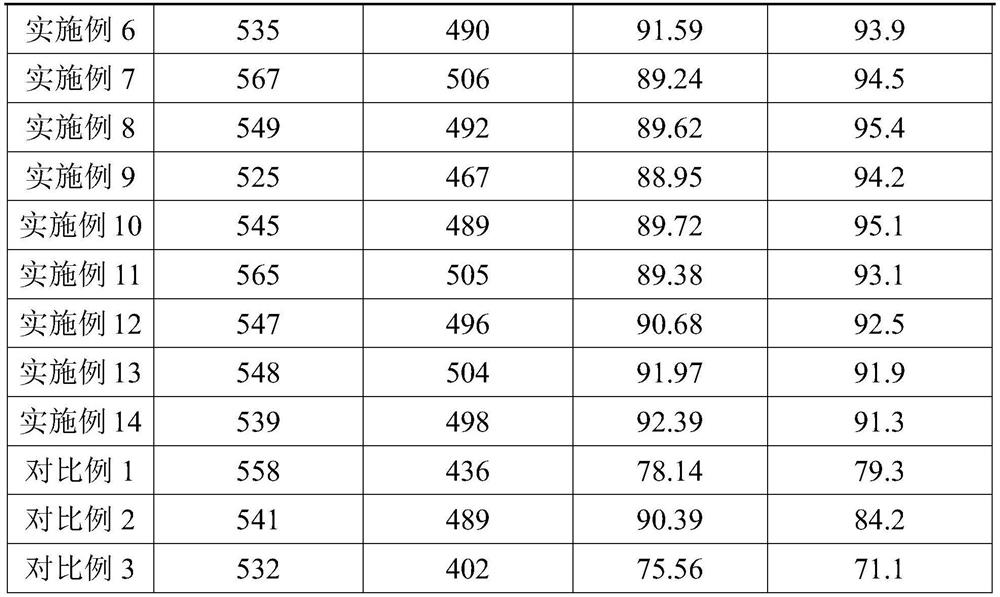

Embodiment 1

[0080] This embodiment provides a hard carbon negative electrode composite material and a preparation method thereof.

[0081] (1) 100 g of sucrose is pulverized by a ball mill to obtain carbon-containing raw material particles with D50=30 μm;

[0082] (2) Carry out heat treatment under air atmosphere, the temperature of heat treatment is 200 ℃, time is 10h, prepare and obtain hard carbon precursor;

[0083] (3) Mix 9.0 g of the hard carbon precursor obtained in step (2) with 0.9 g of lithium carbonate and 0.1 g of pitch, and fuse in a mechanical fusion machine at 230 ° C and a speed of 50 rpm to obtain a surface-coated lithium compound Pre-lithiated hard carbon precursors;

[0084] (4) In an inert atmosphere, the temperature was raised to 850°C at a heating rate of 5°C / min, and the temperature was kept at 3h. The pre-lithiated hard carbon precursor was sintered to prepare the pre-lithiated hard carbon, and cooled to room temperature. The pre-lithiated hard carbon is pulveri...

Embodiment 2

[0087] This embodiment provides a hard carbon negative electrode composite material and a preparation method thereof. The difference from Example 1 is that in step (1), the carbon-containing raw material is replaced by coconut shells from sucrose, and the coconut shells are also pulverized. The material D50=100 μm. The particle size of the finished hard carbon negative electrode composite material finally obtained is D50=16.2 μm, the thickness of the carbon coating layer is 200 nm, and the carbon coating layer accounts for 3.5% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com