Patents

Literature

39results about How to "Easy and flexible production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

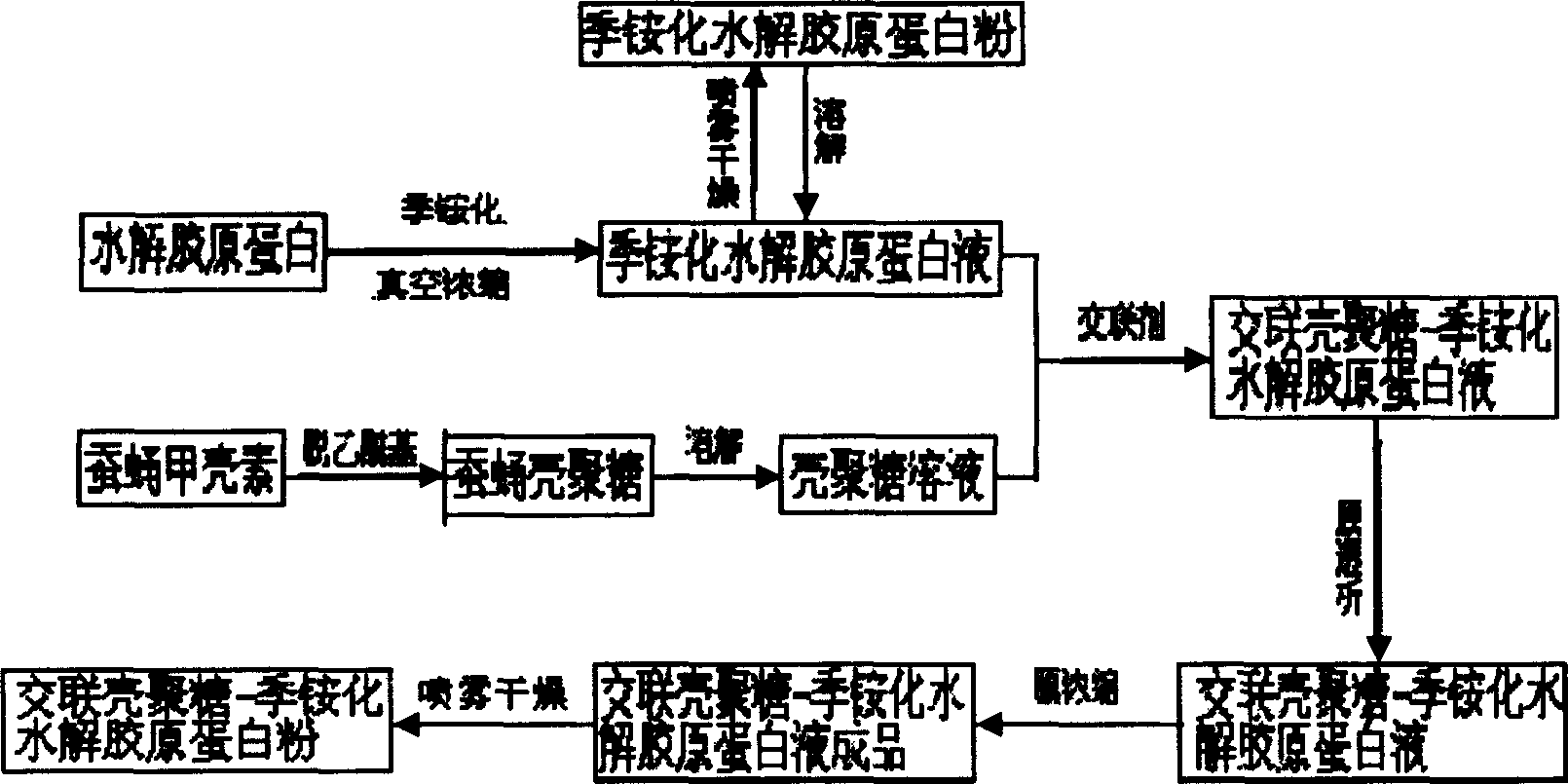

Method for preparing crosslinked chitin-glycan-quaterisation collagen hydrolysate

InactiveCN1640913AEasy and flexible productionStrong adhesionCrosslinked chitosanBiological dressing

The present invention is crosslinked chitosan-quaternized hydrolyzed collagen preparing process and relates to antibiotic biological material preparation. The crosslinked chitosan-quaternized hydrolyzed collagen is prepared with silkworm pupa chitin and hydrolyzed collagen as material. The preparation process includes mixing two kinds of solution, adding crosslinking agent to perform crosslinking reaction, membrane concentration, regulating pH value, and volumetric or spray drying to produce powder. The present invention can prepare solution or sol product and into the product, various water soluble functional factors, such as skin growth factor, moisture maintaining factor, vitamin, etc. may be added to form multifunctional biological dressing.

Owner:CHONGQING UNIV

Chitosan composite fiber and preparation method thereof

ActiveCN108914248AAvoid churnEasy and flexible productionArtifical filament manufactureAnti bacterialMechanical property

The invention relates to a chitosan composite fiber and a preparation method thereof. The method comprises the following steps: spinning mixed liquor of chitosan quaternary ammonium salt / alginic acidsol and chitosan spinning solution to prepare the chitosan composite fiber, wherein a dispersion phase particle in the chitosan quaternary ammonium salt / alginic acid sol is a chitosan quaternary ammonium salt / alginic acid conjugate mainly. The prepared chitosan composite fiber is mainly formed by a chitosan fiber matrix and the chitosan quaternary ammonium salt / alginic acid conjugate distributed in the chitosan fiber matrix. The chitosan quaternary ammonium salt / alginic acid conjugate is mainly formed by bonding chitosan quaternary ammonium salt and alginic acid through an ionic bond. The chitosan quaternary ammonium salt / alginic acid conjugate is bonded with the chitosan fiber matrix through a hydrogen bond mainly. According to the chitosan composite fiber and the preparation method thereof provided by the invention, the preparation method is simple in operation, the prepared chitosan composite fiber is stable in structure, good in mechanical property, anti-bacterial property and hygroscopic property, and has a good promotional value.

Owner:TIANE CHEM FIBER GROUP CORP BAODING +1

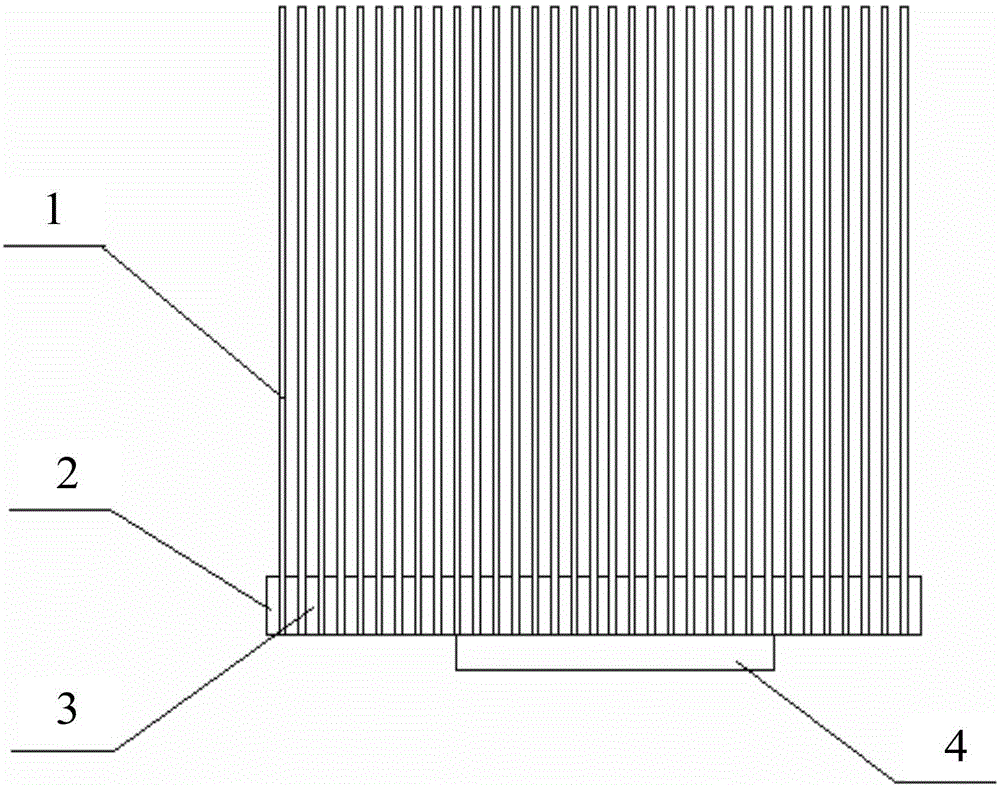

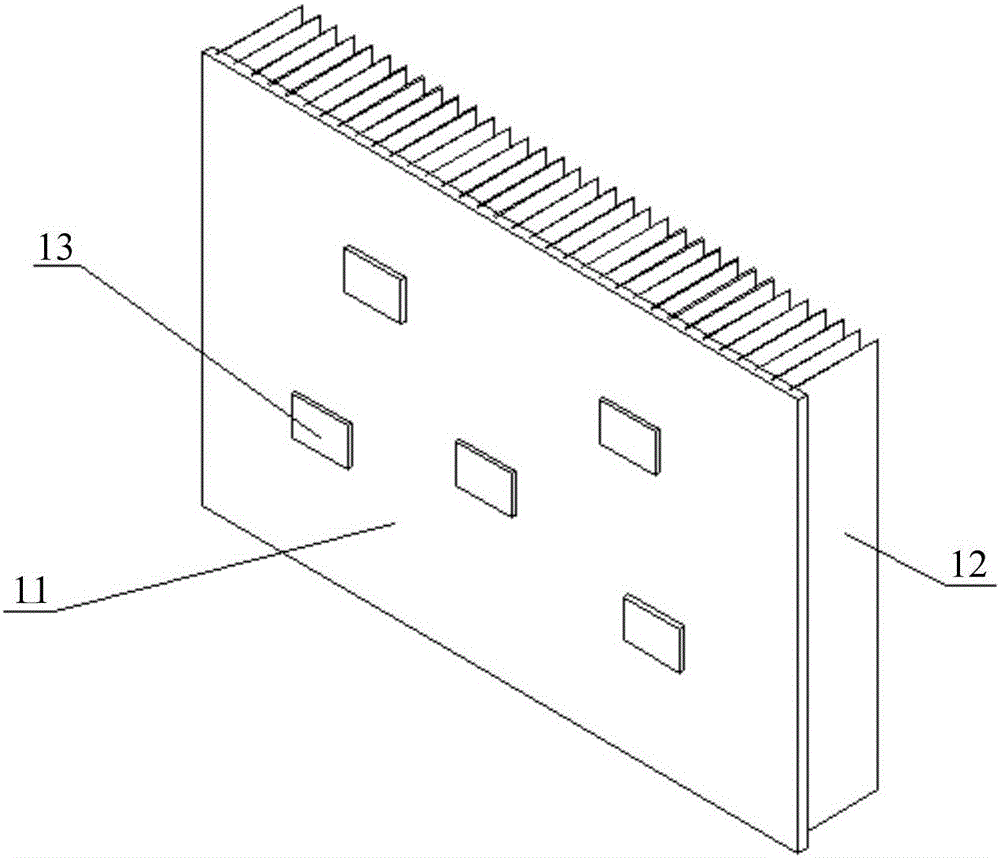

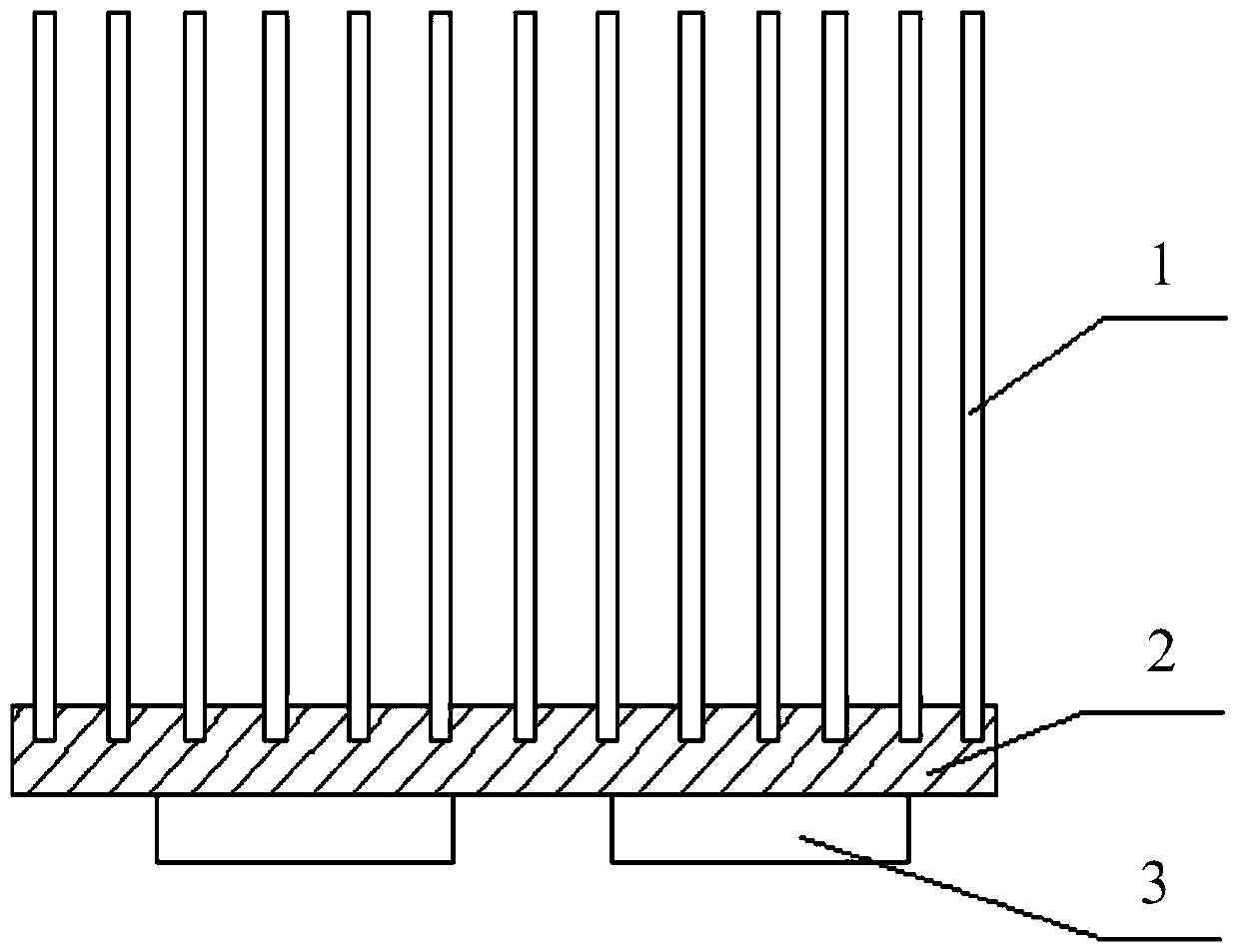

Heat-superconducting radiator and manufacturing method thereof

ActiveCN105140194AFast thermal conductivityHigh fin efficiencySemiconductor/solid-state device detailsSolid-state devicesHeat conductingEngineering

Owner:ZHEJIANG JIAXI TECH CO LTD

Preparation method of cellulose/carbon nanotube composite fiber

ActiveCN106435797AEvenly dispersedStable in natureMonocomponent cellulose artificial filamentArtifical filament manufactureCelluloseFiber

The invention relates to a preparation method of a cellulose / carbon nanotube composite fiber. The preparation method comprises the steps that a cellulose solvent is adopted to dissolve a low-polymerization-degree cellulose, and a carrier solution for carbon nanotubes is prepared; under the strong shear effect provided by a stirring device, the carbon nanotubes is mixed with the carrier solution to prepare a carbon nanotube mother solution; the carbon nanotube mother solution is injected into a cellulose spinning solution in an online adding mode, the spinning solution is subjected to extrusion, solidification and drawing to prepare the cellulose / carbon nanotube composite fiber. For solving the problem that the carbon nanotubes are difficultly and uniformly mixed with a high-viscosity spinning solution, the carbon nanotube mother solution is injected into the cellulose spinning solution, and further the cellulose / carbon nanotube composite fiber is prepared in a spin-forming mode. The mother solution carrier used by the method solidifies and is formed with the fiber without the operation of feeding an additional additive into a solvent and coagulation bath system. The preparation method is simple, flexible and efficient, and production of the cellulose / carbon nanotube composite fiber can be achieved based on a conventional production line.

