Patents

Literature

121results about How to "Enhanced capillary action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

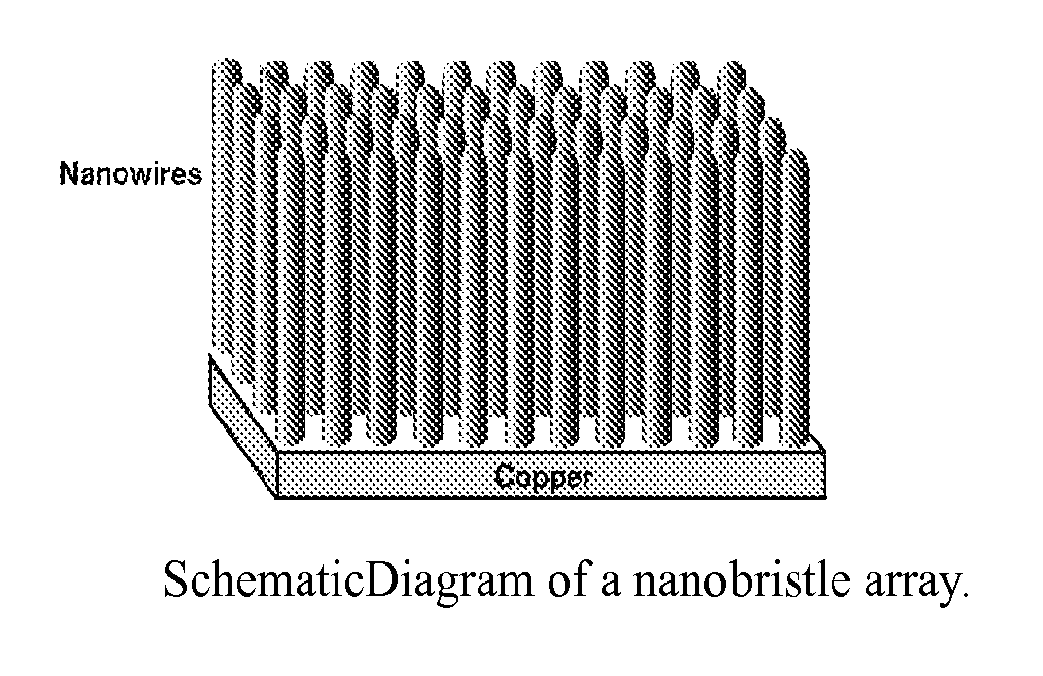

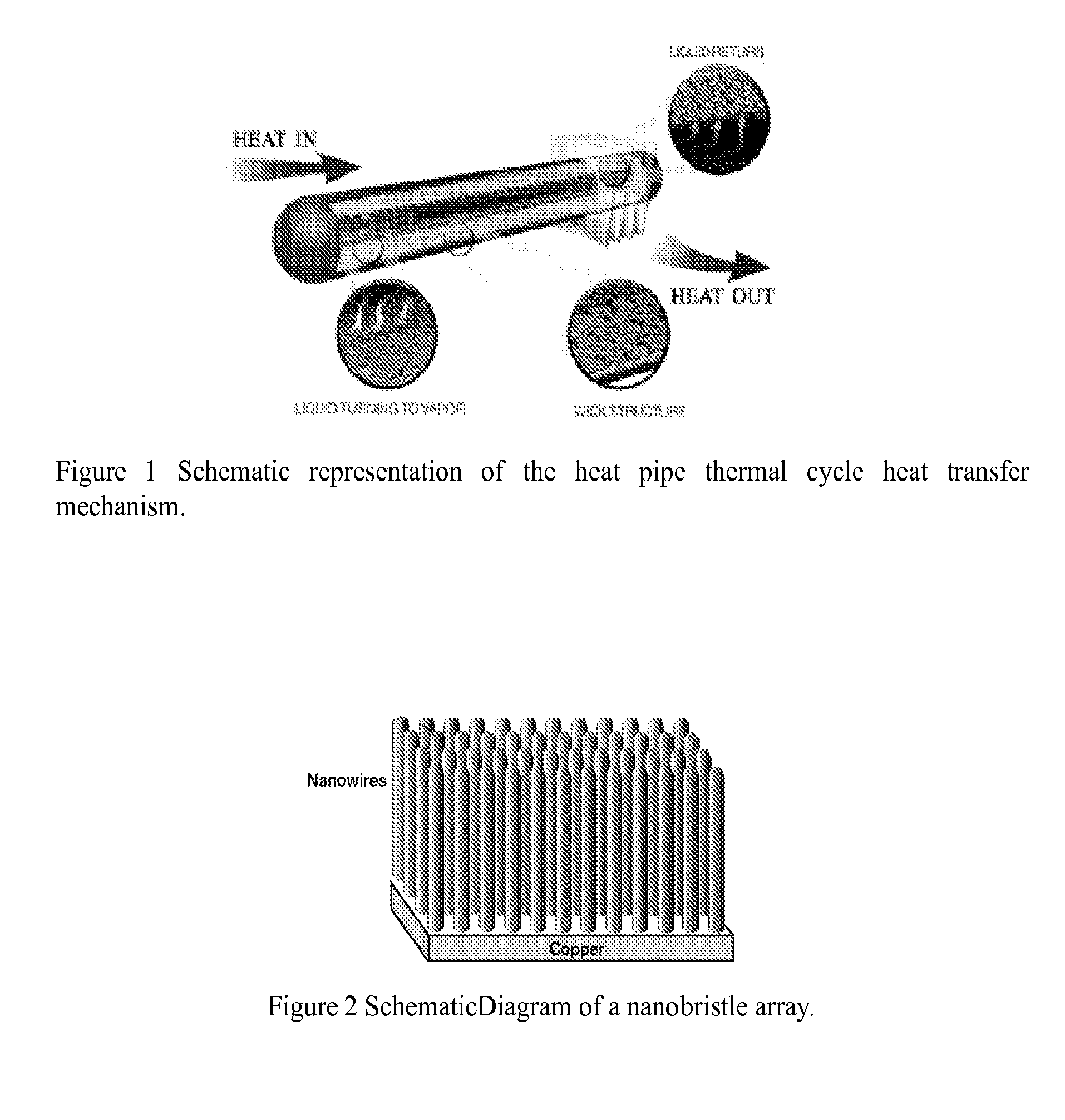

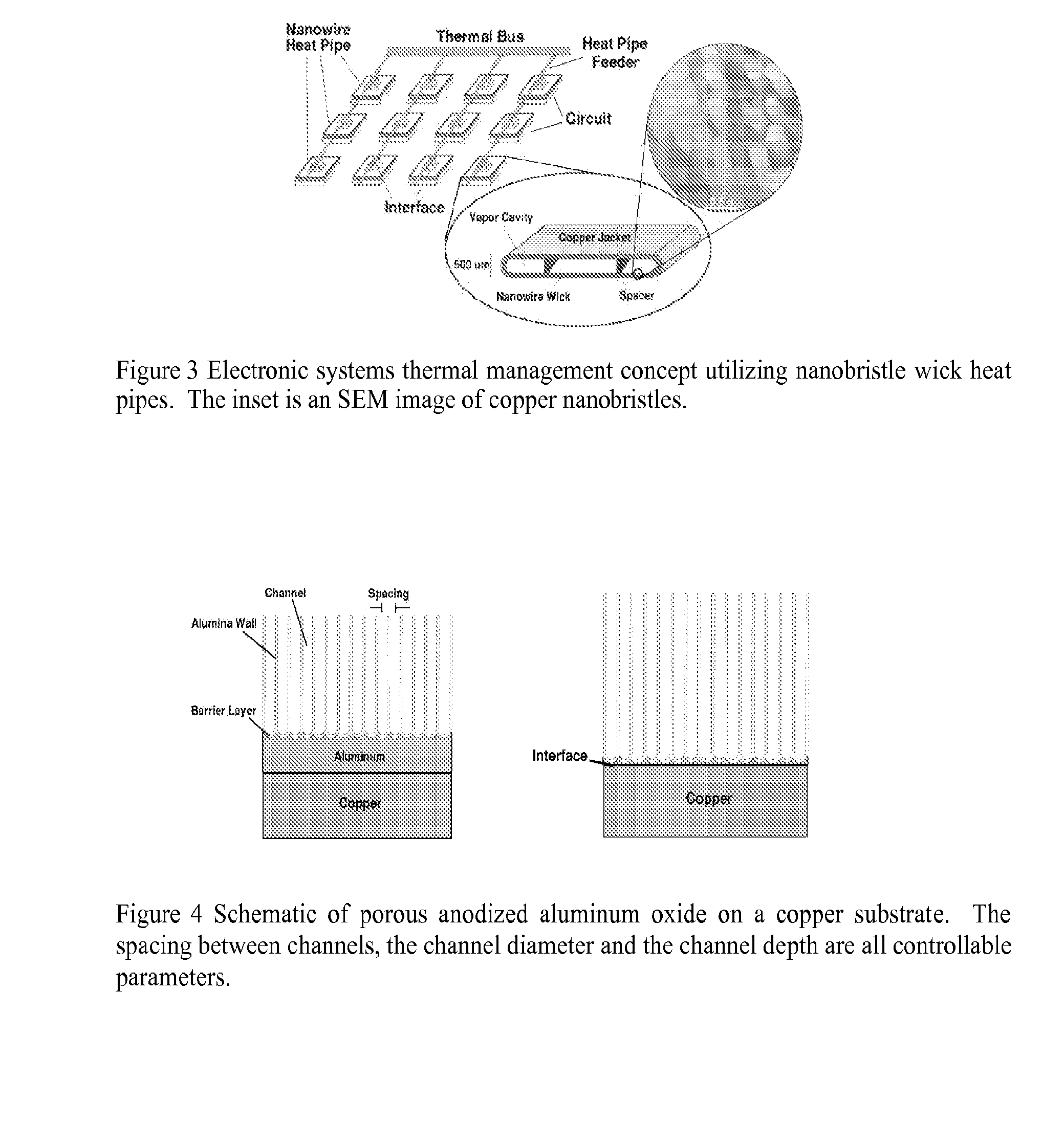

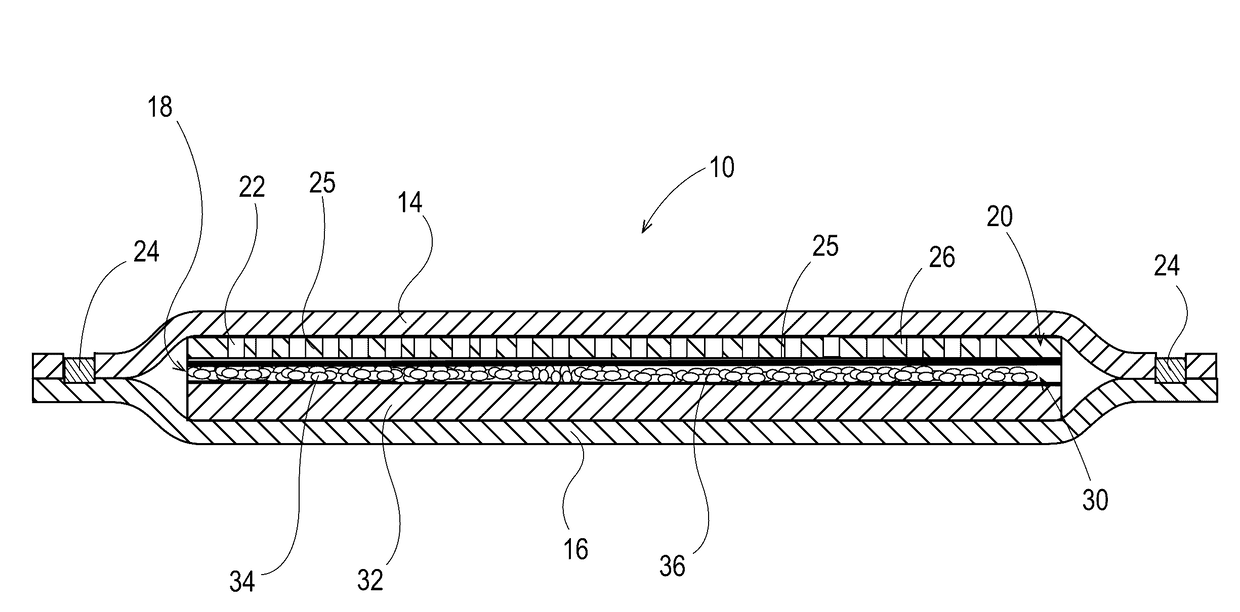

Heat Pipe with Nanostructured Wick

InactiveUS20100200199A1Improve efficiencyPerformance advantageMaterial nanotechnologyAnodisationNanowireBristle

A heat pipe with a nanostructured wick is disclosed, with the method of forming the nanostructured wick on a metal substrate. The wicking material is a pattern of metallic nanostructures in the form of bristles or nanowires attached to a substrate, where the bristles are substantially freestanding.

Owner:ILLUMINEX CORP

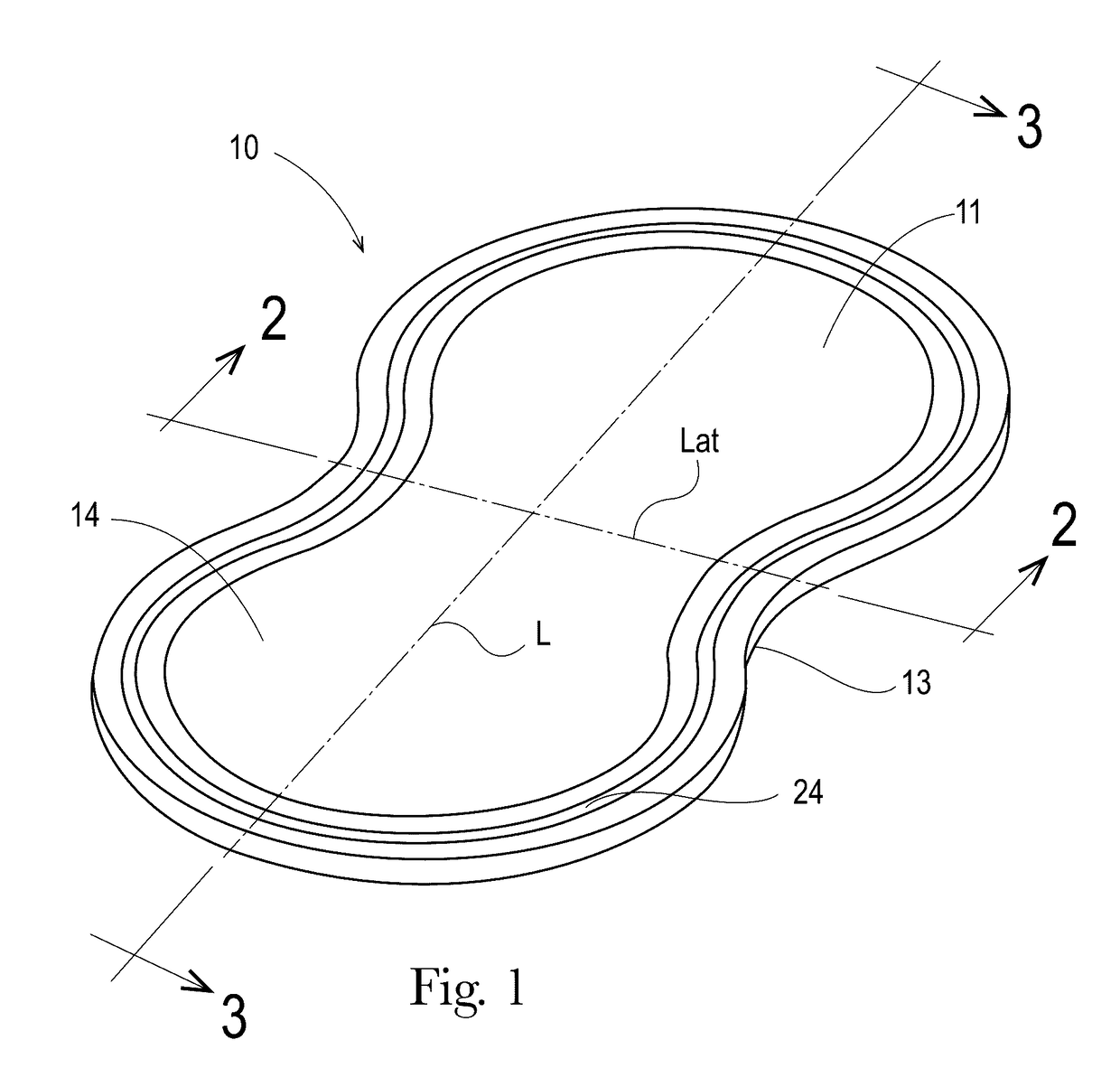

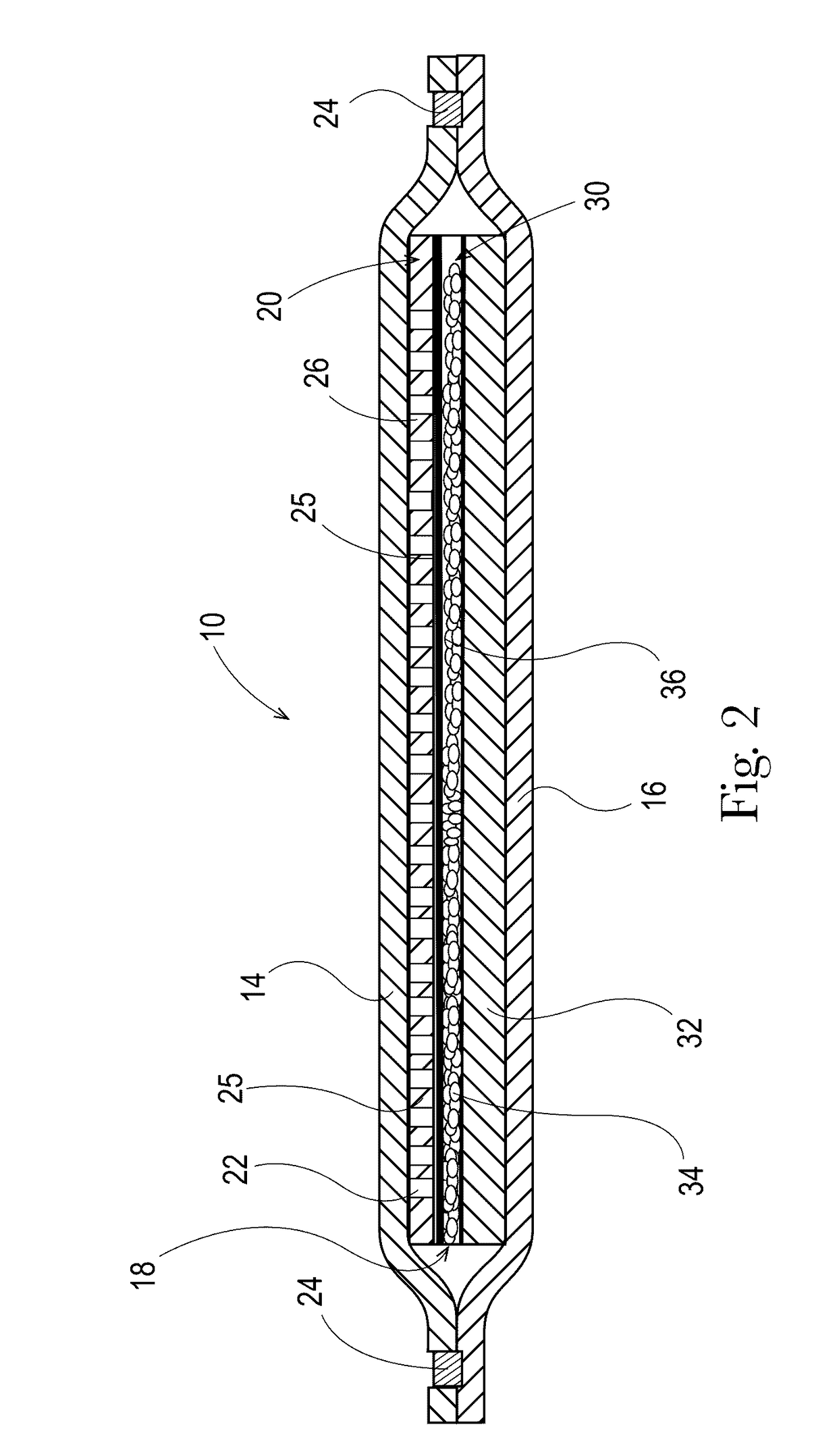

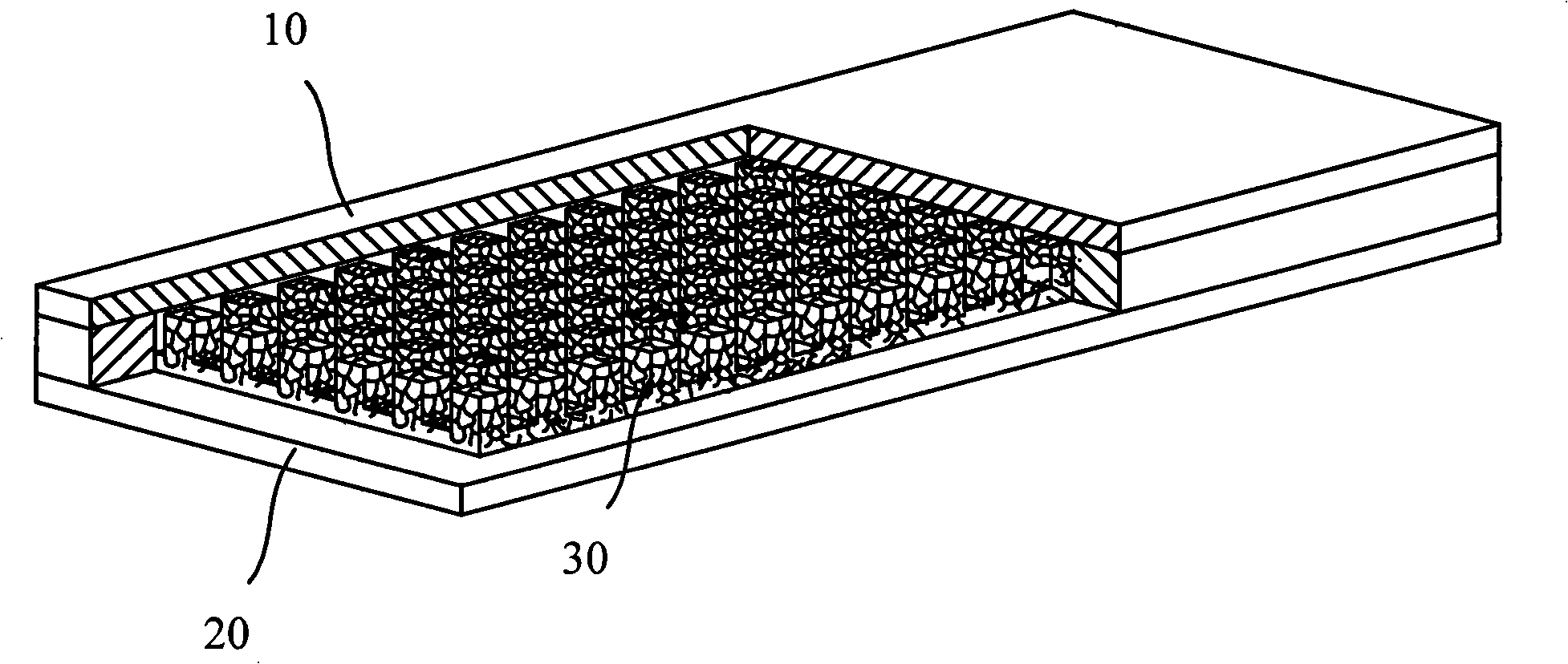

Heterogeneous mass comprising foam absorbent core structure

InactiveUS20170119598A1Enhanced capillary actionImprove permeabilityAbsorbent padsBaby linensEngineeringVertical axis

An absorbent core structure comprising two or more layers wherein the upper layer is a heterogeneous mass layer comprising a longitudinal axis, a lateral axis, a vertical axis, one or more enrobeable elements, and one or more discrete open-cell foam pieces wherein the open-cell foam pieces.

