Core-sheath composite cross-section fiber with excellent hygroscopicity and wrinkle resistance

A composite section and fiber technology, applied in fiber treatment, conjugated synthetic polymer rayon, textile, etc., can solve the problems of poor wearing comfort, sticky feeling, insufficient moisture absorption and release performance, etc., and achieve excellent moisture absorption performance , Excellent wrinkle resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

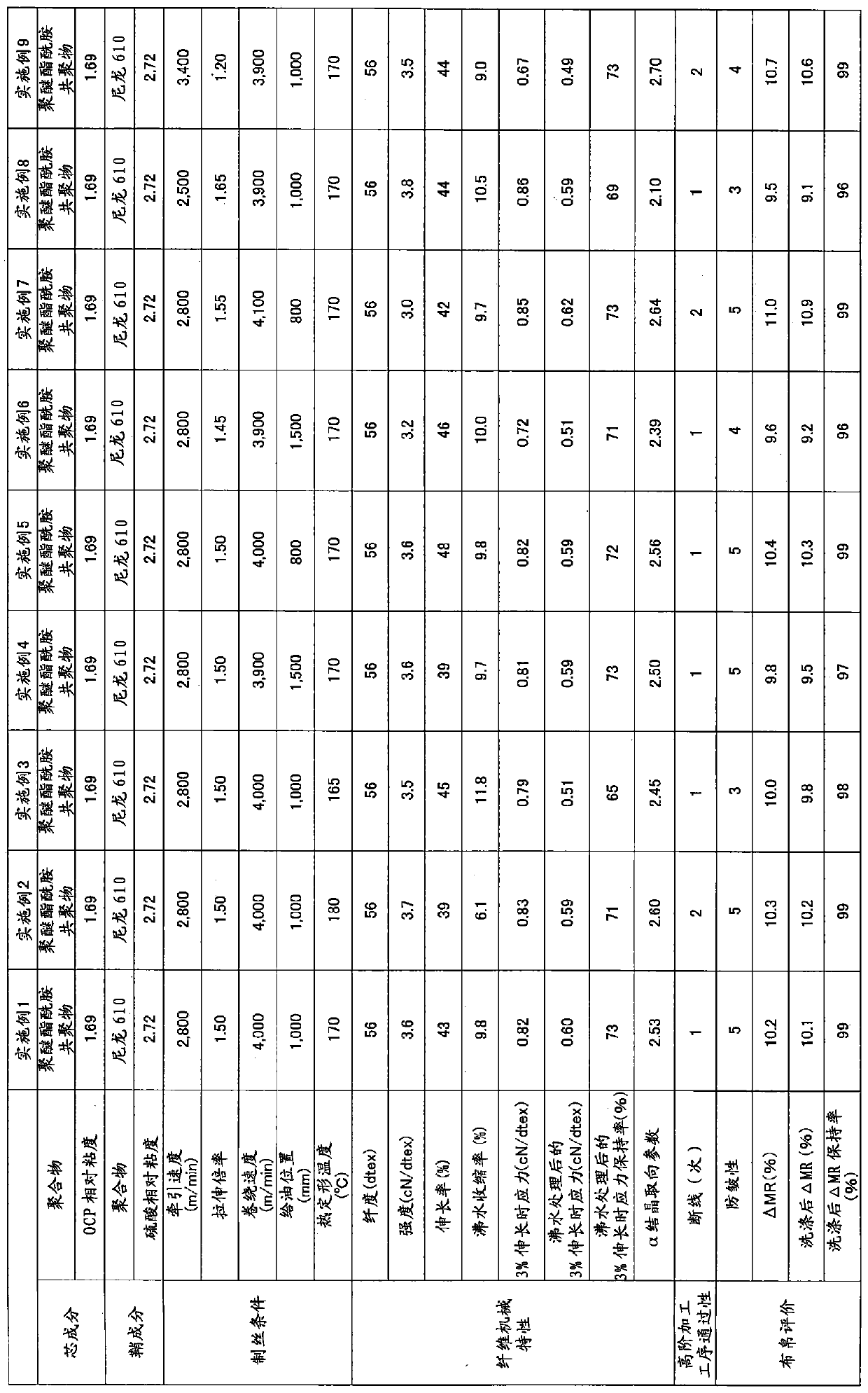

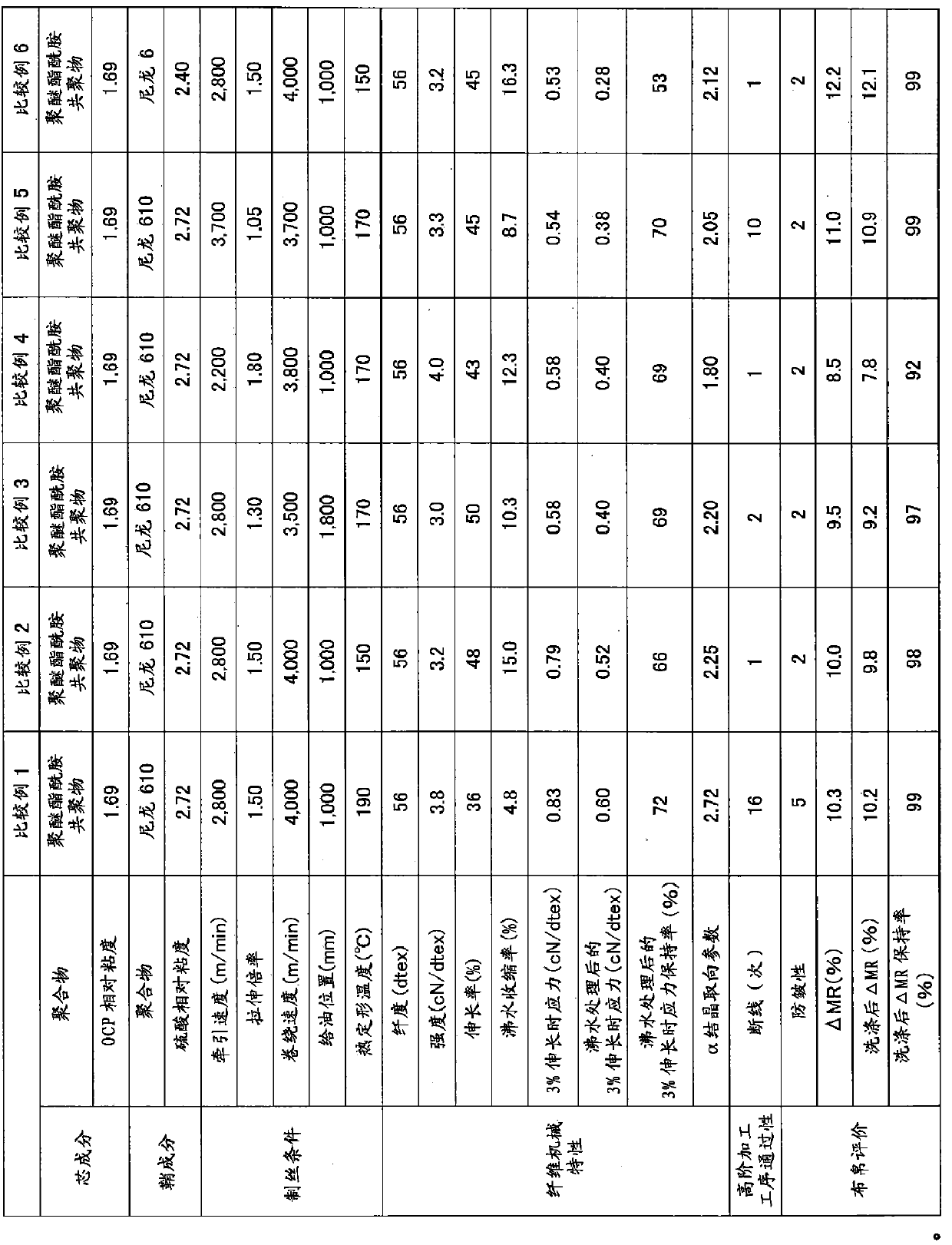

Embodiment 1

[0112] Using a polyether ester amide copolymer with a relative viscosity of o-chlorophenol of 1.69 (manufactured by Alkema, MH1657 (crumb ΔMR: 18.9)) as the core, and nylon 610 with a relative viscosity of sulfuric acid of 2.72 as the sheath, respectively, at 270°C Melted and spun from a die for concentric core-sheath compounding so that the core / sheath ratio (parts by weight) = 50 / 50.

[0113]At this time, the rotational speed of the gear pump was selected so that the total fineness of the obtained core-sheath composite yarn became 56 dtex, and each was set at a discharge rate of 22 g / min. Further, the filaments are cooled and solidified by the filament cooling device, and the non-aqueous oil is supplied by the oil supply device to the oil supply position 1000 mm away from the lower surface of the die, and then the interweaving is carried out with the first fluid interweaving nozzle device, so that as the first The peripheral speed of the traction roll of 1 roll is 2800m / min,...

Embodiment 2

[0116] A core-sheath composite cross-section fiber of 56 dtex / 24F was obtained by the same method as in Example 1 except that the heat setting temperature of the heating roll was 180°C.

[0117] With regard to the obtained core-sheath composite cross-section fibers, fineness, strength, elongation, stress per unit fineness at 3% elongation, boiling water shrinkage, stress retention at 3% elongation before and after boiling water treatment, and α-crystallinity Orientation parameters were determined. In addition, the obtained fabrics were evaluated for wrinkle resistance, ΔMR, ΔMR after washing, and ΔMR retention after washing. These results are shown in Table 1.

Embodiment 3

[0119] A core-sheath composite cross-section fiber of 56 dtex / 24F was obtained by the same method as in Example 1 except that the heat setting temperature of the heating roll was 165°C.

[0120] With regard to the obtained core-sheath composite cross-section fiber filaments, fineness, strength, elongation, stress per unit fineness at 3% elongation, shrinkage in boiling water, retention of stress at 3% elongation before and after boiling water treatment, α Crystallographic orientation parameters were determined. In addition, the obtained fabrics were evaluated for wrinkle resistance, ΔMR, ΔMR after washing, and ΔMR retention after washing. These results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com