Patents

Literature

52results about How to "Stay hygroscopic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

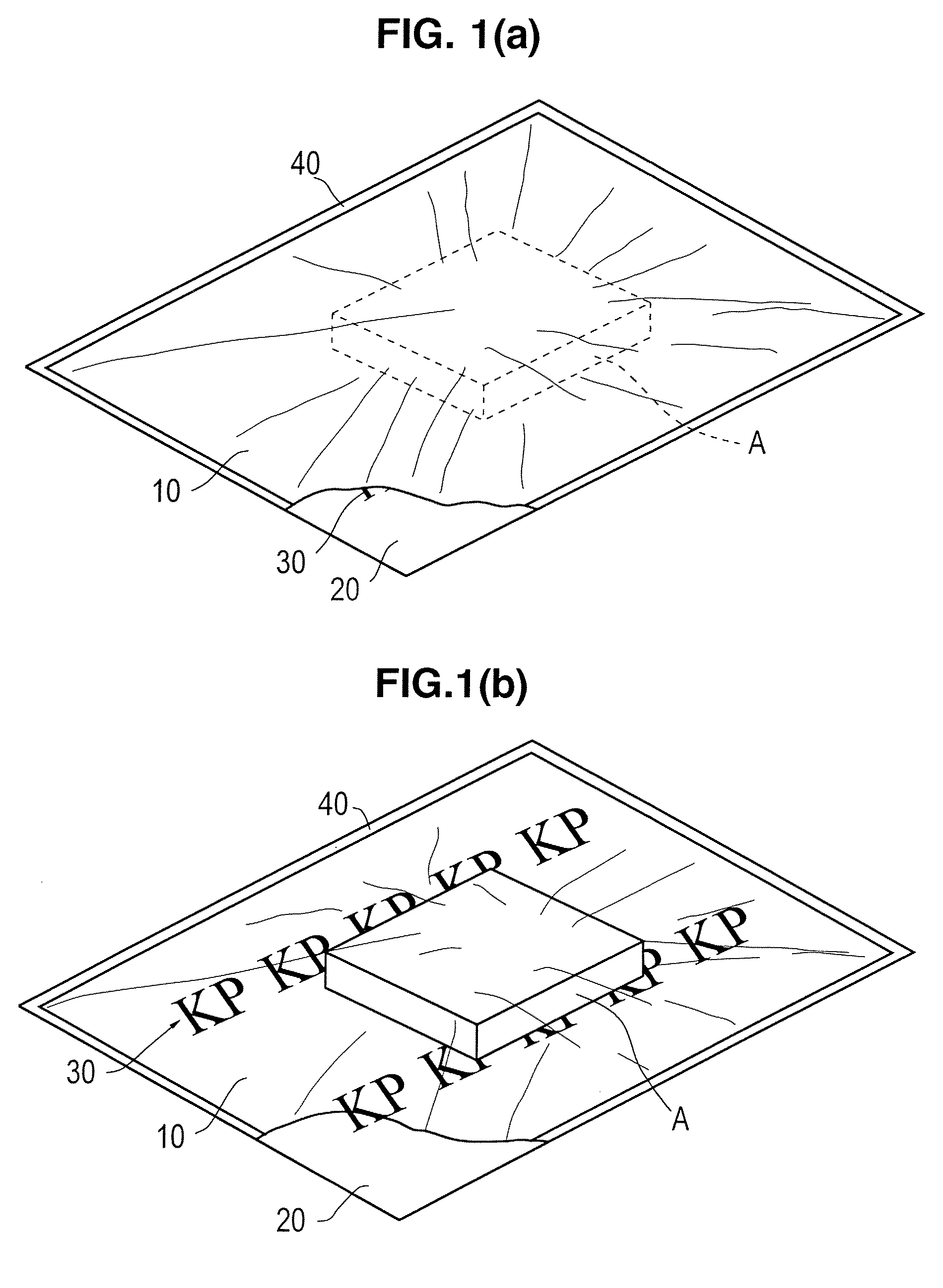

Packaging bag and drying agent with moisture absorption indicator function

InactiveUS20090022434A1High transparencyStay hygroscopicContainer/bottle contructionDomestic containersDesiccantWater vapor