Owner:THE PROCTER & GAMBLE COMPANY

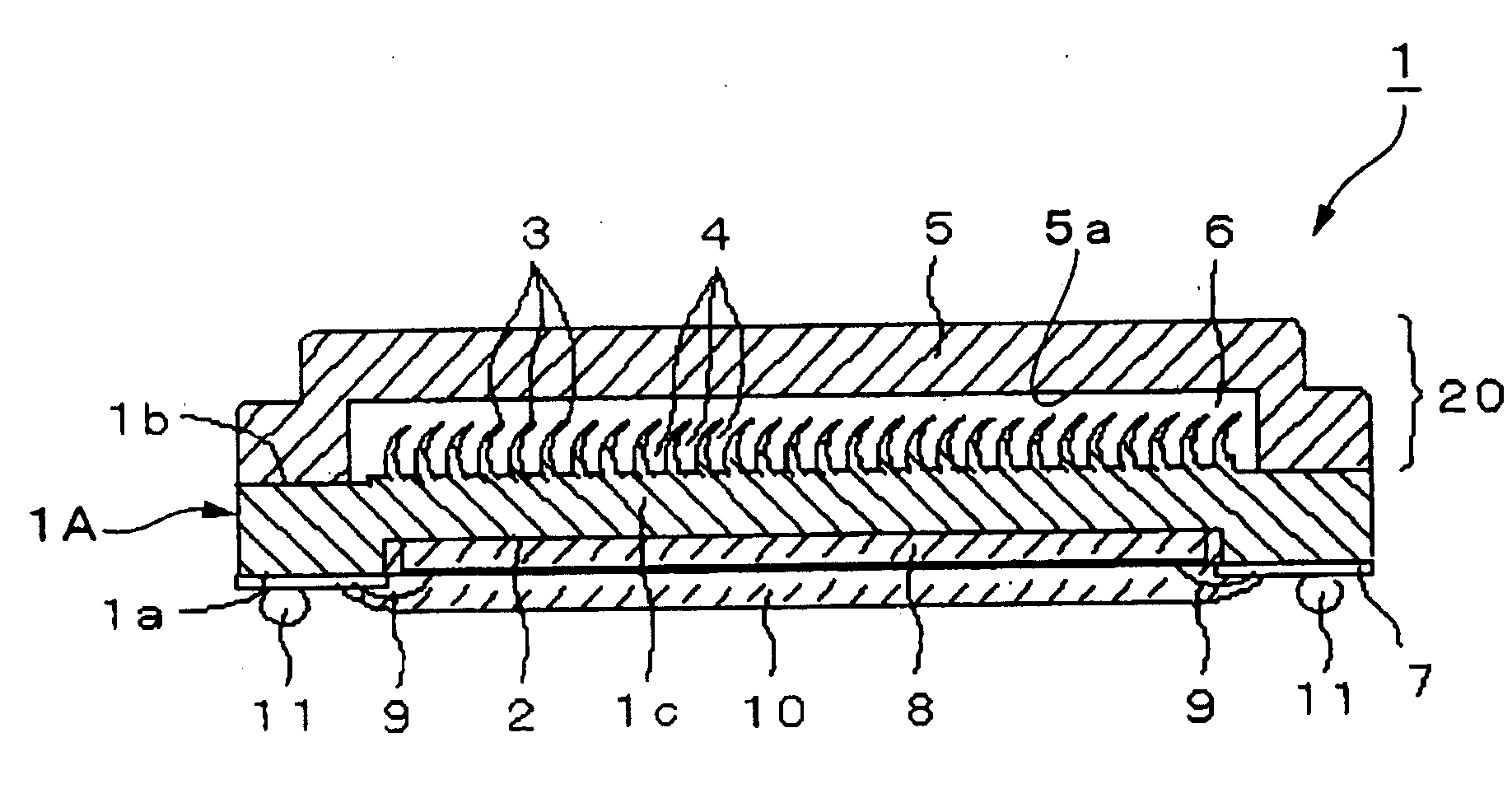

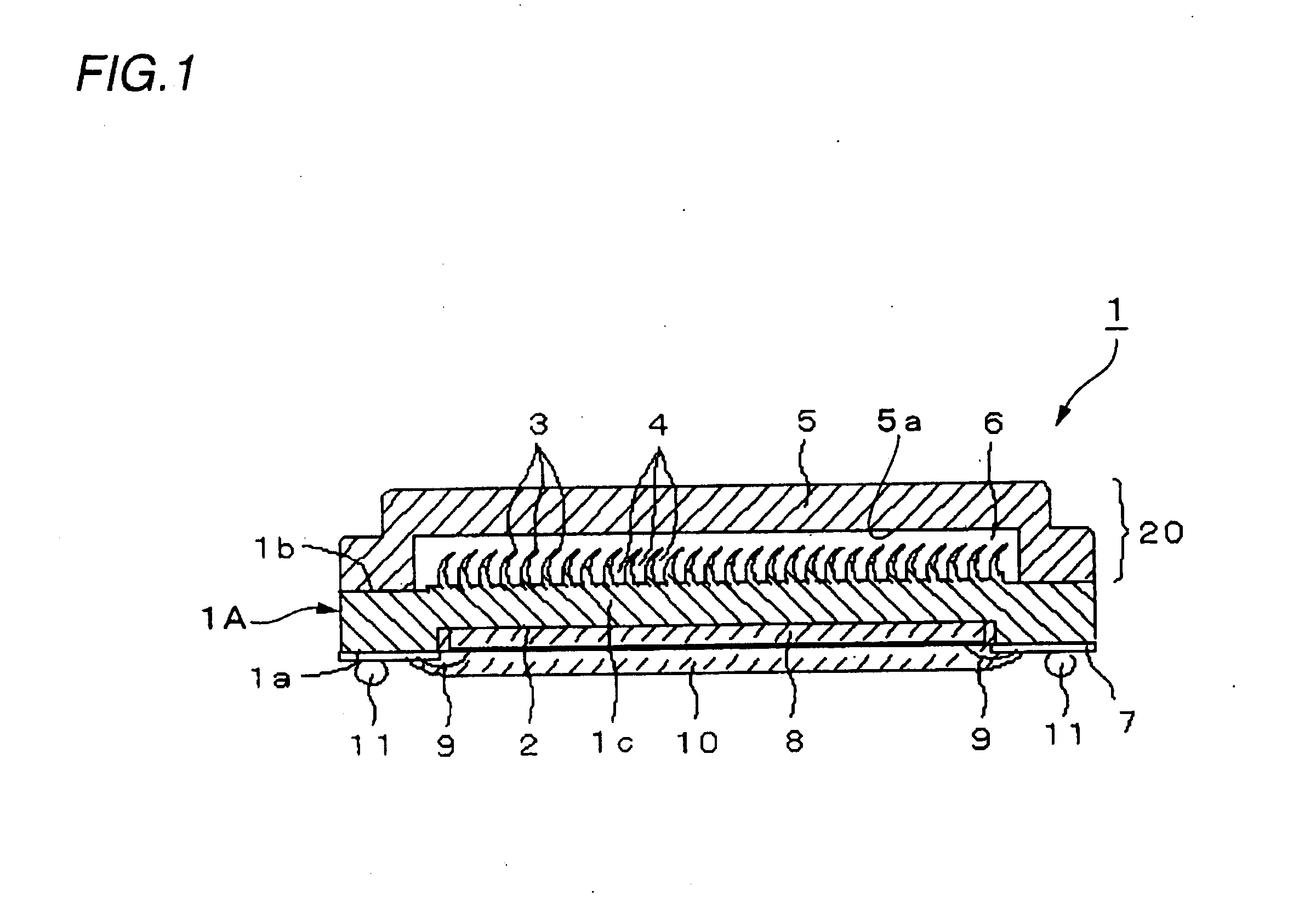

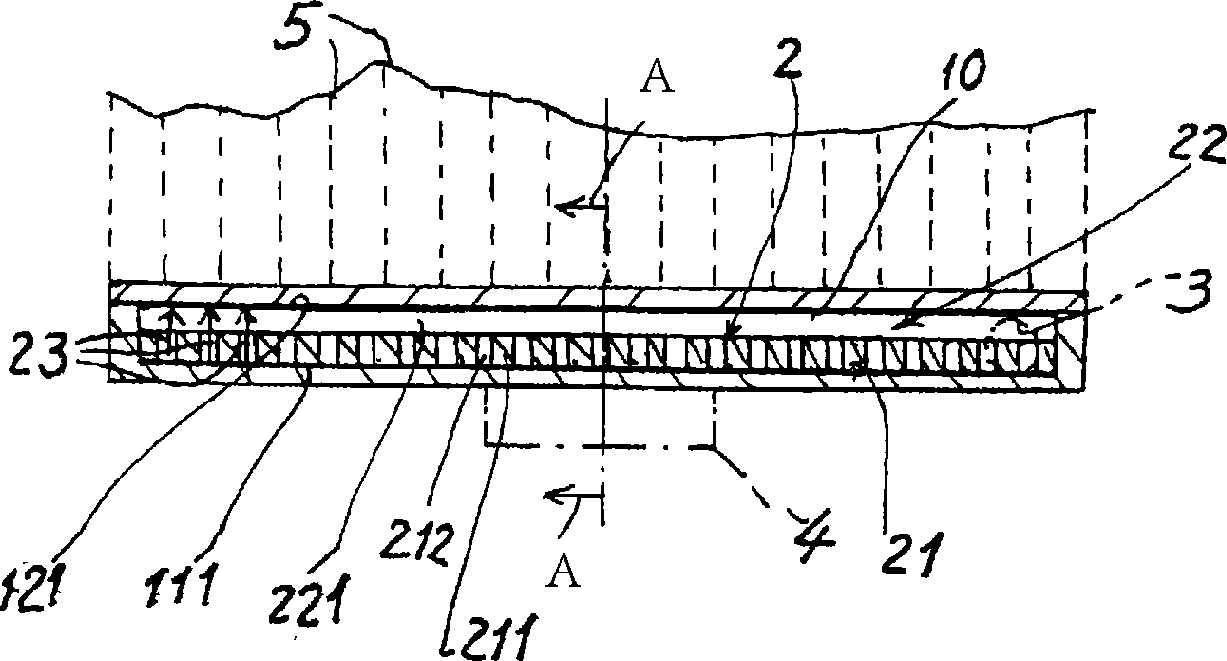

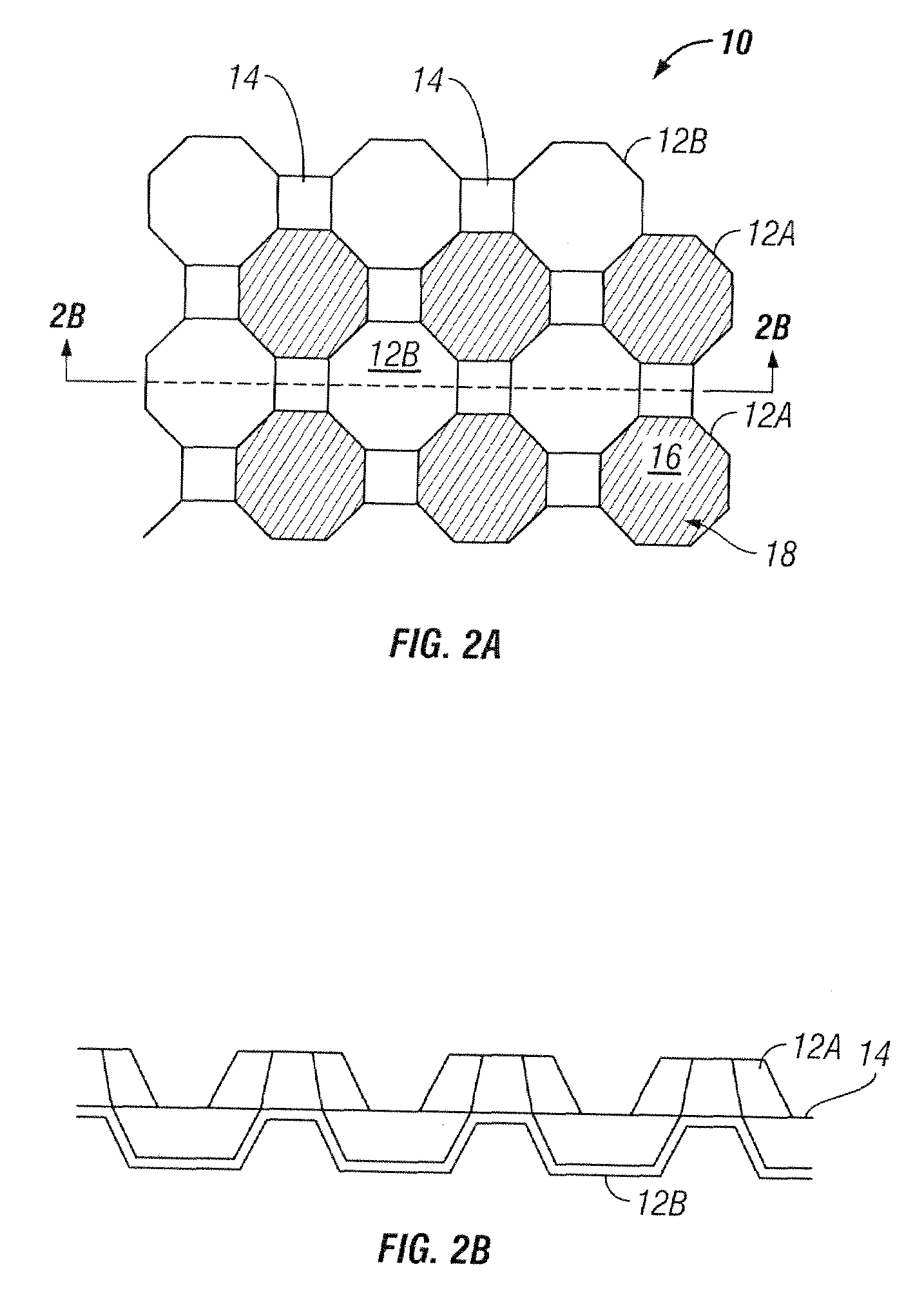

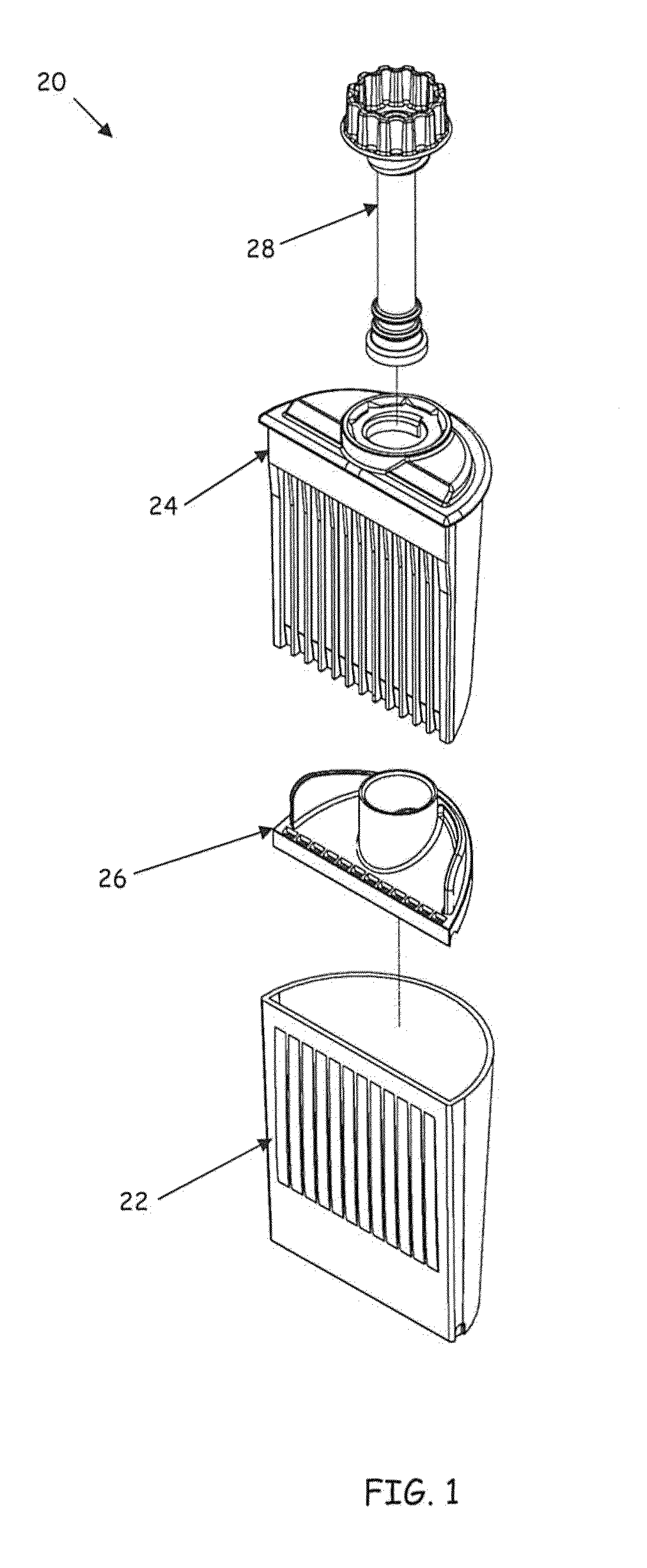

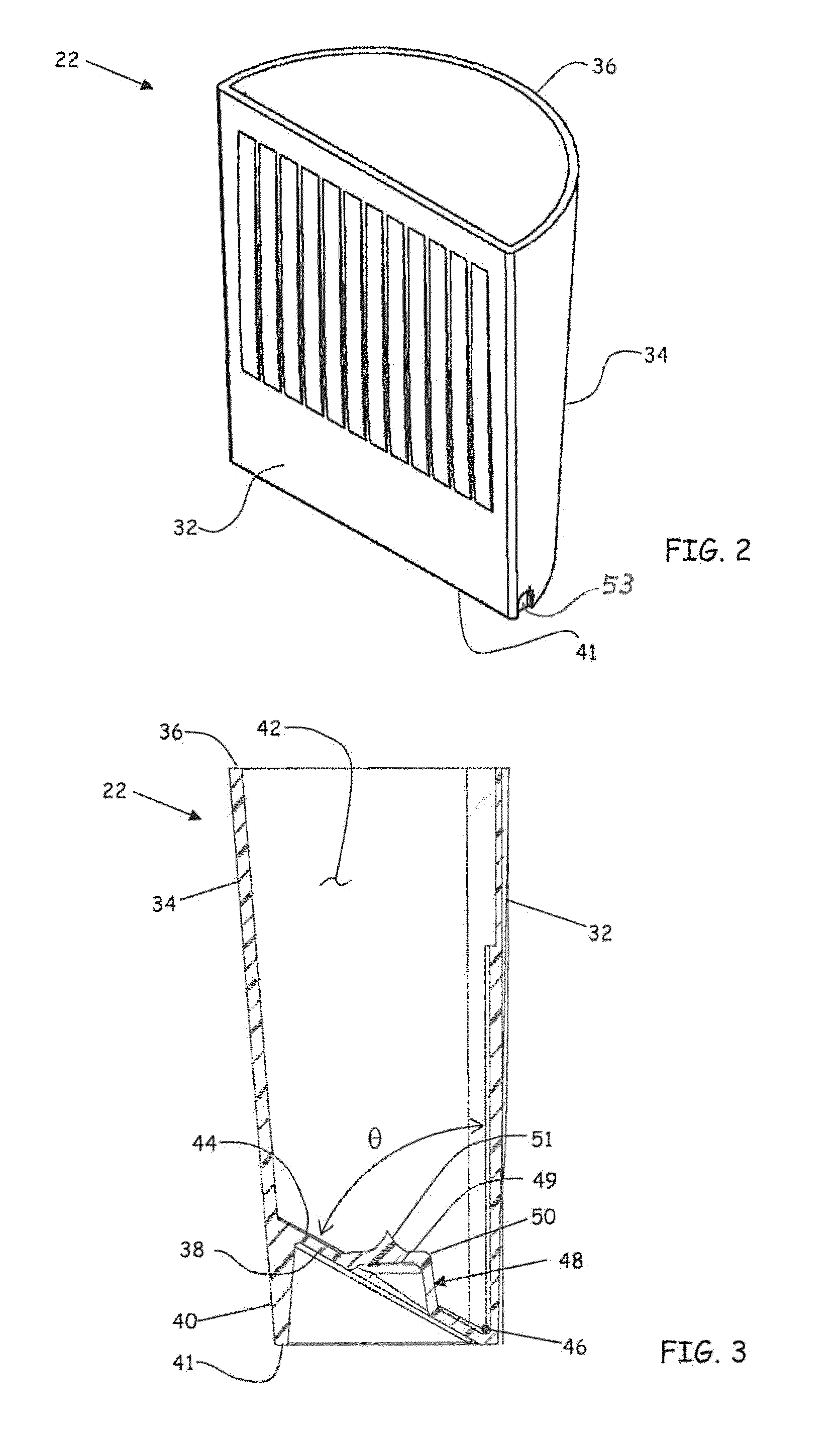

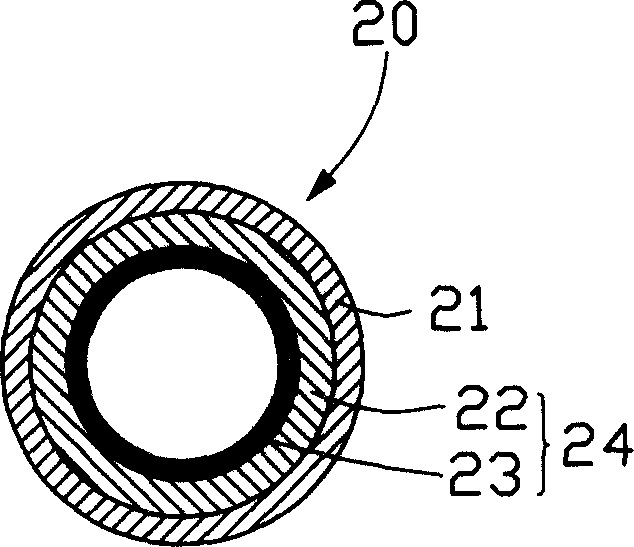

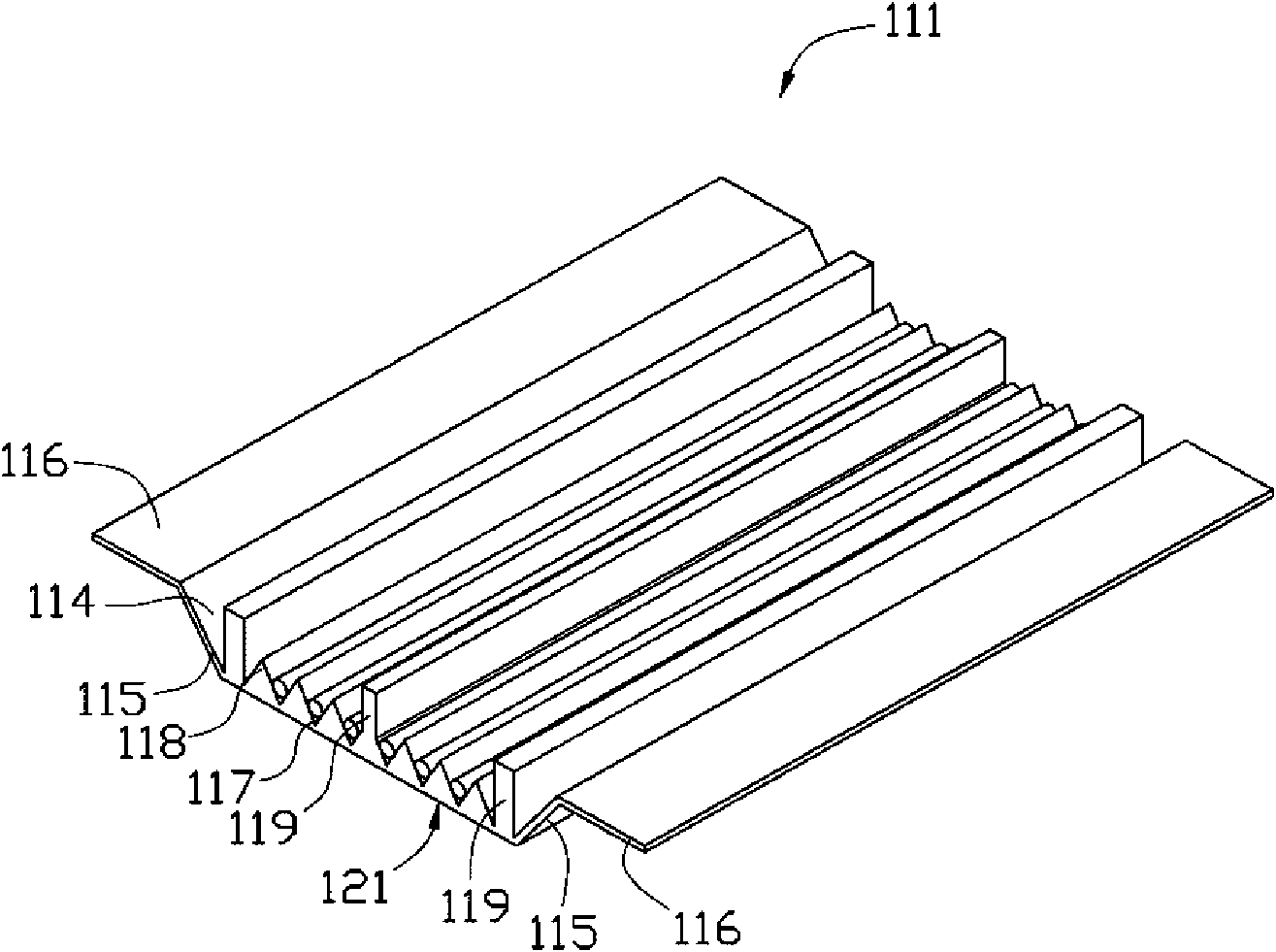

Component package having heat exchanger

InactiveUS20070163749A1Good cooling functionEfficient executionSemiconductor/solid-state device detailsSolid-state devicesWorking fluidCarve out

In an electrical component package (1) provided with a liquid-cooled heat exchanger (20), a main-body plate (1A) of the package and a crowning member (5) that are composed of metal plates are joined together, forming a hollow part (6) therebetween for use as a liquid-cooled heat exchanger in which a working fluid is sealed. A concavity (2) for use in mounting an electrical component (8) to be cooled is formed on the outer surface portion of the main-body plate (1A) of the package disposed opposite to the hollow part (6). An inner surface portion (5a) that faces into the hollow part (6) of the main-body plate (1A) of the package is carved out using a carving tool, whereby fins (3) are formed at a fine pitch on the inner surface portion. Minute channels (4) for moving the working fluid are formed between the fins. A flat electrical component package can [therefore] be provided with a liquid-cooled heat exchanger that has excellent heat-radiating functionality.

Owner:NAKAMURA IND MFG CO LTD

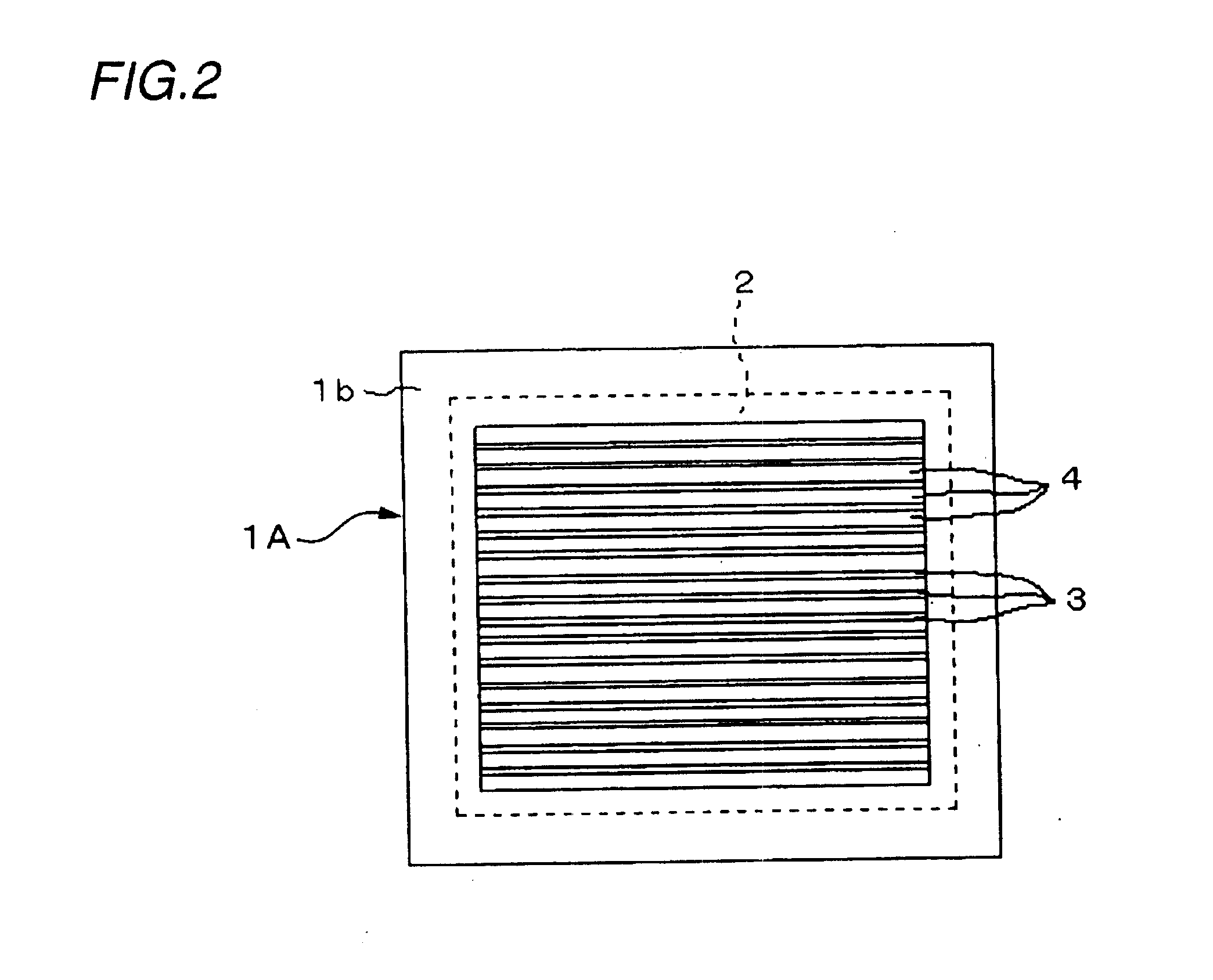

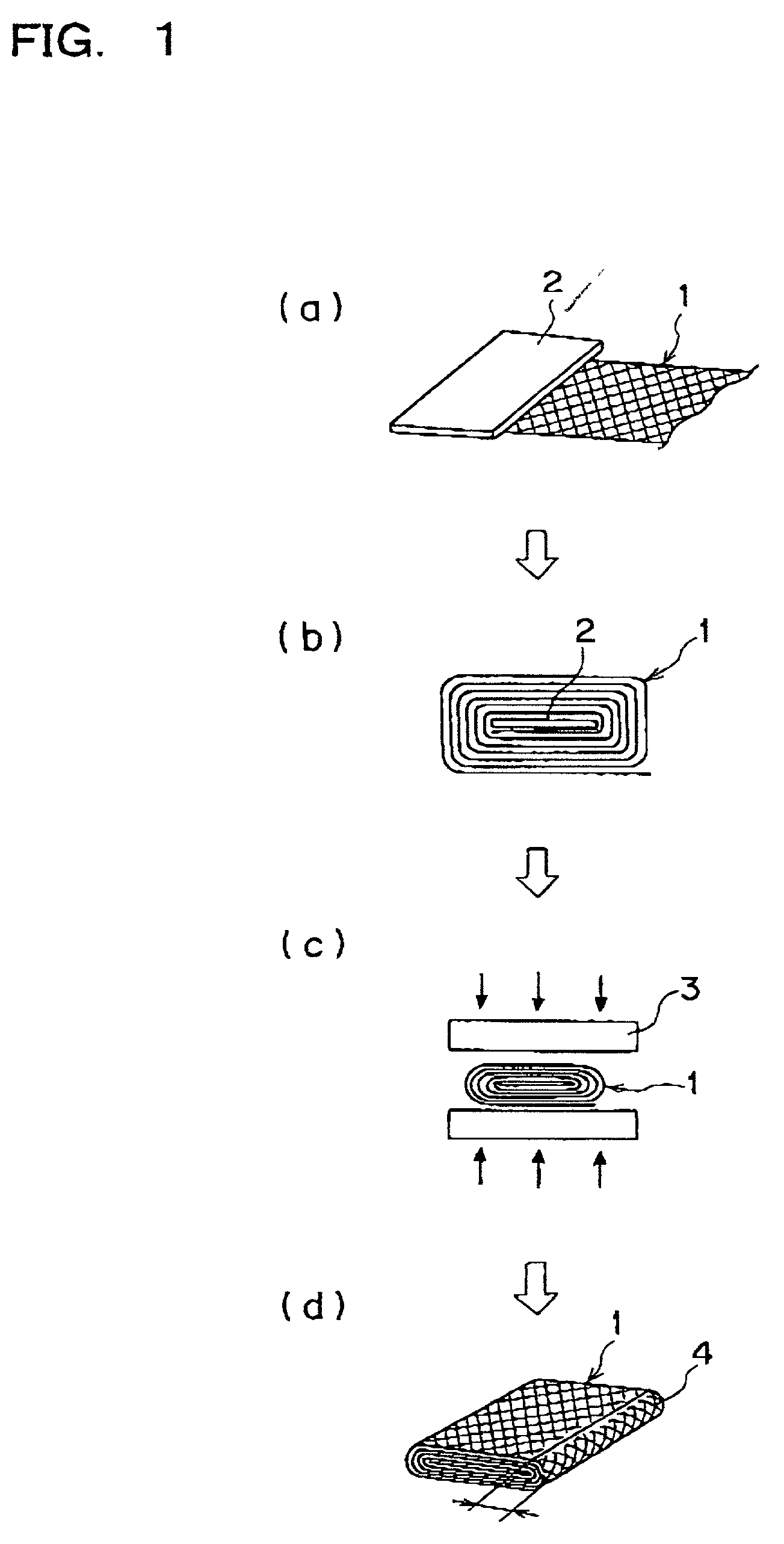

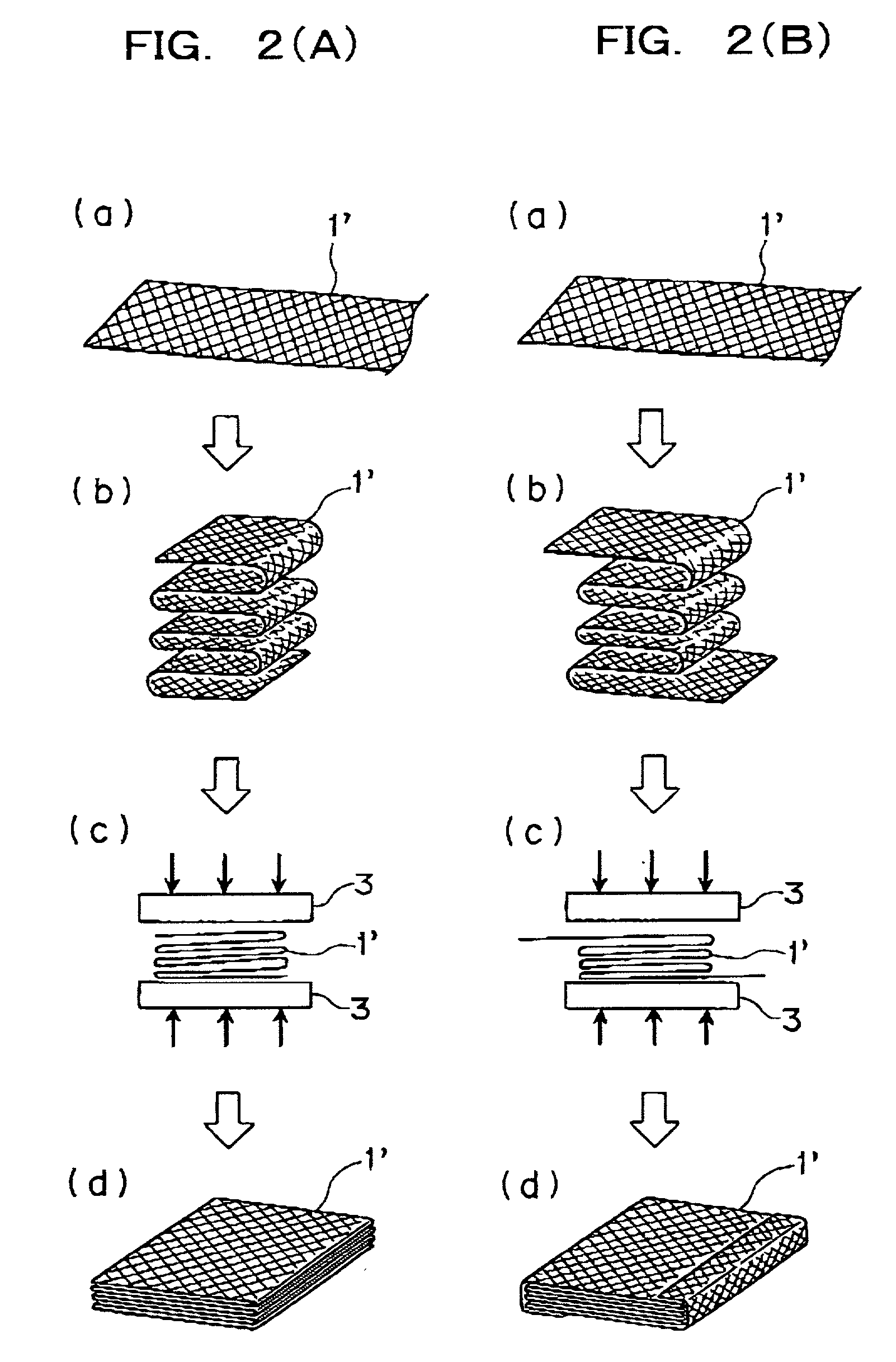

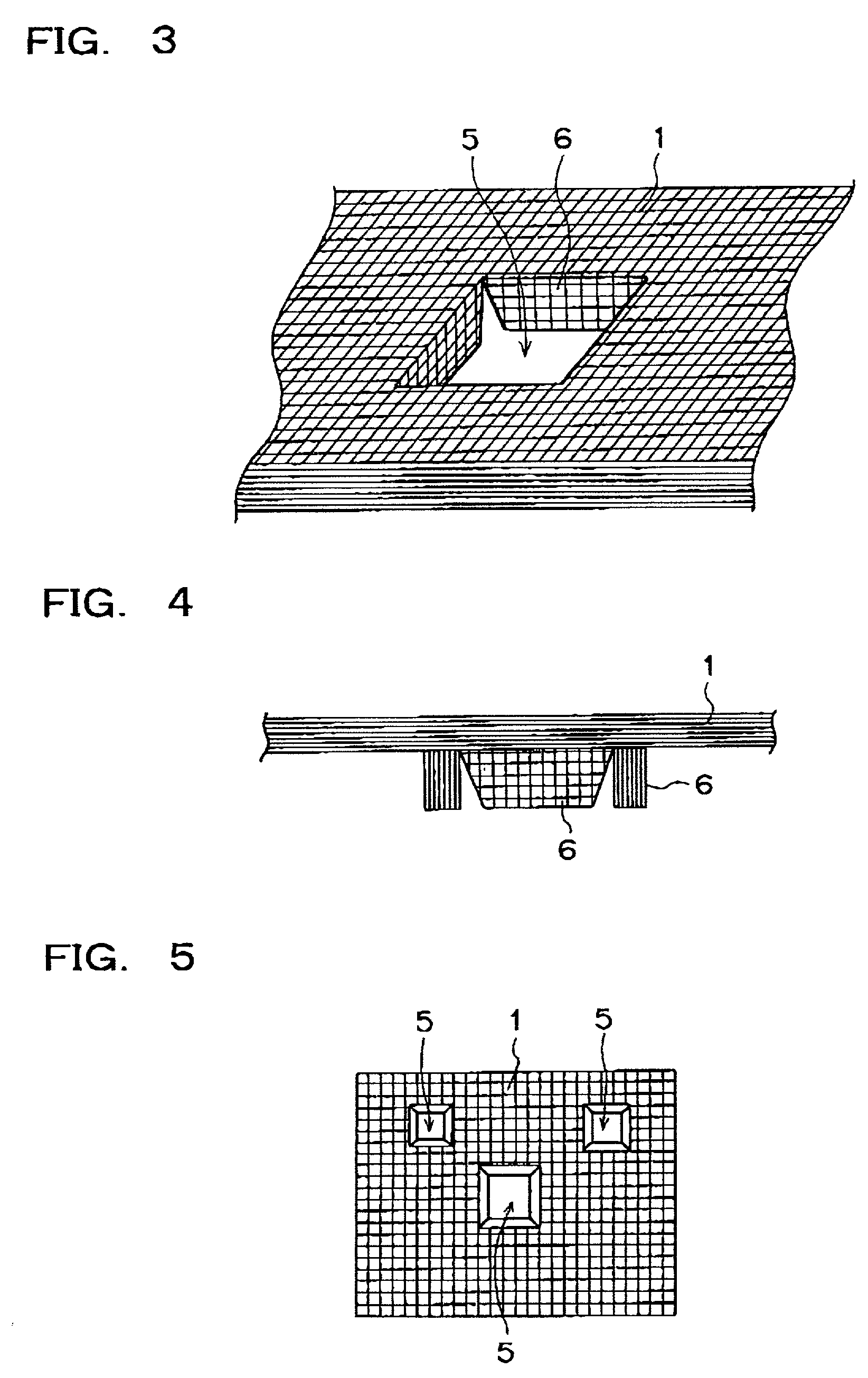

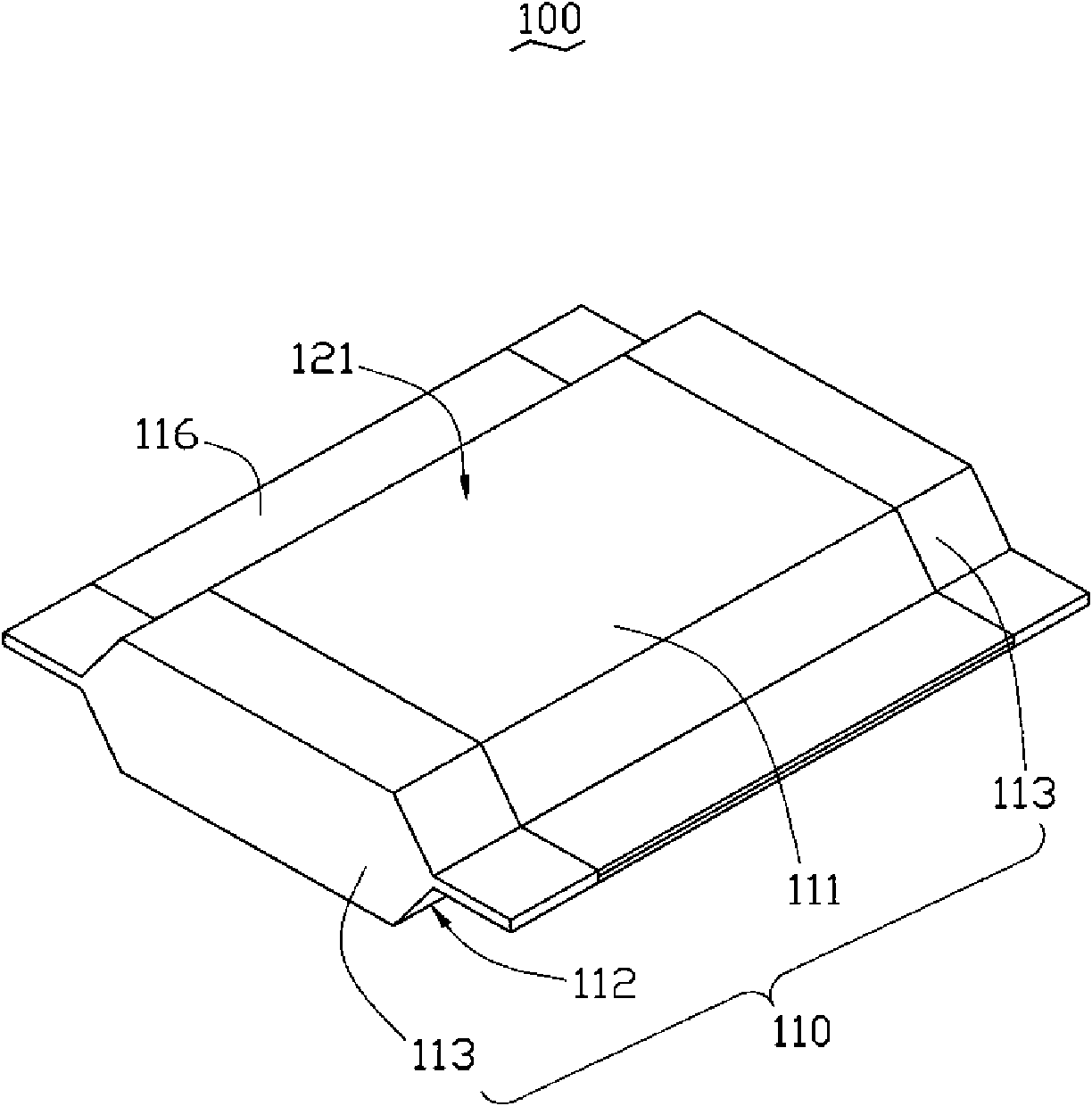

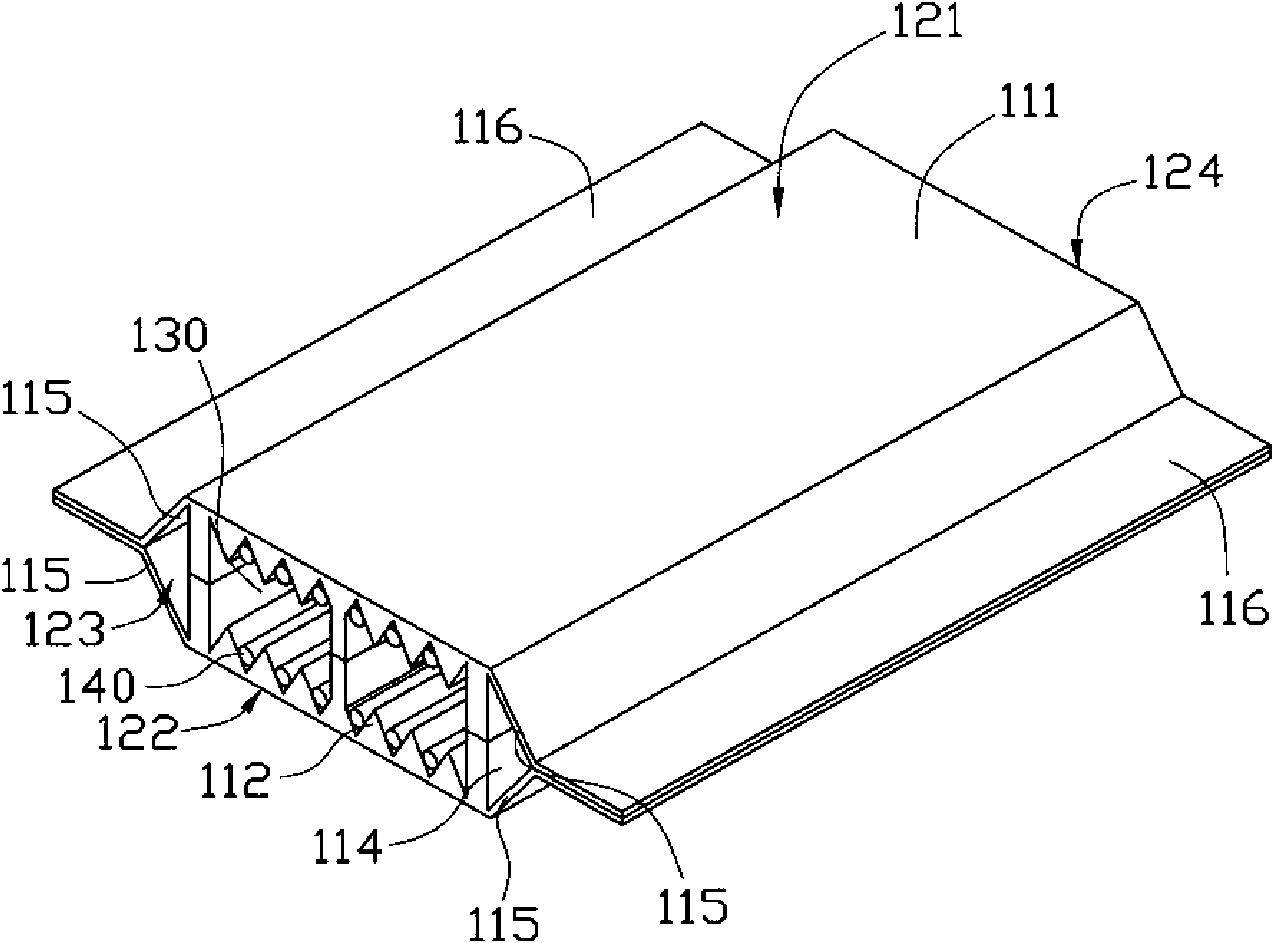

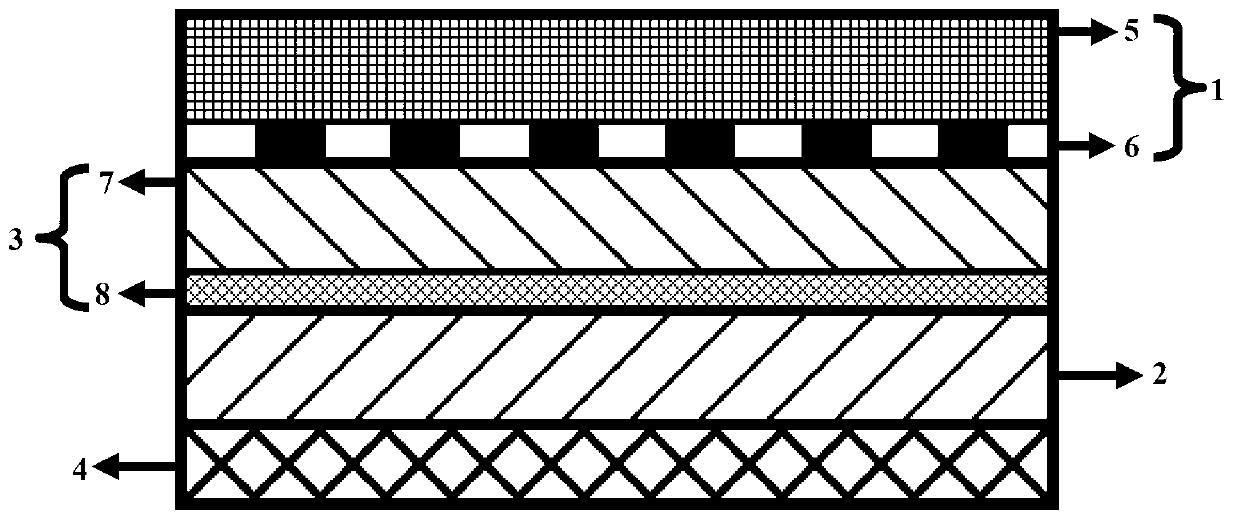

Compressed mesh wick, method for manufacturing same, and plate type heat pipe including compressed mesh wick