Owner:DONGHUA UNIV

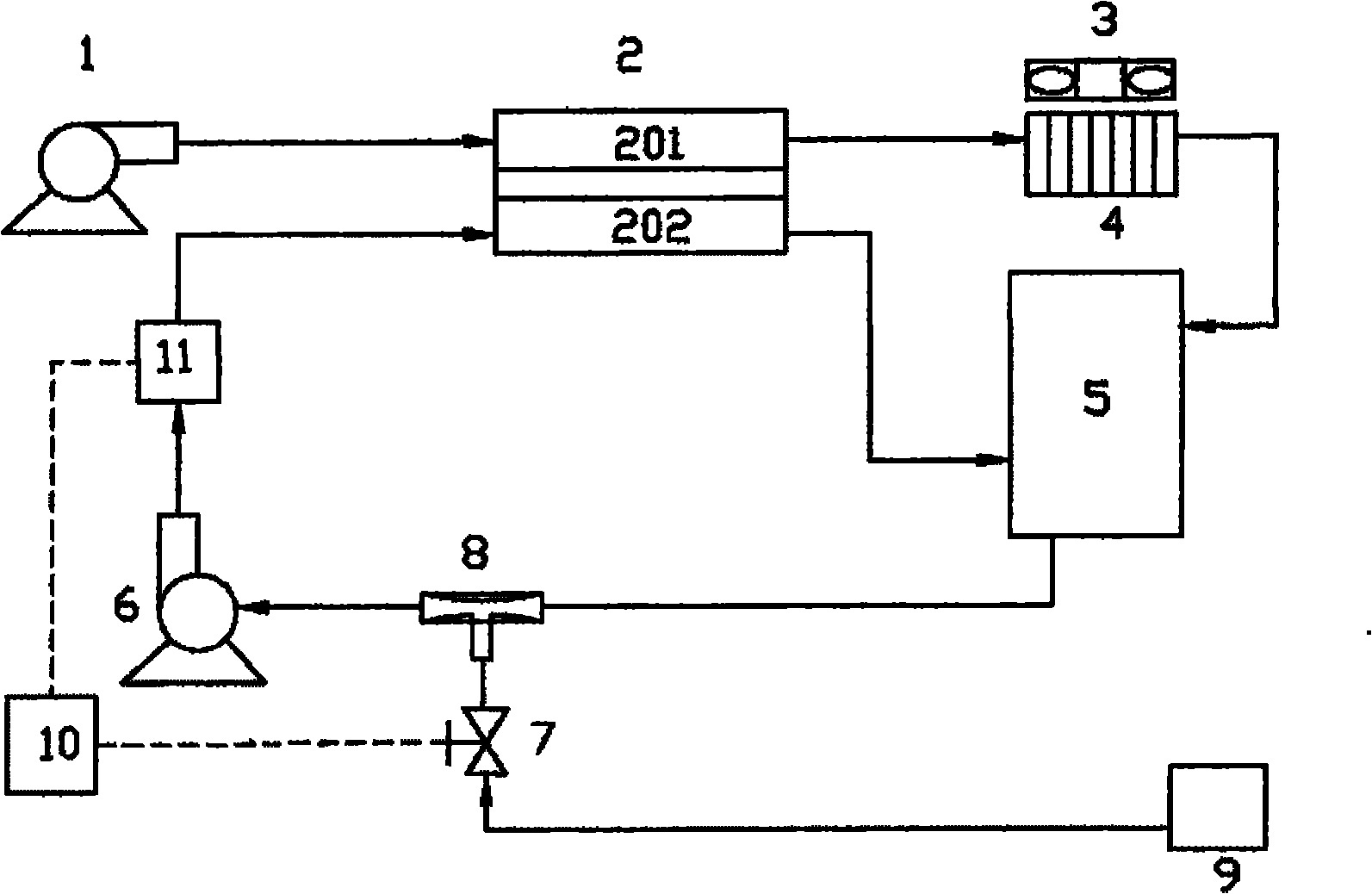

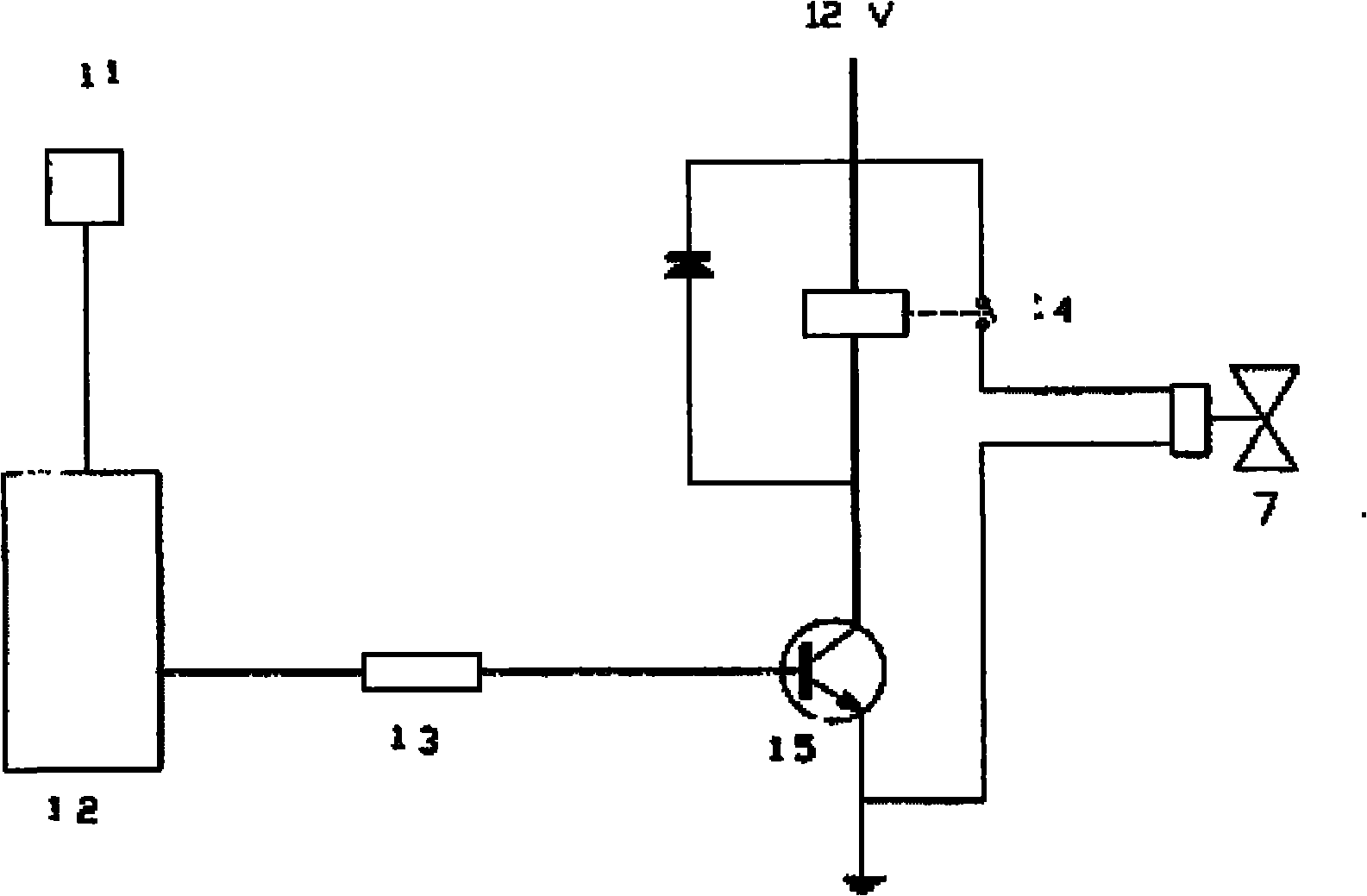

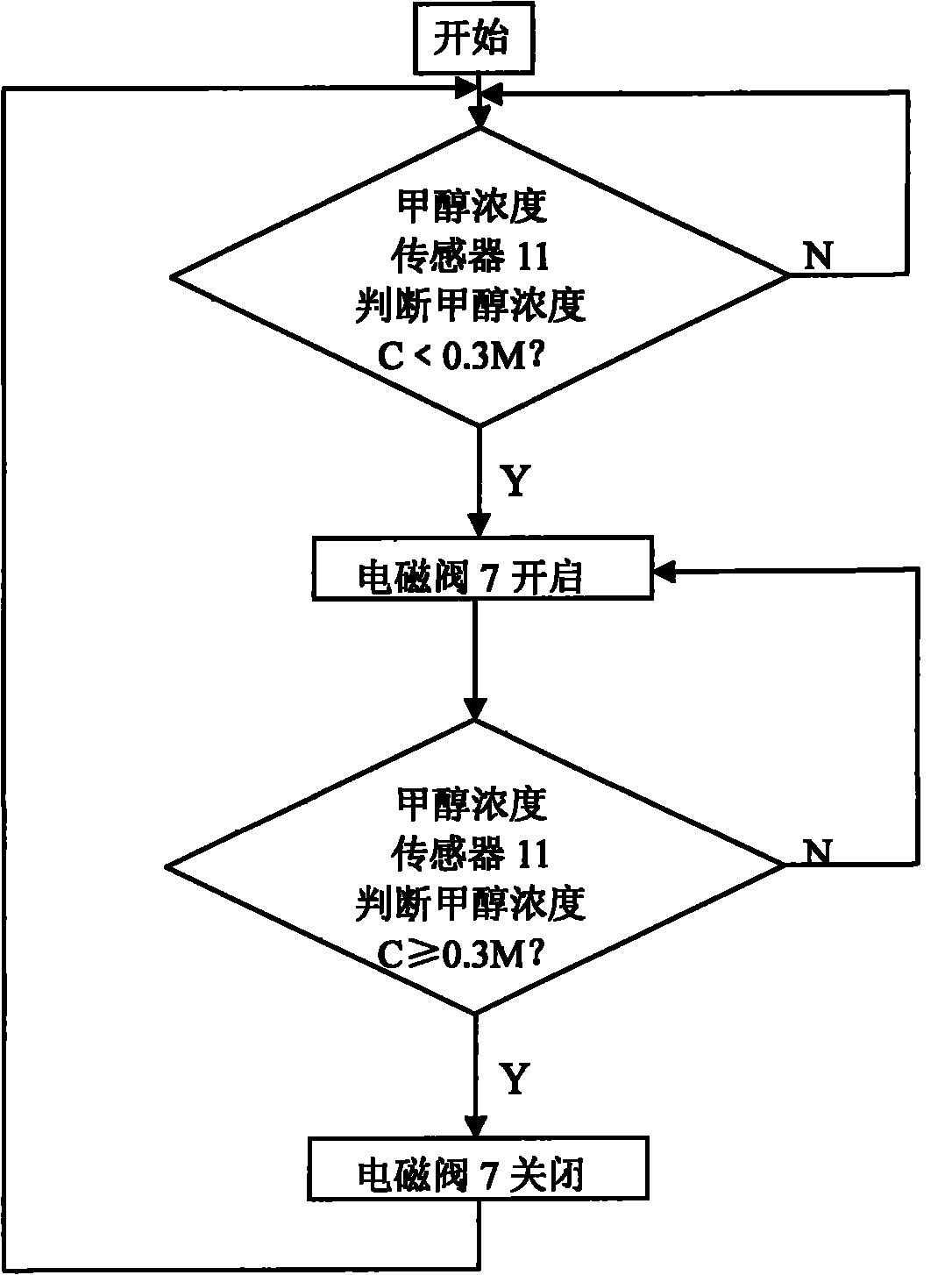

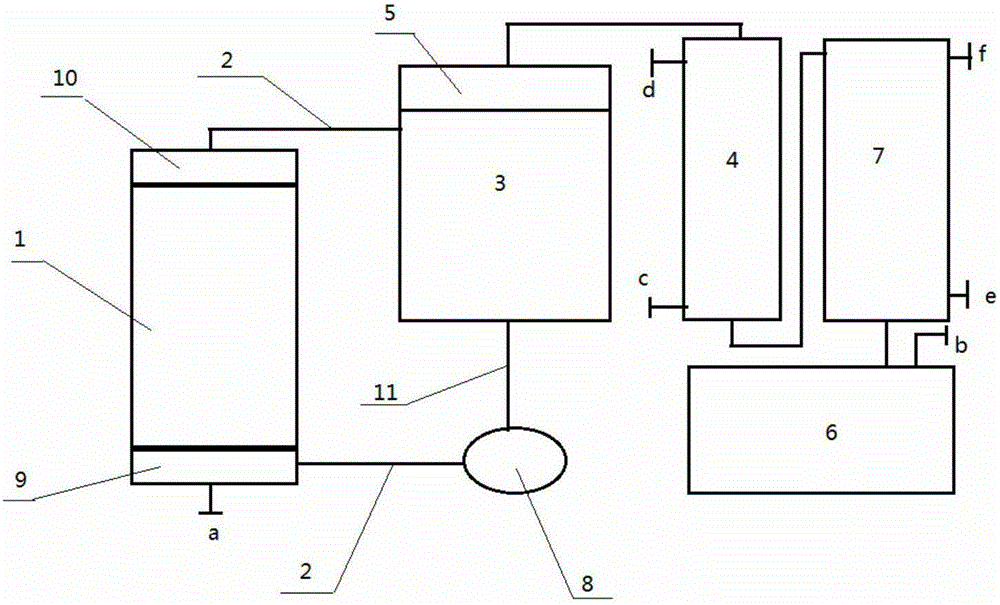

Fuel feeding method of direct liquid fuel cell system

ActiveCN102104161AReduce volatile lossIncrease profitFinal product manufactureFuel cell auxillariesFuel tankLiquid fuel

The invention relates to a fuel feeding method of a direct liquid fuel cell system. The direct liquid fuel cell system comprises a cell galvanic pile, a heat exchanger, a gas-liquid separator and a fuel tank. A gas-liquid mixture positioned on a cathode outlet of the cell galvanic pile passes through the heat exchanger and then enters the gas-liquid separator; a gas-liquid mixture positioned on an anode outlet of the cell galvanic pile directly enters the gas-liquid separator; a connecting pipeline of a material outlet of the gas-liquid separator and an anode inlet of the cell galvanic pile is sequentially provided with a throttling valve and a liquid pump; a branch circuit is arranged between the throttling valve and the liquid pump and connected with a fuel tank pipeline through an electromagnetic valve; fuel inside the fuel tank enters the anode of the cell galvanic pile through the connecting pipeline positioned between the material outlet of the gas-liquid separator and the anodeinlet of the cell galvanic pile, and the anode inlet is provided with a concentration sensor; and an output signal of the concentration sensor is processed by a controller and then electrically connected with the electromagnetic valve through the controller by using a conducting wire. due to the adoption of the fuel feeding method, the usage of moving parts of the direct liquid fuel cell system and the energy consumption of the direct liquid fuel cell system are reduced, the manufacture and usage of the throttling valve are convenient and flexible, the system integration is easier and the system stability is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