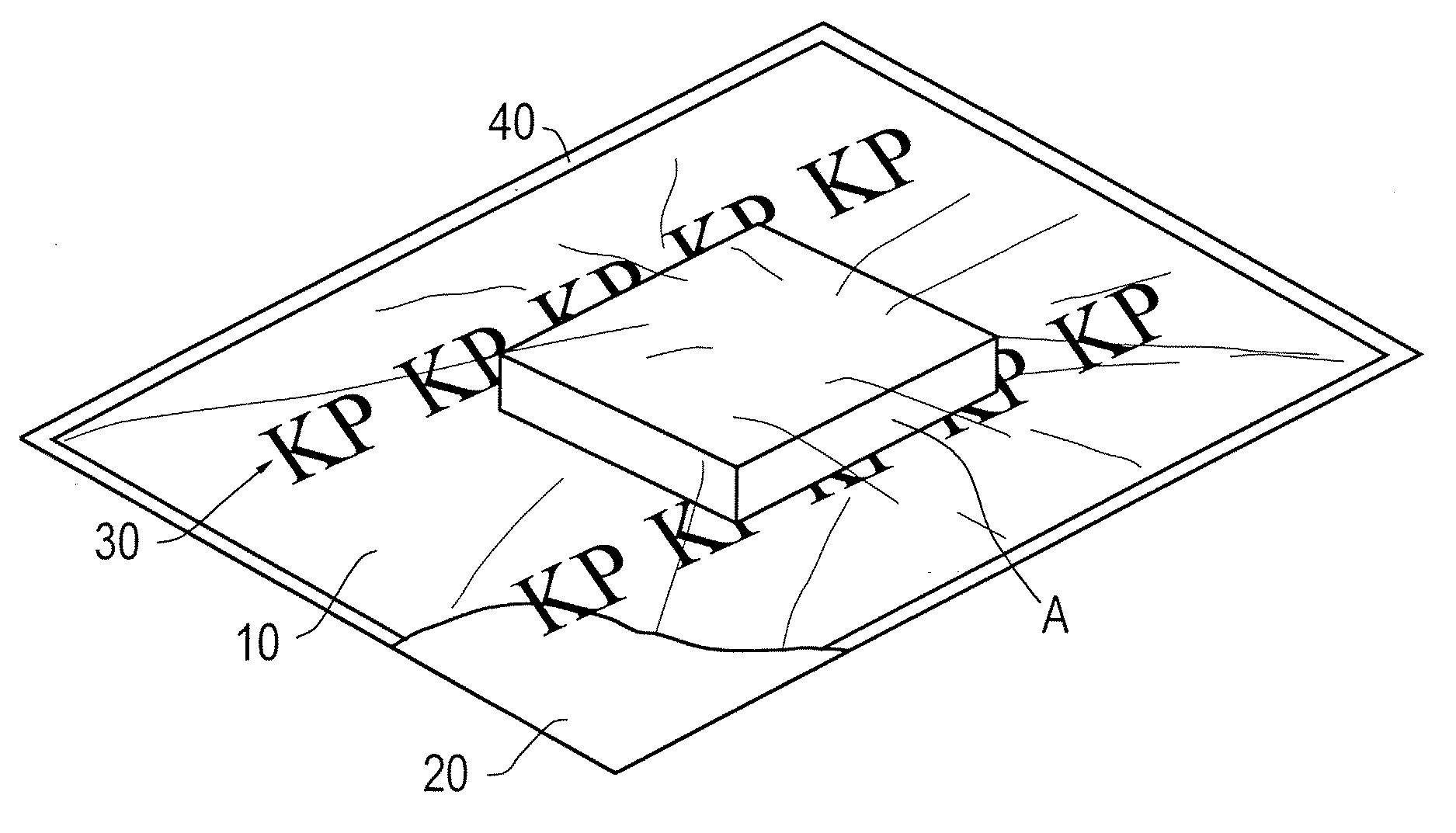

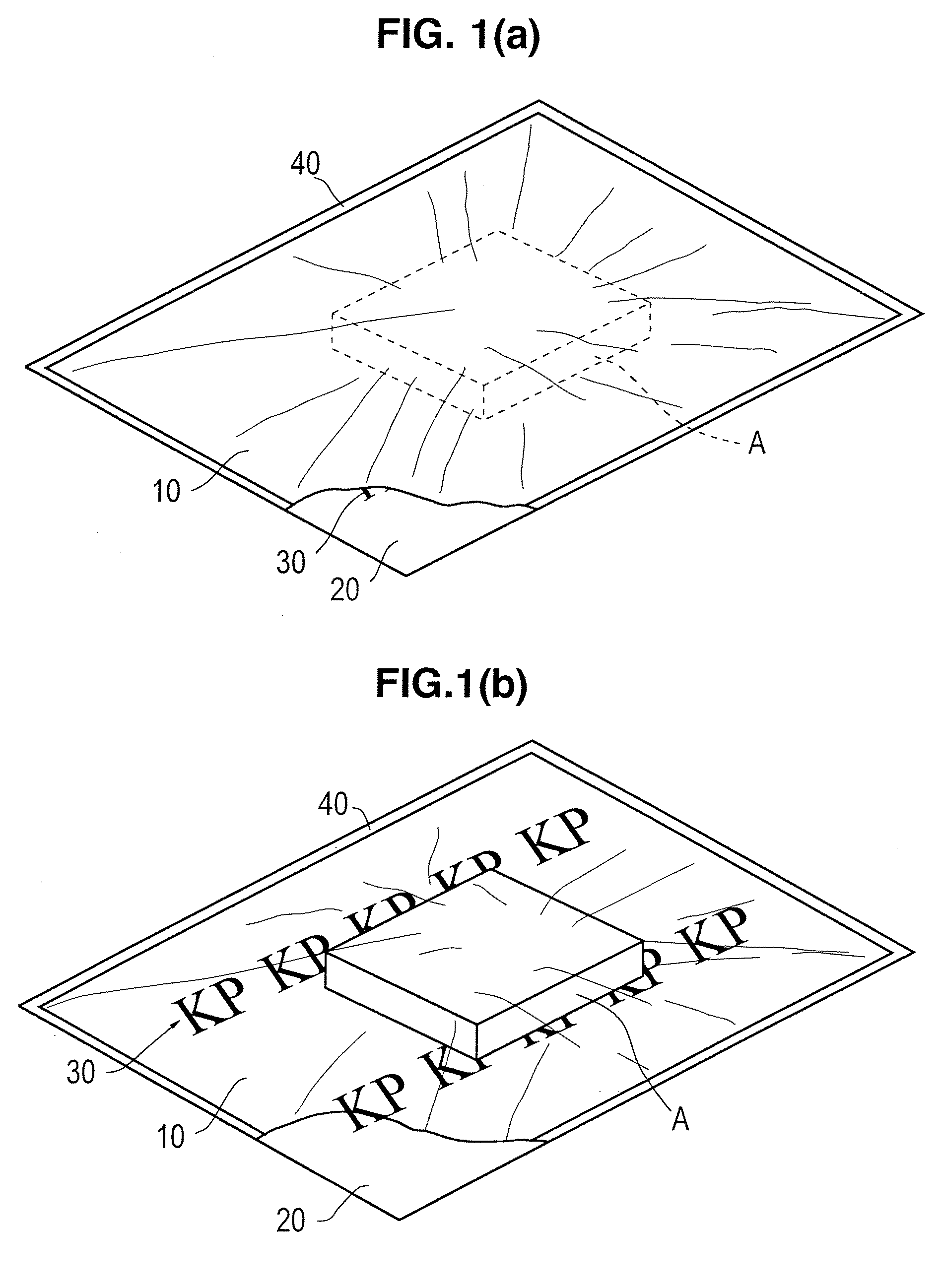

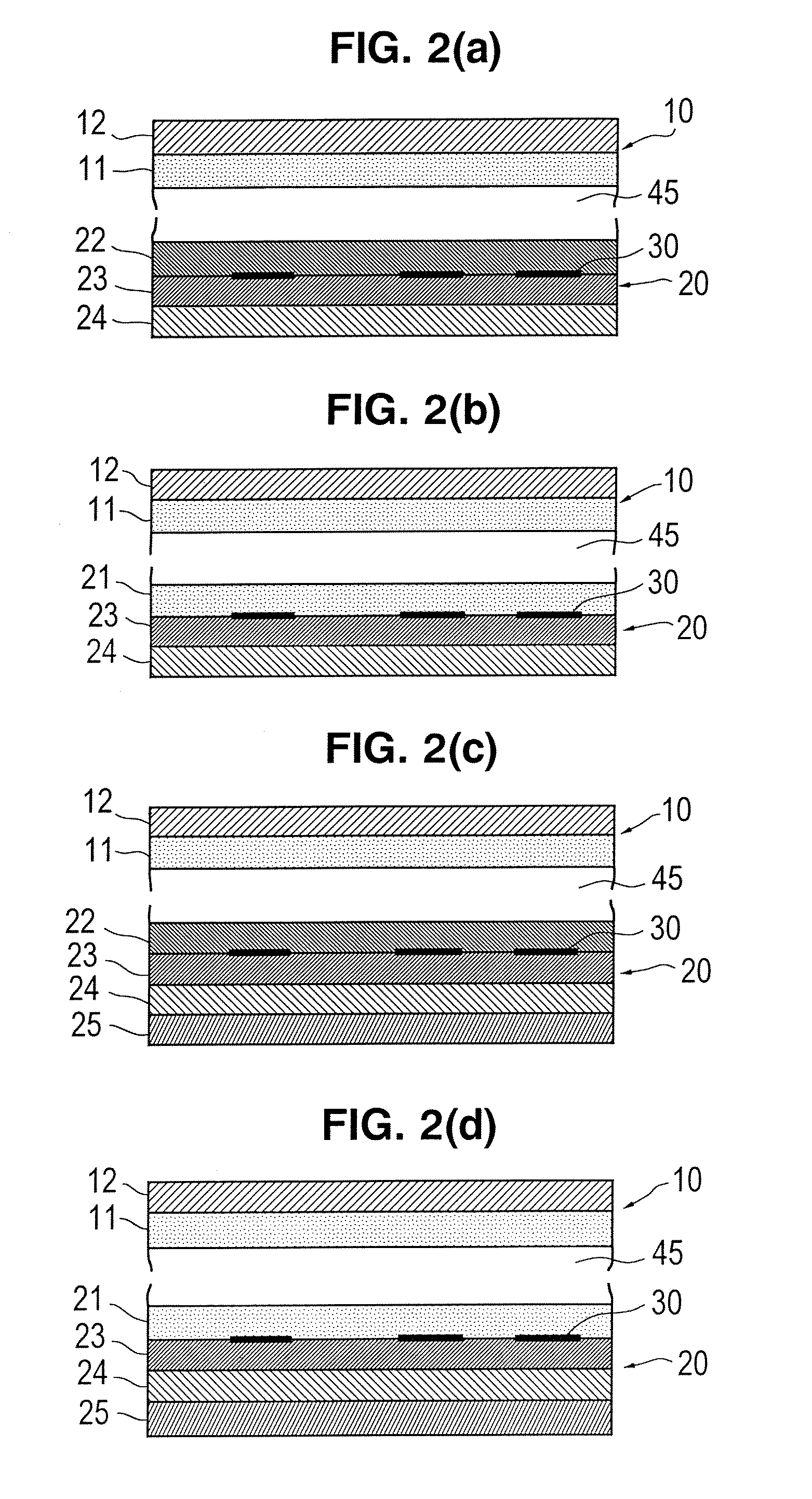

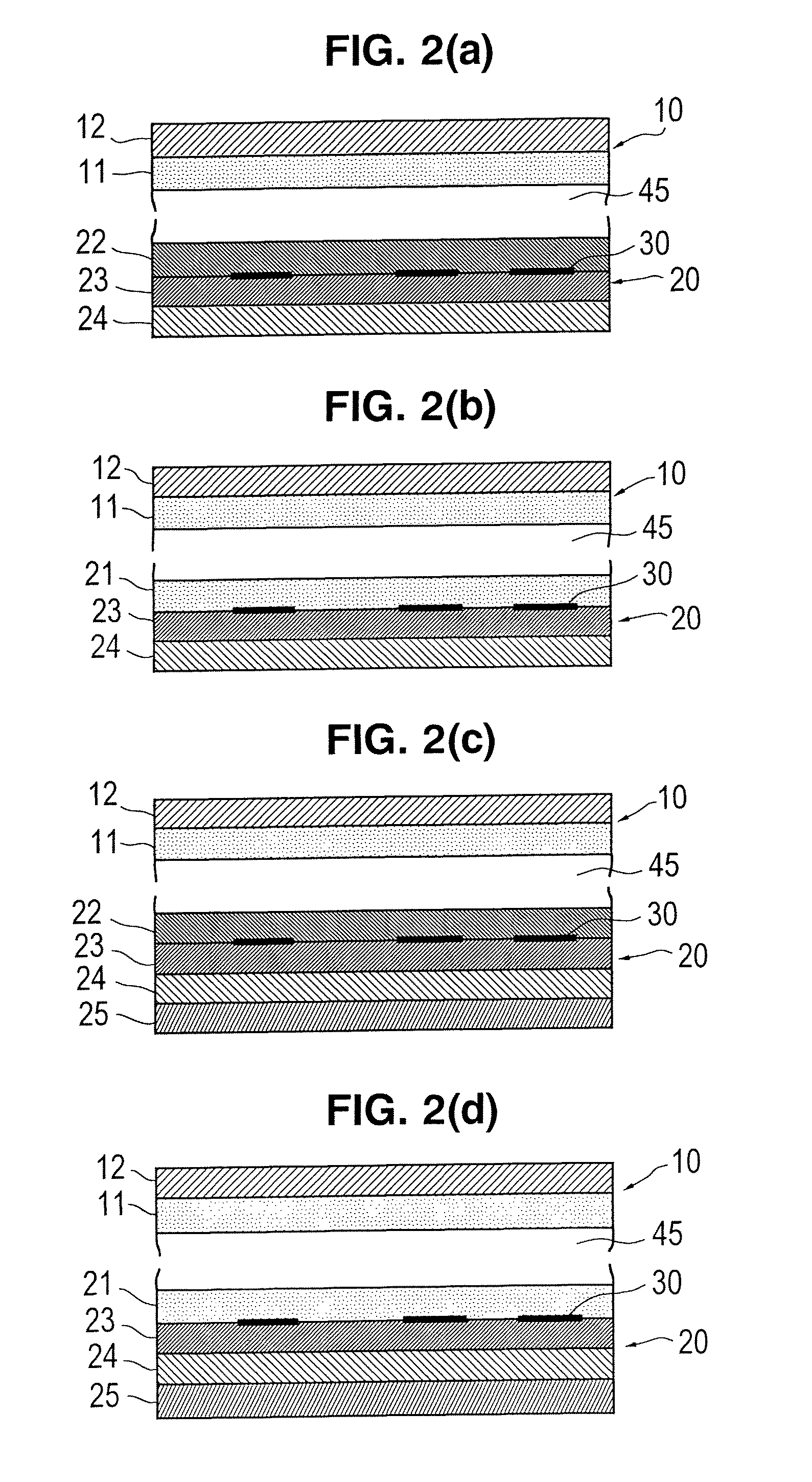

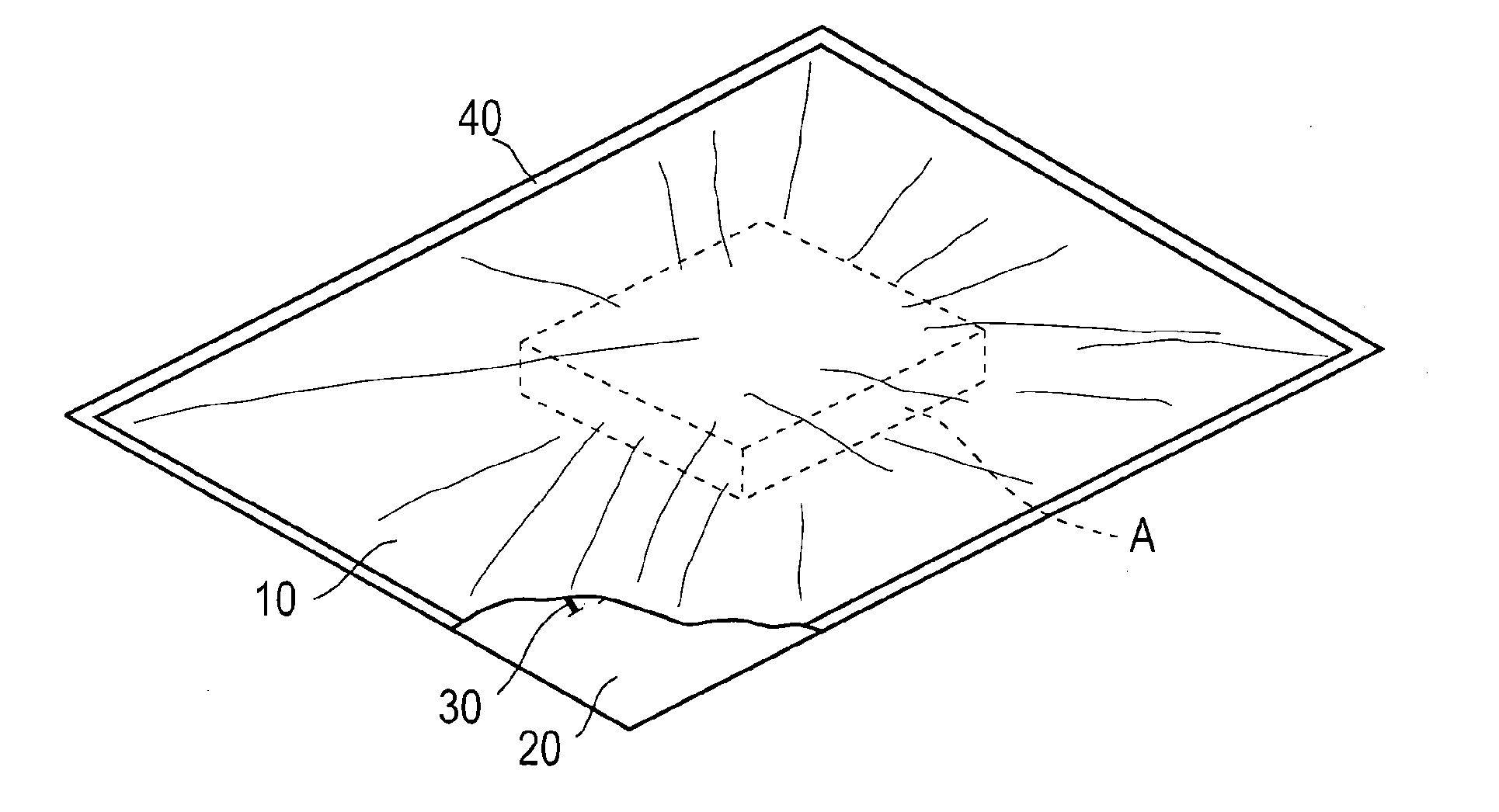

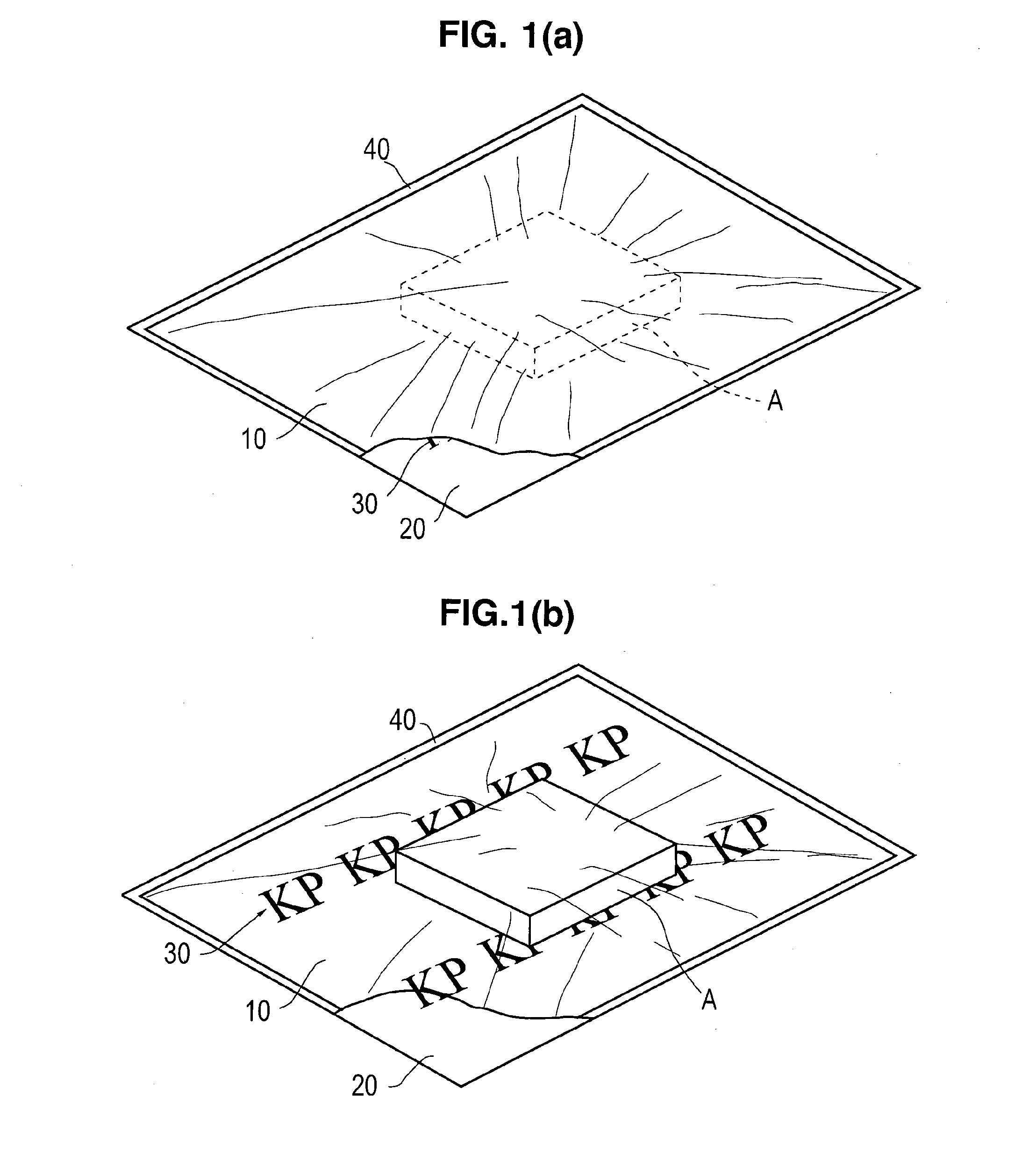

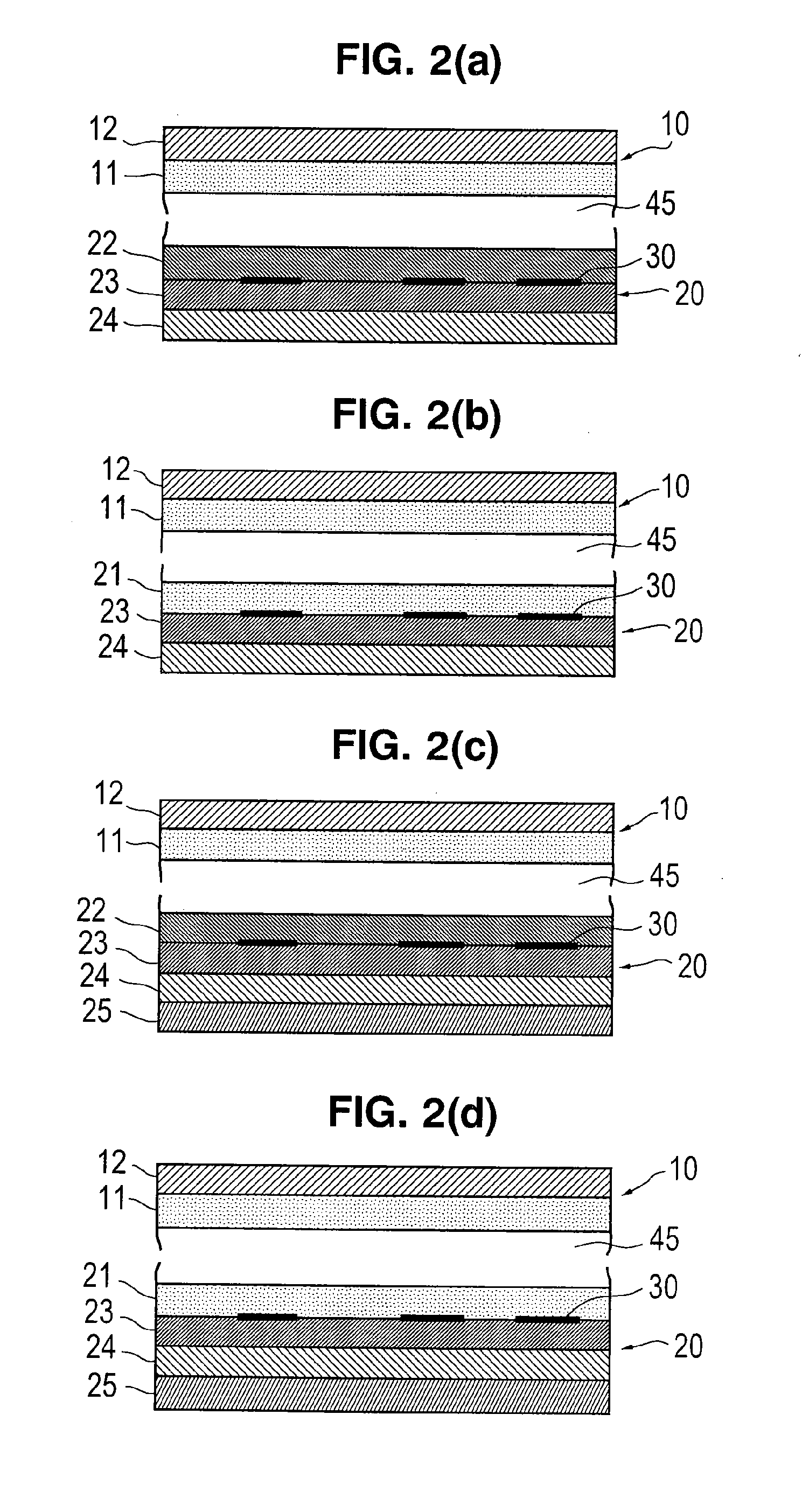

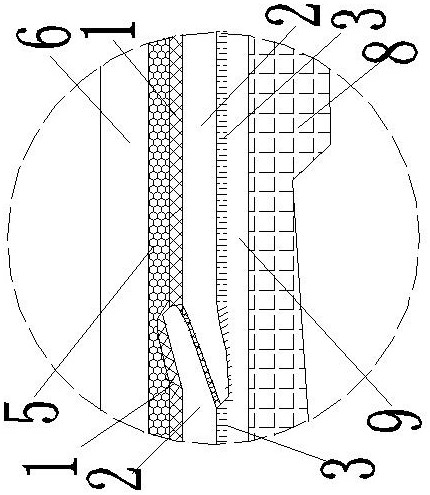

A packaging bag and a drying agent with a moisture absorption indicator function are provided without using a heavy metal harmful to the human body. The packaging bag includes a first packaging material (10) and a second packaging material (20). The first packaging material (10) is provided on an outermost side thereof with a transparent barrier film (12) having a barrier property against water vapor. The second packaging material (20) has a light-reflective or light-absorbing film (24) and a pattern printed layer (23) overlaid on a bag interior side thereof, the pattern printed layer (23) having a printed moisture-absorbing indicator pattern (30). A desiccant-containing resin film (11, 21) which becomes transparent due to moisture absorption is overlaid on a bag interior side of at least one of the first packaging material (10) and the second packaging material (20). The drying agent with a moisture absorption indicator function includes an indicator film layer (70) having a barrier film (75), a pattern printed layer (73) for a moisture absorption indicator, and a moisture-absorbing film (71) containing zeolite, the pattern printed layer (73) and moisture-absorbing film (71) being laminated in this order on the barrier film (75). The drying agent further includes a main desiccant layer (61) and a moisture permeable film (64) that are overlaid on the moisture-absorbing film (71).