InactiveUS20010004934A1Good capillary actionEnhanced capillary actionSemiconductor/solid-state device detailsSolid-state devicesEngineeringBand pattern

Owner:FURUKAWA ELECTRIC CO LTD

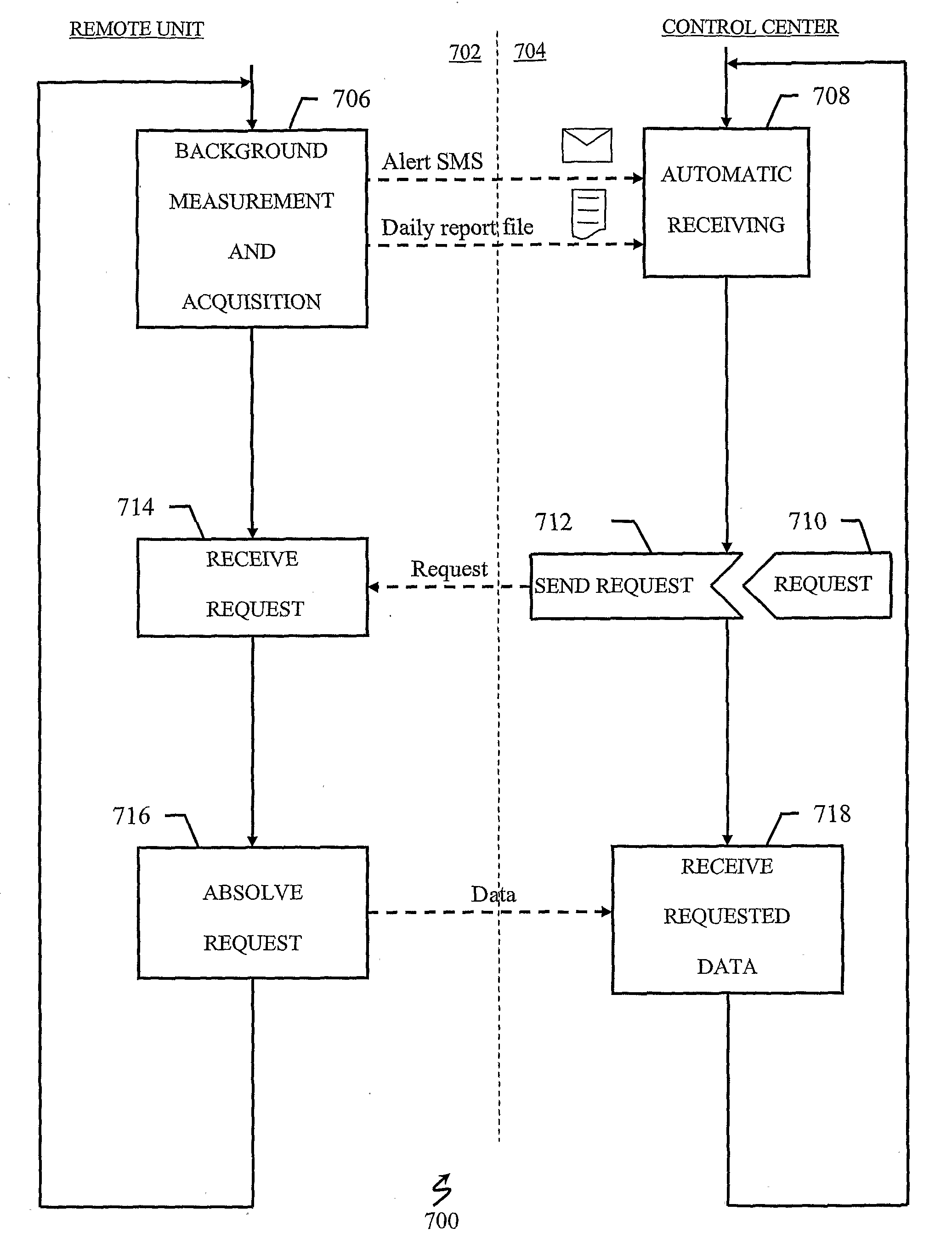

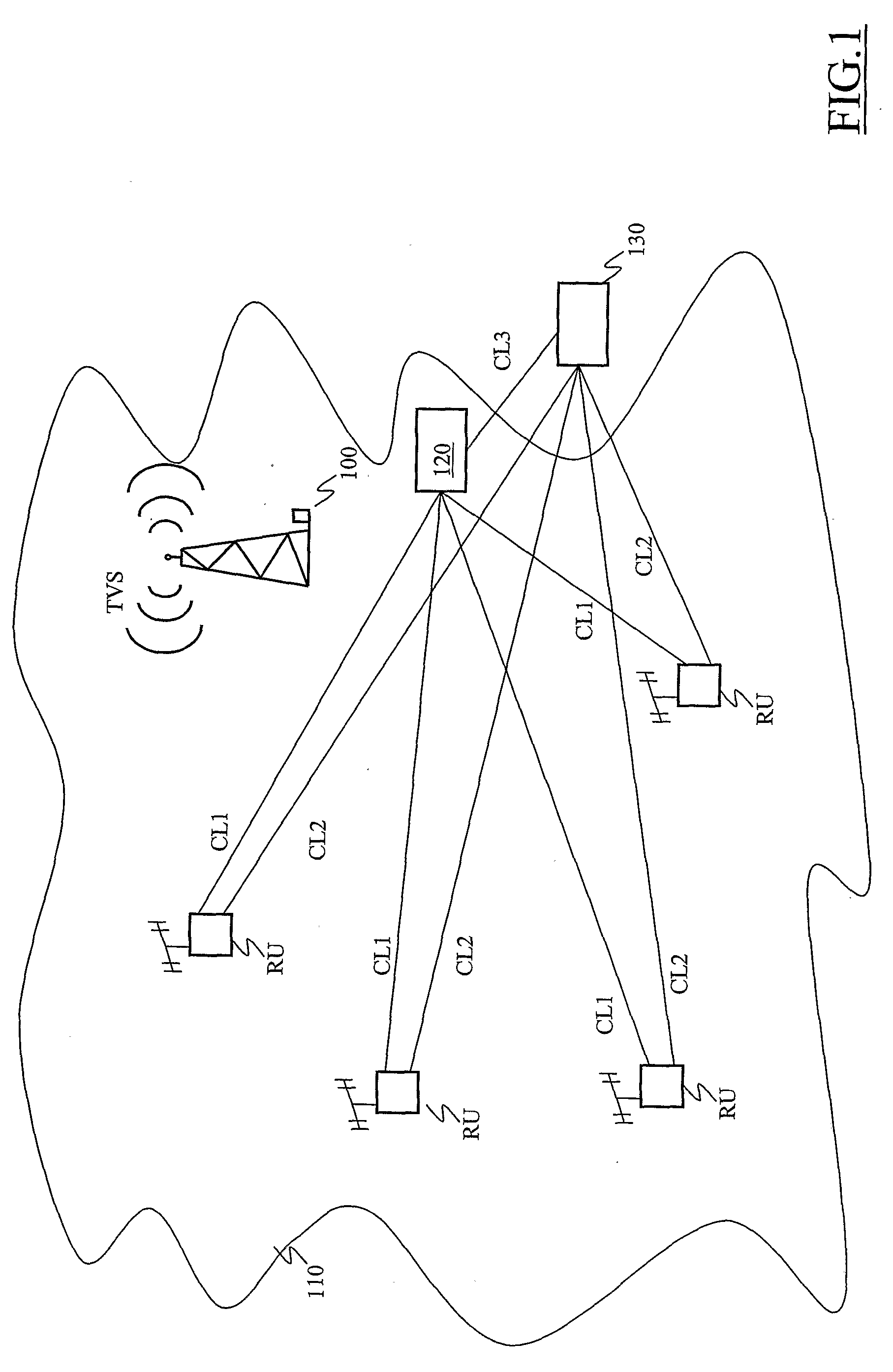

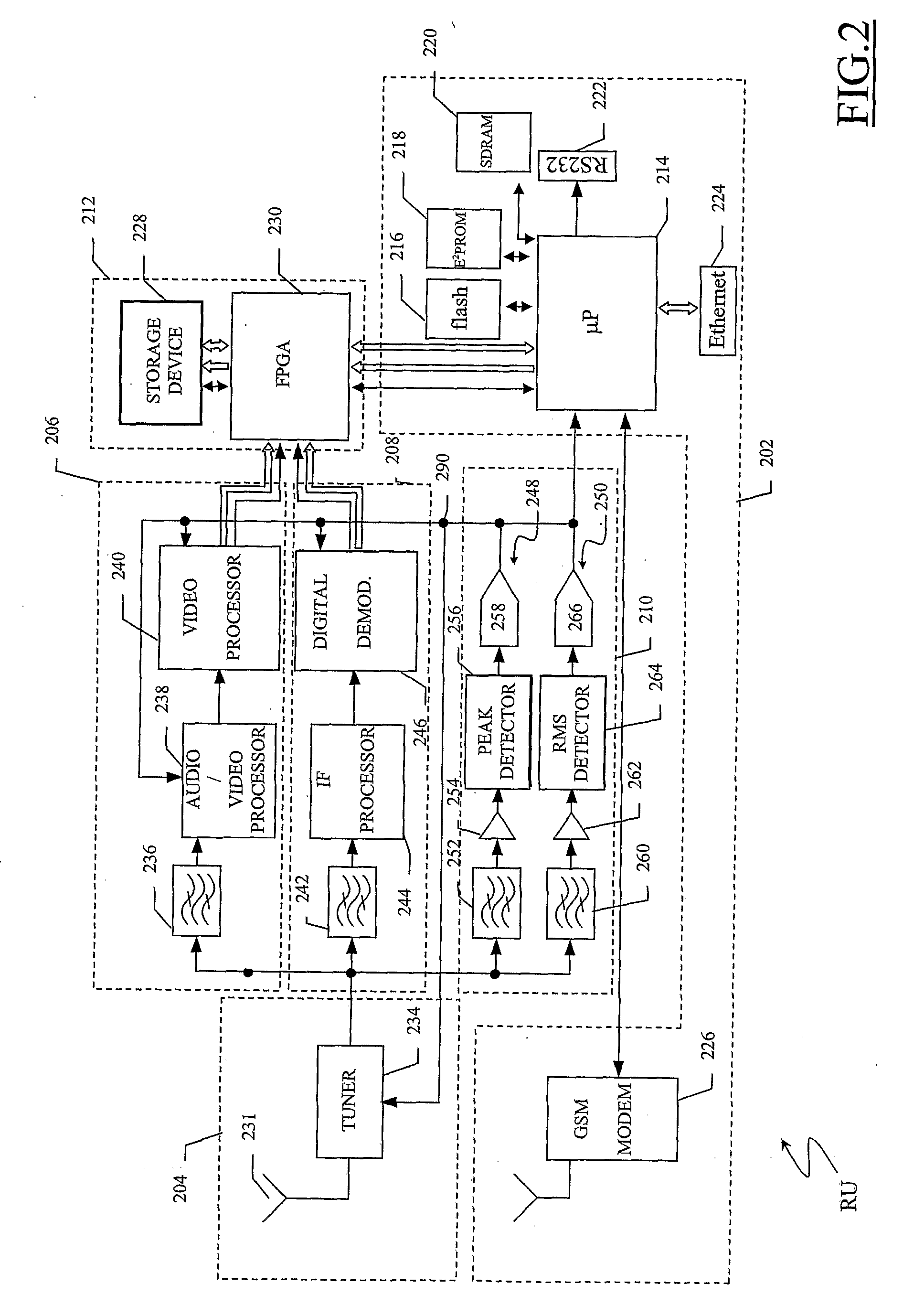

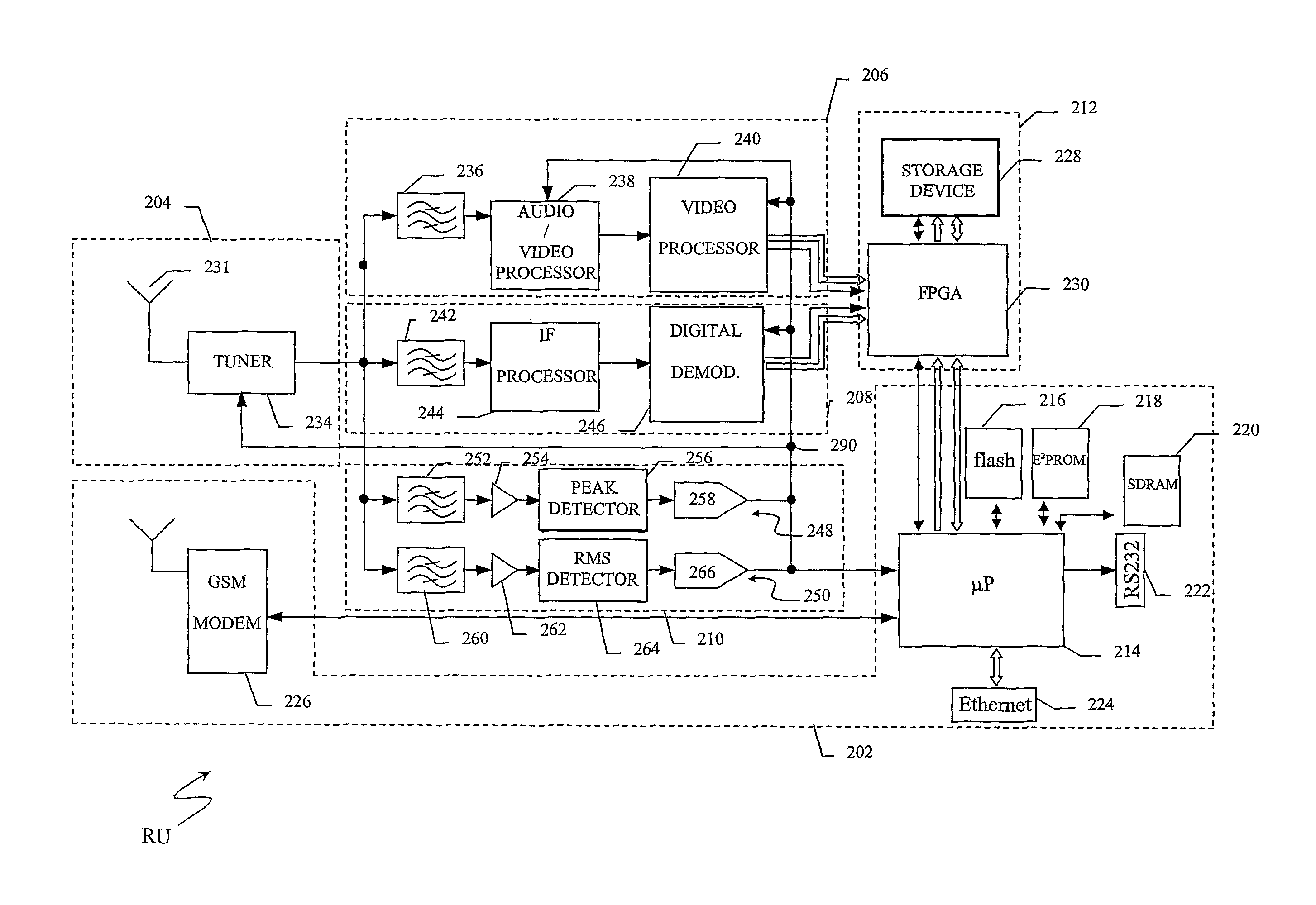

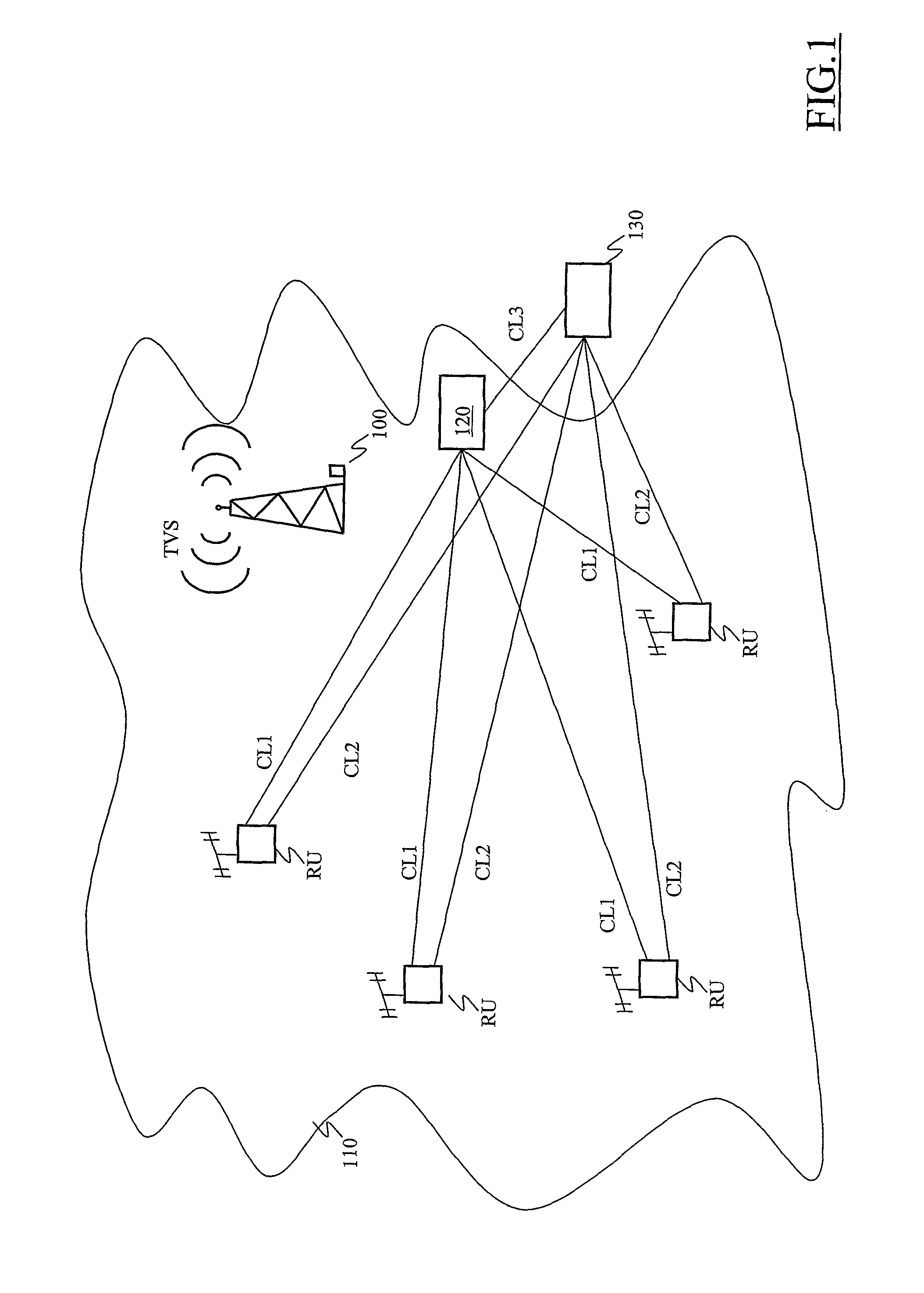

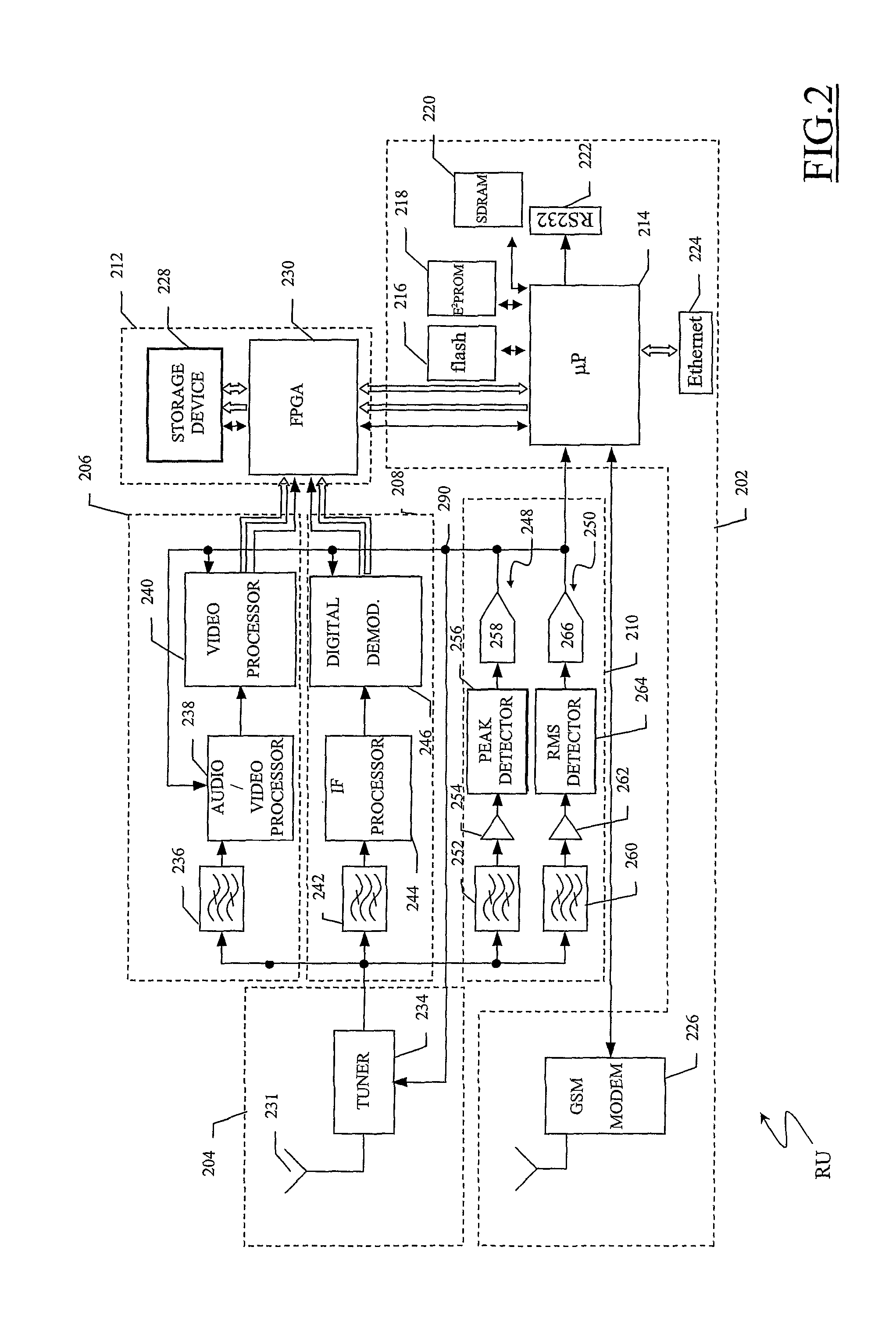

Monitoring System for Monitoring Coverage of Broadcast Transmissions

ActiveUS20090179989A1Enhanced capillary actionOvercomes drawbackTelevision system detailsReceivers monitoringTelecommunications linkCommunications system

A system for monitoring television signals broadcast by at least one transmission antenna in a broadcast area includes a monitoring control center and a plurality of remote monitoring units distributed in television signal receiving locations of the broadcast area remote from the transmission antenna. The remote monitoring units are configured to receive the television signals irradiated in the respective locations, process the television signals and send to the monitoring control center information related to the processed television signal. In particular, the remote monitoring units include a receiver adapted to receive the television signal, a measuring system adapted to perform measures on radio-electric features of the received television signal, and a communication system adapted to communicate measurement results to the remote monitoring center, exploiting a communication link between the remote monitoring unit and the control center.

Owner:TELECOM ITALIA SPA

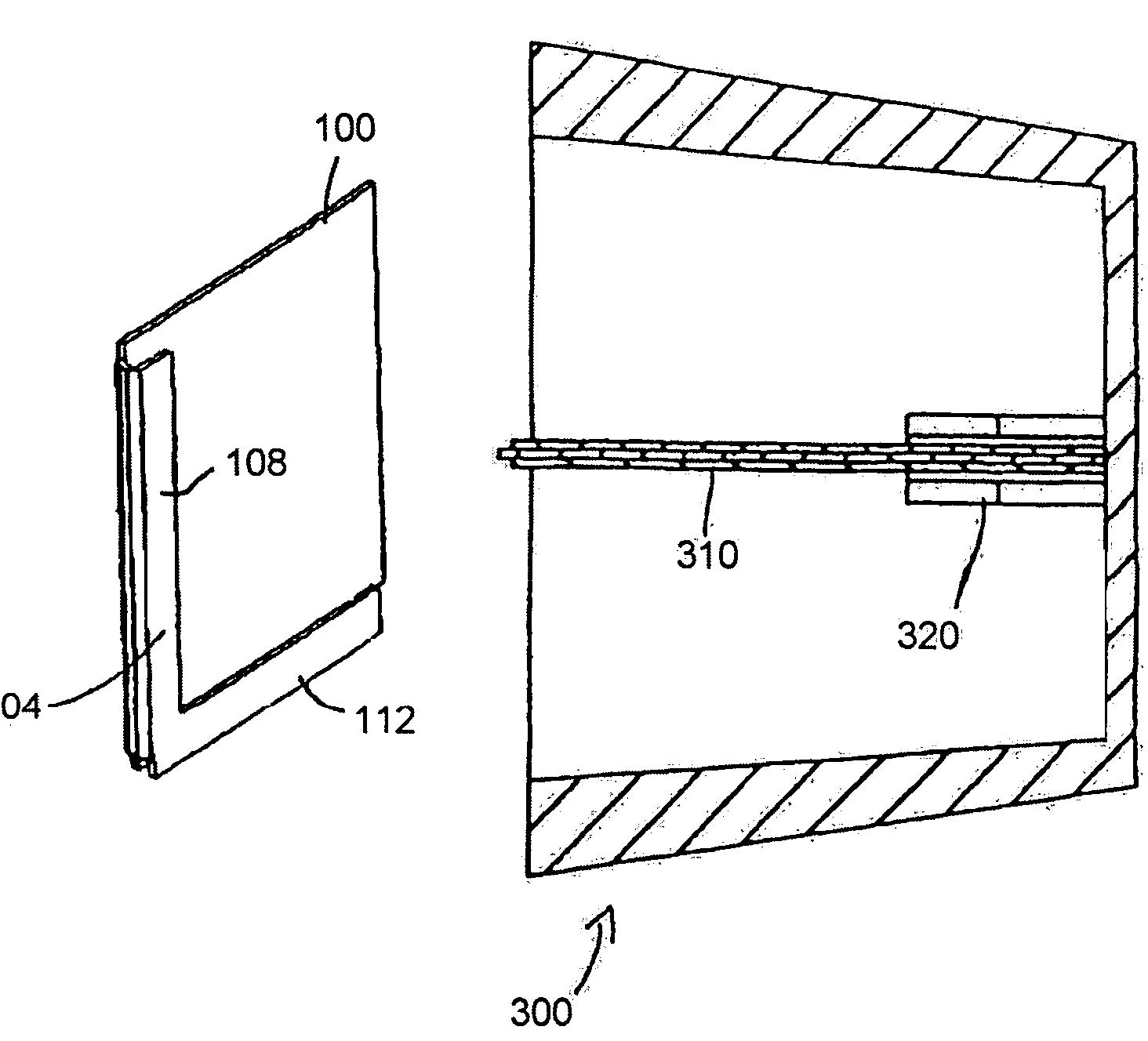

Oil lamp, air freshener and/or fragrance release apparatus and wick therefor

InactiveUS7568913B2Facilitated releaseImprove conductivityCapillary burnersGaseous substancesCapillary TubingEngineering

An oil lamp and fragrance release apparatus for providing a unique flame formation usable in a variety of decorative applications. The lamp includes a body that has an open upper end and that defines a chamber for carrying a combustible liquid. The lamp further includes a sheet wick having a lower end located in the chamber of the body, for contacting the combustible liquid, and an upper end projecting upwardly from the open upper end. The wick of inorganic material may be positioned between first and second plates arranged in a spaced, confronting relationship to enhance capillary action, may be freestanding stone of fibrous, permeable material or may be wrapped about a rigid plate. The wick provides a unique horizontal flame formation, while displaying décor on the outer surface of the flat wall. Optionally, the lamp may include scented oil and a conductive element to promote the release of fragrance upon heating, and the wick can be configured of material having high heat fragrance emanation.