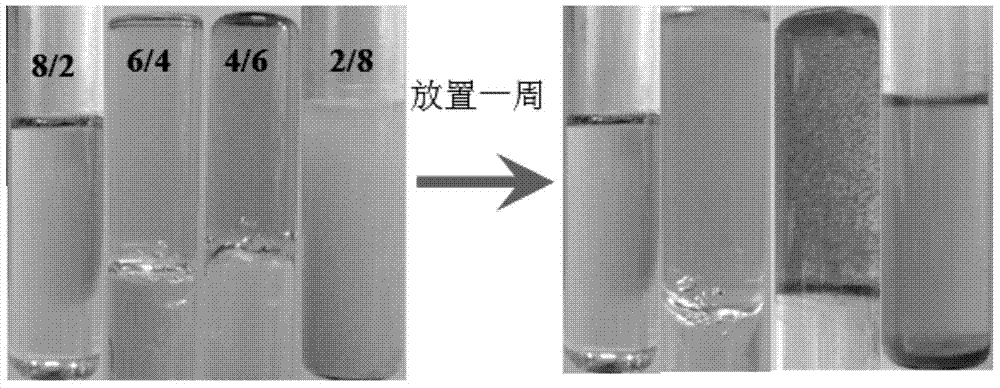

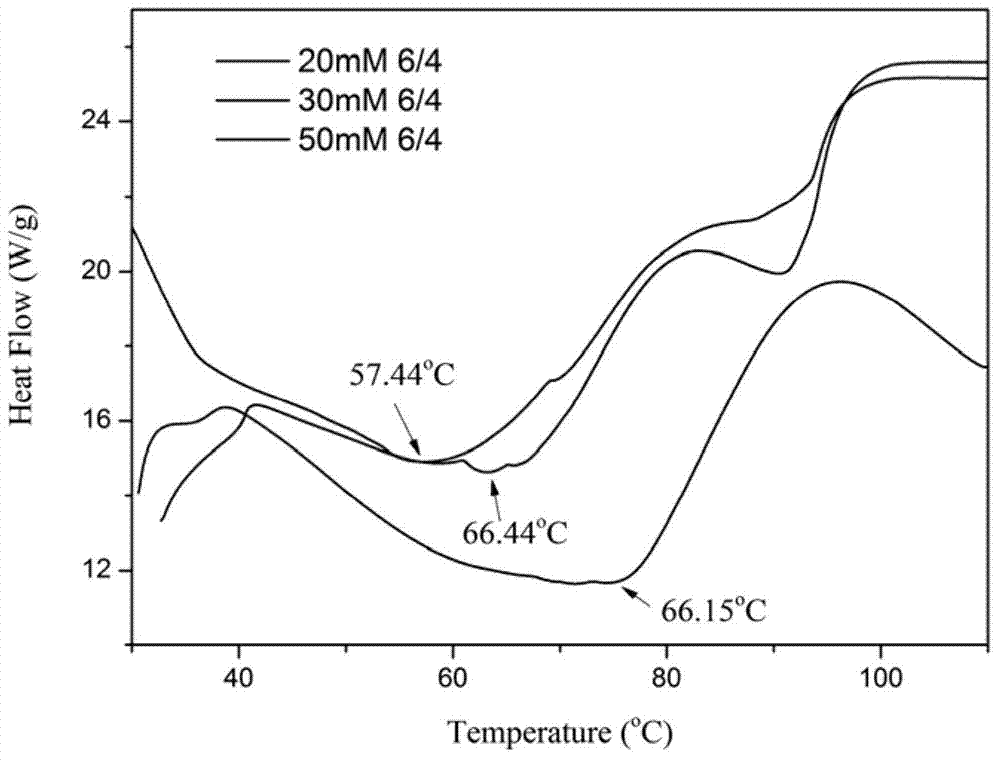

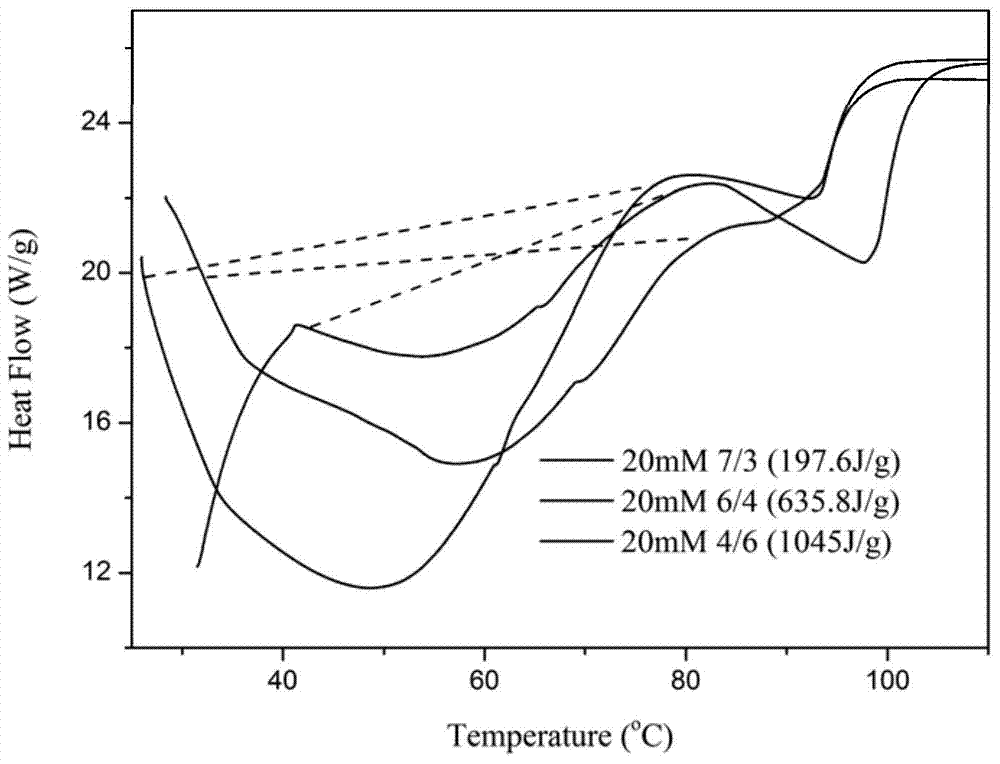

Self-repairing folic acid gel with multiple responses and preparation method thereof

ActiveCN103566842AExcellent optical propertiesZero pollutionColloidal chemistry detailsSolventSmart material

The invention discloses self-repairing folic acid gel with multiple responses and a preparation method thereof. The gel is a mixed system comprising organic gel factor folic acid, water and organic solvent; the folic acid is dissolved in the mixed solvent prepared by the water and the organic solvent under the condition of room temperature, is evenly mixed, and placed still until the solution forms the gel. The gel of the invention has excellent optical characteristics, has four responses of heat, light, force and pH, and can finish reversible conversion between gel and solution under the excitation of corresponding factors, so that a novel feasible path for truly applying the gel to the civil fields such as medical materials, optical materials, intelligent materials and crystal growth templates is provided; the self-repairing folic acid gel has a wide application prospect.

Owner:SHANDONG UNIV

Preparation method for preparing functional chitosan fibers

ActiveCN106400200AEvenly dispersedStable in natureFlame-proof filament manufactureFiberProduction line

The present invention relates to a preparation method for preparing functional chitosan fibers. The method comprises the steps of 1) dissolving the low-molecular-weight chitosan in a chitosan solvent to prepare a carrier solution; 2) under the strong shearing action of a stirring device, mixing up functional powders with the carrier solution to prepare a functional mother liquid; 3) injecting the functional mother liquid into a chitosan spinning solution in the online addition manner to obtain a functional spinning solution; and preparing functional chitosan fibers through the extruding, solidifying and stretching process of the functional spinning solution. According to the technical scheme of the invention, the problem in the prior art that functional powders and the spinning solution are different to mix up and uneven in dispersion according to the traditional method can be solved. An adopted carrier is formed along with the solidification process of fibers, while no extra assistant is fed into a solvent and coagulating bath system. The forming method is simple and efficient, and the production of functional chitosan fibers can be realized based on a conventional production line.

Owner:JIAXING UNIV

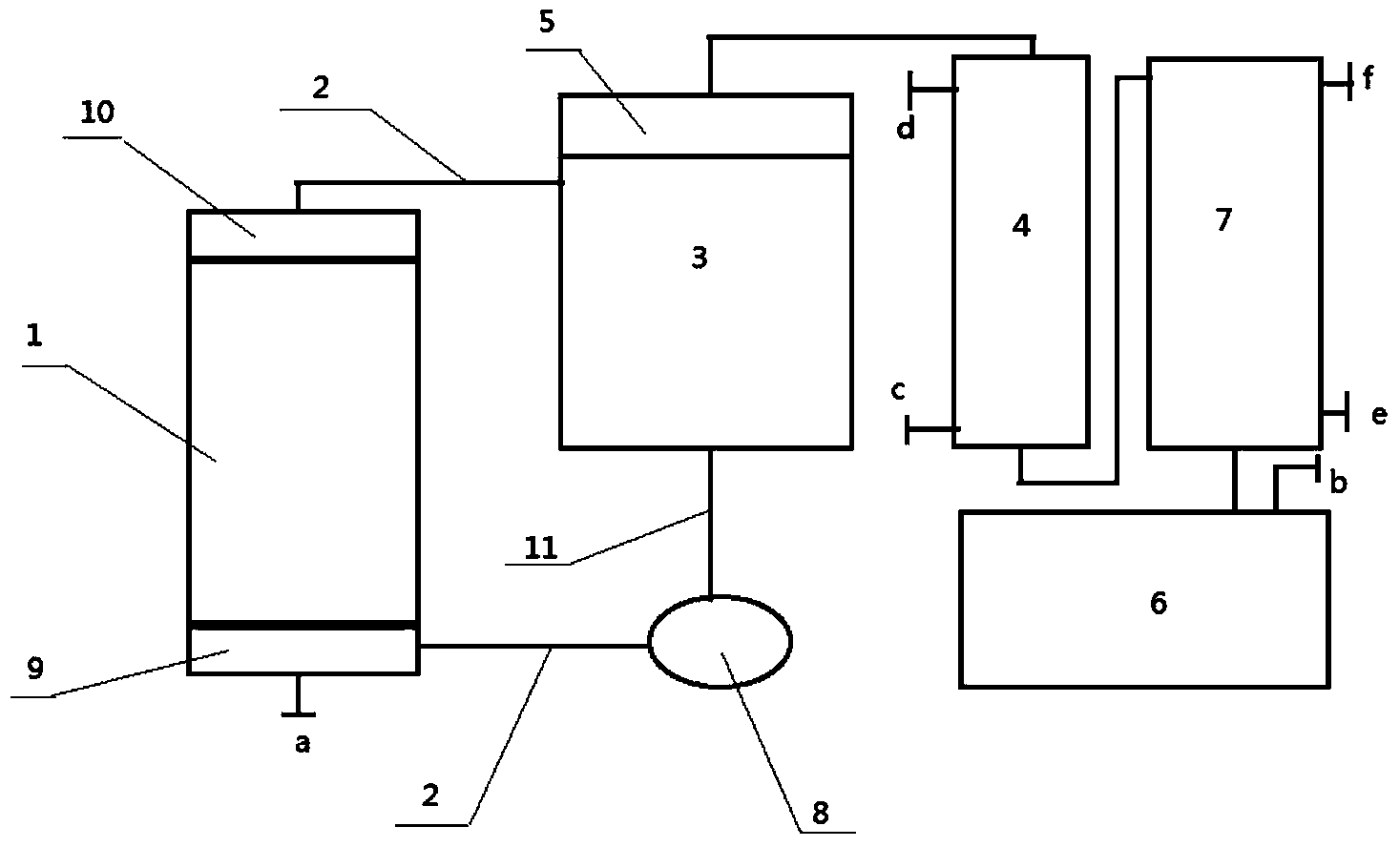

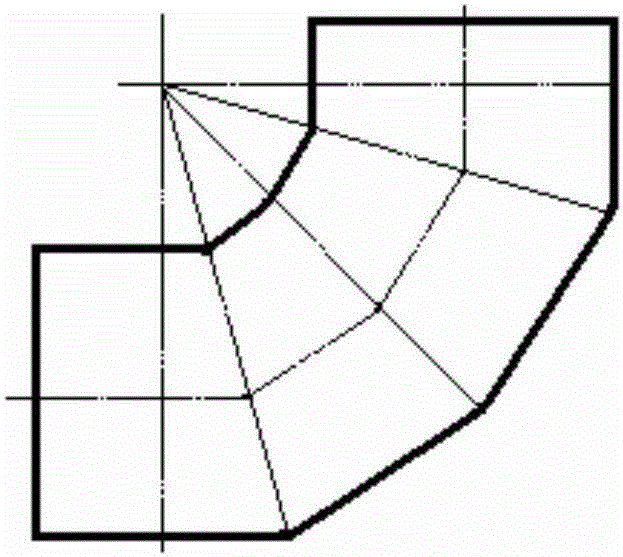

Online tons-level traditional Chinese medicine anti-wall-hanging evaporation and concentration device and operating method thereof

The invention provides an online tons-level traditional Chinese medicine anti-wall-hanging evaporation and concentration device and an operating method thereof. A gas-liquid-solid three-phase natural circulation fluidized bed evaporation and concentration device in an industrial production scale in which the heating area of a heater is 18.9 m<2> and the evaporative power is 1100-1400 kg / h is determined. The inventions and innovations of a screen type discharging device, a 90-degree multi-section short-radius elbow connecting pipe and a demister on the upper part of a separation chamber are designed. At present, the production operation result of the industrial scale device of about 100-ton extracting solutions of Menopause Ease and other over ten traditional Chinese medicines proves that compared with a traditional two-phase flow evaporation concentrator with the heating area of 18 m<2> in a factory and an operating method thereof, the device and the method under approximate operation conditions have the advantages that the total heat transfer coefficient and evaporation intensity are improved, a wall hanging phenomenon of the two-phase flow evaporation concentrator is avoided, the wall hanging phenomenon existing in a traditional Chinese medicine extracting solution evaporation concentrator is eliminated, and high-efficiency continuous and stable operation is realized.

Owner:TIANJIN UNIV

Anti-bacterial cellulose complex fiber and preparation method thereof

ActiveCN108866665AAvoid churnEasy and flexible productionMonocomponent cellulose artificial filamentArtifical filament manufactureCarboxymethyl celluloseCellulose fiber

The invention relates to an anti-bacterial cellulose complex fiber and a preparation method thereof. The preparation method comprises the following step: spinning a mixed solution of water-soluble chitosan / carboxymethylcellulose collosol and a cellulose spinning solution to obtain the anti-bacterial cellulose complex fiber, wherein the dispersion phase particles of the water-soluble chitosan / carboxymethylcellulose collosol are a water-soluble chitosan / carboxymethylcellulose composition. The prepared antibacterial cellulose complex fiber is mainly prepared from a cellulose fiber substrate and the water-soluble chitosan / carboxymethylcellulose composition which is distributed inside and / or outside the cellulose fiber substrate; the water-soluble chitosan / carboxymethylcellulose composition ismainly formed by bonding water-soluble chitosan and carboxymethylcellulose through an ionic bond; the water-soluble chitosan / carboxymethylcellulose composition and the cellulose fiber substrate are mainly bonded through a hydrogen bond. The preparation method is easy to operate, and the prepared anti-bacterial cellulose complex fiber has the advantages of stable structure, high mechanical performance, antibacterial performance, moisture absorbing performance and excellent popularization value.

Owner:TIANE CHEM FIBER GROUP CORP BAODING +1

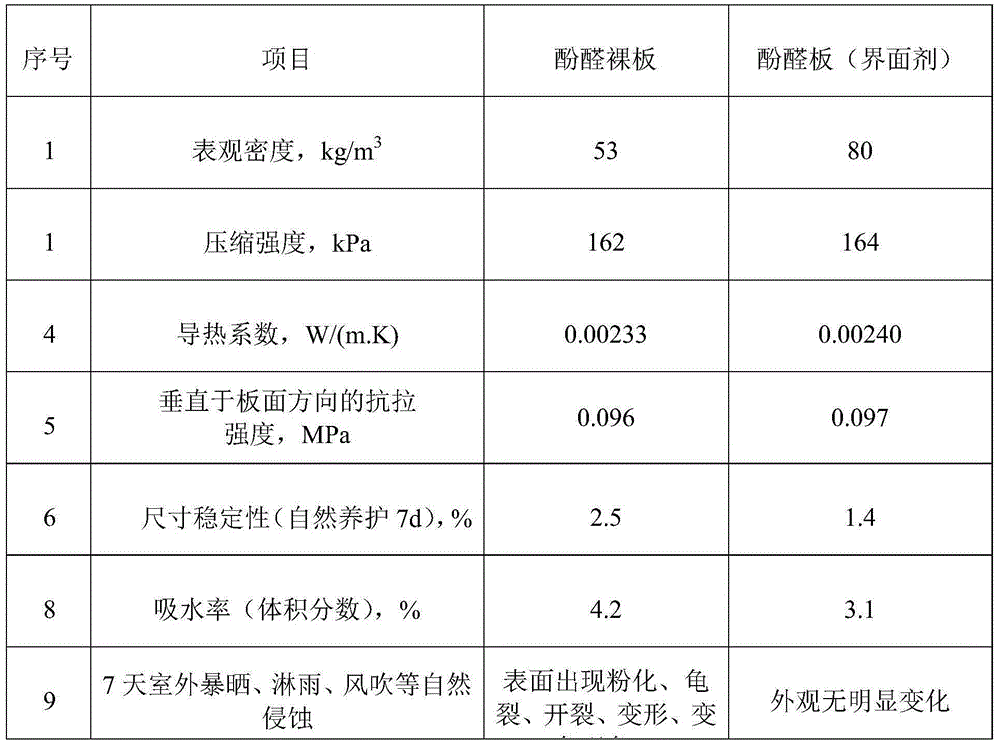

Phenolic foam board interface agent and preparation method thereof

The invention discloses a phenolic foam board interface agent and a preparation method thereof. The phenolic foam board interface agent is prepared by mixing the following components of, by mass, 200-250 parts of 42.5 cement, 550-800 parts of coarse whiting, 50-100 parts of pulverized fuel ash, 40-80 parts of calcium hydroxide, 0.2-1 part of starch ether, 1-4 parts of cellulose, 1-5 parts of hydrophobic powder, 200-300 parts of acrylic acid emulsion and 300-400 parts of water. The phenolic foam board interface agent has the advantage that the bonding strength of the interface agent with a phenolic foam board is high, a protection layer can be formed on the surface of the phenolic foam board, the phenolic foam board can be prevented from erosion of natural phenomena such as weathering, ultraviolet rays and heavy rain wash, and the situation that due to the fact that efflorescence, cracking and deformation occur on the phenolic foam board, properties of the phenolic foam board are affected is avoided; the preparation method of the phenolic foam board interface agent has the advantages of being simple in technology and easy to implement.