Owner:KYODO INSATU KK KYODO PRINTING CO LTD

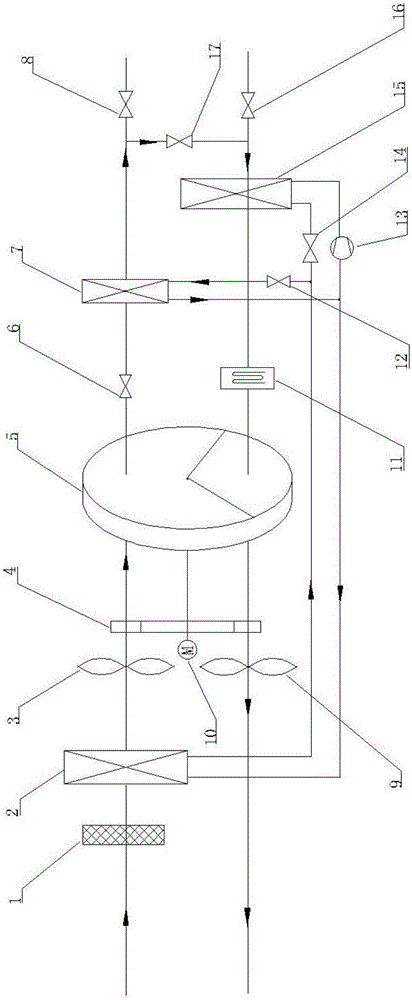

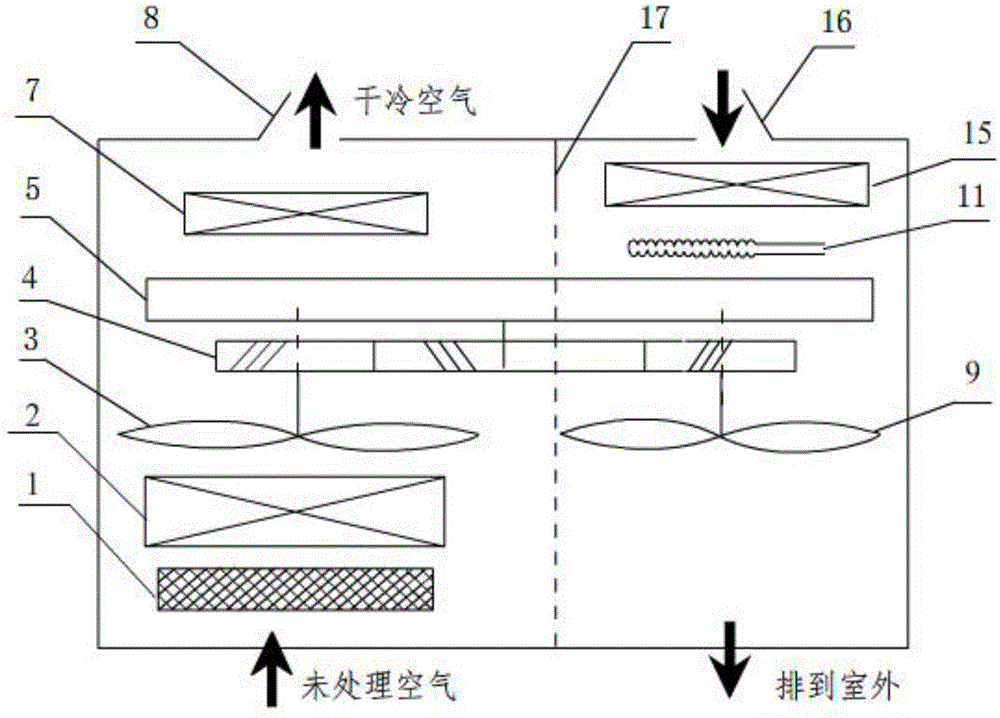

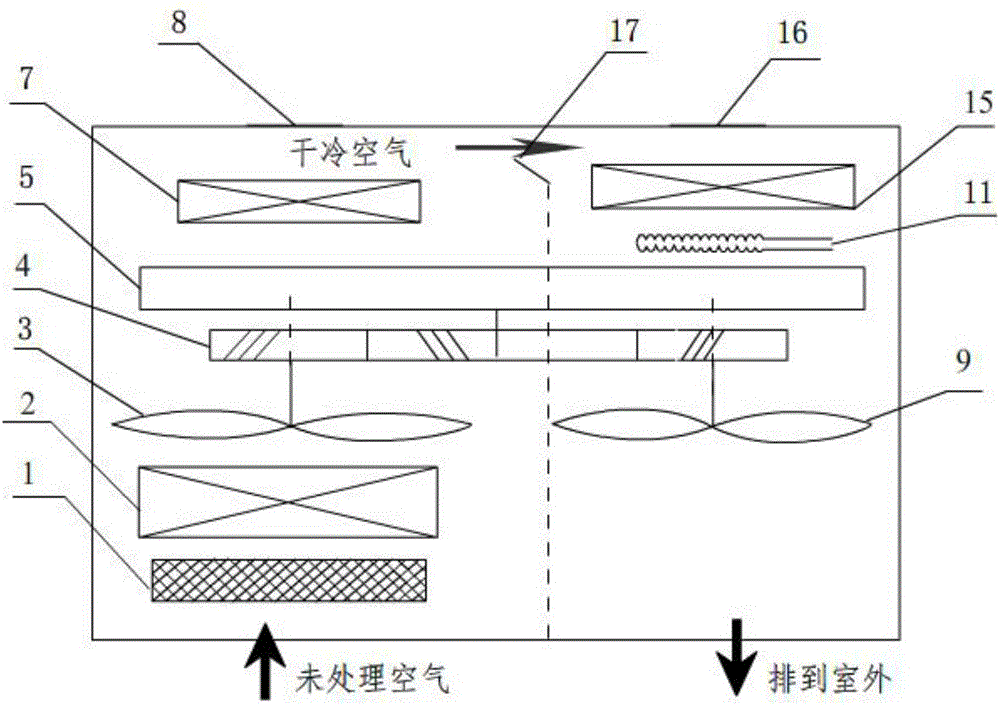

Hybrid refrigeration-turning wheel dehumidification device

ActiveCN106338113ATake advantage ofIncrease profitAir treatment detailsSpace heating and ventilation safety systemsElectricityMoisture absorption

The invention relates to a hybrid refrigeration-turning wheel dehumidification device. The advantages of a refrigeration system and a turning wheel are combined; the waste heat of a condenser is fully utilized to provide regenerated heat for the turning wheel; an auxiliary evaporator and an electric heating device are utilized to realize adjusting the air temperature so as to meet the comfort requirement; indoor humid air is humidified for the first step through a main evaporator after being primarily filtered, enters the turning wheel so as to be further humidified, and is then fed into the auxiliary evaporator for being further cooled to be discharged indoors or fed into the electric heating device for being heated to be discharged indoors according to the actual air supply temperature requirement of a user; and the waste heat of the condenser is fully utilized during a regeneration process, so that the heat required to be provided by the electric heating device is effectively reduced. The hybrid refrigeration-turning wheel dehumidification device provided by the invention provides several operating modes such as hybrid internal and external circulation, and when the air humidity is larger, dried air is utilized to directly and thoroughly desorb the turning wheel, so that the moisture absorption performance is ensured. The hybrid refrigeration-turning wheel dehumidification device provided by the invention has the advantages of high efficiency, low consumption, compact structure, good dehumidifying effect, safety, reliability, capability of stably working for a long time, and the like.

Owner:洞口县万美复合材料有限公司

Production method of spun silk and cotton blended spunlace nonwoven fabric

The invention discloses a production method of spun silk and cotton blended spunlace nonwoven fabric, wherein a flat top card replaces the traditional carding machine used in a nonwoven production line, and can perform sufficient carding of fiber so that the silk cotton net has low trash content and is longitudinally and transversely uniform and the fiber is in regular arrangement. The method performs temperature / humidity control in a production area, control on the spinning adaptability, mixing uniformity and antistatic property of the raw material, and optimization of the cotton net production technology, spunlace forming technology and degreasing and bleaching technology, so that the produced nonwoven fabric product not only maintains the elasticity and moisture absorption of cotton fiber, but also has the additional advantages of softness, smoothness and good glossiness of the spun silk based on the pure cotton cloth. The spun silk and cotton blended spunlace nonwoven fabric produced by the method has good extensibility, soft cloth cover and good water absorption, sufficiently reflects the skin-friendly performance of the spun silk serving as protein fiber filament, and has wide application prospects in the female high-grade make-up mask material.

Owner:ANQING HUAWEI IND FABRICS HI TECH CO LTD

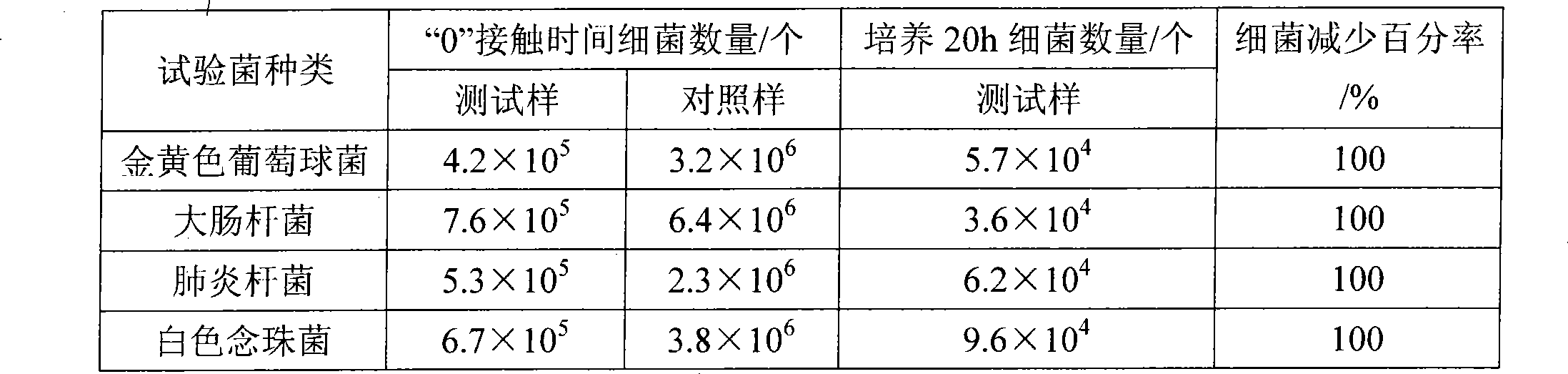

Antibacterial cotton cloth and preparation method

InactiveCN101392454AGuaranteed permeabilityGood combination fastnessVegetal fibresLiquid/gas/vapor textile treatmentCelluloseCotton gauze

Owner:LOGISTICS UNIV OF CAPF

Interwoven fabric interweaved by water absorption and fast drying fiber and cotton and making process

ActiveCN106350916AImprove wear resistanceGood sweat transfer functionHeating/cooling textile fabricsDry-cleaning apparatus for textilesCotton fibreMoisture resistance

The invention relates to interwoven fabric interweaved by water absorption and fast drying fiber and cotton and making process thereof, specifically to moisture absorbent filament and cotton interwoven fabric and a weaving process thereof. In the weaving process, the the fineness of warp and weft , and weaving density are strictly controlled, the warp uses low temperature enzyme desizing in the printing and dyeing process without PVA sizing process,using a low-temperature dyeing method below 100 oC, softener adopts hydrophilic finishing agent for non silicone finishing,which can not affect the moisture absorption of the fabric, but can make the fabric comfort, hygroscopicity, moisture resistance be well maintained,the weaving fabric used in the weaving method of The interwoven fabric has good feel, high comfort, light texture, good water permeability and quick drying effect,which solvesthe problem of poor moisture absorption of the fabric,and fully transfers the body sweat, reduces the breeding of bacteria, greatly makes up for the lack of cotton fiber.