Owner:LUMETIQUE

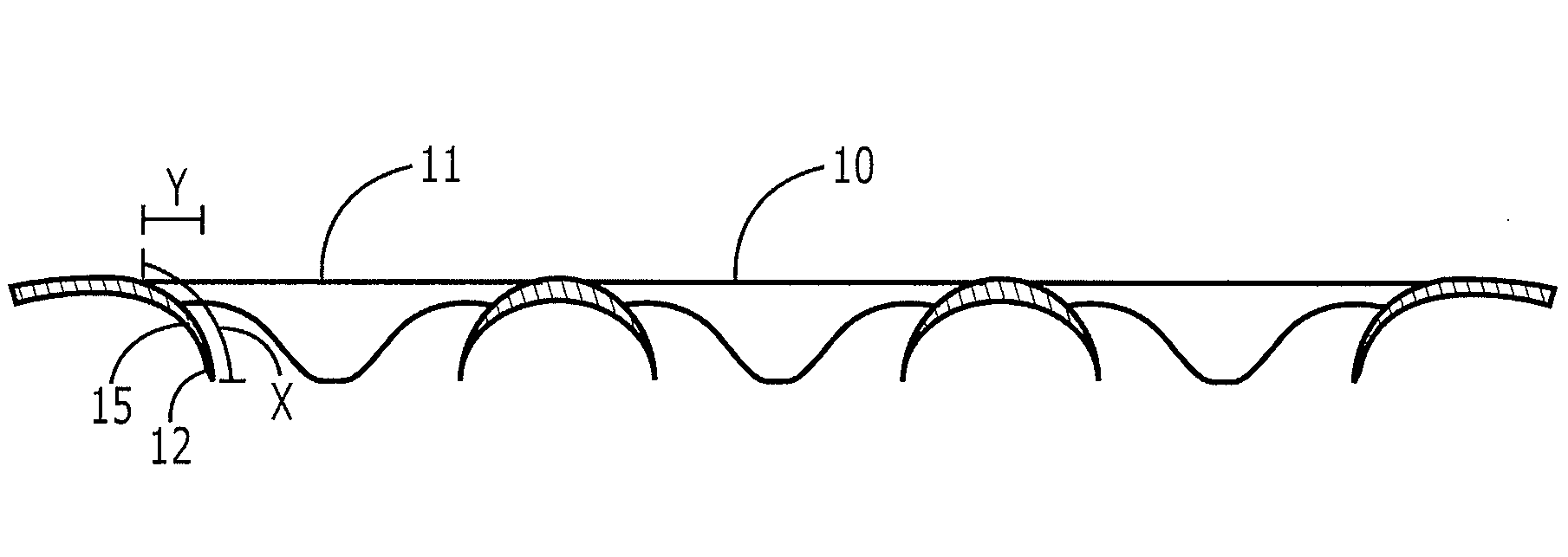

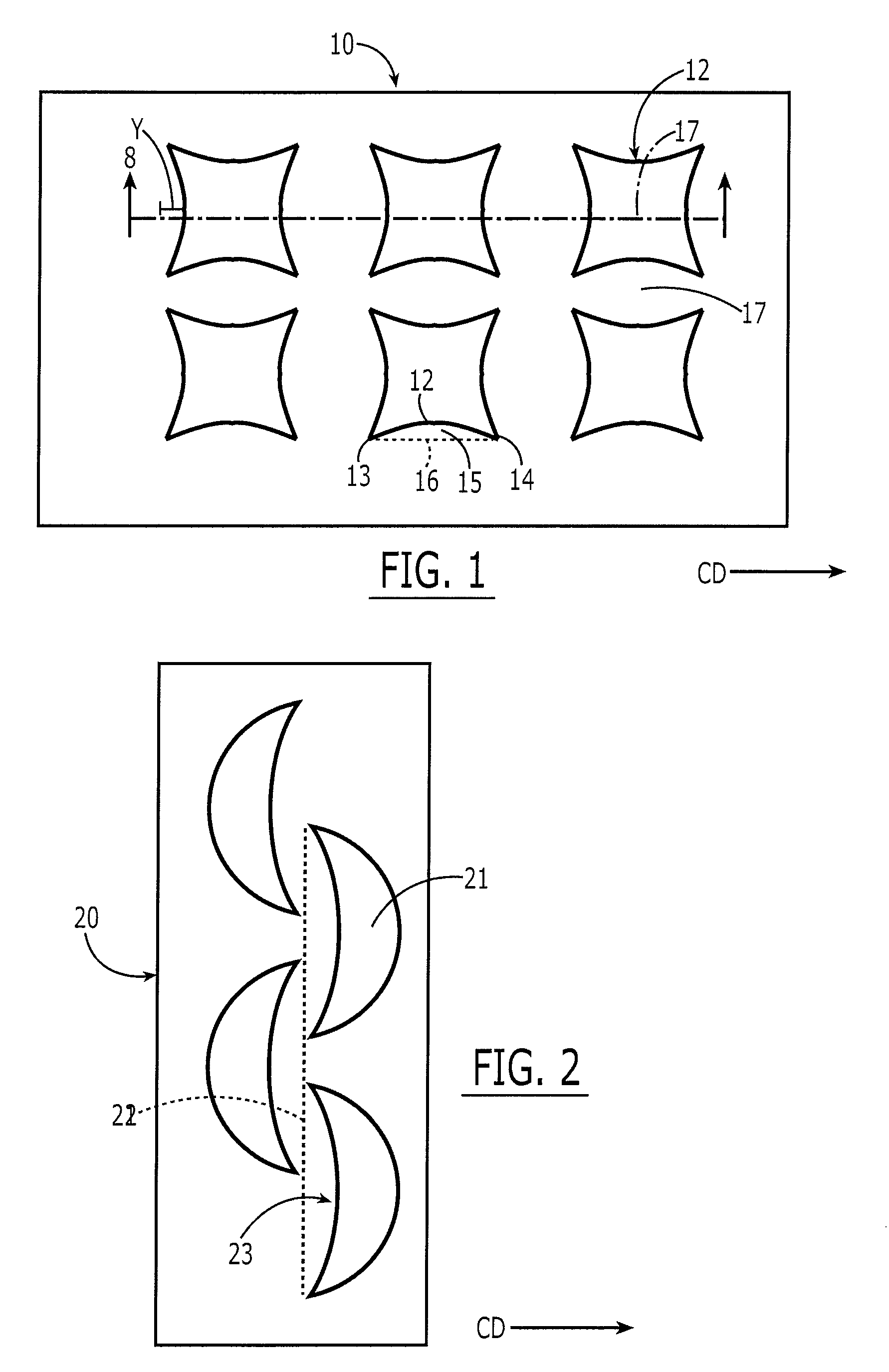

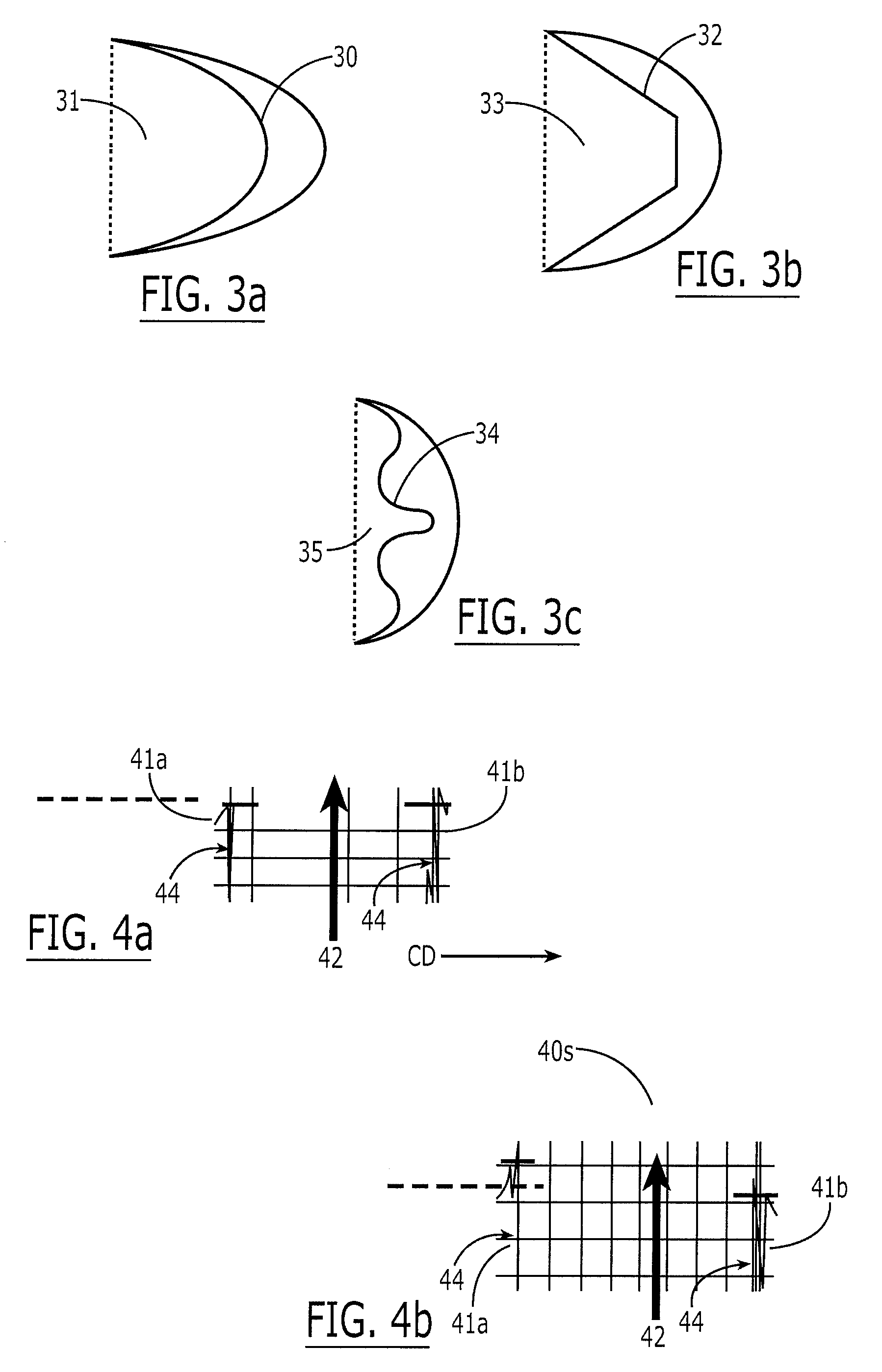

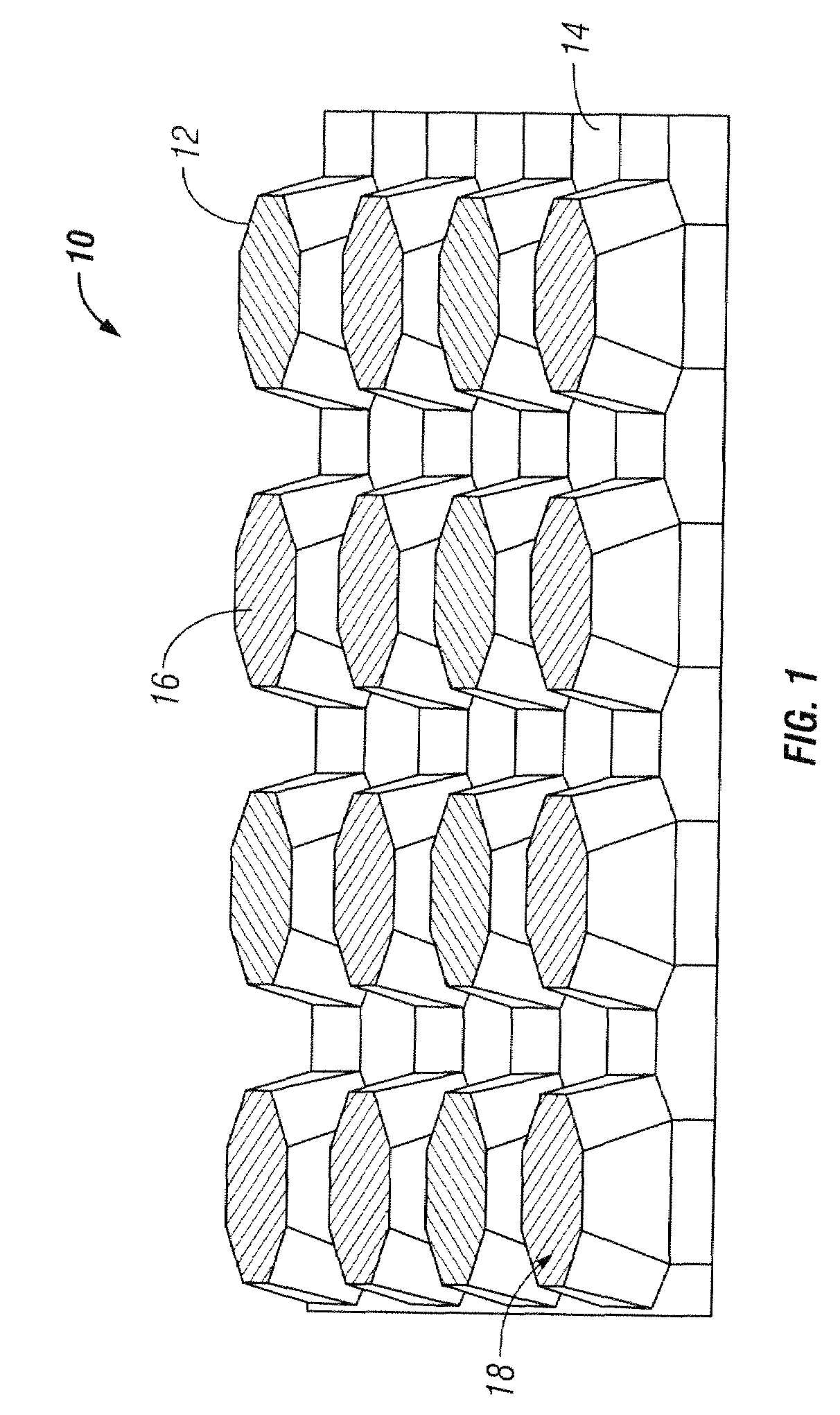

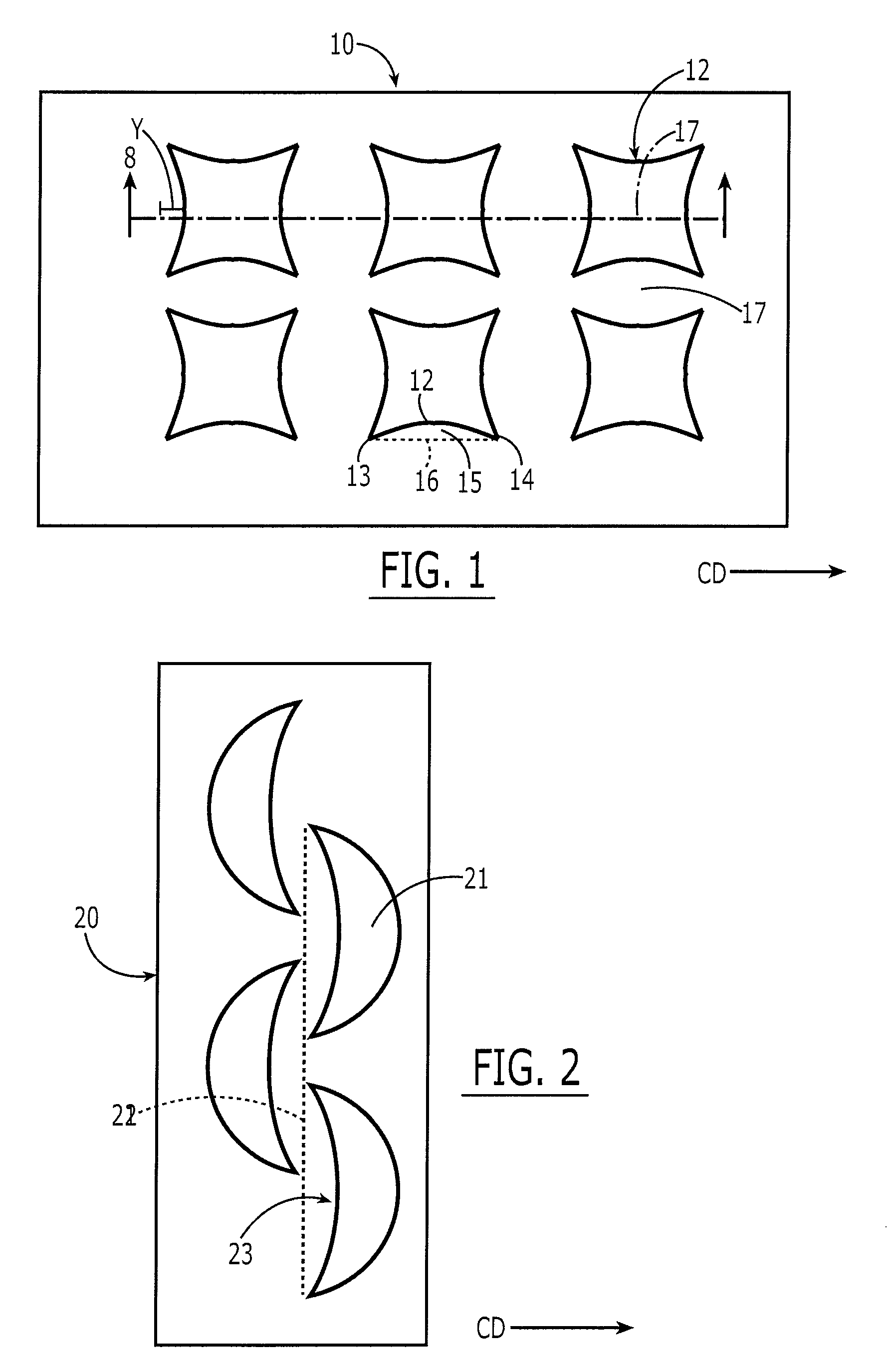

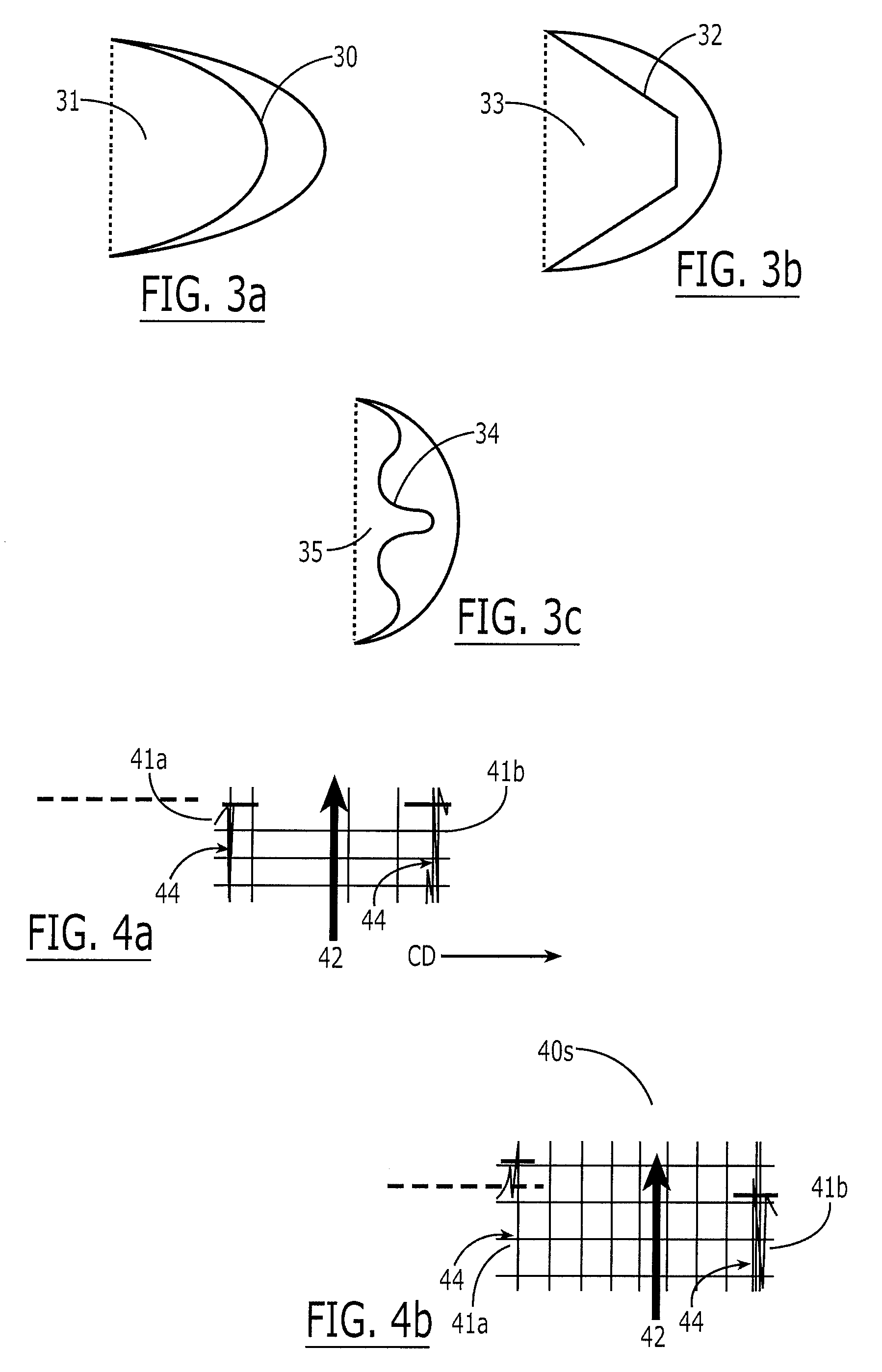

Web having apertures with convex sides

ActiveUS20080138574A1Effective areaFacilitate the passage of large or viscous mensesLayered productsBaby linensConvex sideEngineering

