Phenolic foam board interface agent and preparation method thereof

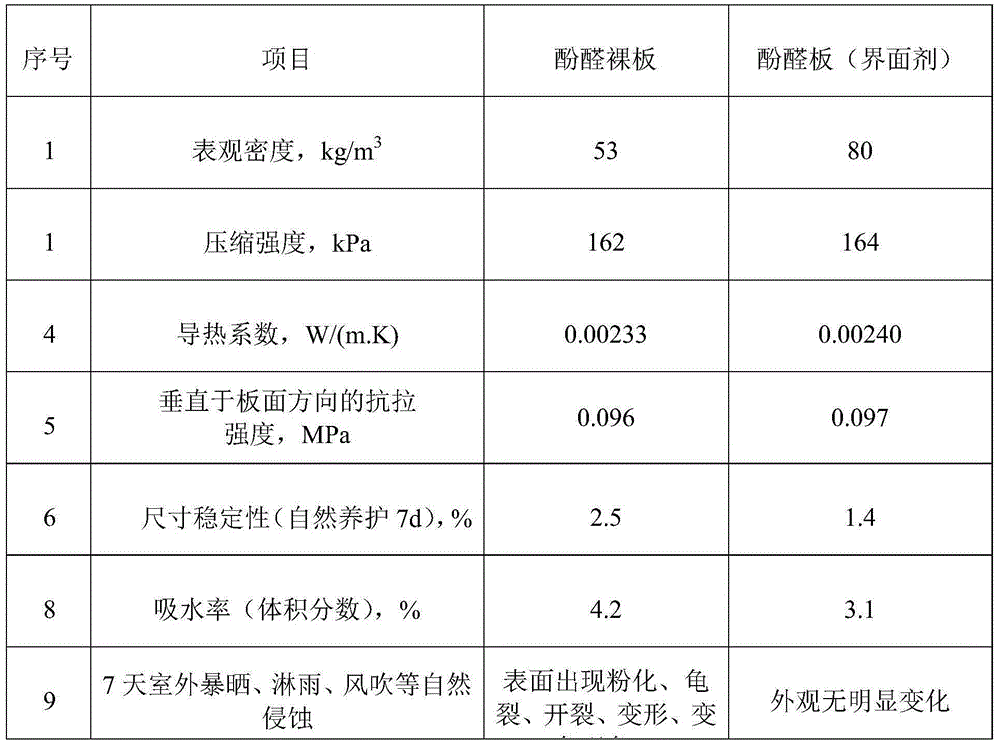

A technology of interface agent and phenolic board, which is applied in the field of interface agent of phenolic foam board and the preparation of interface agent of phenolic foam board. To solve the problems such as chemical change, to achieve the effect of easy implementation, reduced water absorption, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the phenolic plate interface agent provided by the invention specifically comprises the following steps:

[0024] 1) Take 42.5 parts by mass: 200-250 parts of cement, 550-800 parts of heavy calcium, 50-100 parts of fly ash, 40-80 parts of calcium hydroxide, 0.2-1 part of starch ether, 1-4 parts of cellulose 1. 1 to 5 parts of hydrophobic powder, mixed and stirred, and the powdery mixture was obtained after stirring evenly;

[0025] 2) Add acrylic emulsion and water to the powdery mixture obtained in step 1) and stir during the addition process to obtain a solid-liquid mixture. Stop adding acrylic emulsion when the mass fraction of the acrylic emulsion reaches 200-300 parts For emulsion, stop adding water when the mass fraction of water reaches 200-400 parts;

[0026] 3) Stir the solid-liquid mixture obtained in step 2) evenly, and the obtained sprayable mixed viscous fluid is the phenolic board interface agent.

[0027] The preparation method...

Embodiment 1

[0029] A phenolic board interface agent of the present invention is prepared by mixing the following components in parts by weight: 200 parts of 42.5 cement, 800 parts of heavy calcium, 100 parts of fly ash, 50 parts of calcium hydroxide, 0.2 parts of starch ether, fiber 1 part of plain, 1 part of hydrophobic powder, 200 parts of acrylic emulsion, 400 parts of water.

[0030] Among them, 42.5 cement is Portland 42.5 cement; starch ether is a mixture of one or more of hydroxyalkyl starch, carboxymethyl starch or cationic starch; cellulose is 40,000 viscosity cellulose; hydrophobic powder is organic Silicone hydrophobic powder; acrylic emulsion is Arkema or Dow acrylic emulsion.

[0031] The preparation method of this phenolic plate interface agent is as follows:

[0032] 1) Take 200 parts of 42.5 cement, 800 parts of heavy calcium, 100 parts of fly ash, 50 parts of calcium hydroxide, 0.2 parts of starch ether, 1 part of cellulose, and 1 part of hydrophobic powder according to ...

Embodiment 2

[0036] A phenolic board interface agent of the present invention is prepared by mixing the following components in parts by weight: 250 parts of 42.5 cement, 650 parts of heavy calcium, 60 parts of fly ash, 40 parts of calcium hydroxide, 0.5 part of starch ether, fiber 2 parts of plain, 2 parts of hydrophobic powder, 250 parts of acrylic emulsion, 350 parts of water.

[0037] Among them, 42.5 cement is Portland 42.5 cement; starch ether is a mixture of one or more of hydroxyalkyl starch, carboxymethyl starch or cationic starch; cellulose is 40,000 viscosity cellulose; hydrophobic powder is organic Silicone hydrophobic powder; acrylic emulsion is Arkema or Dow acrylic emulsion.

[0038] The preparation method of this phenolic plate interface agent is as follows:

[0039] 1) Take 250 parts of 42.5 cement, 650 parts of heavy calcium, 60 parts of fly ash, 40 parts of calcium hydroxide, 0.5 parts of starch ether, 2 parts of cellulose, and 2 parts of hydrophobic powder according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com