Owner:BEIJING SOLID BUILDING ENG

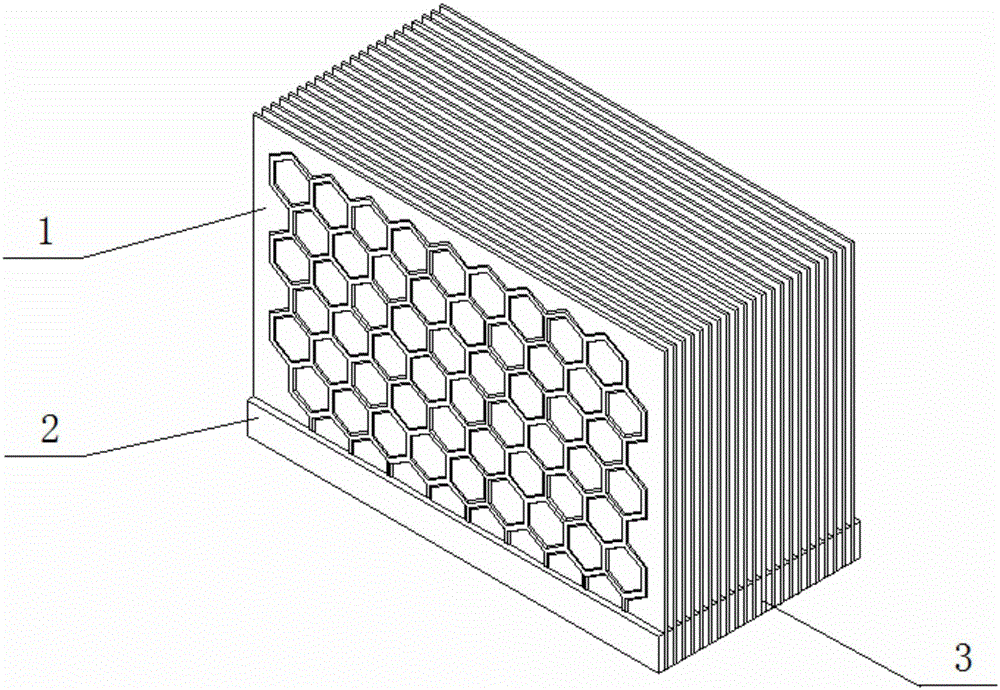

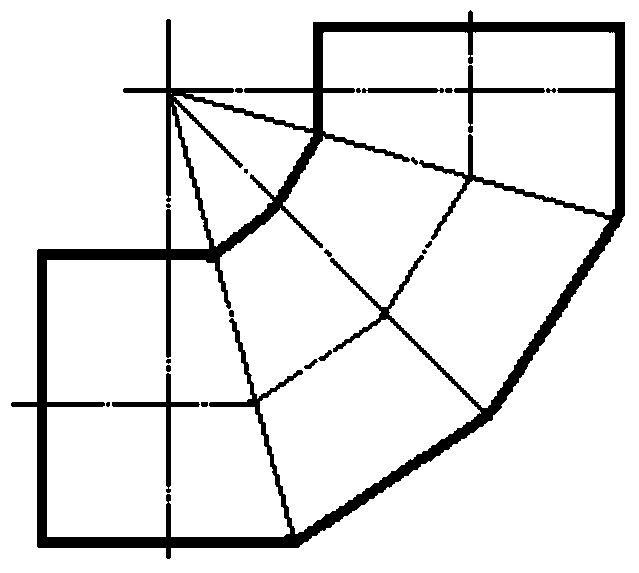

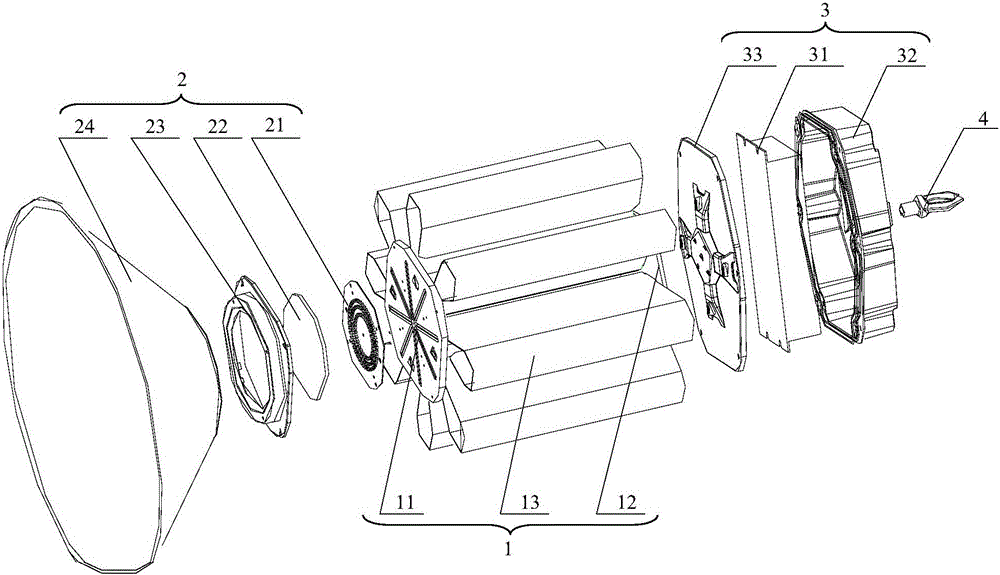

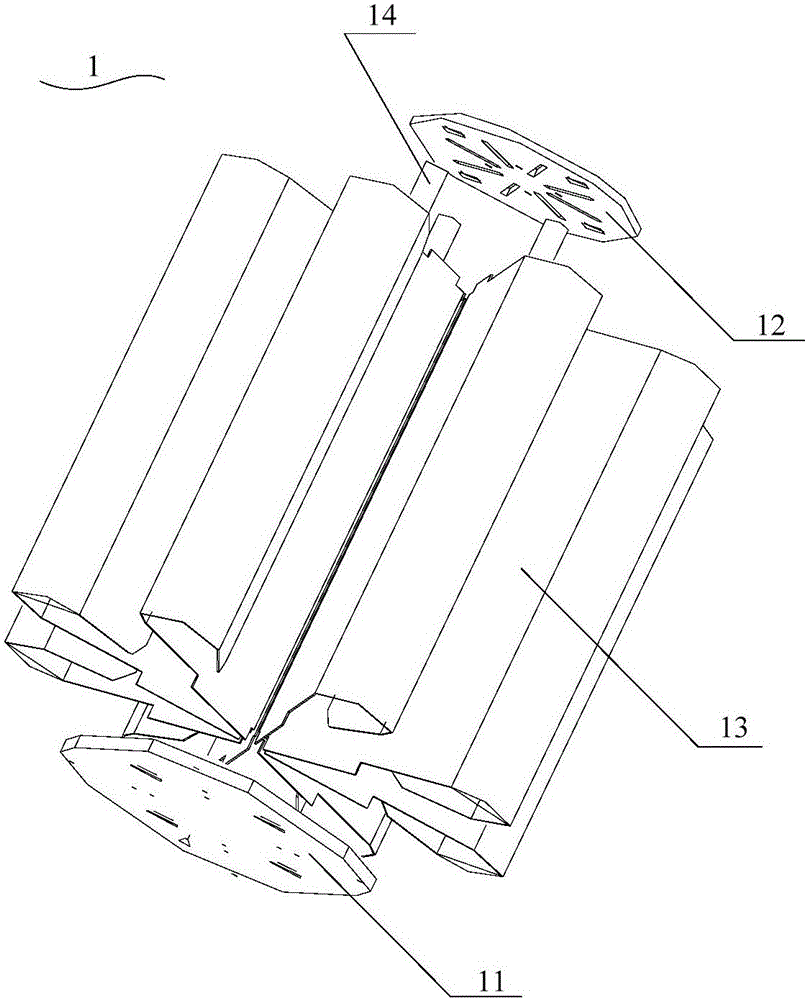

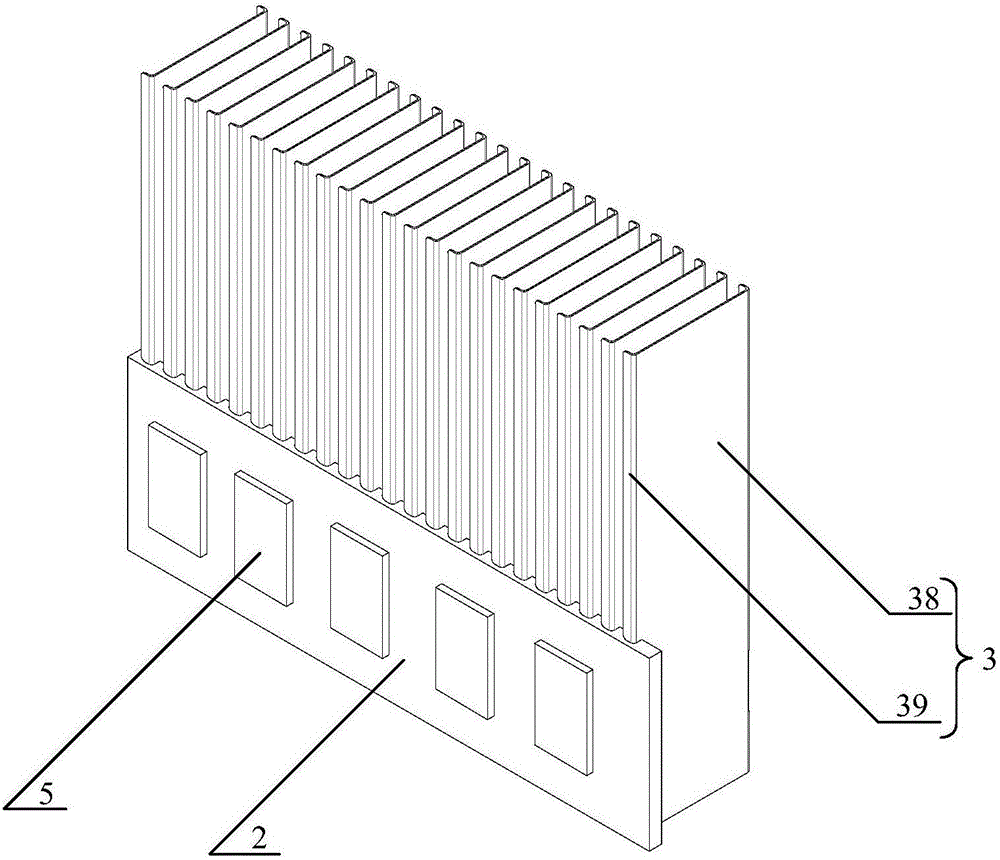

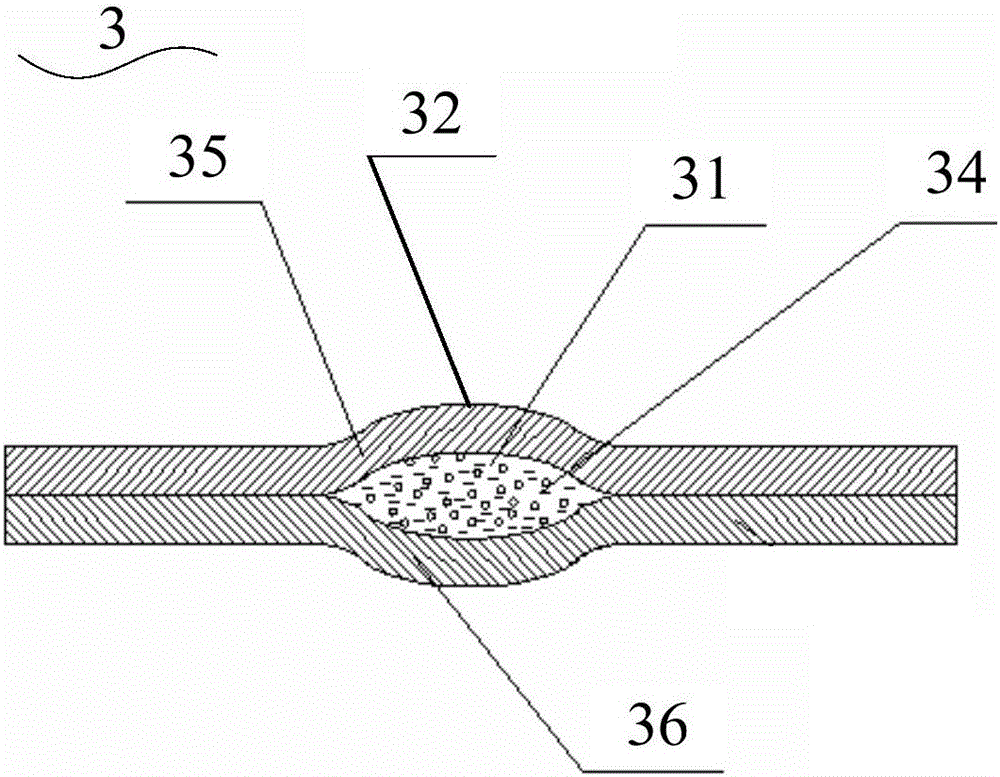

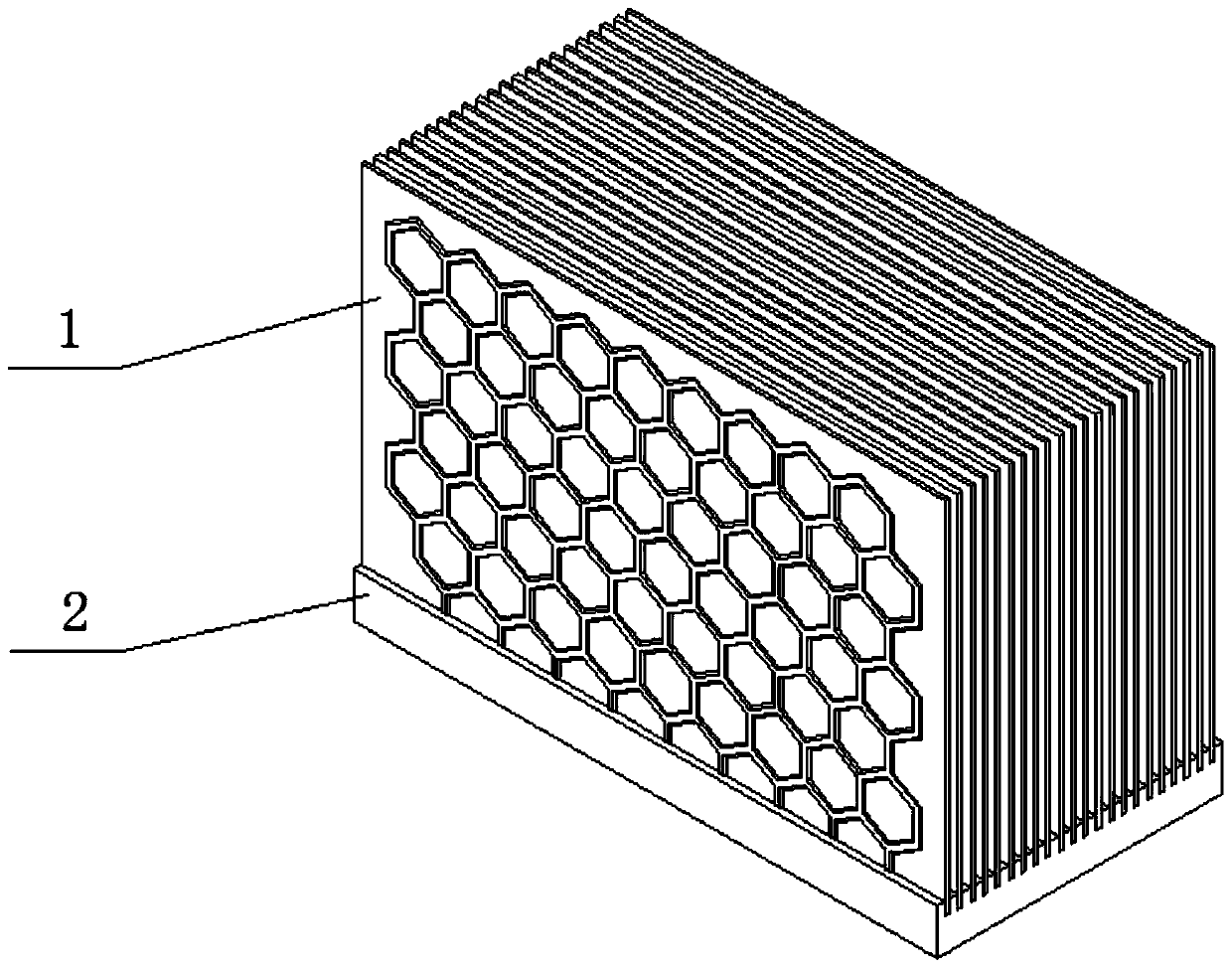

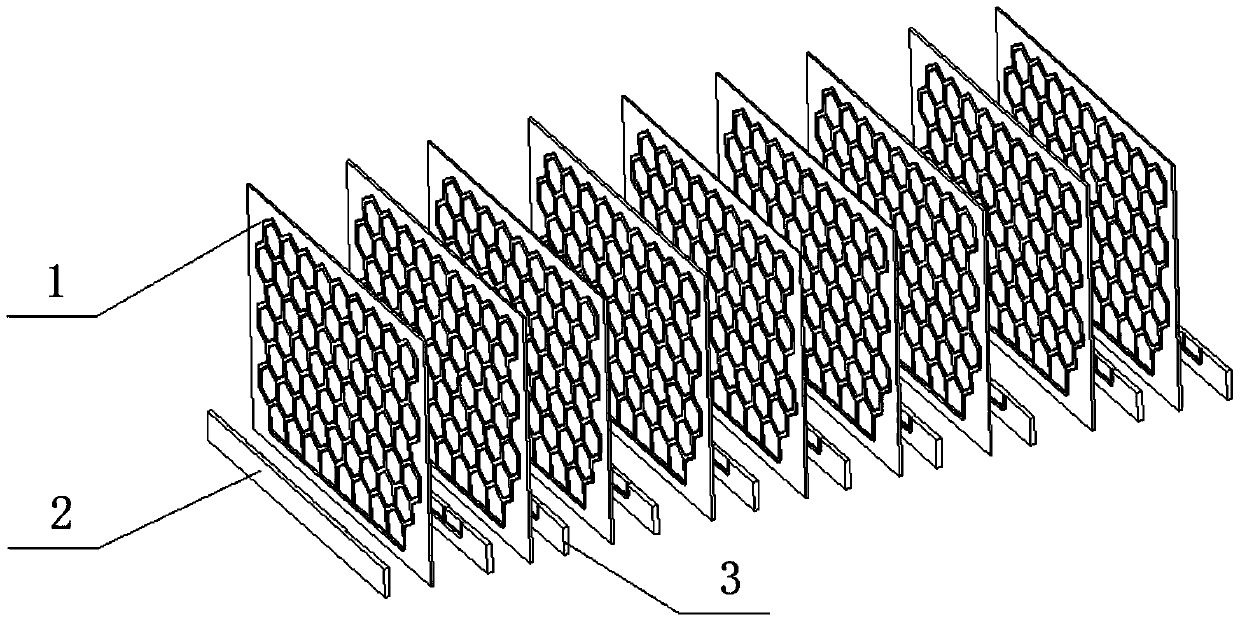

Phase change inhibited fin radiator LED lamp

PendingCN106051482AUnlimited areaImprove thermal conductivityLighting heating/cooling arrangementsSemiconductor devices for light sourcesTemperature differencePhase change

The invention provides a phase change inhibited fin radiator LED (Light-emitting Diode) lamp which comprises a heat radiator structure, a light-emitting component and a power supply assembly, wherein the heat radiator structure comprises a first substrate, a second substrate and a plurality of phase change inhibited heat transfer plates; the first substrate and the second substrate are correspondingly arranged in a parallelly spaced manner; the phase change inhibited heat transfer plates are positioned between the first substrate and the second substrate, and are arranged in a radially distributed manner; heat superconduction pipelines in special shapes are formed in the phase change inhibited heat transfer plates, and are filled with heat transfer working media; the light-emitting component is positioned on the surface, far away from the phase change inhibited heat transfer plates, of the first substrate; and the power supply assembly is positioned on the surface, far away from the phase change inhibited heat transfer plates, of the second substrate. A radial heat radiator is rapid in heat conduction; the efficiency of heat-dissipation fins is high; the temperature difference is low; the efficiency of the heat-dissipation fins and the temperature difference hardly change with the changing of the areas of the phase change inhibited heat transfer plates; and the areas of the phase change inhibited heat transfer plates are free of limitation.