Owner:威海魏桥科技工业园有限公司

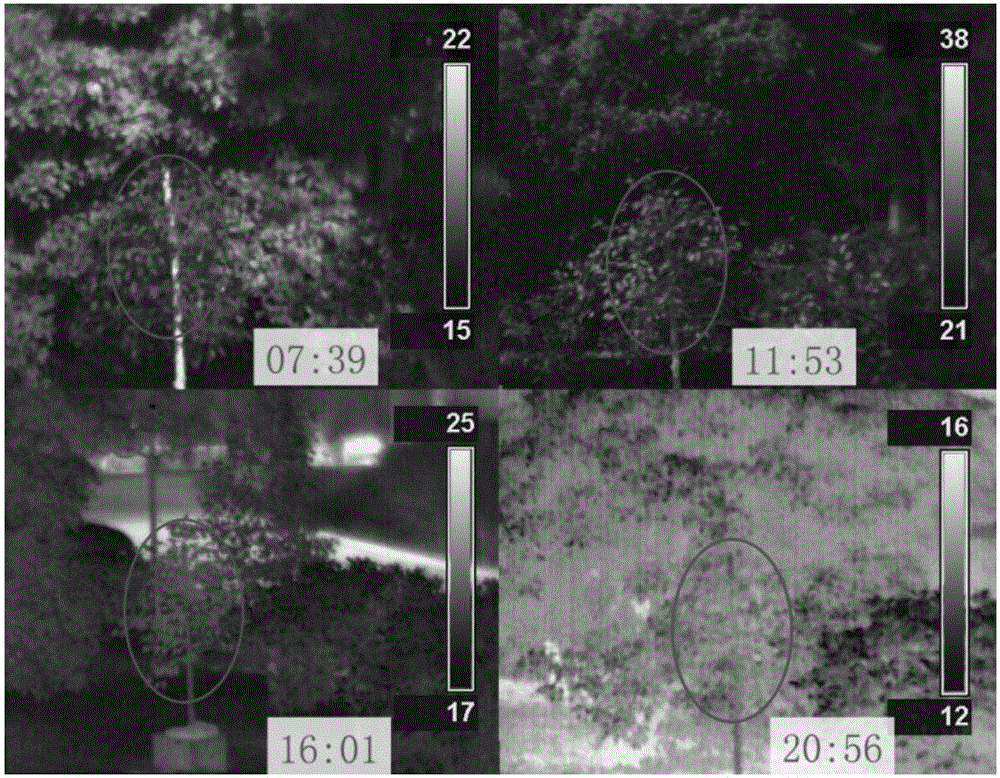

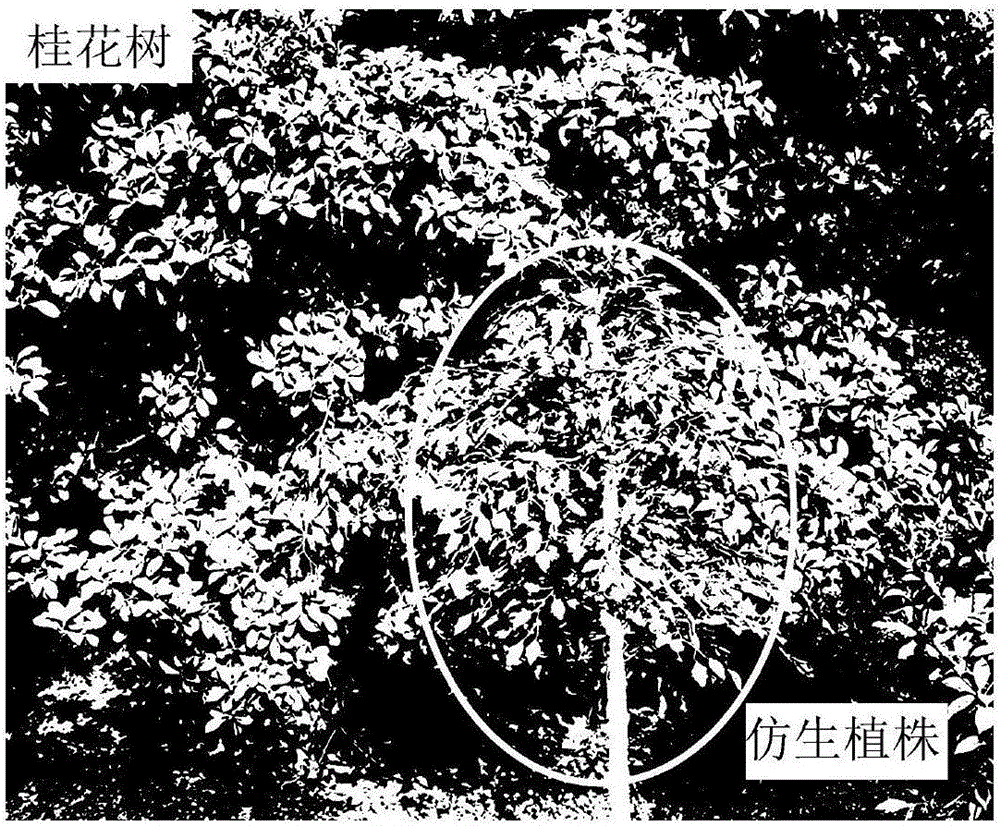

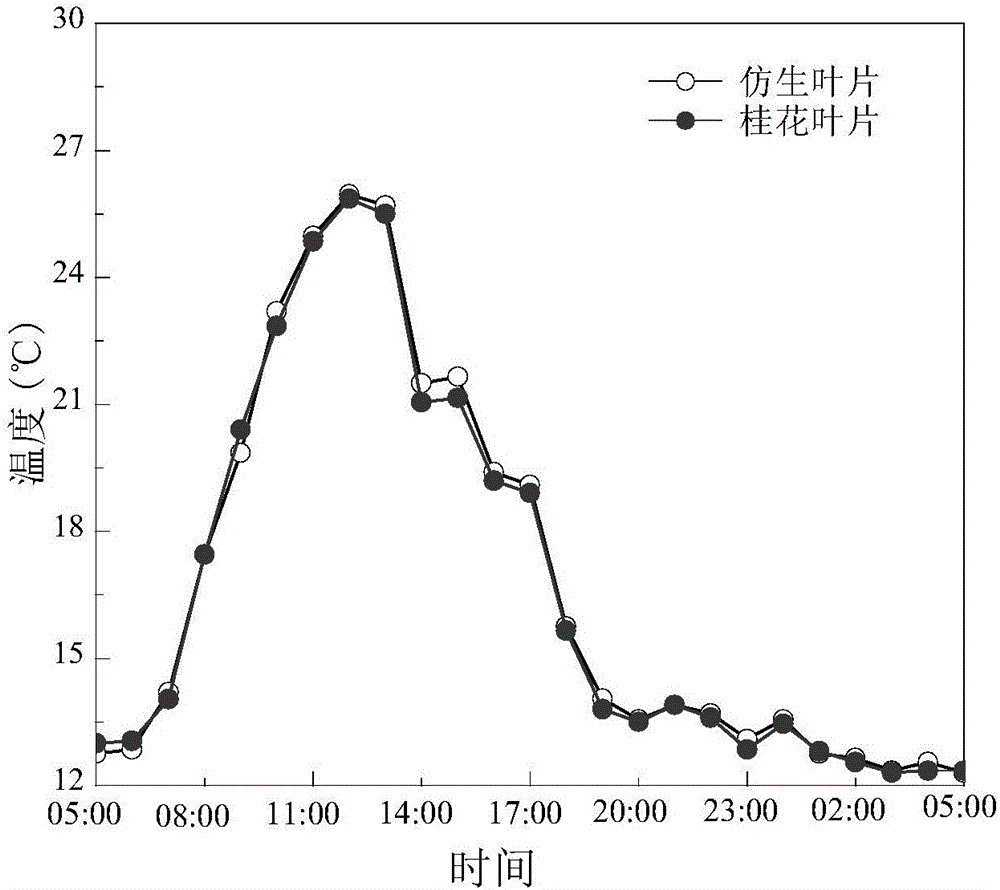

Organic bionic material and preparation method

InactiveCN106751275AGuaranteed Spectral Reflectance PerformanceGuaranteed moisture absorptionMetal chloridePolyvinyl alcohol

The invention discloses an organic bionic material and a preparation method. The organic bionic material is prepared from the following components in parts by weight: 1 to 8 parts of polyvinyl alcohol, 1 to 7 parts of metal chloride, 2 to 6 parts of colouring agent, 2 to 9 parts of cross-linking agent, and 5 to 6 parts of catalyst. The organic bionic material can simultaneously simulate plant leaf transpiration and a spectral reflection characteristic, and can simulate plant appearance, spectral reflection so as to achieve the aims of infrared, spectral imaging camouflage and woodland background visual camouflage.

Owner:合肥昊泰新材料科技有限责任公司

Crease-resistant and shrink-resistant finishing agent for hemp fabric

InactiveCN103668981AGuaranteed feelKeep breathableVegetal fibresBiocompatibility TestingMoisture absorption

A crease-resistant and shrink-resistant finishing agent for a hemp fabric comprises components in parts by mass as follows: 15-25 parts of silk fibroin, 5-10 parts of polyurethane, 1-3 parts of diepoxy triglycol glycidyl ether, 1-5 parts of glyoxal and 2-4 parts of citric acid, preferably, 20 parts of silk fibroin, 8 parts of polyurethane, 2 parts of diepoxy triglycol glycidyl ether, 3 parts of glyoxal and 3 parts of citric acid, wherein the mass ratio of silk fibroin to fatty alcohol-polyoxyethylene ether is 5:2. The provided crease-resistant and shrink-resistant finishing agent adopts silk fibroin as a main finishing agent ingredient, is safe and non-toxic, has excellent biocompatibility, and is particularly suitable for crease-resistant and shrink-resistant finishing of the hemp fabric, so that the crease resistance of the fabric is improved, the hemp fabric has a better washable characteristic, and the hand feeling, the breathability and the moisture absorption of the hemp fabric are kept.

Owner:NANTONG CITY TONGZHOU DISTRICT DADA HEMP TEXTILE

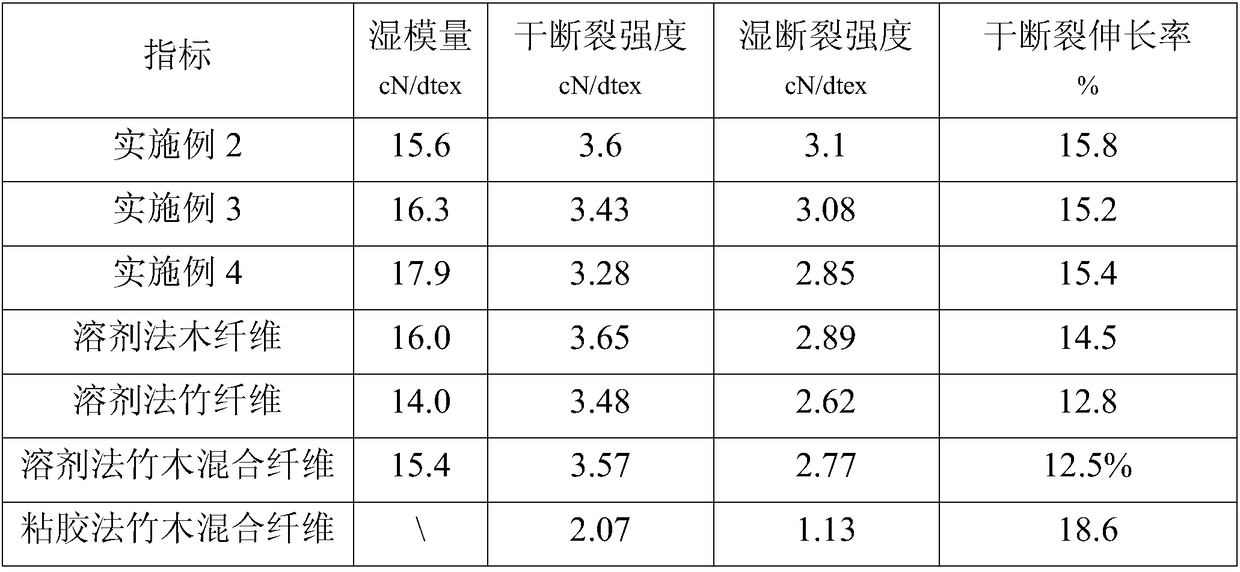

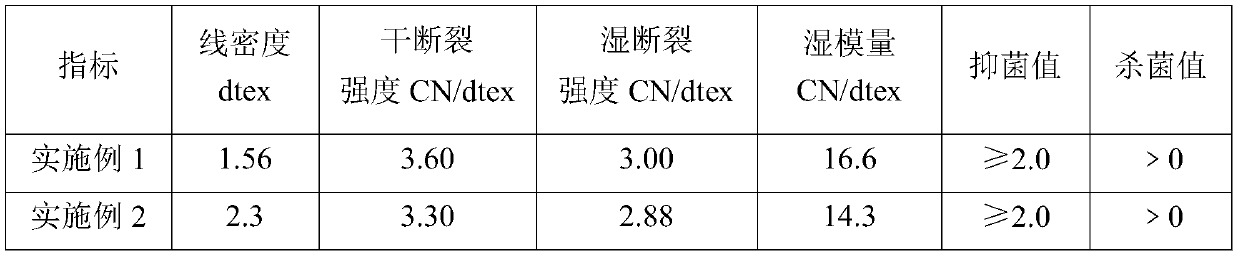

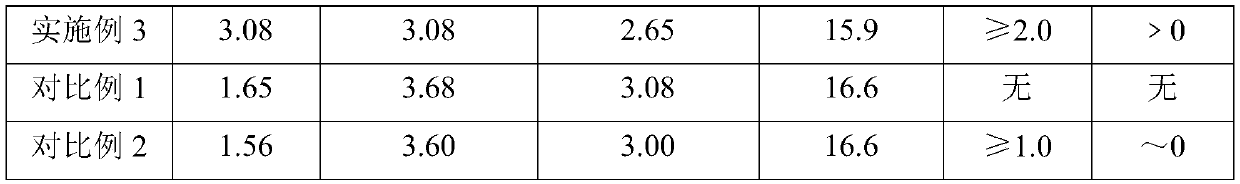

Solvent method based high-wet-modulus bamboo, wood and cotton mixed fiber and preparation method thereof

InactiveCN109355731AEasy to operateProduction without industrial pollutionConjugated cellulose/protein artificial filamentsFiberChemical residue

Owner:SHANGHAI DEFULUN CHEM FIBER +1

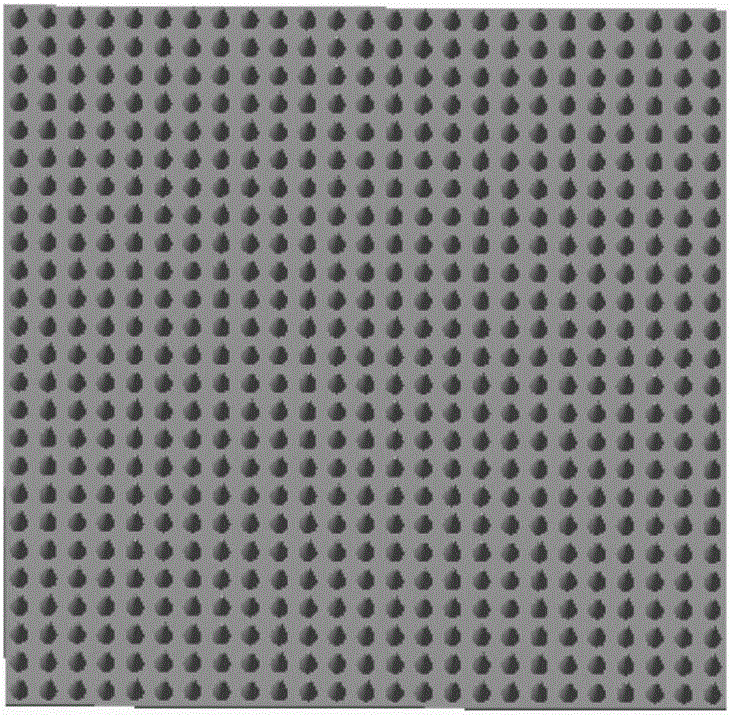

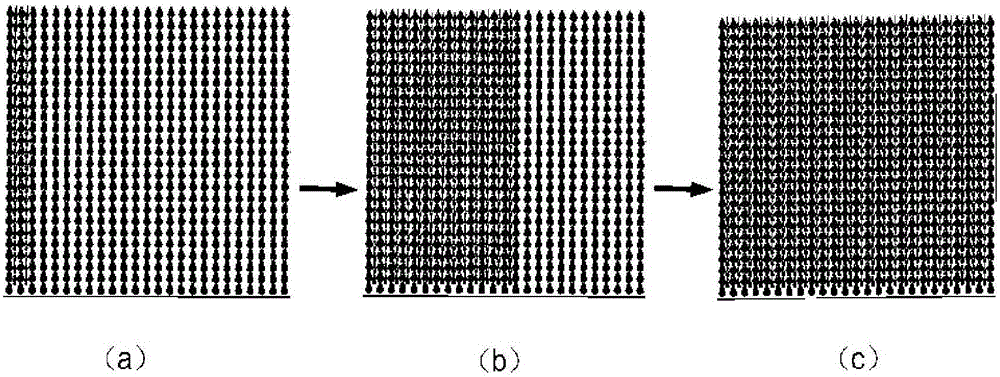

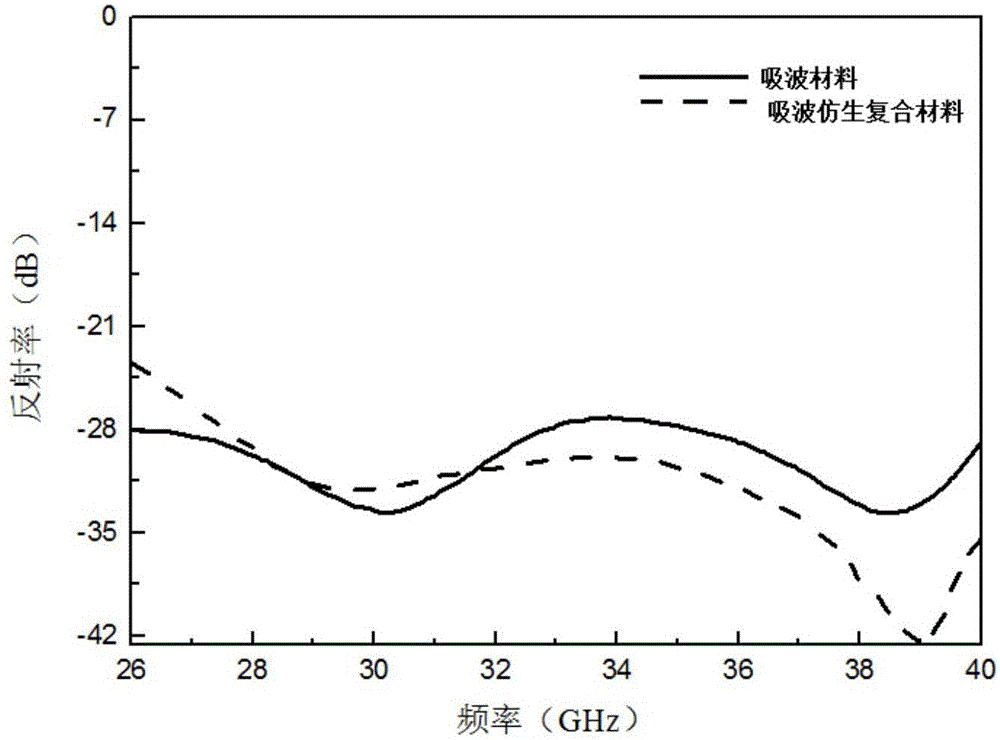

Wave-absorbing biomimetic composite material and preparation method

InactiveCN106751276AGuaranteed Spectral Reflectance PerformanceGuaranteed moisture absorptionOther chemical processesPolyvinyl alcoholMaterials science

The invention discloses a wave-absorbing biomimetic composite material and a preparation method. The wave-absorbing biomimetic composite material is prepared from an organic biomimetic material and a wave-absorbing material, wherein the organic biomimetic material is sheaf-like planted on the wave-absorbing material; the organic biomimetic material is prepared from the following components in parts by weight: 1 to 8 parts of polyvinyl alcohol water-soluble polymer, 1 to 7 parts of metal chloride, 2 to 6 parts of colouring agent, 2 to 9 parts of cross-linking agent, and 5 to 6 parts of catalyst. The wave-absorbing biomimetic composite material simulates plant appearance, spectral reflectance and radar wave absorption characteristics so as to achieve the aims of infrared, spectral imaging camouflage, woodland background visual camouflage and radar camouflage.

