Special quick-drying fabric for clothing and processing technology thereof

A processing technology and fabric technology, applied in the field of clothing, can solve the problems of fabric moisture absorption, poor moisture conduction effect, easy breeding of bacteria, complex processing technology, etc., to achieve excellent antibacterial performance, excellent moisture absorption and dehumidification effect, and excellent quick-drying performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

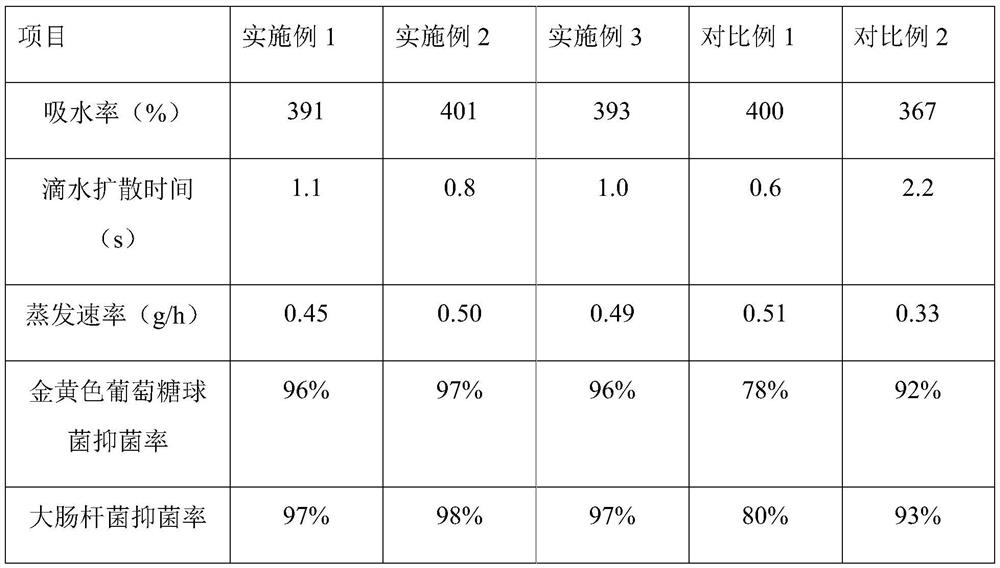

Examples

Embodiment 1

[0054] A processing technology for special quick-drying fabrics for clothing, characterized in that it comprises the following steps:

[0055] (1) Preparation of base cloth:

[0056] Preparation of modified polyurethane fiber: take polyurethane, calcium carbonate and processing aids, mix and stir, melt and extrude after drying, and granulate to obtain material A; take material A and polyurethane slices, mix and stir for 10 minutes, and place them in the spinning screw , melt extrusion, spinning molding, to obtain modified polyurethane fibers; take modified polyurethane fibers and cotton fibers, and weave to obtain base fabrics;

[0057] (2) get the base cloth that step (1) obtains, prepare base cloth;

[0058] Take the hydrophobic finishing agent and deionized water, mix and stir for 10 minutes, then add sodium alginate, and continue stirring for 10 minutes to obtain the printing slurry;

[0059] Take the base fabric obtained in step (1), wash it with hydrochloric acid, plac...

Embodiment 2

[0068] A processing technology for special quick-drying fabrics for clothing, characterized in that it comprises the following steps:

[0069] (1) Preparation of base cloth:

[0070] Preparation of modified polyurethane fiber: Take polyurethane, calcium carbonate and processing aids, mix and stir, melt and extrude after drying, and granulate to obtain material A; take material A and polyurethane slices, mix and stir for 15 minutes, and place them in the spinning screw , melt extrusion, spinning molding, to obtain modified polyurethane fibers; take modified polyurethane fibers and cotton fibers, and weave to obtain base fabrics;

[0071] (2) get the base cloth that step (1) obtains, prepare base cloth;

[0072] Take the hydrophobic finishing agent and deionized water, mix and stir for 12 minutes, then add sodium alginate, and continue stirring for 15 minutes to obtain the printing slurry;

[0073] Take the base fabric obtained in step (1), wash it with hydrochloric acid, plac...

Embodiment 3

[0082] A processing technology for special quick-drying fabrics for clothing, characterized in that it comprises the following steps:

[0083] (1) Preparation of base cloth:

[0084] Preparation of modified polyurethane fiber: Take polyurethane, calcium carbonate and processing aids, mix and stir, melt and extrude after drying, and granulate to obtain material A; take material A and polyurethane slices, mix and stir for 20 minutes, and place them in the spinning screw , melt extrusion, spinning molding, to obtain modified polyurethane fibers; take modified polyurethane fibers and cotton fibers, and weave to obtain base fabrics;

[0085] (2) get the base cloth that step (1) obtains, prepare base cloth;

[0086] Take the hydrophobic finishing agent and deionized water, mix and stir for 15 minutes, then add sodium alginate, and continue stirring for 20 minutes to obtain the printing slurry;

[0087] Take the base fabric obtained in step (1), wash it with hydrochloric acid, plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com