Owner:ZHEJIANG JIAXI TECH CO LTD

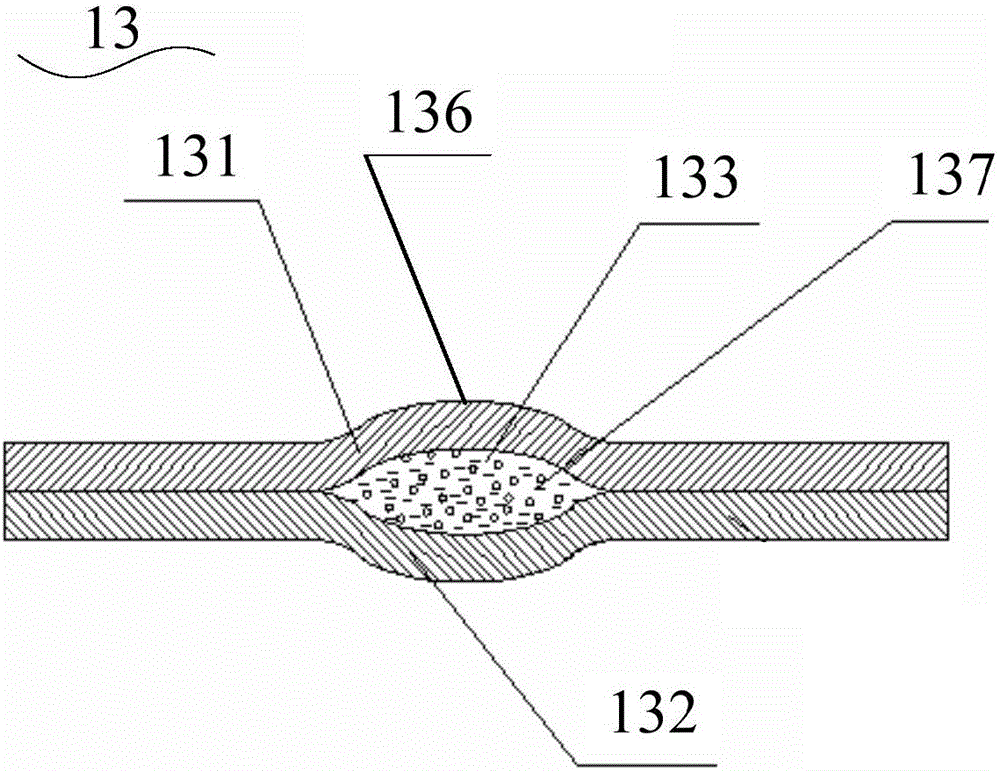

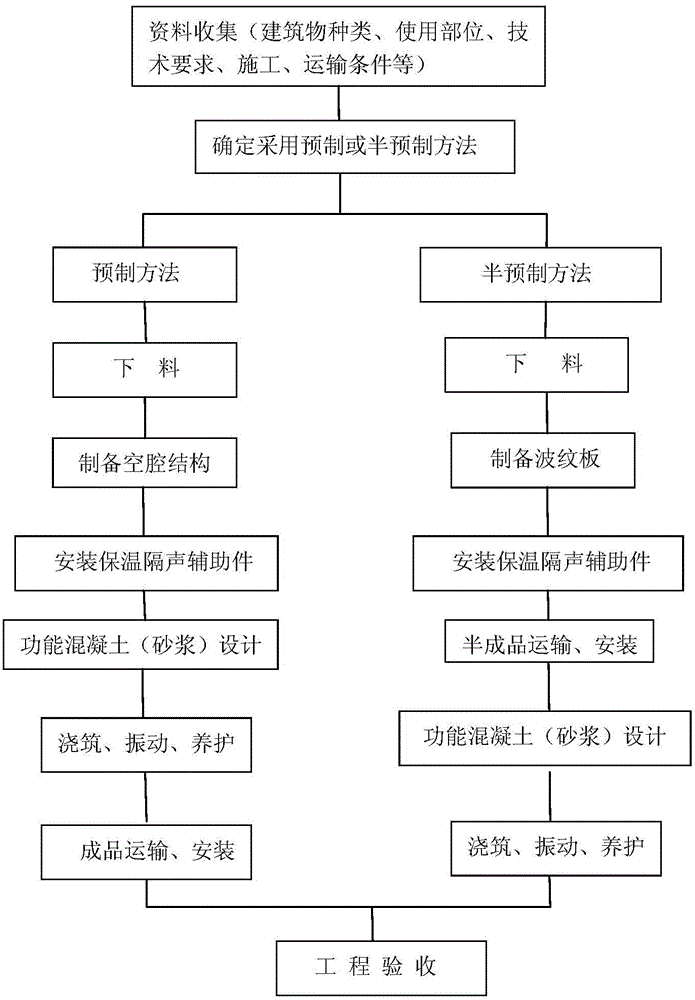

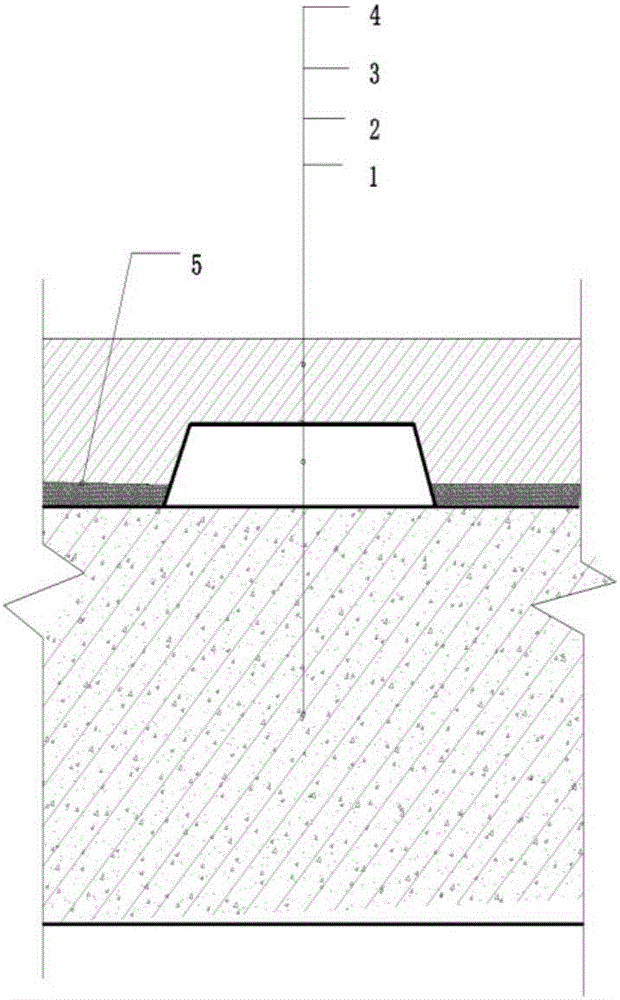

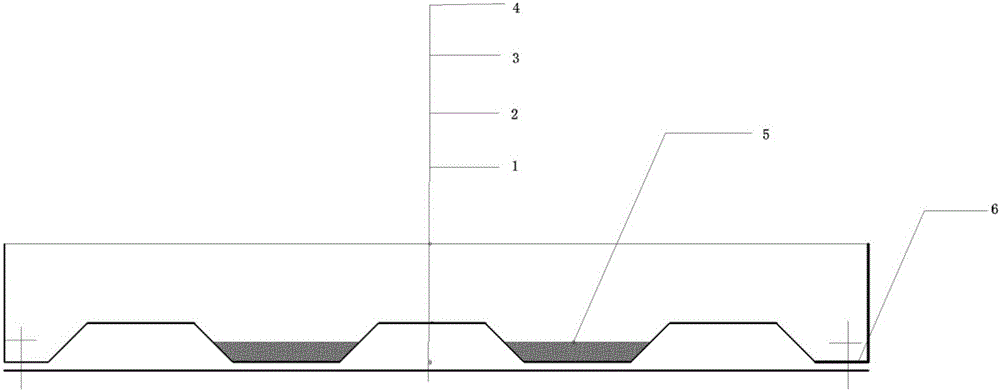

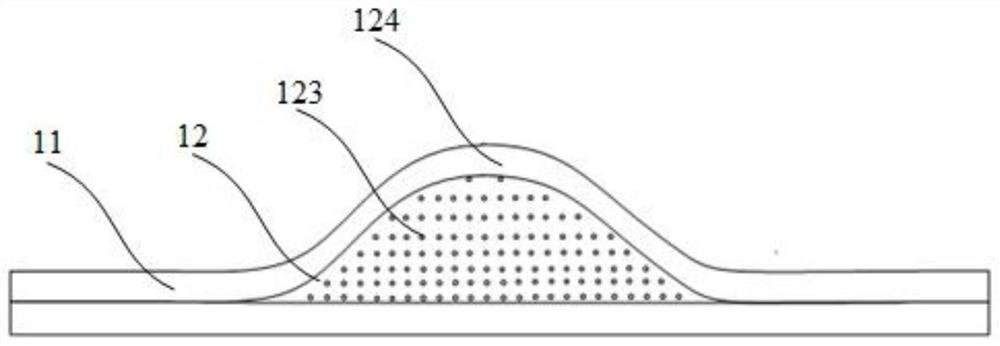

Heat preservation and sound insulation structure of ground layer of building and construction method of heat preservation and sound insulation structure

InactiveCN106013726AWith heat insulation and sound insulation effectGuaranteed StrengthCovering/liningsSolid waste managementHearing preservationPrefabrication

The invention discloses a heat preservation and sound insulation structure of a ground layer of a building and a construction method of the heat preservation and sound insulation structure. Based on that requirements for ground loading and using functions of the building are met, double additional functions of heat preservation and sound insulation of the ground of the building are realized. Light-weight aggregates and heat preservation fillings are utilized to perform heat preservation and modification on conventional ground mortar or concrete, so that the heat preservation effect of the ground of the building is achieved. Based on the heat preservation effect of the ground of the building, materials including cenospheres, rubber particles and the like are added, so that the sound insulation effect is improved. The sound insulation requirement in GB50118 and the green building evaluation criterion cannot be achieved through simple material modification. According to acoustic propagation law, the frequency to which human ears are sensitive is 20-2000HZ, and the human ears are most sensitive to 500HZ. A specific empty cavity structure is additionally arranged, so that impact sound transmission and air sound transmission can be effectively eliminated. The heat preservation and sound insulation structure disclosed by the invention adopts the specific empty structure matched with concrete materials with the functions of heat preservation and sound insulation, and can be in factory-like prefabrication, and the green building assessment index is achieved.

Owner:SOUTHEAST UNIV

Method for preparing magnetic cellulose composite fiber

ActiveCN106400185AMethod introductionStrong maneuverabilityConjugated cellulose/protein artificial filamentsArtifical filament manufactureCarrier solutionSolvent

The invention relates to a method for preparing a magnetic cellulose composite fiber. The method comprises dissolving a cellulose ester by a cellulose solvent to obtain a carrier solution of magnetic powder, mixing the magnetic powder and the carrier solution by a strong shearing force provided by a stirring device to obtain a magnetic functional mother liquor, injecting a cellulose spinning solution into the magnetic functional mother liquor in the form of on-line addition, and carrying out spinning solution extrusion, solidification, drafting and magnetization to obtain the magnetic cellulose composite fibers. In order to solve the problem that the magnetic powder is difficult to be uniformly mixed with the high-viscosity spinning solution, the cellulose spinning solution is injected into the magnetic functional mother liquor and then the magnetic cellulose composite fibers are prepared through spinning. The mother liquor carrier is molded along with fiber solidification and additional adjuvants do not enter the solvent and coagulation bath system. The forming method of the invention is simple, flexible and efficient, and can realize magnetic cellulose composite fiber production based on a conventional production line.