Owner:合肥昊泰新材料科技有限责任公司

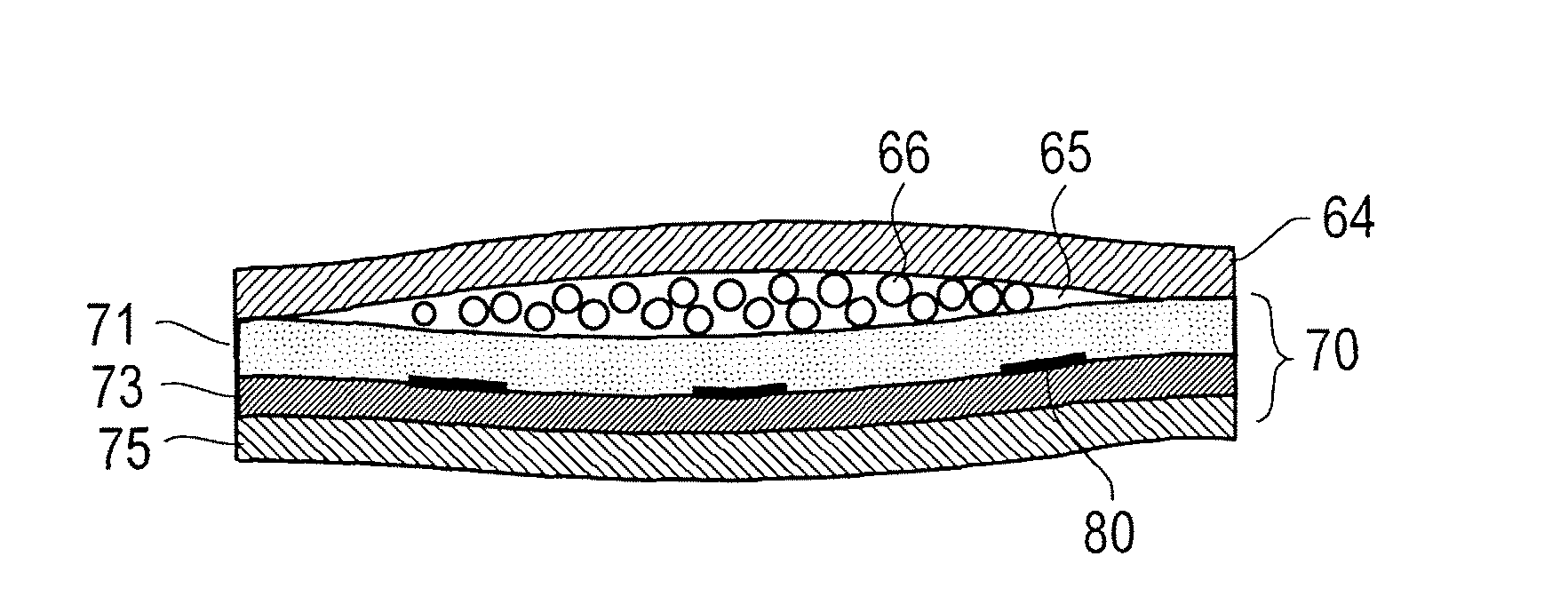

Packaging bag and drying agent with moisture absorption indicator function

InactiveUS7887894B2High transparencyStay hygroscopicContainer/bottle contructionFixed capacity gas holdersWater vaporDesiccant

A packaging bag and a drying agent with a moisture absorption indicator function are provided without using a heavy metal harmful to the human body. The packaging bag includes a first packaging material (10) and a second packaging material (20). The first packaging material (10) is provided on an outermost side thereof with a transparent barrier film (12) having a barrier property against water vapor. The second packaging material (20) has a light-reflective or light-absorbing film (24) and a pattern printed layer (23) overlaid on a bag interior side thereof, the pattern printed layer (23) having a printed moisture-absorbing indicator pattern (30). A desiccant-containing resin film (11, 21) which becomes transparent due to moisture absorption is overlaid on a bag interior side of at least one of the first packaging material (10) and the second packaging material (20). The drying agent with a moisture absorption indicator function includes an indicator film layer (70) having a barrier film (75), a pattern printed layer (73) for a moisture absorption indicator, and a moisture-absorbing film (71) containing zeolite, the pattern printed layer (73) and moisture-absorbing film (71) being laminated in this order on the barrier film (75). The drying agent further includes a main desiccant layer (61) and a moisture permeable film (64) that are overlaid on the moisture-absorbing film (71).

Owner:KYODO INSATU KK KYODO PRINTING CO LTD

Anti-bacterial cellulose complex fiber and preparation method thereof

ActiveCN108866665AAvoid churnEasy and flexible productionMonocomponent cellulose artificial filamentArtifical filament manufactureCarboxymethyl celluloseCellulose fiber

The invention relates to an anti-bacterial cellulose complex fiber and a preparation method thereof. The preparation method comprises the following step: spinning a mixed solution of water-soluble chitosan / carboxymethylcellulose collosol and a cellulose spinning solution to obtain the anti-bacterial cellulose complex fiber, wherein the dispersion phase particles of the water-soluble chitosan / carboxymethylcellulose collosol are a water-soluble chitosan / carboxymethylcellulose composition. The prepared antibacterial cellulose complex fiber is mainly prepared from a cellulose fiber substrate and the water-soluble chitosan / carboxymethylcellulose composition which is distributed inside and / or outside the cellulose fiber substrate; the water-soluble chitosan / carboxymethylcellulose composition ismainly formed by bonding water-soluble chitosan and carboxymethylcellulose through an ionic bond; the water-soluble chitosan / carboxymethylcellulose composition and the cellulose fiber substrate are mainly bonded through a hydrogen bond. The preparation method is easy to operate, and the prepared anti-bacterial cellulose complex fiber has the advantages of stable structure, high mechanical performance, antibacterial performance, moisture absorbing performance and excellent popularization value.

Owner:TIANE CHEM FIBER GROUP CORP BAODING +1

Cotton fabric deodorization treatment method

InactiveCN103882692AGuaranteed breathabilityStay hygroscopicVegetal fibresRoom temperatureCitric acid

The invention discloses a cotton fabric deodorization treatment method. The method comprises the following steps: dry-mixing chitosan with citric acid and a catalyst for 2min, putting the obtained mixture in water, and uniformly stirring to prepare a finishing solution with a chitosan concentration of 0.5%, a citric acid concentration of 10% and a catalyst concentration of 6%; putting a cotton fabric in the finishing solution, immersing at room temperature for 30min, padding the cotton fabric on a vertical electric padding trolley with a solution padding rate of 95%, and repeating immersion and padding once; putting the padded cotton fabric in a shaping dryer, drying at a temperature of 90DEG C for 3min, putting the dried cotton fabric in a baking machine, and carrying out high temperature baking at a temperature of 180DEG C for 90s; and washing with water, and air-drying. The method has a simple process, makes the cloth difficult adhered to microorganisms, aseptic and odorless, and well maintains the original air permeability, hydroscopic property and softness of the cloth.

Owner:QINGDAO TONGGUANWANG IND

Packaging bag and drying agent with moisture absorpotion indicator function

InactiveUS20110089056A1High transparencyStay hygroscopicContainer/bottle contructionDomestic containersWater vaporDesiccant

A packaging bag and a drying agent with a moisture absorption indicator function are provided without using a heavy metal harmful to the human body. The packaging bag includes a first packaging material (10) and a second packaging material (20). The first packaging material (10) is provided on an outermost side thereof with a transparent barrier film (12) having a barrier property against water vapor. The second packaging material (20) has a light-reflective or light-absorbing film (24) and a pattern printed layer (23) overlaid on a bag interior side thereof, the pattern printed layer (23) having a printed moisture-absorbing indicator pattern (30). A desiccant-containing resin film (11, 21) which becomes transparent due to moisture absorption is overlaid on a bag interior side of at least one of the first packaging material (10) and the second packaging material (20). The drying agent with a moisture absorption indicator function includes an indicator film layer (70) having a barrier film (75), a pattern printed layer (73) for a moisture absorption indicator, and a moisture-absorbing film (71) containing zeolite, the pattern printed layer (73) and moisture-absorbing film (71) being laminated in this order on the barrier film (75). The drying agent further includes a main desiccant layer (61) and a moisture permeable film (64) that are overlaid on the moisture-absorbing film (71).

Owner:KYODO PRINTING CO LTD

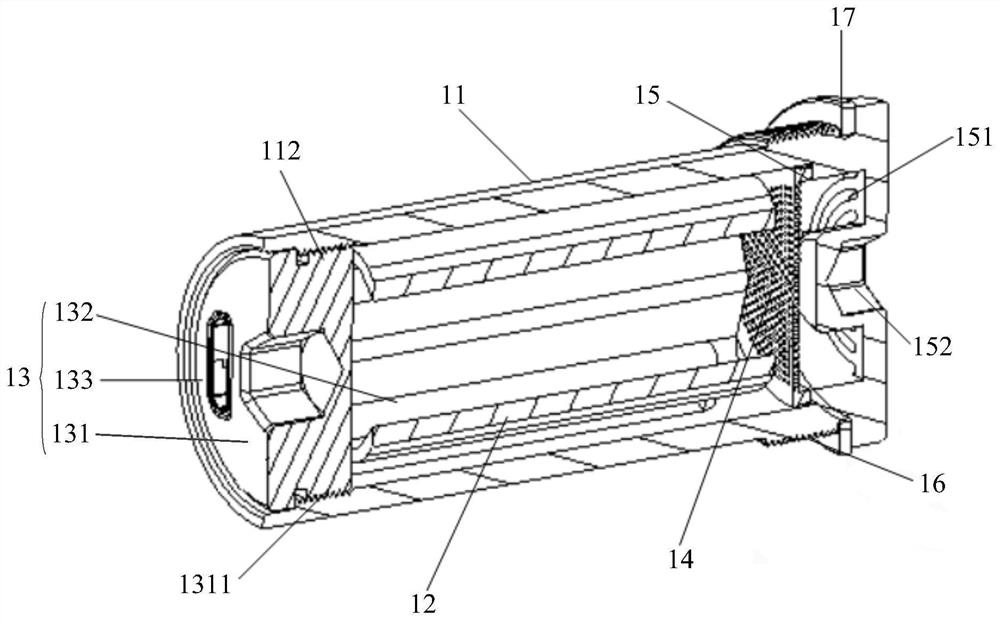

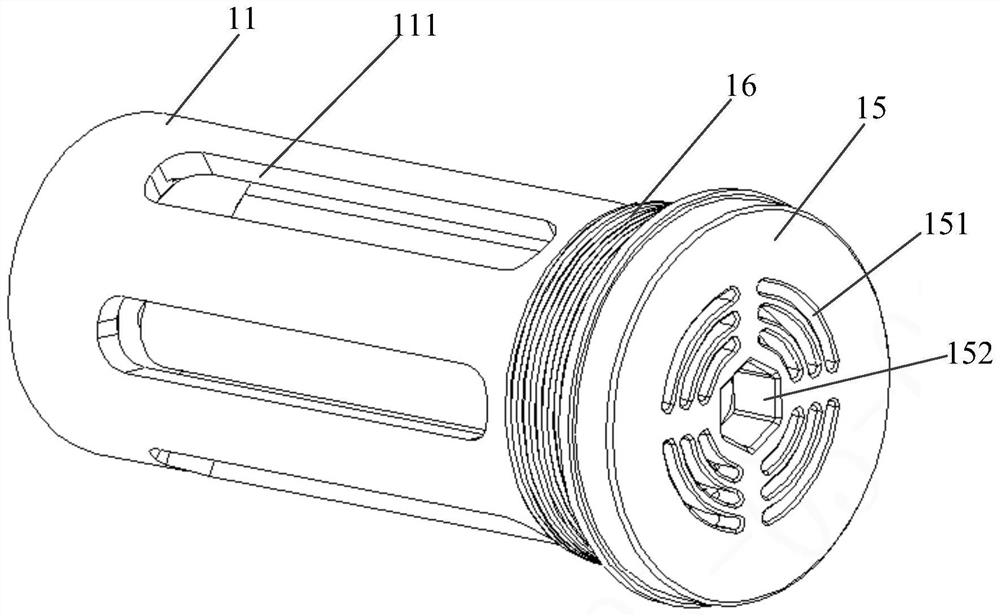

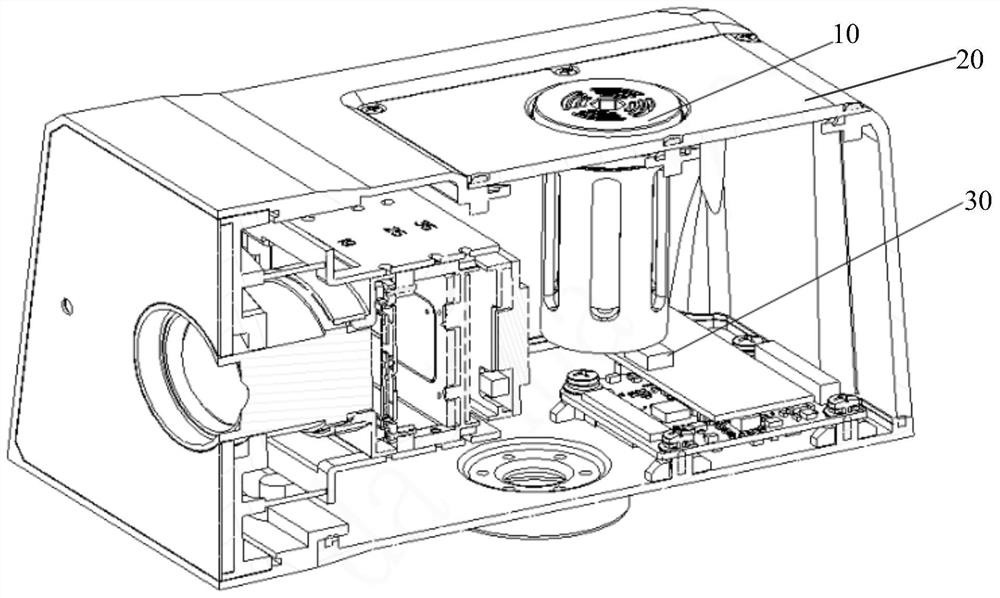

Camera dehumidification device and camera

PendingCN113810570AAvoid fogging up your deviceSolve equipment siphonTelevision system detailsGas treatmentPhysicsEngineering

The invention relates to the technical field of camera demisting and dehumidifying, and discloses a camera dehumidification device and a camera, the dehumidification device comprises a shell, wherein a first end of the shell is connected to a camera shell, an accommodating space is formed in the shell, the surface of the shell is provided with an opening used for communicating the accommodating space with the interior of the camera shell, and the first end of the shell is provided with an opening; a reversible moisture absorption structure which s arranged in the accommodating space; a heating module which is arranged in the accommodating space and used for heating the reversible moisture absorption structure so that the reversible moisture absorption structure can absorb heat and release moisture; and a waterproof breathable film which is arranged at the opening and is used for discharging water vapor in the shell out of the camera shell. According to the dehumidification device disclosed by the invention, the problems of camera siphoning and fog prevention are effectively solved by utilizing the waterproof breathable film, the reversible moisture absorption structure and the heating module.