Owner:TREDEGAR FILM PROD CORP

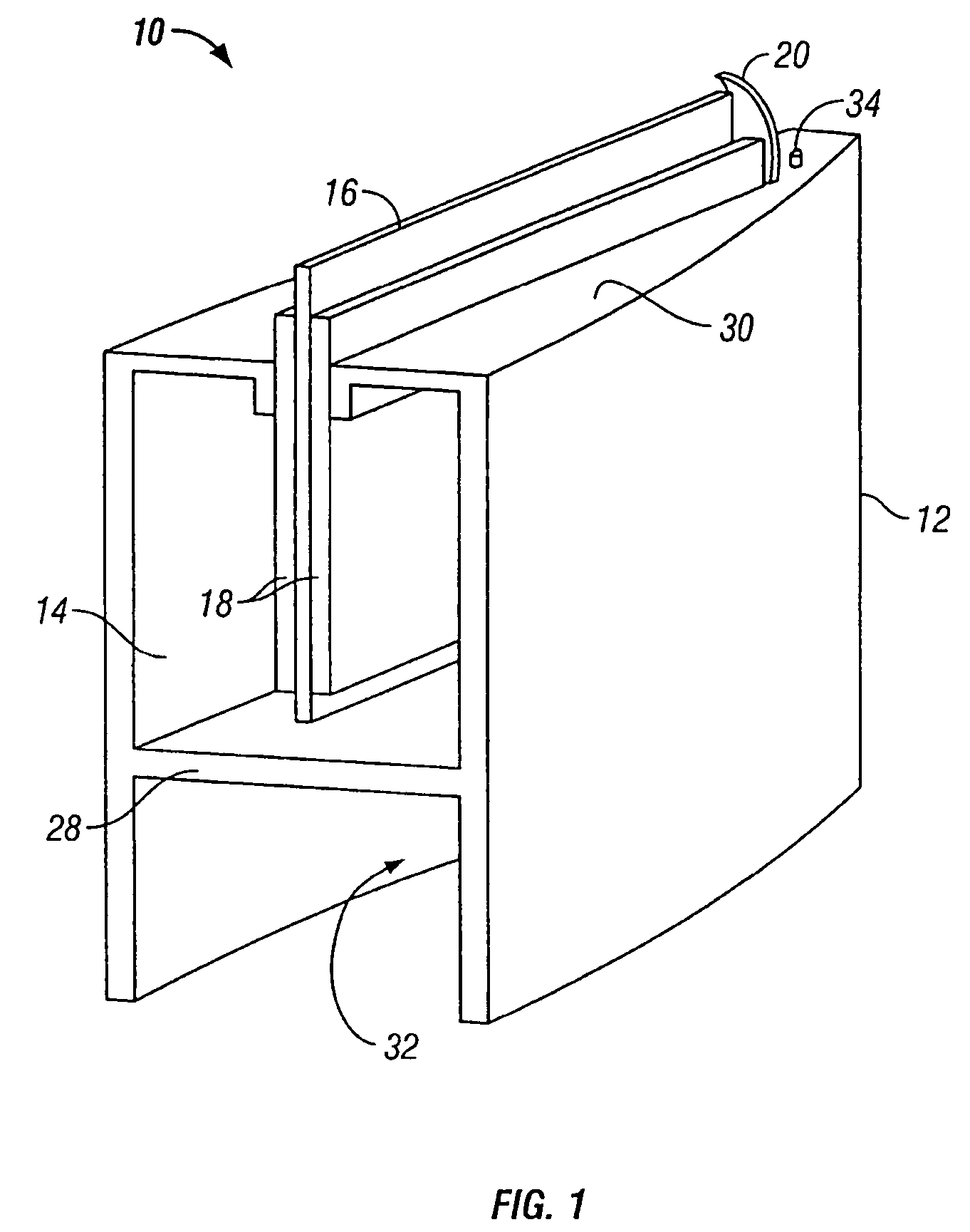

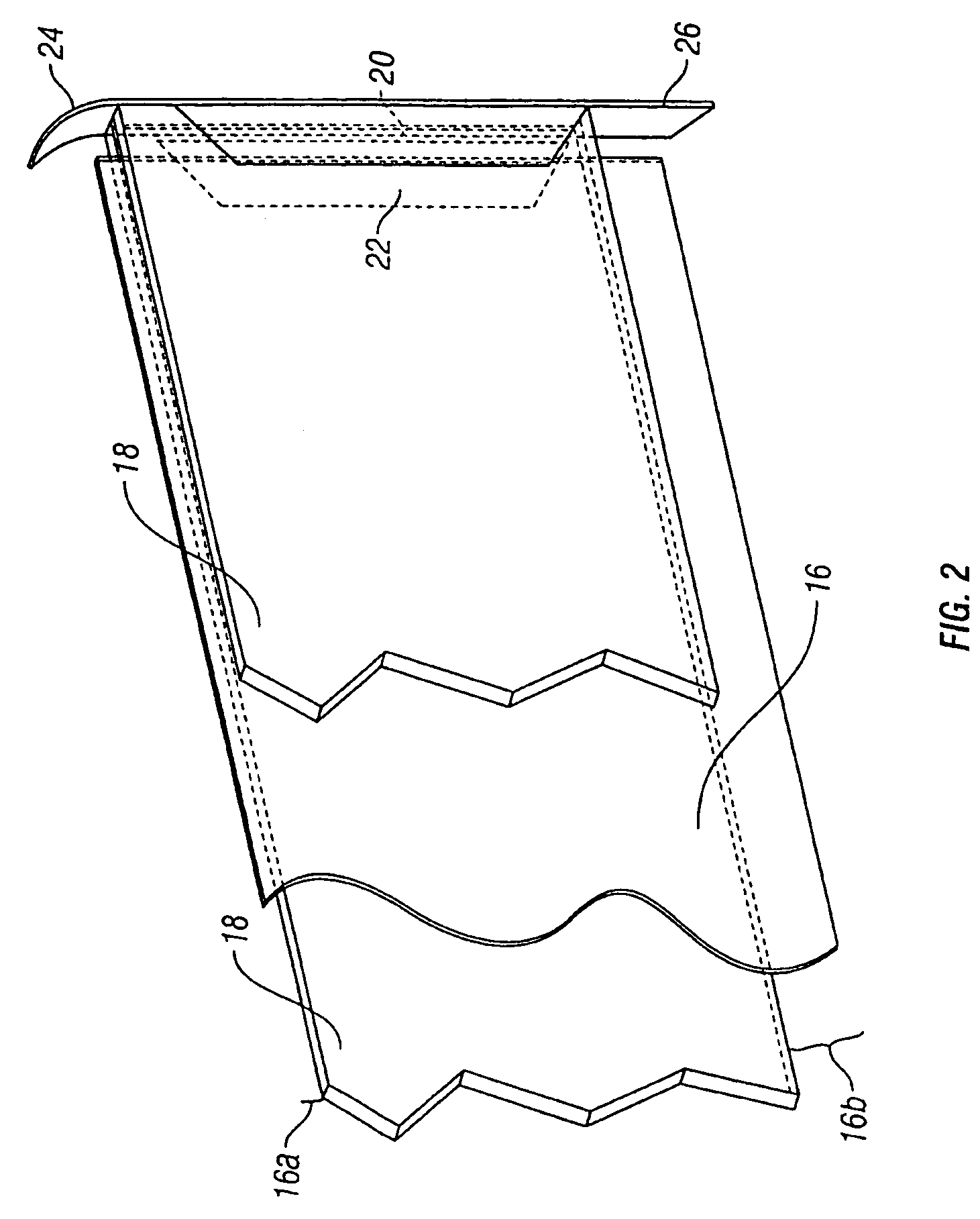

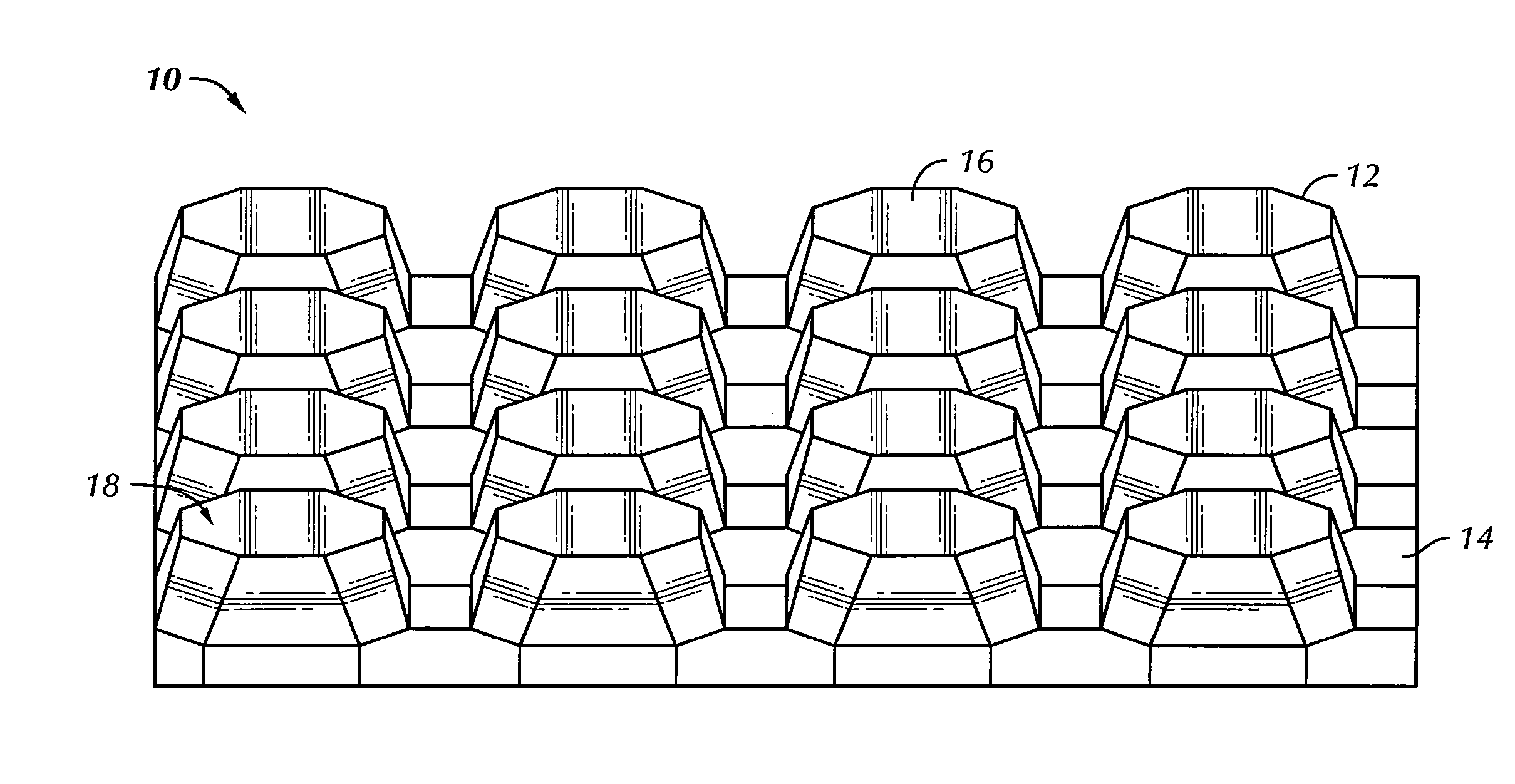

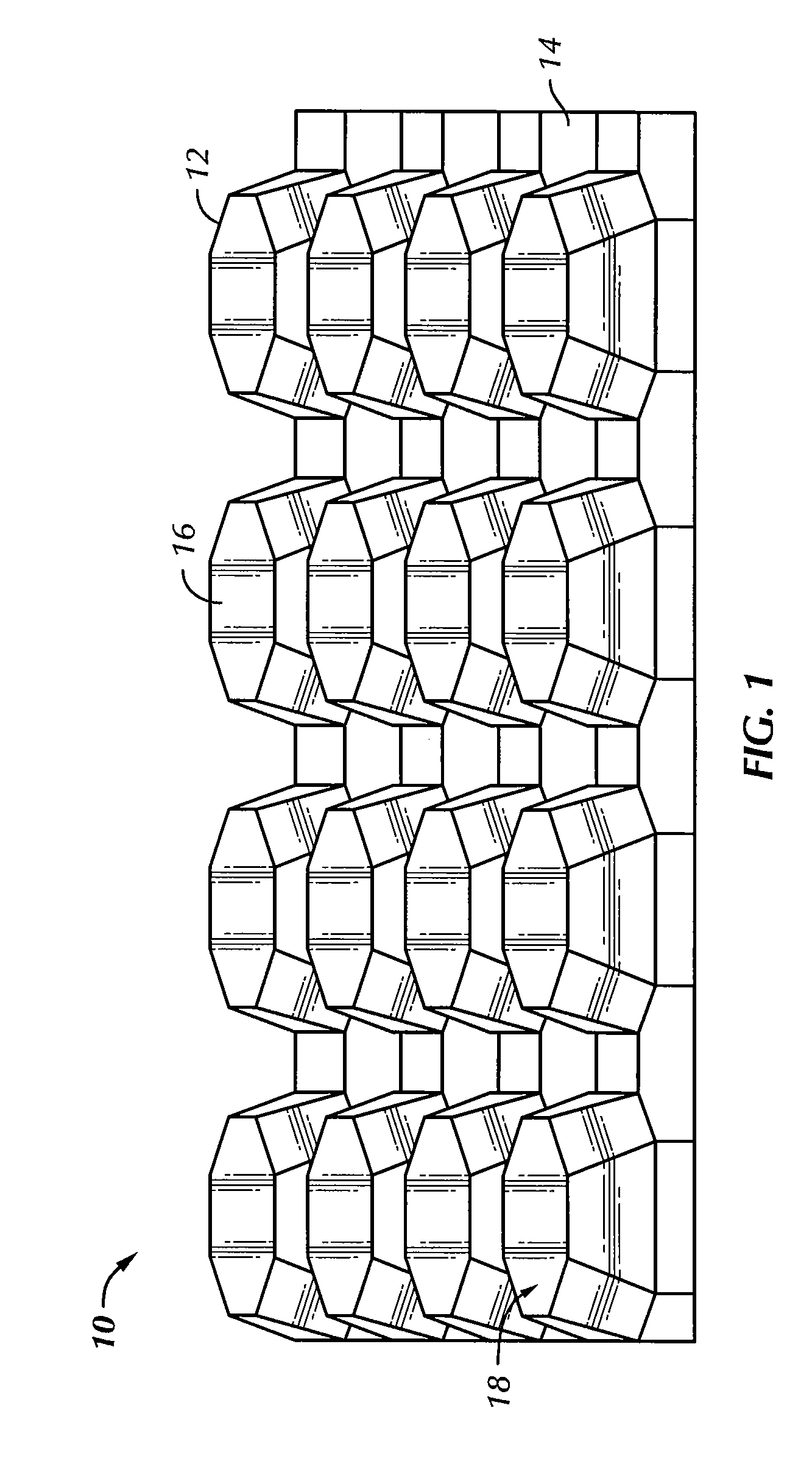

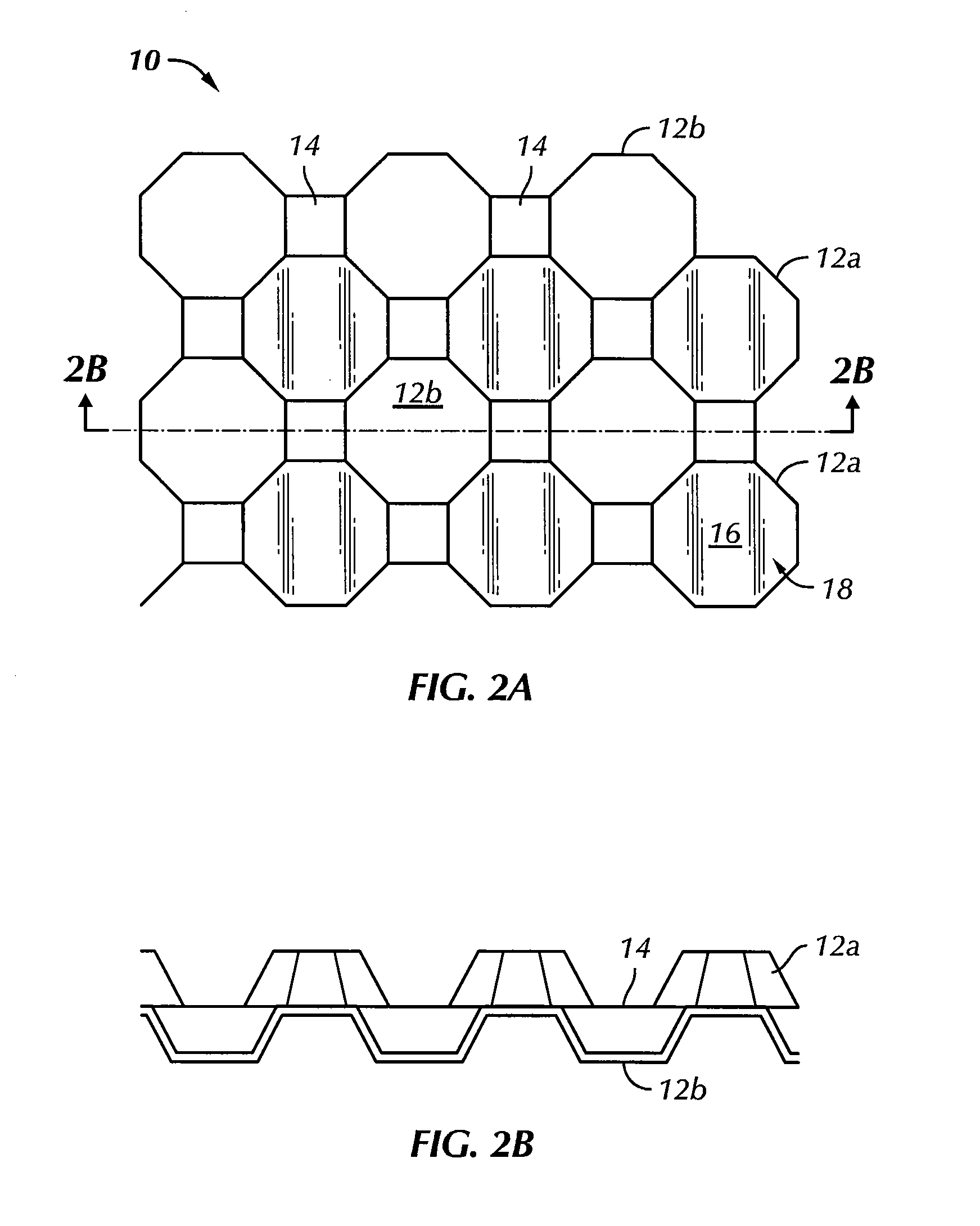

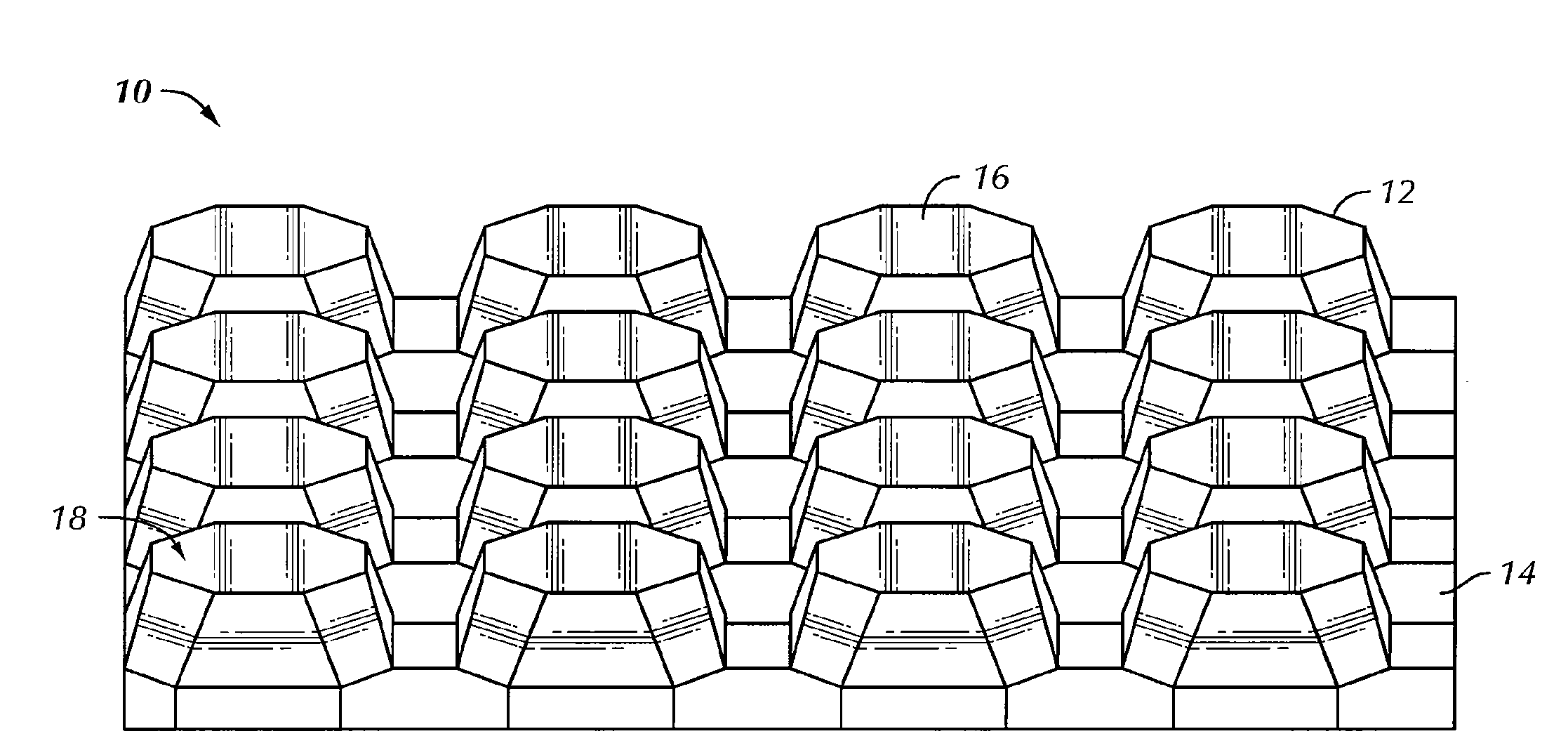

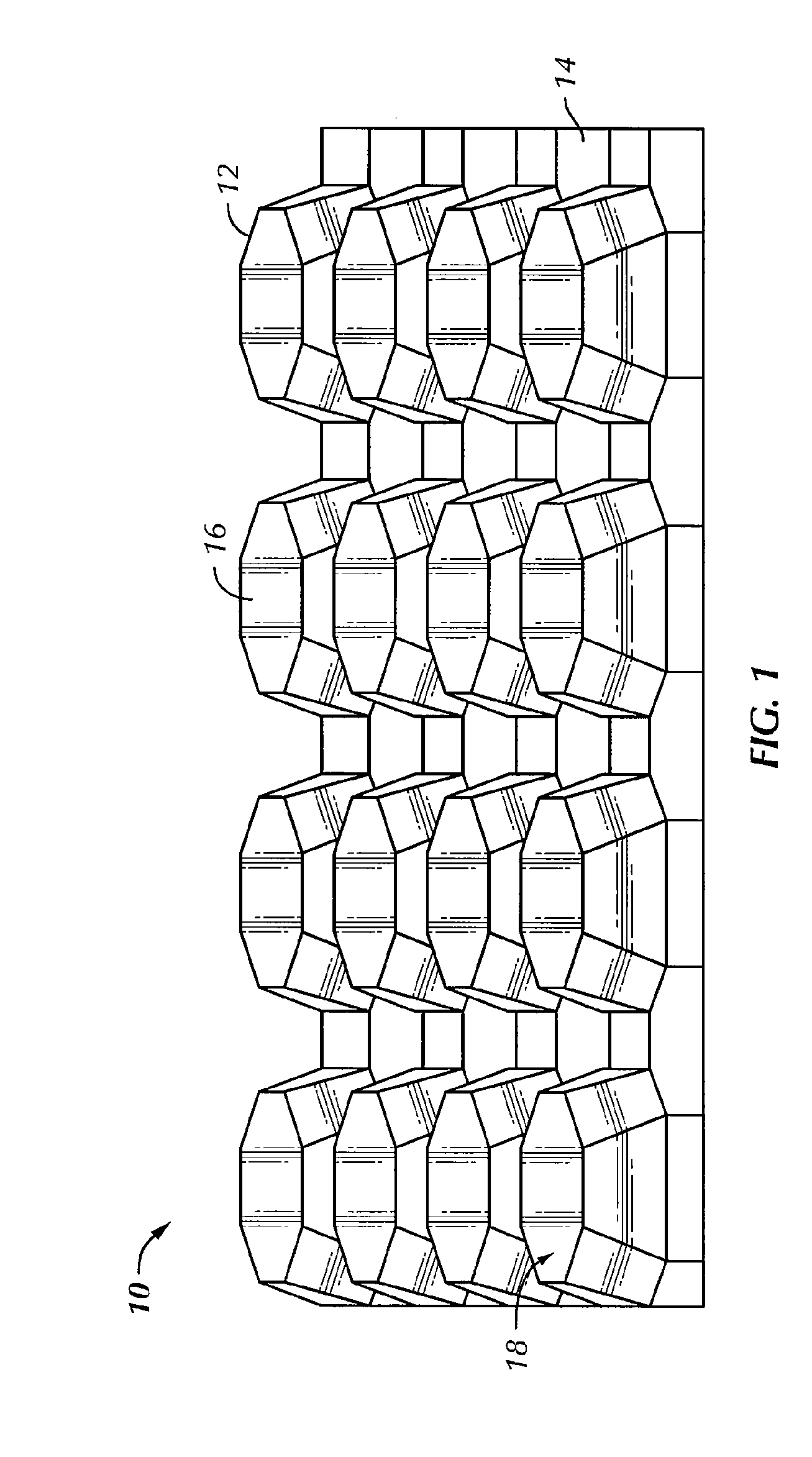

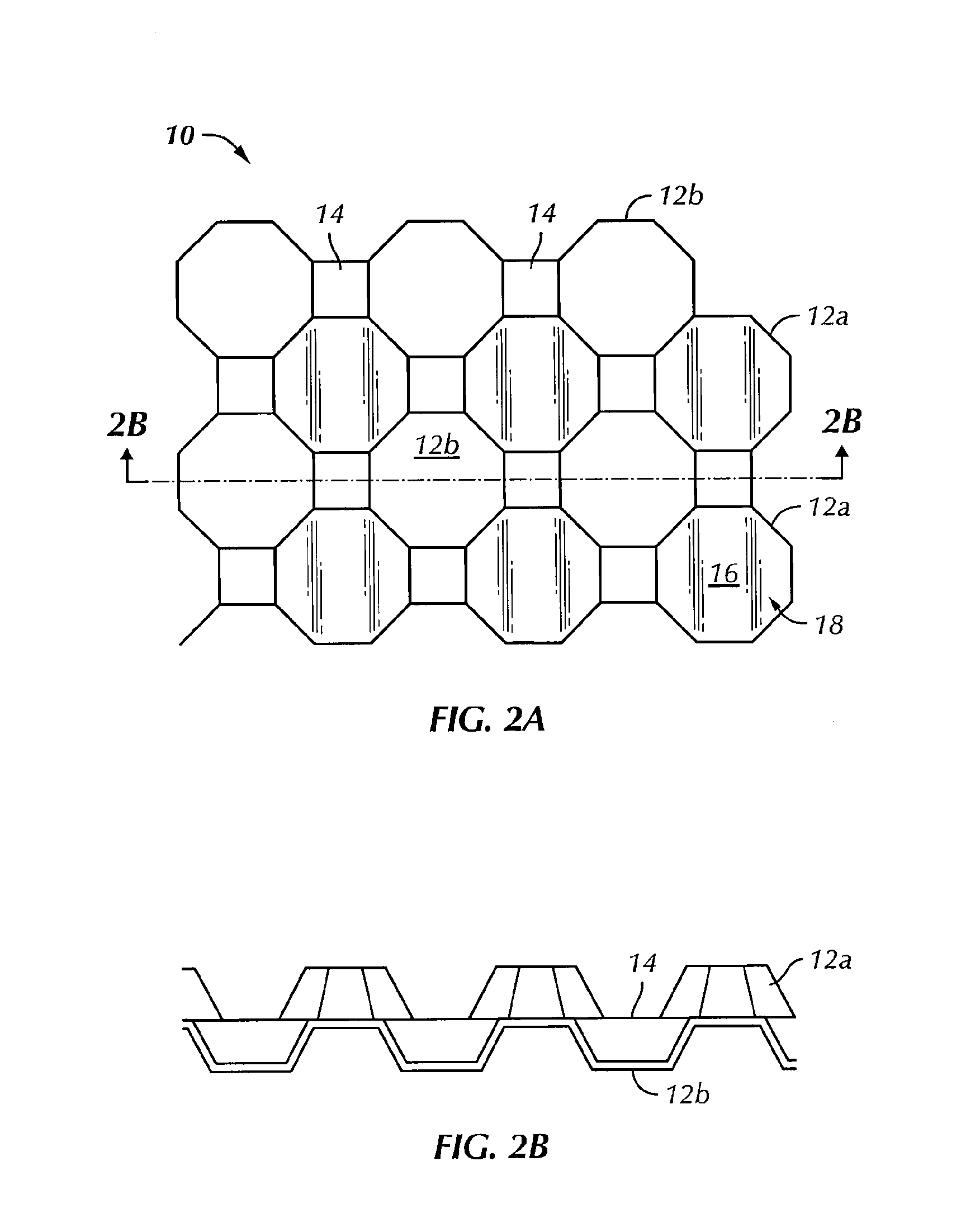

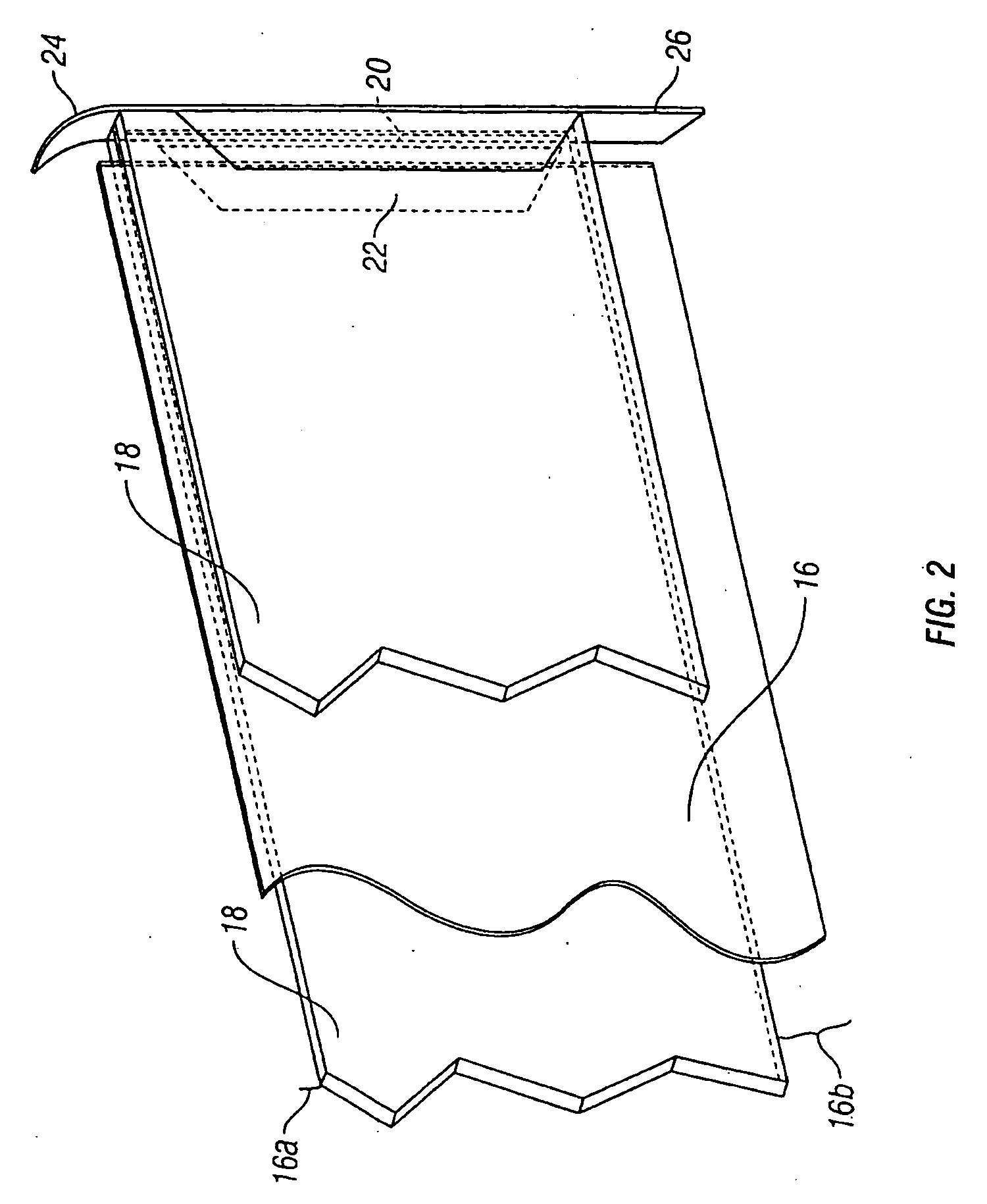

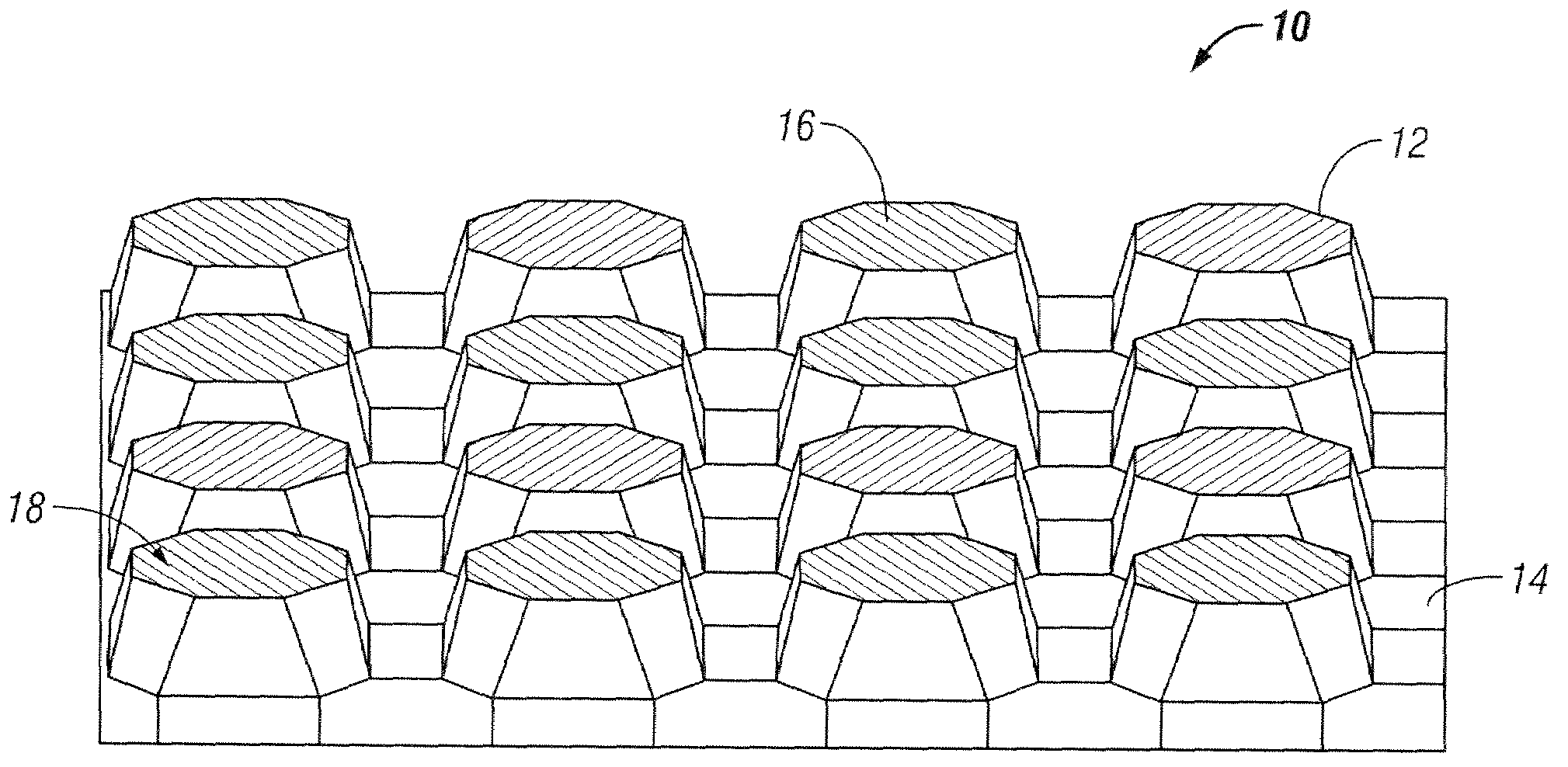

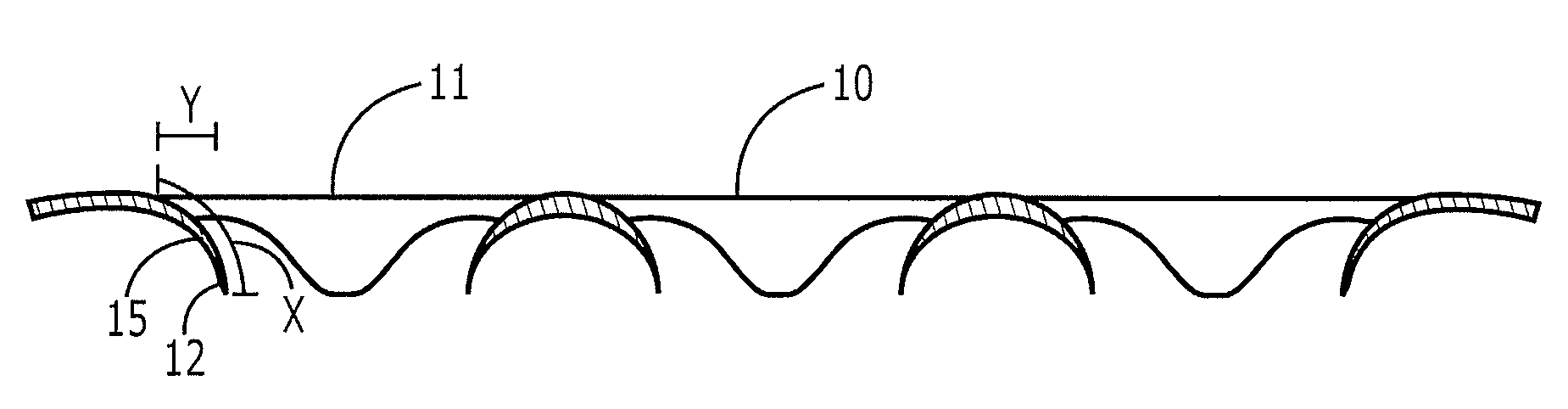

Formed core sandwich structure and method and system for making same

InactiveUS20070243408A1Easy and economical to manufactureEnhanced capillary actionPrinted circuit assemblingSoldering apparatusEngineeringMetal sheet

A method and apparatus for producing a metal core sandwich structure that is lightweight and many times stiffer than regular sheet metal, and which is easily formable into curved structures as well as structures having compound curves. In one embodiment, a formed metal core includes a plurality of cells comprising alternating front and rear projections extending outwardly in front of and behind a median plane, with each projection having a bonding surface area or land configured to be brazed or bonded with corresponding external metal sheets on both sides of the formed metal core. A plurality of micro-abrasions or indentations are formed on the bonding lands, allowing stronger brazing or bonding joints to be formed between the metal core and the external metal sheets by facilitating improved capillary action by the metal core during the brazing or bonding process.

Owner:CELLTECH METALS INC

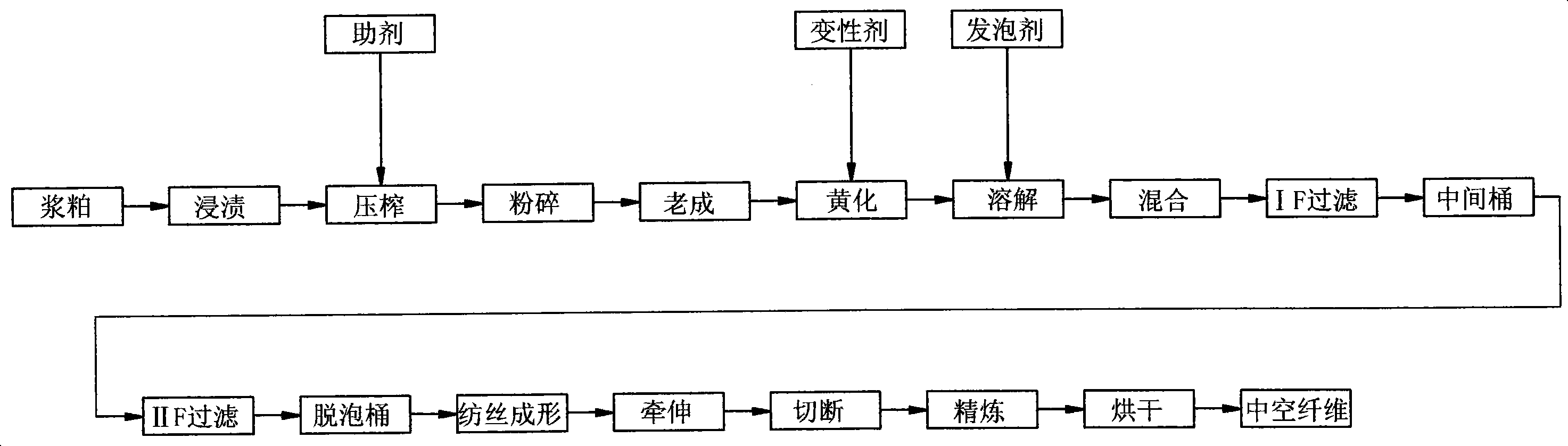

Double-wall sandwich structural microcapsule self-repairing rubber and preparation method thereof

ActiveCN103467791AImprove heat stabilityFully coveredMicroballoon preparationMicrocapsule preparationMolecular sieveCarbon black

The invention provides a double-wall sandwich structural microcapsule self-repairing rubber and a preparation method thereof, and relates to a rubber and a preparation method thereof. The preparation method comprises the step of sequentially mixing a rubber matrix, stearic acid, zinc oxide, an accelerant, an anti-aging agent, carbon black, paraffin, a double-wall sandwich structural self-repairing microcapsule and a nano mesoporous molecular sieve in proportion, wherein the double-wall sandwich microcapsule is utilized and adopts urea-formaldehyde resin as the wall material, so that the sealing performance is high, and the manufactured walls have moderate hardness; the nano mesoporous molecular sieve utilized as a synergist is naturally inorganic filler which can improve the mechanical performance of the rubber, and a double coating brings higher heat-resisting stability, therefore, the contact probability of a repairing agent and the catalyst is greatly increased, and the influence of excessively added repairing agents and catalysts to the mechanical performance of the rubber can be avoided. Once microcrack appears in the material, a plurality of pores act to improve the capillary siphon effect of the microcrack to the microcapsule, thus the probability of the repairing agent and the curing agent to enter the microcrack is greatly increased, and as a result, the repairing effect is greatly improved.

Owner:沈阳双骥橡塑科技有限公司

Formed core sandwich structure and method and system for making same

ActiveUS20080292898A1Easy and economical to manufactureEnhanced capillary actionSoldering apparatusVehicle componentsEngineeringCapillary action

A method and apparatus for producing a sandwich structure that is lightweight and many times stiffer than regular sheet metal, and which is easily formable into curved structures as well as structures having compound curves. In one embodiment, a formed core includes a plurality of cells comprising alternating front and rear projections extending outwardly in front of and behind a median plane, with each projection having a bonding surface area or land configured to be bonded with corresponding external sheets on both sides of the formed core. A plurality of micro-abrasions or indentations are formed on the bonding lands, allowing stronger bonding joints to be formed between the core and the external sheets by facilitating improved capillary action by the core during the bonding process.