Owner:DONGHUA UNIV

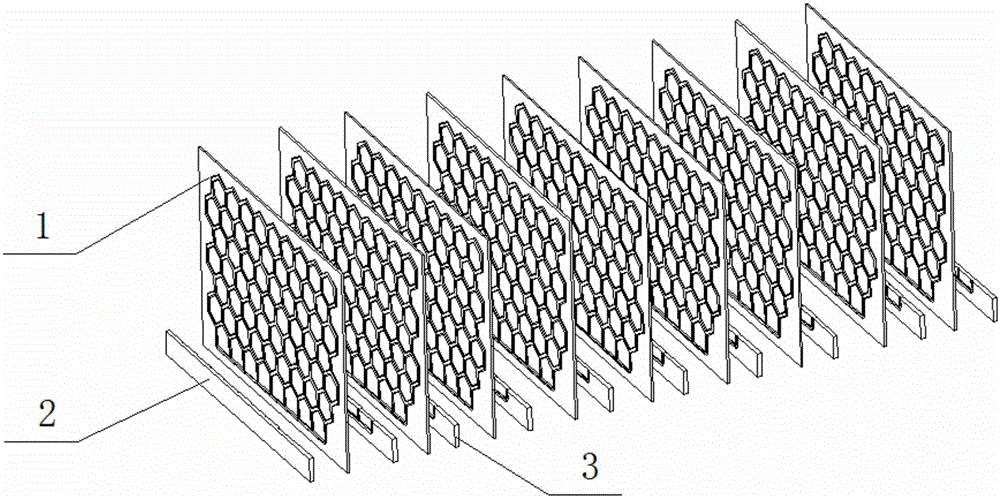

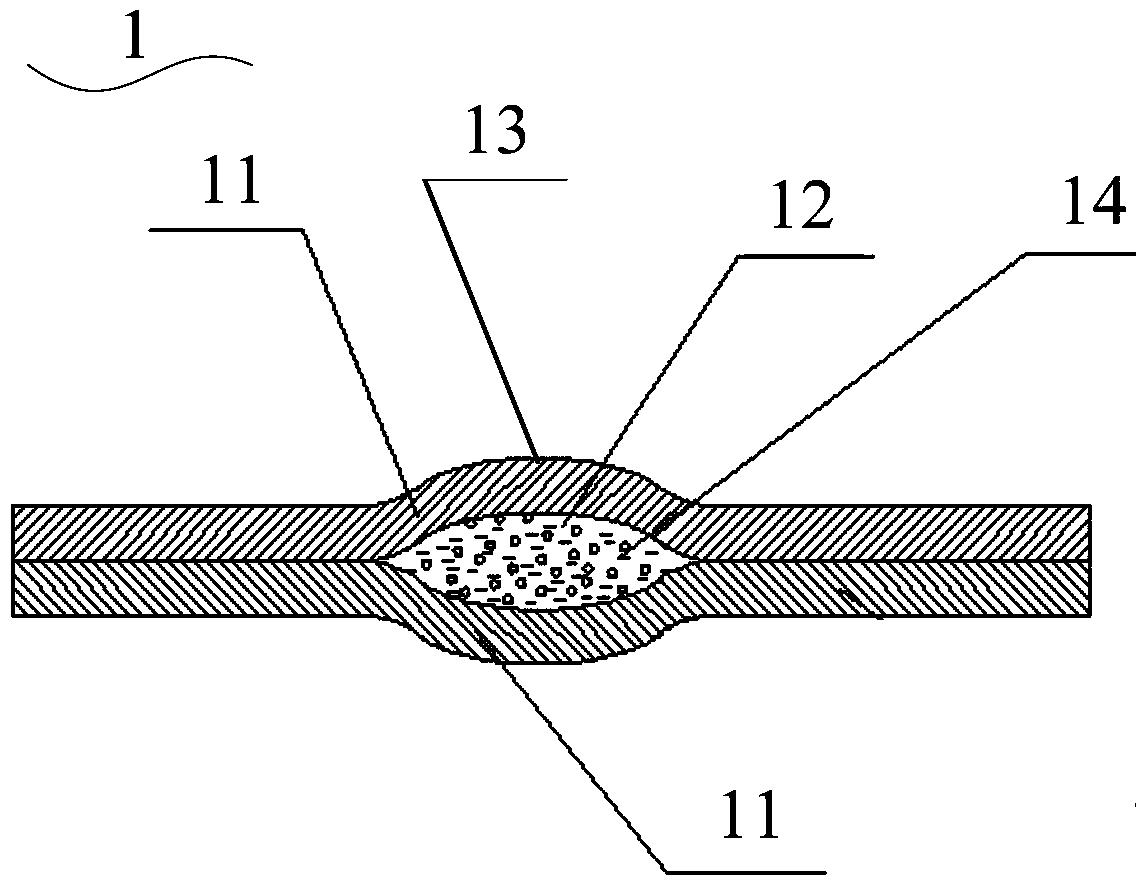

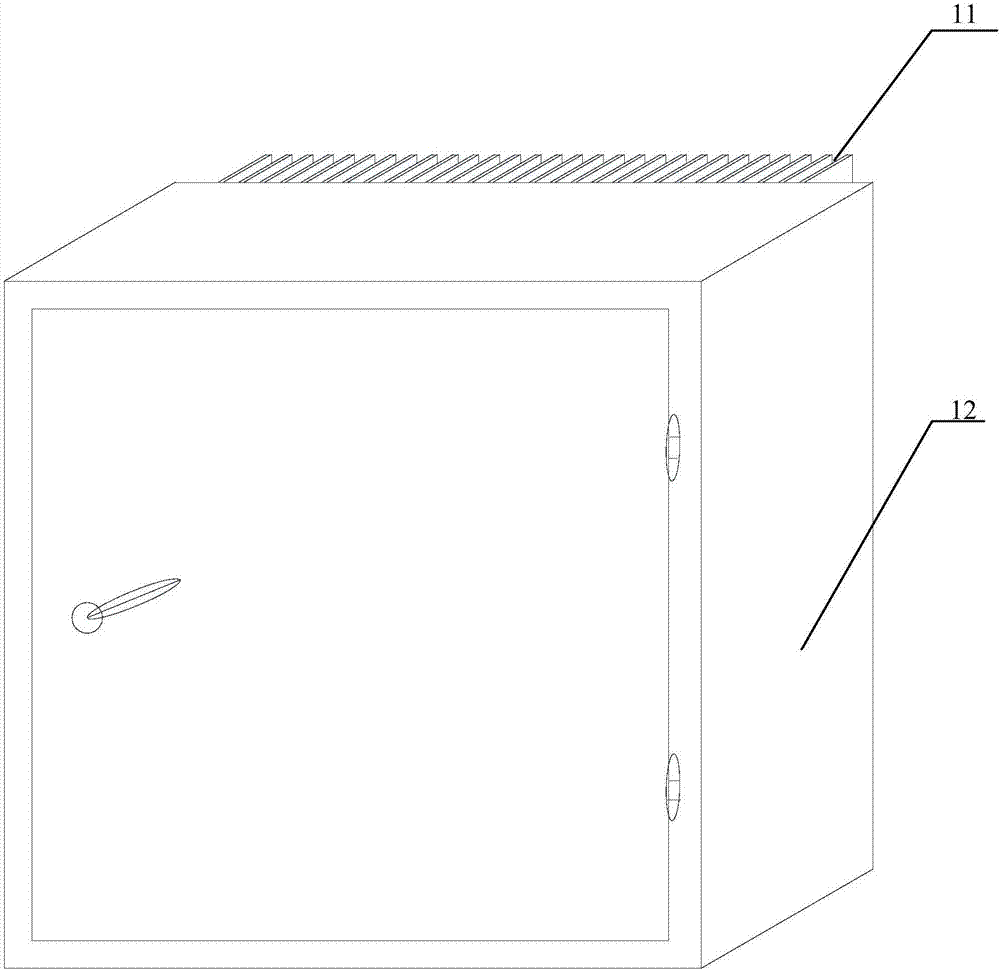

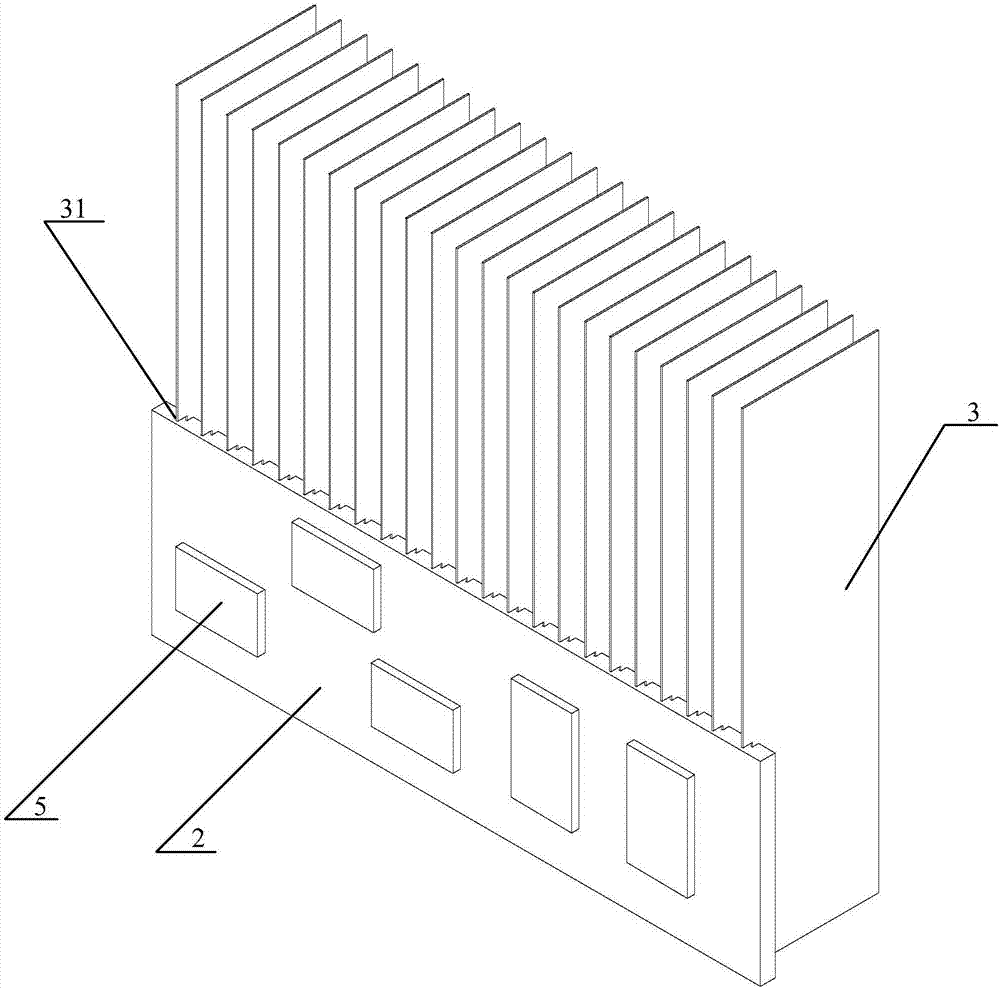

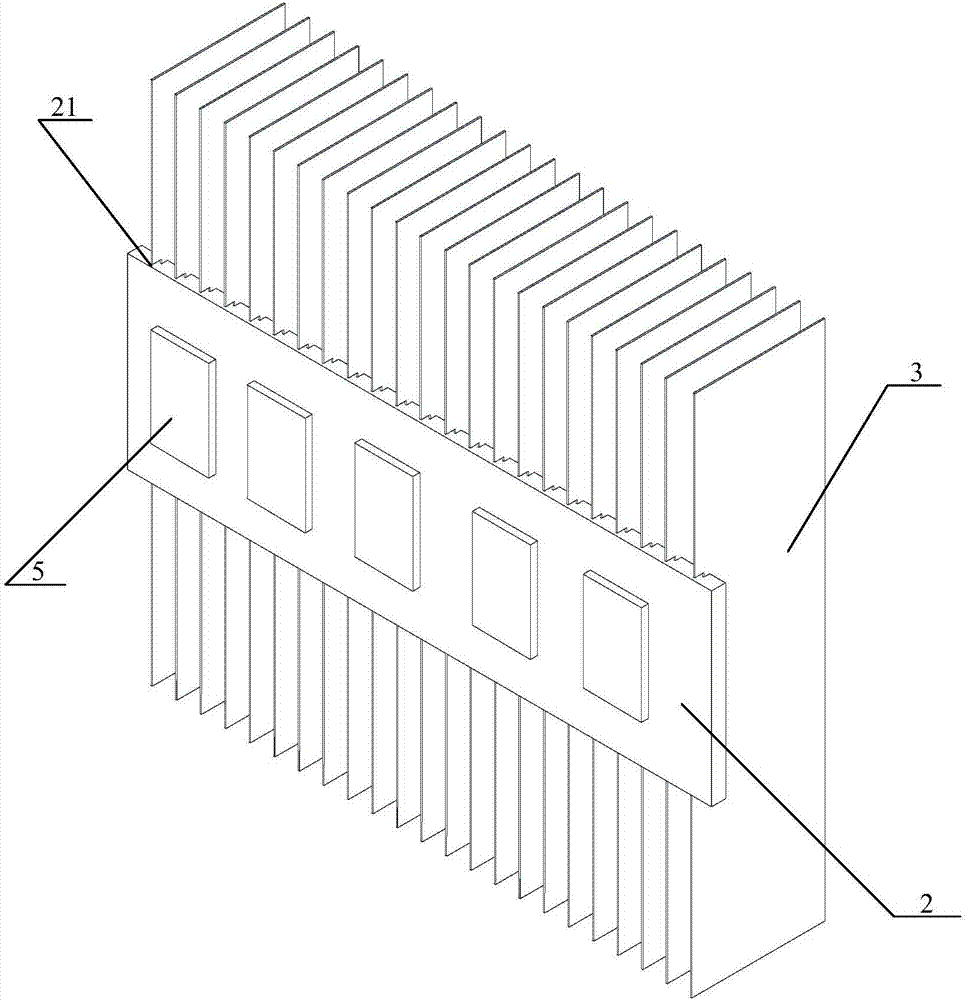

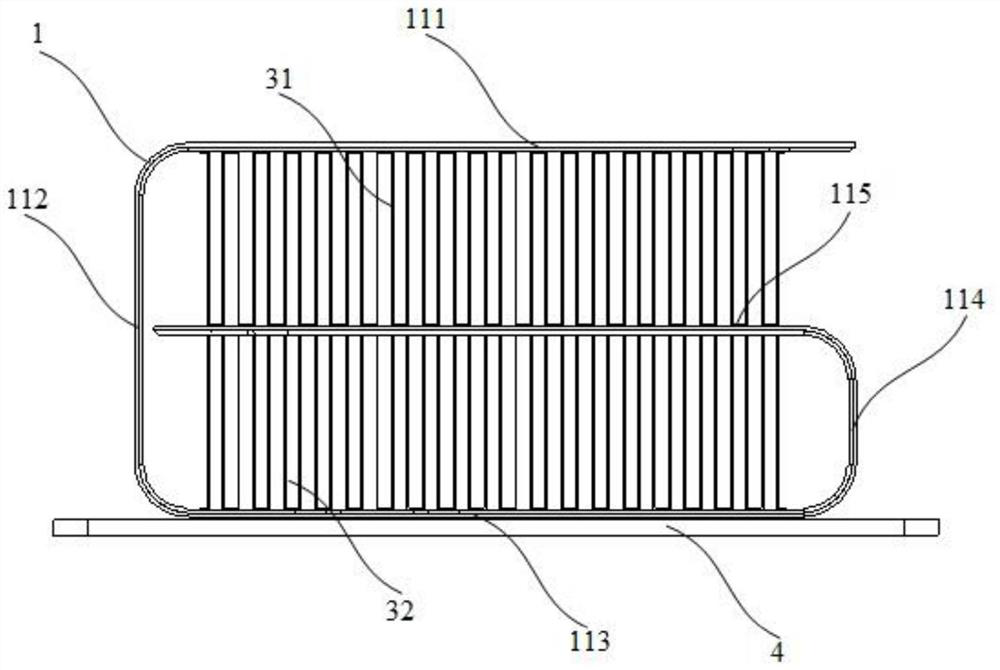

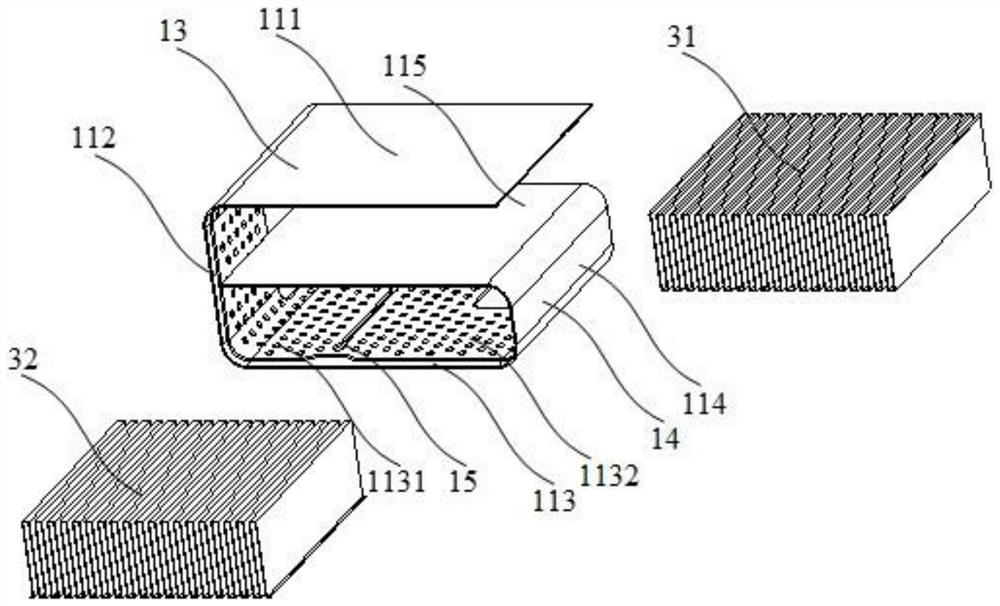

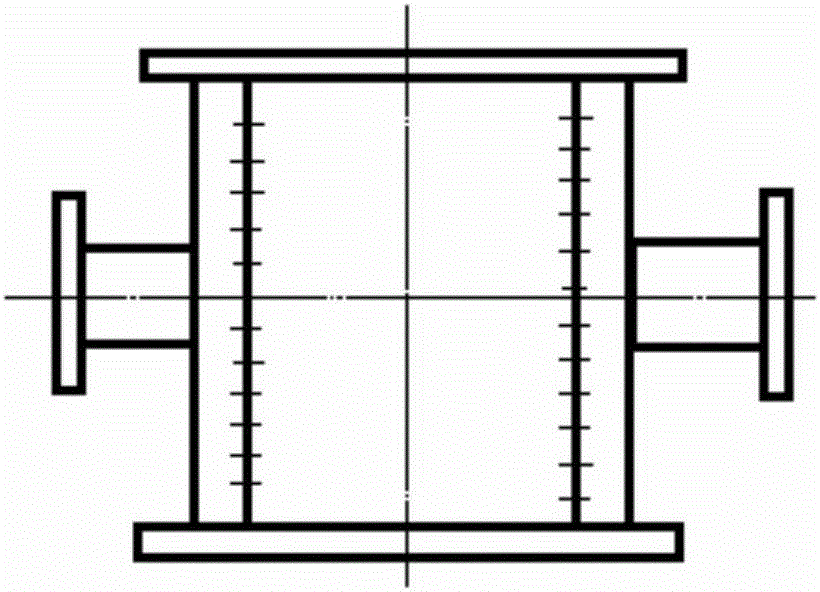

Heat superconducting fin type radiator and electrical device case

ActiveCN106686958AImprove thermal conductivityHigh fin efficiencyCooling/ventilation/heating modificationsComposite plateHeat spreader

The invention discloses a heat superconducting fin type radiator and electrical device case, the heat superconducting fin type radiator comprises a radiator baseplate, a plurality of superconducting radiating fins which is arranged on the surface of the radiator baseplate; the superconducting radiating fin is composite plate structure, a particular shape of heat superconducting line is disposed in the heat superconducting radiating fin. The heat superconducting line is closed line and is stuffed with heat transferring media; the heat superconducting radiating fin is U style plate structure which comprise a flat plate body and a bending side compared to the flat plate body bending; the projection area of a plurality of heat superconducting radiating fins in the plane of the radiator baseplate is larger than that of the radiator basepalte. The projection area of a plurality of the heating superconducting radiating fins in the plane of the radiator baseplate is larger than that of the radiator baseplate; the weight of the radiator is decreased greatly under the precondition of ensuring the heat radiating capability.

