Active printing paste modifier without urea in application, its preparation method and composition

A technology of reactive printing and modifier, applied in dyeing, textile and papermaking, etc., can solve the problems of reducing the color yield of printing, high triethylene glycol consumption, and reducing the use of urea, so as to improve the effect of reactive printing and reduce ammonia nitrogen. The effect of discharging and ensuring hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

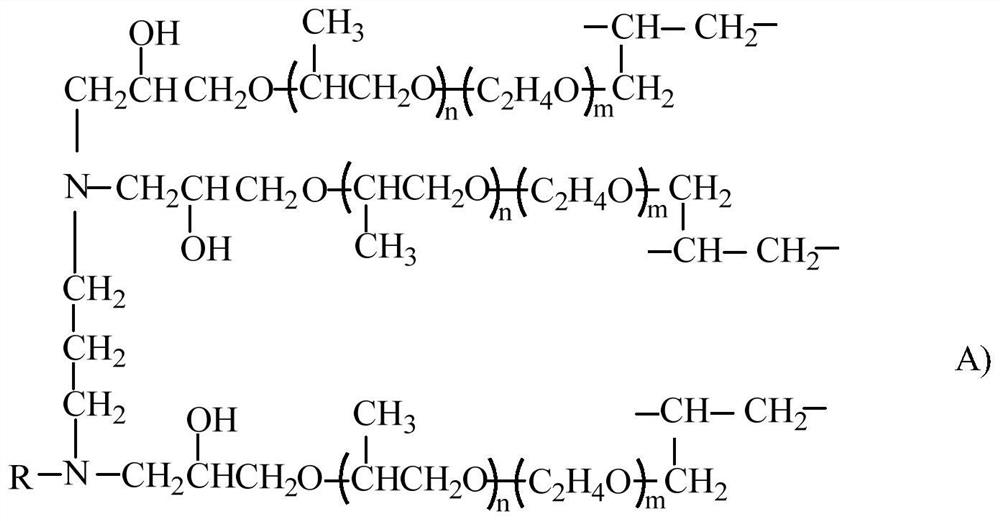

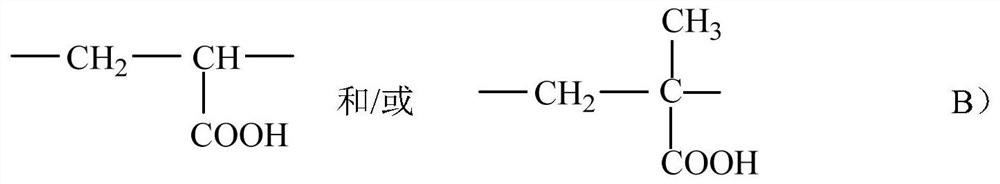

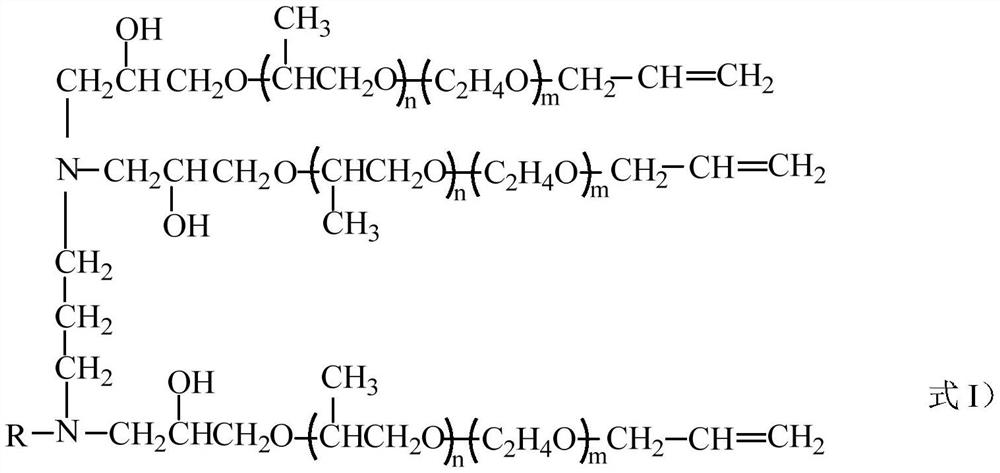

[0028] In a preferred embodiment, the present invention provides a kind of preparation method that does not need the active print paste modifier of urea in application, it comprises the steps:

[0029] Mix 1 mole of R-1,3-propylenediamine and an appropriate amount of solvent such as isopropanol, then add an appropriate amount of deionized water, raise the temperature to 80-90°C, and add 3 moles of allyl polyoxyethylene dropwise Polyoxypropylene epoxy ether (M=500-2000, preferably 1000-1500), after 2-3h dripping, then the temperature is raised to 85-95°C to continue the reaction for 2-4h, and at the same time, a quantitative concentration of 20% over Ammonium sulfate solution and 30-150 moles of (meth)acrylic acid, the reaction temperature is 85-90 ° C, 2-4 hours to drop, and keep warm at 85-95 ° C for 1 hour, cool to 40-50 ° C, add a certain amount of alkali metal Hydroxide, such as sodium hydroxide, to obtain a modifier solution. Finally, the modifier solution is subjected to...

Embodiment 1

[0061] The formula that present embodiment adopts comprises following raw material:

[0062]

[0063] Another aspect of the present invention provides a kind of preparation method of the active printing paste that does not need urea in above-mentioned application, it comprises:

[0064] (1) Preparation of Modifier 1

[0065] Mix 1.62g (0.005mol) of N-oleyl-1,3-propylenediamine and 5g of isopropanol, then add 45.38g of deionized water, raise the temperature to 80°C, add dropwise 22.5g (0.015mol ) of allyl polyoxyethylene polyoxypropylene epoxy ether (M=1500), 2h dripping, then the temperature was raised to 85°C to continue the reaction for 2h, and the concentration of 2.5g was added dropwise at the same time as 20% ammonium persulfate solution and 15g (0.2mol) of acrylic acid, the reaction temperature is 90°C, drop it for 3h, keep it warm at 90°C for 1h, cool down to 45°C, add 8g (0.2mol) of sodium hydroxide to obtain a modifier solution, and finally modify the The agent s...

Embodiment 2

[0069] The formula that present embodiment adopts comprises following raw material:

[0070]

[0071] In the application of the present embodiment, the active printing paste without urea is prepared according to the following steps:

[0072] 1) Preparation of Modifier 2

[0073] Mix 0.84g (0.0025mol) of N-stearyl-1,3-propylenediamine and 5g of isopropanol, then add 56.16g of deionized water, raise the temperature to 85°C, add dropwise 7.5g (0.0075 mol) of allyl polyoxyethylene polyoxypropylene epoxy ether (M=1000), 3h dropwise, then continue to react for 2h at 85°C, while adding dropwise the concentration of 2.5g is 20% ammonium persulfate solution and 20g (0.28mol) of acrylic acid, the reaction temperature is 90°C, drop it in 3h, keep it warm at 90°C for 1h, cool down to 50°C, add 8g (0.2mol) of sodium hydroxide to obtain a modifier solution, and finally The modifier solution was subjected to vacuum distillation, vacuum drying, and grinding to obtain modifier 2 with a pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com