Owner:CELLTECH METALS INC

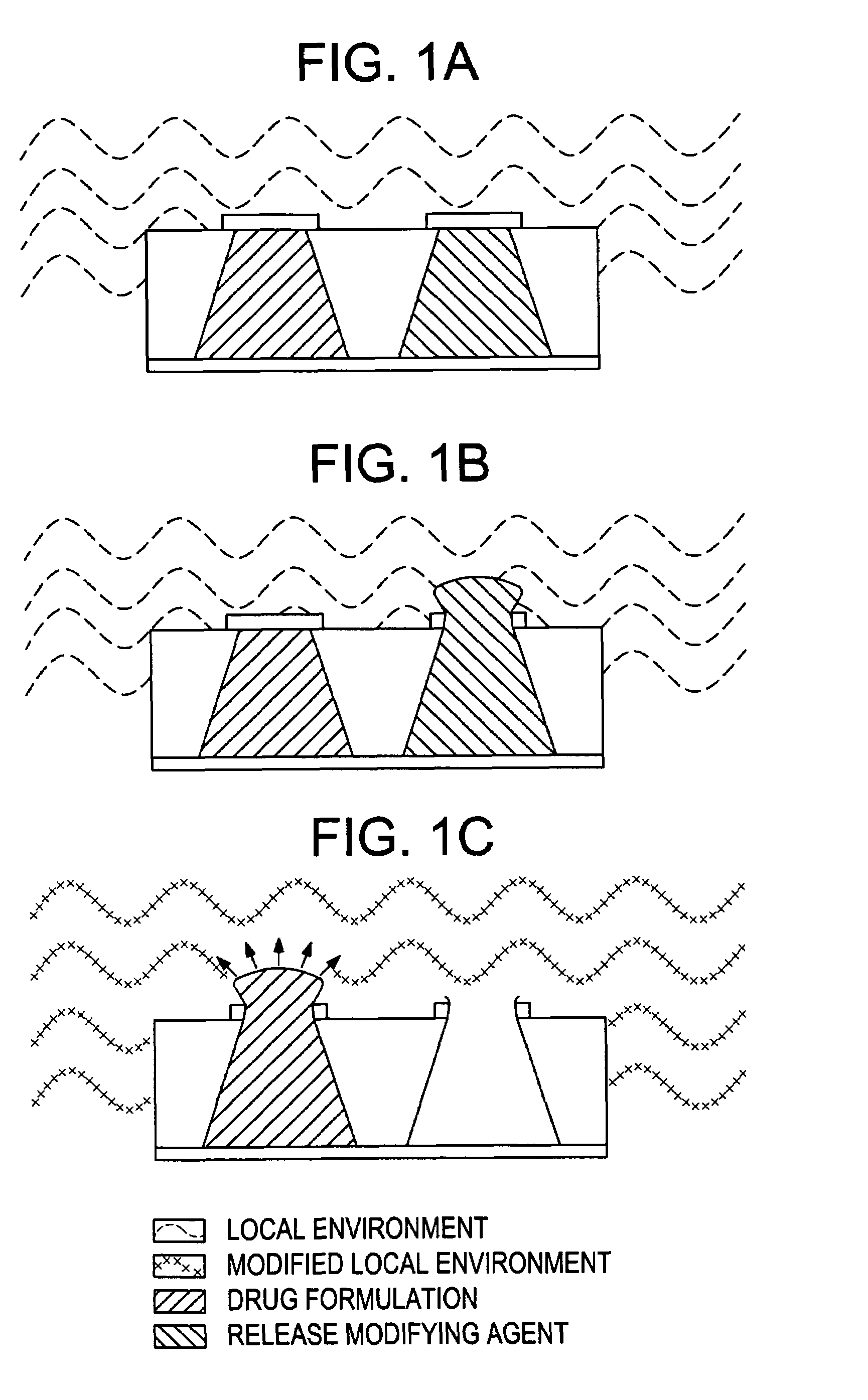

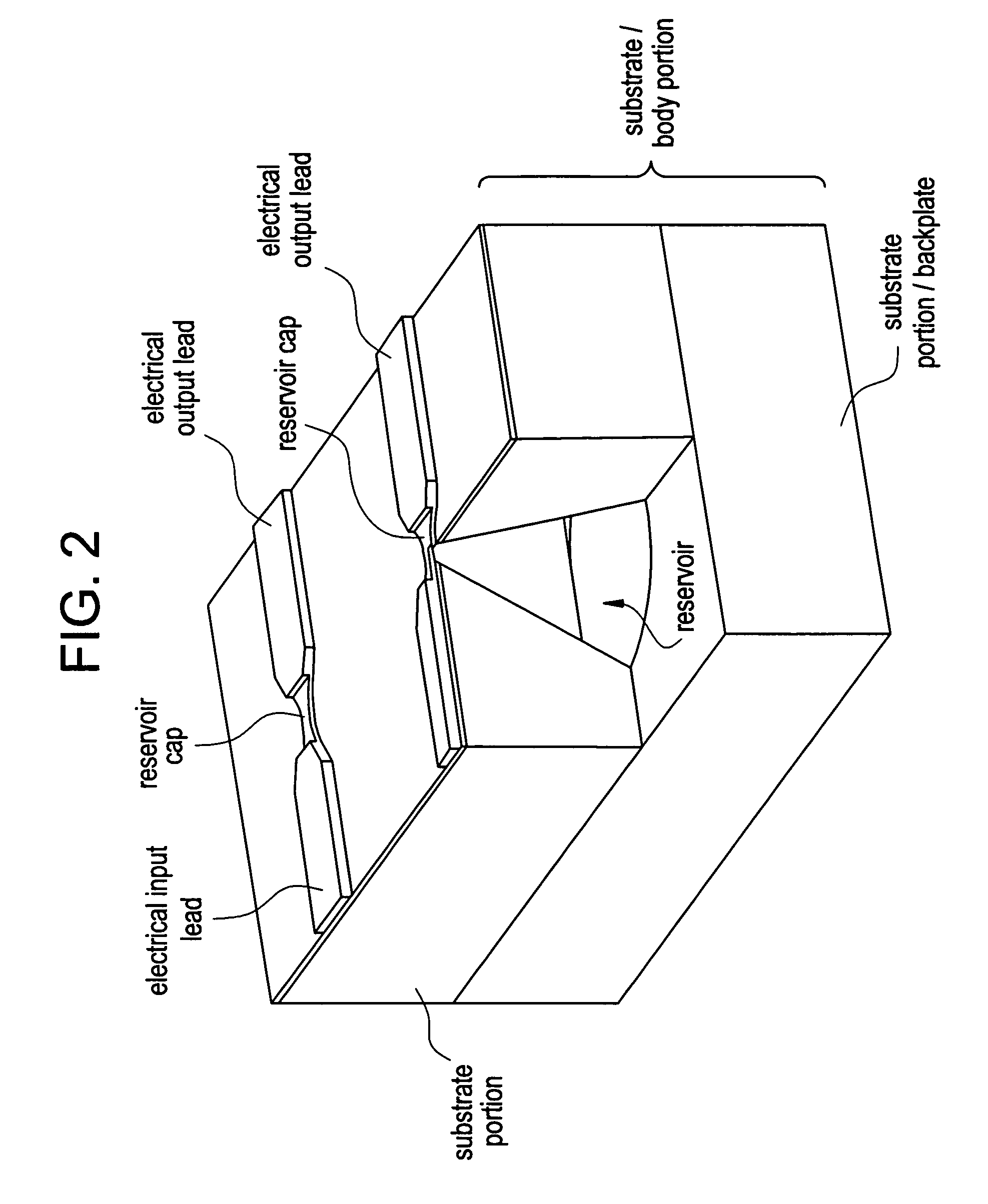

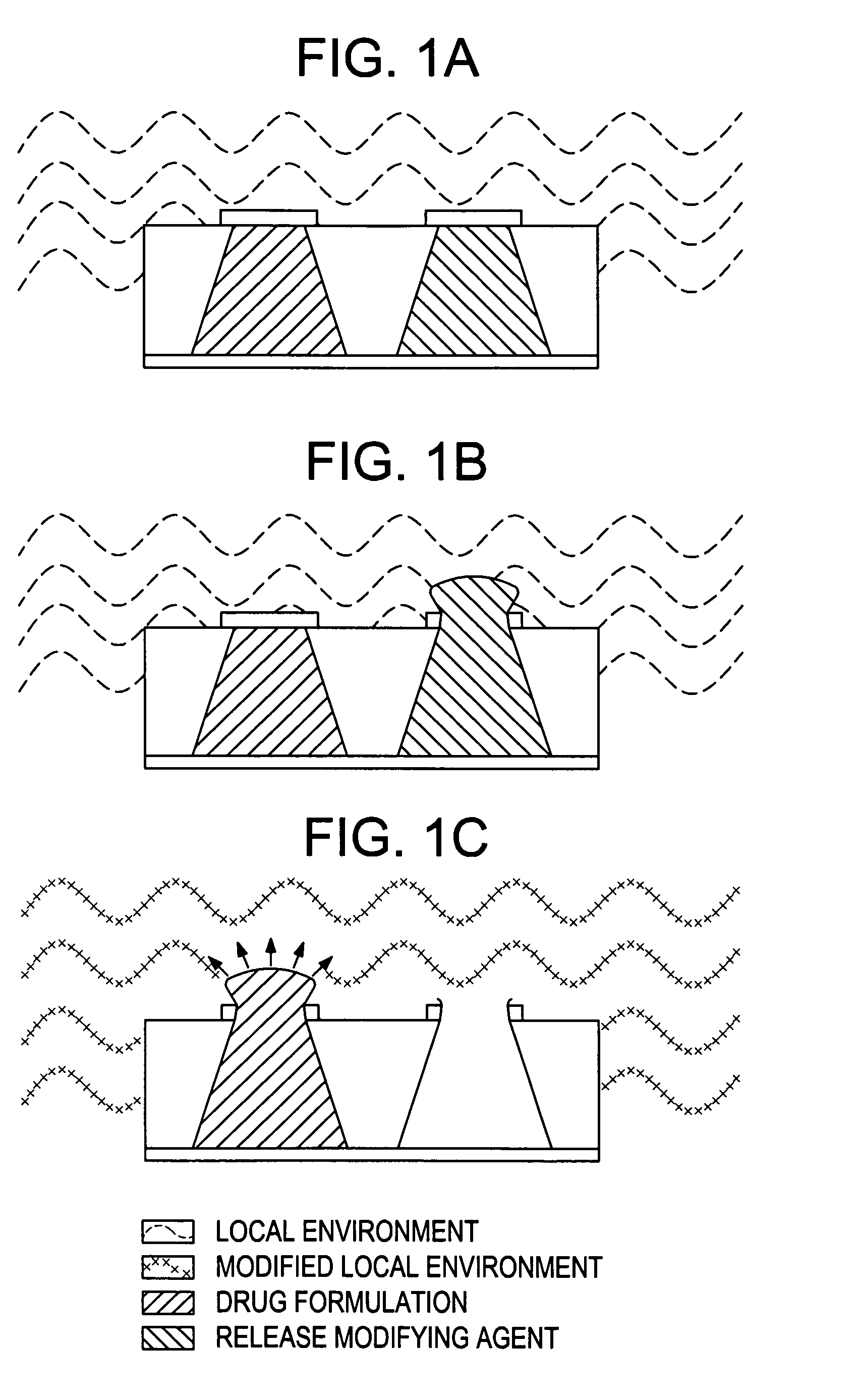

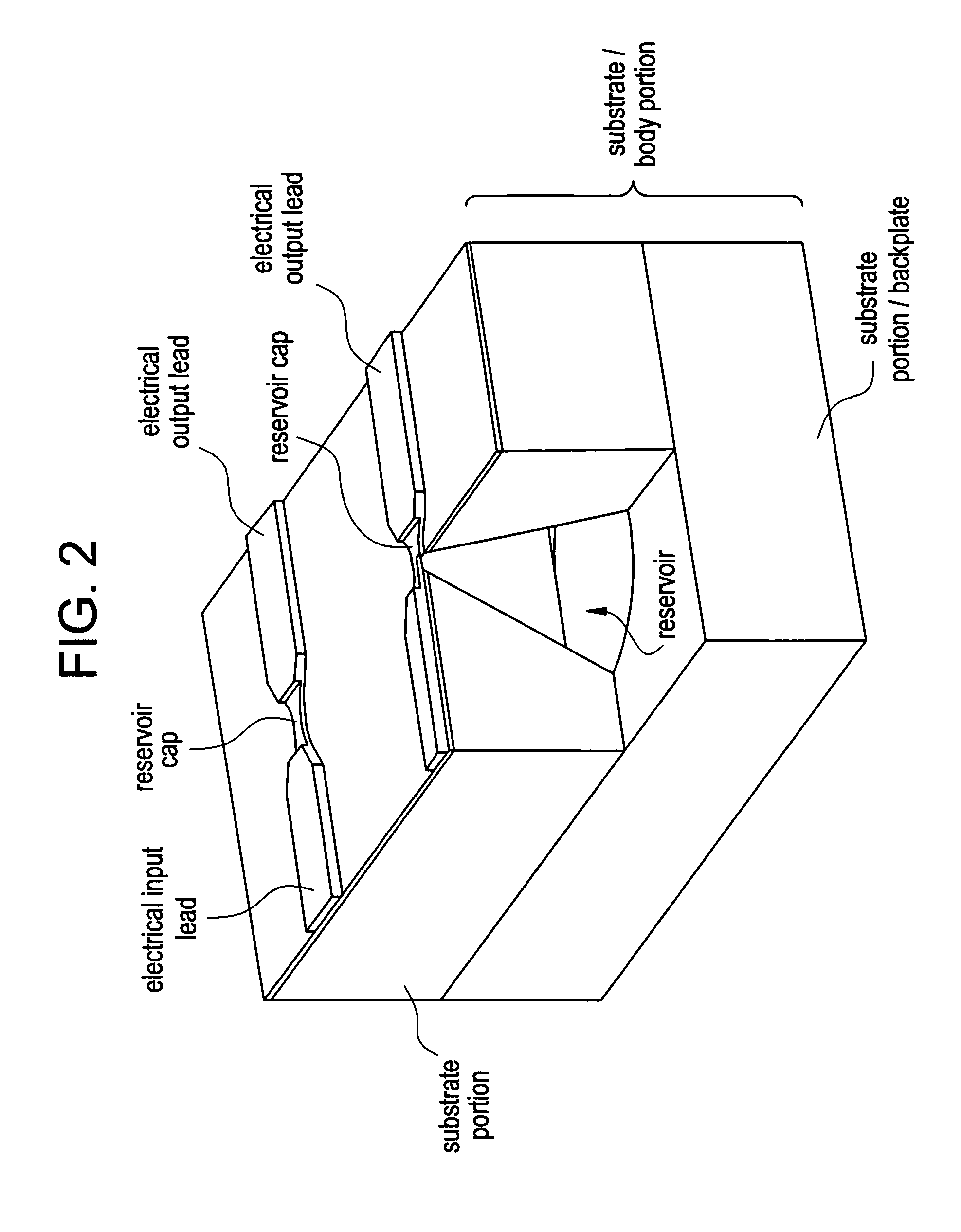

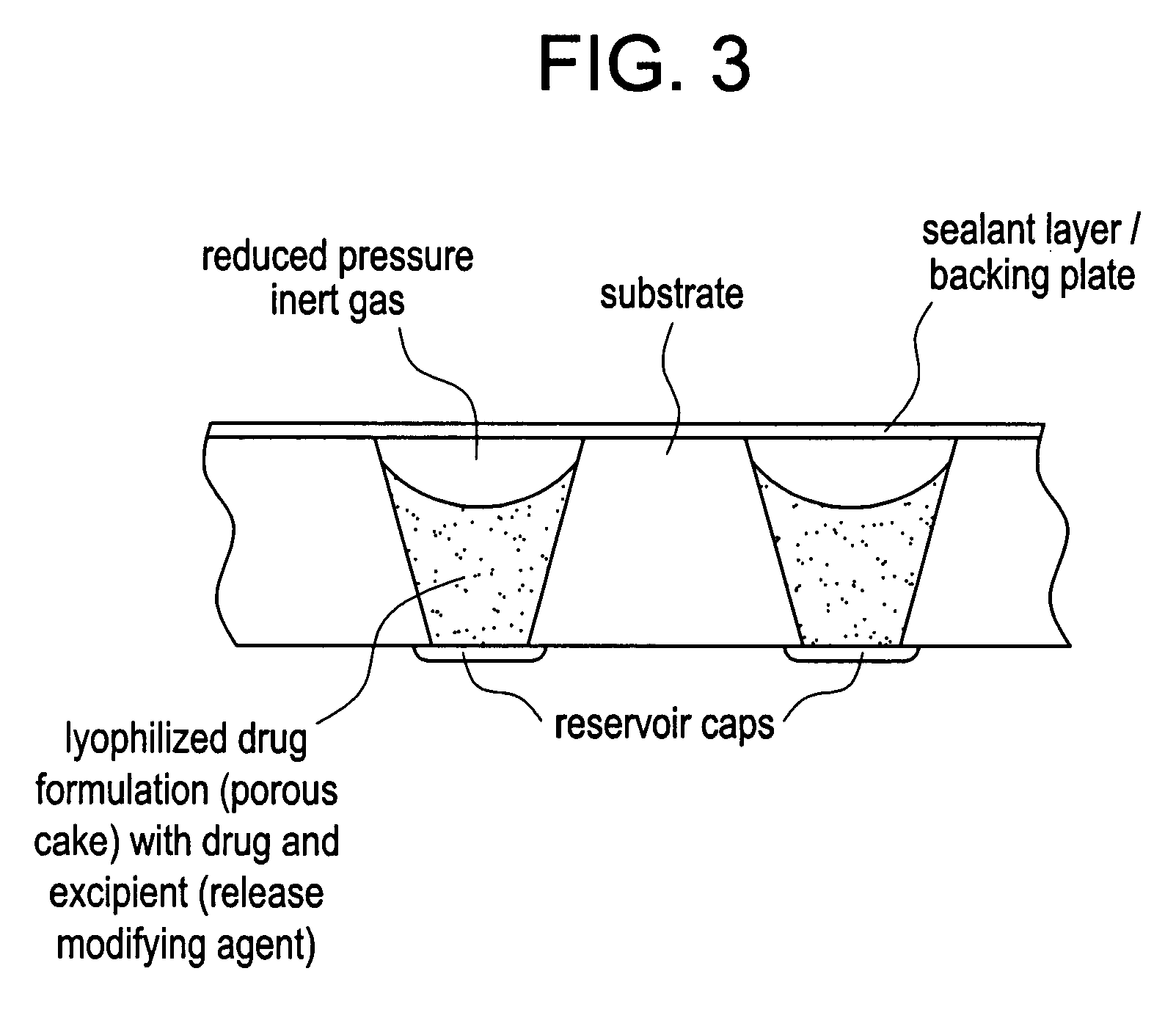

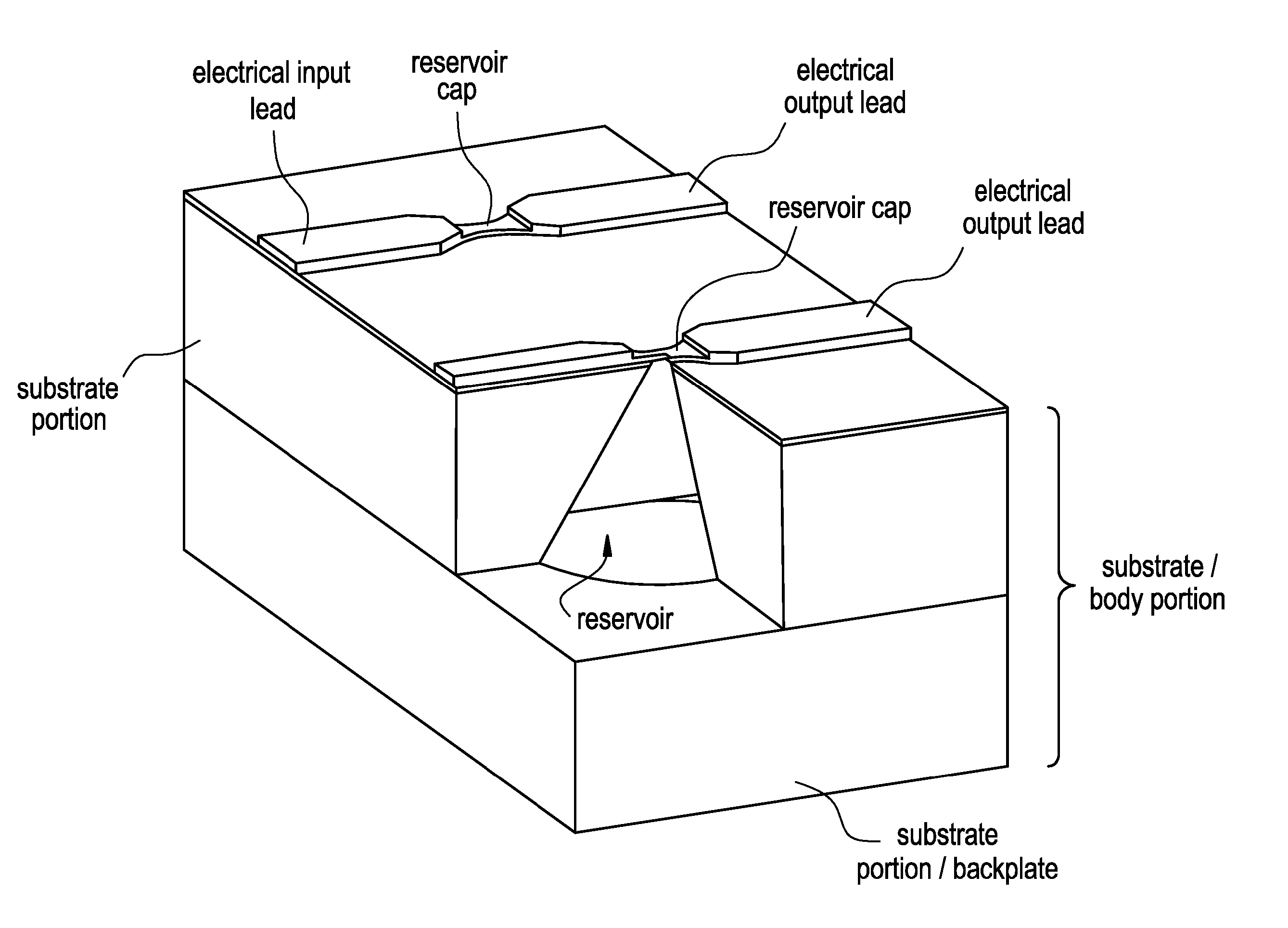

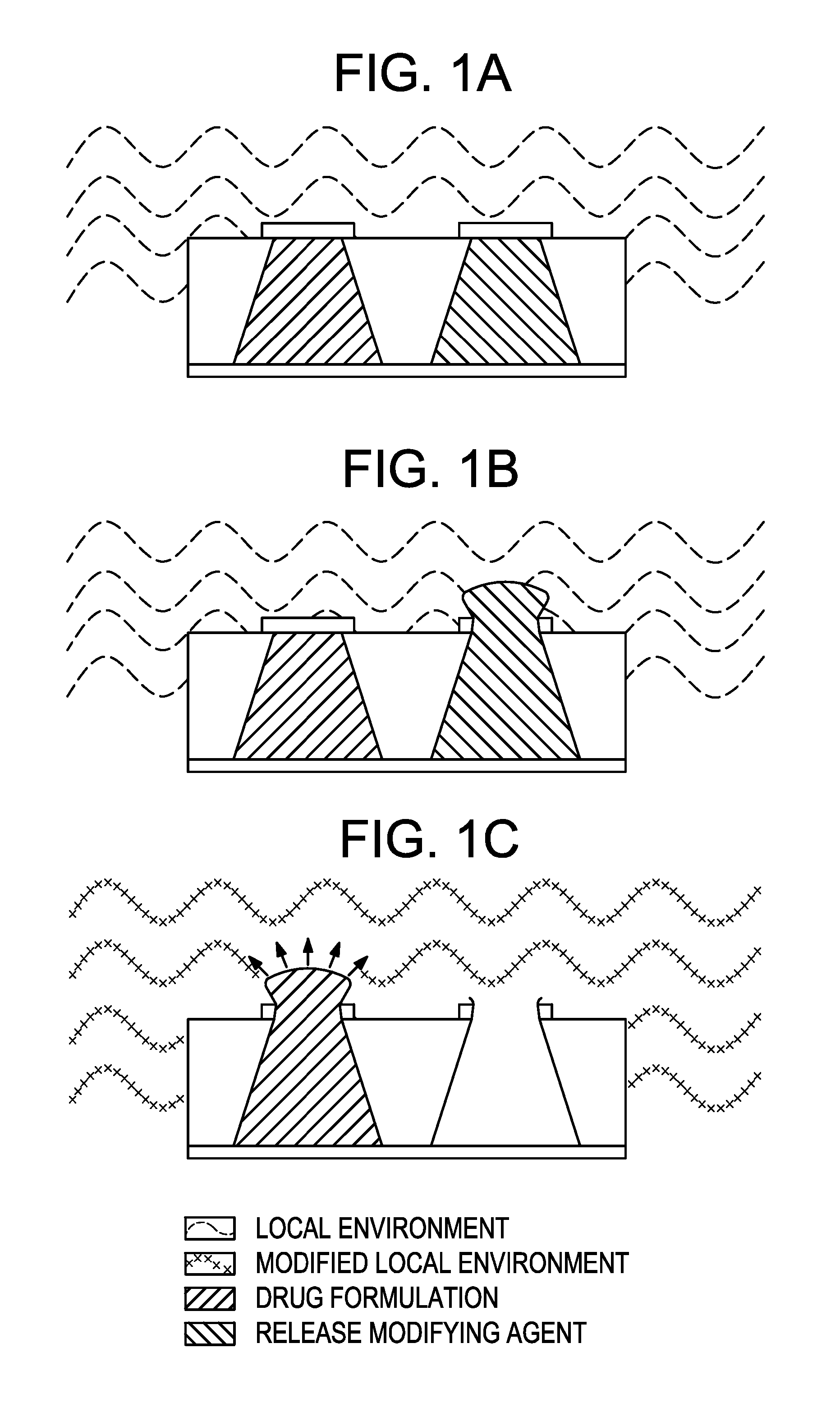

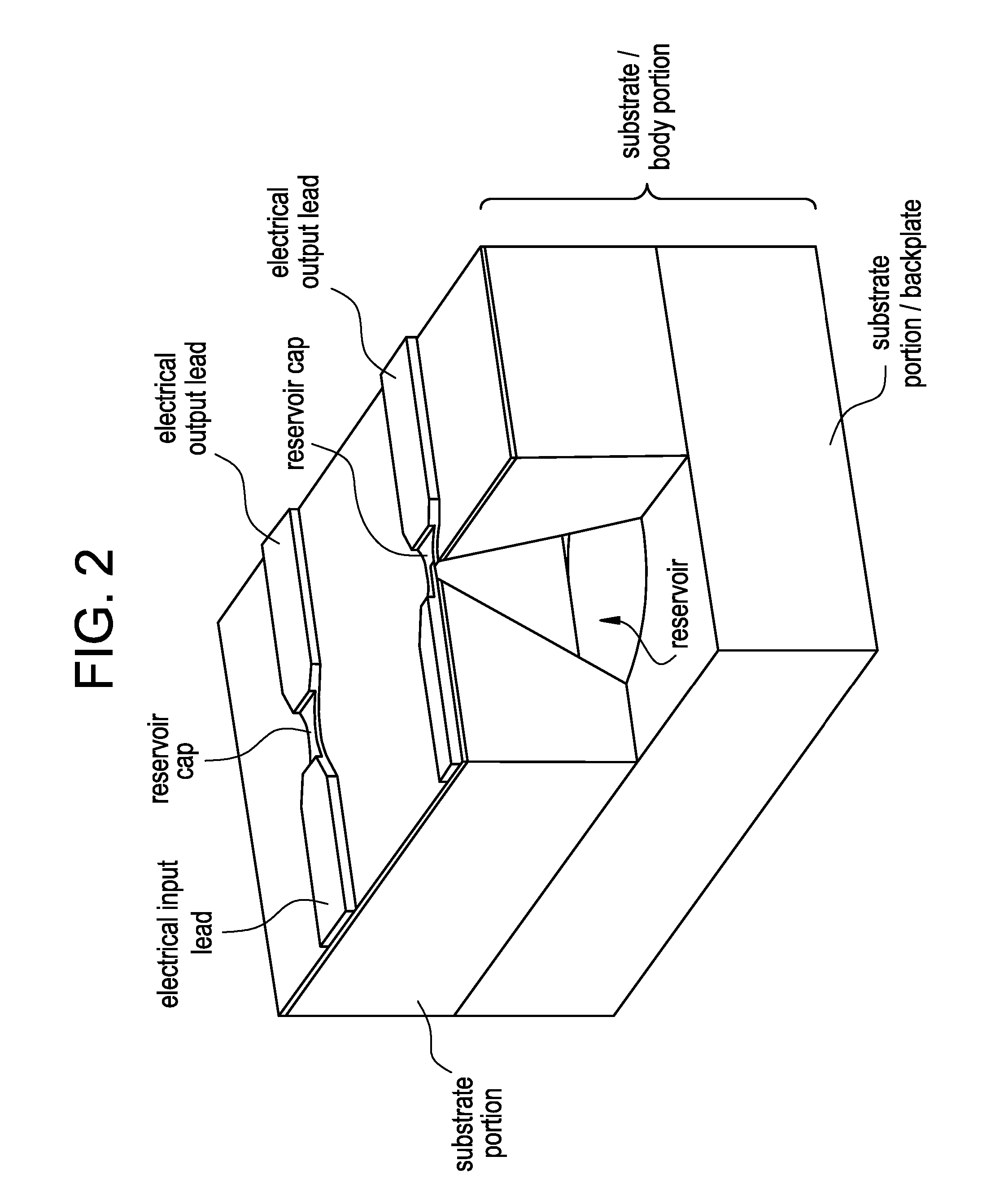

Control of drug release by transient modification of local microenvironments

InactiveUS7488316B2Facilitated releasePrevent oxidationStentsPeptide/protein ingredientsRelease modulatorMedicine

Methods, formulations, and devices are provided for enhancing drug delivery from a medical device. The method is provided for increasing the rate or quantity of a drug formulation released from an implantable drug delivery device, which method comprises the step of providing a release-modifying agent within or proximate to the implantable drug delivery device, in a manner effective to inhibit gelation, aggregation, or precipitation of the drug formulation being released from the device. The drug formulation and the release-modifying agent may be stored together in at least one reservoir in the implantable drug deliver device. Alternatively, the release-modifying agent may be stored in one or more reservoirs separate from the drug formulation.

Owner:MICROCHIPS BIOTECH INC

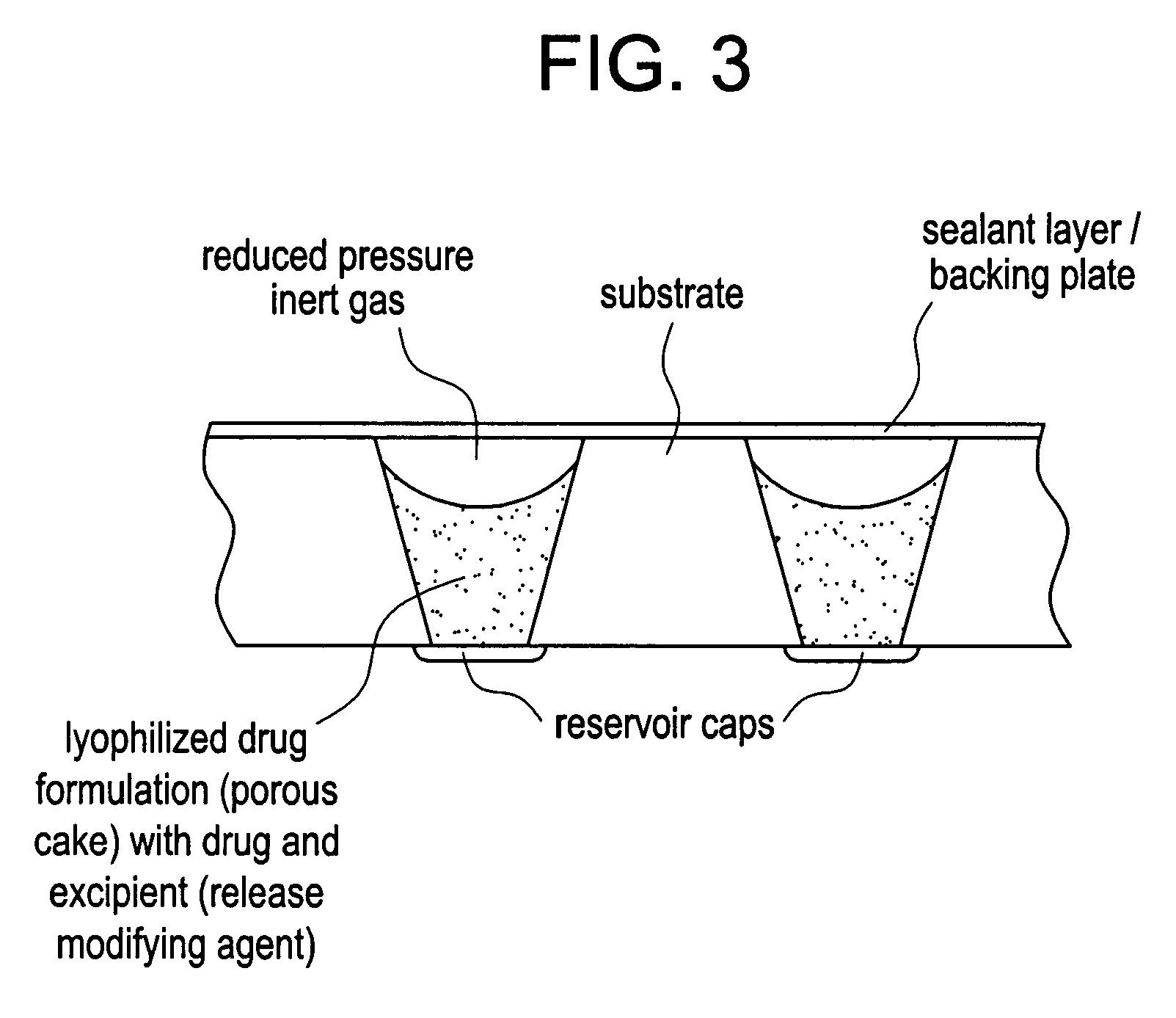

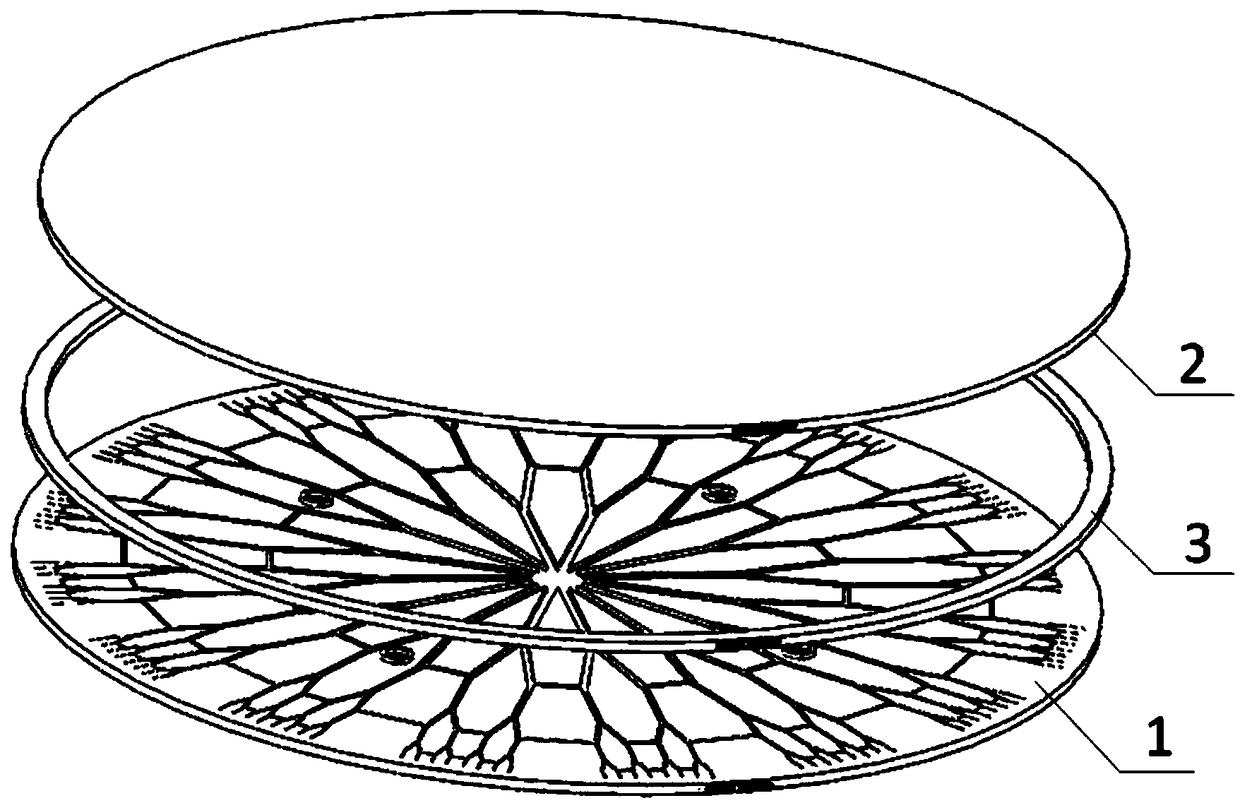

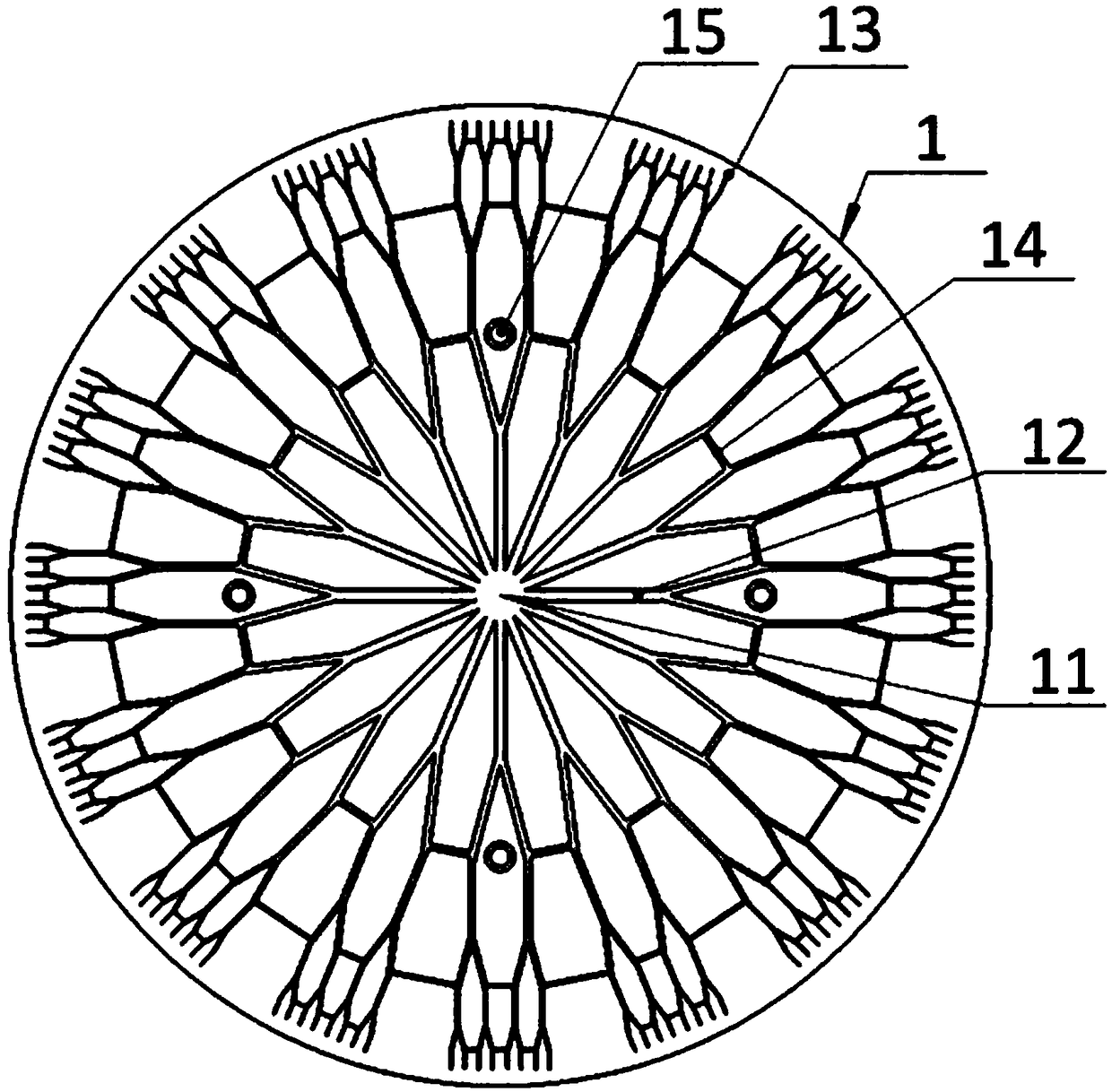

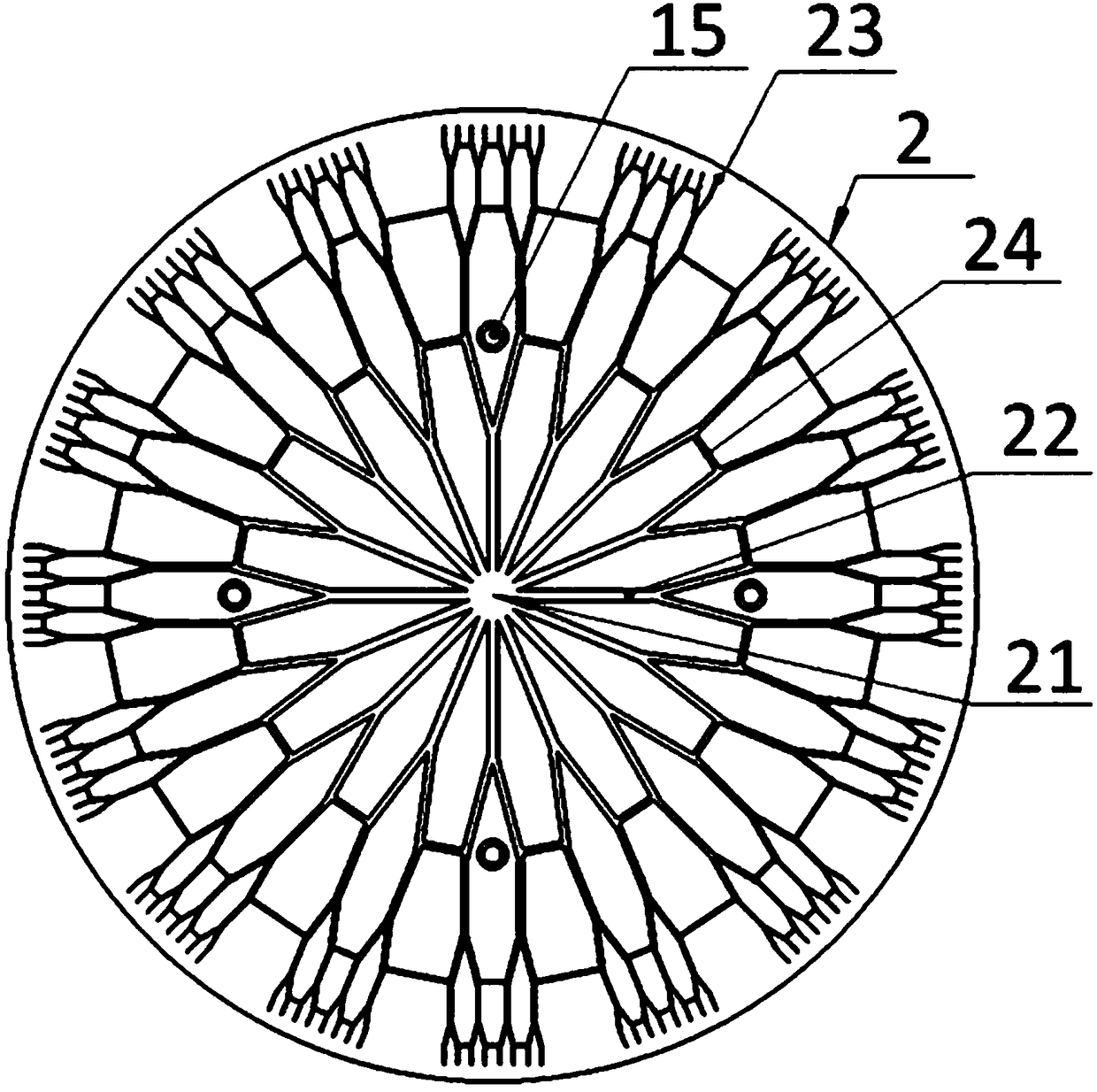

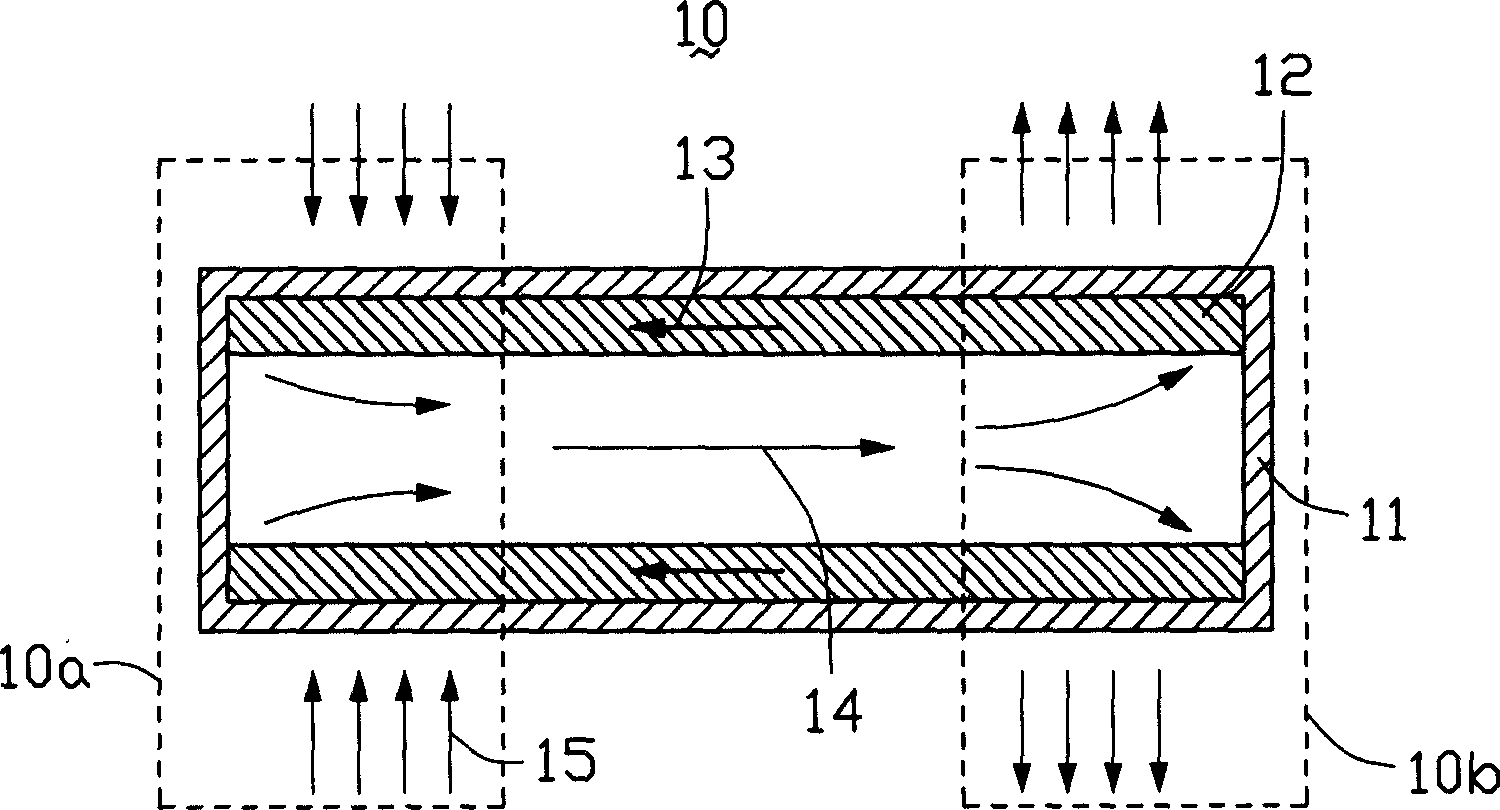

Soaking plate

PendingCN108444324AEnhanced capillary actionFast liquid absorptionIndirect heat exchangersMain channelEvaporation

The invention discloses a soaking plate comprising an evaporation plate, a condensation plate and a connecting plate. The evaporation plate directly faces the condensation plate. The connecting plateis used for connecting the evaporation plate with the condensation plate so as to form a closed cavity, and the closed cavity is filled with a working medium. The evaporation plate is provided with channels for conveying the working medium, and the channels are distributed in the circumferential direction of the evaporation plate and are divergent from the center to the edge of the evaporation plate. According to the soaking plate, the evaporation plate and the condensation plate are provided with bionic vein polygon micro-channel structures, the wall faces of the channels of the evaporation plate and the periphery of support columns are covered with lyophilic liquid sucking cores, thus the wall faces have lyophilic performance, capillary performance of the channel liquid sucking cores isimproved, and liquid sucking speed of the channel liquid sucking cores is increased. The wall faces of the channels of the evaporation plate and the periphery of the support columns are covered with lyophilic materials, liquid spreading is achieved progressively from the edge to the center of the condensation plate, the downward circulation speed of the working medium in main channels is increased, a working medium backflow path is shortened, working medium backflow speed is increased, and heat dissipation benefits are increased.

Owner:GUANGDONG UNIV OF TECH

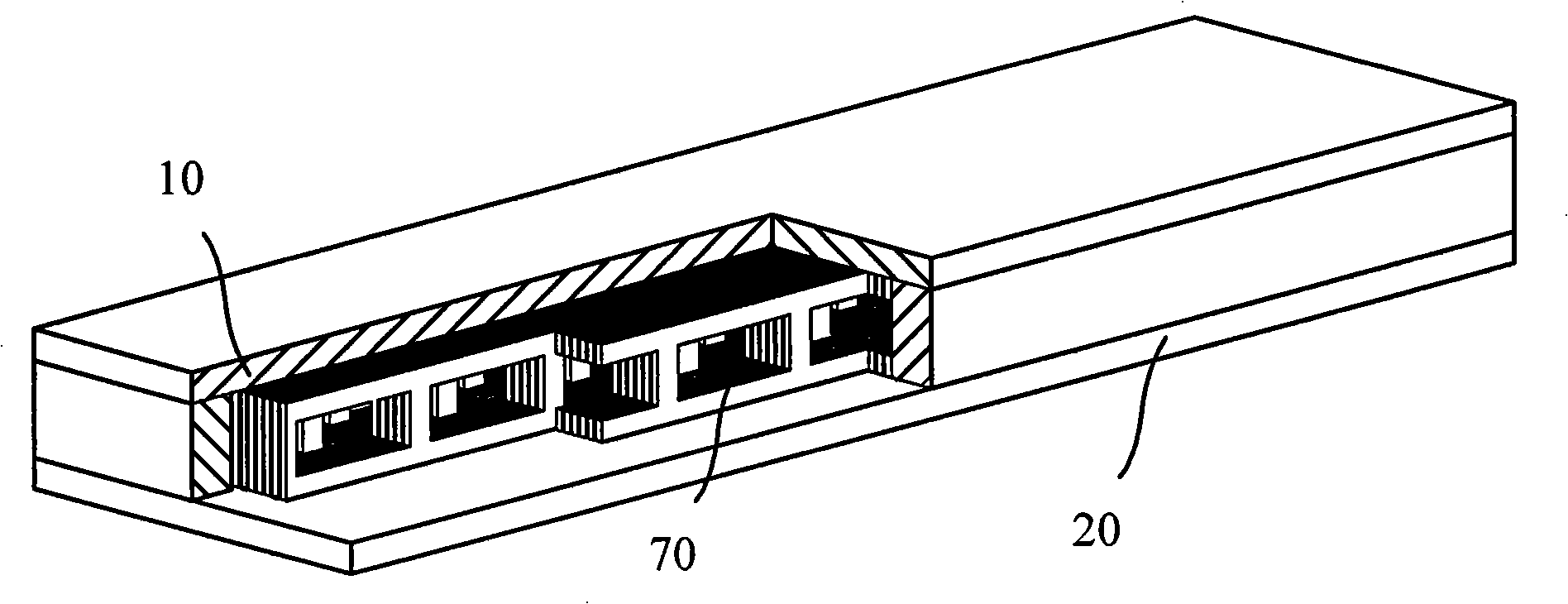

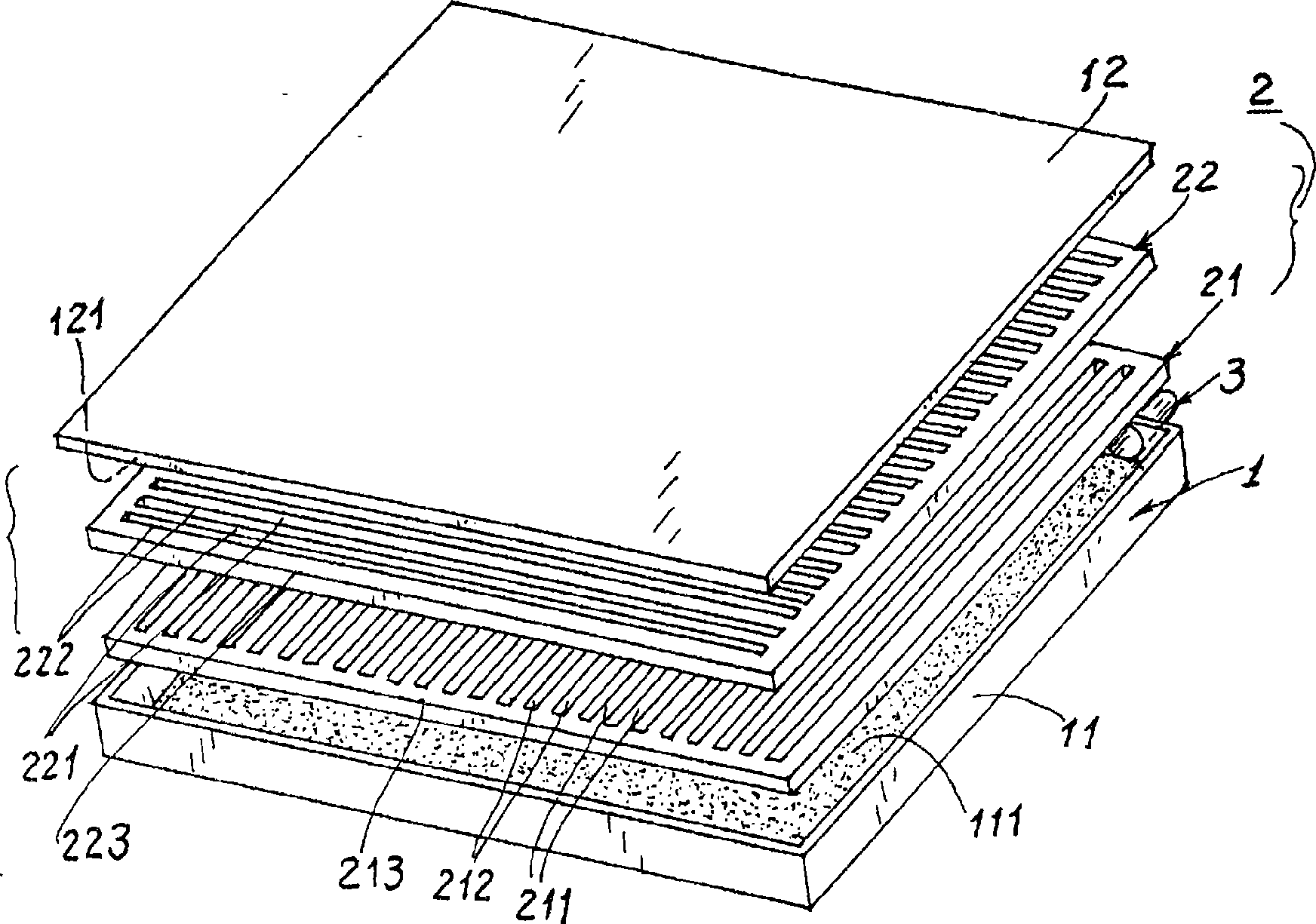

Imbibition chip, imbibition core and plate type integrated hot pipe

InactiveCN101354220AImprove mechanical propertiesStable supportIndirect heat exchangersEngineeringMetal sheet

The invention relates to a fluid suction chip, fluid suction cores and a flat integrated heat pipe; wherein, the fluid suction chip is used for being arranged in the integrated heat pipe to form a fluid suction core with capillary capacity, particularly including that: a metal sheet is flatly overlaid and treated with braze welding for being connected into the fluid suction core and a hole used for guiding condensate to flow back is arranged on the metal sheet. The fluid suction core adopts the fluid suction chip of the invention and the hold is communicated from one end of the fluid suction core to the other end and used for guiding the condensate to flow back. The flat integrated heat pipe comprises two shell bodies which are buckled to form a sealed cavity and a fluid suction core is welded on the inner wall of the shell body in level; a support component is also welded between the inner wall of the shell body and the fluid suction core. The composite fluid suction core structure is integrated with the braze welding of the shell body of the flat integrated heat pipe so as to ensure strong capillary capacity, low flow resistance and good mechanical property of the shell bodies; the product cost can be reduced by utilizing materials with low cost to prepare the shell bodies and simultaneously good heat dissipation can reduce the restricts on the development of electronic components.