Owner:ZHEJIANG JIAXI TECH CO LTD

Thermal superconducting sheet heat sink and manufacturing method thereof

ActiveCN105101751BHigh fin efficiencyImprove thermal conductivityOther manufacturing equipments/toolsCooling/ventilation/heating modificationsHeat flowElectronics cooling

Owner:ZHEJIANG JIAXI TECH CO LTD

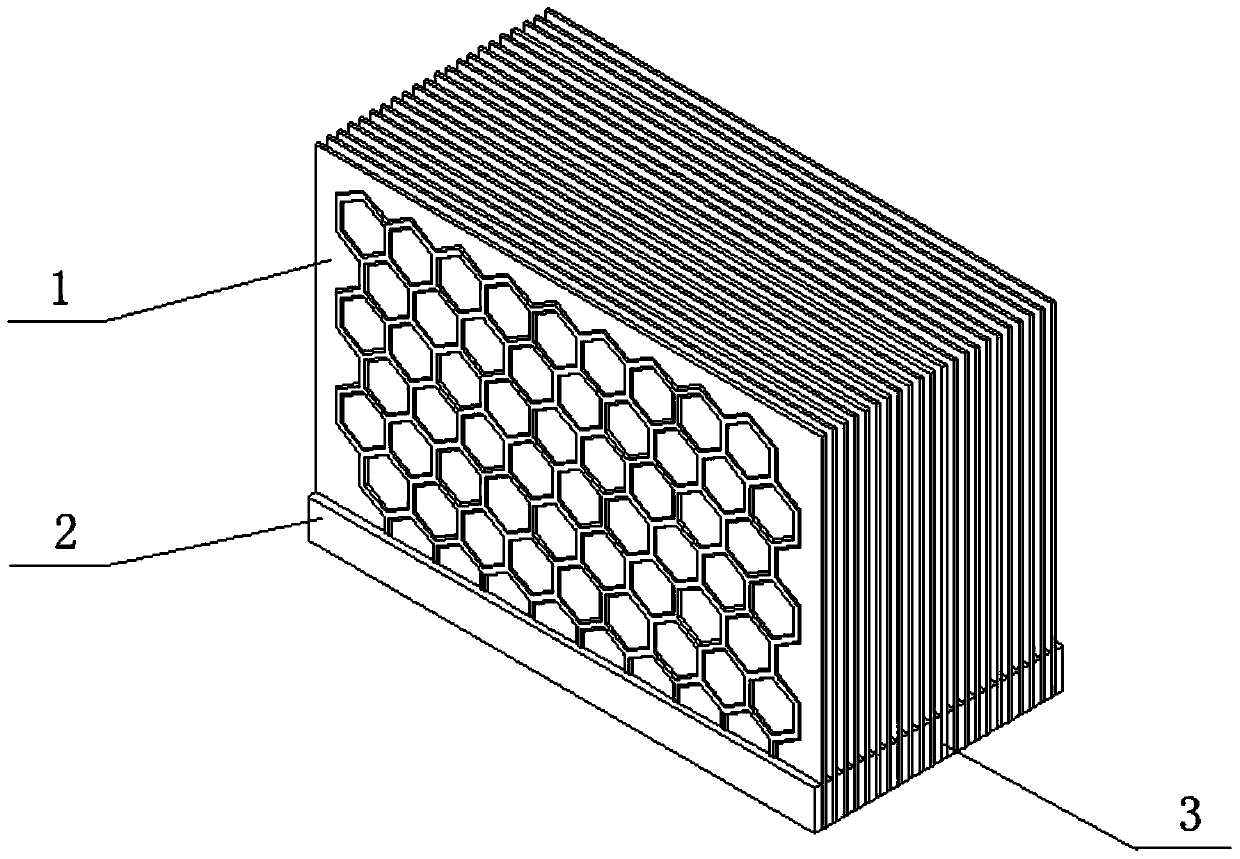

Thermal superconduction fin type radiator and electrical equipment chassis

PendingCN107046794AImprove thermal conductivityHigh fin efficiencyCooling/ventilation/heating modificationsComposite plateClosed tube

The invention provides a thermal superconduction fin type radiator and an electrical equipment chassis. The thermal superconduction fin type radiator comprises a radiator substrate and a plurality of thermal superconduction radiating fins, wherein the thermal superconduction radiating fins are inserted on the surface of the radiator substrate; the thermal superconduction radiating fins are of a composite plate type structure, a special-shaped thermal superconduction pipeline is formed in each thermal superconduction radiating fin, each thermal superconduction pipeline is a closed pipeline, and each thermal superconduction pipeline is filled with a heat transferring working medium; and a projection area of the plurality of thermal superconduction radiating fins in a plane where the radiator substrate locates is greater than an area of the radiator substrate. The thermal superconduction fin type radiator has the advantages of fast thermal conduction, high fin efficiency, flexible and diverse structure, high radiating capacity and the like, and the fin efficiency does not vary with height, length and thickness of the thermal superconduction radiating fins; and the projection area of the plurality of thermal superconduction radiating fins in the plane where the radiator substrate locates is greater than the area of the radiator substrate, thus the weight of the thermal superconduction fin type radiator can be significantly reduced on the premise of ensuring the radiating capacity.

Owner:ZHEJIANG JIAXI TECH CO LTD

A kind of preparation method of cellulose/carbon nanotube composite fiber

ActiveCN106435797BEvenly dispersedStable in natureMonocomponent cellulose artificial filamentArtifical filament manufactureCelluloseFiber

The invention relates to a preparation method of a cellulose / carbon nanotube composite fiber. The preparation method comprises the steps that a cellulose solvent is adopted to dissolve a low-polymerization-degree cellulose, and a carrier solution for carbon nanotubes is prepared; under the strong shear effect provided by a stirring device, the carbon nanotubes is mixed with the carrier solution to prepare a carbon nanotube mother solution; the carbon nanotube mother solution is injected into a cellulose spinning solution in an online adding mode, the spinning solution is subjected to extrusion, solidification and drawing to prepare the cellulose / carbon nanotube composite fiber. For solving the problem that the carbon nanotubes are difficultly and uniformly mixed with a high-viscosity spinning solution, the carbon nanotube mother solution is injected into the cellulose spinning solution, and further the cellulose / carbon nanotube composite fiber is prepared in a spin-forming mode. The mother solution carrier used by the method solidifies and is formed with the fiber without the operation of feeding an additional additive into a solvent and coagulation bath system. The preparation method is simple, flexible and efficient, and production of the cellulose / carbon nanotube composite fiber can be achieved based on a conventional production line.

Owner:DONGHUA UNIV

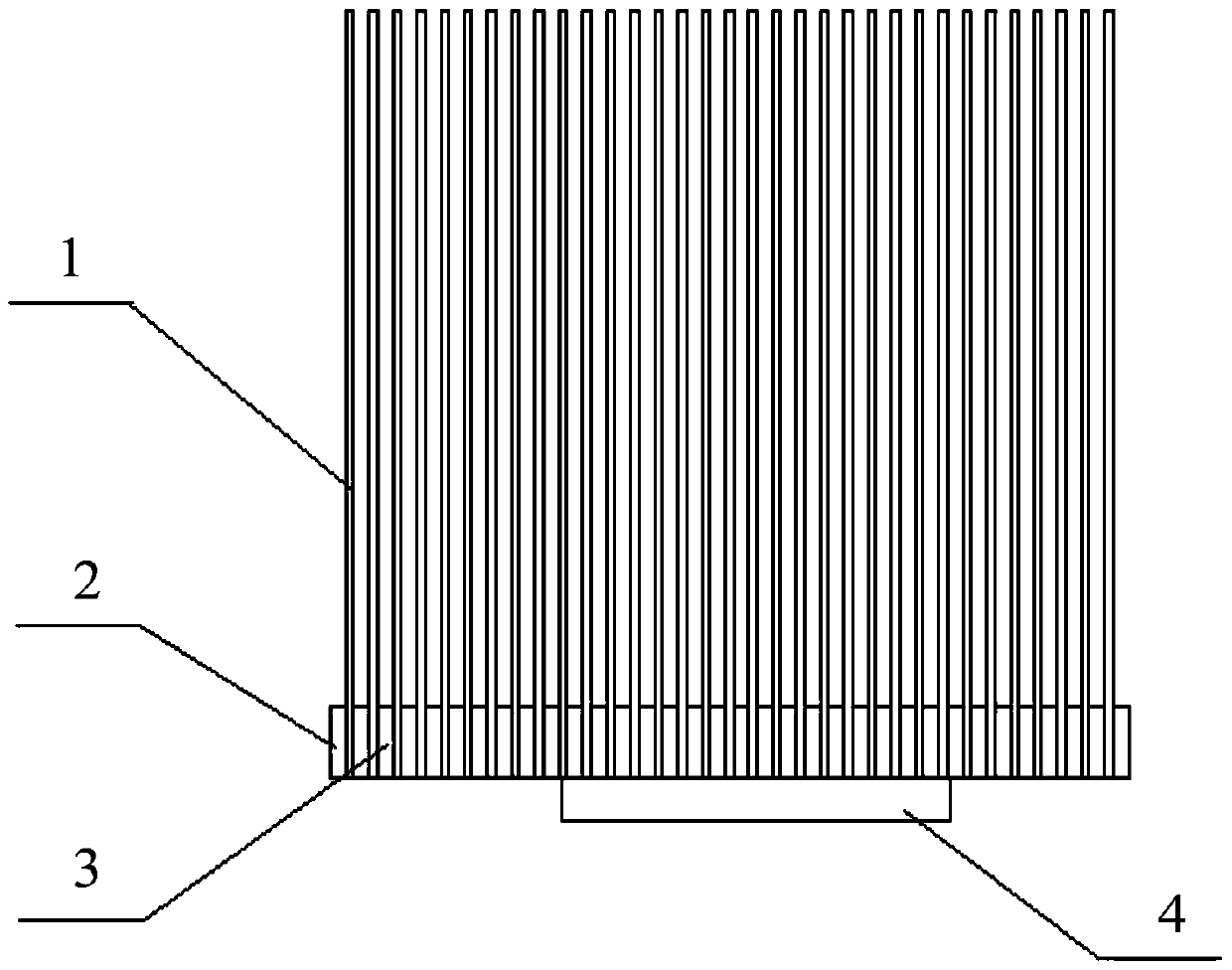

Thermal superconducting heat sink and manufacturing method thereof

ActiveCN105140194BFast thermal conductivityHigh fin efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat spreader

The invention provides a thermal superconducting radiator and a manufacturing method thereof. The thermal superconducting radiator includes several partitions and several thermal superconducting fins; the partitions and the thermal superconducting fins are alternately arranged cloth, and one end surface of the partition is flush with one end surface of the thermal superconducting heat dissipation fin, which together constitute a mounting surface suitable for installing power devices; the thermal superconducting heat dissipation fin is fixed to the partition connect. Using thermal superconducting fins to replace conventional heat sinks in the prior art makes thermal superconducting heat sinks have faster heat conduction rate and higher fin efficiency, and the fin efficiency of heat sinks is not affected by the height, which improves the performance of the heat sink Heat dissipation capacity: The thermal superconducting heat sink of the present invention is convenient and flexible to manufacture, low in cost, large in heat dissipation capacity, light in weight and small in size, and has broad market prospects and huge economic value.

Owner:ZHEJIANG JIAXI TECH CO LTD

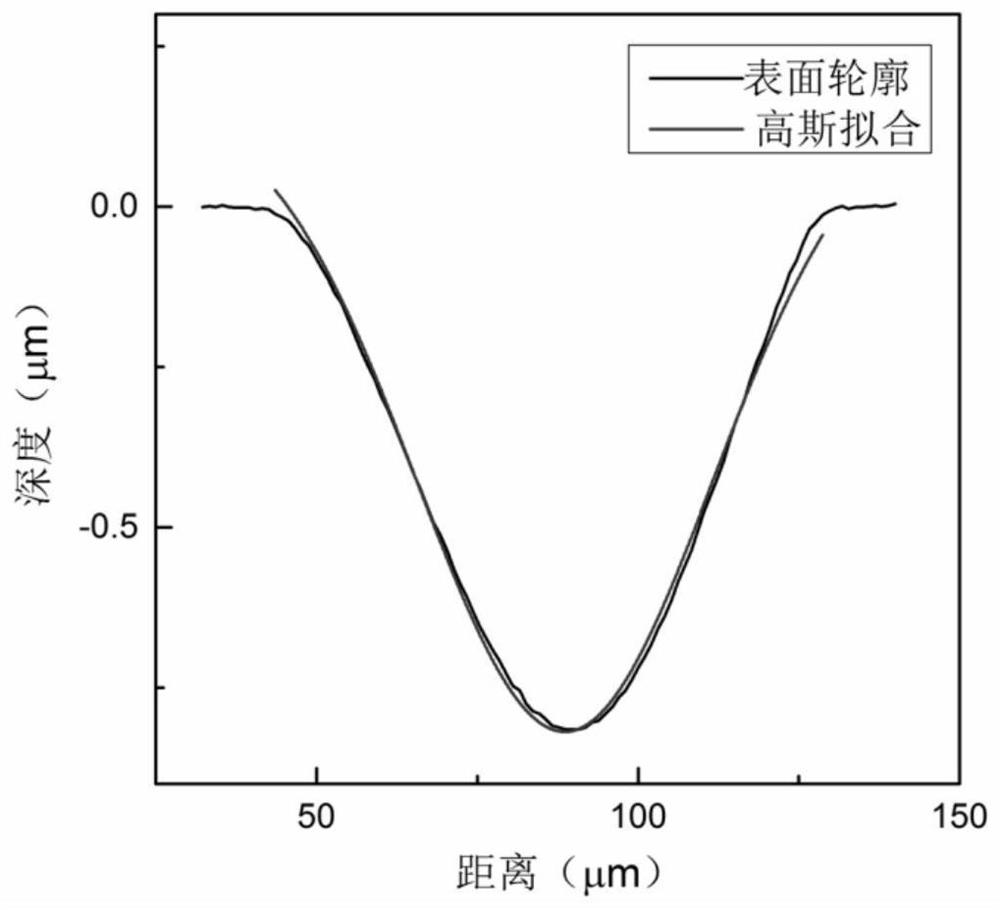

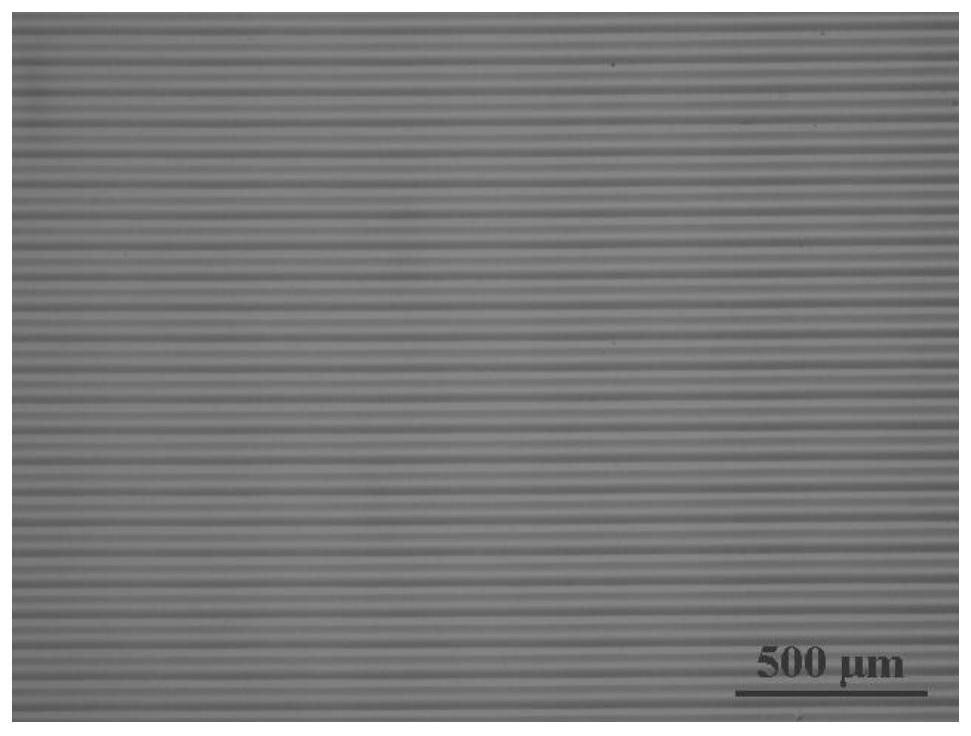

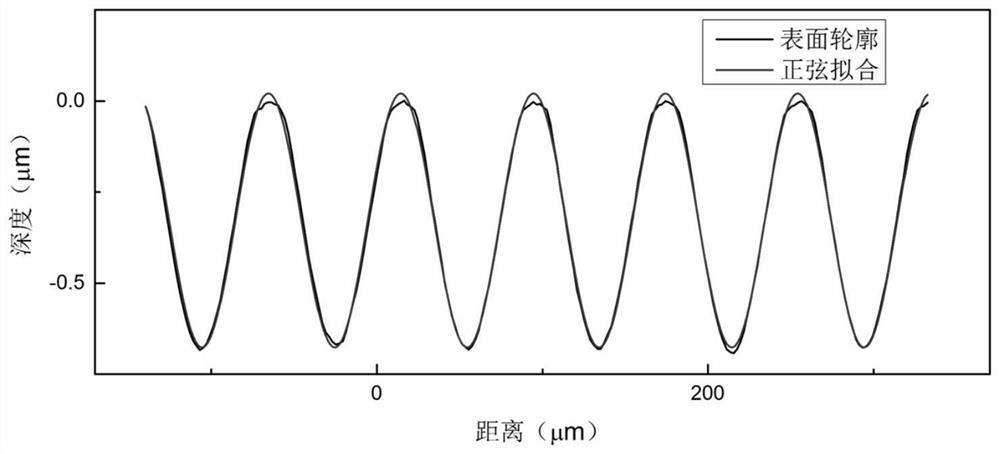

a co 2 Method for Directly Fabricating Sinusoidal Phase Grating on Fused Silica Surface by Laser

ActiveCN113296178BSimple processEasy to implementDiffraction gratingsLaser beam welding apparatusErbium lasersMicrostructure