Owner:ZHEJIANG DAHUA TECH CO LTD

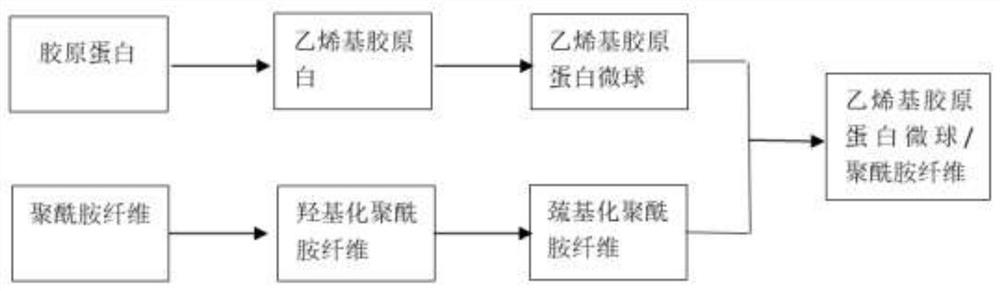

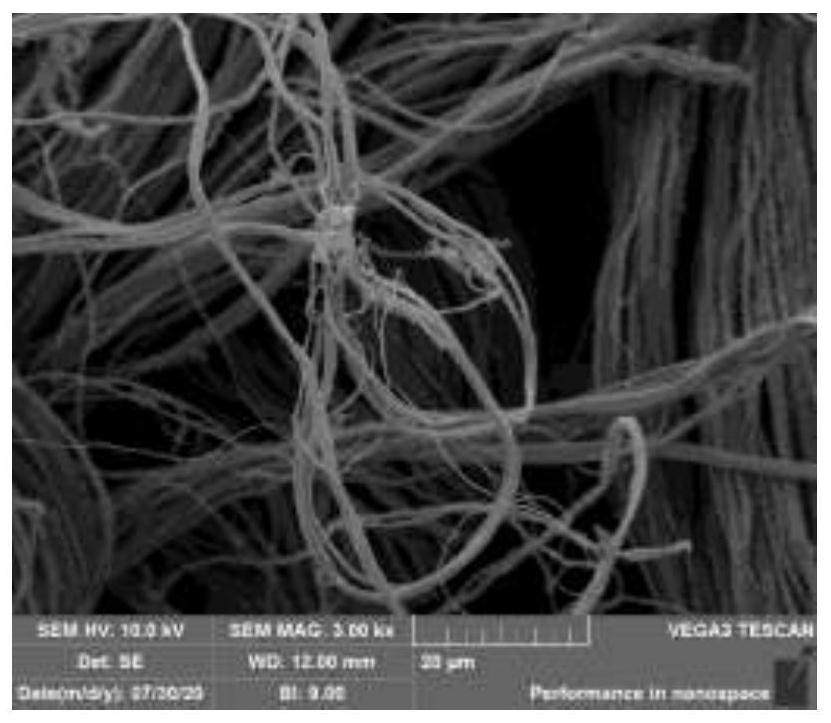

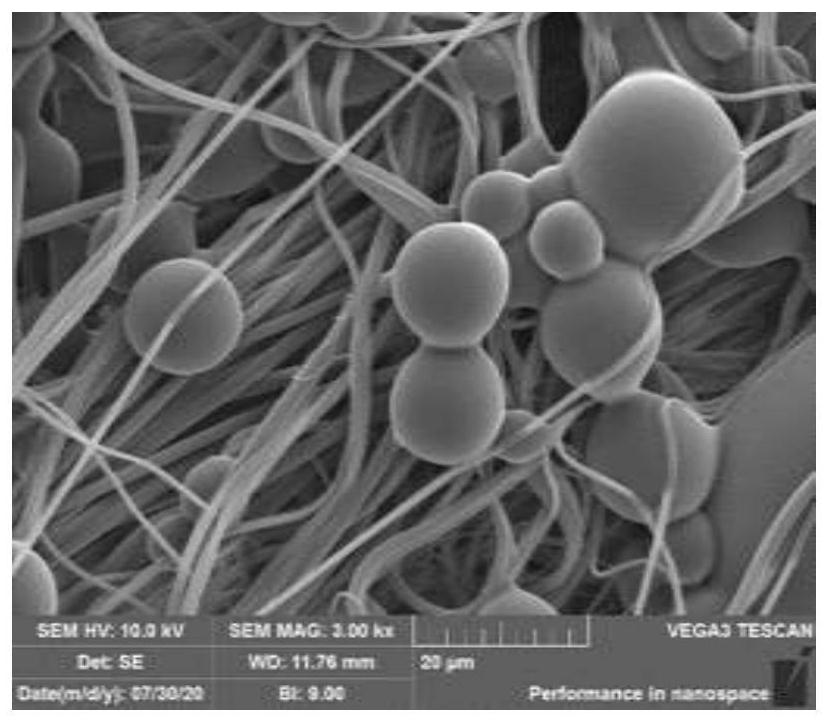

Preparation method of vinyl collagen microsphere/polyamide fiber composite material

InactiveCN112779777ARealize resource utilizationGood moisture permeabilityFibre typesLight/infra-red/X-rays fibre treatmentPolymer scienceCollagenan

Owner:SHAANXI UNIV OF SCI & TECH

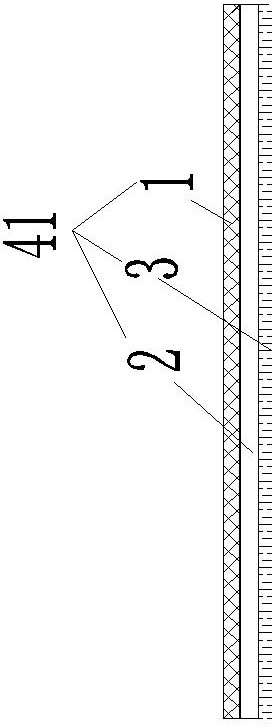

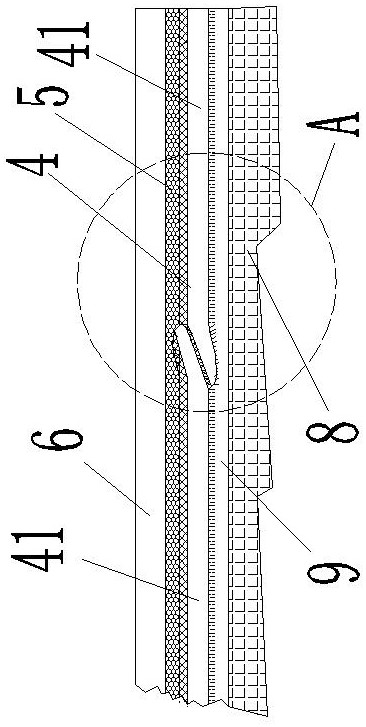

Flexible polymer waterproof coiled material and preparation method thereof

PendingCN112238667AEasy to cutReduce pasteSynthetic resin layered productsLaminationPolyesterPolymer science

The invention discloses a flexible polymer waterproof coiled material and a preparation method thereof. The flexible polymer waterproof coiled material comprises a spraying layer and a base layer; thebase layer comprises a polyvinyl chloride soft layer with the thickness of 0.5-0.9 mm, polypropylene fiber non-woven fabric which is compounded on the top surface of the polyvinyl chloride soft layerin a hot-pressing mode and has a mesh structure, and polyester fabric which is compounded on the bottom surface of the polyvinyl chloride soft layer in a hot-pressing mode and has a matte bottom surface; the spraying layer is sprayed on the top surface of the polypropylene fiber non-woven fabric; and the spraying layer is made of polyurethane or polyurea. The polymer coiled material can adapt tothe environment that a construction area is damp or sundries such as dust and sand exist or a working face is not a flat face, and has the advantages of being easy and convenient to construct and excellent in weather resistance.

Owner:晋盾防护(山西)科技有限公司 +3

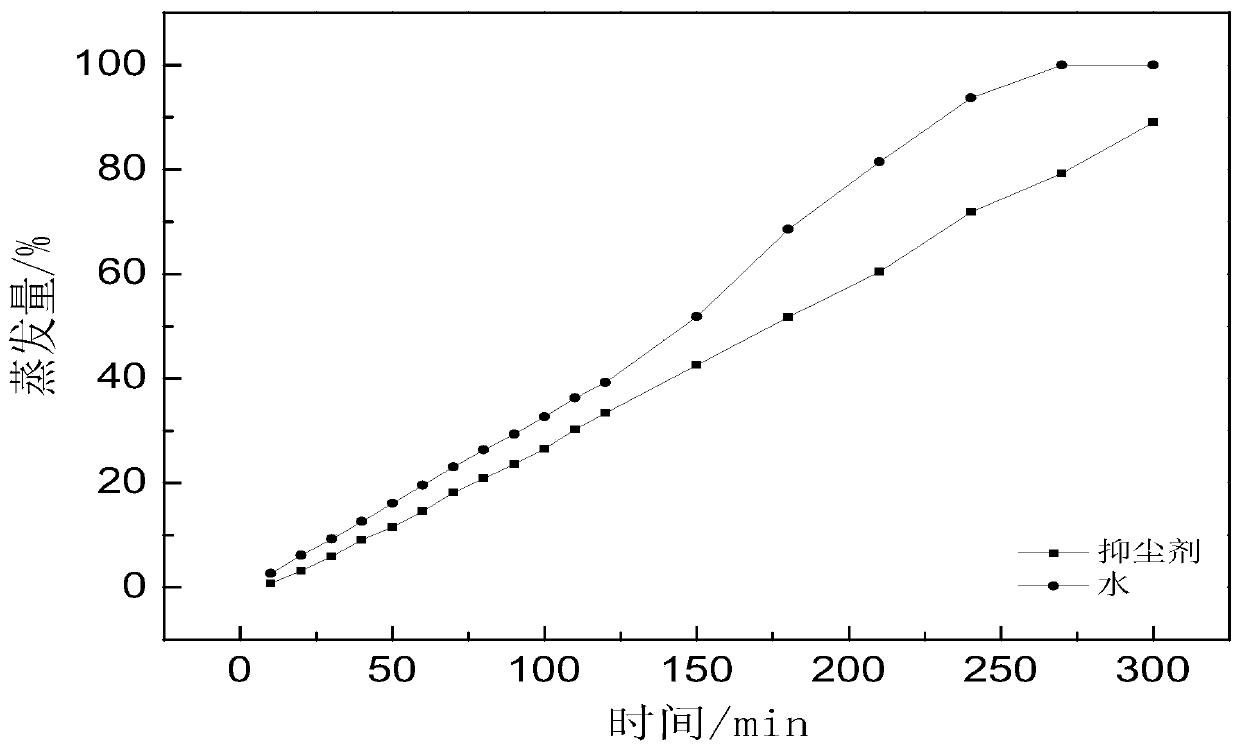

A method for preparing cotton pulp used for high-strength filter paper

ActiveCN109778580AGuaranteed StrengthStay hygroscopicWashing/displacing pulp-treating liquorsPulp beating methodsFilter paperUltimate tensile strength

A method for preparing cotton pulp used for high-strength filter paper is disclosed. The cotton pulp has a degree of polymerization being 550-600, whiteness not less than 84%, an ash content of not more than 0.15%, a beating degree of 20-25 SR and a pH value of 3-5. The hygroscopicity and strength of the filter paper prepared by adopting the method can be ensured.

Owner:山东银鹰股份有限公司

Weighting agent for weighting real silks

The invention discloses a weighting agent for weighting real silks. The weighting agent is characterized by comprising the following substances in parts by weight: 10-20 parts of emulsifying agent, 1-8 parts of surfactant, 10-14 parts of sulfate, 1-3 parts of citric acid, 1-7 parts of washing agent, 1-10 parts of auxiliary agent, 3-9 parts of sodium alginate and 50 parts of water. By virtue of adopting the weighting agent, the weight of the real silk is weighted and the thick and solid feeling of a real silk product is increased; the fluffing property and washability of the real silk are improved and the hand feeling, dyeing property and hygroscopicity of the real silk are also preserved.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

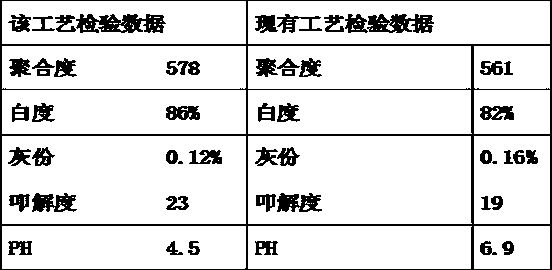

Dust suppressant as well as preparation method and application thereof

ActiveCN110591647AAchieve reuseReduce the impactOther chemical processesFermentationAdhesiveRoad surface

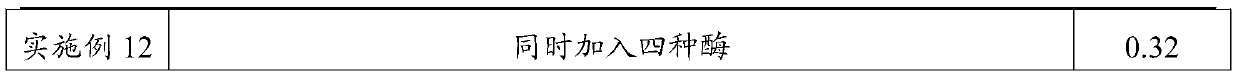

The invention provides a dust suppressant as well as a preparation method and application thereof, and belongs to the field of road dust suppression. The preparation method of the dust suppressant comprises the following steps: mixing cellulase, water and straw, carrying out an enzymolysis reaction, and adding a thickener or an adhesive to obtain the dust suppressant. Straw is used as a raw material and is degraded through cellulase, and macromolecular saccharides such as xylan and cellulose are degraded into low-molecular saccharides; low-molecular carbohydrates are dissolved in a supernatantliquid, water evaporates is achieved after spraying, a soft mucous membrane layer is formed on the road surface due to residual carbohydrates, and the moisture absorption capacity can be kept for a long time, so that the road surface is kept in a relatively humid environment, and flying dust is inhibited; meanwhile, the formed soft mucous membrane layer can be well combined with the road surface;by adding the thickener or the adhesive, the viscosity of the dust suppressant can be improved, flying dust on the road surface can be effectively adhered, and thus the dust suppression effect is enhanced; in addition, the soft mucous membrane layer is not easy to dry to form a shell, so that the anti-rolling effect is better.

Owner:BEIJING UNIV OF TECH

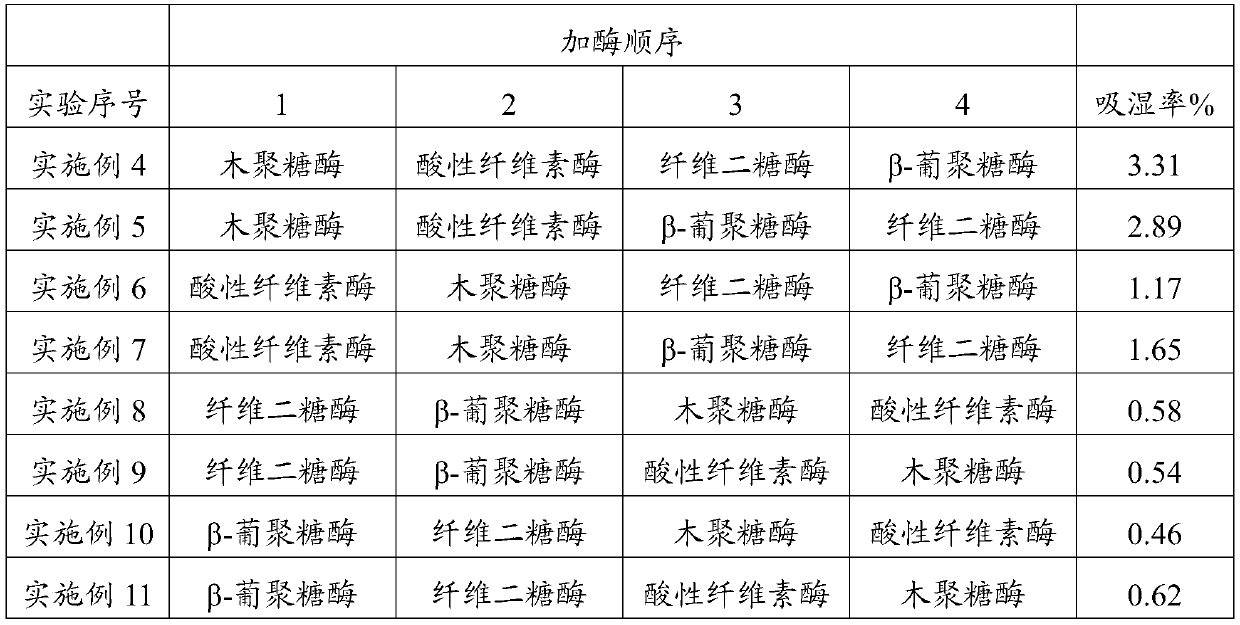

Solvent-process high wet modulus chitin fibers and preparation method thereof

InactiveCN110804766AEasy to operateProduction without industrial pollutionArtificial filament washing/dryingMonocomponent cellulose artificial filamentFiberPolymer science

The invention discloses solvent-process high wet modulus chitin fibers and a preparation method thereof, and belongs to the field of textiles. The preparation method comprises the steps: (A) activating, to be specific, activating pulp dregs by cellulase to obtain paste; (B) squeezing, to be specific, squeezing and dehydrating the paste to obtain water-containing cellulose; (C) pre-dissolving, to be specific, mixing aqueous cellulose, N-methylmorpholine-N-oxide solution and a chitin solution to obtain a pre-dissolved pulp; (D) dissolving, to be specific, dissolving the pre-dissolved pulp in a dissolving machine to obtain a pulp; and (E) spinning, to be specific, performing spinning on the pulp to obtain the solvent-process high wet modulus chitin fibers. The preparation method has the advantages of good operation simplicity, zero industrial pollution to production, low energy consumption, high safety and suitability for large-scale industrial continuous production. The prepared solvent-process high wet modulus chitin fibers have high wet modulus, contain protein components, and are good in breathability and air permeability, comfortable to wear, soft to touch and favorable for continuous dyeing, are convenient to print and dye and are good for producing high-end fabrics.