Owner:DALIAN GOLDEN THERMALWAY TECH +1

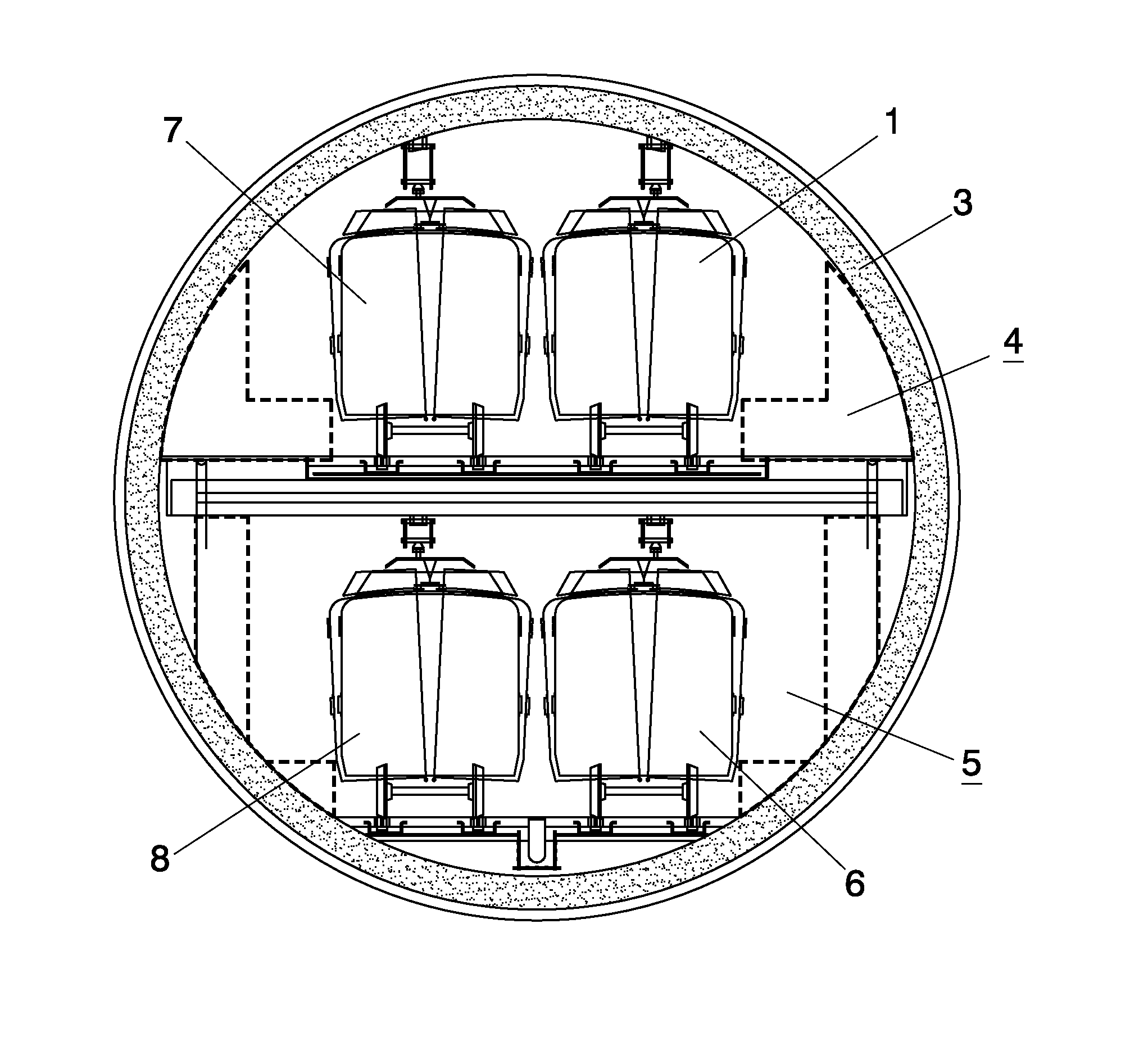

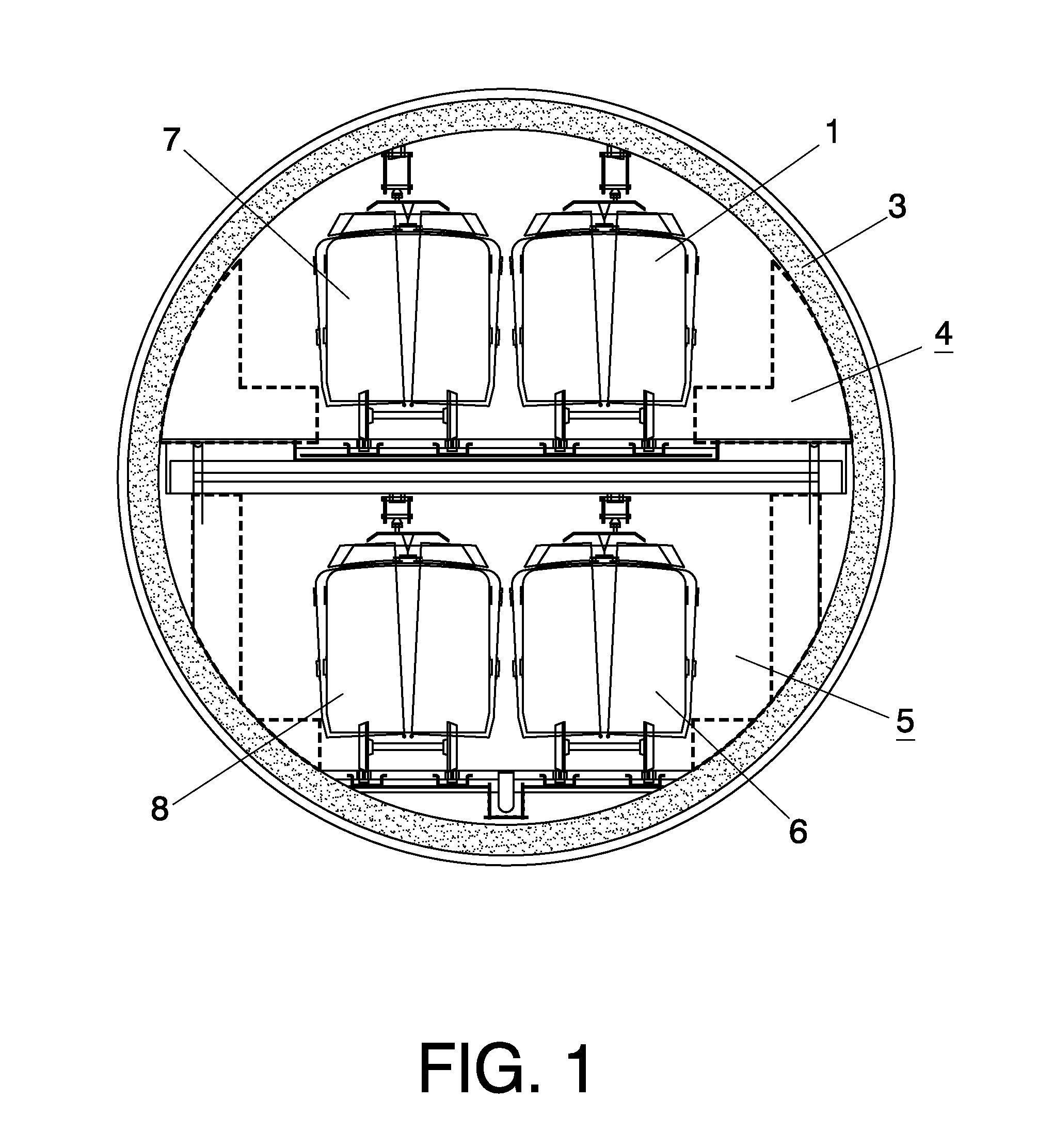

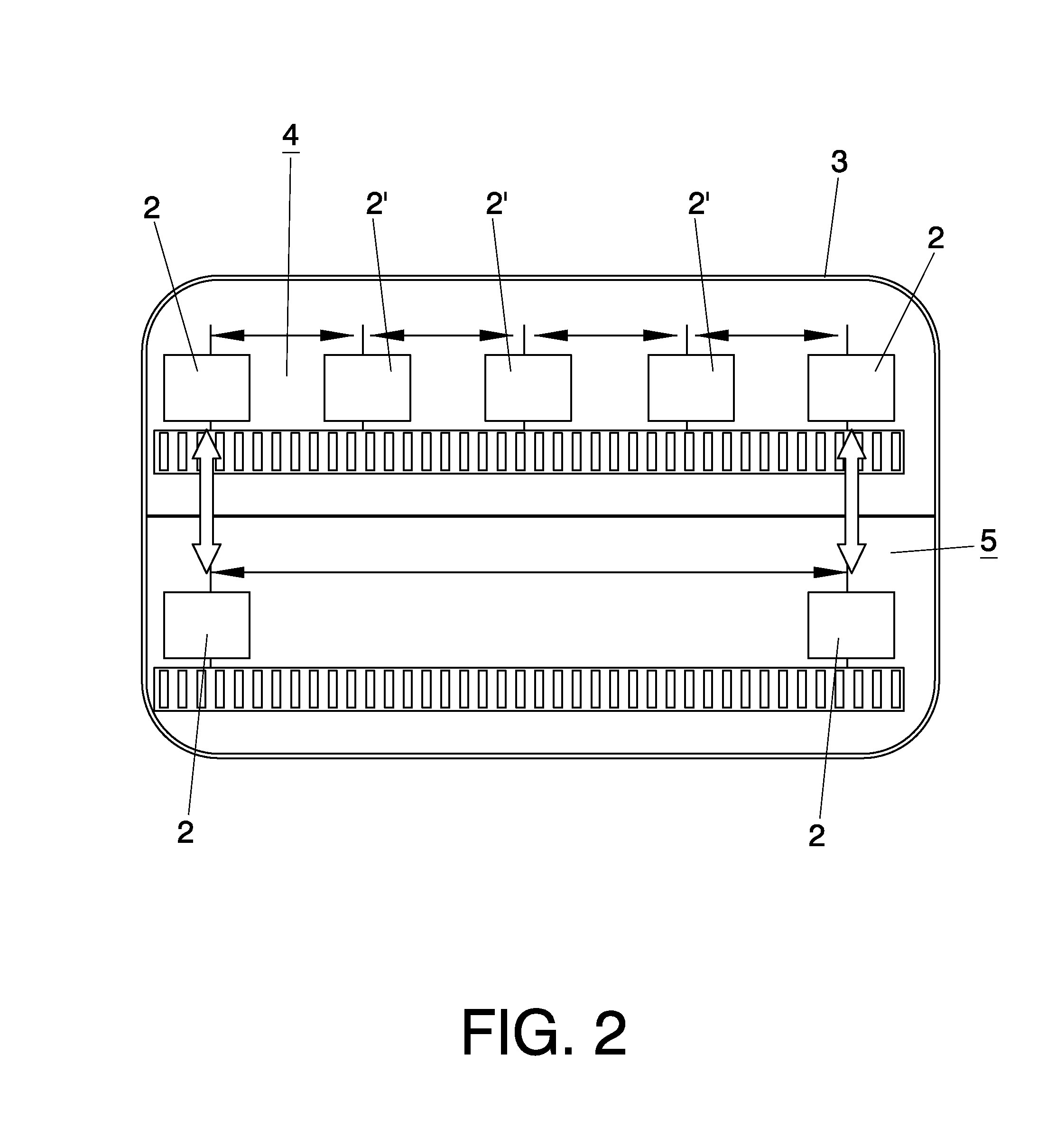

Metropolitan transport system and method

InactiveUS20130125779A1Reduce journey timeIncrease speedRailway tunnelsRailway componentsTransport engineeringTransport system

Metropolitan transport method and system that allows maximizing journey time commitment and network coverage by running a first train in a first direction, defined from a starting point to a finishing point of a route including a plurality of stopping stations, where the first train runs through a tunnel having two levels, the first train running on a first level of the tunnel and stopping at all the stopping stations on the route; the method also including running a second train in the first direction of the route on the second level of the tunnel, where the second train does not stop at all the stopping stations on the route.

Owner:METRO DE MADRID

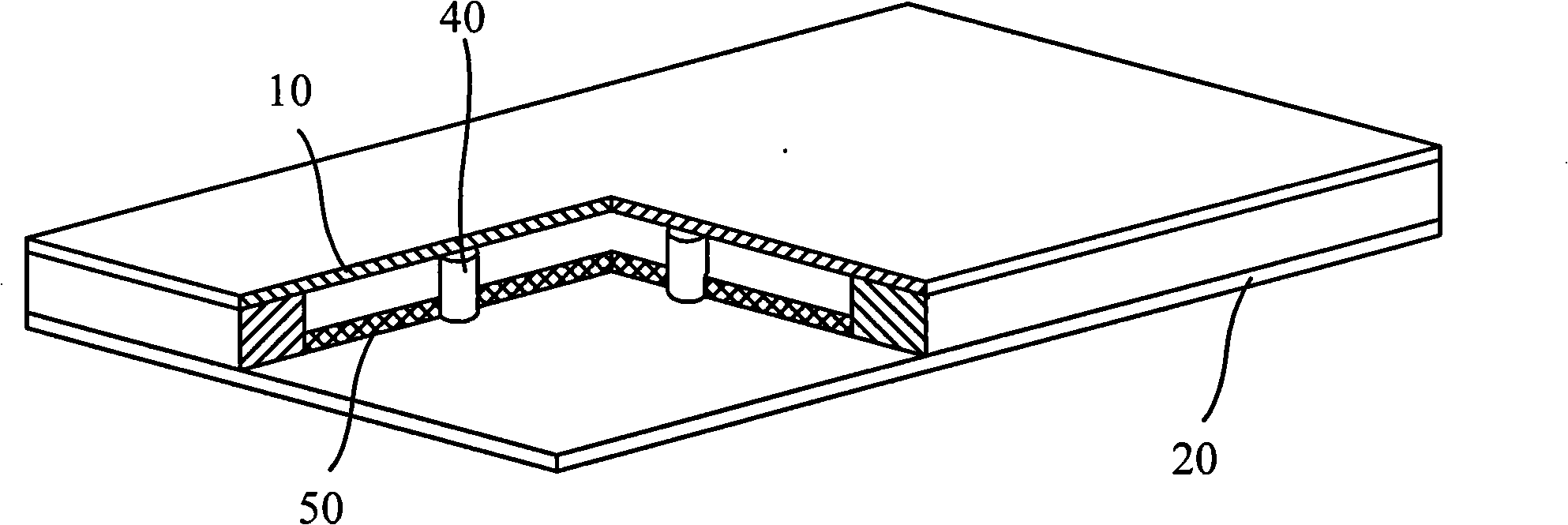

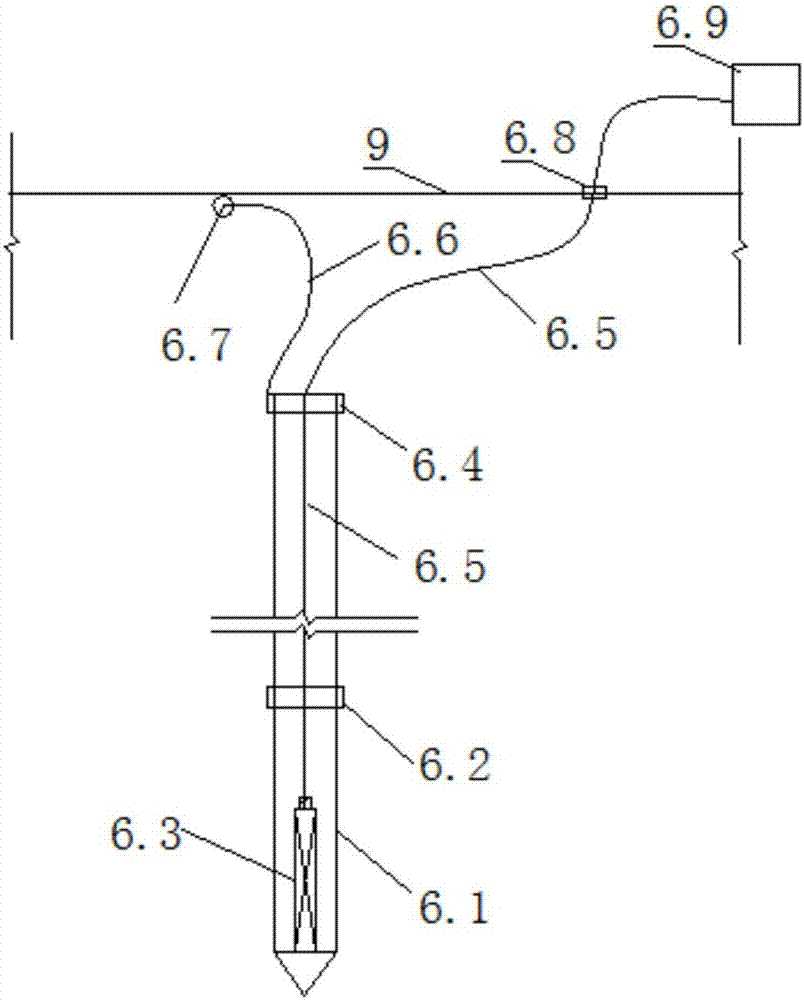

Soakage device capable of reinforcing supporting strength and capillary action

InactiveCN101472450AEnhanced capillary actionQuick and effective removalSemiconductor/solid-state device detailsSolid-state devicesCross-linkWorking fluid

The invention provides a soaking device capable of enhancing support strength and capillary action. The device comprises a casing; a vapor chamber is defined in the casing, and filled with an evaporable working fluid after vacuumized; a net-shaped cross capillary structural body is arranged in the vapor chamber of the casing. Meanwhile, by means of crisscrossed capillary holes, the capillary action of the working fluid in a cavity body is enhanced; multipoint and multidirectional soaking and radiating effects can be achieved; a heating element which is in contact with the soaking device is quickly and effectively dissipated; in addition, the net-shaped cross capillary structural body presents a cross-linking mechanical structure, the support strength can be enhanced, and the structural stability of related products is promoted.

Owner:TAMKANG UNIVERSITY

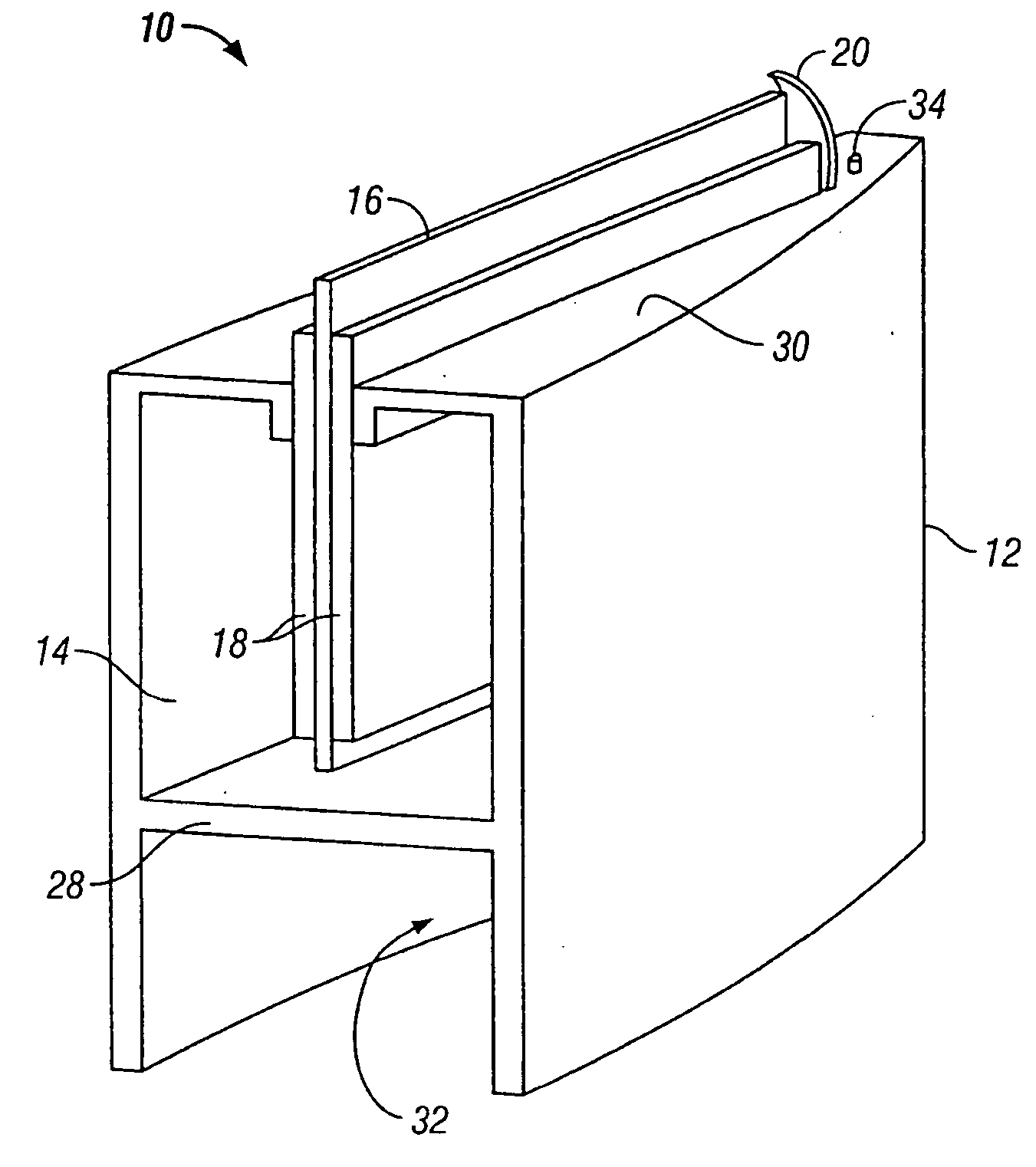

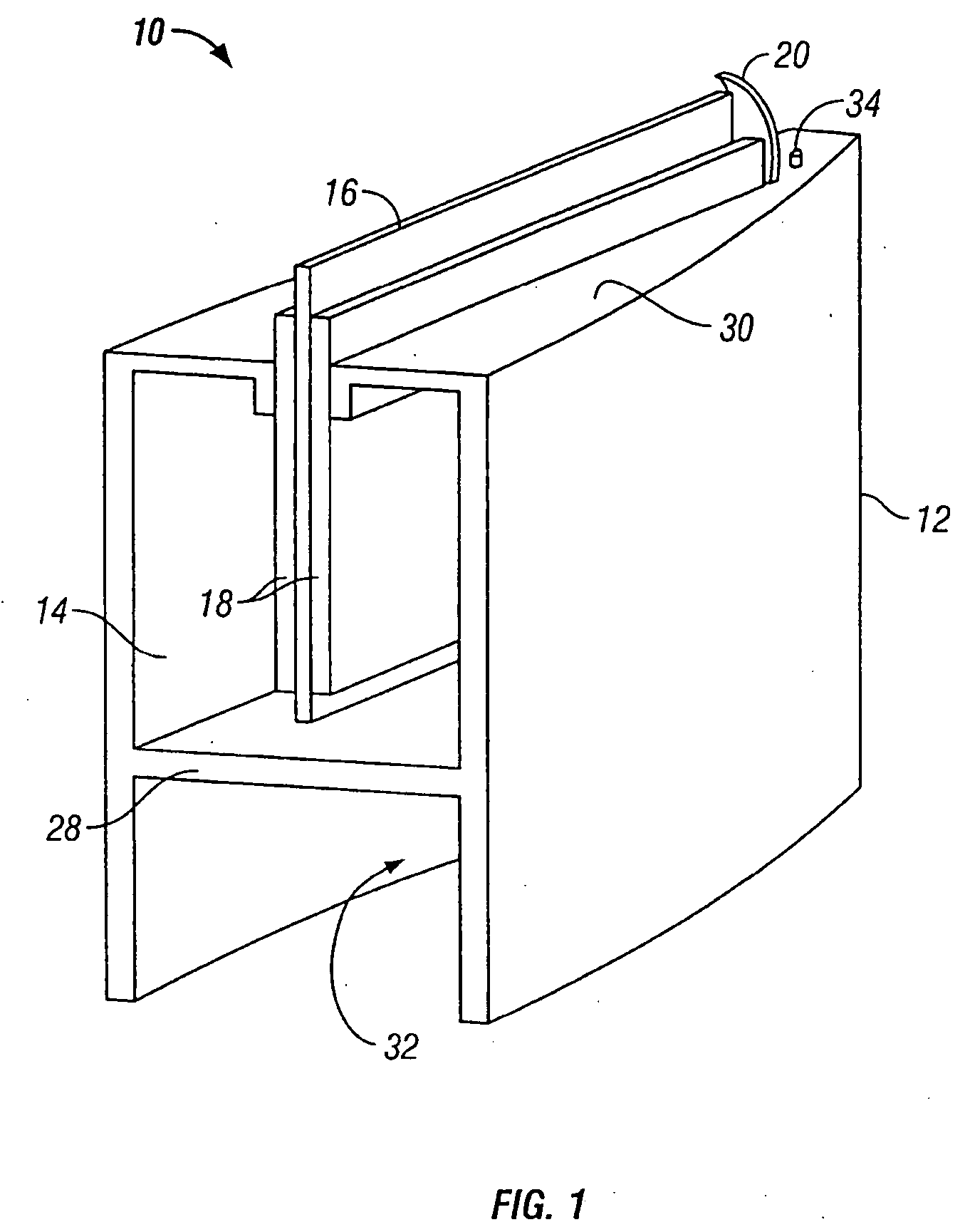

Oil lamp, air freshener and/or fragrance release apparatus and wick therefor

InactiveUS20050037307A1Eliminate emission of sootMaintain securityCapillary burnersGaseous substancesCapillary TubingEngineering

An oil lamp and fragrance release apparatus for providing a unique flame formation usable in a variety of decorative applications. The lamp includes a body that has an open upper end and that defines a chamber for carrying a combustible liquid. The lamp further includes a sheet wick having a lower end located in the chamber of the body, for contacting the combustible liquid, and an upper end projecting upwardly from the open upper end. The wick of inorganic material may be positioned between first and second plates arranged in a spaced, confronting relationship to enhance capillary action, may be freestanding stone of fibrous, permeable material or may be wrapped about a rigid plate. The wick provides a unique horizontal flame formation, while displaying décor on the outer surface of the flat wall. Optionally, the lamp may include scented oil and a conductive element to promote the release of fragrance upon heating, and the wick can be configured of material having high heat fragrance emanation.

Owner:LUMETIQUE

Formed metal core sandwich structure and method and system for making same

ActiveUS20090053548A1Easy and economical to manufactureEnhanced capillary actionLayered productsSoldering apparatusMetal sheetEngineering

A method and apparatus for producing a metal core sandwich structure that is lightweight and many times stiffer than regular sheet metal, and which is easily formable into curved structures as well as structures having compound curves. In one embodiment, a formed metal core includes a plurality of cells comprising alternating front and rear projections extending outwardly in front of and behind a median plane, with each projection having a bonding surface area or land configured to be bonded with corresponding external metal sheets on both sides of the formed metal core. A plurality of micro-abrasions or indentations are formed on the bonding lands, allowing stronger bonding joints to be formed between the metal core and the external metal sheets by facilitating improved capillary action by the metal core during the bonding process.

Owner:CELLTECH METALS INC

Control of drug release by transient modification of local microenvironments

InactiveUS20060171989A1Increase releaseEnhanced capillary actionStentsPeptide/protein ingredientsDrug deliveryPharmaceutical formulation

Methods, formulations, and devices are provided for enhancing drug delivery from a medical device. The method is provided for increasing the rate or quantity of a drug formulation released from an implantable drug delivery device, which method comprises the step of providing a release-modifying agent within or proximate to the implantable drug delivery device, in a manner effective to inhibit gelation, aggregation, or precipitation of the drug formulation being released from the device. The drug formulation and the release-modifying agent may be stored together in at least one reservoir in the implantable drug deliver device. Alternatively, the release-modifying agent may be stored in one or more reservoirs separate from the drug formulation.

Owner:MICROCHIPS BIOTECH INC

Screening device for analysis of bodily fluids

InactiveUS20140134073A1Enhanced capillary actionAvoid testingAnalysis using chemical indicatorsWithdrawing sample devicesEngineeringBody fluid

A screening device for testing bodily fluids for the presence of certain constituents. The device can include a planar front face through which all of the test strips are viewed. The device also includes an inclined surface that directs the fluid under test to test strips with more efficiency, and partitions the fluid that is directed to a given test strip to better assure that the test strip receives an adequate amount of bodily fluid for a valid analysis. In one embodiment, the device includes a three-dimensional gasket that creates a pressurized environment upon insertion of the sampling stem for improved diffusion of the bodily fluid into the test strips.

Owner:PREMIER BIOTECH

Web having apertures with convex sides

ActiveUS7758947B2Effective areaFacilitate the passage of large or viscous mensesLayered productsBaby linensConvex sideEngineering

Owner:TREDEGAR FILM PROD CORP

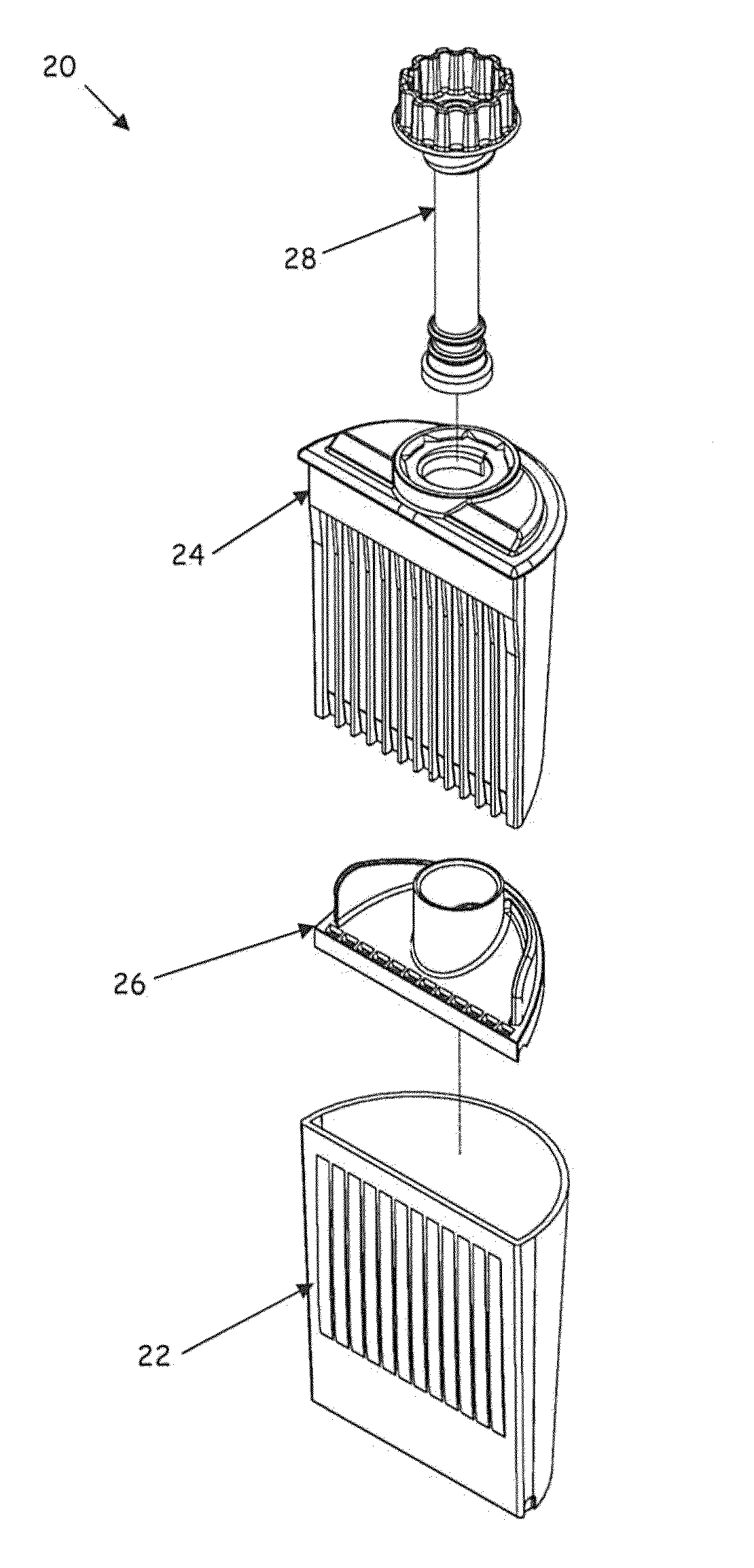

Method and implantable device with reservoir array for pre-clinical in vivo testing

InactiveUS20080076975A1Facilitated releasePrevent oxidationStentsPeptide/protein ingredientsPhysiological fluidPhysiology

Methods of pre-clinical animal testing to monitor physiological parameters of test animals following exposure of molecules sealed in reservoirs on implanted devices. The test molecules are exposed to physiological fluid of the animal. The molecules can be configured as a sensor chemistry that reacts with the physiological fluid. The molecules can be a drug or drug candidate that is released into the animal. The test animals are non-human mammals.