The invention discloses a CO 2 The method of directly preparing sinusoidal phase grating on the surface of fused silica by laser is carried out according to the following steps: S1. Setting CO 2 Laser parameters; S2, ablation on the surface of fused silica to form a smooth Gaussian ablation pit; S3, check whether the surface morphology and contour of the Gaussian ablation pit have no ablation deposition; S4, on the fused silica The surface is ablated to form an adjacent Gaussian ablation pit; S5, step S4 is repeated until each Gaussian ablation pit forms a preset sinusoidal phase grating. The above method is cost-effective and can utilize CO 2 The laser directly prepares sinusoidal phase gratings on the surface of fused silica, which not only can realize one-dimensional sinusoidal phase gratings, but also can easily and flexibly realize the preparation of two-dimensional sinusoidal phase gratings with various structures, and the prepared sinusoidal phase gratings have a high laser damage threshold, which can be realized Strong laser beam splitting has important applications in the field of multi-beam interference microstructure laser processing.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

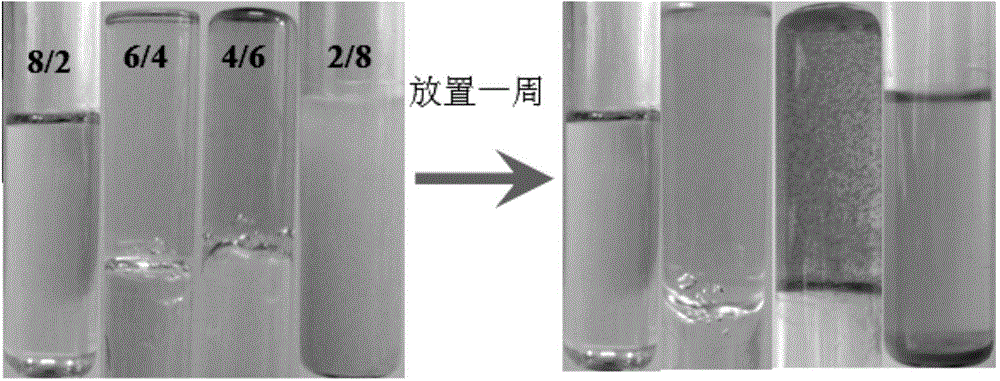

A self-healing folic acid gel with multiple responses and its preparation method

ActiveCN103566842BExcellent optical propertiesZero pollutionColloidal chemistry detailsMulti responseSolvent

The invention discloses self-repairing folic acid gel with multiple responses and a preparation method thereof. The gel is a mixed system comprising organic gel factor folic acid, water and organic solvent; the folic acid is dissolved in the mixed solvent prepared by the water and the organic solvent under the condition of room temperature, is evenly mixed, and placed still until the solution forms the gel. The gel of the invention has excellent optical characteristics, has four responses of heat, light, force and pH, and can finish reversible conversion between gel and solution under the excitation of corresponding factors, so that a novel feasible path for truly applying the gel to the civil fields such as medical materials, optical materials, intelligent materials and crystal growth templates is provided; the self-repairing folic acid gel has a wide application prospect.

Owner:SHANDONG UNIV

A kind of preparation method of tin film

ActiveCN108754562BAchieving controllable equipmentShort processSurface reaction electrolytic coatingSupporting electrolyteElectrolysis

The invention provides a preparation method of TiN film. The method comprises the following steps: adding 0.5-2.0 mass percentage of aluminum nitride into LiCl-KCl supporting electrolyte, uniformly mixing to obtain mixed molten salt electrolyte, adding the mixed molten salt electrolyte in an electrolytic tank and increasing the temperature to 430-450 DEG C, carrying out electrolysis by taking metallic titanium as an anode and taking metallic aluminum as a cathode, wherein the anode current density is 20-100mA / cm<2> and the electrolysis time is 10-20 hours; and obtaining dense TiN film on the surface of the anode. The preparation method of the TiN film is short in process, simple in equipment, convenient to operate and low in cost; the bonding strength between the TiN film and the substrateis high; the TiN film with different thicknesses can be obtained by controlling the current density or the electrolysis time.

Owner:JIANGXI UNIV OF SCI & TECH

2U-shaped radiator

PendingCN112969354AImprove cooling effectReduce temperature riseCooling/ventilation/heating modificationsMechanical engineeringHeat spreader

The invention provides a 2U-shaped radiator. The 2U-shaped radiator comprises a phase change restraining, heat transfer and radiating fin, a first fin and a second fin, wherein the phase change restraining, heat transfer and radiating fin comprises a first section, a second section, a third section, a fourth section and a fifth section which are sequentially connected, the first section, the second section and the third section form a first U-shaped part, the third section, the fourth section and the fifth section form a second U-shaped part, the opening directions of the first U-shaped part and the second U-shaped part are opposite, and the fifth section is located in the first U-shaped part; and the first fin is located between the first section and the fifth section, and the second fin is located between the third section and the fifth section. The 2U-shaped radiator has the advantages of being low in cost, high in heat dissipation capacity, uniform in heat dissipation, small in temperature rise and the like, and has wide market prospects.

Owner:ZHEJIANG JIAXI TECH CO LTD

Preparation method of chitosan/hydroxyapatite composite fiber

ActiveCN106400201BEvenly dispersedStable in natureConjugated artificial filamentsArtifical filament manufactureFiberRegular Production

The invention relates to a preparation method of chitosan / hydroxyapatite composite fibers. The preparation method includes the steps of 1), dissolving low-molecular-weight chitosan by adopting chitosan solvent to obtain a carrier solution; 2), mixing hydroxyapatite ha powder with the carrier solution through the high shearing action provided by stirring equipment to obtain hydroxyapatite mother liquid; 3), injecting a chitosan spinning liquid into the hydroxyapatite mother liquid in an online adding mode to obtain the chitosan / hydroxyapatite spinning liquid, and subjecting the chitosan / hydroxyapatite spinning liquid to a wetting method or a dry spraying wet method to obtain the chitosan / hydroxyapatite composite fibers. By the arrangement, the hydroxyapatite ha powder is uniformly distributed, an adopted carrier is formed with coagulation of the fibers, and no additional additives are added to the solvent and coagulation bath system. The preparation method is simple and efficient in forming, and the functional chitosan fibers can be produced on the basis of conventional production lines.

Owner:嘉兴市荣明佳通纺织科技股份有限公司

Antibacterial cellulose composite fiber and its preparation method

ActiveCN108866665BAvoid churnEasy and flexible productionMonocomponent cellulose artificial filamentArtifical filament manufactureCarboxymethyl cellulosePolymer science

The invention relates to an anti-bacterial cellulose complex fiber and a preparation method thereof. The preparation method comprises the following step: spinning a mixed solution of water-soluble chitosan / carboxymethylcellulose collosol and a cellulose spinning solution to obtain the anti-bacterial cellulose complex fiber, wherein the dispersion phase particles of the water-soluble chitosan / carboxymethylcellulose collosol are a water-soluble chitosan / carboxymethylcellulose composition. The prepared antibacterial cellulose complex fiber is mainly prepared from a cellulose fiber substrate and the water-soluble chitosan / carboxymethylcellulose composition which is distributed inside and / or outside the cellulose fiber substrate; the water-soluble chitosan / carboxymethylcellulose composition ismainly formed by bonding water-soluble chitosan and carboxymethylcellulose through an ionic bond; the water-soluble chitosan / carboxymethylcellulose composition and the cellulose fiber substrate are mainly bonded through a hydrogen bond. The preparation method is easy to operate, and the prepared anti-bacterial cellulose complex fiber has the advantages of stable structure, high mechanical performance, antibacterial performance, moisture absorbing performance and excellent popularization value.

Owner:TIANE CHEM FIBER GROUP CORP BAODING +1

A kind of preparation method of cellulose/biological glass composite fiber

ActiveCN106435816BEvenly dispersedStable in natureConjugated cellulose/protein artificial filamentsAbsorbent padsProduction lineGlass fiber

Owner:DONGHUA UNIV

Chitosan composite fiber and preparation method thereof

ActiveCN108914248BAvoid churnEasy and flexible productionArtifical filament manufactureAnti bacterialMaterials science

The invention relates to a chitosan composite fiber and a preparation method thereof. The method comprises the following steps: spinning mixed liquor of chitosan quaternary ammonium salt / alginic acidsol and chitosan spinning solution to prepare the chitosan composite fiber, wherein a dispersion phase particle in the chitosan quaternary ammonium salt / alginic acid sol is a chitosan quaternary ammonium salt / alginic acid conjugate mainly. The prepared chitosan composite fiber is mainly formed by a chitosan fiber matrix and the chitosan quaternary ammonium salt / alginic acid conjugate distributed in the chitosan fiber matrix. The chitosan quaternary ammonium salt / alginic acid conjugate is mainly formed by bonding chitosan quaternary ammonium salt and alginic acid through an ionic bond. The chitosan quaternary ammonium salt / alginic acid conjugate is bonded with the chitosan fiber matrix through a hydrogen bond mainly. According to the chitosan composite fiber and the preparation method thereof provided by the invention, the preparation method is simple in operation, the prepared chitosan composite fiber is stable in structure, good in mechanical property, anti-bacterial property and hygroscopic property, and has a good promotional value.

Owner:TIANE CHEM FIBER GROUP CORP BAODING +1

A 10,000-ton online anti-wall-hanging evaporation and concentration device for traditional Chinese medicine and its operating method

ActiveCN103861300BEmission reductionLong-term continuous and stable operationEvaporationEvaporationEngineering

The invention provides an online tons-level traditional Chinese medicine anti-wall-hanging evaporation and concentration device and an operating method thereof. A gas-liquid-solid three-phase natural circulation fluidized bed evaporation and concentration device in an industrial production scale in which the heating area of a heater is 18.9 m<2> and the evaporative power is 1100-1400 kg / h is determined. The inventions and innovations of a screen type discharging device, a 90-degree multi-section short-radius elbow connecting pipe and a demister on the upper part of a separation chamber are designed. At present, the production operation result of the industrial scale device of about 100-ton extracting solutions of Menopause Ease and other over ten traditional Chinese medicines proves that compared with a traditional two-phase flow evaporation concentrator with the heating area of 18 m<2> in a factory and an operating method thereof, the device and the method under approximate operation conditions have the advantages that the total heat transfer coefficient and evaporation intensity are improved, a wall hanging phenomenon of the two-phase flow evaporation concentrator is avoided, the wall hanging phenomenon existing in a traditional Chinese medicine extracting solution evaporation concentrator is eliminated, and high-efficiency continuous and stable operation is realized.

Owner:TIANJIN UNIV

Fibers containing polyelectrolytes and methods of making the same

ActiveCN109208112BAvoid churnEasy and flexible productionArtificial filaments from cellulose solutionsMonocomponent synthetic polymer artificial filamentPolymer scienceSpinning

The invention relates to a fiber containing polyelectrolyte and a preparation method thereof. The preparation method is as follows: spinning the mixed solution of polyelectrolyte sol and spinning solution to obtain the fiber containing polyelectrolyte; the dispersed phase particles in the polyelectrolyte sol mainly It is a polyelectrolyte conjugate. The prepared fiber is mainly composed of a fiber matrix and a polyelectrolyte conjugate distributed in the inner layer and / or outer layer of the fiber matrix. The polyelectrolyte conjugate is mainly composed of soluble cationic polyelectrolyte and soluble anionic polyelectrolyte. Bonding is formed, and the polyelectrolyte conjugate is mainly combined with the fiber matrix through hydrogen bonding. A fiber containing polyelectrolyte and its preparation method according to the present invention can apply cationic polyelectrolyte solution and anionic polyelectrolyte solution to fiber forming, and the prepared fiber containing polyelectrolyte has stable structure, good mechanical properties, and excellent promotional value.

Owner:TIANE CHEM FIBER GROUP CORP BAODING +1

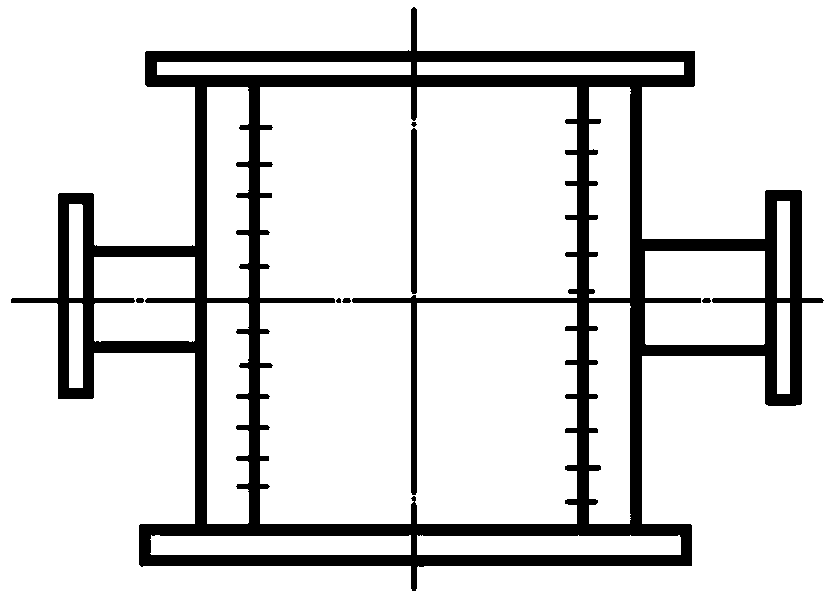

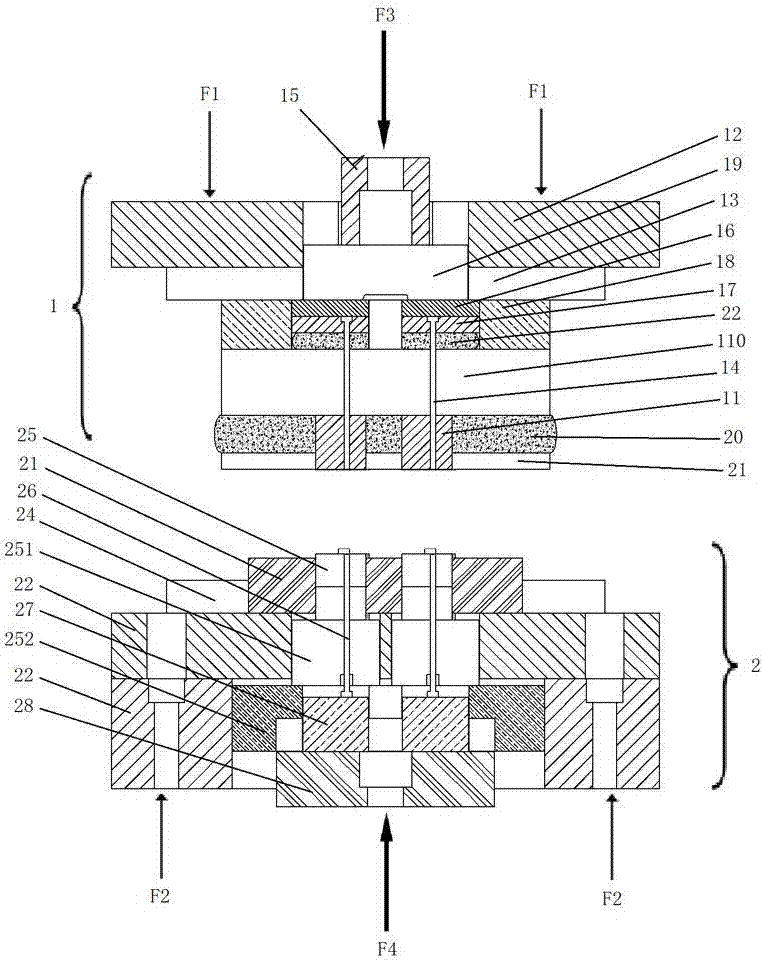

Brake pad steel backing precision stamping die assembly

The invention belongs to the technical field of stamping manufacturing, and particularly relates to a brake pad steel backing precision stamping die assembly. According to the main technical scheme, the assembly is mainly composed of an upper die with a puncher pin and a lower die with a female die; the upper die comprises an upper die base plate and an upper die mounting bottom plate connected with the upper die base plate, the upper portion of the upper die base plate is used for bearing downward precision stamping pressure, the puncher pin is arranged on the lower portion of the upper die mounting bottom plate through a puncher pin mounting plate, the lower die comprises a lower die base and a lower die base plate connected with the lower die base, the female die is arranged on the upper portion of the lower die base plate through a die locking sleeve plate, a cavity in the female die vertically corresponds to the puncher pin, and a puncher pin device capable of stamping a sinking hole in a steel backing to form a convex pin is sleeved with the upper die, and the precision stamping die assembly has the beneficial effects of being easy to operate and capable of carrying out multiple procedures at the same time.

Owner:GUCHENG COUNTY HENGRUN AUTO PARTS CO LTD

Preparation method of functional chitosan fiber

The present invention relates to a preparation method for preparing functional chitosan fibers. The method comprises the steps of 1) dissolving the low-molecular-weight chitosan in a chitosan solvent to prepare a carrier solution; 2) under the strong shearing action of a stirring device, mixing up functional powders with the carrier solution to prepare a functional mother liquid; 3) injecting the functional mother liquid into a chitosan spinning solution in the online addition manner to obtain a functional spinning solution; and preparing functional chitosan fibers through the extruding, solidifying and stretching process of the functional spinning solution. According to the technical scheme of the invention, the problem in the prior art that functional powders and the spinning solution are different to mix up and uneven in dispersion according to the traditional method can be solved. An adopted carrier is formed along with the solidification process of fibers, while no extra assistant is fed into a solvent and coagulating bath system. The forming method is simple and efficient, and the production of functional chitosan fibers can be realized based on a conventional production line.

Owner:JIAXING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com