A 10,000-ton online anti-wall-hanging evaporation and concentration device for traditional Chinese medicine and its operating method

A technology of evaporation concentration and anti-hanging wall, applied in evaporation, separation methods, chemical instruments and methods, etc., can solve problems such as unseen and difficult to meet the evaporation capacity of industrial production, and achieve the effect of improving condensation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

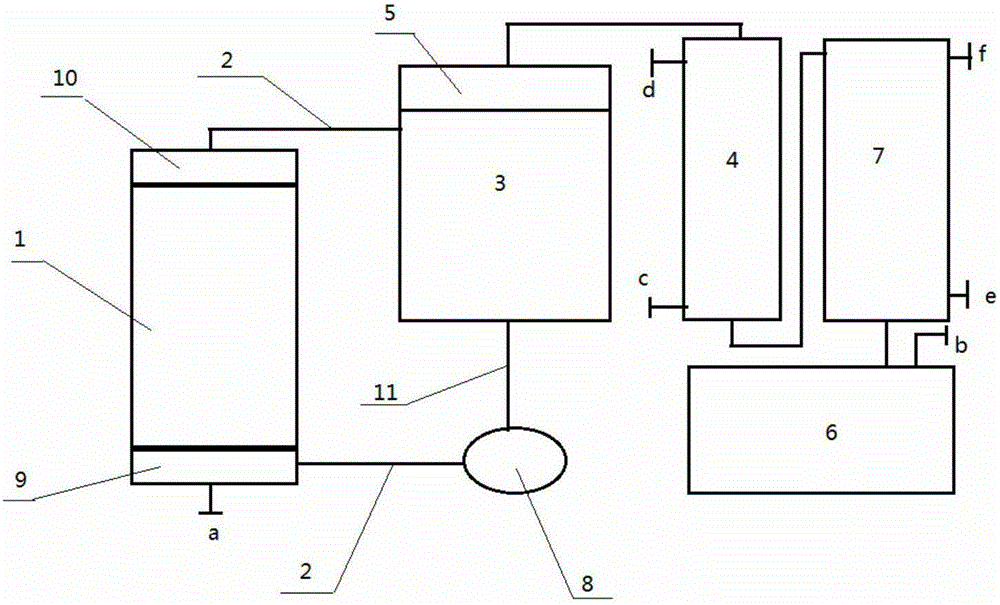

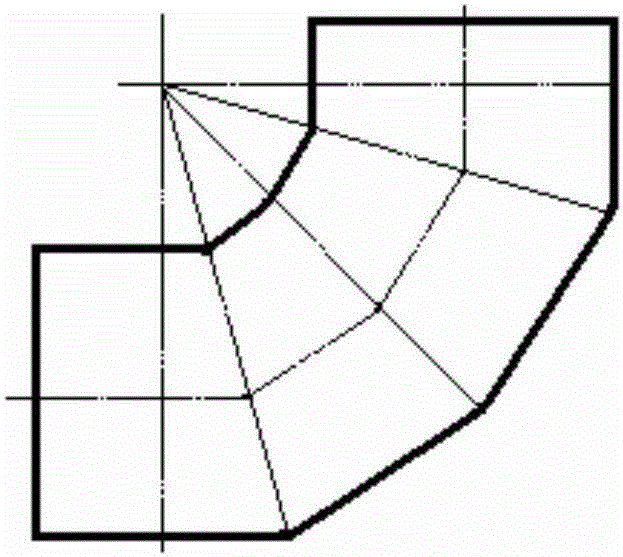

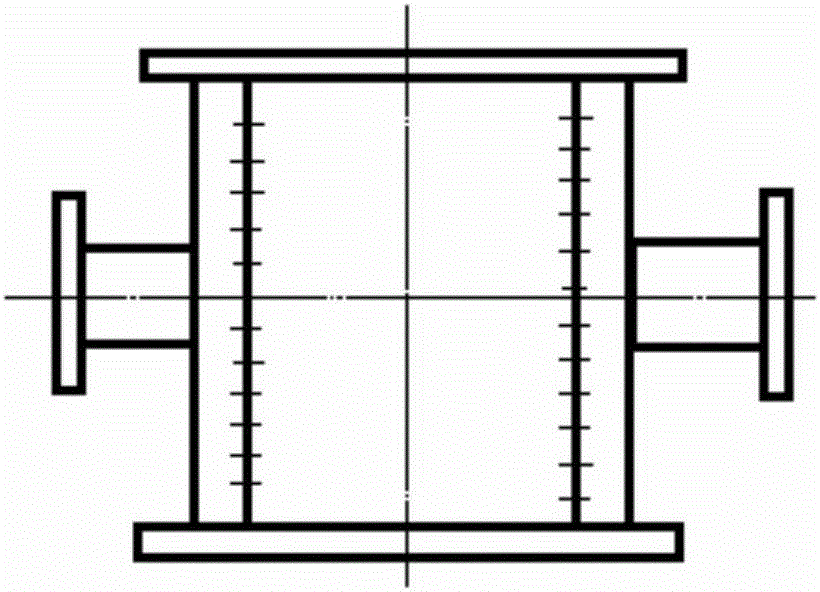

Embodiment 1

[0066] For the Gengnian Anshui extract with a relative density of 1.05, apply the technology, device and operation method of the present invention, under operating conditions such as heating steam gauge pressure 0.02MPa, vacuum gauge reading 0.07MPa in the separation chamber, etc., to evaporate the traditional Chinese medicine extract Concentrate, obtain 100kg of secondary steam condensate in 5 minutes, and the production capacity is 1200kg / h, and finally obtain the mengnian'an complete liquid extract with a relative density of 1.31 when the temperature is 60°C. The screen diameter of the screen type discharge device 8 is 0.3m, the length is 0.3m, the diameter of the screen hole is 0.002m, the opening rate is 30%, and the diameter of the 90 ° multi-section short radius elbow connecting pipe 2 is 0.3m , the number of sections is 4, and the demister 5 is a 304 stainless steel wire mesh with a diameter of 0.7m and a length of 0.3m. The circulating flow of the extraction liquid th...

Embodiment 2