Owner:MICROCHIPS INC

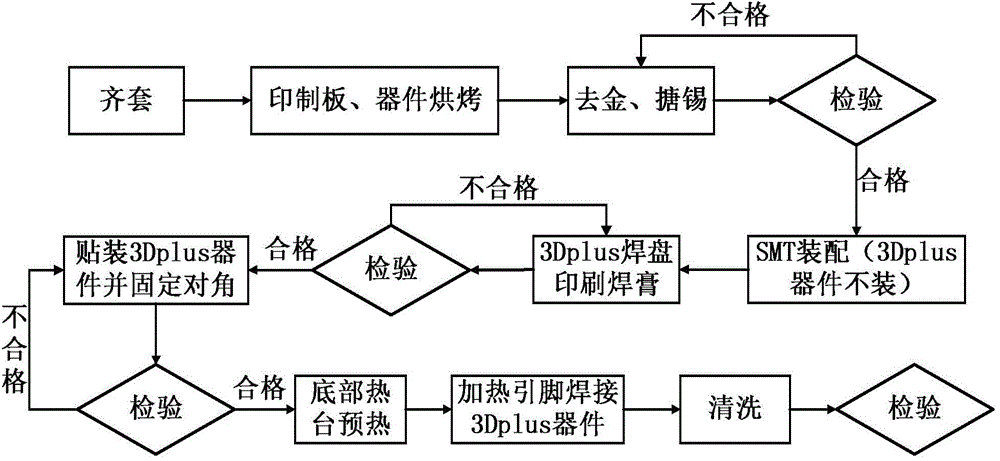

Assembly process method for 3D Plus encapsulating device

ActiveCN104540333AEnhance capillary effectGood solder joint consistencyPrinted circuit assemblingSolder pasteEngineering

The invention discloses an assembly process method for a 3D PLUS encapsulating device, and aims to provide an assembly method, which is simple and efficient and contributes to the realization of stable and reliable quality in order to solve the problems of freeness from soldering tin infiltration on the root part of a device pin and failure in meeting certain standards caused by current manual assembly. According to the technical scheme, the method comprises the following steps: printing soldering paste on a printed board bonding pad by using a steel mesh and finishing device mounting through printing and mounting technologies in an SMT (Surface Mount Technology) assembly technology, printing the soldering paste on the printed board bonding pad, controlling the thickness of the soldering paste printed on the printed board bonding pad at 0.12 millimeter through the thickness of the steel mesh, finishing device mounting by using a maintenance workstation, controlling the lateral deviation of the device pin within 15 percent of the pin width, and fixing diagonal pins of the 3D PLUS encapsulating device through spot welding by using soldering iron after mounting; performing non-contact integral board preheating on the bottom of the printed board by using a heating stage welding technology and a tool gasket; and after preheating time is reached, manually heating the exposed pins of the device by using the soldering iron, and melting the soldering tin through thermal conduction to finish welding.

Owner:10TH RES INST OF CETC

Monitoring system for monitoring coverage of broadcast transmissions

ActiveUS8325237B2Enhanced capillary actionOvercomes drawbackTelevision system detailsReceivers monitoringTelecommunications linkCommunications system

A system for monitoring television signals broadcast by at least one transmission antenna in a broadcast area includes a monitoring control center and a plurality of remote monitoring units distributed in television signal receiving locations of the broadcast area remote from the transmission antenna. The remote monitoring units are configured to receive the television signals irradiated in the respective locations, process the television signals and send to the monitoring control center information related to the processed television signal. In particular, the remote monitoring units include a receiver adapted to receive the television signal, a measuring system adapted to perform measures on radio-electric features of the received television signal, and a communication system adapted to communicate measurement results to the remote monitoring center, exploiting a communication link between the remote monitoring unit and the control center.

Owner:TELECOM ITALIA SPA

Heat pipe

InactiveCN1624411AImprove thermal efficiencyHydrophilicIndirect heat exchangersWorking fluidEngineering

The invention relates to a heat pipe which includes a hollow pipe shell, solution absorption core stick to the inner wall of the shell: with filled liquid. There is a larger of hydrophilic material on the surface of solution absorption core , which can increase the coefficient of surface tension of solution absorption core, resulting in increased the efficiency of heat pipe. The heat pipe supplied by the invention with high efficiency of heat pipe , is suitable for heat sink device in electric instrument.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Heat pipe

InactiveCN101619947AEnhance heat transfer functionImprove heat transfer performanceIndirect heat exchangersThin metalWorking fluid

The invention provides a heat pipe, comprising a heat conductor, working fluid and a carbon nanotube array; wherein, the heat conductor comprises a first metal cover, a second metal cover and two third metal covers; the first metal cover and the second metal cover are correspondingly arranged to form a front opening end and a back opening end; the first metal cover and the second cover are respectively provided with a groove, and the opposite sides thereof are respectively extended out to form two thin metal flanges; the bottom of each groove is provided with a microchannel, and two supporting plates are arranged in each groove near the two sides; the two third metal covers are respectively buckled on the front opening end and the back opening end to form a vacuum sealing space in the heat conductor. The carbon nanotube array is fixed in the microchannel. The working fluid is filled into the heat conductor. The heat pipe of the invention uses flat metal covers internally provided with a microchannel and fixes carbon nanotube in the microchannel to increase the heat conductivity and capillary capacity and improve heat conductivity of the heat pipe.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

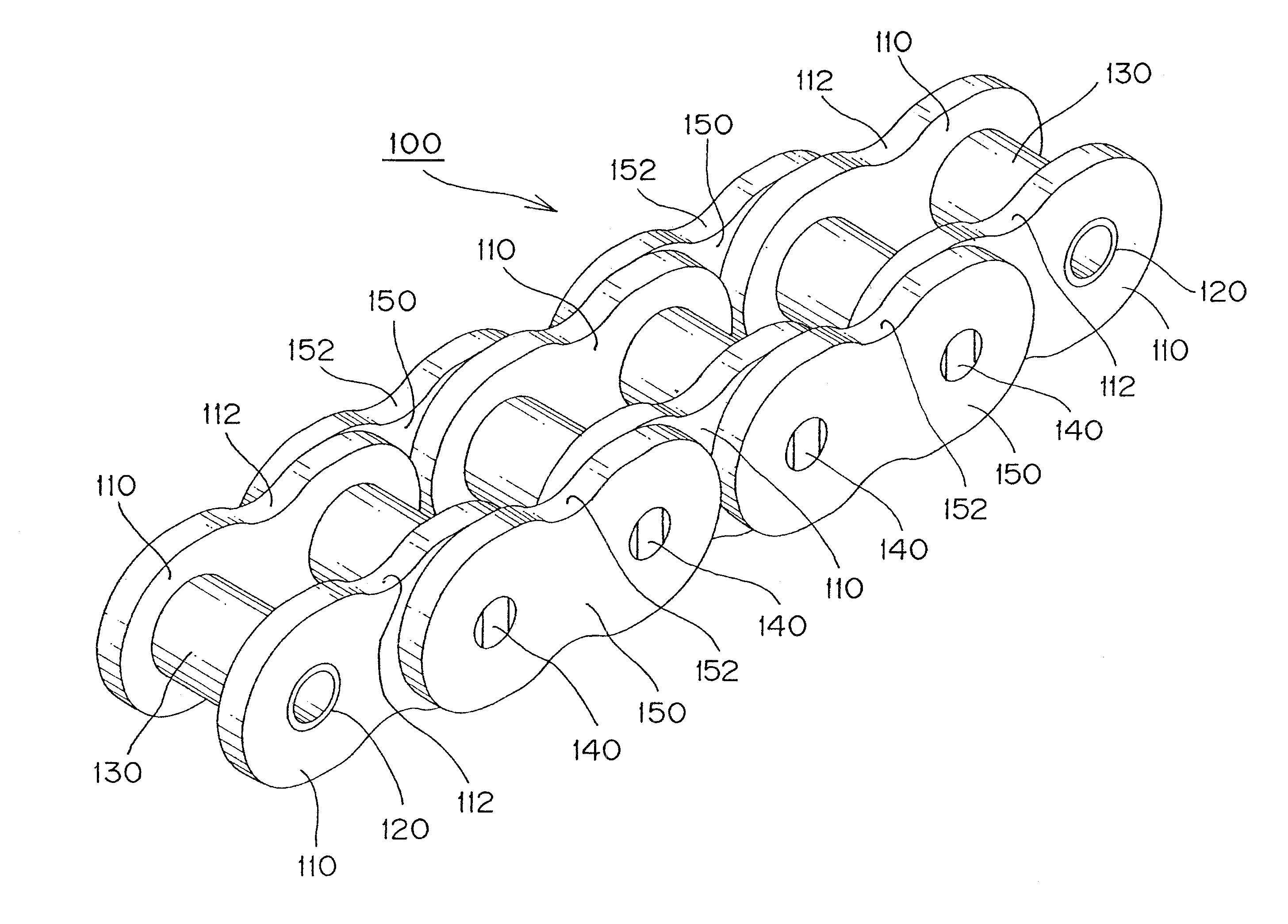

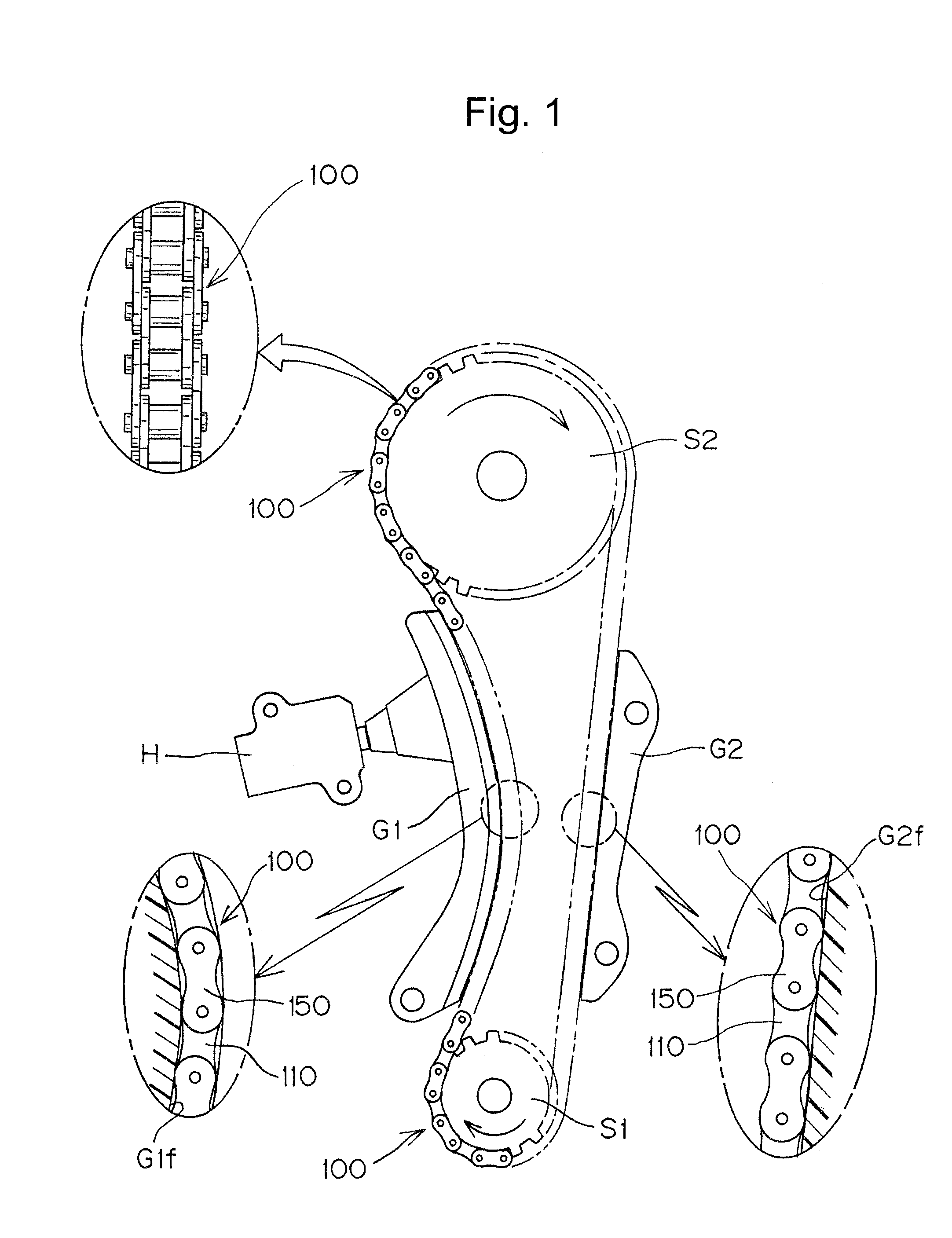

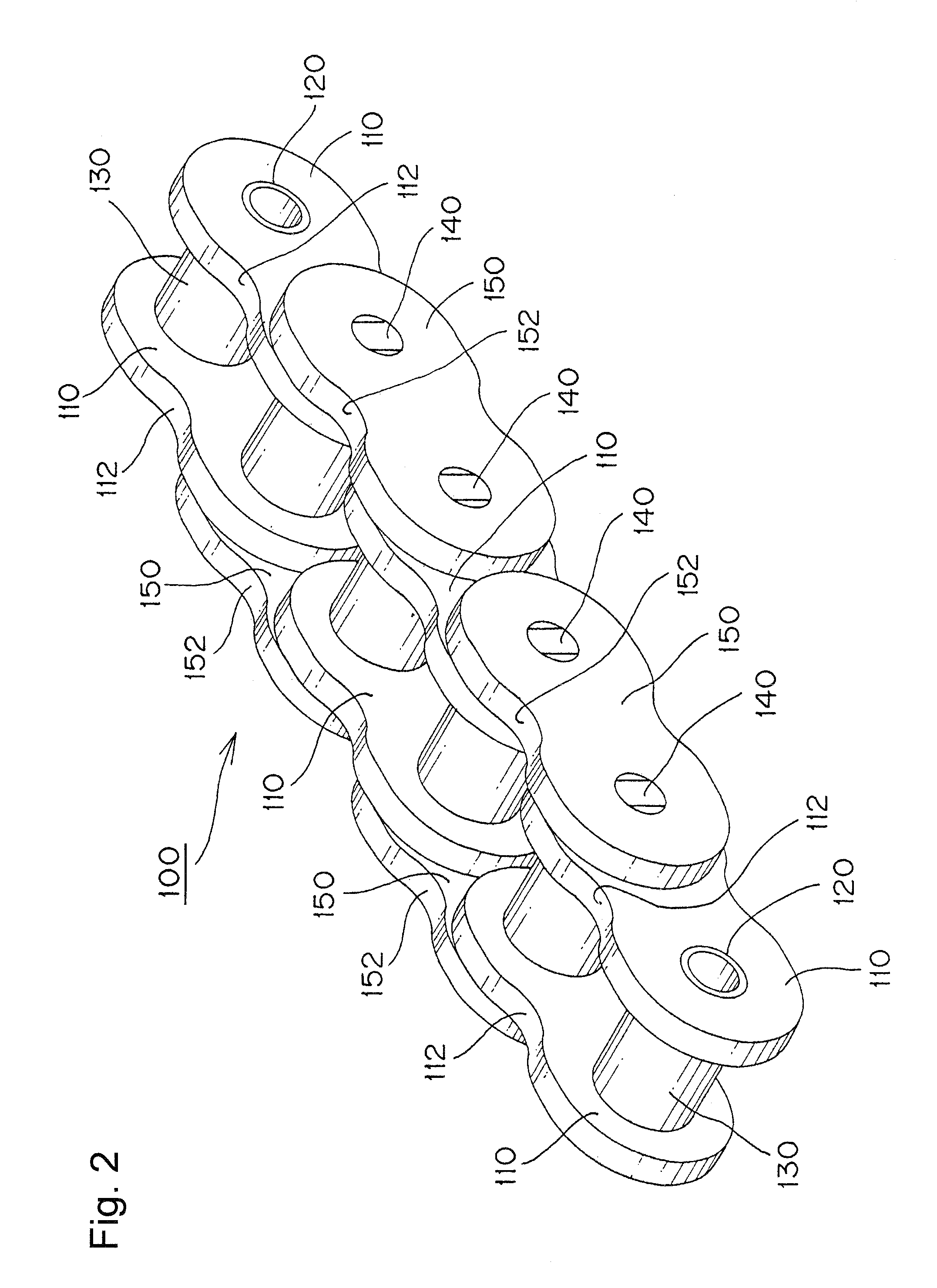

Transmission chain for use in engine

The plates of transmission chain for an engine are formed with a guide-contacting configuration composed of spaced flat surfaces that come into sliding contact with a flat chain guide, and convex surfaces, continuous with and between the flat surfaces, for sliding contact with a convex chain guide. The convex surfaces are connected by a concave surface that, with the guide surface, forms an oil-retaining clearance. The radius of curvature of the convex curved surfaces of the plate preferably increases gradually from the location where they meet the flat surfaces toward the location where they meet the concave surface. The plates can have the same configuration on the side facing the inside of chain loop as on the side facing the outside of the chain loop.

Owner:TSUBAKIMOTO CHAIN CO

Windproof warm-keeping composite garment fabric

ActiveCN103340483AReduce air permeabilityImprove breathabilitySynthetic resin layered productsCeramic layered productsPolyesterPolymer science

The invention discloses a windproof warm-keeping composite garment fabric. The windproof warm-keeping composite garment fabric comprises a windproof waterproof moisture-permeable outer layer, a far infrared warm-keeping layer, a moisture-guiding sweat-discharging inner layer and a mesh lining in sequence from outside to inside. The windproof waterproof moisture-permeable outer layer is made of high count and high density base cloth and a polytetrafluoroethylene microporous membrane in a laminated and composite mode through adhesive, the moisture-guiding sweat-discharging inner layer is made of polypropylene fibers having good moisture conductivity and / or polypropylene fibers having irregular sections, and the yarn count of each polypropylene fiber is 45s-60s. The far infrared warm-keeping layer is made of warm-keeping layer base cloth and a far infrared ceramic nanofiber membrane in a composite mode, the mesh lining is a warp knitted mesh fabric, and the warp knitted mesh fabric is made of polyester fibers with irregular sections. The windproof warm-keeping composite garment fabric has good windproof, warm-keeping and moisture-permeable performance, and has a good using effect.

Owner:SWOTO PROTECTION & TECH CO LTD +1

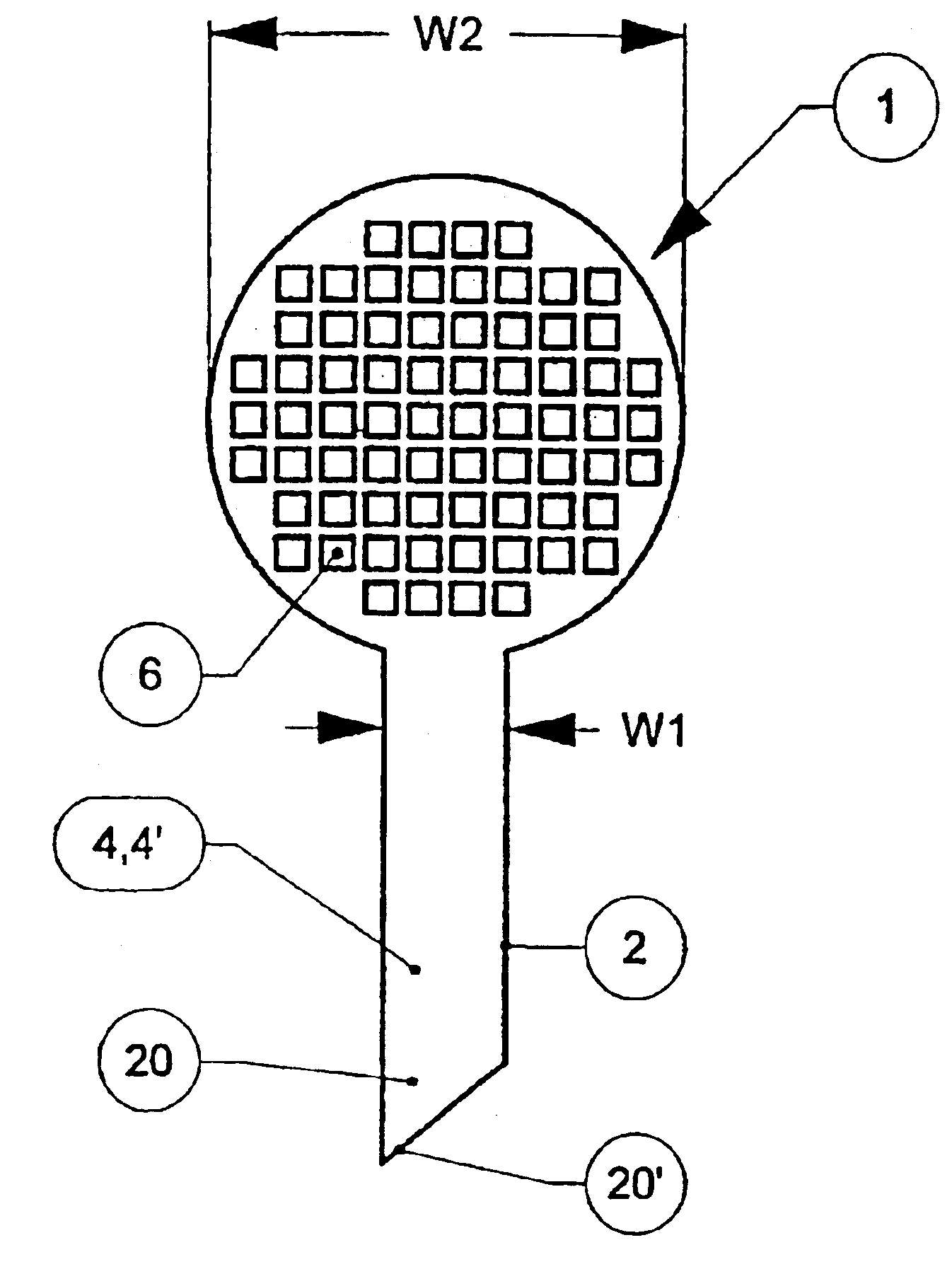

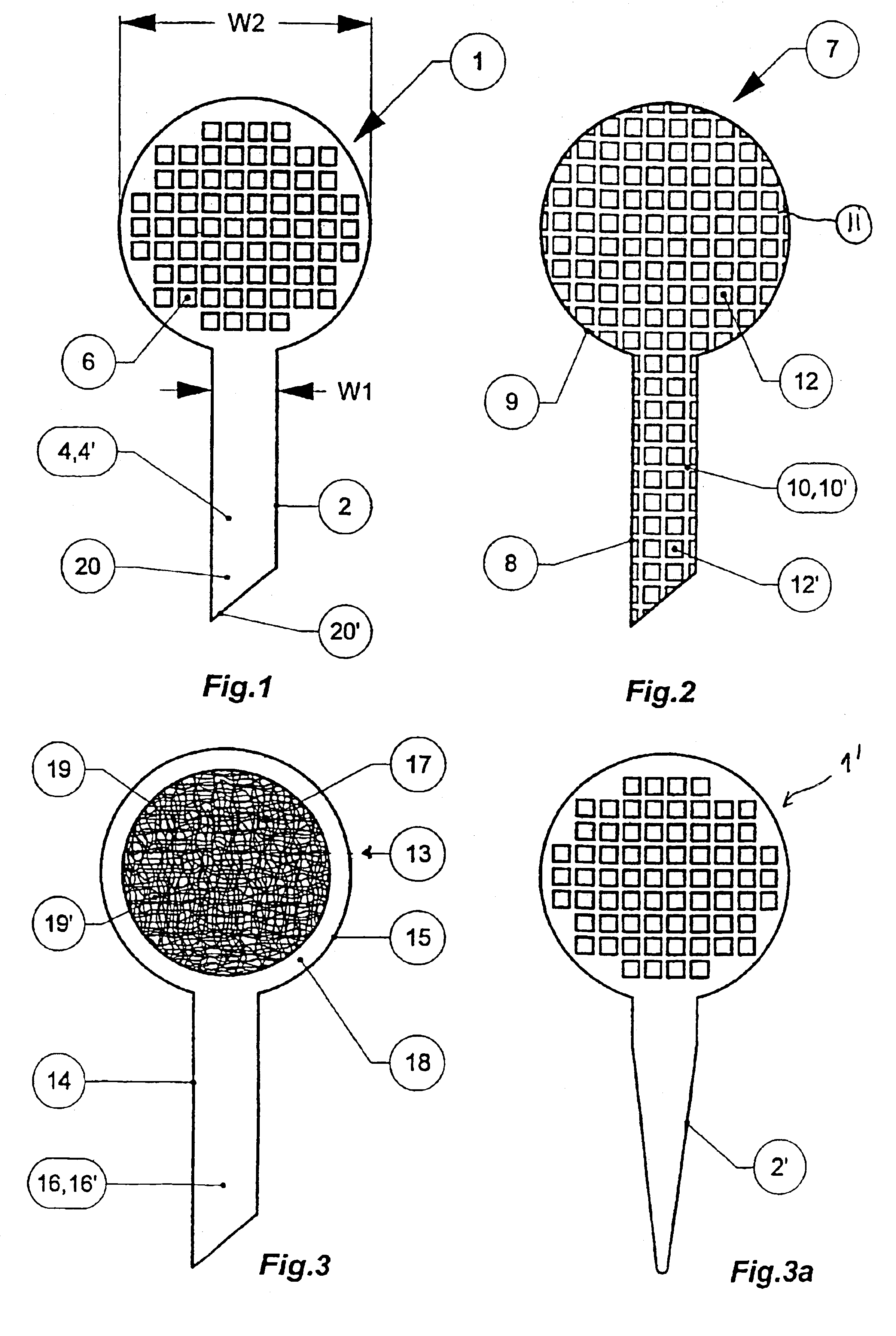

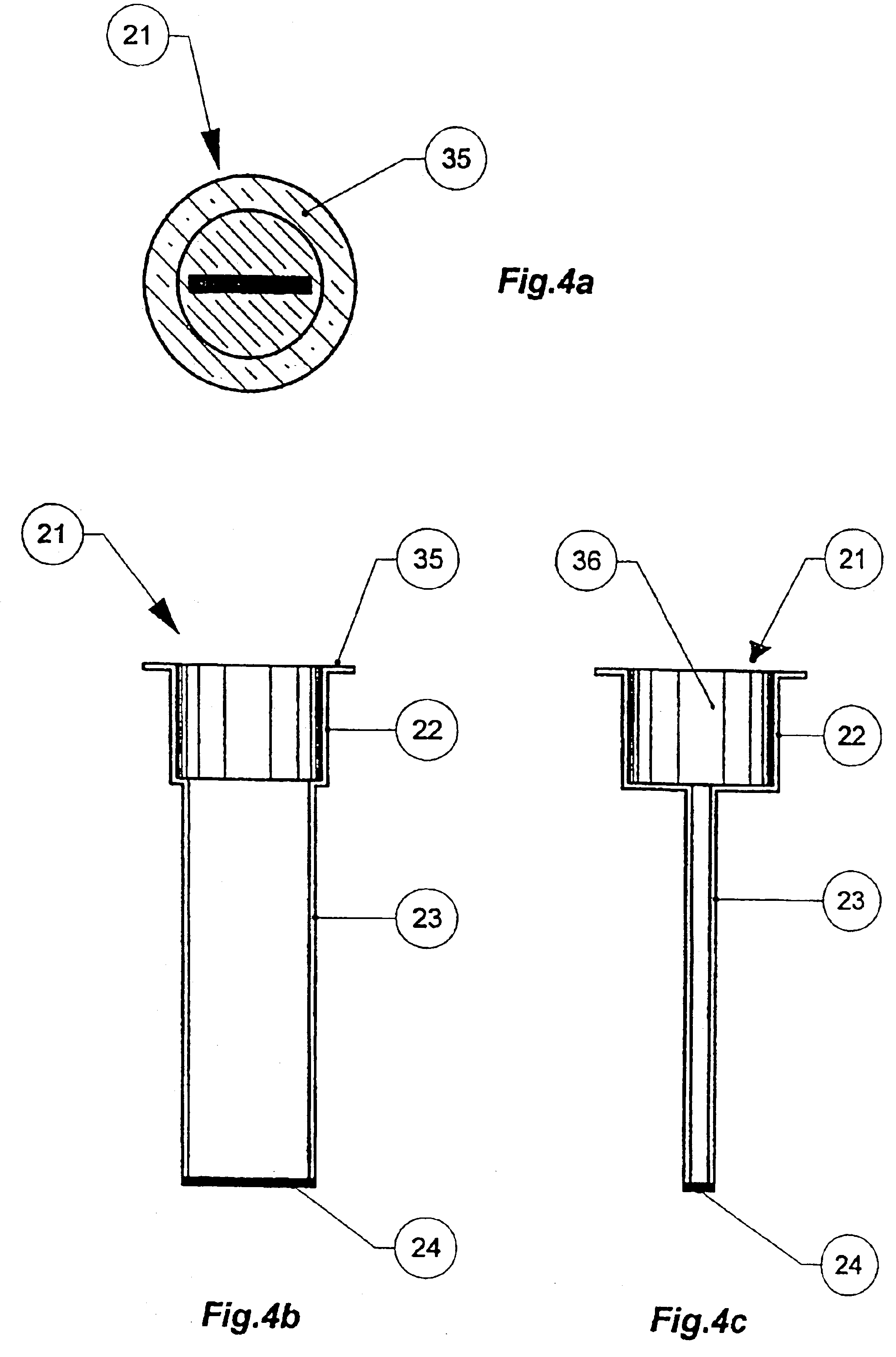

Unit for the transfer and distribution of a liquid and method of manufacturing the same

InactiveUS6921025B2Enhanced capillary actionEasy piercingLiquid flow controllersTobacco devicesEngineeringCapillary action

A unit (1) for the transfer and distribution of a liquid (27) using capillary action has an elongated shaft (2) and a screen (3). The shaft (2) includes a first capillary medium (4) suitable for drawing the liquid (27) from a reservoir (26) into the shaft (2) when a bottom portion (20) of the shaft (2) is disposed in the liquid. The screen (3) is connected to the shaft (2) and includes a second capillary medium (5) suitable for receiving the liquid (27) drawn by the first capillary medium (4) and distributing it over at least a major part of the screen (3) where it evaporates.

Owner:GIVAUDAN SA

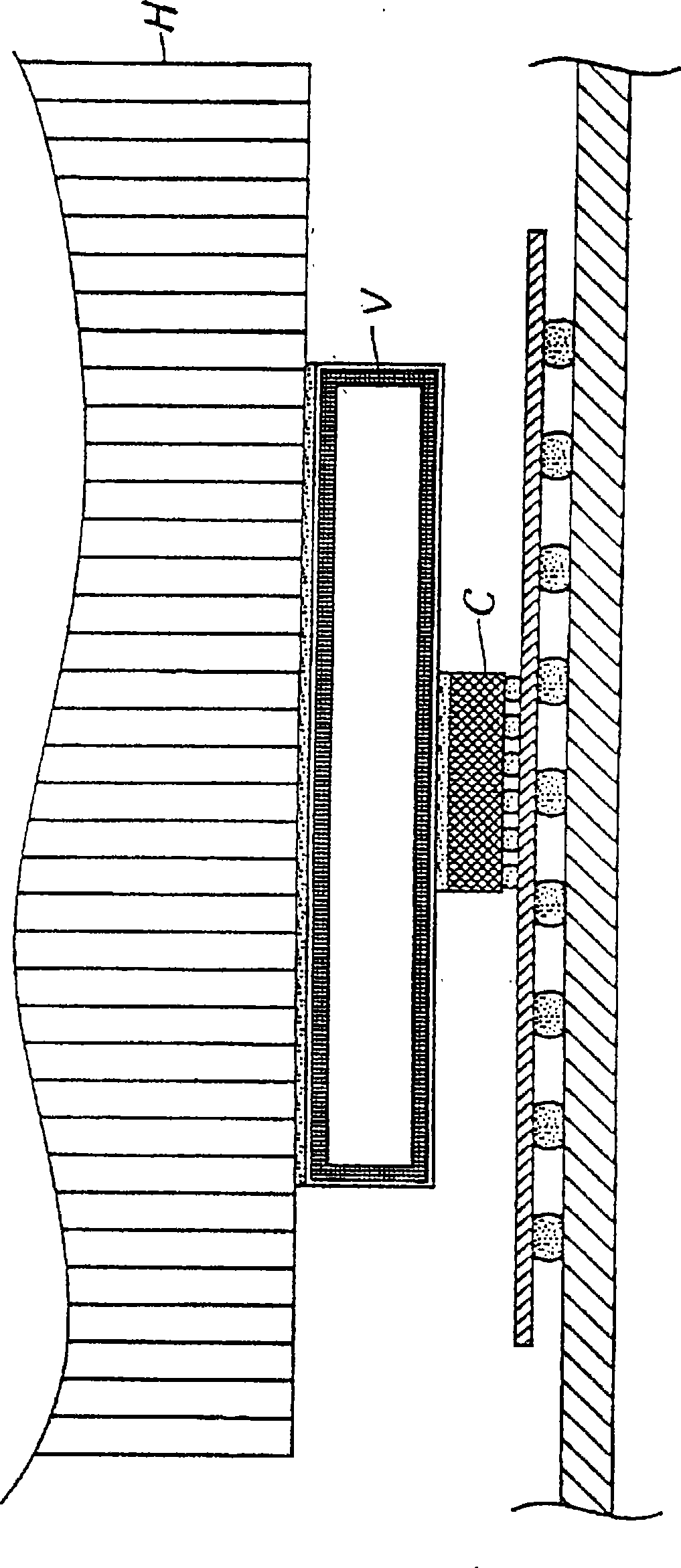

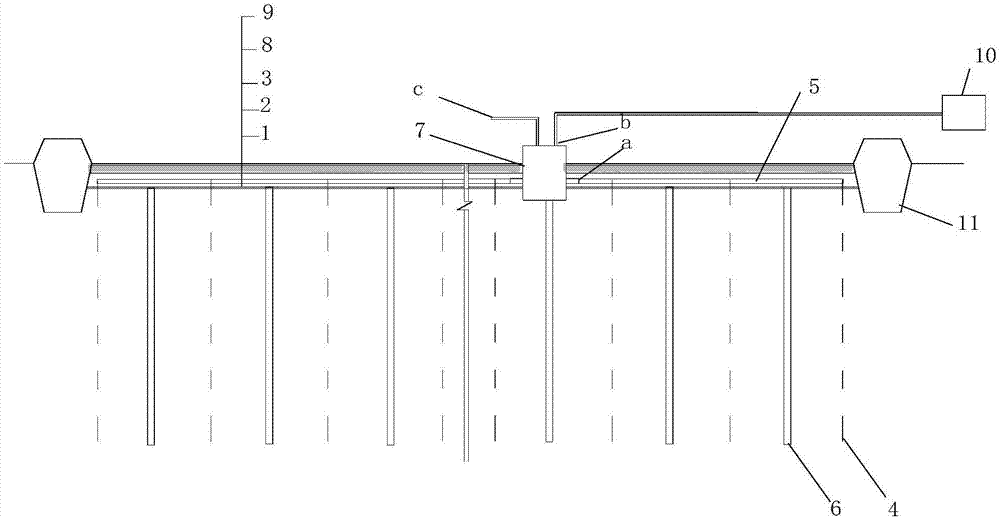

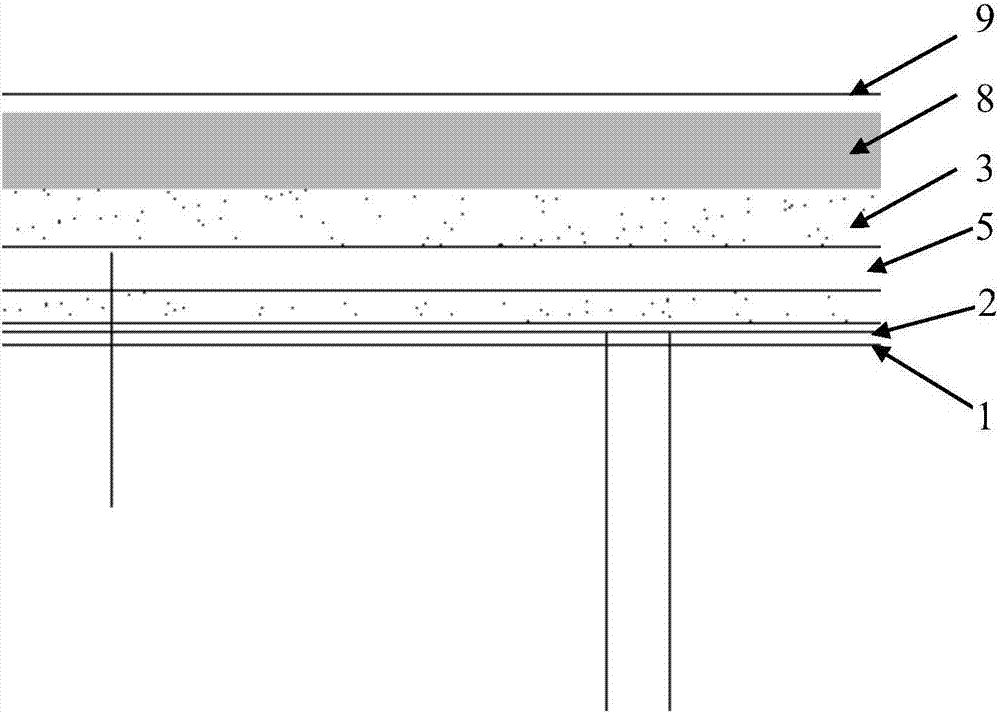

Foundation heating device and construction method for foundation heating combined vacuum prepressing of soft soil foundation by applying such device

PendingCN107190729AReasonable designImprove the heating effectSoil preservationTemperature controlThermal insulation

The invention discloses a foundation heating device and a construction method for foundation heating combined vacuum prepressing of a soft soil foundation by applying such device. Vertical plastic draining plates are arranged in a foundation, plate heads of the vertical plastic draining plates are connected to transversely arranged filter pipes, outlet ends of all filter pipes are communicated with an inlet of a pressure guiding flow separating device, heating devices are further arranged in the foundation, a sand cushion layer is paved on the foundation, the filter pipes are buried in the sand cushion layer, a thermal insulation layer is paved on the sand cushion layer, and a sealing film is paved on the thermal insulation layer to form a closed vacuum prepressing system. During work, the pressure guiding flow separating device is firstly opened to perform foundation reinforcing treatment by a general vacuum prepressing method; when general drainage consolidation is performed to the later stage, a temperature control heating body is opened to perform foundation heating, meanwhile the foundation is vacuumized, and by controlling a foundation heating temperature and a foundation absolute pressure, water content in the foundation is converted to a gas state from a liquid state, and therefore, the water content of the foundation is further reduced, and the strength of the foundation is increased.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com