Owner:SHANGHAI LYOCELL FIBER DEV

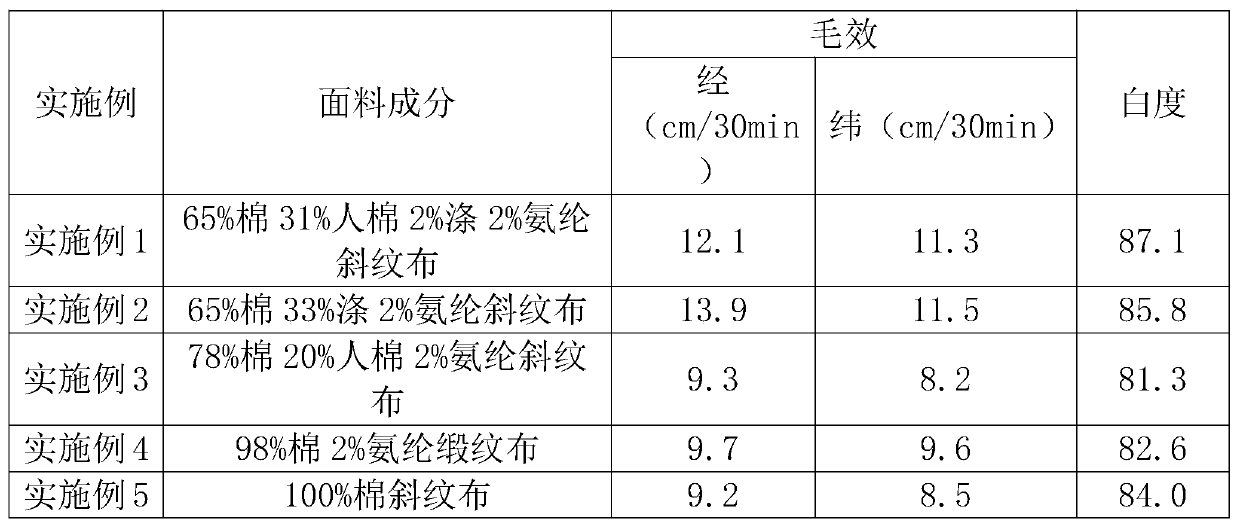

Short-flow pretreatment processing method for cotton blending woven fabric

InactiveCN110284317AEfficient removalStay hygroscopicBiochemical treatment with enzymes/microorganismsVegetal fibresElectricityProcess engineering

The invention provides a short-flow pretreatment processing method for a cotton blending woven fabric. Desizing, scouring and bleaching are carried out in one step after a singeing process. The method specifically comprises the following seven steps of dipping and rolling of a cold heap liquid, wherein the rolling rate is 100%, and a two-dipping and two-rolling mode is adopted; cold heaping; first water washing; dipping and rolling of a steaming liquid, wherein the rolling rate is 100%, and the two-dipping and two-rolling mode is adopted; steaming; second water washing; drying. According to the processing method, the traditional desizing, scouring and bleaching processes of the cotton blending woven fabric are realized by means of a one-step method, the process flow is shortened, the production efficiency is improved, and meanwhile the consumption of water, electricity and steam is reduced.

Owner:佛山市顺德金纺集团有限公司

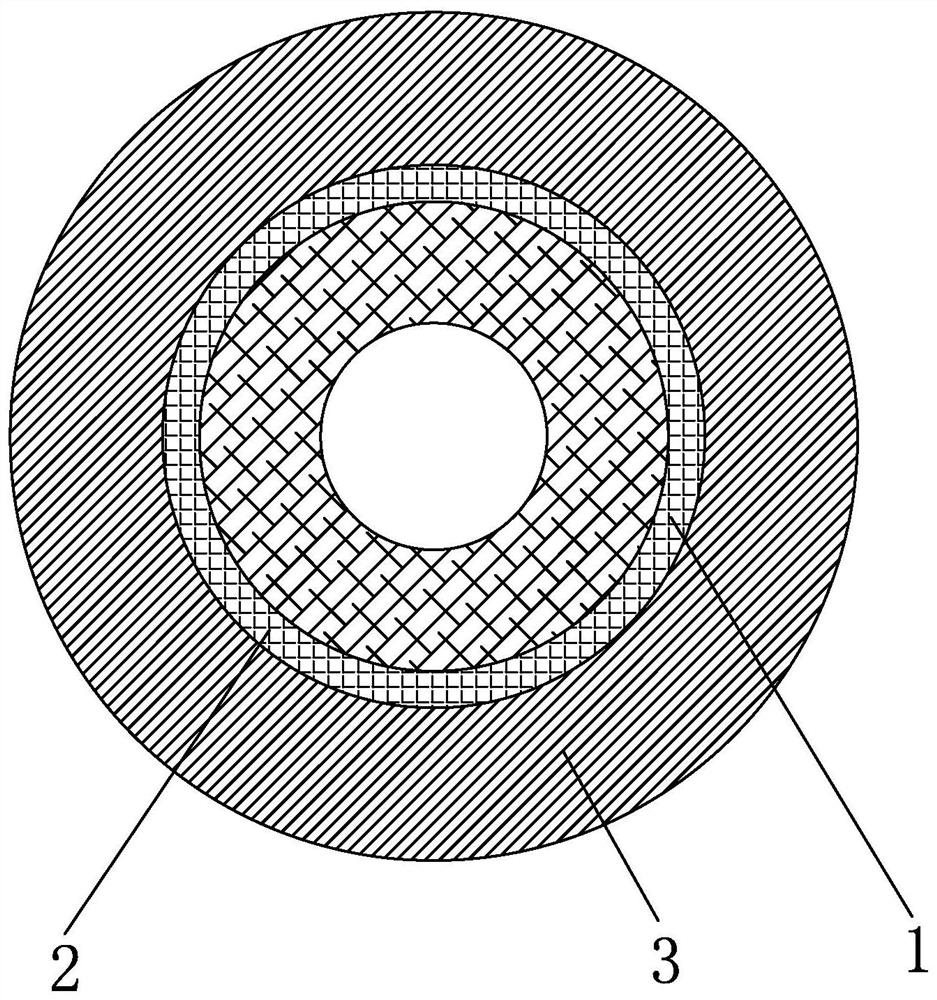

Blended yarn deeply developed from silkworms and spinning process

The invention discloses blended yarn deeply developed from silkworms and a spinning process of the blended yarn. The blended yarn comprises a yarn body, wherein the yarn body is hollow yarn and comprises a hollow inner core layer, a sericin film layer and a winding skin layer which are sequentially arranged from inside to outside, the hollow inner core layer is made of mulberry bark fibers, the mulberry bark fibers are spirally wound outside a hollow core hole of the yarn body, the sericin film layer is formed by coating sericin outside the hollow inner core layer to form a film layer structure, the winding skin layer adopts winding filaments, and the winding filaments are spirally wound outside the sericin film layer to form an outer wrapping structure. According to the blended yarn deeply developed from the silkworms and the spinning process of the blended yarn, the silkworm industry is deeply developed, resources are fully utilized, and the mulberry fibers, the sericin, pupa proteinviscose filaments or spun silk are used for spinning the novel blended yarn; and the blended yarn is low in cost, high in yarn strength, soft and smooth in touch, washable, good in shrink-proof and crease-resistant performance, good in water absorption and air permeability and excellent in comprehensive performance.

Owner:SUZHOU CITY XINGJINGZE FIBER TECH CO LTD

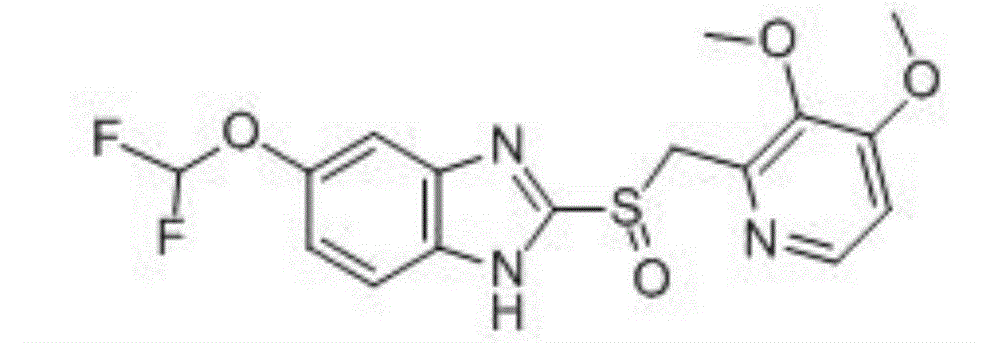

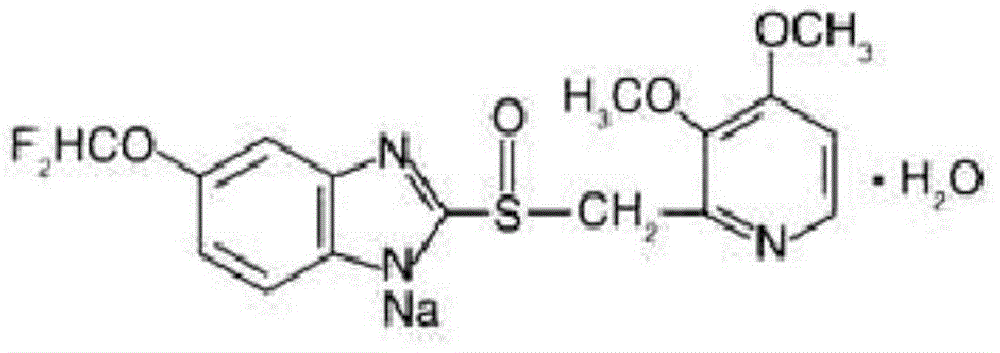

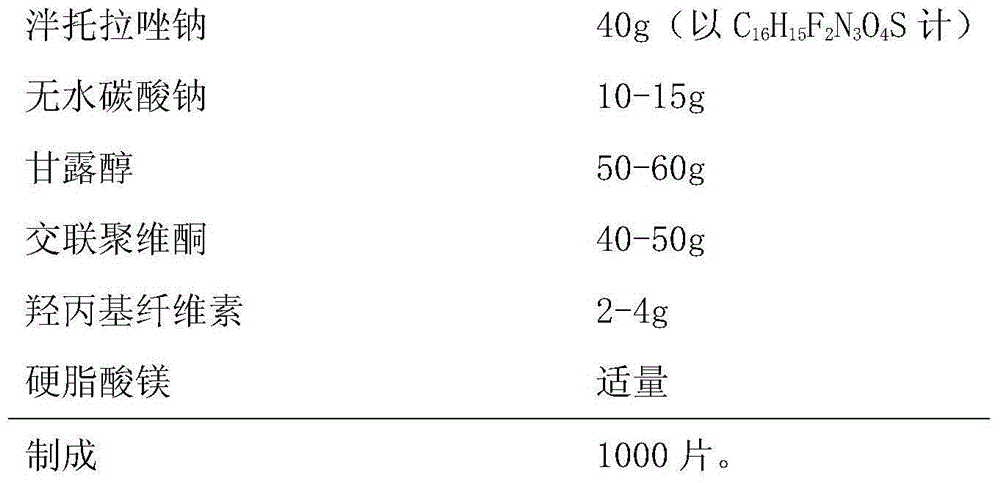

A kind of pantoprazole sodium enteric-coated tablet and preparation method thereof

ActiveCN104146977BImprove securityGood hygroscopicityOrganic active ingredientsDigestive systemMedicineIsolation layer

The present invention discloses a pantoprazole sodium enteric coated tablet and a preparation method thereof. In the invention, an optimal prescription, an optimal process prescription and optimal isolation layer and enteric coating process choices are obtained by researching the prescription and production technology of the core of the pantoprazole sodium enteric coated tablet, and processes of the isolation layer and the enteric coating. The pantoprazole sodium enteric coated tablet prepared on the basis of the above optimal prescription, production technology, isolation layer and enteric coating has the advantages of good stability, good acid resistance, good release, and bioavailability improvement. The preparation method is simple and stable, and is suitable for industrial production.

Owner:JINAN LIMIN PHARMA

Special quick-drying fabric for clothing and processing technology thereof

ActiveCN112477330AExcellent moisture absorption and dehumidification effectExcellent quick-drying performanceBiochemical fibre treatmentSynthetic resin layered productsCotton fibreAnti bacterial

The invention discloses a special quick-drying fabric for clothing and a processing technology thereof. In the preparation process, calcium carbonate is added into polyurethane, melt extrusion granulation is conducted, then the mixture is blended with polyurethane slices, spinning forming is conducted, modified polyurethane fibers are obtained, then the modified polyurethane fibers and cotton fibers are taken and woven, and base cloth is obtained; subsequent base cloth, middle cloth and surface cloth are subjected to process improvement on the basis of base cloth. The invention discloses a special quick-drying fabric for clothing and a processing technology thereof, the prepared quick-drying fabric not only has excellent moisture absorption and moisture removal effects and excellent quick-drying performance, but also has excellent antibacterial performance, breeding of bacteria in the water vapor infiltration and moisture removal process can be effectively avoided, and the quick-dryingfabric can be applied to multiple fields, and has high practicability.

Owner:依文服饰股份有限公司

Special fertilizer capable of improving soil structure for lotus root

InactiveCN107867941AIncrease productionFast releaseAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPotassiumAmmonium nitrate

The invention discloses special fertilizer capable of improving a soil structure for lotus root. The special fertilizer is prepared from the following raw materials in parts by weight: 60 to 80 partsof ammonium nitrate, 50 to 60 parts of potassium polyphosphate, 20 to 40 parts of potassium chloride, 10 to 20 parts of ammonium phosphate, 15 to 25 parts of trace element fertilizer, 0.4 to 0.8 partof sodium naphthalene acetate, 4 to 8 parts of compound protein, 20 to 30 parts of diatomite, 6 to 10 parts of talcum powder, 8 to 14 parts of attapulgite, 20 to 30 parts of a coating agent and 90 to100 parts of water. The compound protein is prepared by adopting the following process: uniformly mixing house-flies larva protein, peanut protein and a formaldehyde solution; adding a sodium hydroxide solution for stirring; adding chitosan and melamine for continuously stirring, raising the temperature, stirring and cooling to obtain the compound protein. The special fertilizer disclosed by the invention can be used for adsorbing metal ions in the soil, contains various nutritional ingredients needed for the growth of the lotus root as well as has a good slow release effect and obvious effects of promoting roots and strengthening seedlings, activating the soil, increasing the yield and improving the quality; the production of the lotus root is greatly increased.

Owner:定远县英华种植家庭农场

Active printing paste modifier without urea in application, its preparation method and composition

ActiveCN109594363BStay hygroscopicAchieve hygroscopicityDyeing processTextile printerAmmoniacal nitrogen

