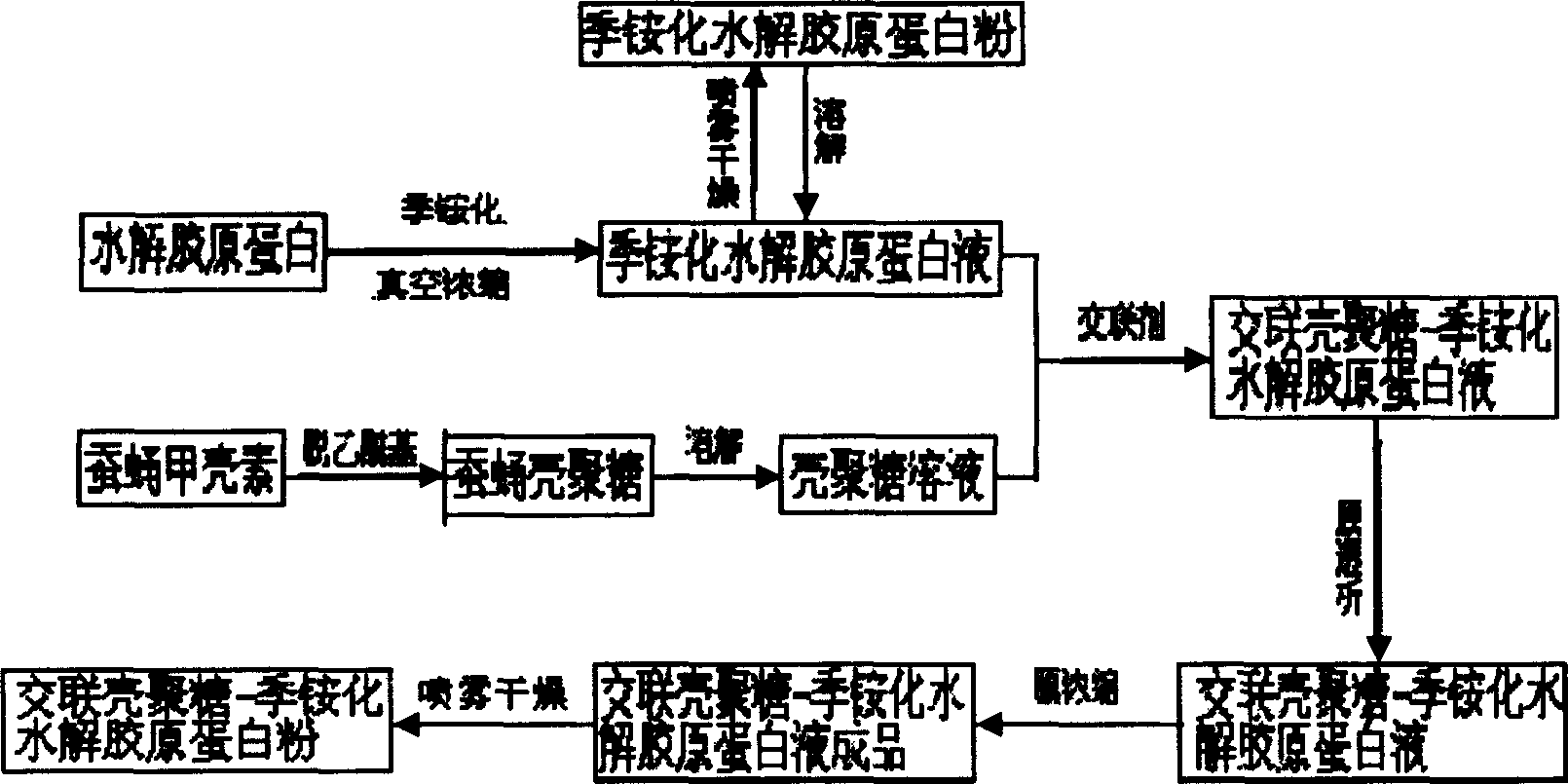

Method for preparing crosslinked chitin-glycan-quaterisation collagen hydrolysate

A technology of hydrolyzing collagen and cross-linking chitosan, which is applied in the field of antibacterial biomaterial preparation, can solve the problems of poor air permeability, easy peeling and brittleness, etc., and achieve strong adhesion, antibacterial property and good air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific embodiments.

[0022] The steps of a preparation method of cross-linked chitosan-quaternized hydrolyzed collagen solution are as follows:

[0023] 1. Preparation of Quaternized Hydrolyzed Collagen Solution

[0024] Take 1000 grams of hydrolyzed collagen with a protein concentration of 30% and an average molecular weight of 3500D, adjust and control its pH value to 8.0 with NaOH solution, and slowly add 60 grams of 40% N- Dodecyl dimethyl hydroxypropyl ammonium chloride quaternizing agent solution, after continuous reaction for 1.5 hours, adjust the pH value to 4.0 with dilute HCl, then carry out vacuum filtration, and the filtrate is quaternized hydrolyzed collagen solution , the average concentration of quaternized hydrolyzed collagen is 25%; the filtrate can also be spray-dried under the conditions of controlling the inlet air temperature at 155°C, the outlet air temperature at 85°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com