Foundation heating device and construction method for foundation heating combined vacuum prepressing of soft soil foundation by applying such device

A technology of heating device and construction method, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of small increase in strength, can not meet the requirements of foundation use, etc., achieve effective stress increase, increase vacuum suction and Capillary action, good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

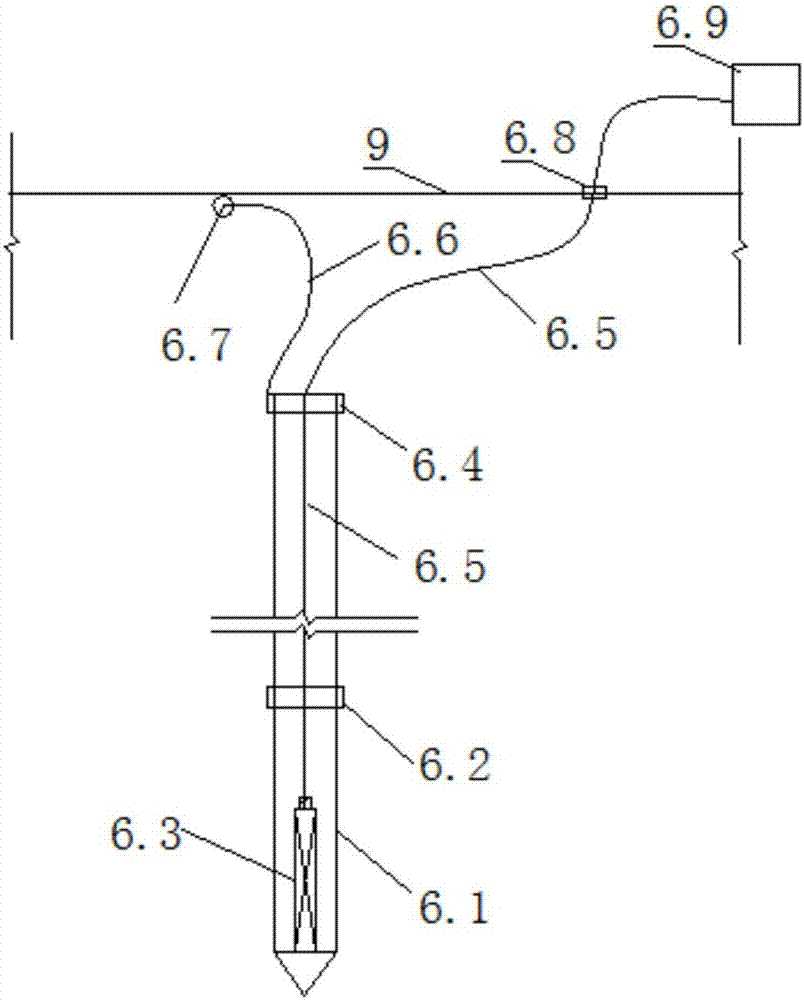

[0032] See attached figure 1 , a ground heating device, comprising a steel pipe 6.1, the bottom of which is tapered so as to be inserted into the soft soil foundation, the overall length of the steel pipe 6.1 is 6-10m, and can be spliced by multi-section steel pipes through the flange 6.2, and the steel pipe is provided with Electric heating tube 6.3 and heat conduction oil, the top of the steel pipe is provided with a sealing cover 6.4, the electric heating tube 6.3 is connected with a power supply wire 6.5, the power supply wire passes through the sealing cover 6.4, and a cable 6.6 is arranged on the sealing cover. The ring 6.7 is used to pull the steel pipe out of the foundation through the cable 6.6; when in use, the power supply wire 6.5 leads out the sealing film through the film-exiting device and connects to an external power supply.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com