Owner:TAICANG BAONI IND CO LTD

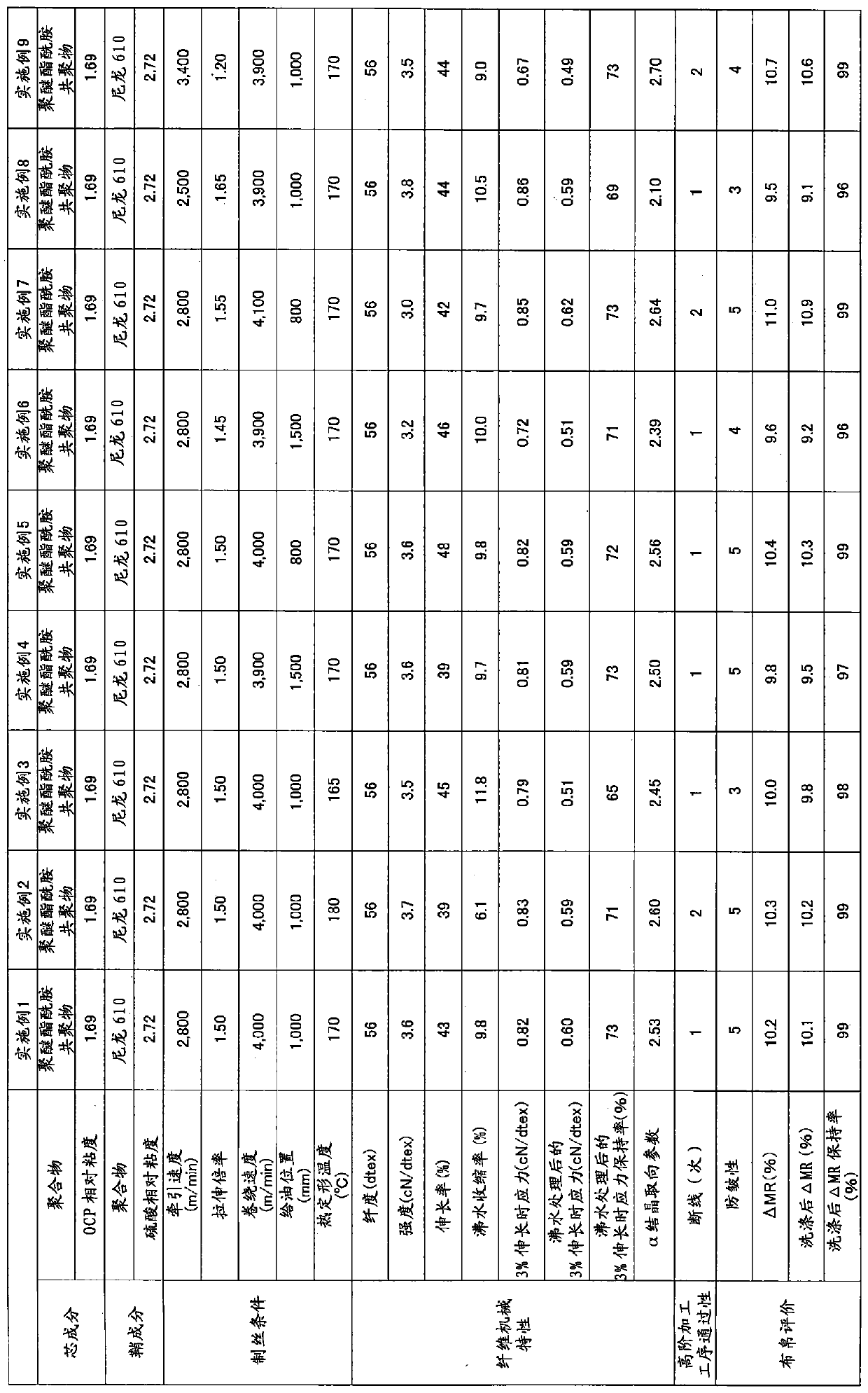

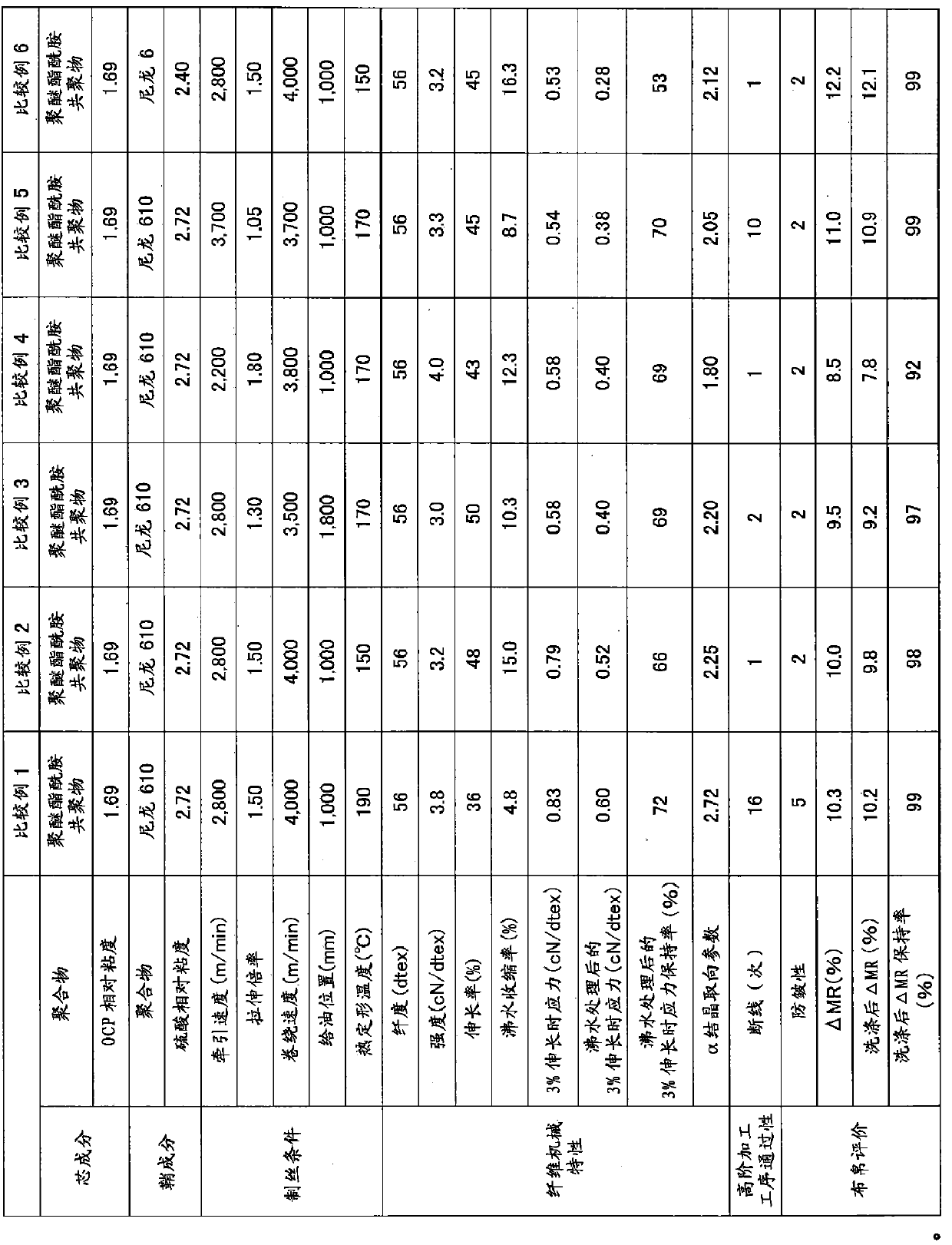

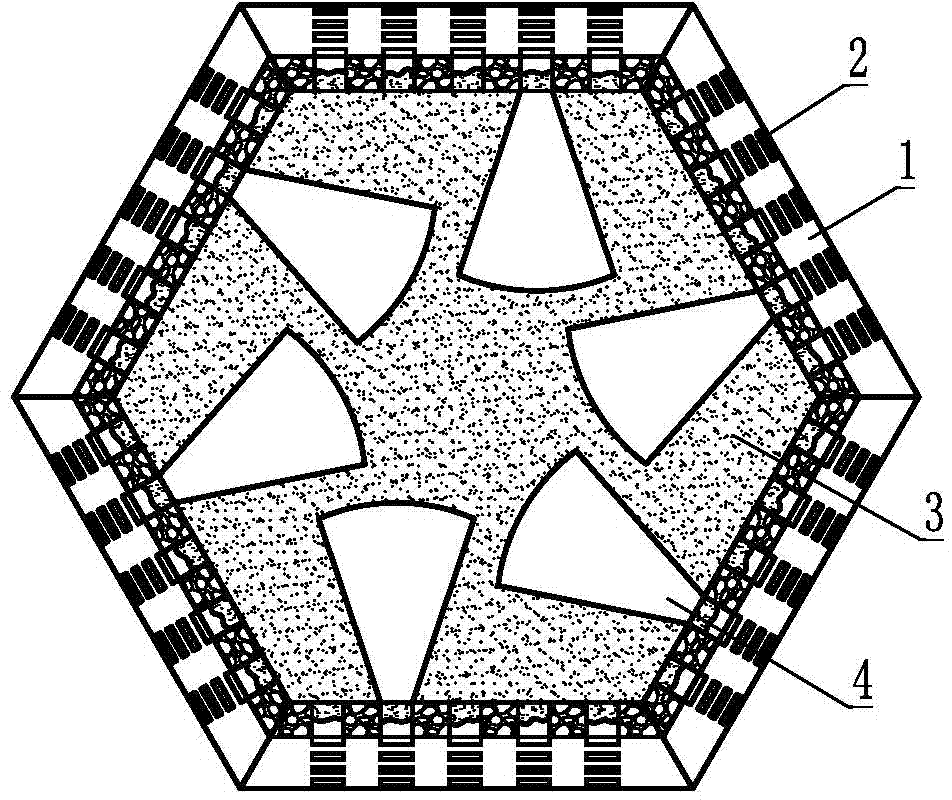

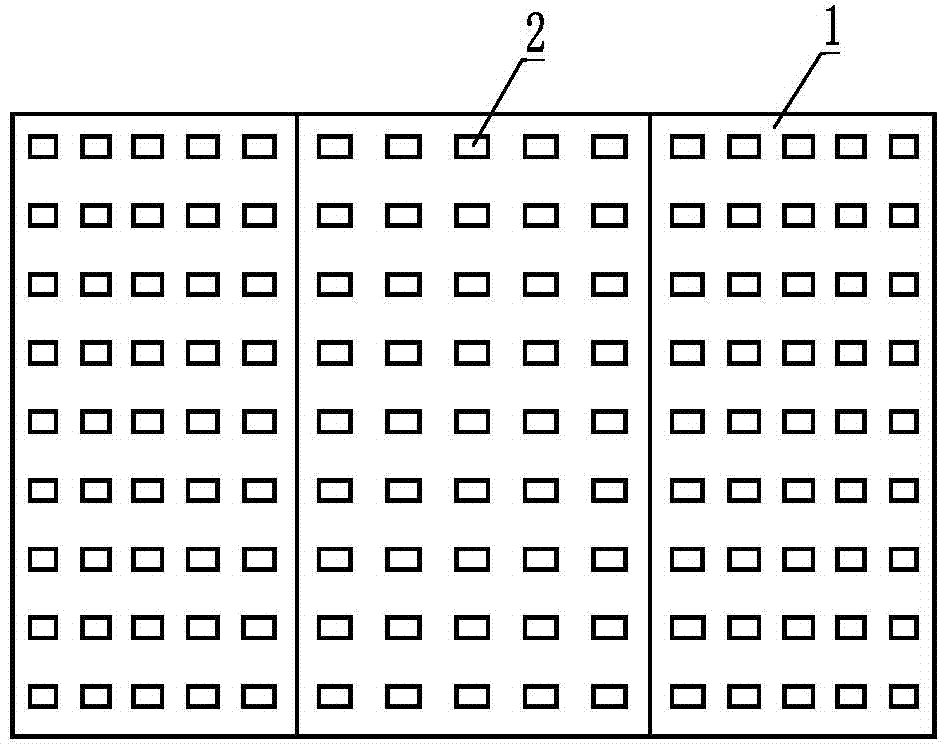

Core-sheath composite cross-section fiber with excellent hygroscopicity and wrinkle resistance

ActiveCN108138378BGood hygroscopicityImprove wrinkle resistanceFilament/thread formingWoven fabricsFiberPolymer science

Owner:TORAY IND INC

A scorpion raising device that simulates a natural environment

InactiveCN103598152BMaintain humidityEasy to climb in and outAnimal husbandryMoisture absorptionEngineering

The invention discloses a scorpion raising device capable of simulating natural environment. The device comprises vertical plates defining a scorpion nest, wherein ventilating holes are formed in the vertical plates, the scorpion nest is filled with filler, the filler is provided with a plurality of scorpion holes, and each scorpion hole is communicated with a ventilating hole. A moisture absorption drainage top cover is installed above the scorpion nest. The scorpion holes are communicated with the ventilating holes, so that humidity in the scorpion holes can be better dissipated, and humidity in the filler of the scorpion nest can be further dissipated through the ventilating holes in the vertical plate so as to realize the propose of ventilating and discharging humidity, so that the humidity of the whole scorpion nest meets the ecdysis and growth demands of scorpions and scorpions can stay in the ventilating holes or crawl in and out of the filler such as soil in the ventilating holes. Temperature in the scorpion nest is not manually adjusted basically, and is automatically adjusted along with natural temperatures in all seasons. The device disclosed by the invention provides a growing environment which is close to the natural environment for ecdysis and growth of scorpions, so that the ecdysis survival rate of scorpions is greatly improved, and the device is suitable for artificial breeding in a large scale.

Owner:谢正波

Production method of spun silk and cotton blended spunlace nonwoven fabric

The invention discloses a production method of spun silk and cotton blended spunlace nonwoven fabric, wherein a flat top card replaces the traditional carding machine used in a nonwoven production line, and can perform sufficient carding of fiber so that the silk cotton net has low trash content and is longitudinally and transversely uniform and the fiber is in regular arrangement. The method performs temperature / humidity control in a production area, control on the spinning adaptability, mixing uniformity and antistatic property of the raw material, and optimization of the cotton net production technology, spunlace forming technology and degreasing and bleaching technology, so that the produced nonwoven fabric product not only maintains the elasticity and moisture absorption of cotton fiber, but also has the additional advantages of softness, smoothness and good glossiness of the spun silk based on the pure cotton cloth. The spun silk and cotton blended spunlace nonwoven fabric produced by the method has good extensibility, soft cloth cover and good water absorption, sufficiently reflects the skin-friendly performance of the spun silk serving as protein fiber filament, and has wide application prospects in the female high-grade make-up mask material.

Owner:ANQING HUAWEI IND FABRICS HI TECH CO LTD

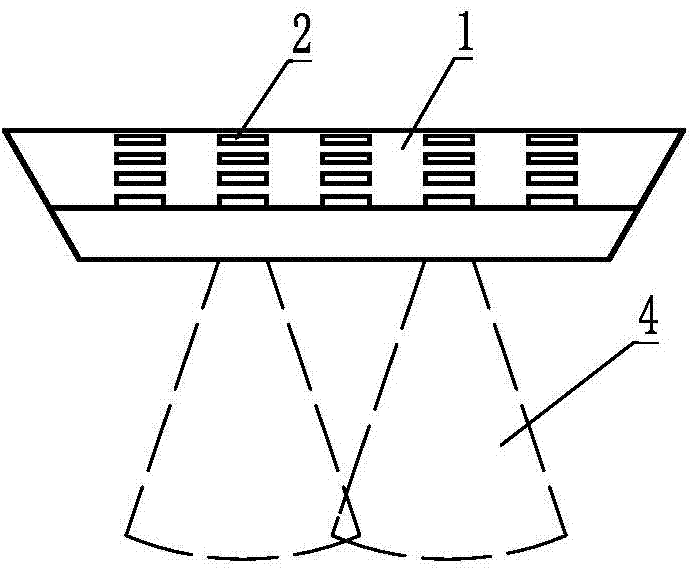

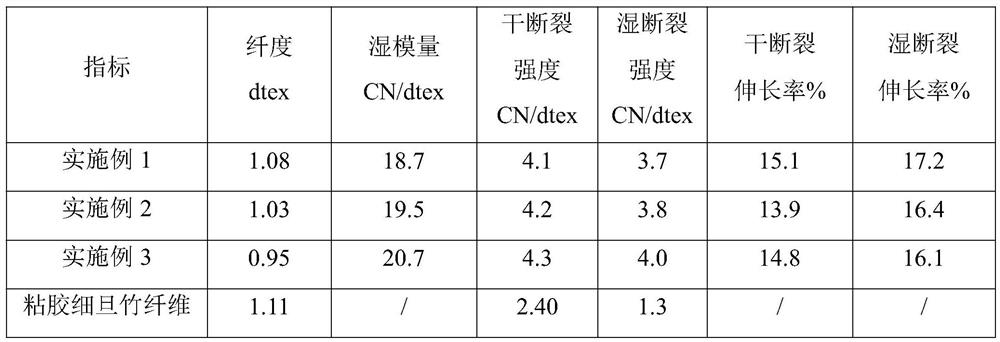

Solvent-process high-wet-modulus fine-denier bamboo fibers and preparation method thereof

PendingCN112481723AEasy to operateProduction without industrial pollutionArtificial filaments from cellulose solutionsFilament/thread formingFiberTextile technology

The invention relates to the technical field of textiles, in particular to solvent-process high-wet-modulus fine-denier bamboo fibers and a preparation method thereof. The preparation method comprisesthe following steps of performing activation: adding bamboo pulp with the polymerization degree of 600-1200 into deionized water, adjusting the pH value, adding cellulase for activation, and adding alkali for adjusting the pH value; performing squeezing: performing vacuum dehydration squeezing; performing pre-dissolving: adding an aqueous solution containing 65-86% by mass of N-methylmorpholine-N-oxide; performing dissolving: entering dissolving equipment, performing heating, vacuumizing, dewatering, dissolving, homogenizing and defoaming; performing filtration; performing spinning: performing spinning and forming by adopting a dry-wet process; performing washing with water; performing bleaching; performing oiling; and performing drying. The preparation method is easy to operate, free ofindustrial pollution, low in energy consumption, high in safety performance and suitable for large-scale industrial continuous production of the solvent-process fine-denier bamboo fibers; and the fineness of the prepared fine-denier bamboo fibers is 0.95-1.08 dtex, the wet modulus is larger than 18.0 CN / dtex, the natural physical and chemical properties of the fine-denier bamboo fibers are reserved, no harmful chemical residues exist, and the wet modulus is relatively high.

Owner:SHANGHAI LYOCELL FIBER DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com