[0068] For the water extract of Baohe Oral Liquid with a relative density of 1.01, apply the technology, device and operation method of the present invention, under the operating conditions such as heating steam gauge pressure 0.1MPa, vacuum gauge reading 0.07MPa in the separation chamber, etc., carry out the extraction of Chinese medicine extract Concentrated by evaporation, 23.33 kg of secondary steam condensate was obtained in 1 minute, with a production capacity of 1400 kg / h, and finally Baohe Oral Liquid Complete Liquid Extract with a relative density of 1.2 at a temperature of 60°C was obtained. The screen diameter of the screen type discharge device 8 is 0.2m, the length is 0.8m, the diameter of the screen hole is 0.001m, the opening rate is 5%, and the diameter of the 90 ° multi-section short radius elbow connecting pipe 2 is 0.2m , the number of sections is 3, and the demister 5 is a 304 stainless steel wire mesh with a diameter of 0.2m and a length of 0.1m. The circula...

Embodiment 3

[0070] For the Zhibai Dihuang water extract with a relative density of 1.01, the technology, device and operation method of the present invention are used to evaporate the traditional Chinese medicine extract under operating conditions such as a heating steam gauge pressure of 0.05MPa and a vacuum gauge reading of 0.07MPa in the separation chamber. Concentrate, obtain 9.2kg of secondary steam condensate in 30 seconds, the production capacity is 1100kg / h, and finally obtain Zhibai Dihuang complete liquid extract with a relative density of 1.3 when the temperature is 55°C. The screen diameter of the screen type discharge device 8 is 0.8m, the length is 0.2m, the diameter of the screen hole is 0.01m, the opening rate is 50%, and the diameter of the 90 ° multi-section short radius elbow connecting pipe 2 is 0.8m , the number of sections is 10, and the demister 5 is a 304 stainless steel wire mesh with a diameter of 0.8m and a length of 0.5m. The circulating flow of the extraction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com